1. Introduction

Refrigerant alternatives and saving energy have become hot topics in the field of refrigeration and air conditioning. As a natural refrigerant, carbon dioxide has received increasing attention owing to its zero ODP and negligible GWP. Furthermore, carbon dioxide also has desirable thermodynamic properties, such as large specific heat, low viscosity, and large heat conductivity. However, due to the high throttling loss, the energy efficiency of the basic transcritical CO

2 cycle is lower than that of the conventional low pressure refrigeration cycle. In order to improve the performance of the transcritical CO

2 cycle, some modifications of the basic cycle have been tried, such as the introduction of internal heat exchangers [

1–

3], the use of two-stage compression systems to enhance the compression process [

4,

5], or an expander or an ejector to recover the expansion work [

6,

7]. Cecchinato

et al. [

5] discovered that thermodynamically the double-throttling, double-compression split cycle presents the greatest COP improvement among the different two-stage CO

2 cycles. Cho

et al. [

8] experimentally found that the double-compression transcritical CO

2 cycle with gas injection yields a 16.5% improvement of the cooling COP over that of the two-stage non-injection cycle. Cho

et al. [

9] numerically found that the single-stage CO

2 cycle with an expander, the double-stage external intercooler cycle, and the double-stage CO

2 cycle with vapor injection yield 28.3%, 13.1%, 18.3% improvements of the cooling COP over that of the basic CO

2 cycle, respectively. Wang

et al. [

10] carried out an experiment on the two-stage compression cycle using R744 as a refrigerant, and showed that the COP of the double-stage flash intercooler cycle is 10.97% higher than that of the double-stage external intercooler cycle.

Application of an expander to substitute the throttle valve is expected to enhance the cycle performance. Yang

et al. [

11] thermodynamically found that the employment of an expander to replace a throttle valve leads to about 33% COP improvement in the transcritical cycle. Baek

et al. [

12,

13] developed a piston-cylinder-type expander and represented that the device can improve the cooling COP by 6.6% through the theoretical and experimental studies. Li

et al. [

14] experimentally found that their developed rolling-piston expander prototype can improve the COP of the system by at least 10%. Jia

et al. [

15] represented that a maximum COP improvement of 27.2% can be achieved by the use of the vane expander prototype.

However, comprehensive investigations on the effect of expanders on the performance improvement of the transcritical CO

2 double-compression cycle are very limited in the open literature. Baek

et al. [

16] theoretically found that the double-stage external intercooler cycle with an expander can achieve an improvement of up to 42% in COP over the basic cycle. Kohsokabe

et al. [

17] experimentally found that the employment of an expander in the double-stage external intercooler cycle leads to more than a 30% improvement in COP over the basic cycle. Kim

et al. [

18] performed a theoretical analysis of the DCEIE cycle, and showed that the improvement of COP and cooling capacity over the basic cycle was 23.5% and 8.6%, respectively. Zhili

et al. [

19] investigated the performance of several different expander-compressor arrangements for the double-stage external intercooler cycle, and found that the cycle with an expressor as the main compressor can yield the highest COP. But significantly less literature is available on the topic of the performance of the double-stage flash intercooler cycle with an expander.

In this paper, the thermodynamic model of the double-compression CO

2 cycles with and without an expander was developed. Based on this model, a steady-state simulation of the systems has been carried out. The CO

2 thermodynamic property data is based on REFPROP [

20]. The performance improvement of each of the double-compression cycle technologies was evaluated.

