Numerical Study of Double-Layered Microchannel Heat Sinks with Different Cross-Sectional Shapes

Abstract

:1. Introduction

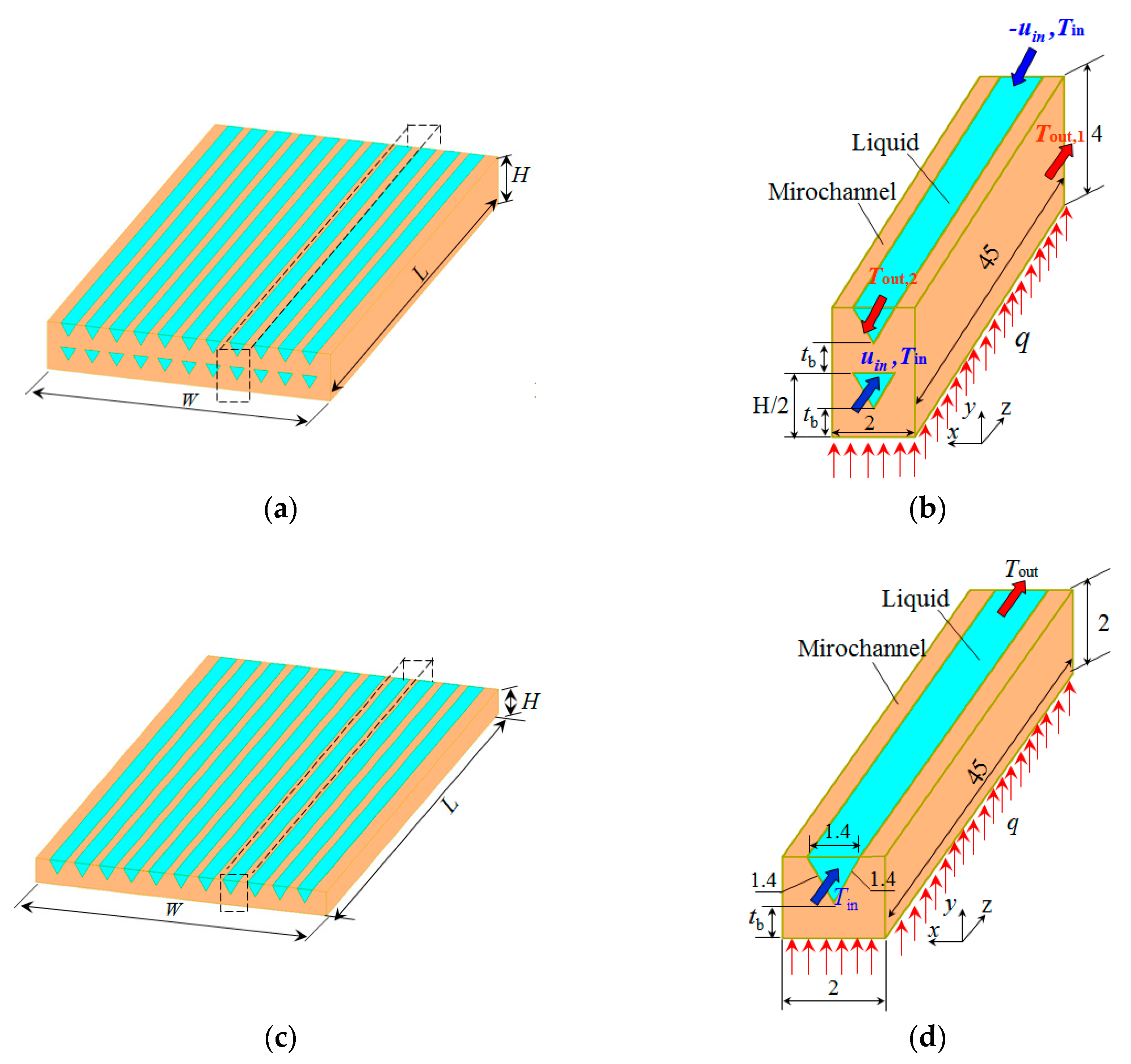

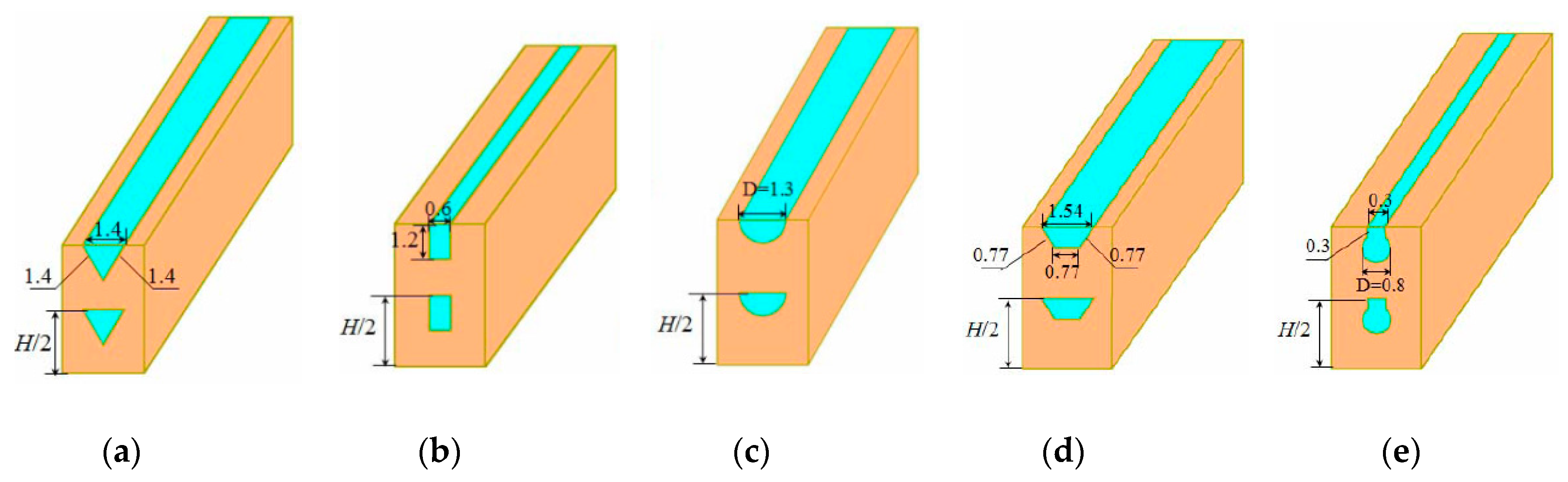

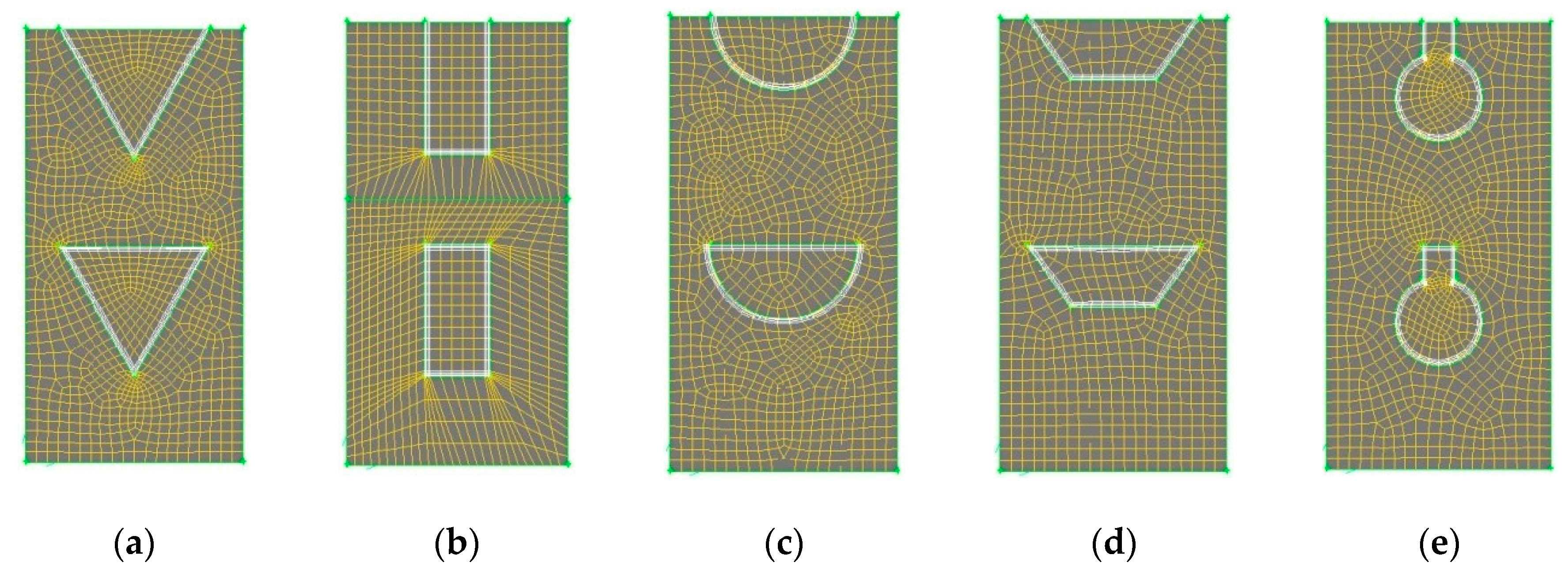

2. Model Description

3. Numerical Methods

3.1. Governing Equations and Models

3.2. Boundary Conditions

3.3. Numerical Methods

3.4. Data Reduction

3.5. Validation of Models and Methods

