Effect of Co and Gd Additions on Microstructures and Properties of FeSiBAlNi High Entropy Alloys

Abstract

1. Introduction

2. Experimental

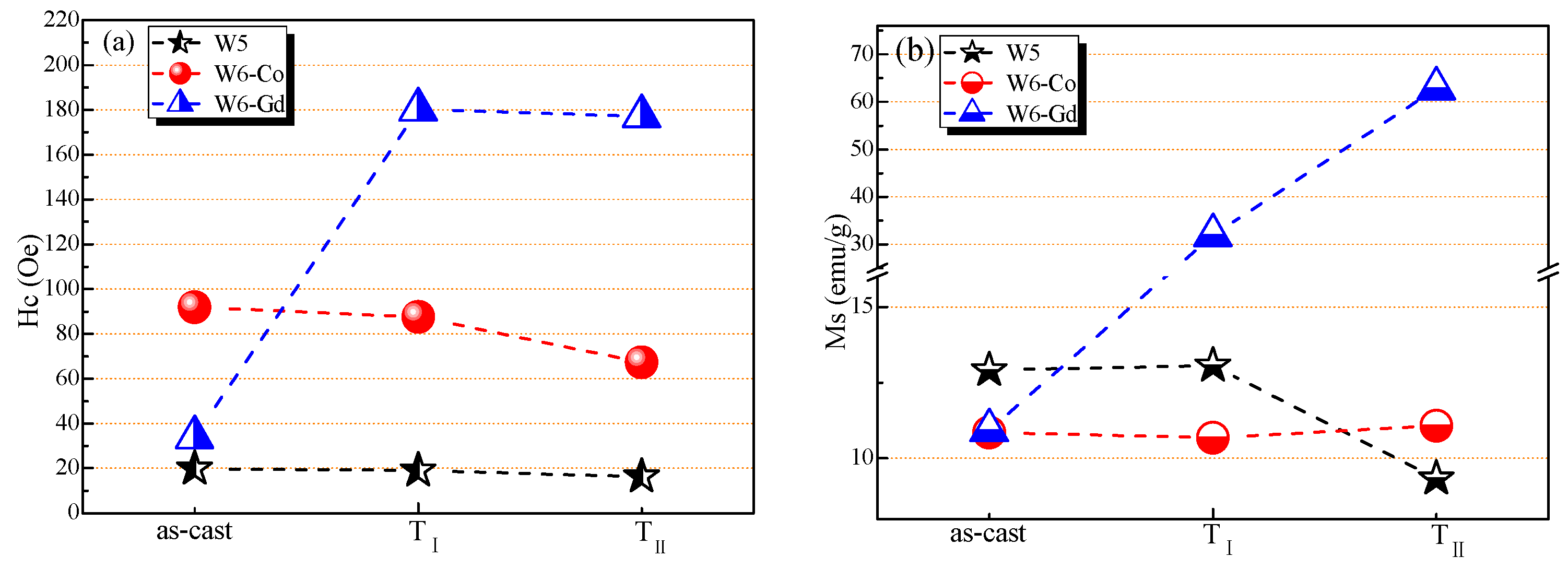

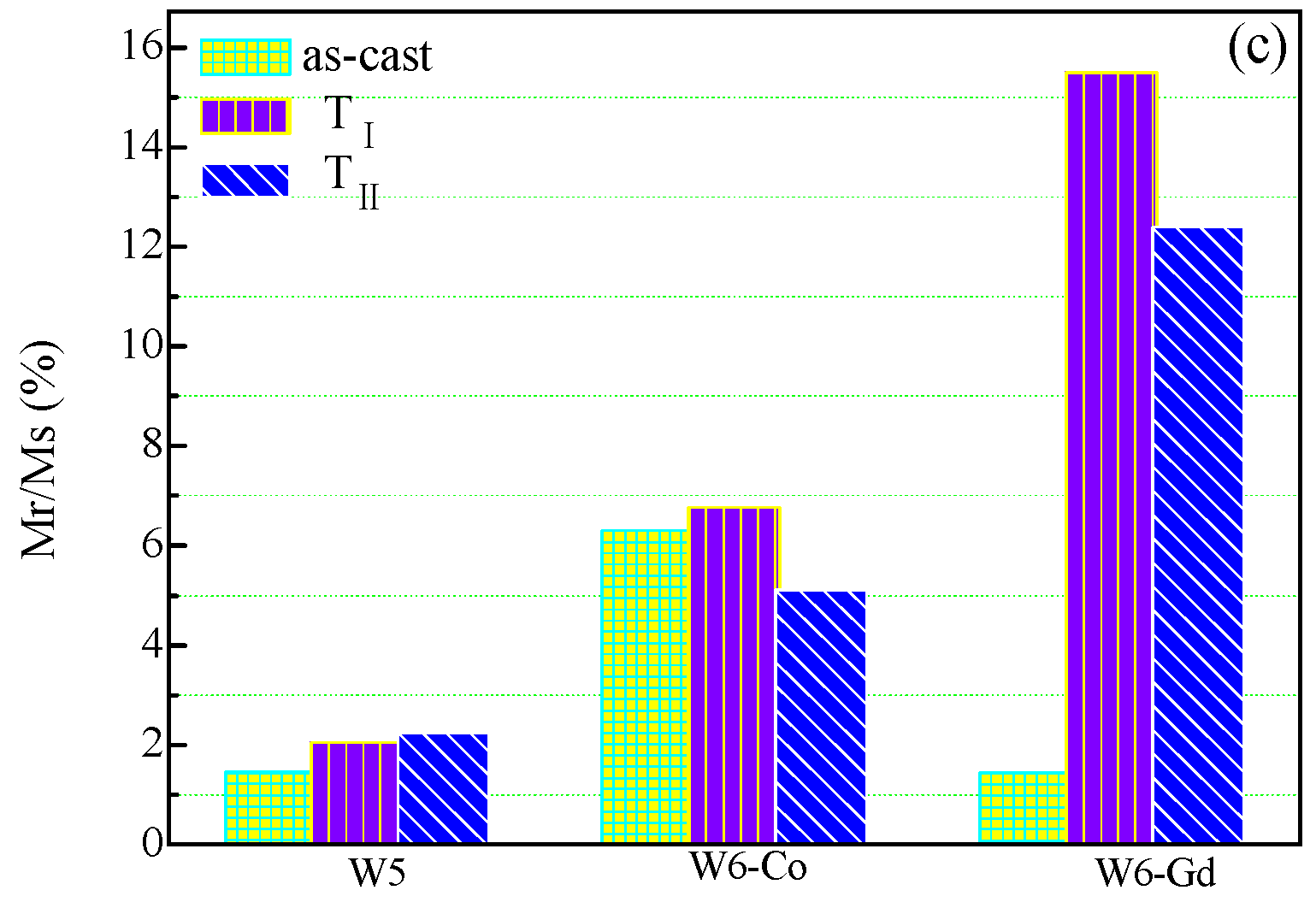

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructure development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Dong, Y.; Zhou, K.Y.; Lu, Y.P.; Gao, X.X.; Wang, T.M.; Li, T.J. Effect of Vanadium Addition on the Microstructure and Properties of AlCoCrFeNi High Entropy Alloy. Mater. Des. 2014, 57, 67–72. [Google Scholar] [CrossRef]

- Wu, Z.; Bei, H.; Pharr, G.M.; George, E.P. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. Acta Mater. 2014, 81, 428–441. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Duval, T.; Hung, U.D.; Yeh, J.W.; Shih, H.C. Microstructure and electrochemical properties of high entropy alloys-a comparison with type-304 stainless steel. Corros. Sci. 2005, 47, 2257–2279. [Google Scholar] [CrossRef]

- Ji, W.; Wang, W.M.; Wang, H.; Zhang, J.Y.; Wang, Y.C.; Zhang, F.; Fu, Z.Y. Alloying behavior and novel properties of CoCrFeNiMn high-entropy alloy fabricated by mechanical alloying and spark plasma sintering. Intermetallics 2015, 56, 24–27. [Google Scholar] [CrossRef]

- Li, P.P.; Wang, A.D.; Liu, C.T. A ductile high entropy alloy with attractive magnetic properties. J. Alloys Compd. 2017, 694, 55–60. [Google Scholar] [CrossRef]

- Zuo, T.T.; Gao, M.C.; Ouyang, L.Z.; Yang, X.; Cheng, Y.Q.; Feng, R.; Chen, S.Y.; Liaw, P.K.; Hawk, J.A.; Zhang, Y. Tailoring magnetic behavior of CoFeMnNiX (X = Al, Cr, Ga, and Sn) high entropy alloys by metal doping. Acta Mater. 2017, 130, 10–18. [Google Scholar] [CrossRef]

