Cognitive Factories: Modeling Situated Entropy in Physical Work Carried Out by Humans and Robots

Abstract

1. Introduction

2. Background

3. Conceptual Framework

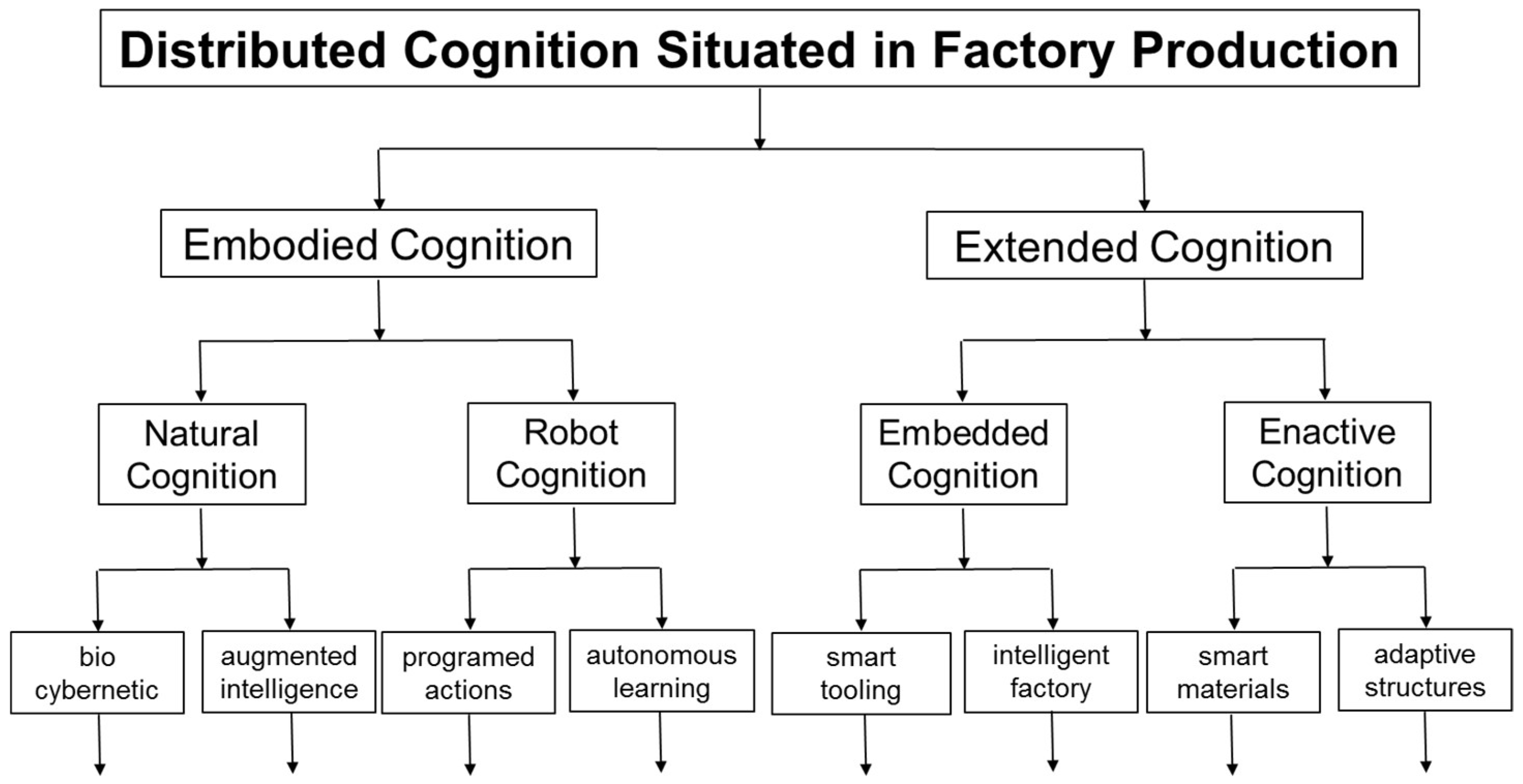

3.1. Extant Theoretical Frameworks

