Synthesis of Carvedilol–Organotin Complexes and Their Effects on Reducing Photodegradation of Poly(Vinyl Chloride)

Abstract

1. Introduction

2. Materials and Methods

2.1. General

2.2. Synthesis of Organotin Complexes 1 and 2

2.3. Synthesis of Organotin Complexes 3 and 4

2.4. Preparation of PVC Films

2.5. Characterization of PVC Photodegradation Using FTIR Spectrophotometry

2.6. Monitoring of PVC Photodegradation Using Weight Loss

3. Results and Discussion

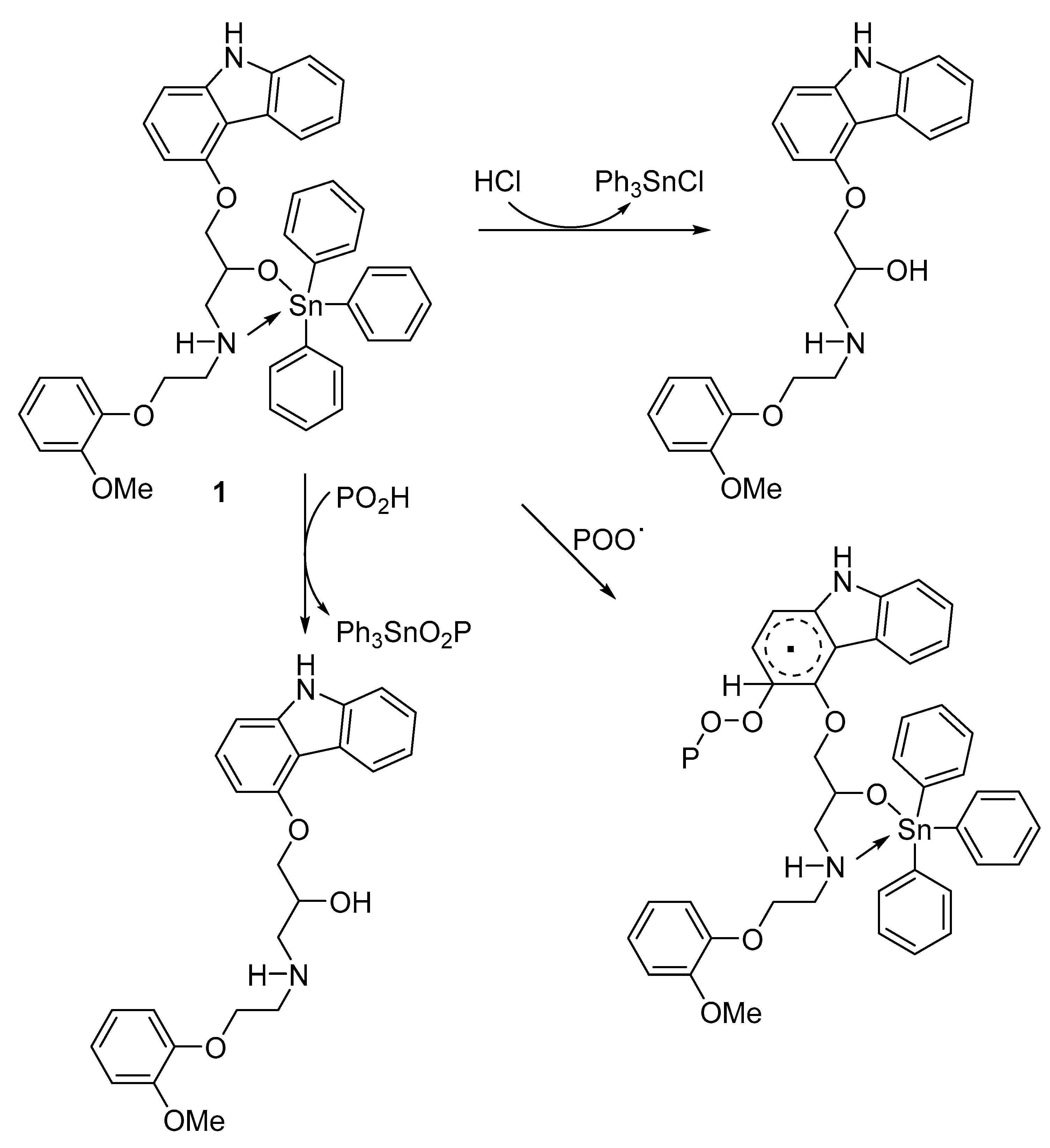

3.1. Synthesis of Tin Complexes 1–4

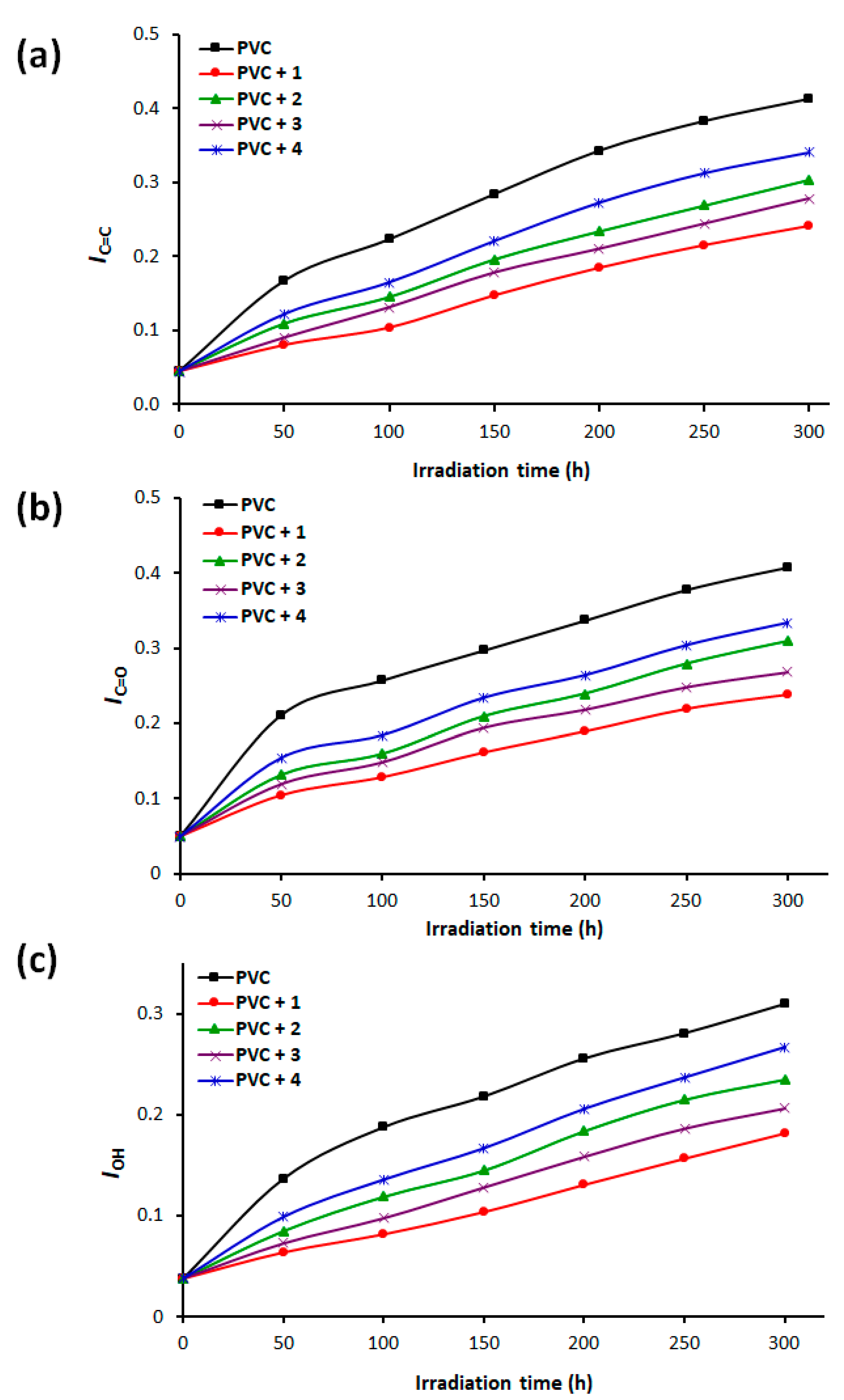

3.2. PVC Photodegradation Using FTIR Spectroscopy

3.3. PVC Photodegradation Using Weight Loss

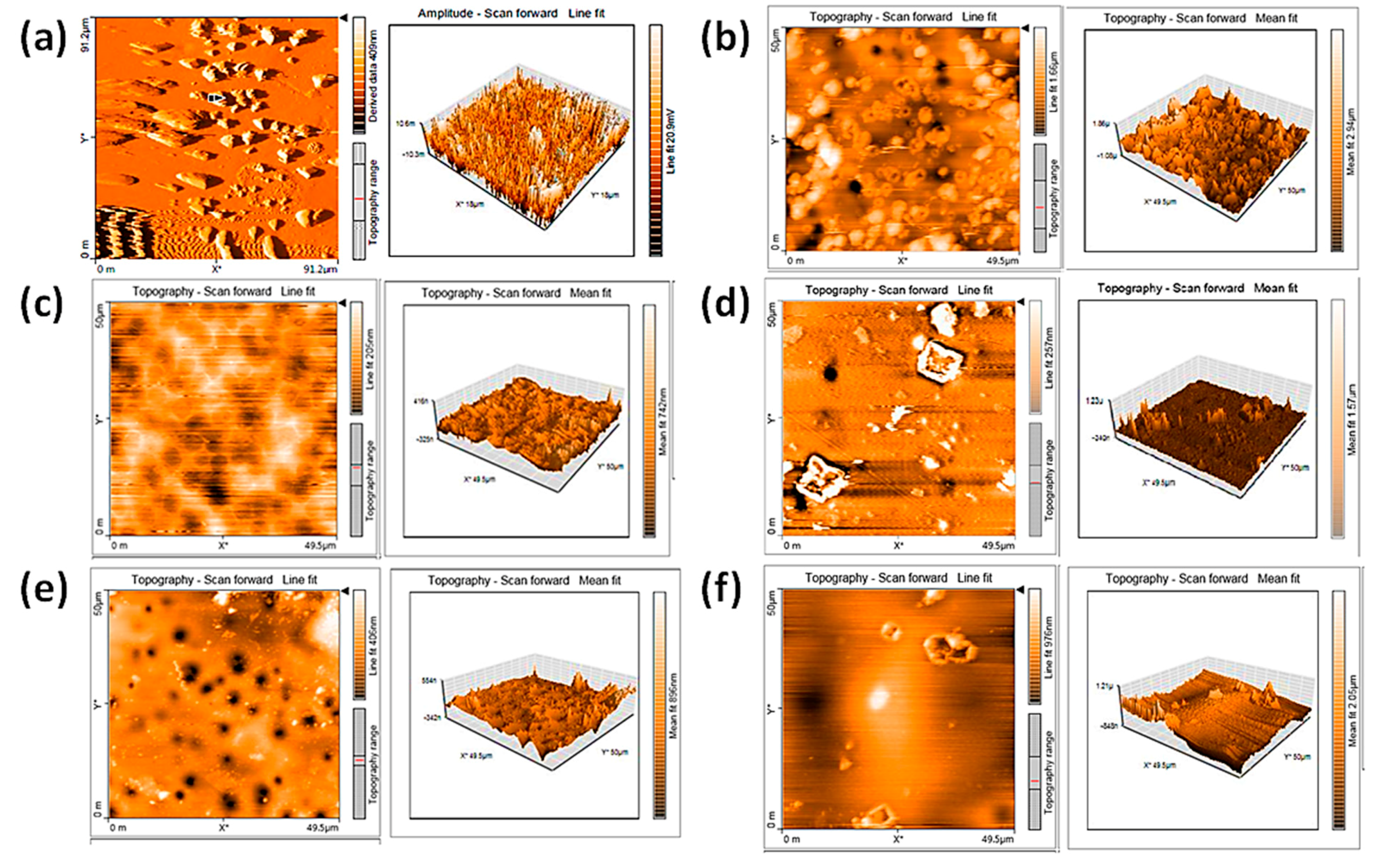

3.4. Surface Morphology of PVC Films

3.5. PVC Photostabilization Proposed Mechanisms

