Energy and Exergy Analysis for Improving the Energy Performance of Air-Cooled Liquid Chillers by Different Condensing-Coil Configurations

Abstract

:1. Introduction

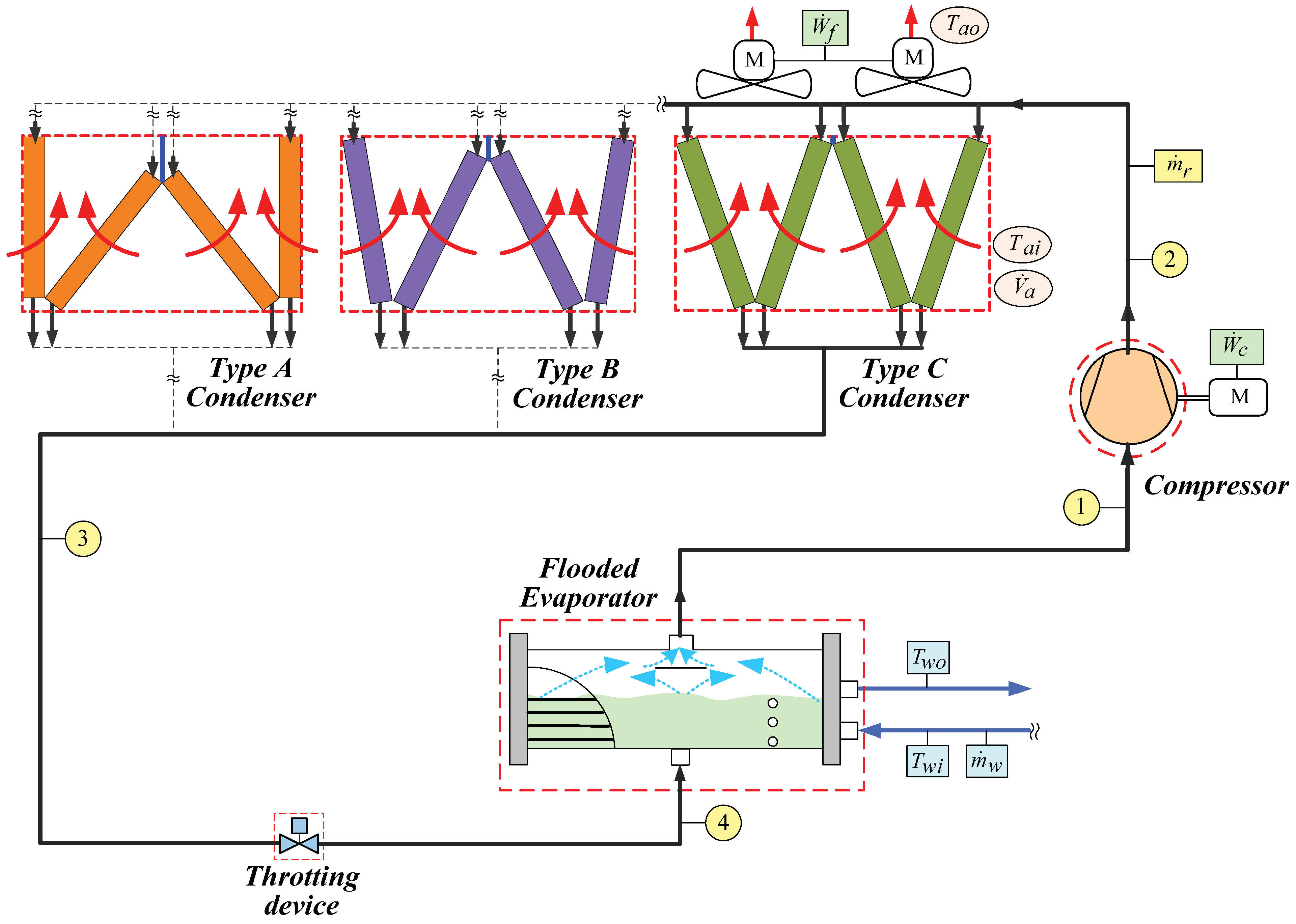

2. Energy Model of Development

2.1. System Description

| Heat Exchanger Configuration | Value | Unit |

|---|---|---|

| Length (L) | 4760 | mm |

| Height (H) | 1200 | mm |

| Tubes for coil | 90 | - |

| Vertical tube spacing | 38.1 | mm |

| Horizontal tube spacing | 33.0 | mm |

