Advancing Pressure-Based Flow Rate Soft Sensors: Signal Filtering Effects and Non-Laminar Flow Rate Determination

Abstract

1. Introduction

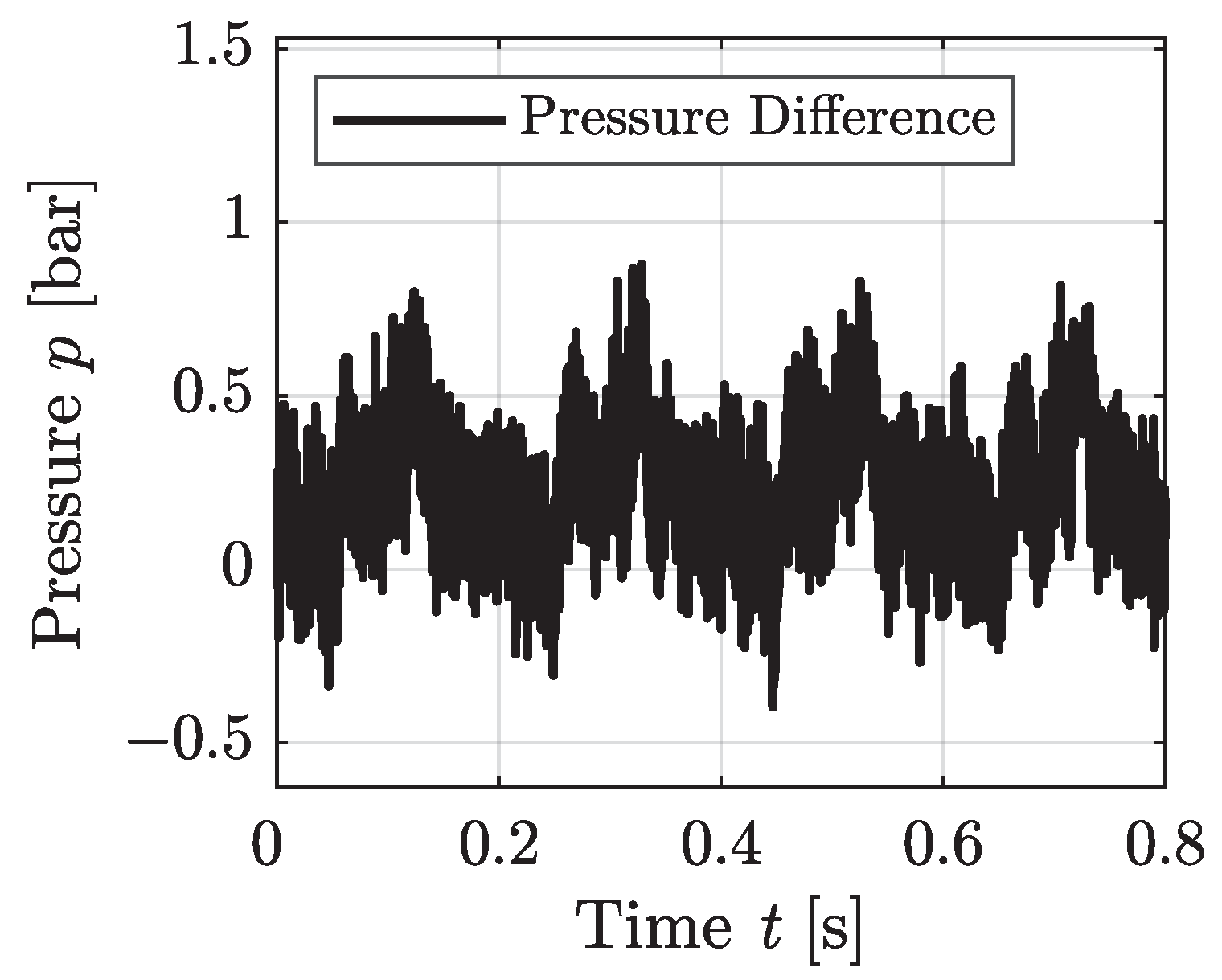

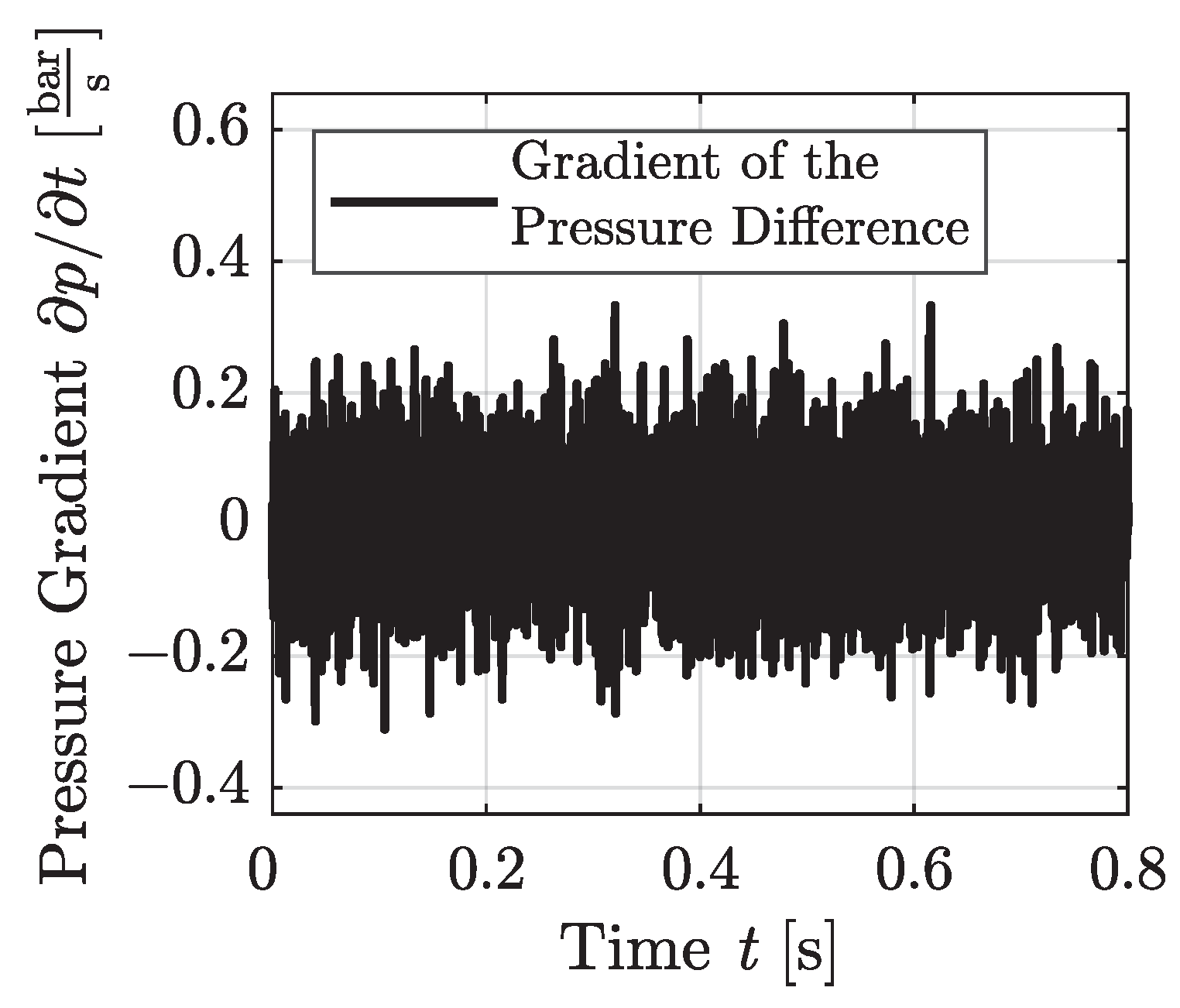

2. Materials and Methods

2.1. Flow Rate Measurement Methods & Models

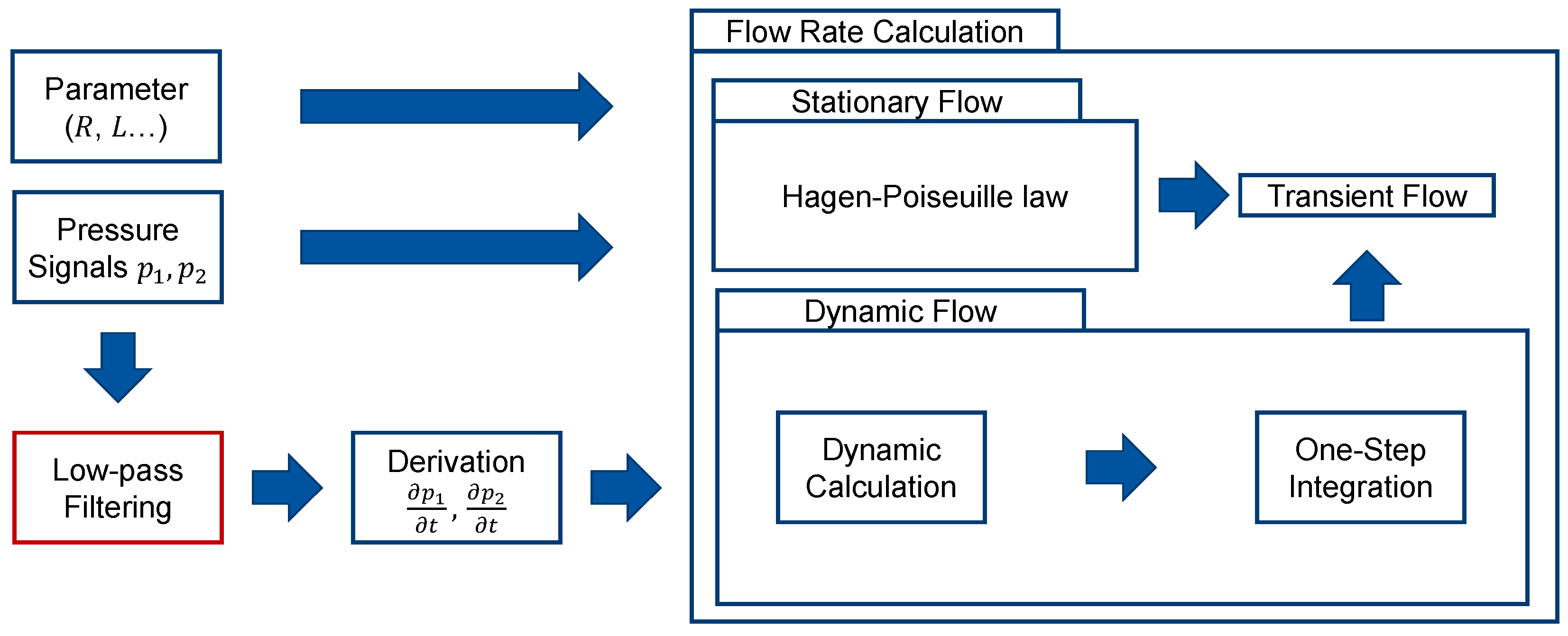

2.2. Pressure-Based Flow Rate Soft Sensor

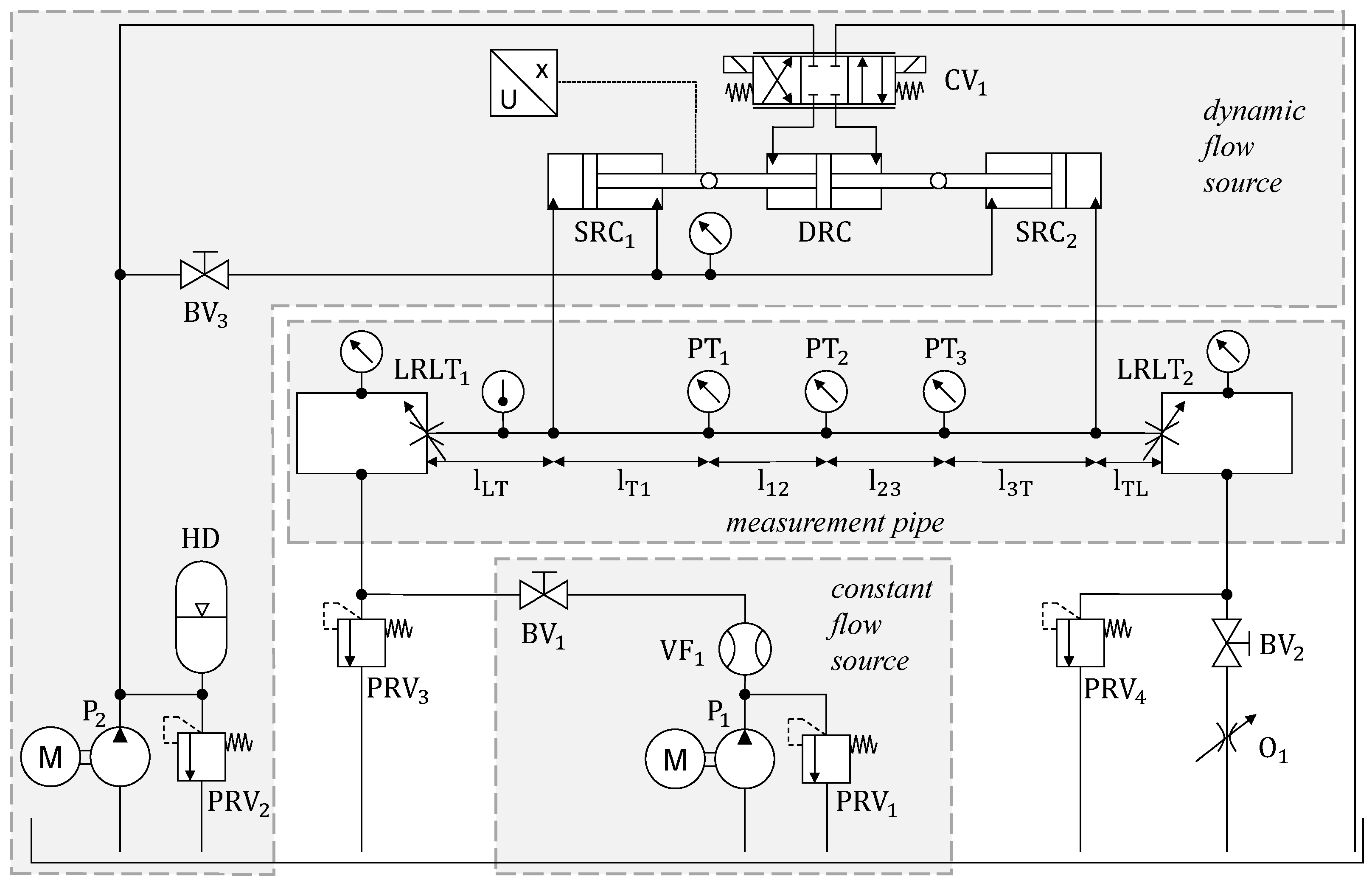

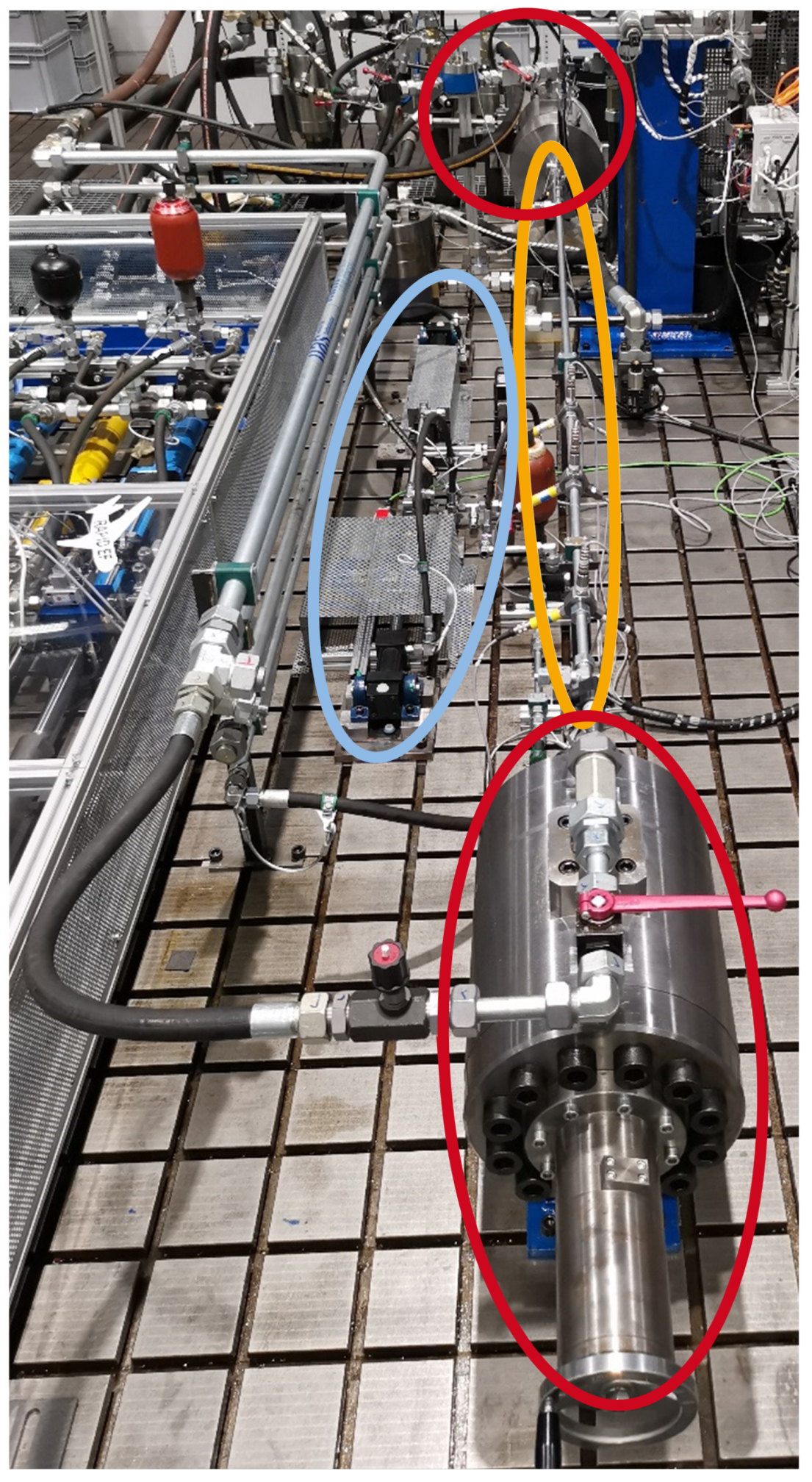

2.3. Test Rig

2.4. Test Cases