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Feldman, D. Polymer history. Des. Monomers Polym. 2008, 11, 1–15. [Google Scholar] [CrossRef]

- Burgess, R.H. Manufacture and Processing of PVC; Elsevier Applied Science Publishers Ltd: London, UK, 2005. [Google Scholar]

- Titow, W.V. PVC Plastics Properties, Processing, and Applications; Elsevier Applied Science Publishers Ltd: London, UK, 1990. [Google Scholar]

- Abu Bakar, A.; Hassan, A.; Yusof, A.F.M. Mechanical properties of silane and zirconate coupling agent-treated oil palm empty fruit bunch fiber-filled acrylic-impact modified poly (vinyl chloride) composites. Polym. Plast. Technol. Eng. 2010, 49, 1563–1570. [Google Scholar] [CrossRef]

- Porta, M.; Zumeta, E. Implementing the Stockholm treaty on persistent organic pollutants. Occup. Environ. Med. 2002, 59, 651–652. [Google Scholar] [CrossRef]

- Zheng, X.G.; Tang, L.H.; Zhang, N.; Gao, Q.H.; Zhang, C.F.; Zhu, Z.B. Dehydrochlorination of PVC materials at high temperature. Energy Fuels 2003, 17, 896–900. [Google Scholar] [CrossRef]

- Yousif, E.; Hasan, A. Photostabilization of poly(vinyl chloride)—Still on the run. J. Taibah Uiv. Sci. 2015, 9, 421–448. [Google Scholar] [CrossRef]

- Gao, A.X.; Bolt, J.D.; Feng, A.A. Role of titanium dioxide pigments in outdoor weathering of rigid PVC. Plast. Rubber Compos. 2008, 37, 397–402. [Google Scholar] [CrossRef]

- Chai, R.D.; Zhang, J. Synergistic effect of hindered amine light stabilizers/ultraviolet absorbers on the polyvinyl chloride/powder nitrile rubber blends during photodegradation. Polym. Eng. Sci. 2013, 53, 1760–1769. [Google Scholar] [CrossRef]

- Cadogan, D.F.; Howick, C.J. Plasticizers. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH: Weinheim, Germany, 2000. [Google Scholar]