| Number of tube rows | 3 | |

| Tubes per row | 30 | |

| Fins per inch | 14 | - |

| Fin thickness | 0.25 | mm |

| Outside tube diameter | 15.9 | mm |

| Tube thickness | 0.5 | mm |

2.2. Model Description

2.2.1. Compressor

2.2.2. Condenser

2.2.3. Throtting Device

2.2.4. Evaporator

2.2.5. Systems Analysis of Energy Efficiency

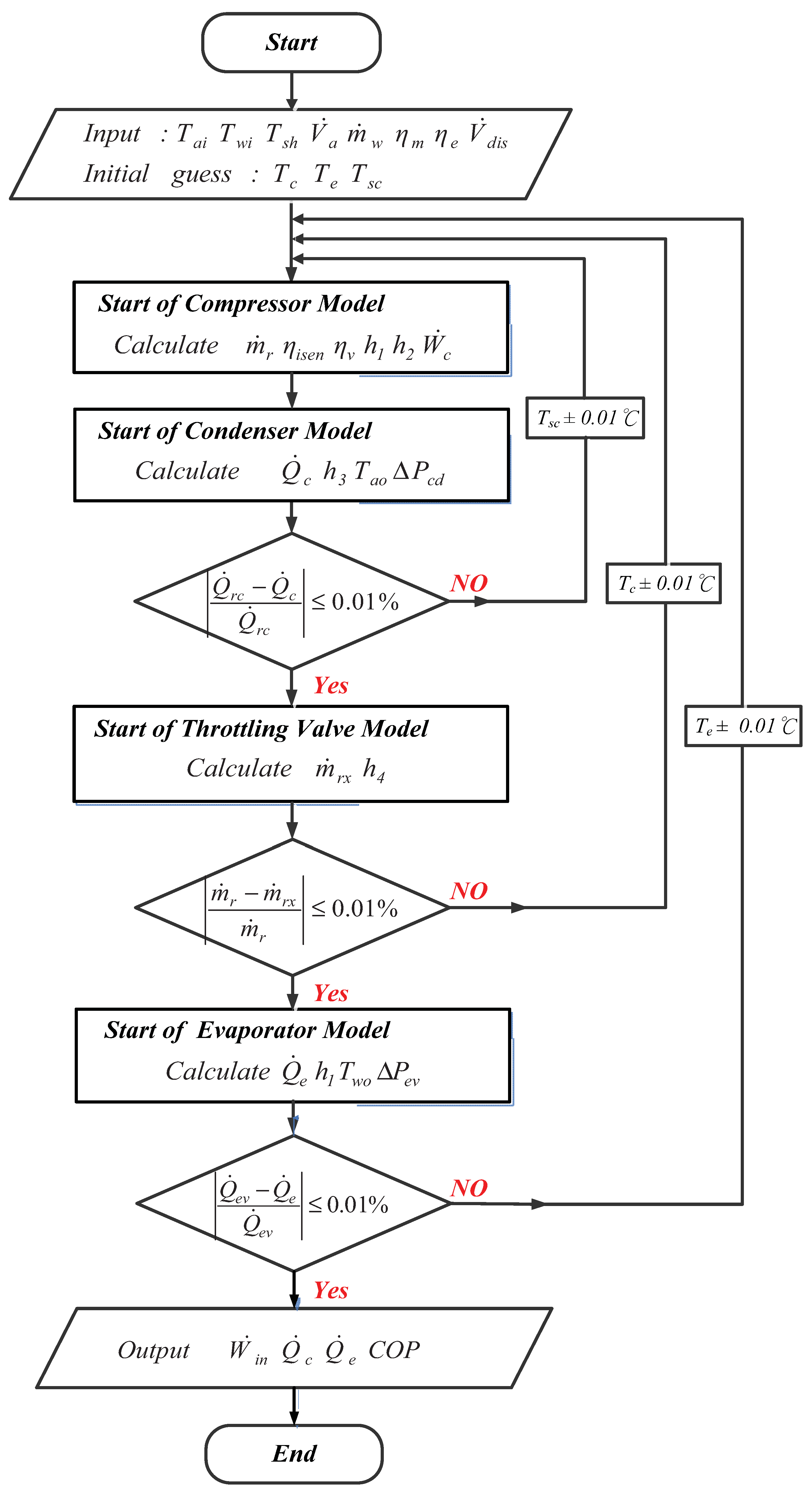

2.3. Simulation System Solving and Analytical Process

3. Exergy Model of Development

- (1)