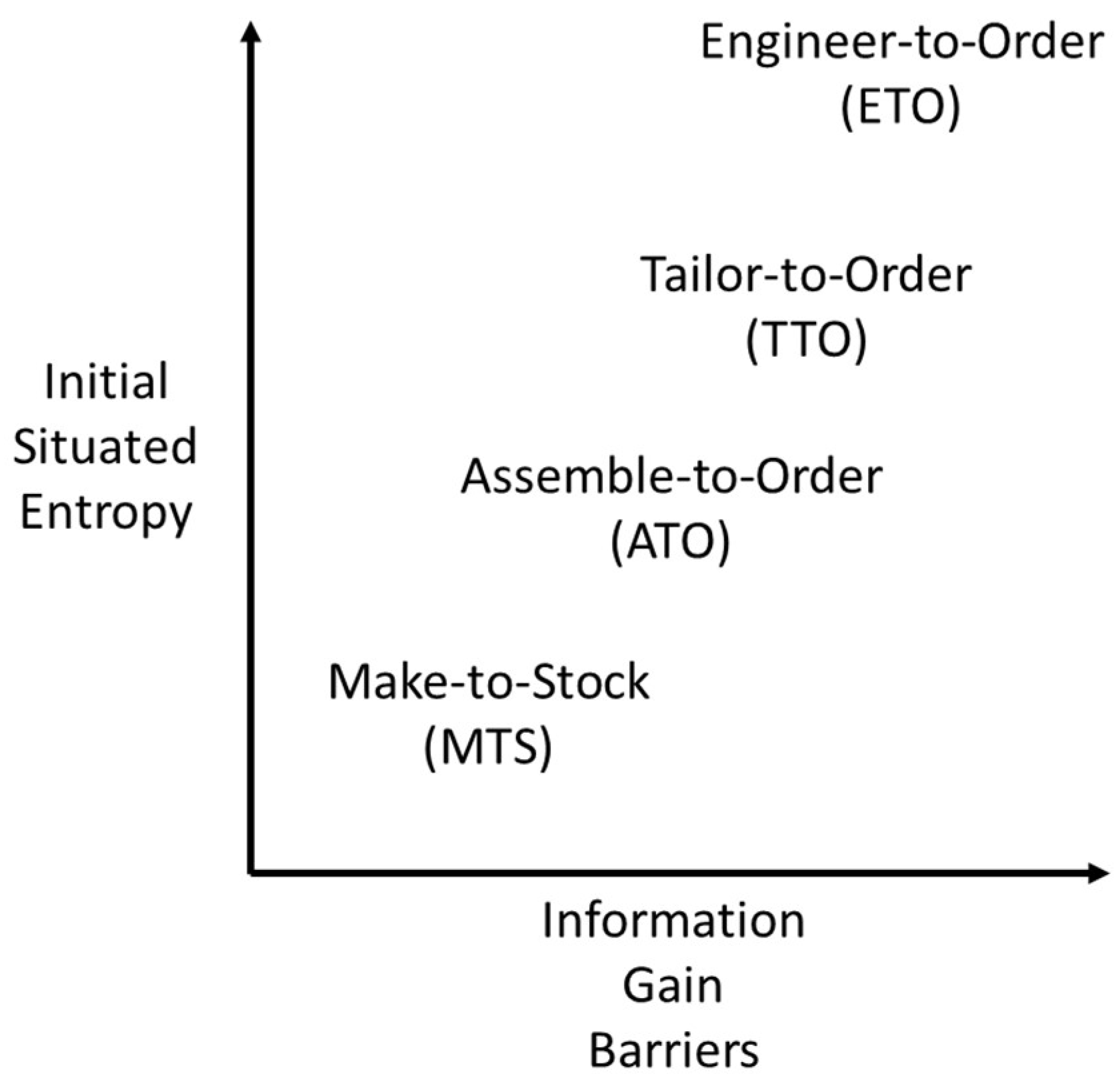

3.2. Conceptual Framework for Modelling

4. Modelling Examples

4.1. Discrete Equal Probability

4.2. Discrete Unequal Probability

4.3. Joint Entropy

0.25/5log0.25/5 + 0.25/5log0.25/5 + 0.25/5log0.25/5]