- El-Hiti, G.A.; Ahmed, D.S.; Yousif, E.; Alotaibi, M.H.; Star, H.A.; Ahmed, A.A. Influence of polyphosphates on the physicochemical properties of poly(vinyl chloride) after irradiation with ultraviolet light. Polymers 2020, 12, 193. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, D.S.; El-Hiti, G.A.; Yousif, E.; Hameed, A.S. Polyphosphates as inhibitors for poly(vinyl chloride) photodegradation. Molecules 2017, 22, 1849. [Google Scholar] [CrossRef]

- Sabaa, M.W.; Oraby, E.H.; Abdel Naby, A.S.; Mohammed, R.R. Anthraquinone derivatives as organic stabilizers for rigid poly(vinyl chloride) against photo-degradation. Eur. Polym. J. 2005, 41, 2530–2543. [Google Scholar] [CrossRef]

- Balakit, A.A.; Ahmed, A.; El-Hiti, G.A.; Smith, K.; Yousif, E. Synthesis of new thiophene derivatives and their use as photostabilizers for rigid poly(vinyl chloride). Int. J. Polym. Sci. 2015, 2015, 510390. [Google Scholar] [CrossRef]

- El-Hiti, G.A.; Alotaibi, M.H.; Ahmed, A.A.; Hamad, B.A.; Ahmed, D.S.; Ahmed, A.; Hashim, H.; Yousif, E. The morphology and performance of poly(vinyl chloride) containing melamine Schiff bases against ultraviolet light. Molecules 2019, 24, 803. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, A.A.; Ahmed, D.S.; El-Hiti, G.A.; Alotaibi, M.H.; Hashim, H.; Yousif, E. SEM morphological analysis of irradiated polystyrene film doped by a Schiff base containing a 1,2,4-triazole ring system. Appl. Petrochem. Res. 2019, 9, 169–177. [Google Scholar] [CrossRef]

- Shaalan, N.; Laftah, N.; El-Hiti, G.A.; Alotaibi, M.H.; Muslih, R.; Ahmed, D.S.; Yousif, E. Poly(vinyl chloride) photostabilization in the presence of Schiff bases containing a thiadiazole moiety. Molecules 2018, 23, 913. [Google Scholar] [CrossRef]

- Ahmed, D.S.; El-Hiti, G.A.; Hameed, A.S.; Yousif, E.; Ahmed, A. New tetra-Schiff bases as efficient photostabilizers for poly(vinyl chloride). Molecules 2017, 22, 1506. [Google Scholar] [CrossRef] [PubMed]

- Yousif, E.; Hasan, A.; El-Hiti, G.A. Spectroscopic, physical and topography of photochemical process of PVC films in the presence of Schiff base metal complexes. Polymers 2016, 8, 204. [Google Scholar] [CrossRef]

- Schiller, M. PVC Additives: Performance, Chemistry, Developments, and Sustainability; Carl Hanser Verlag: Munich, Germany, 2015. [Google Scholar]

- Yang, T.C.T.; Noguchi, T.; Isshiki, M.; Wu, J.H. Effect of titanium dioxide particles on the surface morphology and the mechanical properties of PVC composites during QUV accelerated weathering. Polym. Compos. 2016, 37, 3391–3397. [Google Scholar] [CrossRef]

- Yang, T.C.; Noguchi, T.; Isshiki, M.; Wu, J.H. Effect of titanium dioxide on chemical and molecular changes in PVC sidings during QUV accelerated weathering. Polym. Degrad. Stab. 2014, 104, 33–39. [Google Scholar] [CrossRef]

- Mahmood, Z.N.; Yousif, E.; Alias, M.; El-Hiti, G.A.; Ahmed, D.S. Synthesis, characterization, properties, and use of new fusidate organotin complexes as additives to inhibit poly(vinyl chloride) photodegradation. J. Polym. Res. 2020, 27, 267. [Google Scholar] [CrossRef]

- Ahmed, D.S.; El-Hiti, G.A.; Ibraheem, H.; Alotaibi, M.H.; Abdallh, M.; Ahmed, A.A.; Ismael, M.; Yousif, E. Enhancement of photostabilization of poly(vinyl chloride) doped with sulfadiazine tin complexes. J. Vinyl Addit. Techn. 2020, 25, 370–379. [Google Scholar] [CrossRef]

- Mohammed, A.; El-Hiti, G.A.; Yousif, E.; Ahmed, A.A.; Ahmed, D.S.; Alotaibi, M.H. Protection of poly(vinyl chloride) films against photodegradation using various valsartan tin complexes. Polymers 2020, 12, 969. [Google Scholar] [CrossRef]

- Hadi, A.G.; Jawad, K.; El-Hiti, G.A.; Alotaibi, M.H.; Ahmed, A.A.; Ahmed, D.S.; Yousif, E. Photostabilization of poly(vinyl chloride) by organotin(IV) compounds against photodegradation. Molecules 2019, 24, 3557. [Google Scholar] [CrossRef]

- Hadi, A.G.; Yousif, E.; El-Hiti, G.A.; Ahmed, D.S.; Jawad, K.; Alotaibi, M.H.; Hashim, H. Long-term effect of ultraviolet irradiation on poly(vinyl chloride) films containing naproxen diorganotin(IV) complexes. Molecules 2019, 24, 2396. [Google Scholar] [CrossRef]