4. Results and Discussion

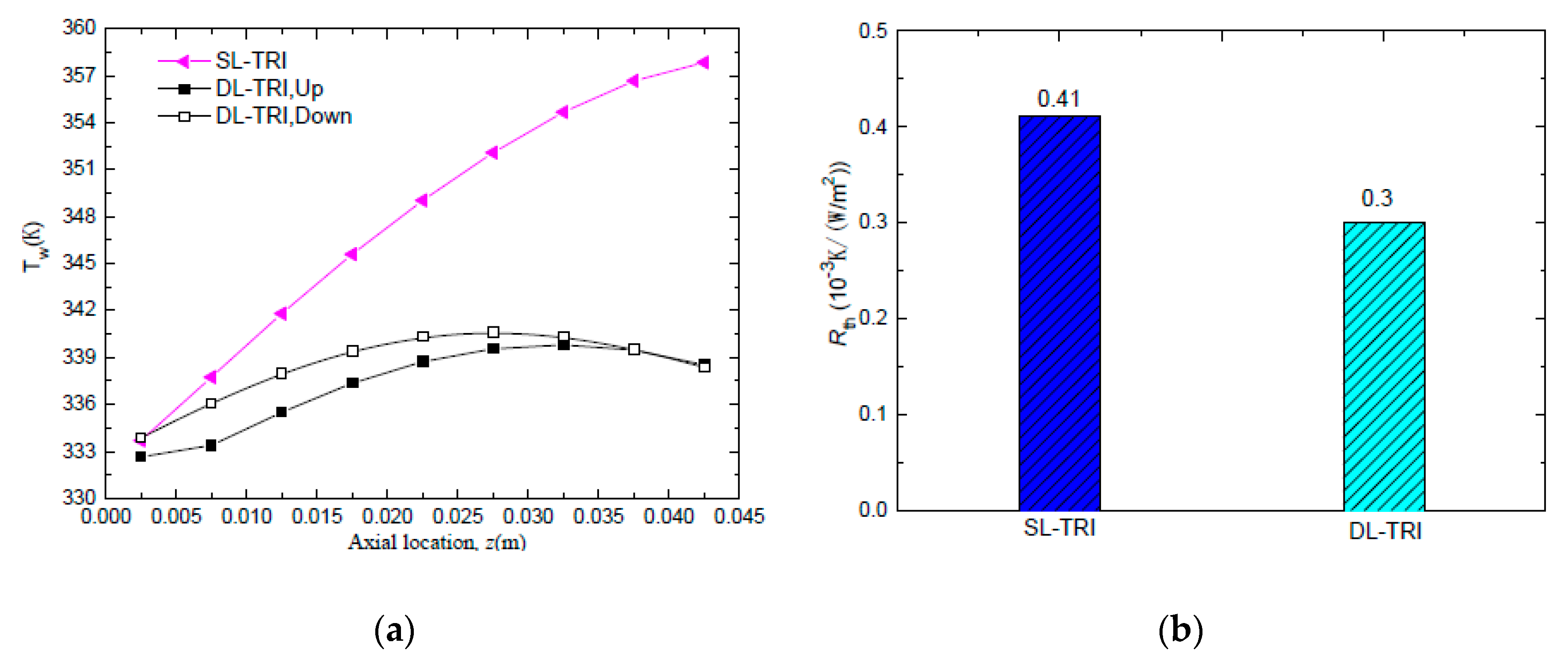

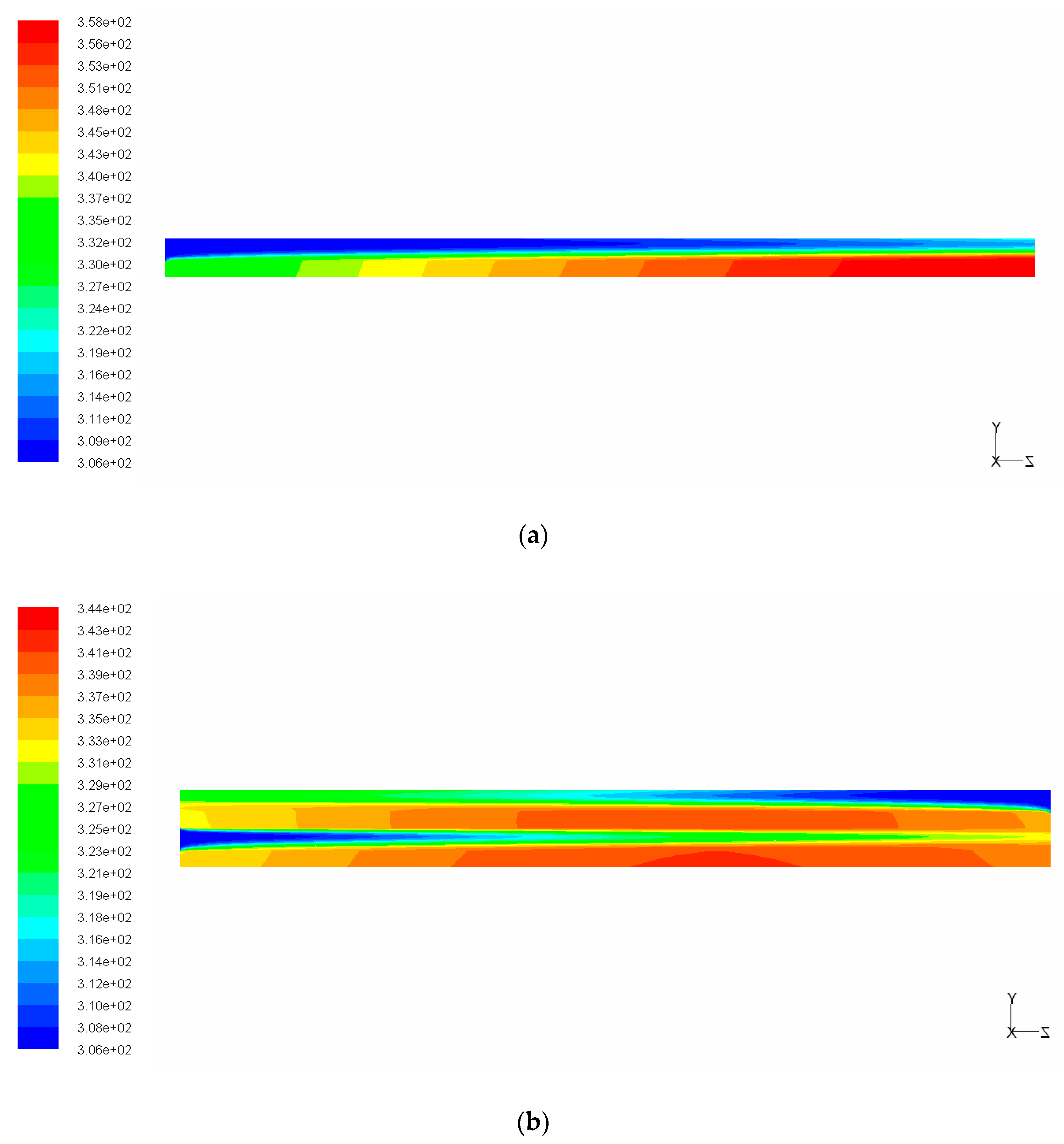

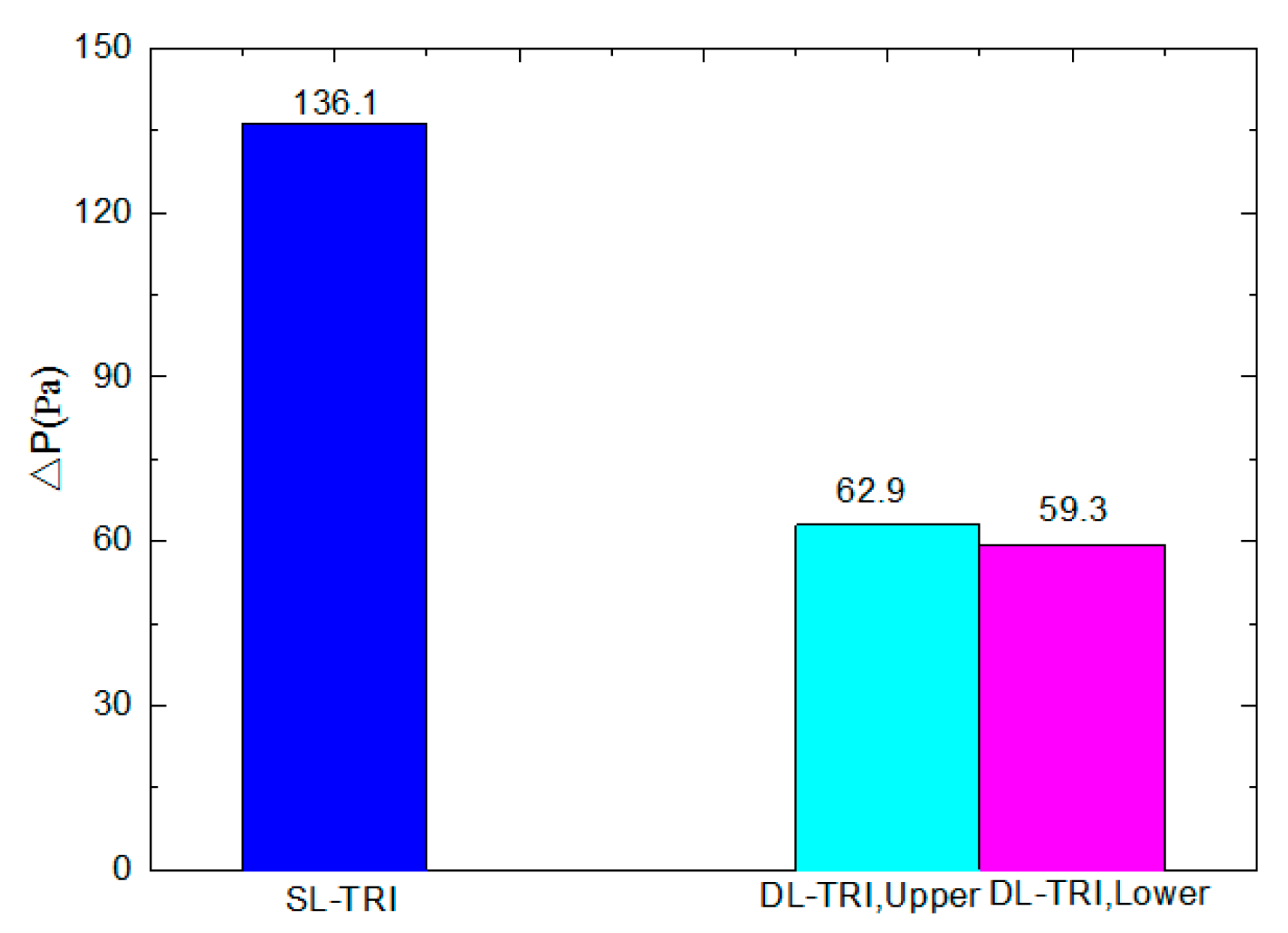

4.1. Heat Transfer Enhancement and Pressure Drop Reduction of DL-MCHS

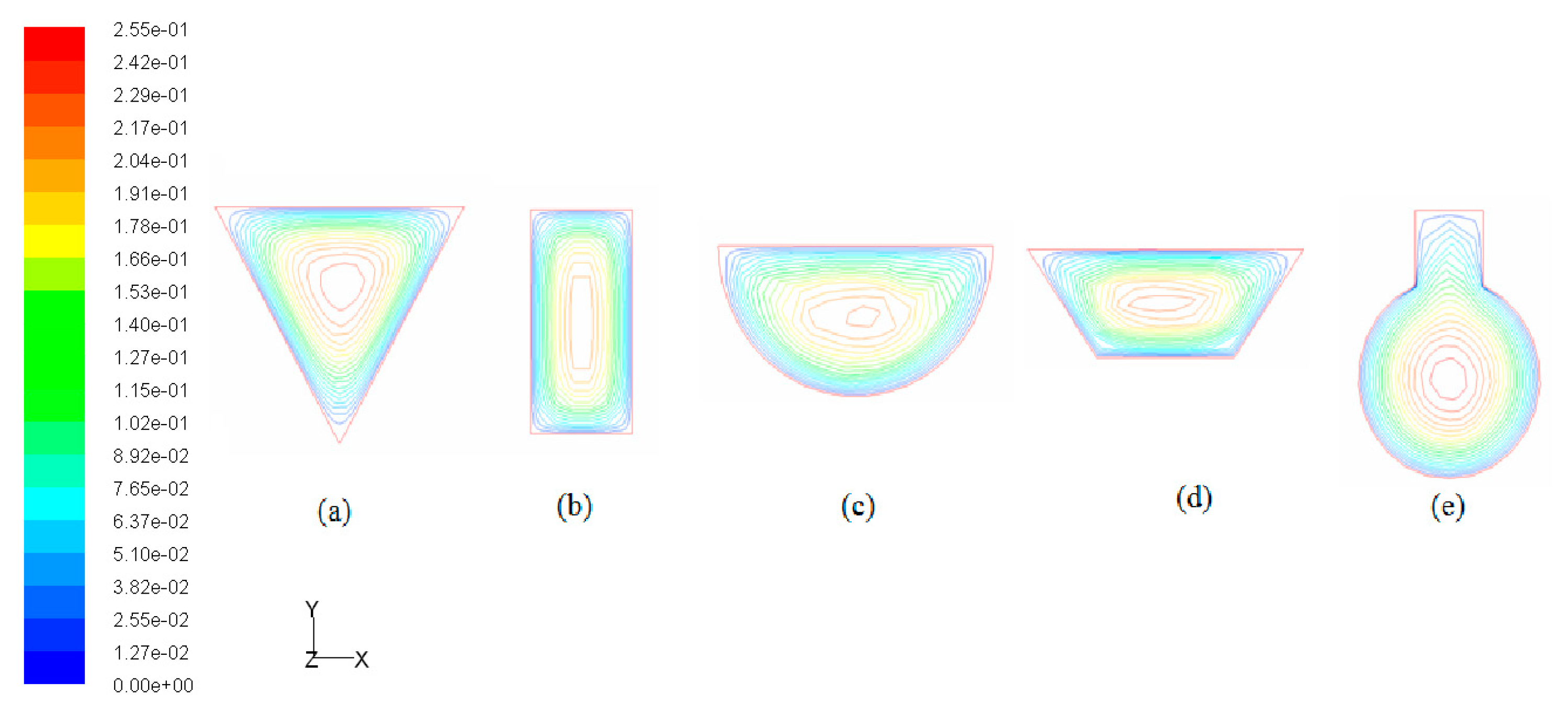

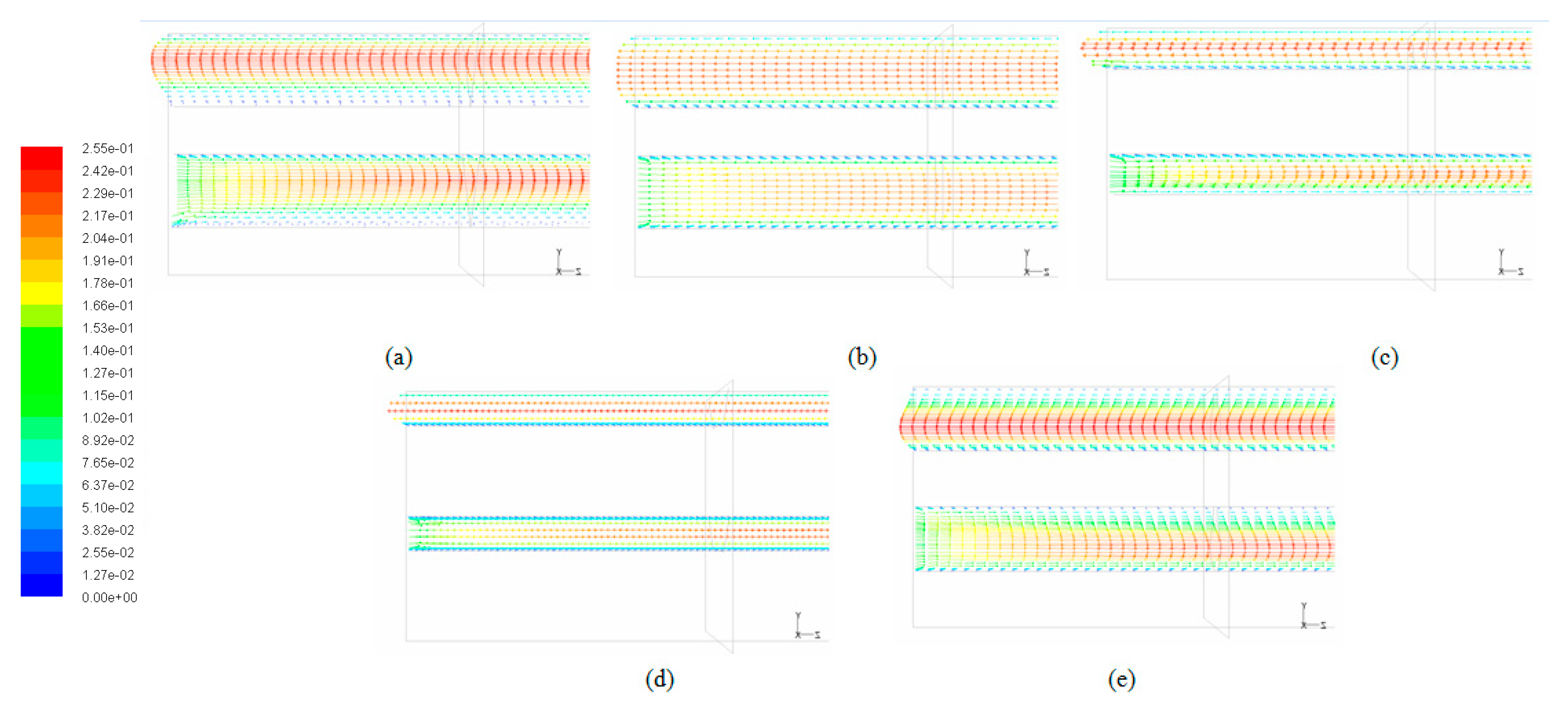

4.2. Effects of Microchannel Shape on the Performance of DL-MCHS

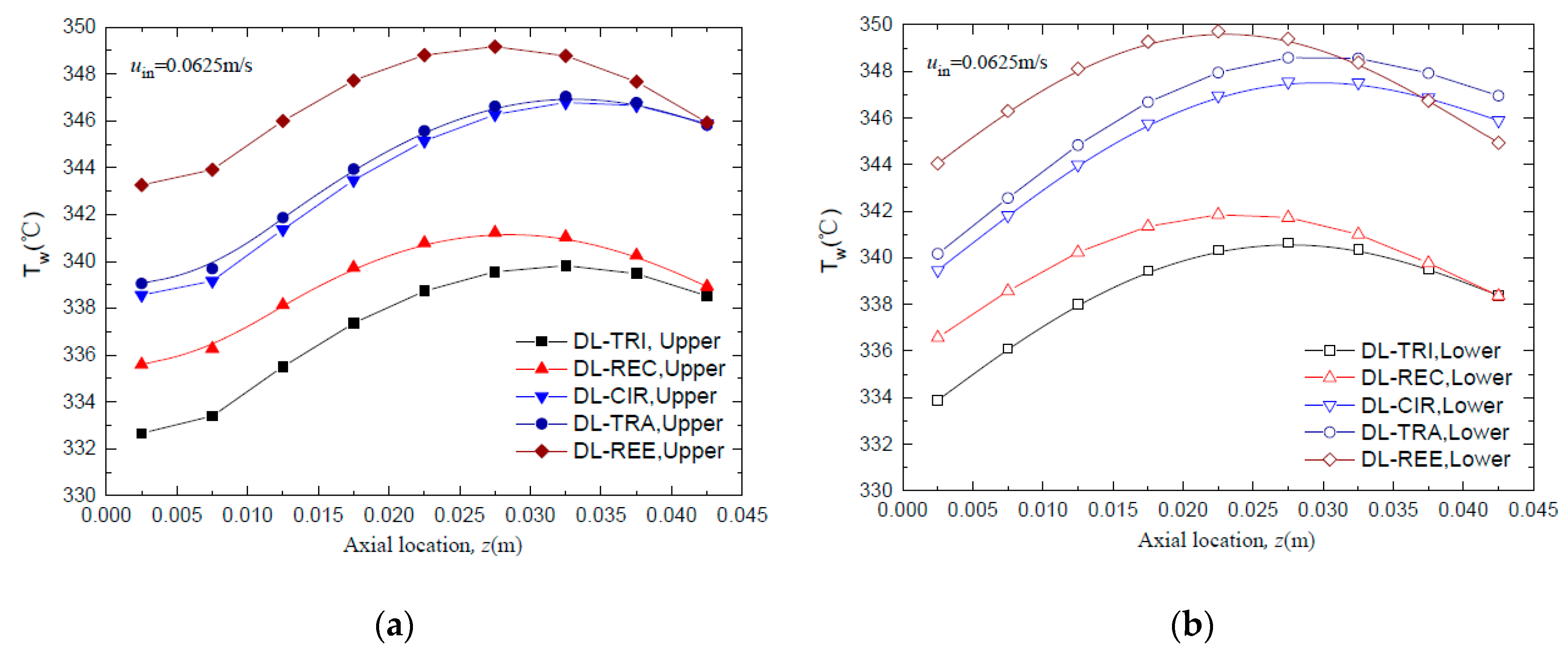