4.4. Conditional Entropy

4.5. Differential Entropy

5. Preliminary Modelling Methodology

5.1. Methodology Focus—Net Information Gain

5.2. Methodology Strategy One: Apply Engineering Methods

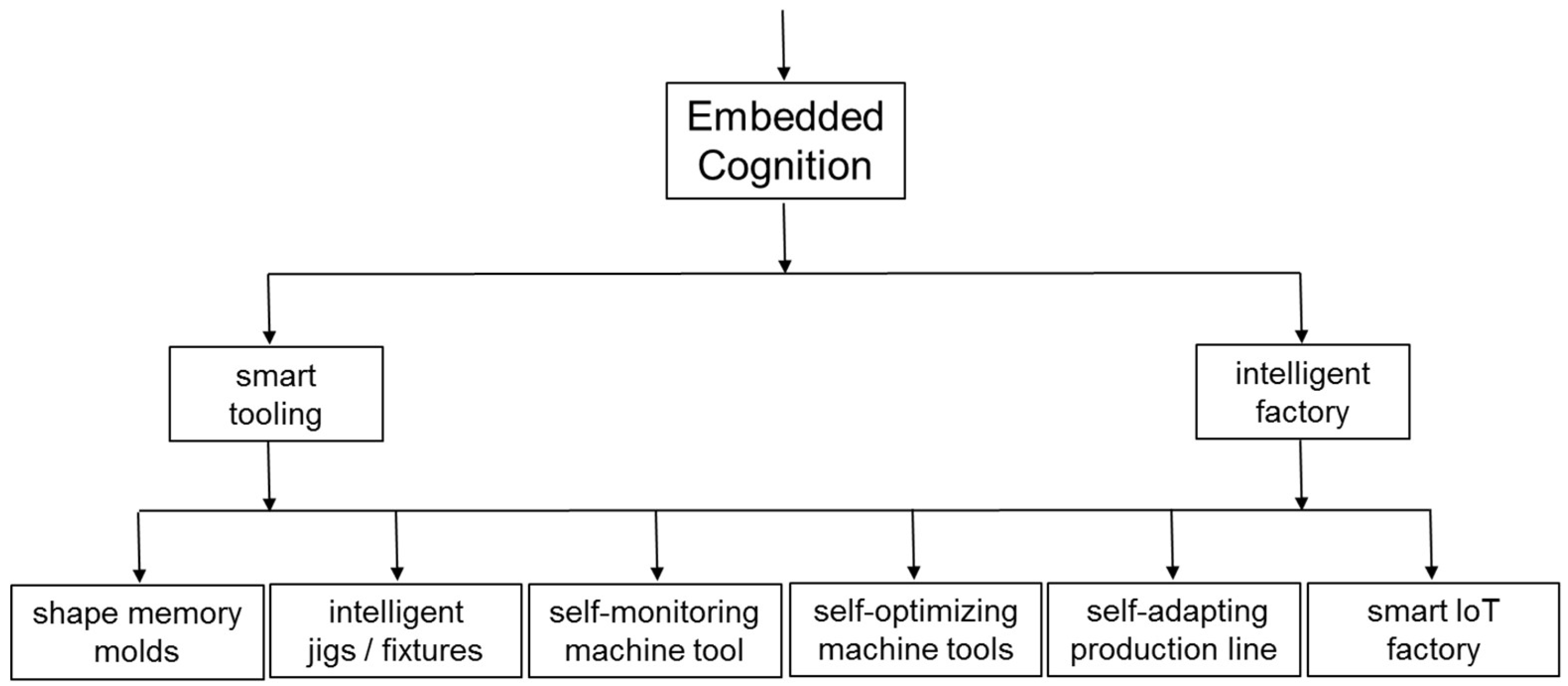

5.3. Methodology Strategy Two—Introducing Embedded Artificial Cognition

5.4. Methodology Strategy Three—Introducing Enactive Artificial Cognition

5.5. Methodology Strategy Four—Enhance Embodied Artificial Cognition

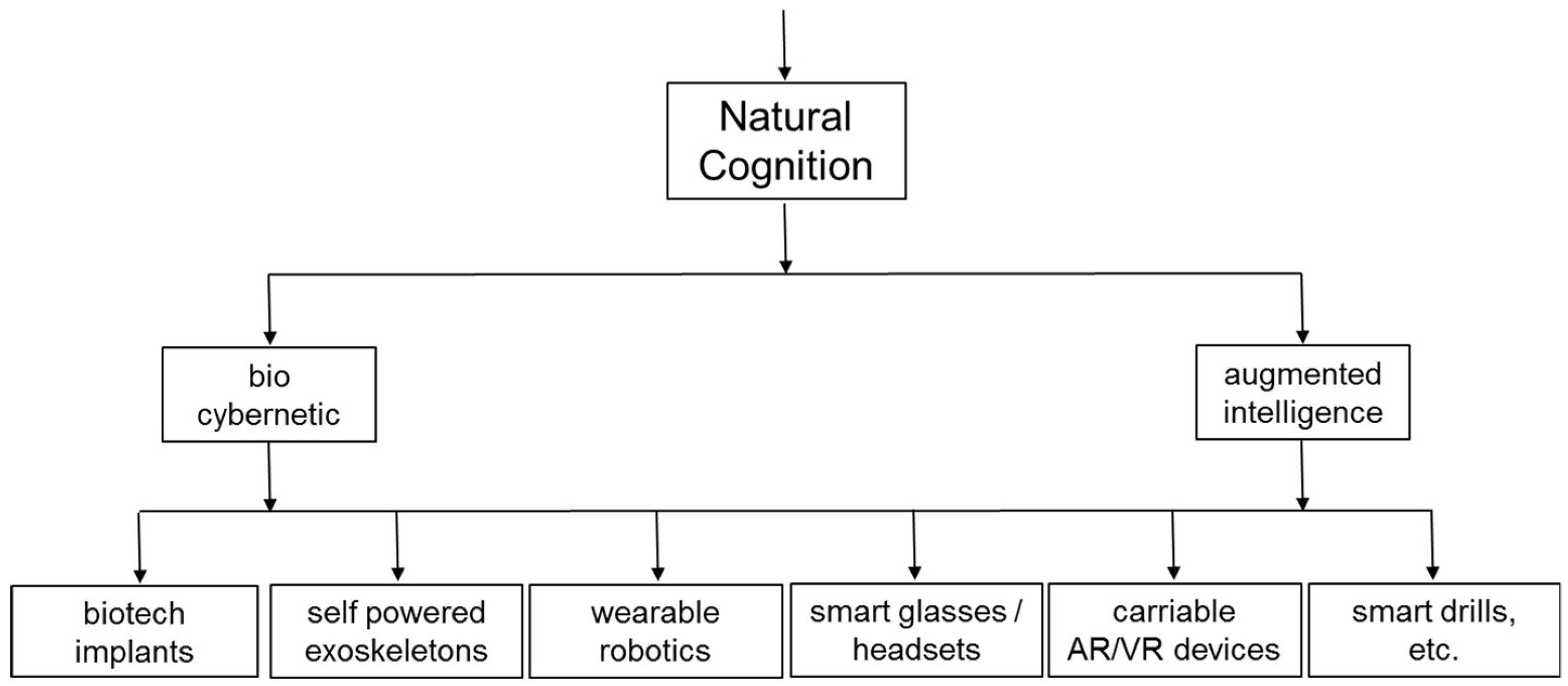

5.6. Methodology Strategy Five—Enhance Embodied Cognition of Human Operatives

5.7. Methodology Strategy Six—Balance Deployment of Artificial and Natural Embodied Cognition

5.8. Methodology Summary

6. Discussion

6.1. Implications for Theory Building

6.2. Implications for Applied Research

6.3. Implications for Practice

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Erdem, E.; Haspalamutgil, K.; Patoglu, V.; Uras, T. Causality-based planning and diagnostic reasoning for cognitive factories. In Proceedings of the 17th IEEE Conference on Emerging Technologies & Factory Automation (ETFA), Krakow, Poland, 17–21 September 2012; pp. 1–8. [Google Scholar]