- Ghazi, D.; El-Hiti, G.A.; Yousif, E.; Ahmed, D.S.; Alotaibi, M.H. The effect of ultraviolet irradiation on the physicochemical properties of poly(vinyl chloride) films containing organotin(IV) complexes as photostabilizers. Molecules 2018, 23, 254. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.M.; El-Hiti, G.A.; Yousif, E. Photostabilizing efficiency of poly(vinyl chloride) in the presence of organotin(IV) complexes as photostabilizers. Molecules 2016, 21, 1151. [Google Scholar] [CrossRef]

- Adeyemi, J.O.; Onwudiwe, D.C. Organotin(IV) dithiocarbamate complexes: Chemistry and biological activity. Molecules 2018, 23, 2571. [Google Scholar] [CrossRef] [PubMed]

- Khan, N.; Farina, Y.; Mun, L.K.; Rajab, N.F.; Awang, N. Syntheses, characterization, X-ray diffraction studies and in vitro antitumor activities of diorganotin(IV) derivatives of bis(p-substituted-N-methylbenzylaminedithiocarbamates). Polyhedron 2015, 85, 754–760. [Google Scholar] [CrossRef]

- Gaumet, S.; Gardette, J.-L. Photo-oxidation of poly(vinyl chloride): Part 2–A comparative study of the carbonylated products in photo-chemical and thermal oxidations. Polym. Degrad. Stab. 1991, 33, 17–34. [Google Scholar] [CrossRef]

- Bacchi, A.; Bonardi, A.; Carcelli, M.; Mazza, P.; Pelagatti, P.; Pelizzi, C.; Pelizzi, G.; Solinas, C.; Zani, F. Organotin complexes with pyrrole-2,5-dicarboxaldehyde bis(acylhydrazones). Synthesis, structure, antimicrobial activity and genotoxicity. J. Inorg. Biochem. 1998, 69, 101–112. [Google Scholar] [CrossRef]

- Al-Jibouri, M.N.A.; Al-Ameri, S.A.H.; Al-Jibouri, W.M.; Al-Souz, M.A.K. Spectroscopic study of the effect of a new metal chelate on the stability of PVC. J. Assoc. Arab Univ. Basic Appl. Sci. 2013, 14, 67–74. [Google Scholar] [CrossRef]

- Tarafder, M.T.H.; Chew, K.-B.; Crouse, K.A.; Ali, M.A.; Yamin, B.M.; Fun, H.-K. Synthesis and characterization of Cu(II), Ni(II) and Zn(II) metal complexes of bidentate NS isomeric Schiff bases derived from S-methyldithiocarbazate (SMDTC): Bioactivity of the bidentate NS isomeric Schiff bases, some of their Cu(II), Ni(II) and Zn(II) complexes and the X-ray structure of the bis[S-methyl-β-N-(2-furyl-methyl)methylenedithiocarbazato]zinc(II) complex. Polyhedron 2002, 21, 2683–2690. [Google Scholar] [CrossRef]

- Morozov, O.S.; Vyshinskii, N.N.; Rudnevskii, N.K. Investigation of some organotin compounds and their complexes by IR spectroscopy. J. Appl. Spectrosc. 1981, 35, 1019–1023. [Google Scholar] [CrossRef]

- Masood, H.; Ali, S.; Mazhar, M.; Shahzadi, S.; Shahid, K. 1H, 13C, 119Sn NMR, Mass, Mössbauer and biological studies of tri-, di- and chlorodiorganotin(IV) carboxylates. Turk. J. Chem. 2004, 28, 75–86. [Google Scholar]

- Shahid, K.; Ali, S.; Shahzadi, S.; Badshah, A.; Khan, K.M.; Maharvi, G.M. Organotin(IV) complexes of aniline derivatives. I. Synthesis, spectral and antibacterial studies of di- and triorganotin(IV) derivatives of 4-bromomaleanilic acid. Synth. React. Inorg. Met Org. Chem. 2003, 33, 1221–1235. [Google Scholar] [CrossRef]

- Rehman, W.; Baloch, M.K.; Badshah, A.; Ali, S. Synthesis and characterization of biologically potent di-organotin(IV) complexes of mono-methyl glutarate. J. Chin. Chem. Soc. 2005, 52, 231–236. [Google Scholar] [CrossRef]

- Salam, M.A.; Affan, M.A.; Arafat, M.A.; Saha, R.; Nasrin, R. Synthesis, characterization, and antibacterial activities of organotin(IV) complexes with 2-acetylpyridine-N(4)-cyclohexylthiosemicarbazone (HAPCT). Heteroatom Chem. 2013, 24, 43–52. [Google Scholar] [CrossRef]

- Srinivas, P.; Suresh, T.; Revanasiddappa, M.; Khasim, S. Synthetic, spectral and thermal studies of tin(IV) complexes of 1,5-benzodiazepines. J. Chem. 2008, 5, 627–633. [Google Scholar] [CrossRef]