2. System Description and Analysis

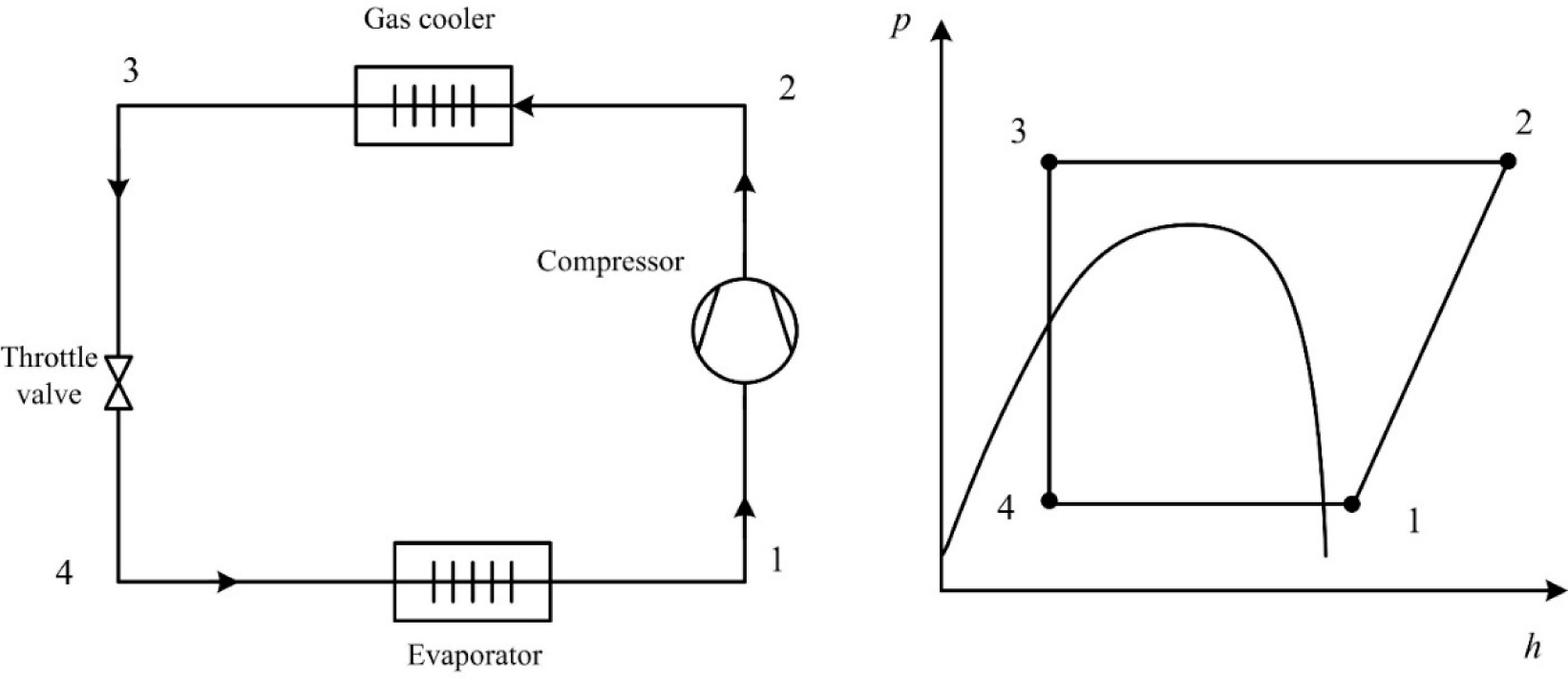

The schematic diagram and corresponding pressure enthalpy diagram of the base transcritical CO

2 refrigeration cycle are illustrated in

Figure 1. The base cycle is composed of four basic processes: compression (1–2), heat rejection (2–3), expansion (3–4) and heat absorption (4–1).

In order to improve the performance of the transcritical CO

2 refrigeration cycles, the following double-stage compression cycles are investigated:

