KECA Similarity-Based Monitoring and Diagnosis of Faults in Multi-Phase Batch Processes †

Abstract

1. Introduction

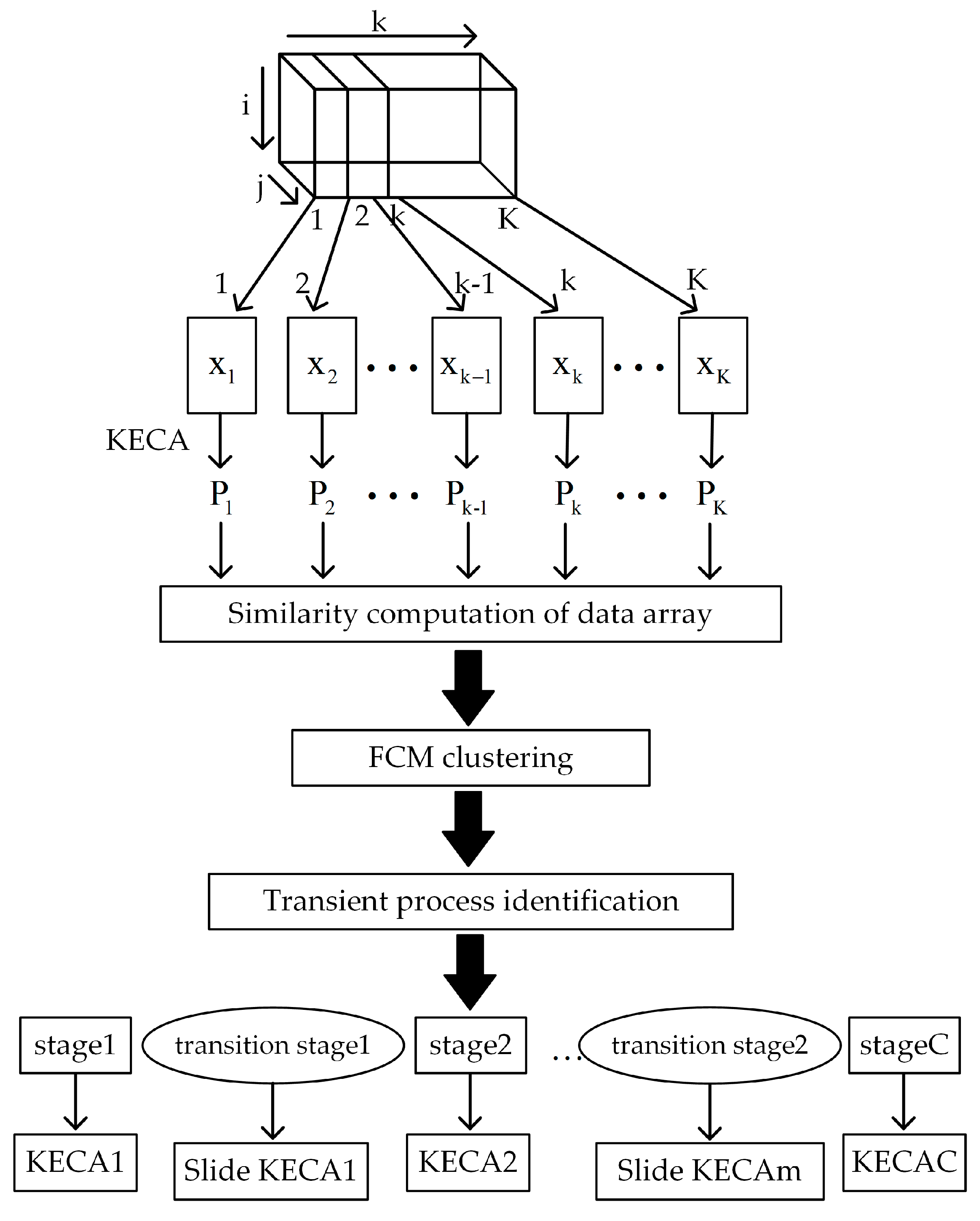

2. Phase Partitioning Based on KECA Similarity

2.1. KECA

2.2. Definition of the KECA-based Similarity Metric

2.3. Phase Partitioning Based on the KECA Similarity

- (1)

- Extend the matrix of the three-way model data in the direction of the batch and standardize the matrix. Perform vertical cutting in the direction of time to produce and standardize the time slice matrix.

- (2)

- Map each of the time slice matrices to the high-dimensional feature space using the kernel entropy. Let denote the load matrix, representing the correlation between procedure variables.

- (3)

- For each , compute the similarity , where , and is the input sample of the cluster.

