Abstract

Thermoelectric (TE) materials represent a critical frontier in sustainable energy conversion technologies, providing direct thermal-to-electrical energy conversion with solid-state reliability. The optimizations of TE performance demand a nuanced comprehension of structure–property relationships across diverse length scales. This review summarizes established and emerging spectroscopic and microscopic techniques used to characterize inorganic and polymer TE materials, specifically poly(3,4-ethylenedioxythiophene): poly(styrenesulfonate) (PEDOT:PSS). For inorganic TE, ultraviolet–visible (UV–Vis) spectroscopy, energy-dispersive X-ray (EDX) spectroscopy, and X-ray photoelectron spectroscopy (XPS) are widely applied for electronic structure characterization. For phase analysis of inorganic TE materials, Raman spectroscopy (RS), electron energy loss spectroscopy (EELS), and nuclear magnetic resonance (NMR) spectroscopy are utilized. For analyzing the surface morphology and crystalline structure, chemical scanning electron microscopy (SEM), transmission electron microscopy (TEM), and X-ray diffraction (XRD) are commonly used. For polymer TE materials, ultraviolet−visible–near-infrared (UV−Vis−NIR) spectroscopy and ultraviolet photoelectron spectroscopy (UPS) are generally employed for determining electronic structure. For functional group analysis of polymer TE, attenuated total reflectance–Fourier-transform infrared (ATR−FTIR) spectroscopy and RS are broadly utilized. XPS is used for elemental composition analysis of polymer TE. For the surface morphology of polymer TE, atomic force microscopic (AFM) and SEM are applied. Grazing incidence wide-angle X-ray scattering (GIWAXS) and XRD are employed for analyzing the crystalline structures of polymer TE materials. These techniques elucidate electronic, structural, morphological, and chemical properties, aiding in optimizing TE properties like conductivity, thermal stability, and mechanical strength. This review also suggests future research directions, including in situ methods and machine learning-assisted multi-dimensional spectroscopy to enhance TE performance for applications in electronic devices, energy storage, and solar cells.

1. Introduction

The increasing global energy demand and escalating evidence of environmental issues have spurred intensive research into alternative energy technologies. Over two-thirds of the energy consumed globally is dissipated or lost as heat energy released into the environment. This presents a noteworthy opportunity to harness this mostly unexploited waste heat energy for generating clean and renewable energy with no emissions, providing economic and environmental benefits for sustainable development.

Thermoelectric generators (TEGs) are solid-state instruments that directly transform thermal energy into electrical energy according to the principle of the Seebeck effect [1,2]. According to the Seebeck effect, TEGs can change the temperature difference across the hot and cold side values (ΔT) into electricity [3]. In contrast, when electrically powered, they can produce a ΔT value that enables active heating or cooling, with the capability of switching between hot and cold sides as required [4]. TEGs possess numerous advantages compared with other energy harvesting devices, including their long lifespan, scalability, high reliability, and lack of moving parts, providing compatibility with various systems [5,6]. Hence, they serve different purposes in industries like automotive, portable electronic devices, buildings, and aerospace [7,8,9,10,11,12]. Nevertheless, the extensive adoption of TE technology is restricted because of the lower efficacy of existing devices and materials. To overcome this restriction, extensive development efforts have been dedicated to finding more efficient TEGs [13].

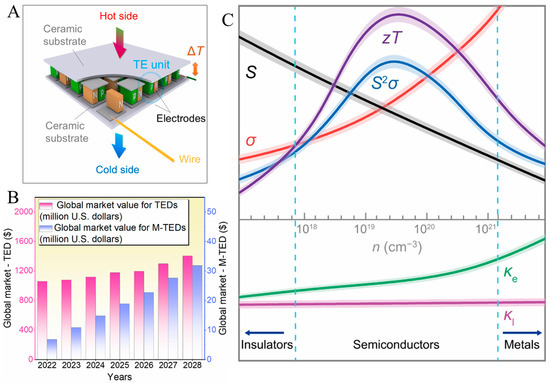

All TE devices, regardless of type, can share a basic architecture encompassing many kinds of p-and n-type legs, which are connected electrically in series and thermally in parallel [14,15], as portrayed in Figure 1A. TE devices (specifically micro-TE devices) have received increasing commercial value in recent years, with a promising future, as illustrated in Figure 1B. As such, the development of TE devices with multifunctional, stable, and high performance remains a commercially promising direction with broad application potential.

The efficiency of current TE materials is technically determined by the dimensionless figure of merit ZT = (σS2T)/κ, where σ, S, κ, and T are the electrical conductivity, the Seebeck coefficient, the total thermal conductivity, and the absolute temperature [16,17,18,19], respectively, and high ZT values correspond to the high theoretical efficiency (η) of a TE material and device. In addition to improving ZT, enhancing η involves optimizing heat transfer, decreasing internal resistance, and using rational device designs to attain mechanical flexibility [20].

In recent years, remarkable progress has been attained in TE materials science and engineering [21]. Deep understanding of the mechanisms of charge and heat transport, together with advances in fabrication techniques and multiscale structural design, has led to substantial enhancement in TE material performance [22]. Thus far, TE materials including GeTe [23,24,25,26], PbTe [27], SnSe [28,29], Cu2Se [30], and AgSbTe2 [31] have exhibited ZT values greater than 2, with some approaching 3 through microstructural engineering and compositional tuning. On the TE device side, innovations in manufacturing technologies have realized TE devices with η values above 13% [27,32,33] under laboratory conditions.

Figure 1.

(A). Illustration of a representative TE device made of many kinds of p-type and n-type TE materials. (B). Global markets for TE devices and micro-TE devices by millions of U.S. dollars during 2022–2028. Adapted with permission from ref. [34], Copyright 2025, American Chemical Society. (C). Variations in ZT, S2σ, σ, S, and κ (including lattice κl and electronic κe contributions) with n. Reproduced with permission from ref. [35], Copyright 2024, Wiley.

Nevertheless, most of these inorganic-based TE applications have the disadvantage of higher cost and possess comparatively low conversion η values (<6%) [36]. Also, the manufacturing process steps of these inorganic TE materials are complex, with multiple stages and techniques such as hot pressing and melting-spinning, which require significant time and advanced instruments [37]. Inorganic TE materials possess a rigid surface, which will limit the contact area when the surface is uneven. Another limitation is that most inorganic TE raw materials are less-abundant resources, which can make these TE applications more costly. Additionally, some elements are toxic, including Bi and Te; therefore, TE is not appropriate for applications requiring direct human body contact [38,39,40].

In the past several years, organic materials like conductive polymers, small molecules, and organic TE composite materials and devices have made substantial progress owing to their diverse advantages including largely adjustable molecular configuration/structure, lower cost, super-flexibility, abundant sources, tunable electrical properties, lightweight characteristics, high mechanical flexibility, environmentally benign nature, low-cost fabrication, and solution processability methods [38,41,42,43,44,45,46,47,48,49,50,51,52]. Due to their relatively unchanging and low k (generally ranging from 0.1 to 0.4 W/mK), even with increases in σ, their TE properties/performance are usually estimated by employing the power factor (PF, S2σ) instead of ZT. Various kinds of TE materials have been established in different forms, such as free-standing films, thin films, and bulk. Thin-film organic TE material fabrication, usually with a thickness varying from several nanometers to micrometers, can provide numerous benefits compared to bulk TE materials, such as versatile engineering design possibilities, owing to their dimensionality reduction, compatibility with microfabrication approaches, cost-effectiveness, scalability, and improved conversion efficiency [44,53,54,55,56,57]. These attributes can fabricate film-based TEGs, especially appropriate for integration into physical and chemical sensors, heat sources with curved surfaces, and flexible and wearable electronic devices. Thus far, several prudential approaches of both the synthesis of materials and the manufacture of super-flexible instruments have been established, and their corresponding TE properties/performances have been enhanced [58,59,60,61]. However, they are still far from practical applications. Hence, engineering of existing materials or material ingenuity, as well as understanding of the in-depth fundamental molecular mechanism for TE property improvement, is urgent.