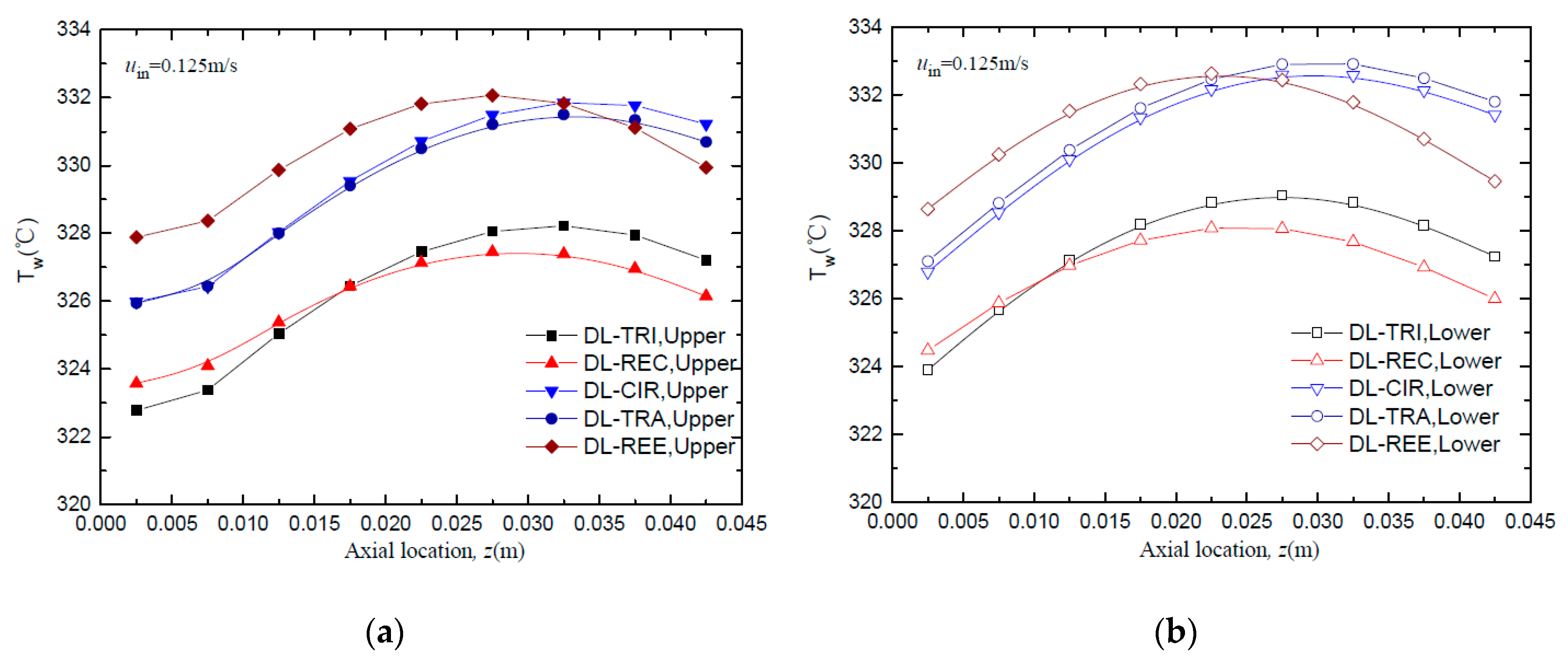

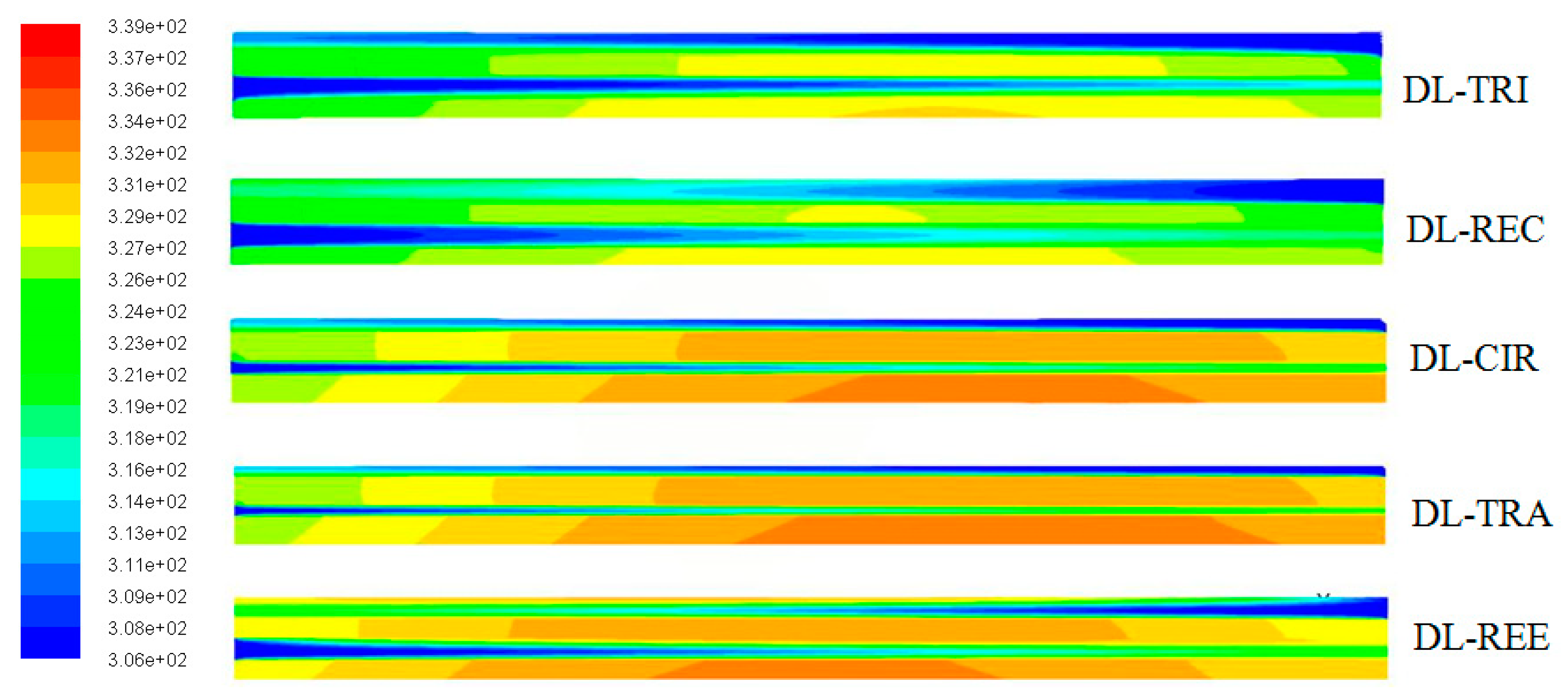

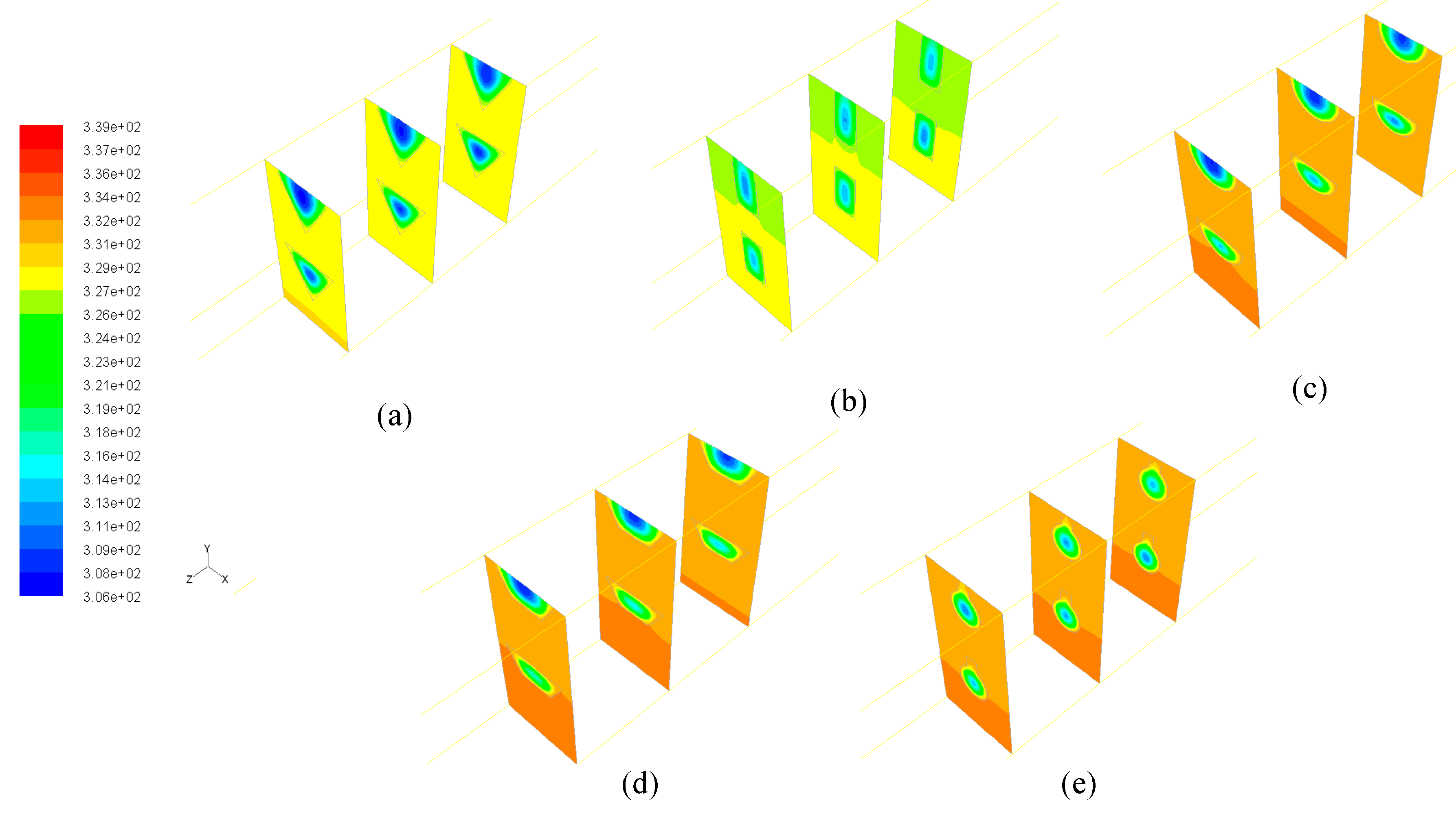

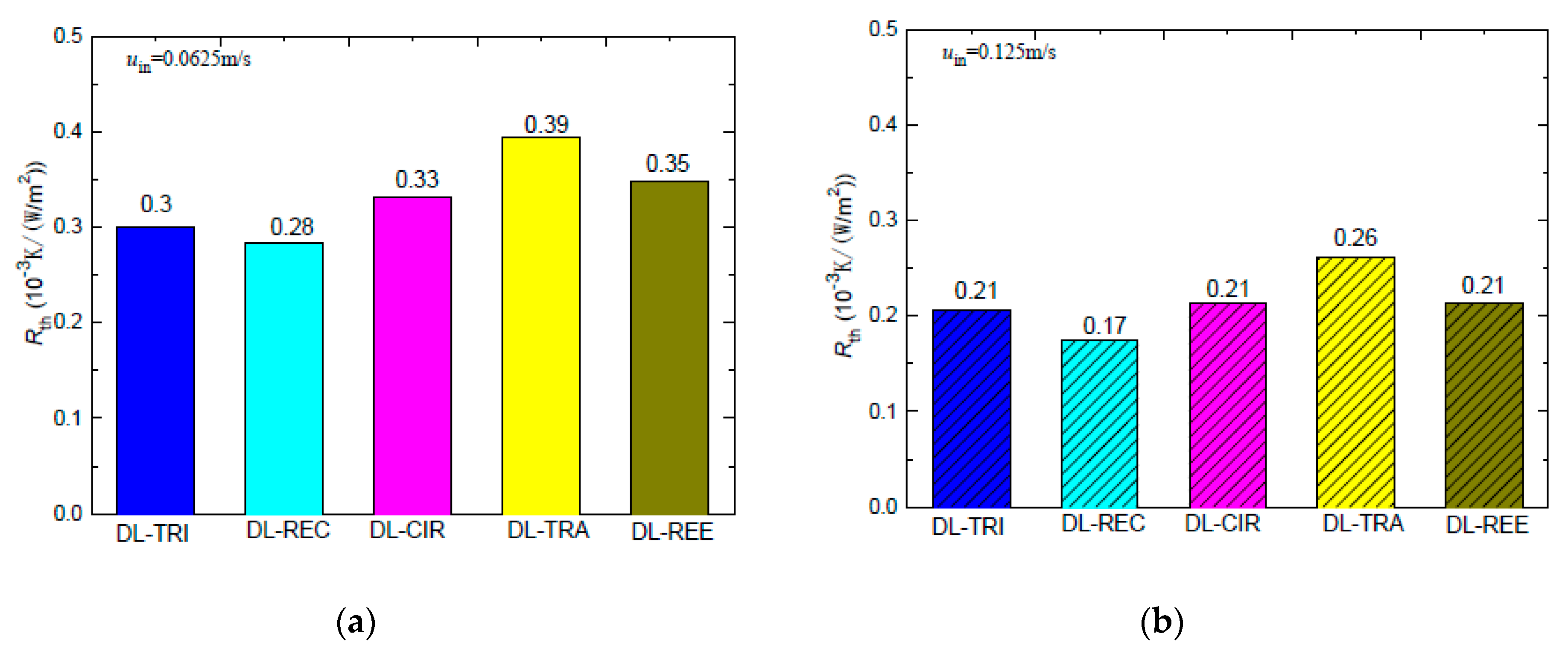

4.2.1. Thermal Characteristics

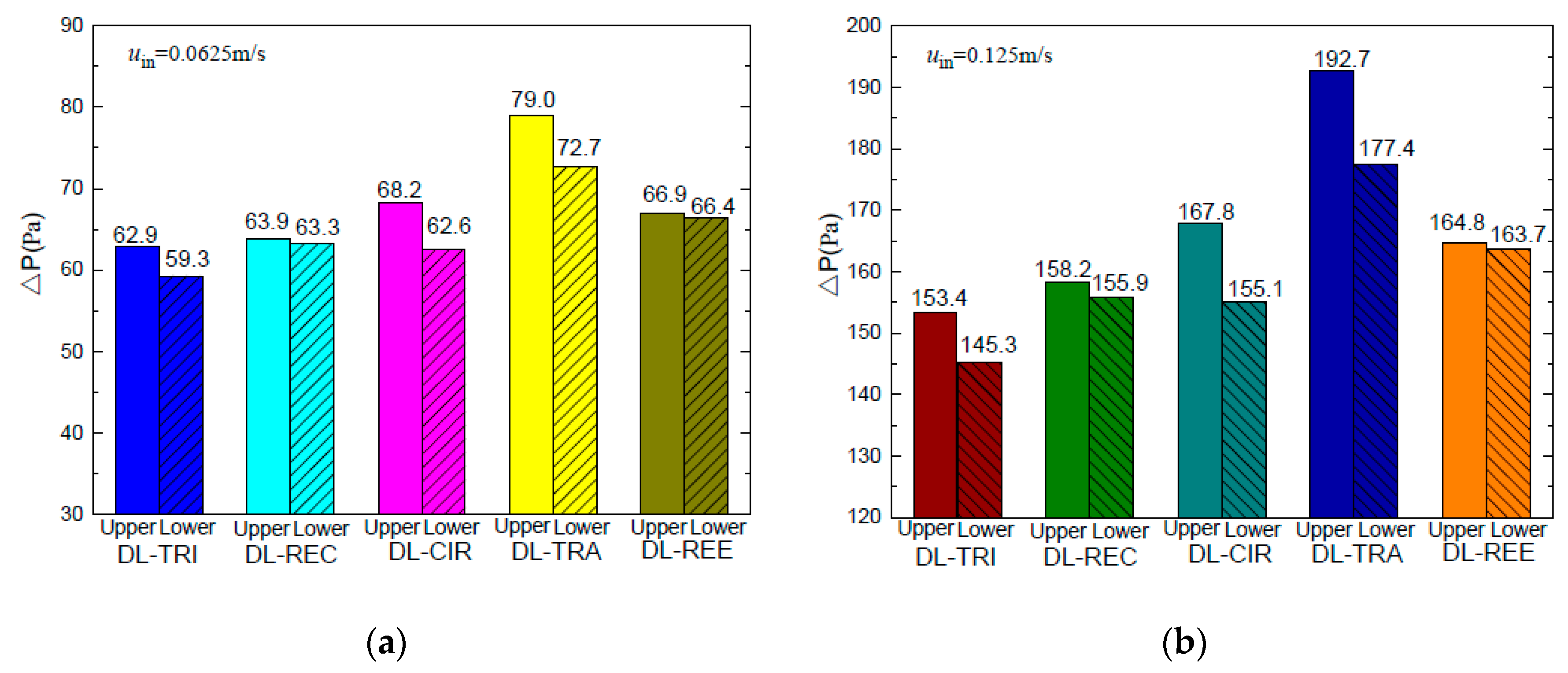

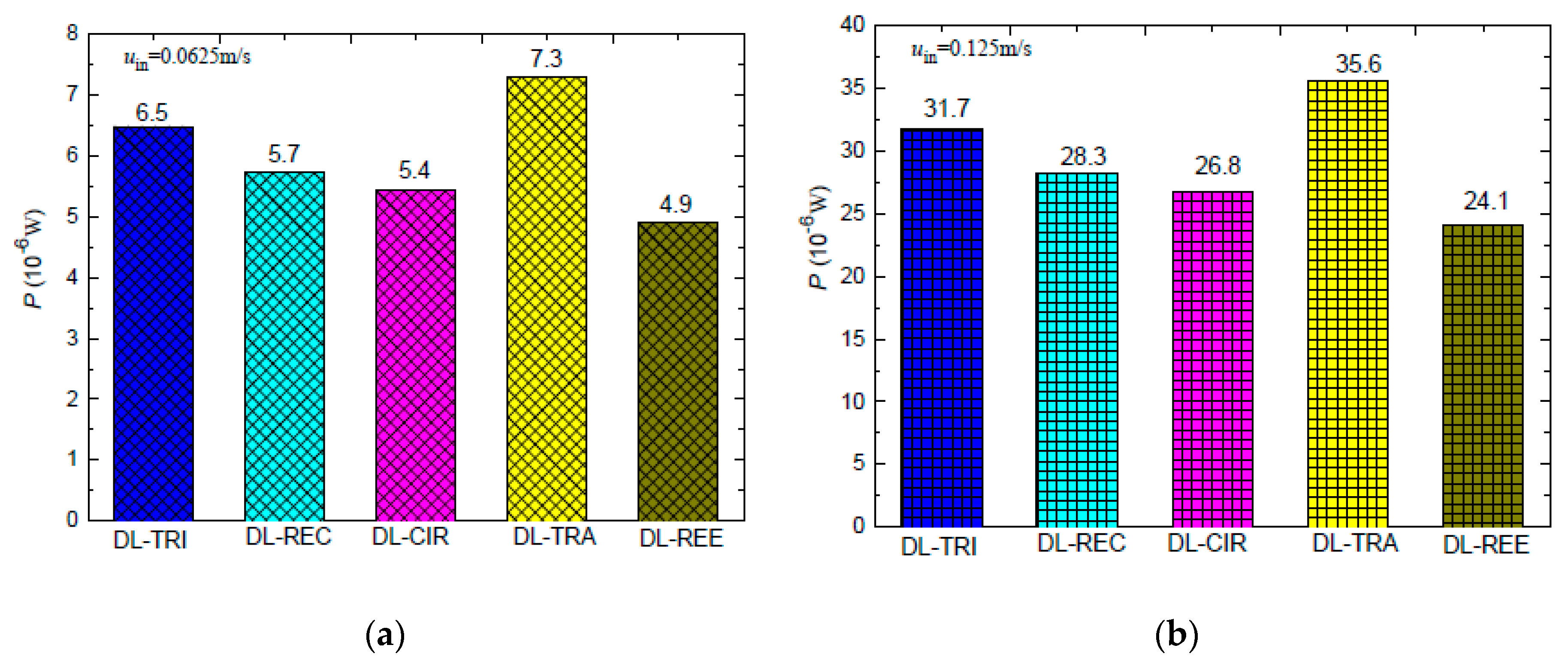

4.2.2. Pressure Drop and Pumping Power

4.2.3. Overall Performance Evaluation