- The control volume in each component is a steady-state, steady-flow process;

- (2)

- Kinetic and potential energy changes at the input and output points of control volume in each component can be disregarded;

- (3)

- The irreversibility of suction pipes, exhaust pipes, and tubes can be overlooked;

- (4)

- The throttling device functions as an isenthalpic process;

- (5)

- The control volume of the condenser includes the refrigerant and air side;

- (6)

- The control volume of the evaporator includes the refrigerant and chilled water sides.

| Components | Mass Balance | Energy Balance | Entropy Balance | Irreversibility |

|---|---|---|---|---|

| Compressor | ||||

| Condenser | ||||

| Throttling Device | ||||

| Evaporator |

| Components | Mass Balance | Energy Balance | Entropy balance | Exergy |

|---|---|---|---|---|

| Compressor | ||||

| Condenser | ||||

| Throttling Device | ||||

| Evaporator |

4. Results and Discussion

4.1. Validation of the Chiller Model

| Item | Unit | Experiment | Simulation | Error |

|---|---|---|---|---|

| Condenser | kW | 579.5 | 581.5 | 0.35% |

| Evaporator | kW | 439.5 | 441.8 | 0.52% |

| Compressor | kW | 140.0 | 139.7 | −0.21% |

| COP | - | 2.93 | 2.97 | 1.37% |

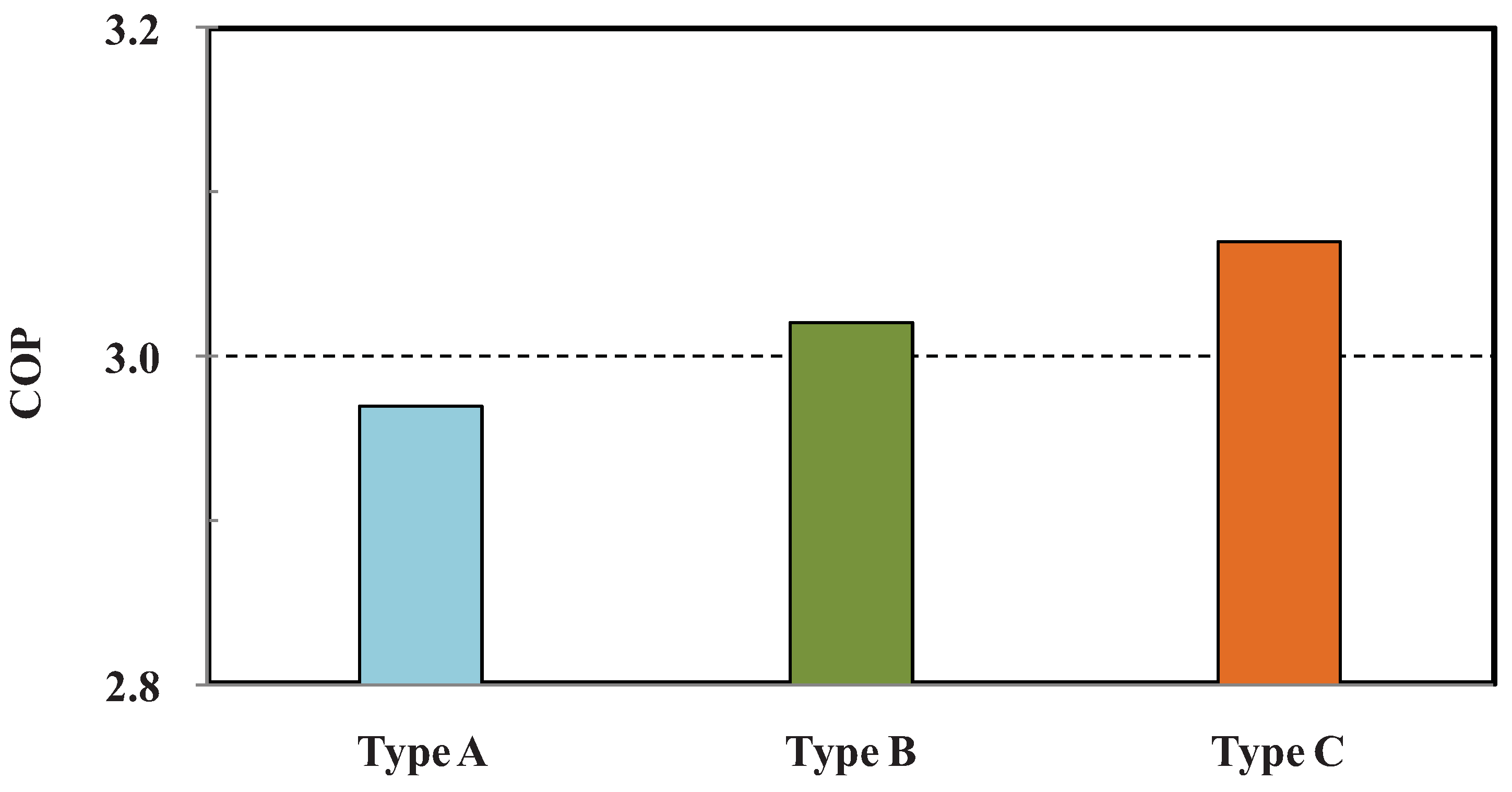

4.2. Influence on System Performance

| Item | Unit | Type A | Type B | Type C |

|---|---|---|---|---|

| Tc | °C | 50.4 | 50.1 | 49.8 |

| Te | °C | 5.4 | 5.3 | 5.2 |

| Tsc | °C | 0.4 | 1.2 | 2.0 |

| Tao | °C | 44.9 | 44.6 | 44.3 |

| Condenser | kW | 581.5 | 584.9 | 588.1 |

| Evaporator | kW | 441.8 | 445.8 | 449.7 |

| Compressor | kW | 139.7 | 139.0 | 138.4 |

4.3. Influence on Component Irreversibility

5. Conclusions

Nomenclature

heat capacity (kW K−1) | |

| Cpa | specific heat capacity of air (kJ kg−1 K−1) |

| Cpv | specific heat capacity of wet air (kJ kg−1 K−1) |

| Cpw | specific heat capacity of water (kJ kg−1 K−1) |

| h | enthalpy (kJ kg−1) |

exergy destruction or irreversibility (kW) | |

flow factor for throttling device | |