Amongst all of the organic or polymer TE materials, poly(3,4-ethylenedioxythiophene):poly(styrene sulfonate) (PEDOT:PSS) is probably the most extensively studied and the most successful conducting polymers (CPs) related to several practical applications, as PEDOT:PSS can be easily dispersed in water or some polar organic solvents, whereas most CPs in the conductive state are intractable and insoluble in any solvent. Moreover, it possesses easy film formation, superior transparency in the visible range, and superior thermal stability [62], as well as high S and high σ with superior TE behaviors that can be used for flexible TE generators. Therefore, PEDOT:PSS with excellent TE behaviors can be employed for flexible TEGs. It must have both superior σ and S. Nevertheless, σ and S are interdependent. To overcome these challenges, various materials and approaches have been developed to boost the TE performance/properties of PEDOT:PSS [62], including the manufacture of inorganic particles/PEDOT:PSS composites [63,64], secondary doping and dedoping engineering [43,65,66], doping, dedoping process and ionic energy filtering [65], sulfuric acid crystallization [67,68], solvent treatment [41,69,70,71,72,73], construction of polymer nanostructure [74,75,76], and various pre- or post-treatment techniques, as summarized in Table 1. Indeed, TE research of PEDOT:PSS has already established a breakthrough in achieving higher PF and ZT. For instance, extremely high PF and ZT values of 1285 ± 67 µW/mK2 and 0.80 ± 0.04, respectively [77], have been reported for acid (H2SO4), base (NaOH), dimethyl sulfoxide (DMSO), and a DMSO solution of tetrathiafulvalene (TTF) sequentially treated PEDOT:PSS thin film. In another study [65], the same authors have reported PF and ZT values of, respectively, 1285 ± 67 µW/mK2 and 1.05 (world record values) at room temperature for acid, base, and vitamin C (i.e., a reductant), and then coated with 1-ethyl-3-methylimidazolium dicyanamide (EMIM:DCA) (i.e., an ionic liquid)-treated PEDOT:PSS thin film in the organic TE field, which are almost similar to those state-of-the-art inorganic-based TE counterparts. With regard to the future time perspective, PEDOT:PSS films are a potential candidate for TE materials for practical functions, and there have been substantial progress and notable improvement in the TE of PEDOT:PSS in more recent years. However, PEDOT:PSS-based TE devices/materials are still in their initial stage of development as their TE properties/performance, with respect to ZT and PF values, are presently inadequate for practical purposes [65,77].

In order to further boost the PF of PEDO:PSS films, various efforts can be made to improve their S value by employing different methods like chemical doping, including charge transfer doping, protonic acid doping, and oxidative (or reductive) doping, and molecular engineering, as well as nanostructuring [65,78,79,80,81,82,83,84,85,86]. Nevertheless, the S of organic materials (including PEDOT:PSS) with higher TE performance/properties is substantially lower compared to their inorganic counterparts [87]. It should also be noted that S depends upon the free (mobile) charge carrier concentration, n, and charge carrier effective mass, m*, with a relationship as S∼m*/n2/3 [88]. Figure 1C portrays the connection of n with ZT, PF (S2σ), σ, S, and κ2 [35]. As can be observed in Figure 1C, the bottleneck of TE materials lies in optimizing these often-correlated parameters simultaneously. The sensitivity of the materials themselves to impurities and dopant concentrations further complicates measurements. This is because of the strong dependence of σ and to a lesser extent of S on n. The development of TE materials with higher properties/performance requires a comprehensive understanding of structure–property relationships at atomic, nanoscale, and mesoscale levels [6,35,89,90]. As a result, the use of the energy filtering method is likely a remedy that can boost the S greatly and slightly decrease the σ through manipulation of the electronic transport behaviors [65,83,87].

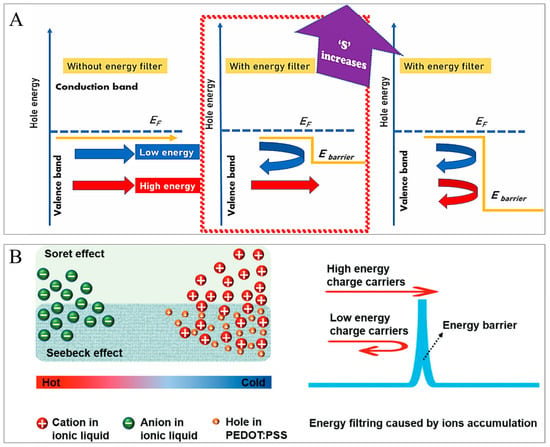

The energy filtering (EF) effect is a technique wherein the lower-energy charge carriers are solely filtered out, only allowing higher-energy charge carriers to pass through, for the improvement of the S and hence the PF, which cannot be established in traditional bulk materials [91,92,93,94,95]. The mechanism is that hotter electrons can pass an additional barrier, while colder electrons get blocked at this barrier. The mechanism is that it allows the passing of only hot electrons (higher-energy carriers) and blocks the cold electrons (lower-energy carriers) by using barriers like nano-inclusions or nanocomposites, as presented in Figure 2A. As a result, the S is enhanced [96]. Such a filtering effect has been reported for ZnO-based materials [97,98,99], indium gallium arsenide superlattice films [100], nanocrystalline PbTe [101,102,103], bulk PbTe with Pb nanoparticles [104], and nanostructured SiGe [105]. An additional benefit which usually comes together with such an EF mechanism is an additional phonon scattering [100,102,103,106], which decreases the phonon part of the k and can thereby also enhance the ZT. One disadvantage of the filtering effect is often a decline in the σ [107].

Figure 2.

(A). Diagrammatic representation of EF effect with various heights of energy barrier incorporating nanocomposites and nano-inclusions. The transport of holes with higher and lower energies is illustrated correspondingly with the red and blue straight arrows. The return arrows show the filtering of the lower-energy holes through the energy barrier. Adapted with permission from ref. [96] Copyright 2024, Elsevier. (B). Schematic of the EF of E/PABV films. Sketch of the hole and ion accumulations in an E/PABV heterostructure due to temperature gradient (left side); and schematic illustration of the EF of the holes of PABV through the potential barrier made through the cation accumulation of EMIM:DCA owing to temperature gradient (right side). Adapted with permission from ref. [65] Copyright 2025, Wiley.

Fascinatingly, the incorporation of nanostructure interfaces into TE materials to filter lower-energy charge carriers through EF also functions effectively in polymer TE composites. For instance, boosts in the S and PF in polyaniline (PANI)/carbon nanotube (CNT) and tellurium (Te)/PEDOT:PSS composites have been reported by several researchers and ascribed to the EF effect [108,109,110,111,112,113]. Thus, the utilization of nanocomposite materials is an effective technique for boosting the TE behaviors of polymer-based composites. Amongst these materials, carbon-based materials such as graphene and CNTs have been employed owing to their mechanical behaviors and higher σ. Introduction of these fillers can enhance the σ by forming better network conductivity and potentially leading to enhanced S through lower-energy charge carrier filtering at the carbon filler and PEDOT junction. Other fillers, conversely, provide the merit of a higher value of S by integrating the merits of both inorganic and conductive polymers TE materials for an enhanced PF. When there is no appropriate energy barrier, the holes with lower and higher energy can be easily accumulated toward the cold end by the temperature gradient, resulting in a lower S. In the presence of any suitable energy barrier for the charge carriers within the material, the holes with lower energy can be filtered, which are near the Fermi level [114]. Consequently, the mean energy of the accumulated holes increases, giving rise to an enhancement in the S. Nevertheless, this energy barrier has not been very high, as an extremely high energy barrier can result in blocking of the holes of both lower and higher energies and thereby remarkably decrease the σ of the material [87]. These strategies open up new paths for the development of polymer TE materials with boosted S and elevated PF [87,115,116].