- (4)

- Perform the preliminarily partitioning of the phases using the fuzzy C-mean clustering (FCM) algorithm. Firstly, partition the process into c phases according to the rule of maximum membership degree. Afterwards, detect the outliers having the maximum membership degree during each phase, using the single-variable control diagram. The succession of outliers mostly occurs at the start or end of a phase. This can be used as the criterion to determine the start and the end of the transitional phase. Finally, after the transitional phase is eliminated, the remaining phase is the stable phase.

- (5)

- Determine the control limit of the single-variable control diagram through several iterations, i.e., obtain the control limit for the current data in iteration using the traditional single-variable control diagram. Then, remove the outliers beyond the control limit and update the data. Repeat these steps until the control limit converges. Since the control limit is determined using the local statistical method rather than subjectively, the transitional phase is determined in a more objective and reasonable manner.

3. Phase-Wise Monitoring and Diagnosis Based on KECA Similarity

3.1. CS Statistic

3.2. Model of the Stable Phase

- (1)

- Extend the three-way reference data matrix in the direction of the batch and then vertically cut the matrix in the time direction to yield the time slice matrices. Normalize each of the time slice matrices. Combine the normalized data of all time slices during each stable phase together and extend it into a 2-D matrix , where denotes the number of sampling points collected in the c-th stable phase. Normalize the data.

- (2)

- Establish the KECA model for to obtain the principal component matrix. Set the kernel function and kernel parameters. Compute the kernel matrix K for each of the pre-processed time slice matrices. Obtain eigenvalues and feature vectors of the kernel matrix through matrix decomposition. Obtain the Rayleigh entropy corresponding to each eigenvalue based on Equation (4). According to the Rayleigh entropy procedure, choose the top l principal component vectors to constitute the principal component matrix.

- (3)

- Determine the control limit of the statistic. Compute the statistic CS based on Equation (8) at each moment k. Obtain the control limit R1 of CS through the kernel density approximation.

3.3. Modelling of the Transitional Phase

- (1)

- Arrange the three-way reference data of each transitional phase into the 2D data matrix in the direction of the variable, where denotes the number of sampling points at the transitional phase m.

- (2)

- Establish a sliding KECA model using the input samples . In general, at the early stage of the transition, the process at each time instance is similar to the previous phases. Afterwards, at the late stage of the transition, the process changes to contain the status of the next phase. Hence, we can establish a weighted KECA model for at the transitional phase, yielding a principal component matrix , and , where denotes the principal component matrix obtained from the KECA model constructed at the stable phase before the transitional phase starts, denotes the principal component matrix obtained from the model constructed in the subsequent stable phase after the transitional phase ends. , where denotes the time instance at the current transitional phase, and denote the ending time of the previous stable phase and the starting time of the subsequent stable phase. This enables the model to make transition from the previous stable phase to the next stable phase.

- (3)

- Determine the control limit of the statistic. Compute the statistic CS at each time moment k based on Equation (8). Obtain the control limit R2 of CS through kernel density approximation.

3.4. SV-KCP-based Fault Diagnosis

4. Simulation Experiment

PenSim Simulation Platform

5. Industrial Applications

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhao, C.H.; Wang, F.L.; Yao, Y.; Gao, F.R. Phase-based statistical modeling, online monitoring and quality prediction for batch processes. Acta Autom. Sin. 2010, 36, 366–374. [Google Scholar] [CrossRef]

- Yan, H.L.; Yang, W.D.; Zhang, H.; Tao, B.; Zheng, Y. Density Peaks Clustering Based Sub-phase Partition and Monitoring for Batch Process. In Proceedings of the 2017 6th Data Driven Control and Learning Systems (DDCLS), Chongqing, China, 26–27 May 2017; pp. 297–301. [Google Scholar]

- Gao, X.; Hou, J. An improved SVM integrated GS-PCA fault diagnosis approach of Tennessee Eastman process. Neurocomputing 2016, 174, 906–911. [Google Scholar] [CrossRef]

- Liang, Q.Q.; Hua, H.; Cui, X.; Bo, G.U. Fault diagnosis for refrigeration system based on PCA-PNN. CIESC J. 2016, 67, 1023–1031. [Google Scholar]

- Kosanovich, K.A.; Piovoso, M.J.; Dahl, K.S.; Macgregor, J.F.; Nomikos, P. Multi-way PCA applied to an industrial batch process. In Proceedings of the 1994 American Control Conference—ACC ’94, Baltimore, MD, USA, 29 June–1 July 1994; pp. 1294–1298. [Google Scholar]