- Chee, D.N.A.; Affan, M.A.; Ahmad, F.B.; Asaruddin, M.R.; Sam, N.; Salam, M.A.; Ismail, A.; Tan, S.H. Synthesis, characterization, and antibacterial activity of organotin(IV) complexes with 2-hydroxyacetophenone thiocarbohydrazone. J. Coord. Chem. 2011, 64, 4191–4200. [Google Scholar] [CrossRef]

- Andrady, A.; Searle, N. Photodegradation of rigid PVC formulations. II. Spectral sensitivity to light-induced yellowing by polychromatic light. J. Appl. Polym. Sci. 1989, 37, 789–2802. [Google Scholar] [CrossRef]

- Gardette, J.L.; Gaumet, S.; Lemaire, J. Photooxidation of poly(vinyl chloride). 1. A reexamination of the mechanism. Macromolecules 1989, 22, 2576–2581. [Google Scholar] [CrossRef]

- Almond, J.; Sugumaar, P.; Wenzel, M.N.; Hill, G.; Wallis, C. Determination of the carbonyl index of polyethylene and polypropylene using specified area under band methodology with ATR-FTIR spectroscopy. e-Polymers 2020, 20, 369–381. [Google Scholar] [CrossRef]

- Rabek, J.F.; Shur, Y.J.; Rårnby, B. Studies of the photooxidation mechanism of polymers. III. Role of tetrahydrofuran in the photooxidative degradation of poly(vinyl chloride). J. Polym. Sci. Pol. Chem. 1975, 13, 1285–1295. [Google Scholar] [CrossRef]

- Mehmandoust, S.G.; Sokhandani, P.; Abdi, A.M.; Babaluo, A.A.; Alizadeh, R. Effect of long time exposure on the chemical and physical properties of polyvinyl chloride/titanium dioxide nanocomposites. J. Thermoplast. Compos. Mater. 2016, 29, 1498–1516. [Google Scholar] [CrossRef]

- Jafari, A.J.; Donaldson, J.D. Determination of HCl and VOC emission from thermal degradation of PVC in the absence and presence of copper, copper(II) oxide and copper(II) chloride. J. Chem. 2009, 6, 685–692. [Google Scholar] [CrossRef]

- Rabie, S.T.; Ahmed, A.E.; Sabaa, M.W.; Abd El-Ghaar, M.A. Maleic diamides as photostabilizers for polystyrene. J. Ind. Eng. Chem. 2013, 19, 1869–1878. [Google Scholar] [CrossRef]

- Valko, L.; Klein, E.; Kovařík, P.; Bleha, T.; Šimon, P. Kinetic study of thermal dehydrochlorination of poly(vinyl chloride) in the presence of oxygen: III. Statistical thermodynamic interpretation of the oxygen catalytic activity. Eur. Polym. J. 2001, 37, 1123–1132. [Google Scholar] [CrossRef]

- Yousif, E.; El-Hiti, G.A.; Hussain, Z.; Altaie, A. Viscoelastic, spectroscopic and microscopic study of the photo irradiation effect on the stability of PVC in the presence of sulfamethoxazole Schiff’s bases. Polymers 2015, 7, 2190–2204. [Google Scholar] [CrossRef]

- Hashim, H.; El-Hiti, G.A.; Alotaibi, M.H.; Ahmed, D.S.; Yousif, E. Fabrication of ordered honeycomb porous poly(vinyl chloride) thin film doped with a Schiff base and nickel(II) chloride. Heliyon 2018, 4, e00743. [Google Scholar] [CrossRef] [PubMed]

- Nikafshar, S.; Zabihi, O.; Ahmadi, M.; Mirmohseni, A.; Taseidifar, M.; Naebe, M. The effects of UV light on the chemical and mechanical properties of a transparent epoxy-diamine system in the presence of an organic UV absorber. Materials 2017, 10, 180. [Google Scholar] [CrossRef]

- Alotaibi, M.H.; El-Hiti, G.A.; Yousif, E.; Ahmed, D.S.; Hashim, H.; Hameed, A.S.; Ahmed, A. Evaluation of the use of polyphosphates as photostabilizers and in the formation of ball-like polystyrene materials. J. Polym. Res. 2019, 26, 161. [Google Scholar] [CrossRef]

- Shi, W.; Zhang, J.; Shi, X.-M.; Jiang, G.-D. Different photodegradation processes of PVC with different average degrees of polymerization. J. Appl. Polym. Sci. 2008, 107, 528–540. [Google Scholar] [CrossRef]

- Mohammed, R.; El-Hiti, G.A.; Ahmed, A.; Yousif, E. Poly(vinyl chloride) doped by 2-(4-isobutylphenyl)propanoate metal complexes: Enhanced resistance to UV irradiation. Arab. J. Sci. Eng. 2017, 42, 4307–4315. [Google Scholar] [CrossRef]