For instance, more recently, Du et al. [65] (2025) have established PEDOT:PSS films with a record-high S of 111 µ/VK and PF of 1285 µW/mK2, leading to a room-temperature ZT of 1.05 by using a combination of doping engineering, dedoping, and the ionic EF effect, as portrayed in Figure 2B. This value is the world record ZT for polymers and polymer composites, which is similar to that of the outstanding inorganic TE materials. They employed a sequential acid, base, vitamin C, and 1−ethyl−3−methylimidazolium dicyanamide (EMIM:DCA) treatment of PEDOT:PSS films (abbreviated as E/PABV) [65]. The anions and cations of EMIM:DCA collect at the hot and cold ends, correspondingly, the so-called Soret effect, as illustrated in Figure 2B (left side). The accumulated cations can create an electric field, which can become an energy barrier for the collection of the holes at the PEDOT:PSS (p-type) cold side, in accordance with Maxwell’s equation (Figure 2B, right side). Consequently, the lower-energy holes are blocked, resulting in a high mean energy (ET) of the holes collected at the cold end. Hence, the S is elevated as it is linearly related to the difference between ET and the Fermi energy (EF), as S ∝ |ET − EF|. This mechanism can account for the elevated S of E/PABV as compared to Na:DCA/PABV.

Recently, various characterization methods have been used for the investigation of typical behaviors of materials. Herein, we present a comparison between various characterization techniques in terms of sample preparation, information, advantages, and limitations, and details are summarized in Table 2. The basic principles of the different microscopy and spectroscopy techniques and general guidelines for interpreting the chemical composition, functional groups, morphology data, and crystal structure information offered by these characterization approaches can be obtained in the references [117,118] and references listed therein. The TE performance of a certain type of material strongly associates with its electronic, structural, and morphological as well as chemical properties; hence, a thorough characterization of these properties is essential to deeply understand the behaviors of TE materials as well as to design novel materials with required behaviors for property enhancement. Various spectroscopic and microscopic approaches have been applied for the characterization of TE materials nowadays to examine the mechanism for TE enhancement and study material features, including structure, composition, and various properties—such as chemical, physical, electrical, etc. More advanced methods can provide additional information on the chemical properties and molecular structure as well as interfacial surface properties. The development of highly effective TE materials has offered different novel approaches for boosting the recital of TE materials owing to chemical, physical, and structural behaviors. Spectroscopic and microscopic characterization techniques play a pivotal role in understanding these fundamental properties, providing crucial insights for rational design and optimization strategies [119,120].

Despite the many review articles reported in the field of TE materials [2,34,121,122,123,124,125,126,127,128,129,130,131,132], there remains a lack of reviews in the published literature on applied spectroscopic and microscopic techniques for inorganic and organic TE materials and how these modern approaches/techniques contribute to understanding the mechanism of TE behaviors of both inorganic and polymer TE materials in terms of electronic, structural, morphological, and chemical features. The objective of this review is to bridge the gap in the literature by systematically comparing spectroscopic and microscopic techniques for inorganic and organic TE materials. In this review, we will emphasize spectroscopic and microscopic techniques that have already been applied for TE characterization—with examples and general guidelines for interpreting observations/data derived from each characterization technique for both inorganic and polymer TE materials. Section 1 introduces basic TE principles and summarizes various recent strategies for boosting the TE recital of both inorganic and organic materials. Section 2 focuses on various spectroscopic and microscopic data interpretation derived from inorganic TE materials. Section 3 highlights the interpretation of various spectroscopic and microscopic techniques data generated for polymer-based TE materials, specifically PEDOT:PSS. Ultimately, this review offers a summary and recommends the future directions in TE research and strategies.

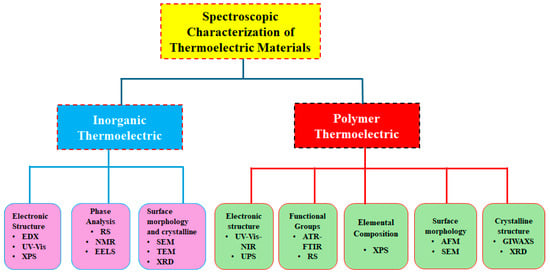

This review paper is intended to summarize the various spectroscopy and microscopy techniques that have already been applied for the characterization of inorganic and polymer TE materials, as illustrated in Figure 3. For inorganic TE, energy-dispersive X-ray (EDX) spectroscopy, X-ray photoelectron spectroscopy (XPS), and ultraviolet–visible (UV-Vis) spectroscopy are widely applied for electronic structure characterization. For phase analysis of inorganic TE materials, Raman spectroscopy (RS) and nuclear magnetic resonance (NMR) spectroscopy, as well as electron energy loss spectroscopy (EELS), are utilized. For analyzing the surface morphology and crystalline structure, scanning electron microscopy (SEM), transmission electron microscopy (TEM), and X-ray diffraction (XRD) were commonly used. For polymer TE materials, ultraviolet–visible–near-infrared (UV−Vis−NIR) spectroscopy and ultraviolet photoelectron spectroscopy (UPS) are generally employed for determining electronic structure. For functional group analysis of polymer TE materials, RS and attenuated total reflectance Fourier-transform infrared spectroscopy (ATR−FTIR) are broadly utilized. XPS is used for elemental composition analysis of polymer TE. For the surface morphology of polymer TE, atomic force microscopy (AFM) and SEM are applied. Grazing incidence wide-angle X-ray scattering (GIWAXS) and XRD are employed for analyzing the crystalline structure of polymer TE materials. In this paper, each spectroscopic technique is discussed by providing examples of spectroscopic techniques that have already been employed for TE characterization. We believe the review will provide information about advanced spectroscopic and microscopic characterization techniques to predict the performance of composites and data interpretation guidelines for potential applications in various disciplines such as electronic devices, including memristors and neuromorphic devices, organic electrochemical transistors (OECTs), light-emitting diodes (LEDs), photodetectors, and a hole transport layer (HTL) for solar cells, as well as energy storage devices including batteries and supercapacitors.

Figure 3.

Various characterization approaches for inorganic and polymer (specifically PEDOT:PSS) TE materials.

2. Spectroscopies and Microscopy Techniques of Inorganic TE Materials

Inorganic TE materials, often semi-conductors, generally exhibit higher TE performance; however, they are more expensive and less flexible [130,132]. Inorganic materials—including chalcogenides (e.g., SnSe, PbTe, Bi2Te3) [133,134], Zintl phase compounds [135,136], skutterudites, clathrates [137], and oxides—have shown significant promise as TE materials [122,132].

The fundamental mechanisms that contribute to the boosted TE performance of inorganic materials are elucidated by using different spectroscopy characterizations, including EDX, UV−Vis spectroscopy, XPS, XRD, RS, NMR, and EELS. The general data interpretation guidelines for inorganic TE materials are explained in the sections below.