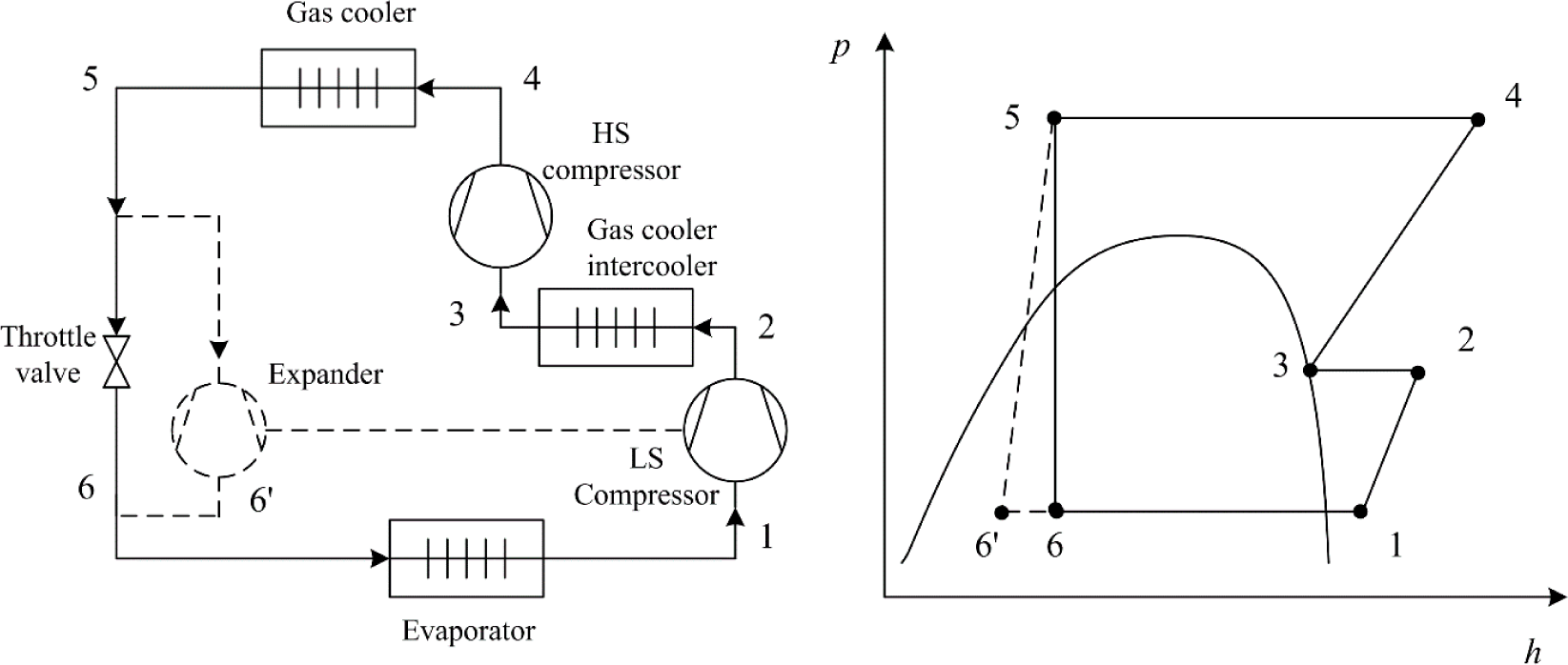

Double-Compression External Intercooler (DCEI) cycle: the schematic diagram and corresponding pressure enthalpy diagram of this cycle are illustrated by the continuous line in

Figure 2. This cycle consists of an evaporator, two compressors (LS compressor and HS compressor) with inter-cooling of the vapor at the intermediate pressure through a heat exchanger, a gas cooler, and a throttling valve.

Double-Compression External Intercooler cycle with an Expander (DCEIE): This cycle is similar to the DCEI cycle except with the expander replacing the throttle valve and using the recovery work to drive the compressor. The expansion process of the expander is illustrated by the broken line in this cycle, as shown in

Figure 2. The recovered power of the expander is used to offset the work of the low-stage compressor.

Double-Compression Flash Intercooler cycle (DCFI): the cycle is represented by the continuous line in

Figure 3. The high pressure refrigerant after the gas cooler is divided into two streams: one of them is throttled down to the intermediate pressure through the throttle valve A, and flows into the flash chamber. The entered refrigerant flashes into vapor, cools the residual stream of high pressure gas, mixes and exchanges heat with the discharged high temperature refrigerant from the LS compressor. Then the resulting mixed saturated vapor is sucked by the HP compressor. The cooled high pressure gas is expanded in the throttle valve B and then fed to the evaporator.

Double-Compression Flash Intercooler cycle with an Expander (DCFIE): This cycle is similar to the DCFI cycle except for substituting the throttle valve B with an expander and using the recovery work to drive the compressor. The expander expansion process of the DCFIE cycle is expressed by the broken line in

Figure 3. The recovered work of the expander is transmitted to the low-stage compressor.

The cycles were theoretically investigated using an original simulation code under the following assumptions:

Steady-state operation.

No pressure losses in pipes and heat exchangers.

Saturated vapor at the evaporator outlet.

The compressor and the expander are treated adiabatically.

The isentropic efficiency of the compressor is calculated by [

21]:

The coefficient of performance of the DCEI cycle can be written as:

For the DCEIE cycle, it can be expressed as:

For the DCFI cycle and the DCFIE cycle, the energy balance equation for the flash intercooler can be written as follows:

where

m1 is the mass flow rate of the low stage compressor,

m2 is the mass flow rate of the high stage compressor.

The coefficient of performance of the DCFI cycle can be written as:

For the DCFIE cycle, it can be expressed as:

3. Results and Discussion

In this study, the results were obtained by varying one parameter according to its practical application, while other parameters were kept at the design values. Unless otherwise specified, the evaporating temperature is 0 °C, the outlet refrigerant temperature of the gas cooler is 35 °C. The isentropic efficiency of the expander is taken to be 0.5. The temperature difference between point 7 and point 3 in the DCFI cycle is taken to be 3 °C.