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mahajan, R.; Chia-pin, C.; Chrysler, G. Cooling a microprocessor chip. Proc. IEEE 2006, 94, 1476–1486. [Google Scholar] [CrossRef]

- Tuckerman, D.B.; Pease, R.F.W. High-performance heat sinking for VlSI. IEEE Electron. Device Lett. 1981, 2, 126–129. [Google Scholar] [CrossRef]

- Deng, D.; Wan, W.; Tang, Y.; Wan, Z.; Liang, D. Experimental investigations on flow boiling performance of reentrant and rectangular microchannels—A comparative study. Int. J. Heat Mass Transf. 2015, 82, 435–446. [Google Scholar] [CrossRef]

- Li, P.; Xie, Y.; Zhang, D.; Xie, G. Heat Transfer Enhancement and Entropy Generation of Nanofluids Laminar Convection in Microchannels with Flow Control Devices. Entropy 2016, 18, 134. [Google Scholar] [CrossRef]

- Deng, D.; Wan, W.; Qin, Y.; Zhang, J.; Chu, X. Flow boiling enhancement of structured microchannels with micro pin fins. Int. J. Heat Mass Transf. 2017, 105, 338–349. [Google Scholar] [CrossRef]

- Vafai, K.; Zhu, L. Analysis of two-layered micro-channel heat sink concept in electronic cooling. Int. J. Heat Mass Transf. 1999, 31, 1176–1186. [Google Scholar] [CrossRef]

- Chong, S.H.; Ooi, K.T.; Wong, T.N. Optimization of single and double layer counter flow microchannel heat sinks. Appl. Therm. Eng. 2002, 22, 1569–1585. [Google Scholar] [CrossRef]

- Cheng, Y.J. Numerical simulation of stacked microchannel heat sink with mixing-enhanced passive structure. Int. Commun. Heat Mass Transf. 2007, 34, 295–303. [Google Scholar] [CrossRef]

- Wei, X.J.; Joshi, Y.; Patterson, M.K. Experimental and numerical study of a stacked microchannel heat sink for liquid cooling of microelectronic devices. ASME J. Heat Transf. 2007, 129, 1432–1444. [Google Scholar] [CrossRef]