2.1. Electronic Structure Characterization

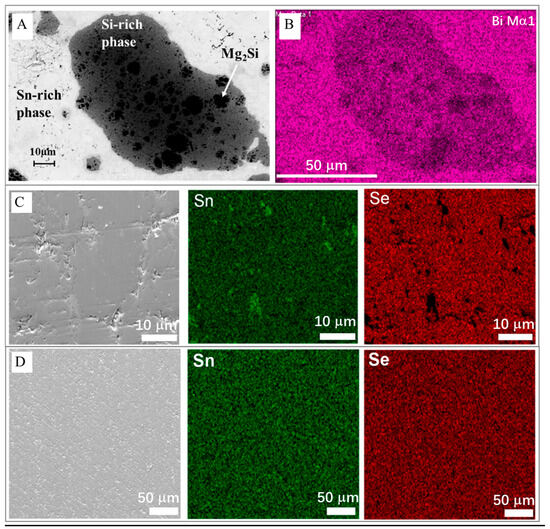

2.1.1. EDX Spectroscopy

Characterization of TE materials using EDX spectroscopy is pivotal for understanding their microstructural and electronic properties. EDX, often combined with scanning electron microscopy (SEM), allows for the analysis of local carrier concentration and band alignment, which are crucial for optimizing TE performance. This technique can effectively assess the band diagram and estimate band offsets in multi-phase materials—enhancing the filtering of undesired charge carriers [138]. As can be seen from Figure 4A, it also provides detailed elemental composition and distribution data essential for optimizing their performance. The paper utilizes SEM with EDX to characterize multi-phase TE materials, assessing local carrier concentration and band alignment, which are crucial for optimizing TE performance in magnesium silicide-based composites [139]. According to Cha et al. [140], the characteristic SEM picture and its corresponding elemental maps obtained by using EDS were recorded on the polished surface of the spark plasma sintering (SPS) processed specimen; the Sn precipitate was seemingly invisible in the SEM-EDS detection limit (Figure 4B), contrary to the result for the specimen that was subjected to further ball milling and annealing (Figure 4D). These results showed that isolated Sn would be better pulverized and homogenously distributed by the ball milling process.

Figure 4.

(A). Backscattered electron image and (B) corresponding EDX mapping for (0.5)Mg2Sn/(0.5)Mg2Si0.98Bi0.02 composite. Adapted with permission from ref. [139] Copyright 2023, Elsevier. (C). SEM image and EDX elemental mapping of Sn and Se for Sn0.90Pb0.15Se0.95Cl0.05 melt-synthesized sample, showing Sn precipitate. (D). SEM image and EDX elemental mapping of Sn Se subject to melting, further ball milling, and annealing, showing uniform element distribution. Adapted with permission from ref. [140] Copyright 2019, American Chemical Society.

2.1.2. UV−Vis Spectroscopy

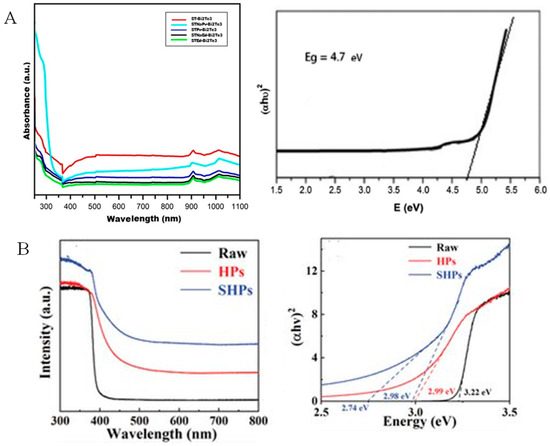

UV−Vis spectroscopy serves as a fundamental instrument for probing optical properties and electronic band structure of TE semi-conductors, measuring absorption, reflection, or transmission of light in the ultraviolet and visible electromagnetic spectrum regions [141,142]. The absorption edge value in the UV-Vis spectrum directly correlates with the material’s optical bandgap, a critical parameter influencing carrier concentration and effective mass, thereby impacting σ and S [37]. For instance, according to Rashad et al. [143], the absorption spectra of Bi2Te3 samples were analyzed by using a UV−Vis spectrophotometer at room temperature, as indicated in Figure 5A (left side). As can be observed in Figure 5A (left side), the absorption spectrum for the compound nanostructures showed absorption peaks for all specimens—including STNaPv−Bi2Te3, STPv−Bi2Te3, ST NaEd−Bi2Te3, STEd−Bi2Te3, and ST−Bi2Te3 at 284, 279, 280, 278.8, and 278 nm, respectively. The peaks were shifted/moved from 278 nm to 284 nm, which showed the impact of the nanostructure morphology and size. In addition, this redshift showed a reduction in Eg, hence raising the size of the particle. Normally, the two absorption peaks between 900 nm and 1100 nm in the IR region showed that the nano-powder of Bi2Te3 possessed the ability of thermal energy absorption from IR, as illustrated in Figure 5A (left side). In addition, Tauc plots derived from UV−Vis data enable the determination of direct or indirect bandgaps with high precision [144,145]. The energy of the bandgap or optical bandgap was determined for all specimens by using Tauc’s equation, as described by αhν = A(hν − Eg)n [146,147], where A is an energy-independent constant, α is the absorption coefficient, and n = 1/2 and 2 for indirect and direct transitions, respectively. The (αhν)2 changes with respect to E (hν) for various Bi2Te3 specimens, and the extrapolation of a straight line to intersect through the E-axis is portrayed in Figure 5A (right side). It can be easily observed that the bandgap type (direct) for these materials resulted from transitions produced by electrons, indicating these materials include solely the electrons between the conduction and valence bands with no interaction in the lattice [143].

Figure 5.

(A). UV−Vis spectra for Bi2Te3 with various sample syntheses (left side) and corresponding Tauc sketches for the determination of bandgap (right side). Adapted with permission from ref. [143] Copyright 2018, Taylor & Francis. (B). UV−Vis absorption spectra (left side) and Tauc plot for determination of bandgap for sample ZnO-based TE materials (right side). Adapted with permission from ref. [142] Copyright 2024, Wiley.

In another study, UV−Vis spectroscopy was employed to elucidate the impact of Ov caused by specific high-pressure synthesis (SHPs) on the ZnO band structure and was applied to reflect the bandgap change. As portrayed in Figure 5B (right side), the bandgap of 3.22 eV of the raw specimen (between the conduction band minimum (CBM) and the valence band maximum (VBM)) was estimated using Tauc sketch from the UV−Vis absorption spectrum, as presented in Figure 5B (left side); the high-pressure synthesis (HPs) and SHPs resulted in decreased bandgaps of, respectively, 2.99 eV and 2.98 eV. Moreover, for the SHPs specimen, there was another abrupt transformation in the absorption spectra at the longer wavelength, as depicted in Figure 5B (left side), resulting in a tail at 2.74 eV, as portrayed in Figure 5B (right side). Therefore, it is judicious that the tail at 2.74 eV can be attributed to the deep impurity states induced by Ovs, i.e., from the CBM level to the Ovs level [142].

2.1.3. XPS

XPS provides surface-sensitive analysis of elemental composition, chemical states, and electronic structure of topmost layers—crucial for understanding surface phenomena affecting TE device performance [148,149]. XPS was utilized to analyze the chemical states and composition of the AZO thin films. XPS measurements were carried out by a PHI−5400 X-ray photoemission spectrometer with a monochromatic Mg Kα (1253.6 eV) radiation source. Core-level binding energy (B.E) shifts reveal information about chemical bonding and oxidation states—particularly important for air-stable TE materials [131]. Recent developments in hard X-ray photoelectron spectroscopy (HAXPES) enable bulk-sensitive electronic structure analysis—bridging bulk and surface property relationships [150,151]. Angle-resolved XPS (ARXPS) provides depth-profiling capabilities essential for understanding interfacial effects and compositional gradients [152,153].