- Zäh, M.F.; Beetz, M.; Shea, K.; Reinhart, G.; Bender, K.; Lau, C.; Ostgathe, M.; Vogl, W.; Wiesbeck, M.; Engelhard, M.; et al. The cognitive factory. In Changeable and Reconfigurable Manufacturing Systems; El, H.A., Maraghy, H.A., Eds.; Springer: London, UK, 2009; pp. 355–371. [Google Scholar]

- Gibbs, S. Mercedes-Benz Swaps Robots for People on Its Assembly Lines; The Guardian: London, UK, 2016. [Google Scholar]

- Nobre, F.S.; Tobias, A.M.; Walker, D.S. The pursuit of cognition in manufacturing organizations. J. Manuf. Syst. 2008, 27, 145–157. [Google Scholar] [CrossRef]

- Fiorentino, A.; Feriti, G.C.; Giardini, C.; Ceretti, E. Part precision improvement in incremental sheet forming of not axisymmetric parts using an artificial cognitive system. J. Manuf. Syst. 2015, 35, 215–222. [Google Scholar] [CrossRef]

- Saribatur, Z.G.; Erdem, E.; Patoglu, V. Cognitive factories with multiple teams of heterogeneous robots: Hybrid reasoning for optimal feasible global plans. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2014), Chicago, IL, USA, 14–18 September 2014; pp. 2923–2930. [Google Scholar]

- Fast-Berglund, Å.; Fässberg, T.; Hellman, F.; Davidsson, A.; Stahre, J. Relations between complexity, quality and cognitive automation in mixed-model assembly. J. Manuf. Syst. 2013, 32, 449–455. [Google Scholar] [CrossRef]

- Woods, D.D.; Dekker, S.; Cook, R.; Johannesen, L.; Sarter, N. Behind Human Error; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Nowakowski, P.R. Bodily Processing: The Role of Morphological Computation. Entropy 2017, 19, 295. [Google Scholar] [CrossRef]

- Van Duijn, M.; Keijzer, F.; Franken, D. Principles of minimal cognition: Casting cognition as sensorimotor coordination. Adapt. Behav. 2006, 14, 157–170. [Google Scholar] [CrossRef]

- Shannon, C.E. A Mathematical Theory of Communication. Bell Syst. Tech. J. 1948, 27, 379–423, 623–656. [Google Scholar] [CrossRef]

- Zurek, W.H. Complexity, Entropy and the Physics of Information; Westview Press: Boulder, CO, USA, 2018. [Google Scholar]

- Fox, S. Reliable autonomous production systems: Combining industrial engineering methods and situation awareness modelling in critical realist design of autonomous production systems. Systems 2018, 6, 26. [Google Scholar] [CrossRef]

- Ziha, K. Uncertainty of multi-level systems of events. In Proceedings of the 23rd IEEE International Conference on Information Technology Interfaces (ITI 2001), Pula, Croatia, 20–22 June 2001; pp. 439–444. [Google Scholar]

- Fox, S. The importance of information and communication design for manual skills instruction with augmented reality. J. Manuf. Technol. Manag. 2010, 21, 188–205. [Google Scholar] [CrossRef]

- Gao, Y.; Feng, Y.; Tan, J. Exploratory study on cognitive information gain modeling and optimization of personalized recommendations for knowledge reuse. J. Manuf. Syst. 2017, 43, 400–408. [Google Scholar] [CrossRef]

- Teo, J.; Abbass, H.A. Multiobjectivity and complexity in embodied cognition. IEEE Trans. Evolu. Comput. 2005, 9, 337–360. [Google Scholar] [CrossRef]

- Amigoni, F.; Luperto, M.; Schiaffonati, V. Toward generalization of experimental results for autonomous robots. Robot. Auton. Syst. 2017, 90, 4–14. [Google Scholar] [CrossRef]

- Moravec, H. Mind Children: The Future of Robot and Human Intelligence; Harvard University Press: Cambridge, MA, USA, 1988. [Google Scholar]

- Fernandez-Gauna, B.; Lopez-Guede, J.M.; Graña, M. Transfer learning with partially constrained models: Application to reinforcement learning of linked multicomponent robot system control. Robot. Autom. Syst. 2013, 61, 694–703. [Google Scholar] [CrossRef]

- Lu, J.; Behbood, V.; Hao, P.; Zuo, H.; Xue, S.; Zhang, G. Transfer learning using computational intelligence: A survey. Knowl.-Based Syst. 2015, 80, 14–23. [Google Scholar] [CrossRef]