- Folarin, O.M.; Sadiku, E.R. Thermal stabilizers for poly(vinyl chloride): A review. Int. J. Phys. Sci. 2011, 6, 4323–4330. [Google Scholar] [CrossRef]

- Sabaa, M.W.; Oraby, E.H.; Naby, A.A.S.; Mohamed, R.R. N-Phenyl-3-substituted-5-pyrazolone derivatives as organic stabilizer for rigid PVC against photodegradation. J. Appl. Polym. Sci. 2005, 101, 1543–1555. [Google Scholar] [CrossRef]

- Nief, O.A. Photostabilization of polyvinyl chloride by some new thiadiazole derivatives. Eur. J. Chem. 2015, 6, 242–247. [Google Scholar] [CrossRef]

- Xiang, X.; Chen, S.; Chai, R. Photodegradation of plasticized poly(vinyl chloride) stabilized by different types of thermal stabilizers. Polym. Eng. Sci. 2011, 51, 624–631. [Google Scholar] [CrossRef]

| Complex | Yield (%) | MP (°C) | Elemental Analyses (%) Found (Calculated) | |||

|---|---|---|---|---|---|---|

| C | H | N | Sn | |||

| 1 | 75 | 121–123 | 66.86 (66.77) | 5.328(5.34) | 3.65(3.71) | 15.58 (15.71) |

| 2 | 73 | 110–113 | 58.56 (58.64) | 6.70 (6.77) | 4.19 (4.27) | 18.01 (18.11) |

| 3 | 71 | 88–90 | 64.30 (64.43) | 6.51 (6.57) | 5.29 (5.37) | 12.23 (11.37) |

| 4 | 70 | 108–111 | 62.52 (62.57) | 5.85 (5.88) | 5.71 (5.84) | 12.23 (12.37) |

| Complex | Wave Number (ν, cm–1) | ||||

|---|---|---|---|---|---|

| NH (Ar) | NH (Ali) | Sn–C | Sn–O | Sn–N | |

| Carvedilol | 3345 | 3059 | — | — | — |

| 1 | 3410 | 3294 | 536 | 466 | 447 |

| 2 | 3340 | 3201 | 543 | 466 | 439 |

| 3 | 3398 | 3290 | 540 | 474 | 435 |

| 4 | 3402 | 3236 | 540 | 474 | 424 |

| Complex | ppm, Hz (DMSO-d6) |

|---|---|

| Carvedilol | 11.28 (s, 1H, NH), 8.29 (d, J = 8.1 Hz, 1H, Ar), 7.50 (d, J = 8.1 Hz, 1H, Ar), 7.38 (t, J = 8.1 Hz, 1H, Ar), 7.35 (d, J = 8.1 Hz, 1H, Ar), 7.31 (d, J = 8.1 Hz, 1H, Ar), 7.18 (t, J = 8.1 Hz, 1H, Ar), 7.12 (d, J = 8.1 Hz, 1H, Ar), 6.95–6.71 (m, 4H, Ar), 5.21 (s, exch., 1H, NH), 4.23–4.16 (m, 4H, OH, CH2 and CH), 4.03 (t, J = 7.1 Hz, 2H, CH2), 3.75 (s, 3H, OMe), 2.97 (m, 2H, CH2), 2.01 (s, 1H, NH) |

| 1 | 11.28 (s, 1H, NH), 8.28 (d, J = 8.0 Hz, 1H, Ar), 7.90–7.82 (m, 5H, Ar), 7.49–7.32 (m, 10H, Ar), 7.28–7.11 (m, 4H, Ar), 6.98–6.86 (m, 5H, Ar), 6.72 (d, J = 8.0 Hz, 1H, Ar), 4.25–4.22 (m, 3H, CH2 and CH), 4.07–4.02 (m, 2H, CH2), 3.75 (s, 3H, OMe), 3.00–2.88 (m, 4H, 2 CH2), 2.10 (s, 1H, NH) |

| 2 | 11.28 (s, 1H, NH), 7.80 (d, J = 8.0 Hz, 1H, Ar), 7.00 (d, J = 8.0 Hz, 1H, Ar), 6.87–7.82 (m, 2H, Ar), 6.69–6.62 (m, 2H, Ar), 6.52–6.40 (m, 4H, Ar), 6.25 (d, J = 8.0 Hz, 1H, Ar), 4.73 (s, 1H, OH), 3.77–3.60 (m, 7H, 3 CH2 and CH), 3.24–3.08 (m, 6H, 3 CH2), 3.30 (s, 3H, OMe), 2.91 (m, 4H, 2 CH2), 2.11 (s, 1H, NH), 1.35 (m, 4H, 2 CH2), 0.98 (t, J = 7.5 Hz, 6H, 2 Me) |