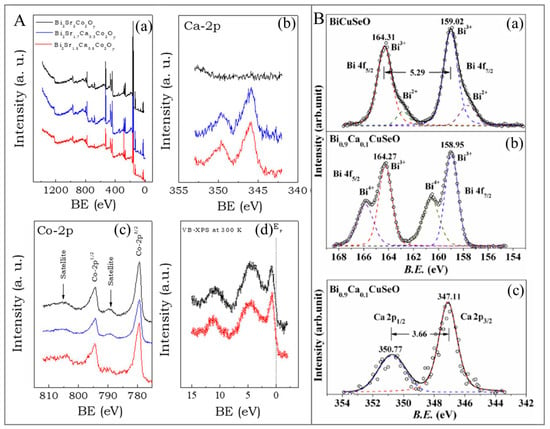

XPS chemical shift analysis enables quantitative assessment of dopant segregation and incorporation phenomena [154,155]. High-resolution XPS studies have revealed preferential dopant segregation at grain boundaries, significantly impacting electrical transport properties [156]. Ultraviolet photoelectron spectroscopy (UPS) complements XPS by probing valence band electronic structure and work function, critical parameters for understanding carrier injection and extraction in TE devices [157,158]. As illustrated in Figure 6, the combined XPS/UPS analysis provides comprehensive electronic structure characterization from core levels to valence band edge [158,159,160]. For instance, the oxidation states of each constituent element in BiCuSeO have thus far been established to be Se2−, Bi3+, O2, and Cu1+ according to the necessity of the overall level of charge neutrality. Presumably, BiCuSeO is not a characteristic ionic compound, and therefore, the oxidation states of the elements have not been clearly defined. As a result, the authors performed XPS tests to verify the oxidation states. Despite a small quantity of Bi2+ being found, most of the Bi was certainly in the 3+ state within the BiCuSeO (undoped), as portrayed in Figure 6(Ba), whereby a smaller peak at the low-B.E side for the Bi3+ peak was observed. Within the Ca-doped specimens, no Bi2+ was evidently seen. Instead, a new peak appeared on the high-B.E side of the Bi3+ peak (see Figure 6(Bb)), showing some Bi ions with a higher oxidation state, apparently Bi4+. On the other hand, calcium (Ca) possesses a stable 2+ oxidation state—which is certainly verified in Figure 6(Bc)—whereby the 2p1/2 and 2p3/2 doublets with the B.E spacing of ca. 3.66 eV and intensity ratio of ∼1:2 are always seen within multiple Ca compounds, including CaO, CaSO4, and CaCO3. Consequently, one of the mechanisms for charge compensation in the doping of Ca2+ was discovered through the oxidation of a certain Bi3+ into Bi4+.

Figure 6.

(A). (a) XPS spectra for Bi2Sr2−xCaxCo2Oy, where x = 0.5, 0.3, and 0 for red, blue, and black lines, respectively. (b) High-resolution XPS spectrum of the Ca-2p core level for x = 0.5, 0.3, and 0 for red, blue, and black lines, respectively. (c) High-resolution XPS of the Co-2p core level for x = 0.5, 0.3, and 0 for red, blue, and black lines, respectively. (d) XPS valence band spectra of Bi2Sr2−xCaxCo2Oy for x = 0.5 (red line) and 0.3 (black line) samples. Adapted with permission from ref. [161] Copyright 2023, MDPI. (B). (a,b) XPS spectra for BiCuSeO at the B.E range in Bi 4f. The smaller open circles denote the estimated experimental points; the solid line represents the total of all the peak fittings portrayed by the dashed lines. (c) XPS spectrum of the Ca (2p). The smaller open circles denote the estimated experimental points; the solid line represents the total of all the peak fittings portrayed by the dashed lines. Adapted with permission from ref. [148] Copyright 2016, Elsevier.

2.2. Phase Analysis

2.2.1. RS

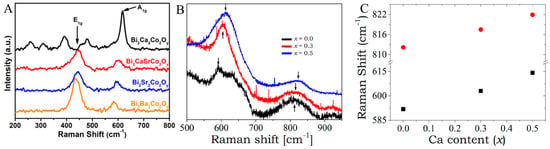

RS provides complementary vibrational analysis to IR, probing different selection rule-allowed phonon modes and offering unique insights into crystal symmetry, stress states, and defect structures [162,163]. RS provides characteristic phonon mode fingerprints, enabling material identification and quality assessment [164,165,166]. Peak positions, widths, and intensities reveal structural distortions, phase transitions, and doping effects on lattice vibrations [163,167]. Temperature-dependent Raman studies reveal anharmonic behavior through frequency shifts and peak broadening, directly correlating with k properties [168,169]. Recent investigations on SnSe single crystals have demonstrated exceptionally strong anharmonicity, contributing to record-low k [170,171]. Structural disorder and defects manifest as Raman peak broadening, frequency shifts, or the appearance of disorder-induced modes [172,173]. Quantitative analysis of peak parameters enables defect concentration estimation and its impact on transport properties [174]. Raman peak position shifts provide sensitive measures of local strain within TE materials [175], as displayed in Figure 7. Micro-Raman mapping enables spatial strain distribution analysis, particularly valuable for understanding stress effects in TE devices [175,176]. Resonance RS—achieved by matching excitation energy to electronic transitions—provides enhanced sensitivity to specific phonon modes and information about electron–phonon coupling [15]. This technique has proven particularly valuable for studying topological insulator TE materials [177].

Figure 7.

(A). Raman spectra of the corresponding samples at 300 K. Adapted with permission from ref. [178] Copyright 2017, AIP Publishing. (B). Raman spectra of Bi2Sr2-xCaxCo2Oy with x = 0.5, 0.3, and 0 specimens at room temperature. (C). Expanded peak positions for the Raman band, which was marked by arrows for (B). Adapted with permission from ref. [161] Copyright 2023, MDPI.

For instance, to examine the lattice characteristics of Bi2[AE]2Co2Oy, Li et al. carried out the RS tests, as depicted in Figure 7A. For Bi2CaSrCo2Oy (BCSCO), Bi2Sr2Co2Oy (BSCO), and Bi2Ba2Co2Oy (BBCO)—there are two notable phonon peaks, i.e., the ~440 cm−1 (E1g) and ~615 cm−1 (A1g) modes—that denote the in-plane vibration and out-of-plane vibration of the oxygen atoms, respectively. The Raman spectrum of Bi2Ca2Co2Oy (BCCO) is different from the specimens, in which the peaks are observed at ~300 cm−1 and ~450 cm−1. It can be due to the relatively prominent Ca2+ and Ca−O layers in contrast to other specimens (BBCO, BSCO, and BCSCO) [178]. Raman spectra tests at room temperature were also performed in order to verify the incorporation of Ca within the Bi2Sr2Co2Oy (BSCO) lattice, as illustrated in Figure 7B. The Raman spectrum for Bi2Sr2−xCaxCo2Oy (for x = 0.5, 0.3, and 0) specimens from 500 cm−1 to 950 cm−1 at a temperature of 300 K was recorded (Figure 7B), showing two noticeable phonon peaks for all samples at ~618 and ~815 cm−1. The observed Raman peak at 618 cm−1 was allocated to A1g modes—signifying the out-of-plane vibrational mode for the oxygen atom. A small Raman peak position shift to the right was seen with the increase in the Ca content (Figure 7C). This observation can be elucidated by the rise in the Ca−O bond strength, with regard to the Sr−O bond [161].

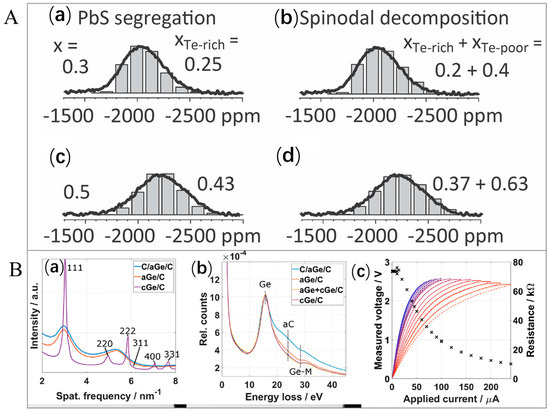

2.2.2. NMR Spectroscopic

Solid-state NMR spectroscopy offers unique insights into dynamic processes, chemical bonding, and local atomic environments and is particularly valuable for understanding the incorporation of dopant and structural disorder effects [179,180]. Solid-state NMR can differentiate crystallographically distinct sites for specific nuclei (e.g., 207Pb, 119Sn, 77Se, and 125Te) within TE materials [181,182]. For instance, as can be seen in Figure 8A, the PbTe-rich part of the phase seen here comprises less sulfur compared to the nominal/theoretical composition; simulation studies yielded values of x Te-rich = 0.45 and 0.26 for nominal x = 0.5 and 0.3, respectively. In addition, excellent fits were discovered from observation of the model of spinodal decomposition, which was anticipated in this concentration area. This observation was in good agreement with the early stage of spinodal decomposition that was inferred from quenching the x = 0.5 specimen from the comprehensive scattering data analysis. A periodically modulated composition in space was generated by spinodal decomposition. This resulted in a local composition distribution; nevertheless, the major contributions were from the maximum and minimum values of x [182].