- Müller, V.C.; Hoffmann, M. What is morphological computation? On how the body contributes to cognition and control. Artif. Life 2017, 23, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Guida, A.; Gobet, F.; Tardieu, H.; Nicolas, S. How chunks, long-term working memory and templates offer a cognitive explanation for neuroimaging data on expertise acquisition: A two-stage framework. Brain Cognit. 2012, 79, 221–244. [Google Scholar] [CrossRef] [PubMed]

- Glăveanu, V.P. Habitual creativity: Revising habit, reconceptualizing creativity. Rev. Gen. Psychol. 2012, 16, 78–92. [Google Scholar] [CrossRef]

- Kalyuga, S.; Rikers, R.; Pass, F. Educational implications of expertise reversal effect in learning and performance of complex cognitive and sensorimotor skills. Educ. Psychol. Rev. 2012, 24, 313–337. [Google Scholar] [CrossRef]

- Klingberg, T. The Overflowing Brain: Information Overload and the Limits of Working Memory; Oxford University Press: New York, NY, USA, 2009. [Google Scholar]

- Lindblom, J.; Thorvald, P. Towards a framework for reducing cognitive load in manufacturing personnel. Adv. Cogn. Eng. Neuroergon. 2014, 11, 233–244. [Google Scholar]

- Léger, P.M.; Davis, F.D.; Cronan, T.P.; Perret, J. Neurophysiological correlates of cognitive absorption in an enactive training context. Comput. Hum. Behav. 2014, 34, 273–283. [Google Scholar] [CrossRef]

- Brown, J.S.; Collins, A.; Duguid, P. Situated cognition and the culture of learning. Educ. Res. 1989, 18, 32–42. [Google Scholar] [CrossRef]

- Skulmowski, A.; Pradel, S.; Kühnert, T.; Brunnett, G.; Rey, G.D. Embodied learning using a tangible user interface: The effects of haptic perception and selective pointing on a spatial learning task. Comput. Educ. 2016, 92, 64–75. [Google Scholar] [CrossRef]

- Chandler, P.; Sweller, J. Cognitive load theory and the format of instruction. Cognit. Instr. 1991, 8, 293–332. [Google Scholar] [CrossRef]

- Varela, F.J.; Thompson, E.; Rosch, E. The Embodied Mind: Cognitive Science and Human Experience; MIT Press: Cambridge, MA. USA, 2017. [Google Scholar]

- Austin, J.L. How to Do Things with Words: The William James Lectures; Harvard University: Cambridge, MA, USA, 1962. [Google Scholar]

- Dant, T. The pragmatics of material interation. J. Consum. Cult. 2008, 8, 11–33. [Google Scholar] [CrossRef]

- Robinson, D. Introducing Performative Pragmatics; Routledge: London, UK, 2013. [Google Scholar]

- Wilson, D.; Sperber, D. Relevance Theory. In The Handbook of Pragmatics; Horn, L.R., Ward, G., Eds.; Blackwell: Oxford, UK, 2004; pp. 607–632. [Google Scholar]

- Pfeifer, R.; Bongard, J. How the Body Shapes the Way We Think: A New View of Intelligence; MIT Press: Cambridge, MA, USA, 2006. [Google Scholar]

- Wilson, M. Six Views of Embodied Cognition. Psychon. B. Rev. 2002, 9, 625–636. [Google Scholar] [CrossRef]

- Wilson, R.A.; Foglia, L. Embodied Cognition. In The Stanford Encyclopedia of Philosophy, Spring 2017 ed.; Zalta, E.N., Ed.; Stanford University: Stanford, CA, USA, 2017; Available online: https://plato.stanford.edu/archives/spr2017/entries/embodied-cognition (accessed on 27 February 2018).

- Burattini, E.; Rossi, S. Periodic activations of behaviours and emotional adaptation in behaviour-based robotics. Connect. Sci. 2010, 22, 197–213. [Google Scholar] [CrossRef]

- Mataric, M.J. Behaviour-based control: Examples from navigation, learning, and group behaviour. J. Exp. Theor. Artif. Intell. 1997, 9, 323–336. [Google Scholar] [CrossRef]

- Jones, J.L. Robot Programming: A Practical Guide to Behavior-Based Robotics; McGraw Hill: New York, NY, USA, 2004. [Google Scholar]

- Sweller, J. Instructional Design in Technical Areas; ACER Press: Camberwell, Australia, 1999. [Google Scholar]

- Searle, J.R. A taxonomy of illocutionary acts. In Language, Mind, and Knowledge; Günderson, K., Ed.; University of Minnesota Press: Minneapolis, USA, 1975; Volume 7, pp. 344–369. [Google Scholar]

- Albano, L.D.; Suh, N.P. The information axiom and its implication. In Intelligent Concurrent Design: Fundamentals, Methodology, Modeling and Practice; ASME Publ. DE 66; ASME: New York, NY, USA, 1993. [Google Scholar]

- Boothroyd, G.; Dewhurst, P.; Knight, W.A. Product Design for Manufacture and Assembly; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Greif, M. The Visual Factory: Building Participation through Shared Information; Productivity Press: New York, NY, USA, 2017. [Google Scholar]

- Ortiz, C.A.; Park, M. Visual Controls: Applying Visual Management to the Factory; CRC Press: New York, NY, USA, 2010. [Google Scholar]