- Lu, N.Y.; Gao, F.R. Sub-PCA modeling and on-line monitoring strategy for batch processes. AIChE J. 2004, 50, 255–259. [Google Scholar] [CrossRef]

- Zhao, C.H.; Wang, F.L.; Mao, Z.Z.; Lu, N.Y.; Jia, M.X. Improved batch process monitoring and quality prediction based on multiphasestatistical analysis. Ind. Eng. Chem. Res. 2008, 47, 835–849. [Google Scholar] [CrossRef]

- Zhao, C.H.; Sun, Y.X. Step-wise sequential phase partition (SSPP) algorithm based statistical modeling and online process monitoring. Chemometr. Intell. Lab. Syst. 2013, 125, 109–120. [Google Scholar] [CrossRef]

- Hu, Y.B.; Gao, X.J.; Li, Y.F.; Qi, Y.S.; Wang, P. Multiphase AR-PCA monitoring for batch processes based on the batch weighted soft classifying. Chin. J. Sci. Instrum. 2015, 36, 1291–1300. [Google Scholar]

- Li, C.L.; Wang, P.; Gao, X.J. Improved multi-stage online monitoring strategy for batch process. In Proceedings of the 2016 35th Chinese Control Conference (CCC), Chengdu, China, 27–29 July 2016; pp. 6832–6836. [Google Scholar]

- Guo, R.X.; Zhang, N.; Wang, J.Q.; Dong, J.K. Phase partition and identification based on a two-step method for batch process. Trans. Inst. Meas. Control 2018, 40, 4472–4483. [Google Scholar] [CrossRef]

- Huang, J.P.; Yan, X.F. Quality Relevant and Independent Two Block Monitoring Based on Mutual Information and KPCA. IEEE Trans. Ind. Electromics 2017, 64, 6518–6527. [Google Scholar] [CrossRef]

- Jaffel, I.; Taouali, O.; Harkat, M.F.; Messaoud, H. Moving window KPCA with reduced complexity for nonlinear dynamic process monitoring. ISA Instrum. Syst. Autom. Soc. 2016, 64, 164–192. [Google Scholar] [CrossRef] [PubMed]

- Jenssen, R. Kernel Entropy Component Analysis. IEEE Trans. Pattern Anal. Mach. Intell. 2010, 32, 847–860. [Google Scholar] [CrossRef]

- Yang, Y.H.; Li, X.L.; Liu, X.Z.; Chen, X.B. Wavelet kernel entropy component analysis with application to industrial process monitoring. Neurocomputing 2015, 147, 395–402. [Google Scholar] [CrossRef]

- Qi, Y.S.; Zhang, H.L.; Gao, X.J.; Wang, P. Novel fault monitoring strategy for chemical process based on KECA. CIESC J. 2016, 67, 1063–1069. [Google Scholar]

- Li, Z.X.; Jiang, Y.; Hu, C.; Peng, Z. Recent Progress on Decoupling Diagnosis of Hybrid Failures in Gear Transmission Systems using Vibration Sensor Signal: A Review. Measurement 2016, 90, 4–19. [Google Scholar] [CrossRef]

- Rostami, H.; Blue, J.; Yugma, C. Automatic equipment fault fingerprint extraction for the fault diagnostic on the batch process data. Appl. Soft Comput. 2018, 68, 972–989. [Google Scholar] [CrossRef]

- Nguyen, T.B.L.; Djeziri, M.; Ananou, B.; Ouladsine, M.; Pinaton, J. Fault prognosis for batch production based on percentile measure and gamma process: Application to semiconductor manufacturing. J. Process Control 2016, 48, 72–80. [Google Scholar] [CrossRef]

- Wang, G.; Li, J.D.; Sun, C.Y.; Jiao, J.F. Least Squares and Contribution Plot Based Approach for Quality-Related Process Monitoring. IEEE Access 2018, 6, 54158–54166. [Google Scholar] [CrossRef]

- Guo, X.P.; Yang, M.; Li, Y. Modified reconstruction-based contribution plots for fault isolation. Chin. J. Sci. Instrum. 2015, 36, 1193–1200. [Google Scholar]

- Yue, H.H.; Qin, S.J. Reconstruction-based fault identification using a combined index. Ind. Eng. Chem. Res. 2001, 40, 4403–4414. [Google Scholar] [CrossRef]

- Zhang, M.M.; Wu, L.X.; Zeng, X.J. Algorithm based on direct signal and entropy optimization Spaceborne/fixed BISAR imaging. Foreign Electron. Meas. Technol. 2015, 34, 23–34. [Google Scholar]

- Cui, W.L.; Pan, J.; He, G.Y.; Pang, Y.W. Class center and feature weighting based feature selection algorithm. Electron. Meas. Technol. 2015, 38, 25–29. [Google Scholar]