Quadrupolar coupling constants and chemical shifts offer detailed information about local symmetry, bond lengths, and coordination environments [183,184]. Recent multinuclear NMR observations on complex chalcogenides have shown subtle local structure variations influencing transport behaviors [185,186]. NMR chemical shift analysis enables estimation of dopant incorporation sites as well as mechanisms [187].

Recent studies on PbTe-based materials have employed 207Pb NMR to elucidate dopant-induced local structure modifications [188,189]. NMR spectroscopy can characterize and detect vacancies, point defects, and interstitial atoms—usually unresolvable by diffraction approaches [190,191]. Variable-temperature NMR offers insights into defect dynamics and their temperature dependence [191,192]. In skutterudite TE materials, NMR has been extensively employed to elucidate rattling dynamics and guest atom filling fractions within cage structures [193]. These tests directly correlate with phonon scattering boost and k reduction [194,195]. NMR relaxation rate analysis can give information about mobility and carrier dynamics, though challenging for excellent conductive TE materials [196,197]. Recent developments in high-field NMR have expanded applicability to more conductive systems [198,199,200].

Figure 8.

(A). 125Te NMR spectra for quenched PbTe1−x Sx (i.e., x = 0.5 and 0.3)—which were compared by bar graphs within the models by presuming incipient separation of phase. (a,b) Model supposing segregation of close to neat PbS—with insignificant NMR signal of 125Te. (c,d) Model of two components approaching the spinodal decomposition. The model indicated in (c,d) offers a more precise composition estimate—supposing that the spinodal decomposition during the early stages has generated inhomogeneous PbTe1−xSx alloying regions within the matrix. Adapted with permission from ref. [182] Copyright 2012, Wiley. (B). Dynamic in situ TE characterization for amorphous Ge (aGe)-based thin films: (a) radial profiles of selected area electron diffraction (SAED) patterns obtained at various stages through the experiment. Reflections that correspond to fcc Ge were indexed. (b) Low-loss electron energy loss (EEL) spectrum recorded at various stages indicated the Ge−M, aC, and Ge edge bulk plasmons. (c) Recorded voltage obtained by applying current for double sweeps as displayed by dashed lines (down) and solid lines (up) with a variation from blue color to red color through the rise in the value of current. The calculated values of resistance at the highest applied current were presented using black crosses for each sweep (secondary y-axis). Adapted with permission from ref. [201] Copyright 2025, Elsevier.

2.2.3. EELS

High-spatial-resolution EELS combined with TEM provides nanoscale elemental and electronic structure information crucial for understanding interfacial phenomena and nanostructure effects [202,203]. EELS enables determination of local bandgaps, plasmon excitations, and oxidation states at nanometer spatial resolution [204]. This capability proves invaluable for characterizing interfaces, grain boundaries, and nanostructures in TE materials [205,206]. EELS analysis for TE interfaces reveals electronic structure modifications, charge transfer phenomena, and local composition variations that affect transport properties [22,207]. Recent studies have demonstrated a correlation between interfacial electronic structure and enhanced S in nanostructured materials [131,208]—EELS compositional mapping provides detailed analysis of element distribution, segregation phenomena, and phase boundaries at nanoscale resolution [209,210]. This information can prove the crucial importance of understanding nanostructure stability and transport property optimization [211].

For instance, Hettler et al. [201] employed a dynamic in situ TE characterization by inducing thermovoltage in the crystallization engineering of an amorphous Ge thin film by the application of higher current densities. The SAED pattern radial profile is portrayed in Figure 8(Ba) with a blue line showing two broad peaks—which were centered close to 3 nm−1 and 5.4 nm−1. The lower-loss EEL spectra (i.e., blue line as presented in Figure 8(Bb)) verified the existence of both Ge, which was reflected through the bulk plasmon near the Ge−M edge and 16 eV, and amorphous C (aC), which was visible at 25 eV (i.e., in the bulk plasmon). After this unplanned initial crystallization, the authors employed a double current sweep in series by increasing the highest current up to 240 A, in order to continue the crystallization engineering process within a controlled condition. The sweeps are portrayed in Figure 8(Bc)—in which dashed and solid lines represent the down- and up-sweeps, respectively—and the colors were blue at first and changed to red with the rising of the highest current. The estimated value of resistance at the highest current for each sweep was sketched using black color crosses and was seen to remain constant (73 K) up to an employed current (I) of 13 A before decreasing owing to the increase in σ of the semi-conducting Ge and an induced Joule heating effect. Above an employed current of about 70 A, the down- and up-sweeps started to vary significantly, showing a sample configurational/structural modification that was induced by the electrical current. The authors mentioned that this alteration was connected to, initially, an entire size growth in the crystallization region and, secondly, a grain size growth in the central area.