- Banas, W.; Sekala, A.; Gwiazda, A.; Foit, K.; Hryniewicz, P.; Kost, G. The modular design of robotic workcells in a flexible production line. Mater. Sci. Eng. 2015, 95, 012099. [Google Scholar] [CrossRef]

- Brolin, A.; Thorvald, P.; Case, K. Experimental study of cognitive aspects affecting human performance in manual assembly. Prod. Manuf. Res. 2017, 5, 141–163. [Google Scholar]

- Chung, K.H.; Ross, M.F. Differences in motivational properties between job enlargement and job enrichment. Acad. Manag. Rev. 1977, 2, 113–122. [Google Scholar] [CrossRef]

- Funk, M.; Dingler, T.; Cooper, J.; Schmidt, A. Stop helping me-I’m bored: Why assembly assistance needs to be adaptive. In Proceedings of the 2015 ACM International Joint Conference on Pervasive and Ubiquitous Computing and Proceedings of the 2015 ACM International Symposium on Wearable Computers, Osaka, Japan, 7–11 September 2015; pp. 1269–1273. [Google Scholar]

- Dahmus, J.B.; Gonzalez-Zugasti, J.P.; Otto, K.N. Modular product architecture. Des. Stud. 2001, 22, 409–424. [Google Scholar] [CrossRef]

- Simpson, T.W.; Jiao, J.; Siddique, Z.; Hölttä-Otto, K. Advances in Product Family and Product Platform Design; Springer: New York, NY, USA, 2014. [Google Scholar]

- Wang, J.; Ma, Y.; Zhang, L.; Gao, R.X.; Wu, D. Deep learning for smart manufacturing: Methods and applications. J. Manuf. Syst. 2018, in press. [Google Scholar] [CrossRef]

- Fox, S. Potential of virtual-social-physical convergence for project manufacturing. J. Manuf. Technol. Manag. 2014, 25, 1209–1223. [Google Scholar] [CrossRef]

- Fitts, P.M.; Posner, M.I. Human Performance; Brooks: Belmont, CA, USA, 1967. [Google Scholar]

- Romiszowski, A. The development of physical skills: Instruction in the psychomotor domain. In Instructional-Design Theories and Models: A New Paradigm of Instructional Theory; Reigeluth, C.M., Ed.; Lawrence Erlbaum Associates: Mahwah, NJ, USA, 1999; Volume II, pp. 457–481. [Google Scholar]

- Michalowicz, J.V.; Nichols, J.M.; Bucholtz, F. Handbook of Differential Entropy; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Reinhart, G.; Patron, C. Integrating augmented reality in the assembly domain-fundamentals, benefits and applications. CIRP Ann. Manuf. Technol. 2003, 52, 5–8. [Google Scholar] [CrossRef]

- Fox, S. Getting real about innovations: Formulating innovation descriptions that can reduce ontological uncertainty. Int. J. Manag. Proj. Bus. 2012, 5, 86–104. [Google Scholar] [CrossRef]

- Scholze, S.; Barata, J.; Kotte, O. Context Awareness for self-adaptive and highly available Production Systems. In Doctoral Conference on Computing, Electrical and Industrial Systems; Springer: Berlin/Heidelberg, Germany, 2013; pp. 210–217. [Google Scholar]

- Wachter, S.; Mittelstadt, B.; Floridi, L. Transparent, explainable, and accountable AI for robotics. Sci. Robot. 2017, 2, eaan6080. [Google Scholar] [CrossRef]

- Benjeddou, A. Smart structures, materials and nano technology in engineering. Int. J. Smart Nano Mater. 2018, 9, 85–87. [Google Scholar] [CrossRef]

- Gu, Y.; Sheng, W.; Crick, C.; Ou, Y. Automated assembly skill acquisition and implementation through human demonstration. Robot. Autom. Syst. 2018, 99, 1–16. [Google Scholar] [CrossRef]

- Billard, A.; Calinon, S.; Dillmann, R.; Schaal, S. Robot programming by demonstration. In Springer Handbook of Robotics; Siciliano, B., Khatib, O., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 1371–1394. [Google Scholar]

- Vishwakarma, D.K.; Kapoor, R.; Dhiman, A. A proposed unified framework for the recognition of human activity by exploiting the characteristics of action dynamics. Robot. Autom. Syst. 2016, 77, 25–38. [Google Scholar] [CrossRef]

- Nehaniv, C.L. Nine Billion Correspondence Problems. In Imitation and Social Learning in Robots, Humans and Animals; Nehaniv, C.L., Dautenhahn, K., Eds.; Cambridge University Press: Cambridge, UK, 2007; pp. 35–42. [Google Scholar]

- Muñoz, P.; R-Moreno, M.D.; Barrero, D.F. Unified framework for path-planning and task-planning for autonomous robots. Robot. Autom. Syst. 2016, 82, 1–14. [Google Scholar] [CrossRef]

- Taylor, E.F. A call to action. Am. J. Phys. 2003, 71, 423–425. [Google Scholar] [CrossRef]

- Feynman, R.P. The Principle of Least Action in Quantum Mechanics. Ph.D. Thesis, Princeton University, Princeton, NJ, USA, 1942. [Google Scholar]

- Terekhovich, V. Metaphysics of the principle of least action. Stud. Hist. Philos. Sci. B 2018, 62, 189–201. [Google Scholar] [CrossRef]