- He, J.Y.; Liu, W.H.; Wang, H.; Wu, Y.; Liu, X.J.; Nieh, T.G.; Lu, Z.P. Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater. 2014, 62, 105–113. [Google Scholar] [CrossRef]

- Xu, J.; Axinte, E.; Zhao, Z.; Wang, Y. Effect of C and Ce addition on the microstructure and magnetic property of the mechanically alloyed FeSiBAlNi high entropy alloys. J. Magn. Magn. Mater. 2016, 414, 59–68. [Google Scholar] [CrossRef]

- Zhuang, Y.X.; Xue, H.D.; Chen, Z.Y.; Hu, Z.Y.; He, J.C. Effect of annealing treatment on microstructures and mechanical properties of FeCoNiCuAl high entropy alloys. Mater. Sci. Eng. A 2013, 572, 30–35. [Google Scholar] [CrossRef]

- Zhu, X.; Zhou, X.; Yu, S.; Wei, C.; Xu, J.; Wang, Y. Effects of annealing on the microstructure and magnetic property of the mechanically alloyed FeSiBAlNiM (M = Co, Cu, Ag) amorphous high entropy alloys. J. Magn. Magn. Mater. 2017, 430, 59–64. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, Z.; Xu, J.; Wang, Y. Microstructure and magnetic properties of mechanically alloyed FeSiBAlNi (Nb) high entropy alloys. J. Magn. Magn. Mater. 2014, 355, 58–64. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, H.; Tan, X.H.; Hou, X.L.; Wu, S.W.; Tan, G.S.; Yu, L.Y. The effects of phase constitution on magnetic and mechanical properties of FeCoNi(CuAl)x (x = 0–1.2) high-entropy alloys. J. Alloys Compd. 2017, 693, 1061–1067. [Google Scholar] [CrossRef]

- Xu, J.; Shang, C.; Ge, W.; Jia, H.; Liaw, P.K.; Wang, Y. Effects of elemental addition on the microstructure, thermal stability, and magnetic properties of the mechanically alloyed FeSiBAlNi high entropy alloys. Adv. Powder Technol. 2016, 27, 1418–1426. [Google Scholar] [CrossRef]

- Tsai, M.H.; Yuan, H.; Cheng, G.; Xu, W.; Tsai, K.Y.; Tsai, C.W.; Jian, W.W.; Juan, C.C.; Shen, W.J.; Chuang, M.H.; et al. Morphology, structure and composition of precipitates in Al0.3CoCrCu0.5FeNi high-entropy alloy. Intermetallics 2013, 32, 329–336. [Google Scholar] [CrossRef]

- Chen, C.; Pang, S.; Cheng, Y.; Zhang, T. Microstructure and mechanical properties of Al20−xCr20+0.5xFe20Co20Ni20+0.5x high entropy alloys. J. Alloys Compd. 2016, 659, 279–287. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.; Cheng, Y.; Liaw, P.K. High-entropy alloys with high saturation magnetization, electrical resistivity, and malleability. Sci. Rep. 2013, 3, 1455. [Google Scholar] [CrossRef]

- Salishchev, G.A.; Tikhonovsky, M.A.; Shaysultanov, D.G.; Stepanov, N.D.; Kuznetsov, A.V.; Kolodiy, I.V.; Tortika, A.S.; Senkov, O.N. Effect of Mn and V on structure and mechanical properties of high-entropy alloys based on CoCrFeNi system. J. Alloys Compd. 2014, 591, 11–21. [Google Scholar] [CrossRef]

- Zhu, Z.G.; Ma, K.H.; Yang, X.; Shek, C.H. Annealing effect on the phase stability and mechanical properties of (FeNiCrMn)(100−x)Cox high entropy alloys. J. Alloys Compd. 2017, 695, 2945–2950. [Google Scholar] [CrossRef]

- Sun, G.F.; Qiang, W.J. Magnetic Material; Chemical Industry Press: Beijing, China, 2007. [Google Scholar]

- Bitoh, T.; Makino, A.; Inoue, A. Origin of low coercivity of (Fe0.75B0.15Si0.10)100−xNbx(x = 1–4) glassy alloys. J. Appl. Phys. 2006, 99, 08F102. [Google Scholar] [CrossRef]