2.3. Surface Morphology and Crystalline Structure Analysis

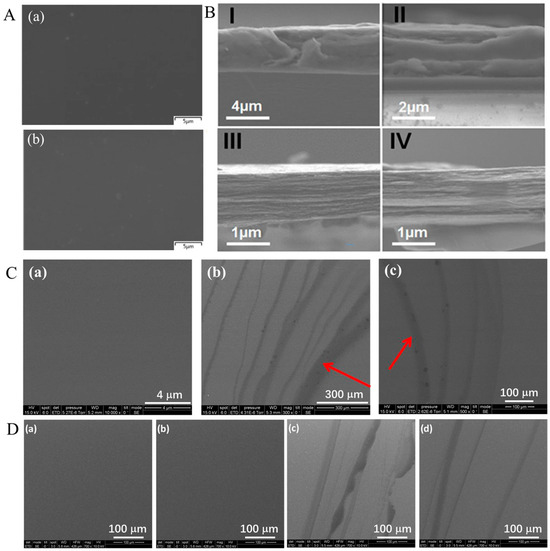

2.3.1. SEM

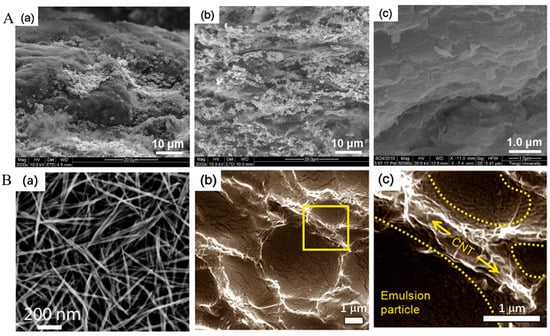

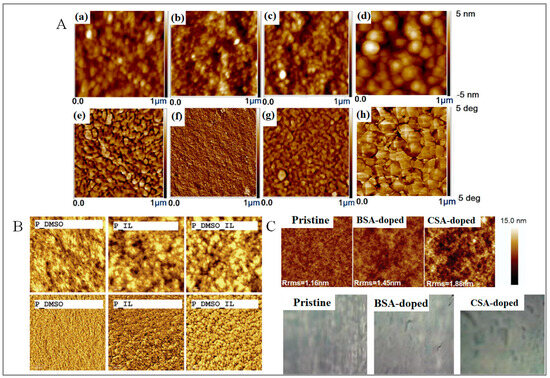

SEM is the fundamental characterization method in which the TE material surface is explored. For instance, Figure 9(Aa–Ac) displays field emission SEM (FESEM) pictures for the prepared Bi2Te3-Bi2Se3 composite fracture surface of specimens, which were hot-pressed at a temperature range of 623–673 K and 80 MPa within a vacuum. These pictures clearly showed that the grain size and density of the composite specimens were both enlarged with sintering temperature. It can be observed from Figure 9A that the grain size of specimens that were hot-pressed at 673 K (Figure 9(Ab,Ac)) is clearly larger compared to that of the specimen that was hot-pressed at 623 K (Figure 9(Aa)) [212]. Figure 9(Ba) shows an SEM picture of a drop-cast film for the crystalline Te nanorod passivated by PEDOT:PSS that was created into a smooth thin-film nanocomposite by using the solution-casting technique [109]. Figure 9(Bb) presents the SEM image of the cross-sections of the composite of CNT (5 wt.%) and polymer (poly(vinyl acetate) (PVAc) following the freeze-fracturing of the composites. The SEM picture with higher magnification is shown in Figure 9(Bc), which was a portion of the specimen in Figure 9(Bb) (i.e., portrayed with a yellow solid square) [213].

Figure 9.

(A). FESEM pictures of the fracture surface of the Bi2Te3-Bi2Se3 composite specimens that were hot-pressed at a temperature of (a) 623 K, and (b,c) 673 K and 80 MPa. Adapted with permission from ref. [212] Copyright 2011, Springer Nature (B). (a) SEM picture of a drop-cast PEDOT:PSS passivated crystalline Te nanorods thin film composite. Adapted with permission from ref. [109] Copyright 2010, American Chemical Society. (b) SEM pictures of the cross-sections of CNT (5 wt.%)—PVAc composites are indicated in panels b and c for freeze-fractured composites. The SEM image with higher magnification indicated in panel (c) is a part of the specimen in (b), as shown by a solid square with yellow color. It obviously indicated that CNTs (as shown with arrows), which are wrapped around particles at the emulsion (as shown with yellow dotted lines) instead of being homogenously blended. Adapted with permission from ref. [213] Copyright 2008, American Chemical Society.

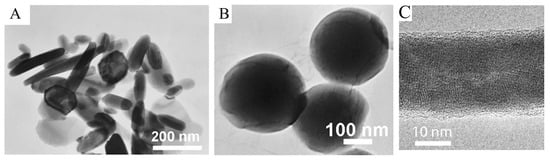

2.3.2. TEM

TEM offers higher resolution as compared to that of SEM for better observations of TE materials. For instance, Figure 10A,B show the TEM pictures of the prepared Bi2Te3 nanopowders and PTH, indicating the differences in shape and particle size. It can be observed from Figure 10A that the prepared Bi2Te3 powders largely comprised nanosheets, with approximate sizes of 50 to 200 nm. The synthesized PTH powders were spherical with a mean diameter of approximately 200 nm (Figure 10B) [214]. Figure 10C presents TEM pictures of the crystalline Te nanorod, which was passivated using PEDOT:PSS [109].

Figure 10.

(A). TEM pictures of the Bi2Te3 nanopowders manufactured through the hydrothermal synthesis approach; (B). TEM images of PTH synthesized through the chemical oxidative polymerization method. Adapted with permission from ref. [214] Copyright 2012, Springer. (C). TEM picture indicating the PEDOT:PSS passivated crystalline Te nanorod. Adapted with permission from ref. [109] Copyright 2010, American Chemical Society.

2.3.3. XRD

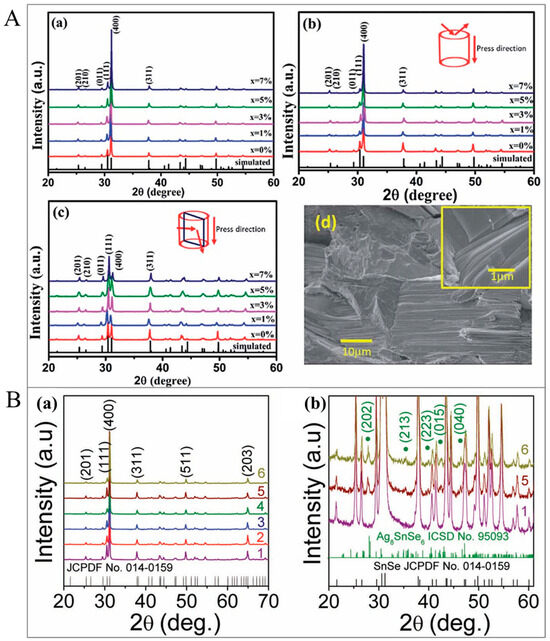

XRD remains indispensable for characterizing the crystal structure, phase purity, and microstructural features of inorganic TE materials [215,216]. XRD results/patterns provide unique crystallographic fingerprints, enabling identification of primary TE phases and secondary phase detection [217,218]. Phase purity critically influences TE performance, as secondary phases can severely degrade transport properties [219,220,221]. Advanced Rietveld refinement techniques enable quantitative phase analysis and precise structural parameter determination [222,223]. Recent developments in machine learning-assisted phase identification have accelerated the discovery of new TE phases [224,225,226]. Precise diffraction peak position analysis enables determination of lattice parameters and their evolution with composition, temperature, and doping level [227,228]. Vegard’s law analysis provides insights into solid solution formation limits and phase boundaries [229,230,231,232].

High-temperature XRD studies have revealed temperature-induced structural transitions, contributing to enhanced TE performance in materials like SnSe and GeTe [233,234,235]. Diffraction peak broadening analysis by the Scherrer equation provides crystallite size information, crucial for understanding nanostructuring effects on k reduction [236,237,238]. Warren–Averbach analysis enables the separation of size and strain broadening contributions [36,239]. Texture analysis through orientation of distribution function calculations reveals preferred crystallographic orientations impacting anisotropic transport properties [240,241]. While XRD cannot directly visualize point defects, systematic analysis of peak intensities, profile shapes, and diffuse scattering provides valuable defect information [207,242]. Advanced pair distribution function (PDF) analysis enables local structure characterization, complementing average structure information [243,244].

For instance, XRD results/patterns of (Sn1−xGex)Se for powders and SPS-pressed samples are presented in Figure 11(Aa–Ac) [216]. The authors showed that diffraction peaks can be well indexed to SnSe with the orthorhombic phase (Pnma space group, PDF #48-1224). The XRD results verified that all the (Sn1−xGex)Se samples were single-phase in the absence of any impurity. The anisotropic structures were seen in all samples sintered by SPS. The relative intensities of the two reflection peaks (111) and (400) were specifically diverse in the patterns of (b) and (c), indicating the inclination of grains growing along these planes. The SEM picture of Figure 11(Ad) indicates the freshly fractured surface morphologies of the specimens parallel to the direction of sintering for (Sn0.99 Ge0.01)Se. The pronounced layered structures were seen arranged along the parallel direction, indicating the grains were preferably reoriented into the disk plane through the sintering stage. Figure 11(Ba) shows the XRD results/patterns of the Sn0.99Na0.01Se-Ag8SnSe6 (Sn0.99Na0.01Se-STSe), SnSe-Ag8SnSe6 (SnSe-STSe), Sn0.98Ag0.01Na0.01Se, Sn0.99Na0.01Se, Sn0.99Ag0.01Se, and SnSe specimens [245]. The main peaks in the XRD results were indexed to the orthorhombic SnSe phase (JCPDF No. 014-0159) with a Pnma symmetry. Moreover, observable peaks pertinent to the orthorhombic β−Ag8SnSe6 (ICSD No. 95093, space group of Pmn21) were seen in the expanded XRD results/patterns of the SnSe−STSe and Sn0.99Na0.01Se−STSe specimens, as demonstrated in Figure 11(Bb).