The effect of gas cooler pressure on the COP of the investigated cycles is shown in

Figure 4. It is observed that there is an optimum gas cooler pressure for the investigated cycles. The optimum gas cooler pressure of the two flash intercooler cycles and the two external intercooler cycles is lower and higher than that of the basic cycle, respectively. It can also be seen that the double-stage cycles outperform the basic cycle owing to the fact that the compressor work reduces by the employment of double-stage compression with intercooling. Furthermore, the application of an expander to replace the throttle valve in the double-stage cycle can further enhance the cycle performance owing to the recovered work and the increased cooling effect. For the studied operating conditions, the DCEI cycle yields maximum COP improvement of 1.7%, whereas that for the DCFI cycle it is 15.3% compared to the basic cycle. Those two figures will increase to 25.9% and 25.4%, respectively, when the expander is used to replace the throttle valve.

Previous studies [

22] show that an optimum intermediate pressure exists for the typical two-stage compression cycle where it exhibits the maximum COP for a given operating condition. The optimum intermediate pressure is usually the square root of the gas cooler pressure times the evaporator pressure from the classical estimate. In this paper, the deviation in the intermediate pressure from the classical estimate is expressed as

R, which is defined as:

Figure 5 shows the variation of the COP of the investigated cycles with

R under the operating conditions. It is observed that the values of COP increase first and then decrease as

R increase. It is obvious that the optimum intermediate pressures of the two-stage cycles are greater than the geometric mean of the gas cooler pressure and the evaporation pressure. Furthermore, the optimum intermediate pressures of the two flash intercooler cycles are lower than that of the two external intercooler cycles. The optimum

R is about 1.1 and 1.2 for the DCFI cycles and DCEI cycles, respectively.

Figure 6 depicts the variations of the optimal gas cooler pressure and optimum intermediate pressure

versus evaporating temperature. It can be seen that along with the growth of the evaporating temperature, the optimum gas cooler pressure of DCEI cycle decreases linearly, but the optimum gas cooler pressure of the other three cycles is quasi-constant. The optimum intermediate pressure increases with the increase of evaporating temperature for all the investigated cycles.

Figure 7 shows the variations of the optimal gas cooler pressure and optimum intermediate pressure with gas cooler exit temperature. As the gas cooler exit temperature goes up, the optimum gas cooler pressures of all the cycles increase. It is apparent that the fluctuation of the optimum gas cooler pressure with the gas cooler exit temperature is more sensitive than with the evaporator temperature. It implies that the evaporating temperature has less influence on the optimum gas cooler pressure of the investigated cycles compared with the gas cooler exit temperature. It can also be seen from

Figure 7 that along with the increase of the gas cooler exit temperature, the optimum intermediate pressures of the two external intercooler cycles increase rapidly, whereas the optimum intermediate pressures of the two flash intercooler cycles increase only slightly.

It can also be noticed from

Figures 6 and

7 that the optimum gas cooler pressure and the intermediate pressure of the DCFI cycle are lower than those of the DCEI cycle under various operating conditions. This tendency is consistent with the experimental results of [

10] where the optimum gas cooler pressure and the intermediate pressure of the DCFI cycle are 0.2 MPa and 0.3 MPa lower than that of the DCEI cycle. It is always preferred to operate the system at lower gas cooler pressure. A decrease in gas cooler pressure improves the safety aspects and prolongs the system life as well. The substitution of throttle valve by an expander in the DCEI cycle leads to a decrease in the optimum gas cooler pressure and little variation of the optimum intermediate pressure. This inclination agrees with the results of [

23]. In comparison, the use of an expander to substitute the throttle valve in the DCFI cycle results in little variation of the optimal gas cooler pressure, and an increase in the optimum intermediate pressure. The slope of the isentropic line in the

p-

h diagram increases from right to left for CO

2, which results in little change of the expander output power and the evaporator cooling effect with the variation of the gas cooler pressure. For example, the increase of the gas cooler enables the increase of the pressure drop in the expander but moves the expansion process to the left. The expansion work (or evaporator cooling effect) improvement due to the pressure drop increase in the expander is compensated by the expansion work (or evaporator cooling effect) decrease due to the movement of the expansion process. Therefore, the use of an expander to substitute the throttle valve in the DCFI cycle results in little variation of the optimal gas cooler pressure. The intermediate pressure affects the inlet temperature of the expander, which influences the expander output power for the DCFIE cycle. For instance, the increase of intermediate pressure enables the inlet temperature of the expander to increase, which moves the expansion process to the right and leads to an increase in expander output power owing to the fact that the slope of the isentropic line in the

p-

h diagram increase from right to left. Therefore, the optimum intermediate pressure is higher than that of the DCFI cycle.