- Wei, R.; Tao, J.; Sun, H.; Chen, C.; Sun, G.W.; Li, F.S. Soft magnetic Fe26.7Co26.7Ni26.6Si9B11 high entropy metallic glass with good bending ductility. Mater. Lett. 2017, 197, 87–89. [Google Scholar] [CrossRef]

- Kong, F.L.; Chang, C.T.; Inoue, A.; Shalaan, E.; Al-Marzouki, F. Fe-based amorphous soft magnetic alloys with high saturation magnetization and good bending ductility. J. Alloys Compd. 2014, 615, 163–166. [Google Scholar] [CrossRef]

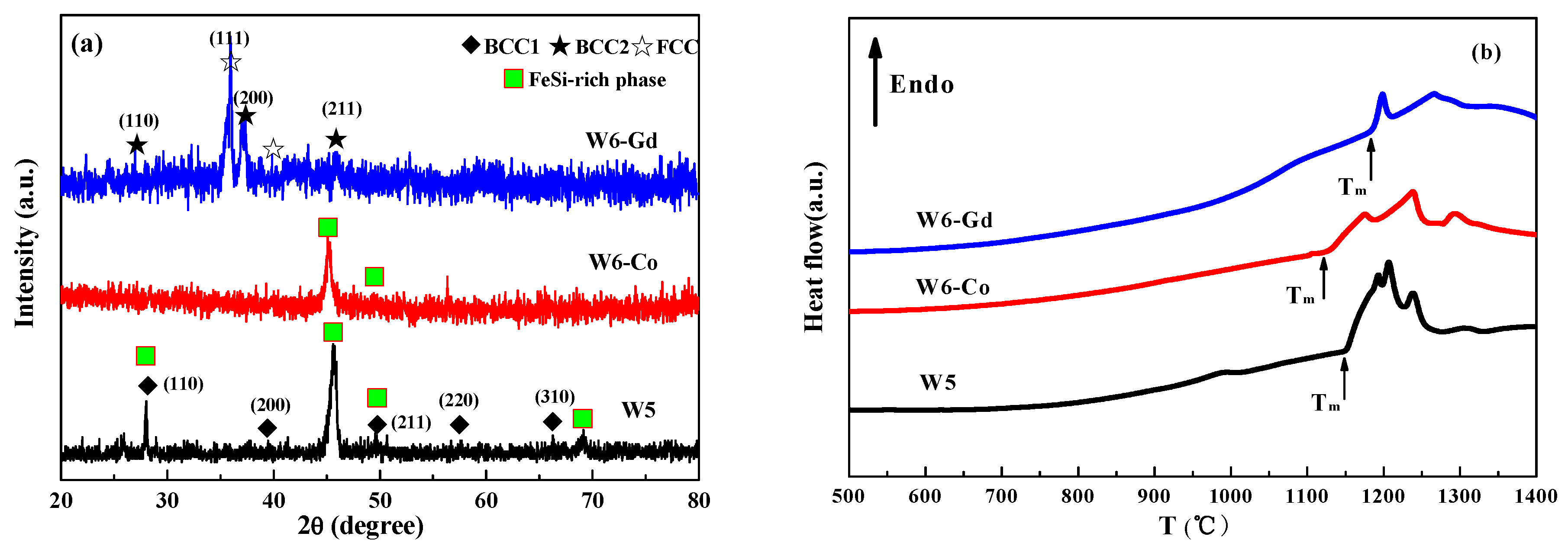

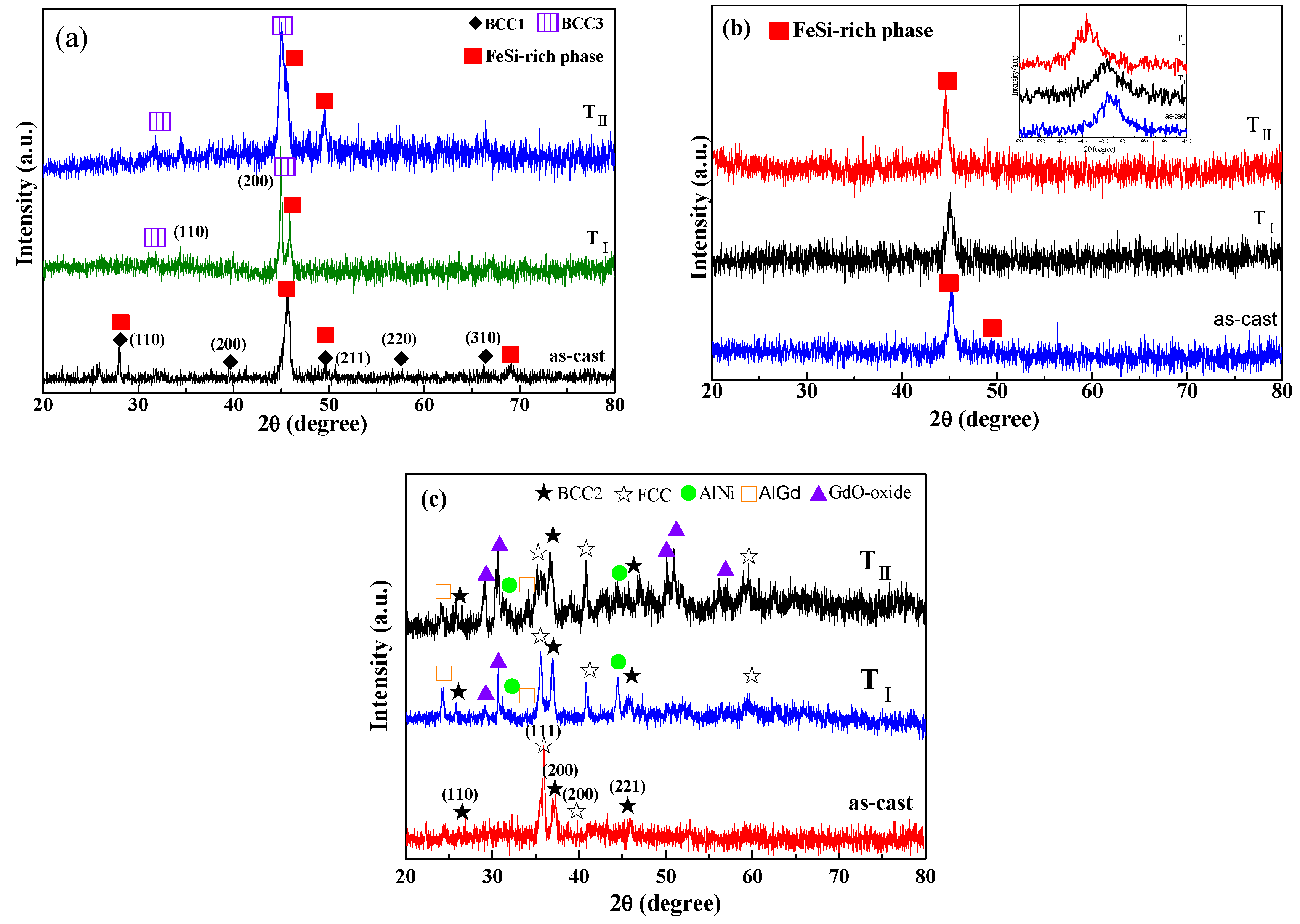

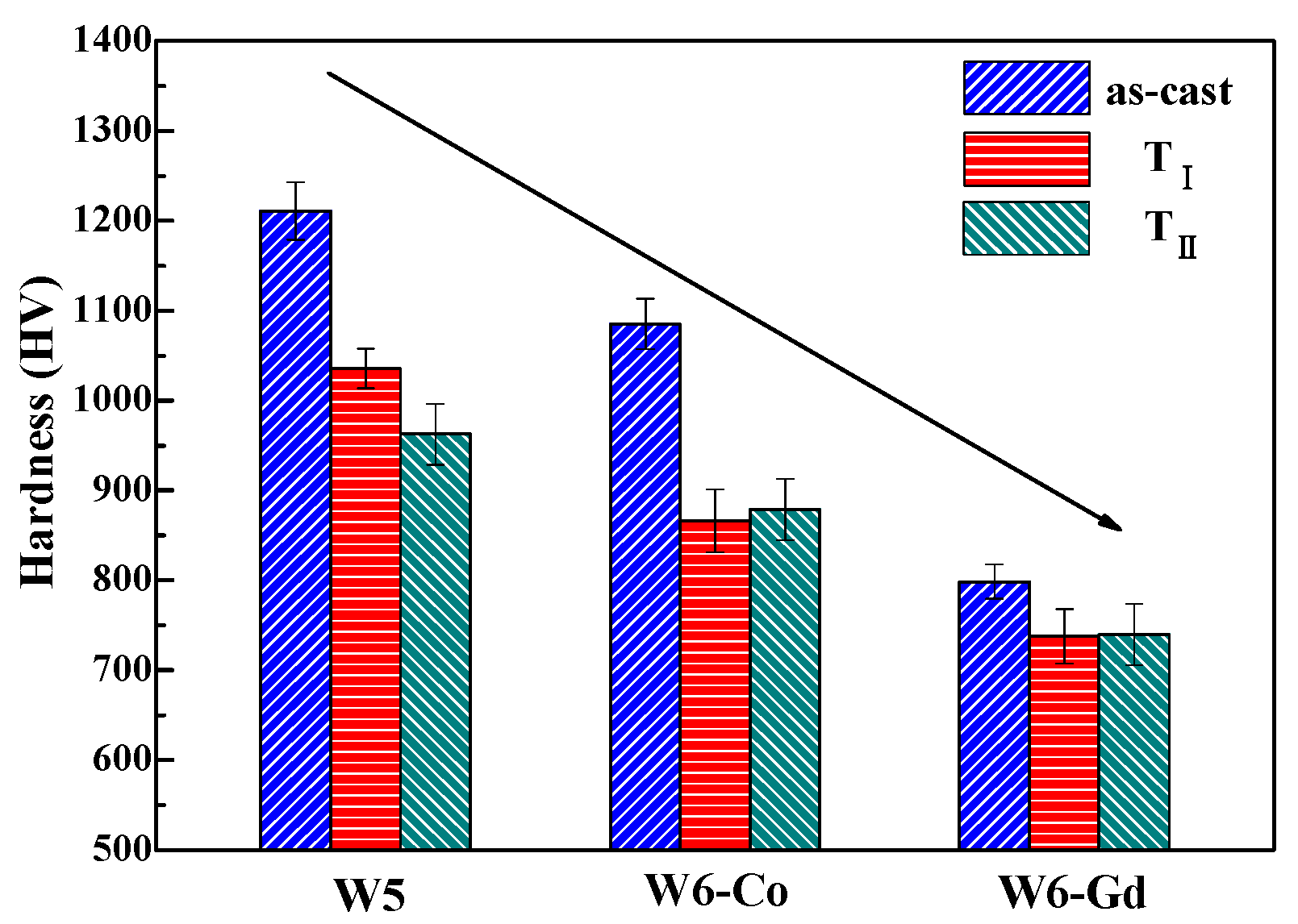

| HEAs | As-Cast | As-Annealed | |

|---|---|---|---|

| TI | TII | ||

| W5 | BCC1+FeSi-rich | BCC3+FeSi-rich | BCC3+FeSi-rich |

| W6-Co | FeSi-rich | FeSi-rich | FeSi-rich |

| W6-Gd | BCC2+FCC | BCC2 + FCC + AlNi + AlGd + Gd-oxide | BCC2 + FCC + AlNi + AlGd + Gd-oxide |