| 3 | 11.36 (s, 2H, 2 NH), 8.26 (d, J = 8.0 Hz, 2H, Ar), 7.49 (d, J = 8.0 Hz, 2H, Ar), 7.38–7.31 (m, 4H, Ar), 7.15–7.06 (m, 4H, Ar), 7.01–6.93 (m, 8H, Ar), 6.73 (d, J = 8.0 Hz, 2H, Ar), 4.35–4.23 (m, 6H, 2 CH2 and 2 CH), 3.75 (s, 6H, 2 OMe), 3.28–3.10 (m, 4H, 2 CH2), 2.10 (s, 2H, 2 NH), 1.79 (m, 8H, 4 CH2), 1.70 (m, 4H, 2 CH2), 1.57–1.53 (m, 4H, 2 CH2), 1.33 (t, J = 7.6 Hz, 4H, 2 CH2), 0.87 (t, J = 7.6 Hz, 6H, 2 Me) |

| 4 | 11.37 (s, 2H, 2 NH), 8.27 (d, J = 8.1 Hz, 2H, Ar), 7.50 (d, J = 8.1 Hz, 2H, Ar), 7.39–7.31 (m, 6H, Ar), 7.16–7.12 (m, 4H, Ar), 7.03–6.89 (m, 6H, Ar), 6.74 (d, J = 8.1 Hz, 2H, Ar), 4.41–4.15 (m, 6H, 2 CH2 and 2 CH), 3.83–3.74 (m, 6H, 3 CH2), 3.59 (s, 6H, 2 OMe), 3.32–3.19 (m, 6H, 3 CH2), 2.32 (s, 2H, 2 NH), 0.84 (s, 6H, 2 Me) |

| Complex | NMR (ppm, Hz, DMSO-d6) | |

|---|---|---|

| 13C | 119Sn | |

| Carvedilol | 156.0, 149.3, 148.2, 141.2, 139.0, 126.5, 124.5, 122.4, 121.8, 121.0, 120.7, 118.6, 113.8, 112.3, 111.7, 110.3, 103.8, 100.5, 70.5, 68.5, 55.5, 52.6, 48.6 | — |

| 1 | 155.0, 149.3, 148.1, 141.2, 139.0, 136.2, 135.8, 129.0, 128.1, 126.5, 124.5, 122.5, 121.8, 121.1, 120.7, 118.6, 113.9, 112.3, 111.6, 110.3, 103.9, 100.5, 70.5, 68.4, 68.3, 55.5, 52.5, 48.8 | −136.2 |

| 2 | 154.5, 148.8, 147.7, 140.7, 138.5, 126.0, 124.0, 122.0, 121.3, 120.6, 120.3, 118.1, 113.4, 111.9, 111.2, 109.9, 104.4, 100.0, 70.0, 68.1, 68.0, 55.0, 52.2, 48.1, 32.0, 27.5, 26.3, 13.5 | −169.5 |

| 3 | 155.8, 149.0, 147.6, 141.2, 139.0, 126.5, 124.5, 122.5, 121.7, 120.7, 120.5, 118.6, 114.4, 112.3, 111.6, 110.4, 104.0, 100.5, 70.2, 68.2, 68.0, 55.4, 51.5, 47.8, 39.2, 26.7, 25.8, 13.7 | −341.8 |

| 4 | 154.8, 149.2, 148.0, 141.2, 139.0, 126.5, 124.6, 122.5, 121.7, 120.7, 120.5, 118.6, 114.8, 112.3, 111.6, 110.4, 104.1, 100.5, 70.1, 66.3, 66.2, 55.4, 51.2, 46.6, 6.7 | −213.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mousa, O.G.; El‐Hiti, G.A.; Baashen, M.A.; Bufaroosha, M.; Ahmed, A.; Ahmed, A.A.; Ahmed, D.S.; Yousif, E. Synthesis of Carvedilol–Organotin Complexes and Their Effects on Reducing Photodegradation of Poly(Vinyl Chloride). Polymers 2021, 13, 500. https://doi.org/10.3390/polym13040500

Mousa OG, El‐Hiti GA, Baashen MA, Bufaroosha M, Ahmed A, Ahmed AA, Ahmed DS, Yousif E. Synthesis of Carvedilol–Organotin Complexes and Their Effects on Reducing Photodegradation of Poly(Vinyl Chloride). Polymers. 2021; 13(4):500. https://doi.org/10.3390/polym13040500

Chicago/Turabian StyleMousa, Omar G., Gamal A. El‐Hiti, Mohammed A. Baashen, Muna Bufaroosha, Ahmed Ahmed, Ahmed A. Ahmed, Dina S. Ahmed, and Emad Yousif. 2021. "Synthesis of Carvedilol–Organotin Complexes and Their Effects on Reducing Photodegradation of Poly(Vinyl Chloride)" Polymers 13, no. 4: 500. https://doi.org/10.3390/polym13040500

APA StyleMousa, O. G., El‐Hiti, G. A., Baashen, M. A., Bufaroosha, M., Ahmed, A., Ahmed, A. A., Ahmed, D. S., & Yousif, E. (2021). Synthesis of Carvedilol–Organotin Complexes and Their Effects on Reducing Photodegradation of Poly(Vinyl Chloride). Polymers, 13(4), 500. https://doi.org/10.3390/polym13040500