- Novak, D.; Riener, R. A survey of sensor fusion methods in wearable robotics. Robot. Autom. Syst. 2015, 73, 155–170. [Google Scholar] [CrossRef]

- Matsuhashi, M.; Hallett, M. The timing of the conscious intention to move. Eur. J. Neurosci. 2008, 28, 2344–2351. [Google Scholar] [CrossRef] [PubMed]

- Dinh, B.K.; Xiloyannis, M.; Cappello, L.; Antuvan, C.W.; Yen, S.C.; Masia, L. Adaptive backlash compensation in upper limb soft wearable exoskeletons. Robot. Autom. Syst. 2017, 92, 173–186. [Google Scholar] [CrossRef]

- Kral, A.; Sharma, A. Developmental neuroplasticity after cochlear implantation. Trends Neurosci. 2012, 35, 111–122. [Google Scholar] [CrossRef] [PubMed]

- Seth, A.K. The Cybernetic Bayesian Brain—From Interoceptive Inference to Sensorimotor Contingencies. In Open MIND; Metzinger, T., Windt, J.M., Eds.; MIND Group: Frankfurt, Germany, 2015. [Google Scholar]

- Kiumarsi, B.; Vamvoudakis, K.G.; Modares, H.; Lewis, F.L. Optimal and autonomous control using reinforcement learning: A survey. IEEE Trans. Neural Netw. Learn. Syst. 2018, 29, 2042–2062. [Google Scholar] [CrossRef] [PubMed]

- Gaidon, A.; Wang, Q.; Cabon, Y.; Vig, E. Virtual worlds as proxy for multi-object tracking analysis. In Proceedings of the Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 6 June–1 July 2016; pp. 4340–4349. [Google Scholar]

- Ramachandran, D.; Amir, E. Bayesian inverse reinforcement learning. In Proceedings of the International Joint Conference on Artificial Intelligence, Hyderabad, India, 6–12 January 2007; pp. 2586–2591. [Google Scholar]

- Wensing, P.M.; Wang, A.; Seok, S.; Otten, D.; Lang, J.; Kim, S. Proprioceptive actuator design in the MIT cheetah: Impact mitigation and high-bandwidth physical interaction for dynamic legged robots. IEEE Trans. Robot. 2017, 33, 509–522. [Google Scholar] [CrossRef]

- Fox, S.; Ehlen, P.; Purver, M. Enabling distributed communication of manual skills. Int. J. Manag. Proj. Bus. 2011, 4, 49–63. [Google Scholar] [CrossRef]

- Shiffrin, R.M.; Geisler, W.S. Visual recognition in a theory of information processing. In Contemporary Issues in Cognitive Psychology: The Loyola Symposium; Solso, R.L., Ed.; V.H. Winston & Sons: Oxford, UK, 1973. [Google Scholar]

- Shiffrin, R.M.; Schneider, W. Controlled and automatic human information processing: Perceptual learning, automatic attending and a general theory. Psychol. Rev. 1977, 84, 127–190. [Google Scholar] [CrossRef]

- Li, B.H.; Hou, B.C.; Yu, W.T.; Lu, X.B.; Yang, C.W. Applications of artificial intelligence in intelligent manufacturing: A review. Front. Inform. Technol. Electron. Eng. 2017, 18, 86–96. [Google Scholar] [CrossRef]

- Khoo, Z.X.; Teoh, J.E.M.; Liu, Y.; Chua, C.K.; Yang, S.; An, J.; Yeong, W.Y. 3D printing of smart materials: A review on recent progresses in 4D printing. Virtual Phys. Prototyp. 2015, 10, 103–122. [Google Scholar] [CrossRef]

- Drath, R.; Horch, A. Industrie 4.0: Hit or hype? IEEE Ind. Electron. Mag. 2014, 8, 56–58. [Google Scholar] [CrossRef]

- Smith, D.J. Reliability, Maintainability and Risk: Practical Methods for Engineers, 9th ed.; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- DeMarco, T. Controlling Software Projects: Management, Measurement, and Estimates; Prentice Hall PTR: Upper Saddle River, NJ, USA, 1986. [Google Scholar]

- Groover, M.P. Work Systems and the Methods, Measurement, and Management of Work; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2007. [Google Scholar]

- Oakland, J.S. Statistical Process Control, 5th ed.; Routledge: New York, NY, USA, 2007. [Google Scholar]

- Pande, P.S.; Neuman, R.P.; Cavanagh, R.R. The Six Sigma Way: How GE, Motorola, and Other Top Companies Are Honing Their Performance; McGraw-Hill: New York, NY, USA, 2000. [Google Scholar]

- Oakland, J.S. Total Quality Management and Operational Excellence; Routledge: Abingdon, UK, 2014. [Google Scholar]

- Crandall, B.; Klein, G.; Klein, G.A.; Hoffman, R.R. Working Minds: A Practitioner’s Guide to Cognitive Task Analysis; MIT Press: Cambridge, MA, USA, 2006. [Google Scholar]

- Holland, J.H. Complex adaptive systems. Daedalus 1992, 121, 17–30. [Google Scholar]