mass flow rate (kg s−1) | |

| NTU | number of transfer unit |

| ΔP | refrigerant pressure difference (kPa) |

heat transfer rate (kW) | |

compression ratio | |

entropy generation (kJ K−1) | |

| s | specific entropy (kJ kg−1 K−1) |

| T | temperature (K) |

| UA | overall heat transfer coefficient (kW K−1) |

volume flow (m3 s−1) | |

| v | specific volume (m3 kg−1) |

work of per unit mass compressed (kJ kg−1) | |

power consumption of compressor (kW) | |

power consumption of fans (kW) | |

power consumption of chiller (kW) | |

exergy destruction (kW) | |

exergy destruction ratio (%) |

Greek Symbols

mechanical efficiency | |

isentropic efficiency | |

motor efficiency | |

volumetric efficiency | |

| ε | effectiveness (0 < ε ≤ 1 |

| ρ | density (kg m−3) |

| ω | humidity ratio (kg kgda−1) |

| ϕ | flow exergy (kW kg−1) |

| μ | viscosity (Pa s) |

Subscripts

| 1 | compressor suction |

| 2 | compressor discharge |

| 2s | compressor discharge for isentropic compression |

| 3 | condenser discharge or throttling device inlet |

| 4 | throttling device outlet or evaporator suction |

| a | air side of condenser |

| ai | air entering the condenser |

| ao | air leaving the condenser |

| ave | average |

| c, cd | condenser |

| c1,c2…,c8 | coefficient |

| dis | discharge |

| e, ev | evaporator |

| r | refrigerant |

| w | water |

| wi | water entering the evaporator |

| wo | water leaving the evaporator |

| wi, wo | chiller water inlet and outlet, respectively |

References

- Lee, T.S.; Wu, W.C.; Chuah, Y.K.; Wang, S.K. An improvement of airflow and heat transfer performance of multi-coil condensers by different coil configurations. Int. J. Refrig. 2010, 33, 1370–1376. [Google Scholar] [CrossRef]

- Brown, M.W.; Bansal, P.K. An elemental NTU-ε model for vapour-comperssion liquid chillers. Int. J. Refrig. 2001, 24, 612–627. [Google Scholar] [CrossRef]

- Fu, L.; Ding, G. Steady-state simulation of screw liquid chillers. Appl. Therm. Eng. 2002, 22, 1731–1748. [Google Scholar] [CrossRef]