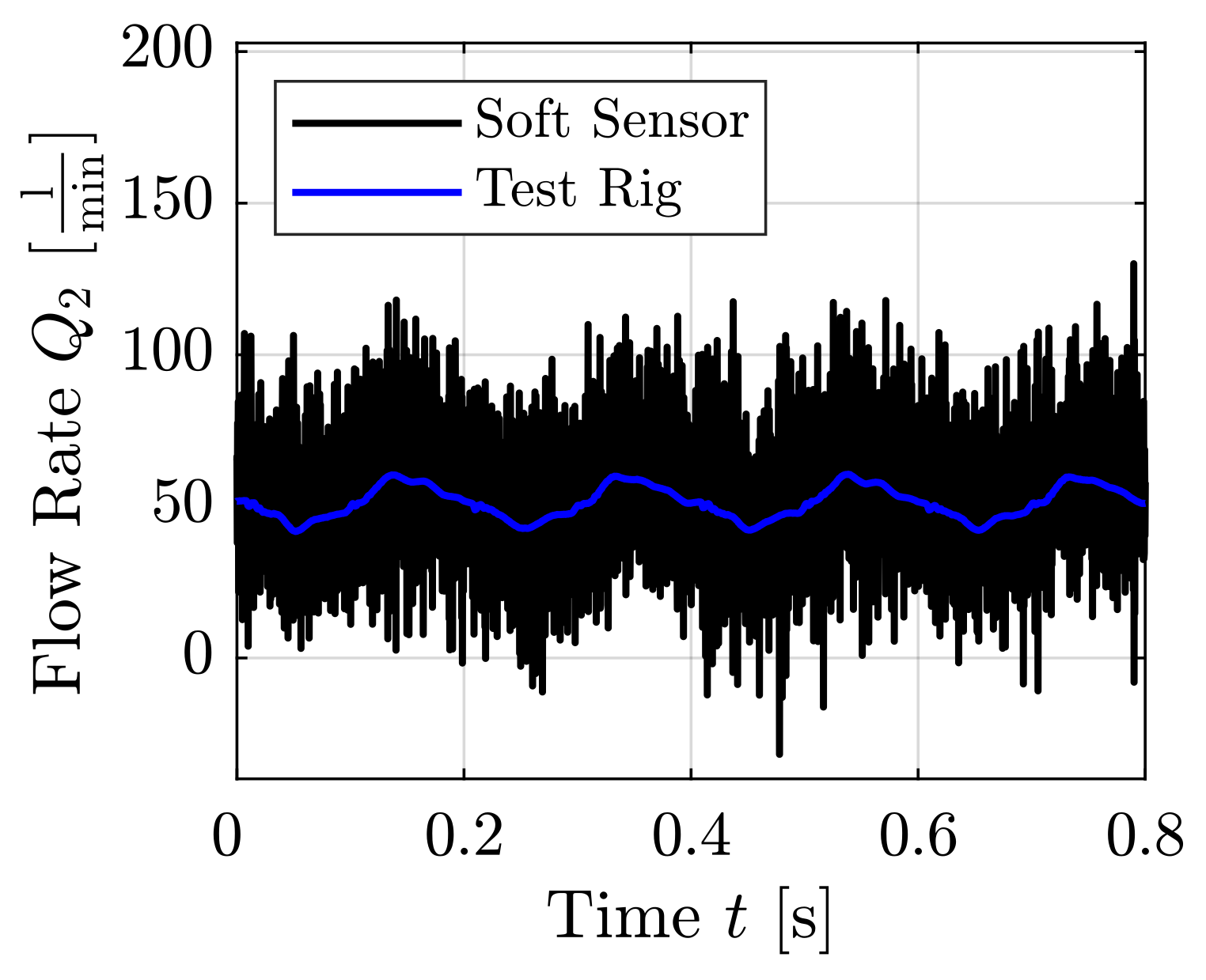

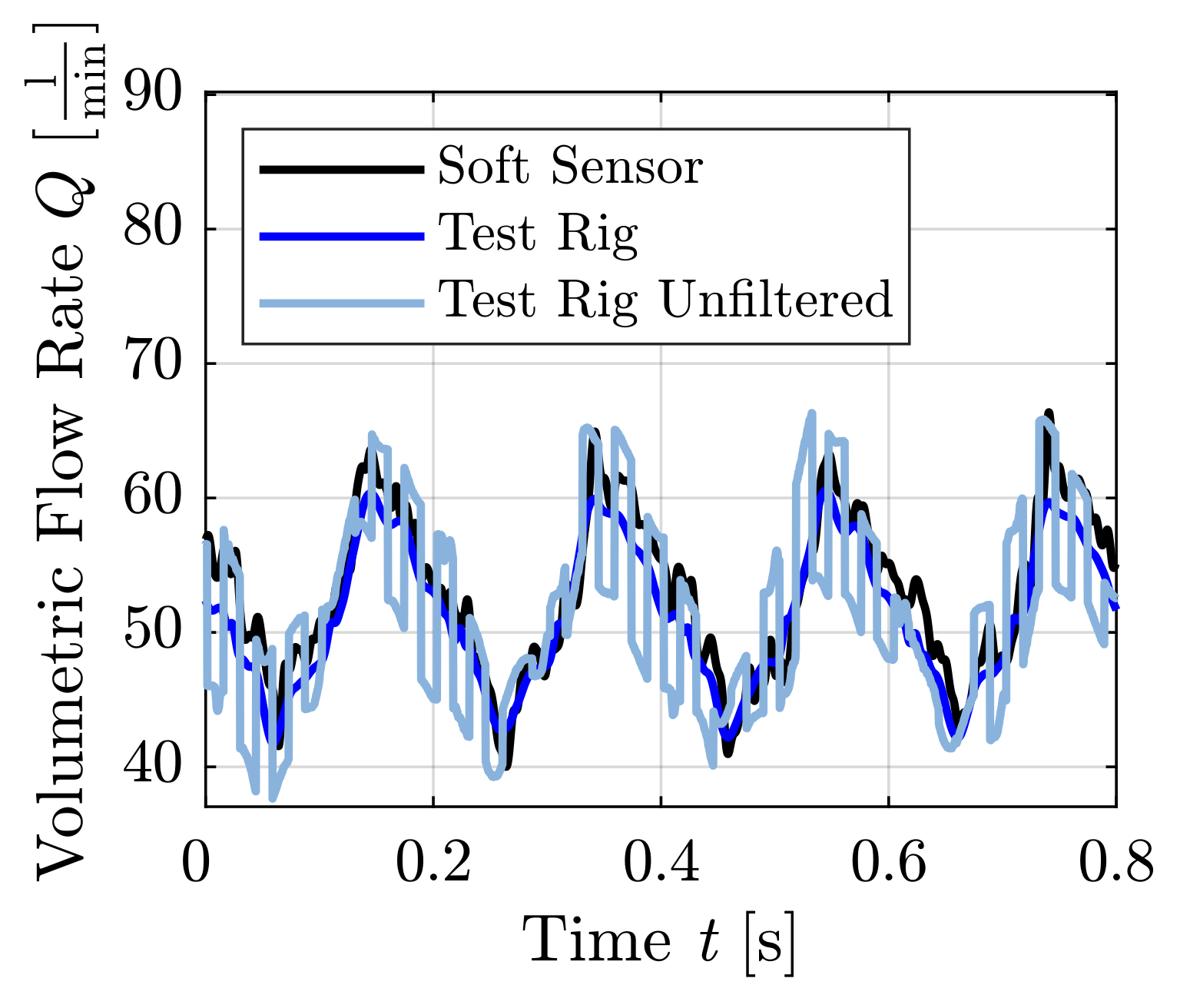

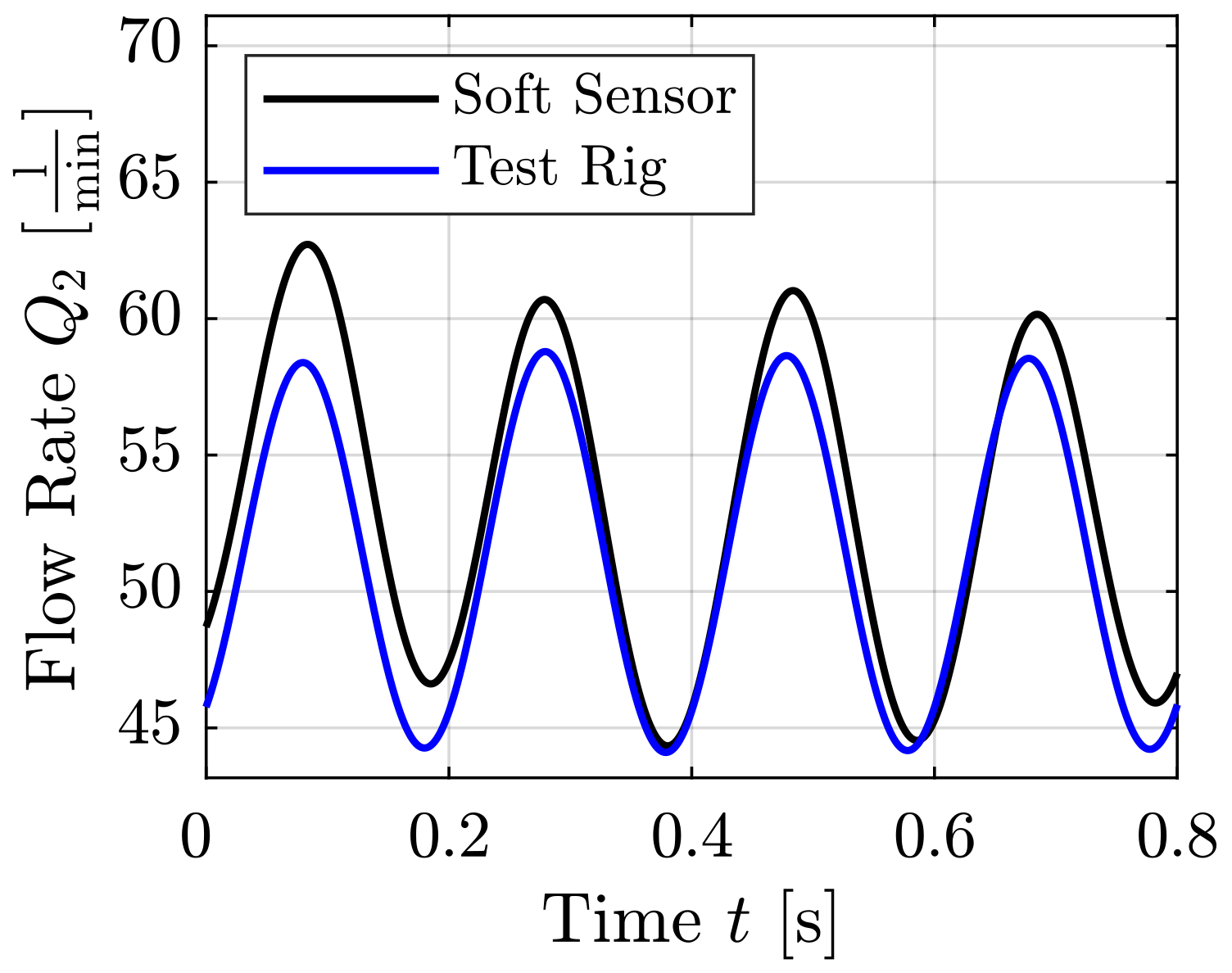

3. Results

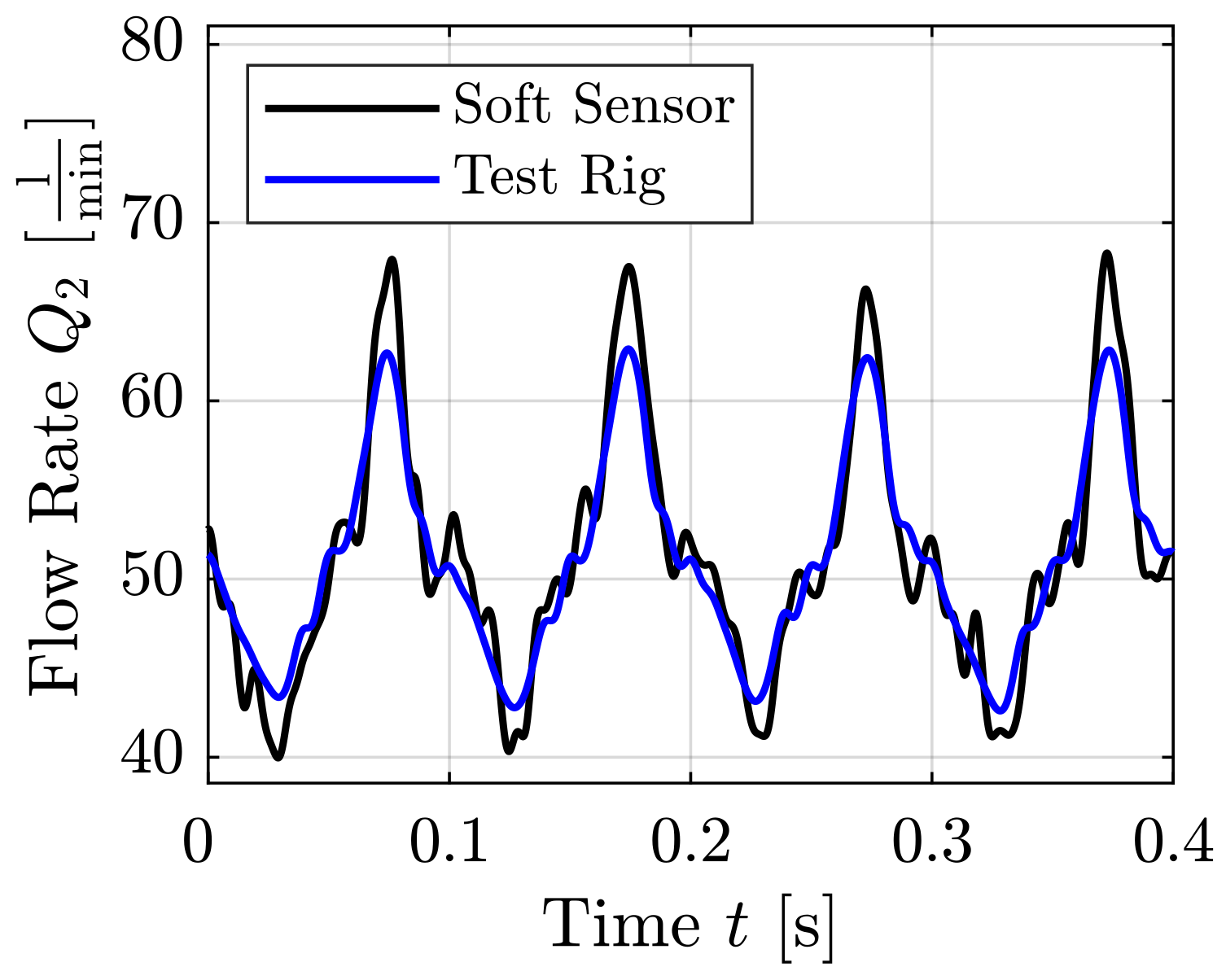

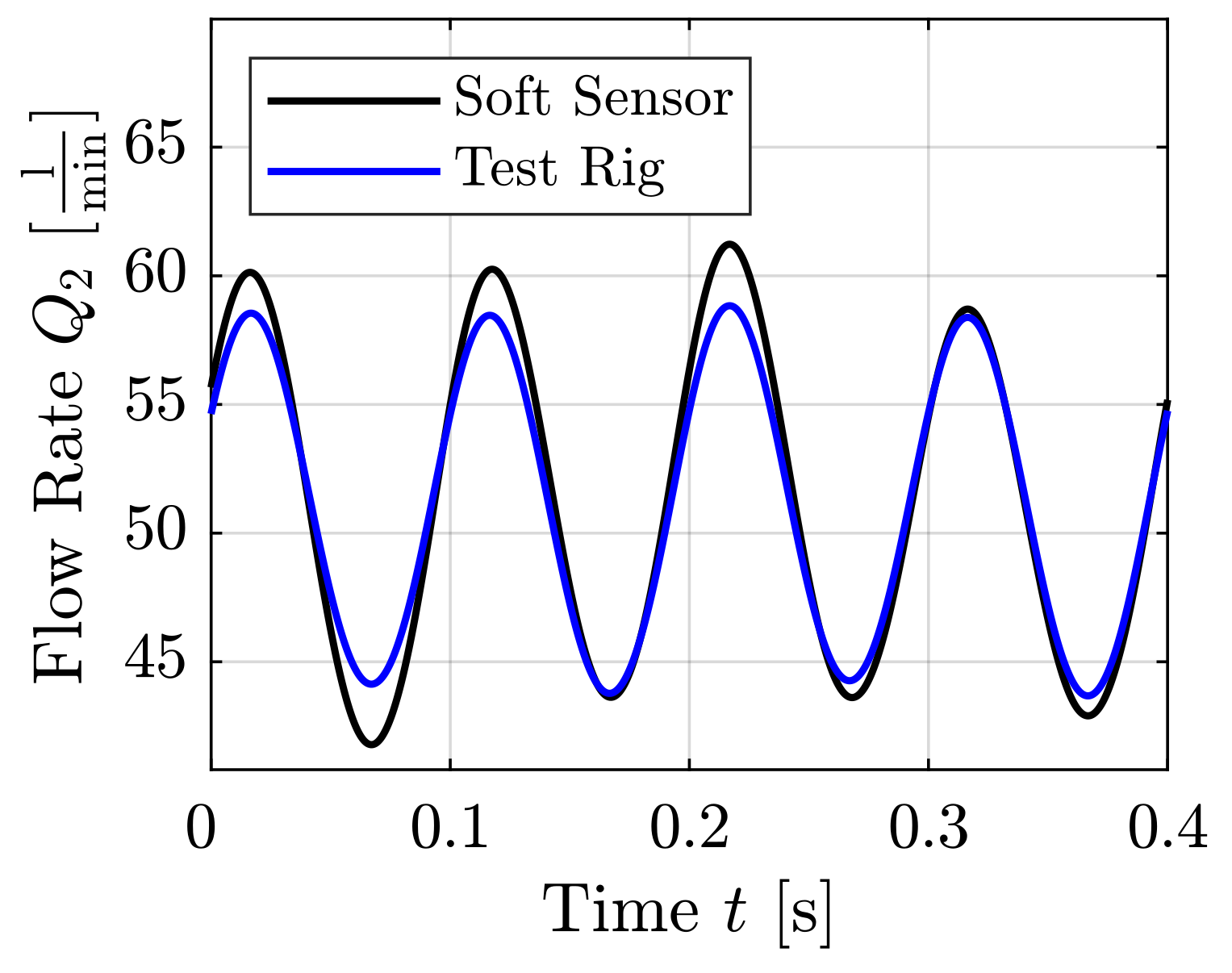

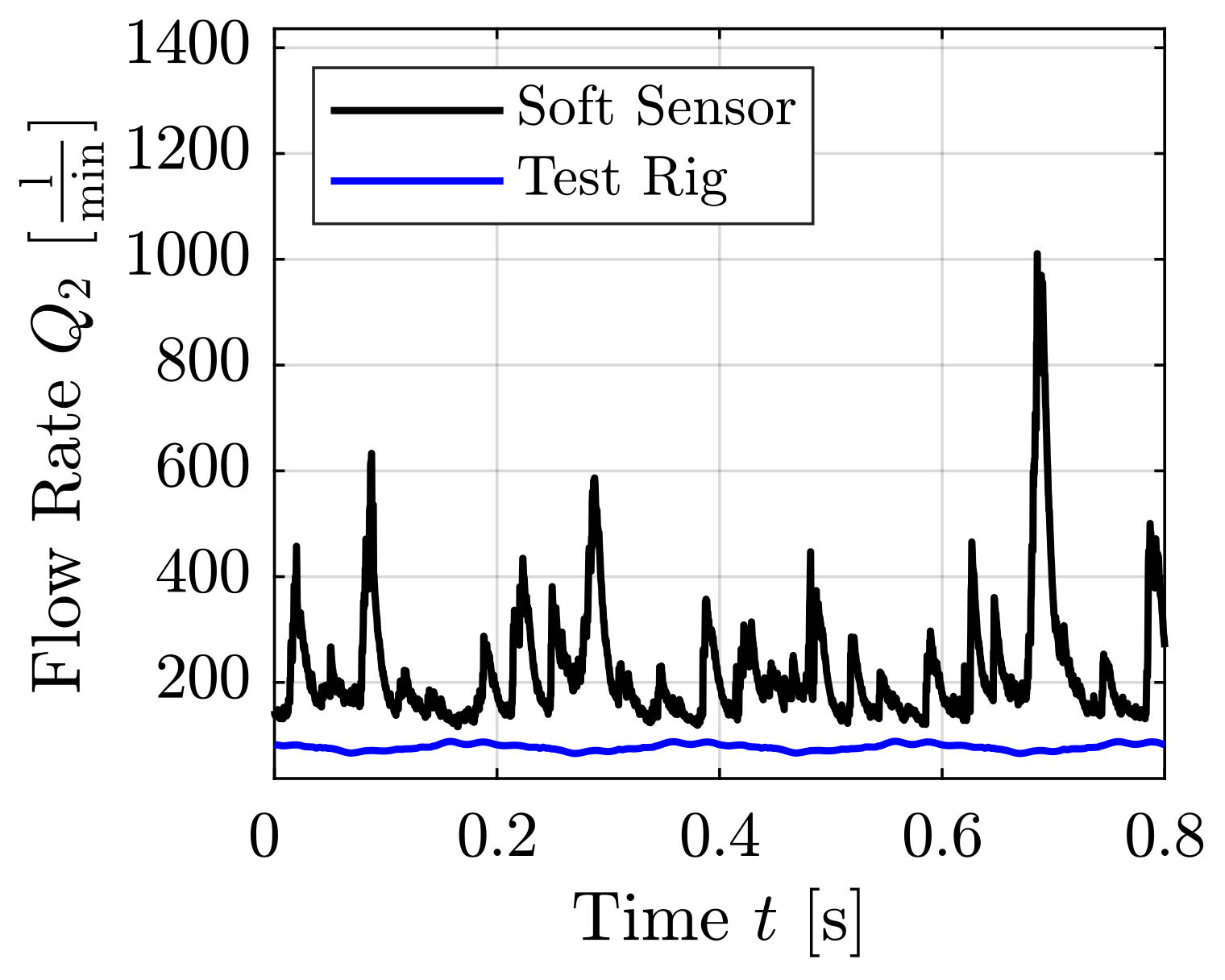

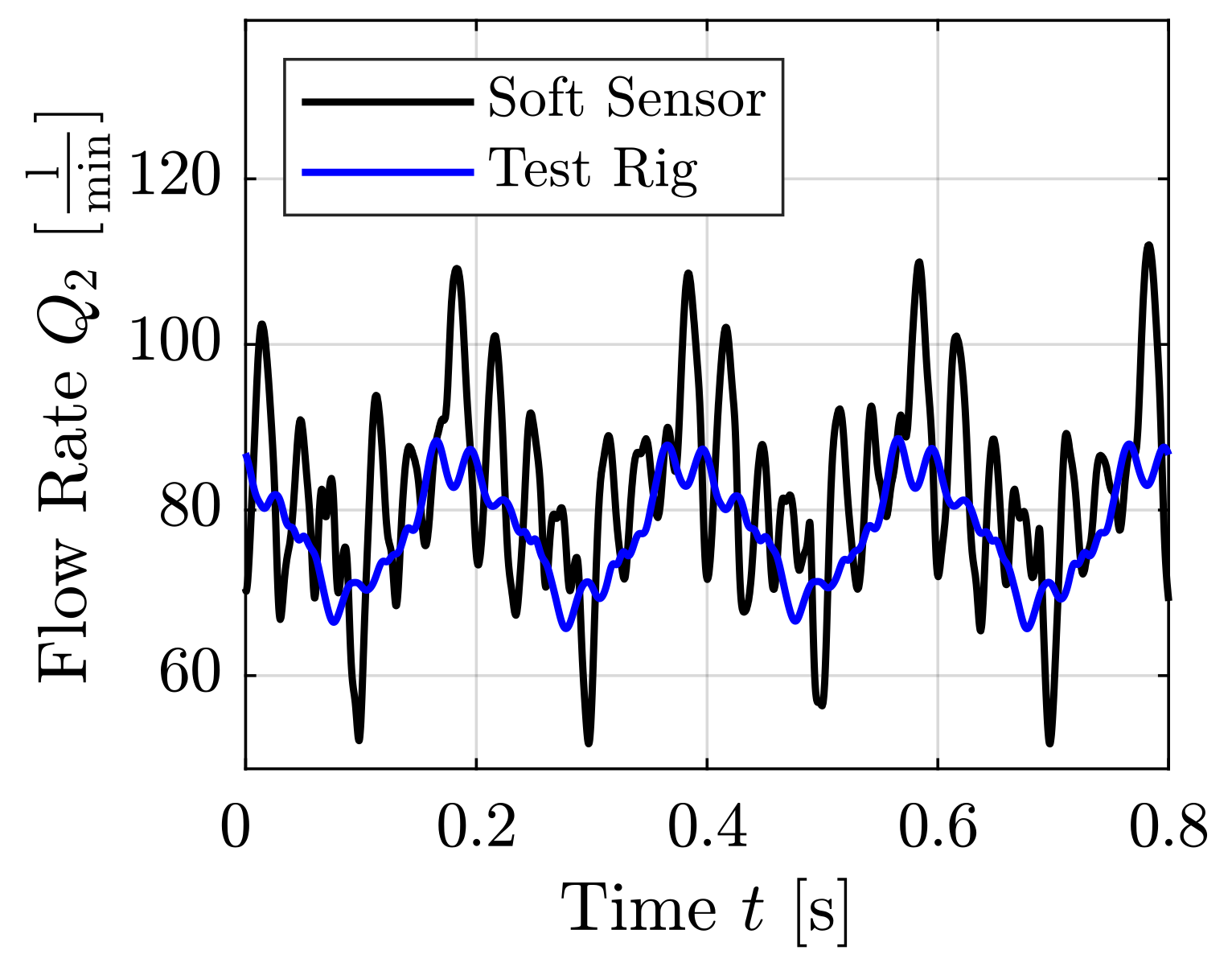

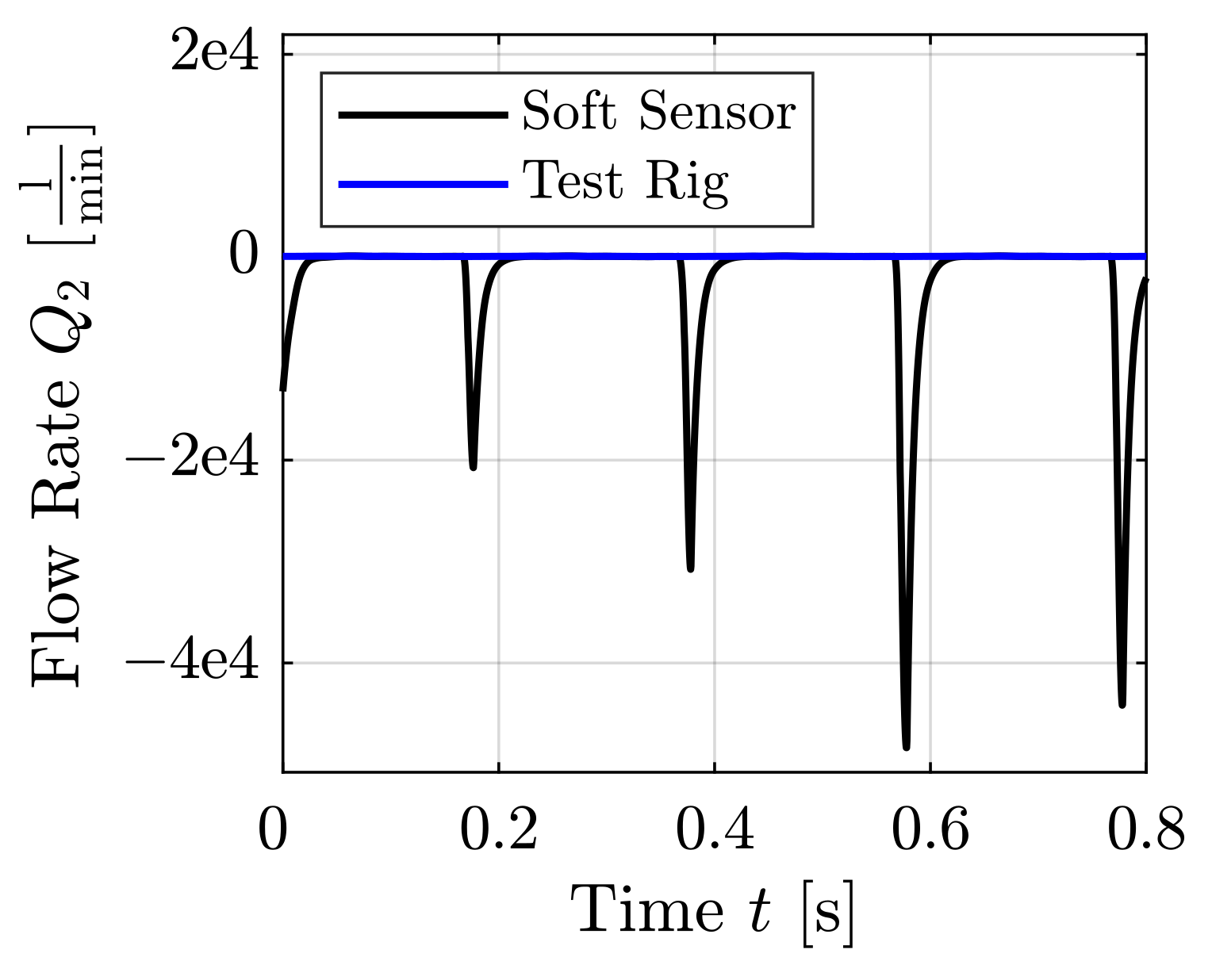

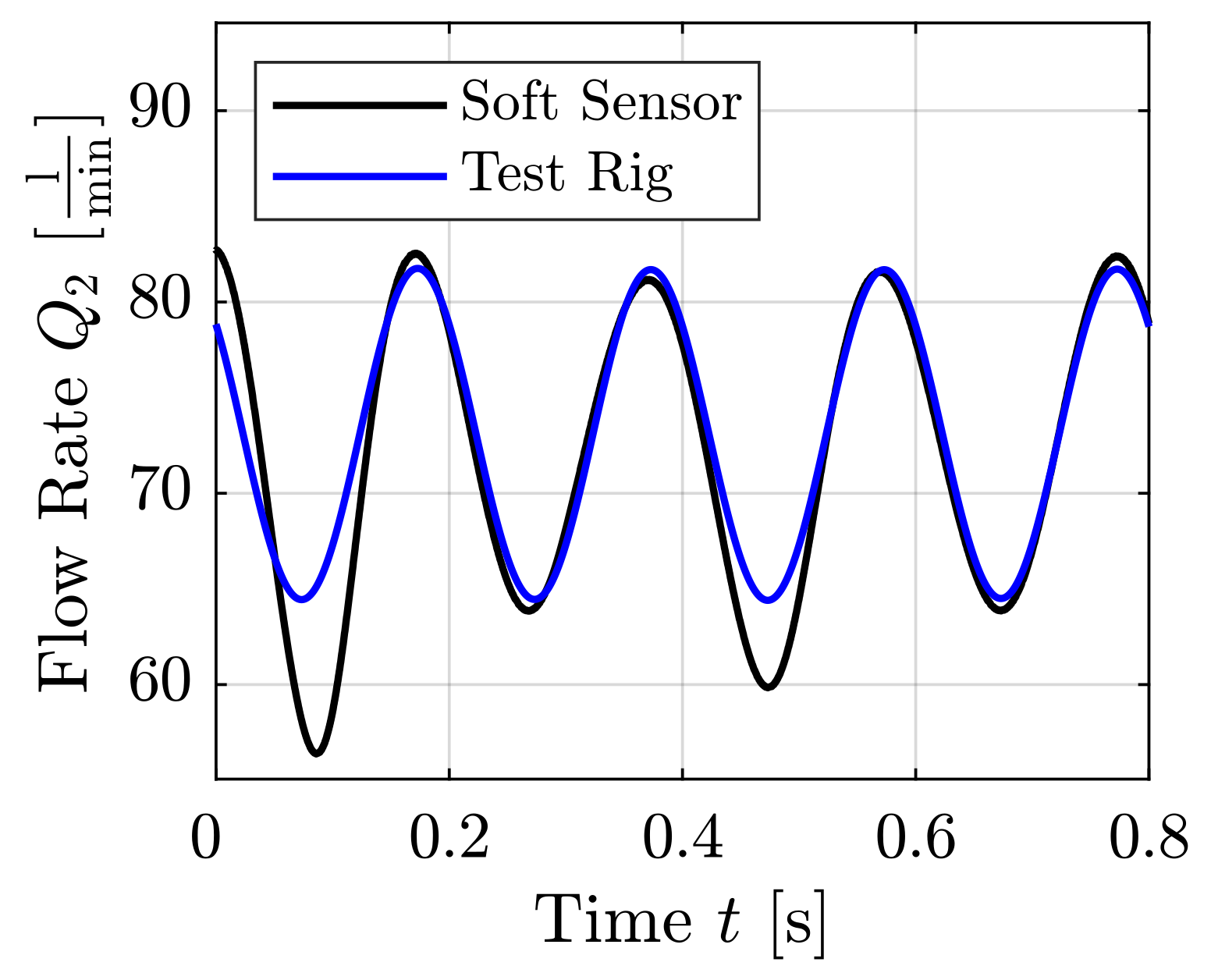

3.1. Laminar Test Cases

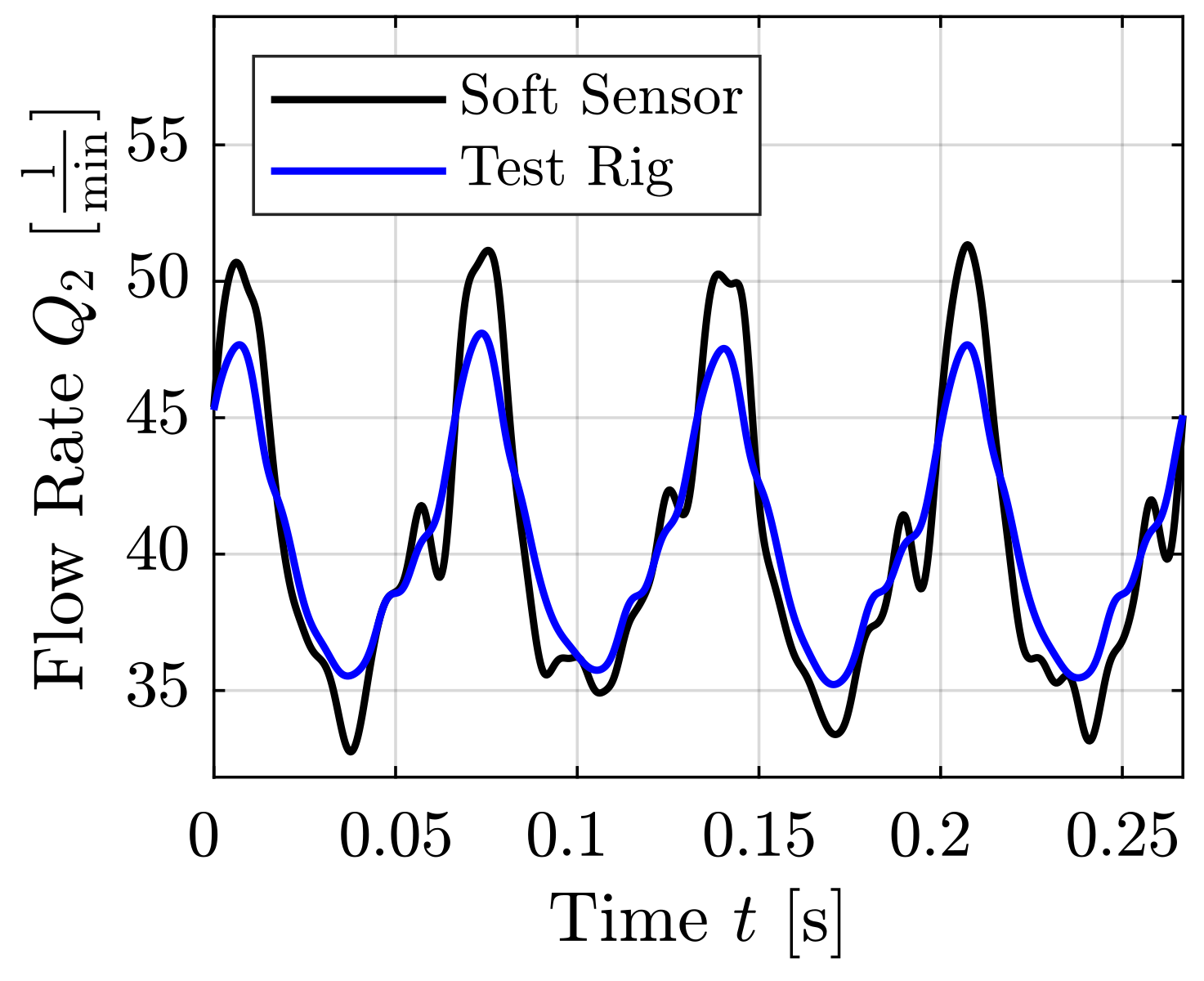

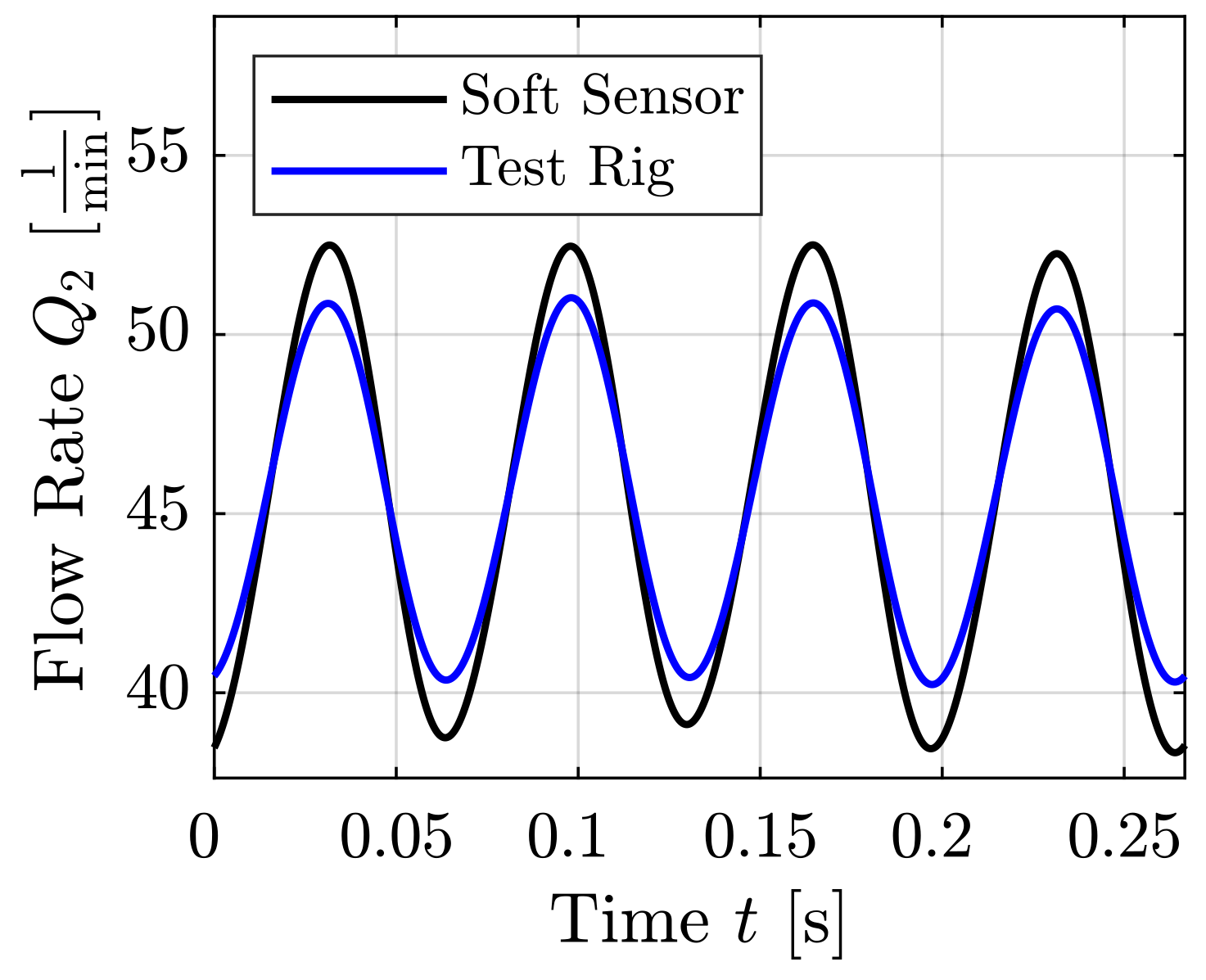

3.2. Non-Laminar Test Cases