Figures 8 and

9 shows the comparison of the percentage improvement in COP of the investigated double-stage cycles over the basic cycle at the different evaporating temperatures and gas cooler outlet temperatures, respectively. The COP of the cycles is the maximum value under identical operating conditions. The results indicate that the percentage gain decreases with the increase of the evaporator temperature for the investigated cycles. As the gas cooler outlet temperature increases, the COP improvement percentage increases for the two external intercooler cycles. It implies that the profit of intercooler and two stage compression becomes larger with the increase of the gas cooler outlet temperature for the two external intercooler cycles, but the COP improvement percentage decreases for the two flash intercooler cycles with the increase of the gas cooler outlet temperature. The reasons for this phenomenon can be explained by

Figure 7 where the optimum gas cooler pressures of the two flash intercooler cycles increase, but the optimum intermediate pressures of the two cycles increase slightly as the gas cooler exit temperature goes up. This implies that the pressure ratio of the HS compressor become higher as the gas cooler exit temperature increases, which results the decrease of the isentropic efficiency of the HS compressor. The HS compressor play a dominant role in the cycle energy efficiency owing to the fact that the mass flow rate of the HS compressor is larger than that of the evaporator and the LS compressor. Thus the COP of the two flash intercooler cycles decrease more than the base cycle and the two external intercooler cycles. In addition, the effect is more significant than that with the evaporating temperature.

It can also be noticed from

Figures 8 and

9 that the percentage improvement in the case of the DCFI cycle is higher than that in a DCEI cycle under all the chosen operating conditions. This tendency is consistent with the experimental results of [

10] where the COP of DCFI cycle is 19.0% higher than that of DCEI cycle. The reason may be that the lower optimum gas cooler pressure of the DCFI cycle makes the pressure ratios of both compressors lower, resulting in higher compressor isentropic efficiency values. More COP improvement is gained by the use of an expander to replace the throttle valve for the DCEI cycle compared to the DCFI cycle. The DCEIE cycle outperforms the DCFIE cycle when the evaporating temperature exceeds 0 °C or the gas cooler outlet temperature surpasses 35 °C. When the gas cooler exit temperature varies from 32 °C to 48 °C, DCEI cycle, DCEIE cycle, DCFI cycle, and DCFIE cycle yields average 4.6%, 29.2%, 12.9% and 22.3% COP improvement over the basic cycle, respectively.

4. Conclusions

In this paper, a thermodynamic analysis of double-stage compression transcritical CO2 refrigeration cycles is presented. The effect of using an expander to replace the throttle valve on the performance of the double-stage refrigeration cycle is investigated theoretically. The result reveals that the staging of compression can improve the cycle cooling COP, which can be further enhanced by the application of an expander to replace the throttle valve. The optimum gas cooler pressure and optimum intermediate pressure of the flash intercooler cycles are lower than those of the external intercooler cycle. The optimum intermediate pressures of the two-stage cycles are greater than the geometric mean of the gas cooler pressure and the evaporation pressure. The substitution of the throttle valve by an expander in the DCEI cycle leads to a decrease in the optimum gas cooler pressure and little variation of the optimum intermediate pressure. However, the replacement of the throttle valve with an expander in the DCFI cycle results in little variation of the optimal gas cooler pressure and an increase of the optimum intermediate pressure. The DCFI cycle outperforms the DCEI cycle under all the chosen operating conditions, but more COP improvement is gained by the use of an expander to replace the throttle valve for the DCEI cycle compared to the DCFI cycle. The DCEIE cycle outperforms the DCFIE cycle when the evaporating temperature exceeds 0 °C or the gas cooler outlet temperature surpasses 35 °C. When the gas cooler exit temperature varies from 32 °C to 48 °C, DCEI cycle, DCEIE cycle, DCFI cycle, and DCFIE cycle yields average 4.6%, 29.2%, 12.9%, 22.3% COP improvement over the basic cycle, respectively.

The DCFI cycles are interesting due to their lower operating pressure and higher energy efficiency. However, the flash intercooler increases the expense of the process and it also makes the process control complicated. The liquid level will need to be controlled in a real process and it will change depending on the refrigeration load. Application of an expander to replace the throttle valve can improve the cycle energy efficiency, especially for the DCEI cycle, but no such expanders have been commercialized so far. This will be both a technical and economic challenge.