- Bansal, P.K.; Tedford, J.D.; Le, C.V. Simulation model of a screw liquid chiller for process industries using local heat transfer integration. Proc. IME E J. Process. Mech. Eng. 2005, 219, 95–107. [Google Scholar]

- Storcker, W.F.; Jones, J.W. Refrigeration and Air Conditioning, 2nd ed.; McGRAW-Hill: New York, NY, USA, 2001. [Google Scholar]

- Chan, K.T.; Yu, F.W. Experimental determination of the energy efficiency of an air-cooled chiller under part load. Energy 2005, 30, 1747–1758. [Google Scholar]

- Chan, K.T.; Yu, F.W. Thermodynamic-behaviour model for air-cooled screw chillers with a variable set-point condensing temperature. Appl. Energ. 2006, 83, 265–279. [Google Scholar] [CrossRef]

- Yu, F.W.; Chan, K.T. Analysis of component characteristics of air cooled chillers for modeling floating condensing temperature control. Energ. Convers. Manag. 2005, 46, 927–939. [Google Scholar]

- Yu, F.W.; Chan, K.T. Part load performance of air-cooled centrifugal chillers with variable speed condenser fan control. Build. Environ. 2007, 42, 3816–3829. [Google Scholar] [CrossRef]

- Yu, F.W.; Chan, K.T. Optimizing condenser fan control for air-cooled centrifugal chillers. Int. J. Therm. Sci. 2008, 47, 942–953. [Google Scholar] [CrossRef]

- Bridges, B.D.; Harshbarger, D.S.; Bullard, C.W. Second law analysis of refrigerators and air conditioners. ASHRAE Trans. 2001, 107, 1. [Google Scholar]

- Yumrutas, R.; Kunduz, M.; Kanoğlu, M. Exergy analysis of vapor compression refrigeration systems. Exergy 2002, 2, 266–272. [Google Scholar] [CrossRef]

- Bilgen, E.; Takahashi, H. Exergy analysis and experimental study of heat pump systems. Exergy 2002, 2, 259–265. [Google Scholar] [CrossRef]

- Esen, H.; Inalli, M.; Esen, M.; Pihtili, K. Energy and exergy analysis of a ground-coupled heat pump system with two horizontal ground heat exchangers. Bldg. Environ. 2007, 42, 3606–3615. [Google Scholar] [CrossRef]

- ASHRAE. Fundamentals ASHRAE Handbook; ASHRAE: Atlanta, GA, USA, 2001. [Google Scholar]

- Lee, T.S. Second-law analysis to improve the energy efficiency of screw liquid chillers. Entropy 2010, 12, 375–389. [Google Scholar] [CrossRef]

- McQuiston, F.C.; Parker, J.D.; Spitler, J.D. Heating, Ventilating, and Air Conditioning Analysis & Design; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005. [Google Scholar]

- NIST. NIST Standard Reference Database 23; Version 8.0.; NIST: Boulder, CO, USA, 2007. [Google Scholar]

- Bejan, A. Advanced Engineering Thermodynamics; John Wiley & Sons, Inc: Hoboken, NJ, USA, 2006. [Google Scholar]

- 2003 standard for performance rating of water-chilling packages using the vapor compression cycle. ARI 550/590; Air-Conditioning, Heating and Refrigeration Institute: Arlington, VA, USA, 2003.

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Wu, W.-C.; Lee, T.-S.; Chang, C.-H. Energy and Exergy Analysis for Improving the Energy Performance of Air-Cooled Liquid Chillers by Different Condensing-Coil Configurations. Entropy 2012, 14, 517-532. https://doi.org/10.3390/e14030517

Wu W-C, Lee T-S, Chang C-H. Energy and Exergy Analysis for Improving the Energy Performance of Air-Cooled Liquid Chillers by Different Condensing-Coil Configurations. Entropy. 2012; 14(3):517-532. https://doi.org/10.3390/e14030517

Chicago/Turabian StyleWu, Wu-Chieh, Tzong-Shing Lee, and Chich-Hsiang Chang. 2012. "Energy and Exergy Analysis for Improving the Energy Performance of Air-Cooled Liquid Chillers by Different Condensing-Coil Configurations" Entropy 14, no. 3: 517-532. https://doi.org/10.3390/e14030517

APA StyleWu, W.-C., Lee, T.-S., & Chang, C.-H. (2012). Energy and Exergy Analysis for Improving the Energy Performance of Air-Cooled Liquid Chillers by Different Condensing-Coil Configurations. Entropy, 14(3), 517-532. https://doi.org/10.3390/e14030517