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| BV | Ball Valve |

| CV | Control Valve |

| DRC | Double-rod Cylinder |

| FFT | Fast Fourier Transform |

| HD | Hydraulic Damper |

| HP | Hagen–Poiseuille |

| LRLT | Low-reflection line terminator |

| O | Adjustable Orifice |

| P | Hydraulic Pump |

| PIV | Particle Image Velocimetry |

| PT | Pressure Transducer |

| Re | Reynolds number |

| SRC | Single-rod Cylinder |

| SV | Switching Valve |

| VF | Volumetric Flow Rate Sensor |

Nomenclature

| Symbol | Definition | Unit |

| * | Denotation of a Variable in the Laplace Domain | [/s] |

| A | Cross-section of the Cylinder | [] |

| First Parameter of Temperature-dependent Viscosity Model | [/s] | |

| First Parameter of the Temperature-dependent Density Model | [kg/°] | |

| Geometric Parameter | [] | |

| Cross-section of the Pipe | [] | |

| Second Parameter of the Temperature-dependent Viscosity Model | [−] | |

| Second Parameter of the Temperature-dependent Density Model | [] | |

| C | Third Parameter of Temperature-dependent Viscosity Model | [1/°C] |

| Dissipation Number | [-] | |

| f | Frequency | [Hz] |

| K | Bulk Modulus | [Pa] |

| l | Pipe section length | [m] |

| L | Length of the Pipe | [m] |

| Pressure Difference | [-] | |

| Pressure at Inlet | [bar] | |

| Pressure at Outlet | [bar] | |

| Q | Volumetric Flow Rate | [/s] |

| Volumetric Flow Rate from the Cylinder | [/s] | |

| Mean Volumetric Flow Rate | [/s] | |

| Stationary Volumetric Flow Rate | [/s] | |

| Dynamic Volumetric Flow Rate | [/s] | |

| Volumetric flow rate at Inlet: and Outlet: | [/s] | |

| R | Radius of the Pipe | [m] |

| Reynolds Number | [-] | |

| Hydraulic Resistance | [Pa/(/s)] | |

| t | Time | [s] |

| Normalized Time | [-] | |

| v | Axial Fluid Velocity | [m/s] |

| v | Velocity of the Cylinder | [m/s] |

| Weighting function at End of the Pipe | [-] | |

| Weighting function at port | [-] | |

| Negative of | [-] | |

| Compressible Weighting Function at port 1 | [-] | |

| Incompressible Weighting Function | [-] | |

| Discharge Coefficient | [-] | |

| Dynamic Viscosity | [Pas] | |

| Kinematic Viscosity | [/s] | |

| Fluid Density | [] | |

| Time | [s] | |

| Normalized Time | [s] |

Appendix A. Fluid Model

| Parameter | C | ||||||

|---|---|---|---|---|---|---|---|

| − | − | ||||||

| − | − | − | 1 | 1 |

References

- Richardson, E.G.; Tyler, E. The transverse velocity gradient near the mouths of pipes in which an alternating or continuous flow of air is established. Proc. Phys. Soc. 1929, 42, 1–15. [Google Scholar] [CrossRef]