- Qi, Y.; Wang, Y.; Lu, C.; Wang, L. Improved batch process monitoring and diagnosis based on multiphase KECA. IFAC-PapersOnLine 2018, 51, 827–832. [Google Scholar] [CrossRef]

- Jenssen, R.; Principe, J.C.; Erdogmus, D. The Cauchy-Schwarz Divergence and Parzen Windowing: Connections to Graph Theory and Mercer Kernel. J. Frankl. Inst. 2006, 343, 614–629. [Google Scholar] [CrossRef]

- Jenssen, R.; Eltoft, T. A New Information Theoretic Analysis of Sum-of-Squared-Error Kernel Clustering. Neurocomputing 2018, 72, 23–32. [Google Scholar] [CrossRef]

- Wang, D.M.; Lu, C.H.; Jiang, W.W.; Xiao, M.X.; Li, B.R. Study on PSO-based decision-tree SVM multi-class classification method. J. Electron. Meas. Instrum. 2015, 29, 611–615. [Google Scholar]

- Scholkopf, B.; Platt, J.; Hofmann, T. Kernel maximum entropy data transformation and an enhanced spectral clustering algorithm. In Conference of Advances in Neural Information Processing Systems; MIT Press: Cambridge, MA, USA, 2006; pp. 633–640. [Google Scholar]

- Birol, G.; Undey, C.; Cinar, A. A modular simulation package for fed-batch fermentation: Penicillin production. Comput. Chem. Eng. 2002, 26, 1553–1565. [Google Scholar] [CrossRef]

| Number | Process Variable | Number | Process Variable |

|---|---|---|---|

| 1 | aeration rate (L·h-1) | 6 | carbon dioxide concentration (g·L−1) |

| 2 | agitator power (W) | 7 | pH |

| 3 | substrate feed rate (K) | 8 | fermentor temperature (K) |

| 4 | dissolved oxygen concentration (%) | 9 | culture volume (L) |

| 5 | substrate feed temperature (kcal) | 10 | cooling water flow rate (L·h−1) |

| Fault Numbers | Procedure Variables | Fault Types |

|---|---|---|

| 1 | Substrate supply rate | Step disturbance |

| 2 | Agitation power | Step disturbance |

| 3 | Ventilation rate | Step disturbance |

| 4 | Substrate supply rate | Slope disturbance |

| 5 | Agitation power | Slope disturbance |

| 6 | Ventilation rate | Slope disturbance |

| Working Condition | Error Rate of Type I (%) | Error Rate of Type Ⅱ (%) | ||||

|---|---|---|---|---|---|---|

| MPCA | Sub-PCA | KECA | MPCA | Sub-PCA | KECA | |

| Normal | 5.71 | 2.51 | 1.78 | — | — | — |

| Fault 1 | 1.54 | 0.79 | 0.67 | 13.46 | 43.08 | 6.8 |

| Fault 2 | 5.69 | 1.43 | 0.47 | 6.97 | 0 | 0 |

| Fault 3 | 7.72 | 2.8 | 1.27 | 12.33 | 0.9 | 0.78 |

| Fault 4 | 3.84 | 1.89 | 1 | 23.4 | 41.7 | 5.2 |

| Fault 5 | 3.13 | 1.36 | 1 | 8.9 | 38.9 | 2 |

| Fault 6 | 3.22 | 0.76 | 0.75 | 55.25 | 42.5 | 3.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, Y.; Meng, X.; Lu, C.; Gao, X.; Wang, L. KECA Similarity-Based Monitoring and Diagnosis of Faults in Multi-Phase Batch Processes. Entropy 2019, 21, 121. https://doi.org/10.3390/e21020121

Qi Y, Meng X, Lu C, Gao X, Wang L. KECA Similarity-Based Monitoring and Diagnosis of Faults in Multi-Phase Batch Processes. Entropy. 2019; 21(2):121. https://doi.org/10.3390/e21020121

Chicago/Turabian StyleQi, Yongsheng, Xuebin Meng, Chenxi Lu, Xuejin Gao, and Lin Wang. 2019. "KECA Similarity-Based Monitoring and Diagnosis of Faults in Multi-Phase Batch Processes" Entropy 21, no. 2: 121. https://doi.org/10.3390/e21020121

APA StyleQi, Y., Meng, X., Lu, C., Gao, X., & Wang, L. (2019). KECA Similarity-Based Monitoring and Diagnosis of Faults in Multi-Phase Batch Processes. Entropy, 21(2), 121. https://doi.org/10.3390/e21020121