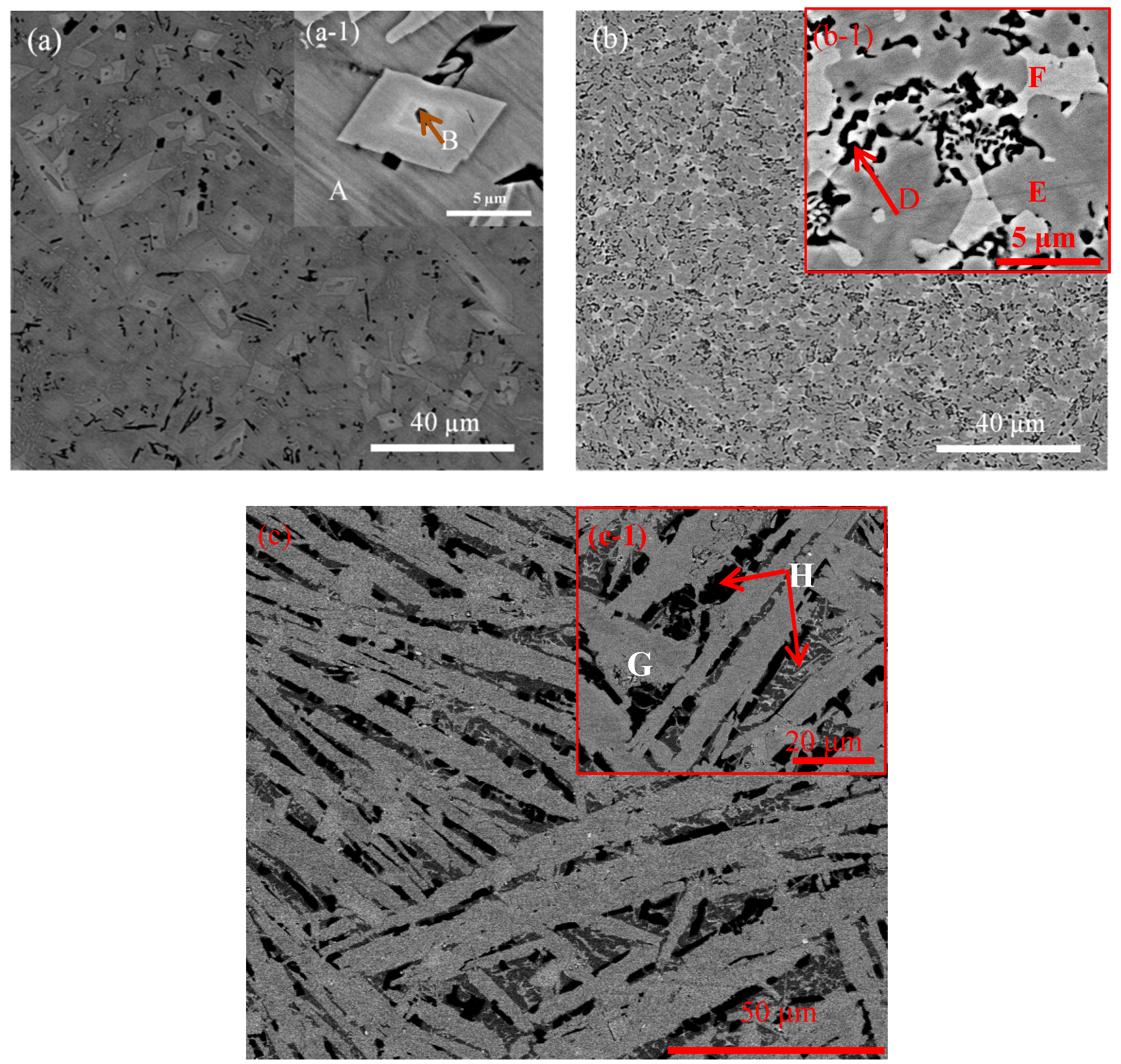

| Regions | Elements (at. %) | ||||||

|---|---|---|---|---|---|---|---|

| Fe | Si | B | Al | Ni | Co | Gd | |

| A | 11.36 | 10.01 | - | 36.29 | 42.34 | - | - |

| B | 39.6 | 33.8 | - | 12.95 | 13.65 | - | - |

| C | 80.9 | 1.65 | 10.97 | 2.6 | 3.87 | - | - |

| D | 41.15 | 27.85 | - | 6.38 | 10.49 | 14.13 | - |

| E | 11.42 | 12.51 | - | 17.59 | 34.78 | 23.7 | |

| F | 24.72 | 22.07 | - | 2.1 | 27.66 | 23.45 | |

| G | 24.5 | 27.9 | - | 0.48 | 17.41 | - | 29.71 |

| H | 14.57 | 2.55 | - | 51.32 | 11.06 | - | 20.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, S.; Wang, W.; Xu, J.; Xu, S.; Zhang, Z.; Wang, Y. Effect of Co and Gd Additions on Microstructures and Properties of FeSiBAlNi High Entropy Alloys. Entropy 2018, 20, 487. https://doi.org/10.3390/e20070487

Zhai S, Wang W, Xu J, Xu S, Zhang Z, Wang Y. Effect of Co and Gd Additions on Microstructures and Properties of FeSiBAlNi High Entropy Alloys. Entropy. 2018; 20(7):487. https://doi.org/10.3390/e20070487

Chicago/Turabian StyleZhai, Sicheng, Wen Wang, Juan Xu, Shuai Xu, Zitang Zhang, and Yan Wang. 2018. "Effect of Co and Gd Additions on Microstructures and Properties of FeSiBAlNi High Entropy Alloys" Entropy 20, no. 7: 487. https://doi.org/10.3390/e20070487

APA StyleZhai, S., Wang, W., Xu, J., Xu, S., Zhang, Z., & Wang, Y. (2018). Effect of Co and Gd Additions on Microstructures and Properties of FeSiBAlNi High Entropy Alloys. Entropy, 20(7), 487. https://doi.org/10.3390/e20070487