- Brumand-Poor, F.; Kotte, T.; Pasquini, E.; Kratschun, F.; Enking, J.; Schmitz, K. Unsteady flow rate in transient, incompressible pipe flow. Z. Angew Math Mech. 2024, 105, e202300125. [Google Scholar] [CrossRef]

- Brumand-Poor, F.; Kotte, T.; Pasquini, E.; Schmitz, K. Signal Processing for High-Frequency Flow Rate Determination: An Analytical Soft Sensor Using Two Pressure Signals. Preprints 2024. [Google Scholar] [CrossRef]

- Brumand-Poor, F.; Schüpfer, M.; Merkel, A.; Schmitz, K. Development of a Hydraulic Test Rig for a Virtual Flow Sensor. In Proceedings of the Eighteenth Scandinavian International Conference on Fluid Power (SICFP’23), Tampere, Finland, 30 May–1 June 2023. [Google Scholar]

- Brumand-Poor, F.; Kotte, T.; Schüpfer, M.; Figge, F.; Schmitz, K. High-Frequency Flow Rate Determination—A Pressure-Based Measurement Approach. Preprints 2024. [Google Scholar] [CrossRef]

- Manhartsgruber, B. Instantaneous Liquid Flow Rate Measurement Utilizing the Dynamics of Laminar Pipe Flow. J. Fluids Eng. 2008, 130, 121402. [Google Scholar] [CrossRef]

- Kashima, A.; Lee, P.; Ghidaoui, M. A selective literature review of methods for measuring the flow rate in pipe transient flows. In Proceedings of the BHR Group—11th International Conferences on Pressure Surges, Lisbon, Portugal, 24–26 October 2012; pp. 733–742. [Google Scholar]

- Wiklund, D.; Peluso, M. Quantifying and Specifying the Dynamic Response of Flowmeters. Conf. ISA 2002, 422, 463–476. [Google Scholar]

- Brunone, B.; Berni, A. Wall Shear Stress in Transient Turbulent Pipe Flow by Local Velocity Measurement. J. Hydraul. Eng. 2010, 136, 10. [Google Scholar] [CrossRef]

- Grant, I. Particle image velocimetry: A review. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1997, 211, 55–76. [Google Scholar] [CrossRef]

- Brereton, G.J.; Schock, H.J.; Rahi, M.A.A. An indirect pressure-gradient technique for measuring instantaneous flow rates in unsteady duct flows. Exp. Fluids 2006, 40, 238–244. [Google Scholar] [CrossRef]

- Brereton, G.J.; Schock, H.J.; Bedford, J.C. An indirect technique for determining instantaneous flow rate from centerline velocity in unsteady duct flows. Flow Meas. Instrum. 2008, 19, 9–15. [Google Scholar] [CrossRef]

- Sundstrom, L.R.J.; Saemi, S.; Raisee, M.; Cervantes, M.J. Improved frictional modeling for the pressure-time method. Flow Meas. Instrum. 2019, 69, 101604. [Google Scholar] [CrossRef]

- Foucault, E.; Szeger, P. Unsteady flowmeter. Flow Meas. Instrum. 2019, 69, 101607. [Google Scholar] [CrossRef]

- García García, F.J.; Fariñas Alvariño, P. On the analytic explanation of experiments where turbulence vanishes in pipe flow. J. Fluid Mech. 2022, 951, A4. [Google Scholar] [CrossRef]

- García García, F.J.; Fariñas Alvariño, P. On an analytic solution for general unsteady/transient turbulent pipe flow and starting turbulent flow. Eur. J. Mech.-B/Fluids 2019, 74, 200–210. [Google Scholar] [CrossRef]

- Urbanowicz, K.; Bergant, A.; Stosiak, M.; Deptuła, A.; Karpenko, M. Navier–Stokes Solutions for Accelerating Pipe Flow—A Review of Analytical Models. Energies 2023, 16, 1407. [Google Scholar] [CrossRef]

- Urbanowicz, K.; Bergant, A.; Stosiak, M.; Karpenko, M.; Bogdevičius, M. Developments in analytical wall shear stress modelling for water hammer phenomena. J. Sound Vib. 2023, 562, 117848. [Google Scholar] [CrossRef]

- Bayle, A.; Rein, F.; Plouraboué, F. Frequency varying rheology-based fluid–structure-interactions waves in liquid-filled visco-elastic pipes. J. Sound Vib. 2023, 562, 117824. [Google Scholar] [CrossRef]

- Bayle, A.; Plouraboue, F. Laplace-Domain Fluid–Structure Interaction Solutions for Water Hammer Waves in a Pipe. J. Hydraul. Eng. 2024, 150, 2. [Google Scholar] [CrossRef]

- Hucko, S.; Krampe, H.; Schmitz, K. Evaluation of a Soft Sensor Concept for Indirect Flow Rate Estimation in Solenoid-Operated Spool Valves. Actuators 2023, 12, 148. [Google Scholar] [CrossRef]

- Butterworth, S. On the Theory of Filter Amplifiers. Exp. Wirel. Wirel. Eng. 1930, 7, 536–541. [Google Scholar]

- Schmitz, K.; Murrenhoff, H. Hydraulik, vollständig neu bearbeitete auflage ed.; Reihe Fluidtechnik; Shaker Verlag: Aachen, Germany, 2018; Volume 2. [Google Scholar]

- Vardy, A.E.; Brown, J.M. Transient Turbulent Friction In Smooth Pipe Flows. J. Sound Vib. 2003, 259, 1011–1036. [Google Scholar] [CrossRef]

- Bartel, D. Simulation von Tribosystemen; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

| Test Case | Mean Volumetric Flow Rate [L/min] | Reynolds Number [-] | Frequency f [Hz] | Temperature T [°C] | Kinematic Viscosity [/s] | Density [] |

|---|---|---|---|---|---|---|

| Sine (Figure 4, Figure 5, Figure 6, Figure 7 and Figure 8) | 50 | 1339 | 5 | |||

| Sine (Figure 9 and Figure 10) | 50 | 1355 | 10 | 57 | 863 | |

| Sine (Figure 11 and Figure 12) | 50 | 1355 | 15 | 57 | 863 | |

| Sine (Figure 13 and Figure 14) | 77 | 3279 | 5 | 47 | ||

| Sine (Figures 16 and 17) | 86 | 2703 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brumand-Poor, F.; Kotte, T.; Hanifa, A.; Reese, C.; Hofmeister, M.; Schmitz, K. Advancing Pressure-Based Flow Rate Soft Sensors: Signal Filtering Effects and Non-Laminar Flow Rate Determination. J. Exp. Theor. Anal. 2025, 3, 8. https://doi.org/10.3390/jeta3010008

Brumand-Poor F, Kotte T, Hanifa A, Reese C, Hofmeister M, Schmitz K. Advancing Pressure-Based Flow Rate Soft Sensors: Signal Filtering Effects and Non-Laminar Flow Rate Determination. Journal of Experimental and Theoretical Analyses. 2025; 3(1):8. https://doi.org/10.3390/jeta3010008

Chicago/Turabian StyleBrumand-Poor, Faras, Tim Kotte, Abdulaziz Hanifa, Christian Reese, Marius Hofmeister, and Katharina Schmitz. 2025. "Advancing Pressure-Based Flow Rate Soft Sensors: Signal Filtering Effects and Non-Laminar Flow Rate Determination" Journal of Experimental and Theoretical Analyses 3, no. 1: 8. https://doi.org/10.3390/jeta3010008

APA StyleBrumand-Poor, F., Kotte, T., Hanifa, A., Reese, C., Hofmeister, M., & Schmitz, K. (2025). Advancing Pressure-Based Flow Rate Soft Sensors: Signal Filtering Effects and Non-Laminar Flow Rate Determination. Journal of Experimental and Theoretical Analyses, 3(1), 8. https://doi.org/10.3390/jeta3010008