- Rego, A. Complexity, simplicity, simplexity. Eur. Manag. J. 2010, 28, 85–94. [Google Scholar]

| Theoretical Frameworks | References | |

|---|---|---|

| Cognitive Load | Situated Cognition | [29] |

| Embodied Cognition | [37] | |

| Embodied Cognitive Load | [30] | |

| Work Pragmatics | Material Interaction Pragmatics | [34] |

| Performative Pragmatics | [33] | |

| Relevance Theory | [36] | |

| Type of Information Gain/Cognitive Load Reduction | Example Knowledge Unit | Mode of Information Gain/Cognitive Load Reduction | Design for Information Gain and Cognitive Load Reduction | |

|---|---|---|---|---|

| Design In Gain Examples | Design Out Load Examples | |||

| Intrinsic | Physical components | Material Interaction Pragmatics | Design components for simplicity of assembly | End ambiguous component assembly features |

| Extraneous | Visual control boards | Performative Pragmatics | Design for jigs/templates for clarity and engagement | End tools stored without visual control boards |

| Germane | Assembly workstations | Schema Relevance | Design work cells for adaptive flexibility | End ad hoc development of factory layouts |

| Type of Information Gain/Load Reduction | Example of Knowledge Unit | Sources of Entropy | References |

|---|---|---|---|

| Intrinsic | Physical components | Picking Orientating Placing | [45,46] |

| Extraneous | Visual control boards | Conceptual Presentational Linguistic | [47,48] |

| Germane | Assembly workstation | Component access Work sequence Physical positioning | [49,50] |

| Type of Information Gain/Load Reduction | Example Knowledge Unit | Sources of Entropy | Entropy | |

|---|---|---|---|---|

| Number of Different Ways of Carrying Out the Same Work | Entropy | |||

| Intrinsic | Physical components | Picking | 1 | 0.00 |

| Orientation | 3 | 1.58 | ||

| Placing | 2 | 1.00 | ||

| Target | 2.58 | |||

| Extraneous | Visual control boards | Conceptual | 1 | 0.00 |

| Presentational | 3 | 1.58 | ||

| Linguistic | words not used | 0.00 | ||

| Target | 1.58 | |||

| Germane | Assembly workstation | Component access | 2 | 1.00 |

| Work sequence | 2 | 1.00 | ||

| Physical positioning | 5 | 2.32 | ||

| Target | 4.32 | |||

| Type of Information Gain/Load Reduction | Example Knowledge Unit | Sources of Entropy | Entropy | |

|---|---|---|---|---|

| Number of Different Ways of Carrying Out the Same Work | Entropy | |||

| Intrinsic | Physical components | Picking | 1 | 0.00 |

| Orientation | (2.0, 0.5, 0.5) 3 | 1.25 | ||

| Placing | 2 | 1.00 | ||

| Target | 2.25 | |||

| Extraneous | Visual control boards | Conceptual | 1 | 0.00 |

| Presentational | (1.0, 1.0, 1.0) 3 | 1.58 | ||

| Linguistic | words not used | 0.00 | ||

| Target | 1.58 | |||

| Germane | Assembly workstation | Component access | 2 | 1.00 |

| Work sequence | 2 | 1.00 | ||

| Physical positioning | (4.0, 0.2, 0.2, 0.2, 0.2) 5 | 1.00 | ||

| Target | 3.00 | |||

| Type of Information Gain/Load Reduction | Example Knowledge Unit | Sources of Entropy | Entropy | ||

|---|---|---|---|---|---|

| Number of Different Ways of Carrying Out the Same Work | Entropy | ||||

| Extraneous | Work Instructions | Information | Conceptual | 1 | 0.00 |

| Presentation | 2 | 1.00 | |||

| Linguistic | 1 | 0.00 | |||

| Target | 1.00 | ||||

| Type of Information Gain/Load Reduction | Example Knowledge Unit | Sources of Entropy | Entropy | ||

|---|---|---|---|---|---|

| Number of Different Ways of Carrying Out the Same Work | Entropy | ||||

| Extraneous | Augmented Reality Work Instructions | Information | Conceptual | 1 | 0.00 |

| Presentation | 1 | 0.00 | |||

| Linguistic | 1 | 0.00 | |||

| Communication | Task fit | 3 | 1.58 | ||

| Place fit | 2 | 1.00 | |||

| Person fit | 2 | 1.00 | |||

| Target | 3.58 | ||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fox, S.; Kotelba, A.; Niskanen, I. Cognitive Factories: Modeling Situated Entropy in Physical Work Carried Out by Humans and Robots. Entropy 2018, 20, 659. https://doi.org/10.3390/e20090659

Fox S, Kotelba A, Niskanen I. Cognitive Factories: Modeling Situated Entropy in Physical Work Carried Out by Humans and Robots. Entropy. 2018; 20(9):659. https://doi.org/10.3390/e20090659

Chicago/Turabian StyleFox, Stephen, Adrian Kotelba, and Ilkka Niskanen. 2018. "Cognitive Factories: Modeling Situated Entropy in Physical Work Carried Out by Humans and Robots" Entropy 20, no. 9: 659. https://doi.org/10.3390/e20090659

APA StyleFox, S., Kotelba, A., & Niskanen, I. (2018). Cognitive Factories: Modeling Situated Entropy in Physical Work Carried Out by Humans and Robots. Entropy, 20(9), 659. https://doi.org/10.3390/e20090659