- Hung, T.C.; Yan, W.M.; Li, W.P. Analysis of heat transfer characteristics of doublelayered layered microchannel heat sink. Int. J. Heat Mass Transf. 2012, 55, 3090–3099. [Google Scholar] [CrossRef]

- Hung, T.C.; Yan, W.M.; Wang, X.D.; Huang, Y.X. Optimal design of geometric parameters of double-layered microchannel heat sinks. Int. J. Heat Mass Transf. 2012, 55, 3262–3272. [Google Scholar] [CrossRef]

- Xie, G.N.; Liu, Y.Q.; Sunden, B.; Zhang, W.H. Computational study and optimization of laminar heat transfer and pressure loss of double-layer microchannels for chip liquid cooling. ASME J. Therm. Sci. Eng. Appl. 2013, 5, 011004. [Google Scholar] [CrossRef]

- Lin, L.; Chen, Y.Y.; Zhang, X.X.; Wang, X.D. Optimization of geometry and flow rate distribution for double-layer microchannel heat sink. Int. J. Therm. Sci. 2014, 78, 158–168. [Google Scholar] [CrossRef]

- Leng, C.; Wang, X.D.; Wang, T.H.; Yan, W.M. Multi-parameter optimization of flow and heat transfer for a novel double-layered microchannel heat sink. Int. J. Heat Mass Transf. 2015, 84, 359–369. [Google Scholar] [CrossRef]

- Jing, D.; He, L. Thermal Characteristics of Staggered Double-Layer Microchannel Heat Sink. Entropy 2018, 20, 537. [Google Scholar] [CrossRef]

- Kulkarni, K.; Afzal, A.; Kim, K. Multi-objective optimization of a double-layered microchannel heat sink with temperature-dependent fluid properties. Appl. Therm. Eng. 2016, 99, 262–272. [Google Scholar] [CrossRef]

- Leng, C.; Wang, X.D.; Wang, T.H. An improved design of double-layered microchannel heat sink with truncated top channels. Appl. Therm. Eng. 2015, 79, 54–62. [Google Scholar] [CrossRef]

- Wang, S.; Li, X.; Wang, X.; Lu, G. Flow and heat transfer characteristics in double-layered microchannel heat sinks with porous fins. Int. J. Heat Mass Transf. 2018, 93, 41–47. [Google Scholar] [CrossRef]

- Osanloo, B.; Mohammadi-Ahmar, A.; Solati, A.; Baghani, M. Performance enhancement of the double-layered micro-channel heat sink by use of tapered channels. Appl. Therm. Eng. 2016, 102, 1345–1354. [Google Scholar] [CrossRef]

- Wong, K.C.; Ang, M.L. Thermal hydraulic performance of a double-layer microchannel heat sink with channel contraction. Int. Commun. Heat Mass Transf. 2017, 81, 269–275. [Google Scholar] [CrossRef]

- Zhai, Y.L.; Xia, G.D.; Liu, X.F.; Wang, J. Characteristics of entropy generation and heattransfer in double-layered micro heat sinks with complex structure. Energy Convers. Manag. 2015, 103, 477–486. [Google Scholar] [CrossRef]

- Sharma, D.; Singh, P.P.; Garg, H. Numerical analysis of trapezoidal shape double layer microchannel Heat Sink. Int. J. Mech. Ind. Eng. 2013, 3, 10–15. [Google Scholar]

- Kulkarni, K.; Khan, A.A.; Kim, K. Performance analysis of double-layer microchannel heat sink with various microchannel shapes. Heat Transf. Res. 2018, 49, 349–368. [Google Scholar] [CrossRef]

- Deng, D.; Wan, W.; Tang, Y.; Shao, H.; Huang, Y. Experimental and numerical study of thermal enhancement in reentrant copper microchannels. Int. J. Heat Mass Transf. 2015, 91, 656–670. [Google Scholar] [CrossRef]

- Wu, J.M.; Zhao, J.Y.; Tseng, K.J. Parametric study on the performance of double-layered microchannels heat sink. Energy Convers. Manag. 2014, 80, 550–560. [Google Scholar] [CrossRef]

- Zhang, S.; Cui, N.; Xiong, Y.; Feng, Y.; Qin, J.; Bao, W. Effect of channel aspect ratio on chemical recuperation process in advanced aeroengines. Energy 2017, 123, 9–19. [Google Scholar] [CrossRef]

| Sample | Arrangement and Cross-Sectional Shape of Microchannels | Width of the Unit Cell W (mm) | Height of the Unit Cell H (mm) | Length of the Unit Cell L (mm) | Thickness of Bottom Wall, tb (mm) | Hydraulic Diameter Dh (mm) | Cross-Sectional Area of Microchannel Ac (mm2) |

|---|---|---|---|---|---|---|---|

| DL-TRI | Double-layered triangular | 2 | 4 | 45 | 0.79 | 0.81 | 0.849 |

| DL-REC | Double-layered rectangular | 2 | 4 | 45 | 0.8 | 0.8 | 0.72 |

| DL-CIR | Double-layered circular | 2 | 4 | 45 | 1.35 | 0.79 | 0.664 |

| DL-TRA | Double-layered trapezoidal | 2 | 4 | 45 | 1.33 | 0.8 | 0.77 |

| DL-REE | Double-layered reentrant | 2 | 4 | 45 | 0.93 | 0.76 | 0.587 |

| SL-TRI | Single-layered triangular | 2 | 2 | 45 | 0.79 | 0.81 | 0.849 |

| Sample | Layer | Inlet Velocity (m/s) | Maximum Temperature of Microchannel Base Tmax (K) | Maximum Wall Temperature Difference ΔTw,max (K) |

|---|---|---|---|---|

| DL-TRI | Upper | 0.0625 | 344 | 7.2 |

| Lower | 6.8 | |||

| Upper | 0.125 | 332 | 5.4 | |

| Lower | 5.2 | |||

| DL-REC | Upper | 0.0625 | 342 | 5.6 |

| Lower | 5.3 | |||

| Upper | 0.125 | 328 | 3.9 | |

| Lower | 3.6 | |||

| DL-CIR | Upper | 0.0625 | 348 | 8.2 |

| Lower | 8.1 | |||

| Upper | 0.125 | 333 | 5.9 | |

| Lower | 5.8 | |||

| DL-TRA | Upper | 0.0625 | 356 | 8.0 |

| Lower | 8.4 | |||

| Upper | 0.125 | 339 | 5.6 | |

| Lower | 5.8 | |||

| DL-REE | Upper | 0.0625 | 350 | 5.9 |

| Lower | 5.6 | |||

| Upper | 0.125 | 333 | 4.2 | |

| Lower | 4 | |||

| SL-TRI | - | 0.125 | 358 | 24.3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, D.; Pi, G.; Zhang, W.; Wang, P.; Fu, T. Numerical Study of Double-Layered Microchannel Heat Sinks with Different Cross-Sectional Shapes. Entropy 2019, 21, 16. https://doi.org/10.3390/e21010016

Deng D, Pi G, Zhang W, Wang P, Fu T. Numerical Study of Double-Layered Microchannel Heat Sinks with Different Cross-Sectional Shapes. Entropy. 2019; 21(1):16. https://doi.org/10.3390/e21010016

Chicago/Turabian StyleDeng, Daxiang, Guang Pi, Weixun Zhang, Peng Wang, and Ting Fu. 2019. "Numerical Study of Double-Layered Microchannel Heat Sinks with Different Cross-Sectional Shapes" Entropy 21, no. 1: 16. https://doi.org/10.3390/e21010016

APA StyleDeng, D., Pi, G., Zhang, W., Wang, P., & Fu, T. (2019). Numerical Study of Double-Layered Microchannel Heat Sinks with Different Cross-Sectional Shapes. Entropy, 21(1), 16. https://doi.org/10.3390/e21010016