Figure 11.

(A). The XRD results/patterns of (Sn1−xGex)Se: (a) powders, (b) planes perpendicular, (c) planes parallel to the direction of SPS pressing, and (d) SEM pictures of the SPS-sintered fractured surfaces of (Sn0.99Ge0.01)Se bulk specimen parallel to the direction of the press. Adapted with permission from ref. [216] Copyright 2016, The Royal Society of Chemistry. (B). (a) Powder XRD patterns of SnSe (1), Sn0.99Ag0.01Se (2), Sn0.99Na0.01Se (3), Sn0.98Ag0.01Na0.01Se (4), SnSeAg8SnSe6 (SnSe-STSe) (5), and Sn0.99Na0.01Se-Ag8SnSe6 (Sn0.99Na0.01Se-STSe) (6) specimens. (b) Expanded XRD results/patterns of SnSe, SnSe-STSe, and Sn0.99Na0.01Se-STSe specimens showing the presence of Ag8SnSe6 as a second phase. Adapted with permission from ref. [245]. Copyright 2018, Wiley.

3. Spectroscopic and Microscopic Approaches Applied to Polymer TE Materials

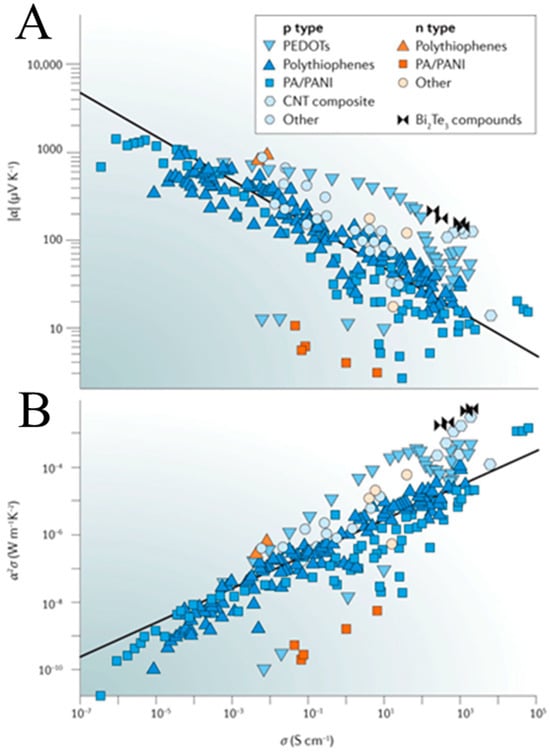

Conducting polymers—also known as synthetic metals because they exhibit properties of metals, or plastics, or semi-conductors—have been extensively studied due to their high σ, low k, low density, advanced portability, and flexibility since they were first discovered in 1977 [246,247]. Organic TE materials—including polycarbazole, polyazulene, polythiophenes, poly(phenylene vinylenes) (PPV), polyacetylene (PA), polypyrrole (PPy), polyaniline (PANI), and their composites with carbon nanostructures or inorganic materials—have been extensively investigated, and all these materials possess π-conjugated structures [248,249,250,251,252,253,254,255,256]. The S and σ parameters of organic TE materials are strongly interdependent. For instance, Russ et al. investigated the change in the S and PF for a variety of organic n-and p-type TE materials and composites with regard to their σ (Figure 12). The authors established that S reduces with the increase in σ via the relation S ∝ σ−1/4, while PF rises with the increase in σ via the empirical relationship PF = σS2 ∝ σ1/2 [257]. Amongst all those usually employed conducting polymers, PEDOT:PSS has attracted increasing interest from both academia and industry owing to its superior σ and S, low k, and solution processability, as well as stability in the air amongst all these organic TE materials. PEDOT is doped by PSS to form dispersion in water and is broadly employed in the field of solar cells and light-emitting diodes, as well as other optical devices [258]. One of the best characteristics of PEDOT:PSS is that n can be controlled without altering S too much through the doping process. Also, PEDOT:PSS is mainly commercially available—and it can be fabricated on a large scale—which makes it a good candidate material for TE applications [259]. Hence, organic-based TE materials, particularly PEDOT:PSS, are promising candidates for use in the field of energy conversion materials in the future. Various treatment approaches have been established to enhance the TE performance/properties of PEDOT:PSS solution or films, by employing various acids, solvents, reducing agents, and ionic liquids, as summarized in Table 1. The enhancement is mainly ascribed to the enhanced σ or S [2,62,65,72,260,261]. However, pre- or post-treatment processing, which involves toxic materials to attain such enhanced TE performance, with unsatisfactory/poorer mechanical flexibility, usually limits the scale-up to industrial production. Therefore, discovering facile methods for the pre- or post-treatment of PEDOT:PSS is crucial, with particular emphasis on achieving chemical/mechanical robustness. There has also been little agreement about the origin and main mechanism responsible for PEDOT:PSS TE performance improvement until now. Hence, further work/research is essential to fully comprehend the fundamental mechanisms of these pre- or post-treatment methods, in order to optimize the TE behaviors/recital of PEDOT:PSS. Herein, in the sections below, we discuss the recent TE characterization techniques that have already been applied to study the mechanism of the boosted TE performance/behaviors of PEDOT:PSS films treated by numerous pre- or post-treatment approaches (as summarized in Table 1) and the general data interpretation guidelines for PEDOT:PSS TE materials.

Figure 12.

The changes of (A) S and (B) PF with respect to the σ of organic and composite/hybrid TE materials. Adapted with permission from ref. [257]. Copyright 2016, Nature.

3.1. Electronic Structure

3.1.1. UV−Vis−NIR Spectroscopy

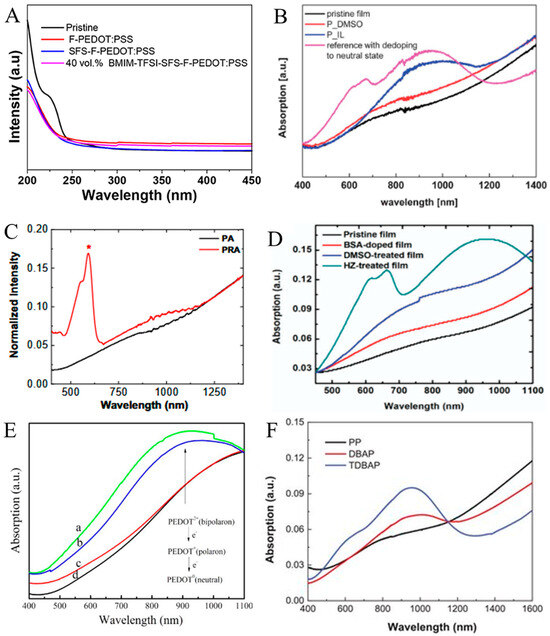

To understand the mechanism of the boosted TE behaviors of PEDOT:PSS films, the untreated and treated PEDOT:PSS films were characterized by employing UV-Vis-NIR spectroscopy. For instance, UV−Vis−NIR spectra for the pristine and sequential formamide (F), sodium formaldehyde sulfoxylate (SFS), and 1−butyl−3−methylimidazolium bis(trifluoromethanesulfonyl) amide (BMIM−TFSI)-treated PEDOT:PSS films are shown in Figure 13A. The absorption peak band detected at ca. 225 nm was mainly ascribed to the PSS. The reduced intensity of the absorption peak band at ca. 225 nm for PEDOT:PSS films indicates the removal of some PSSH chains for the treated PEDOT:PSS films. Compared with the F-PEDOT:PSS spectra—which indicated a notable intensity decrease at ca. 225 nm—the spectra of SFS−F−PEDOT:PSS as well as BMIM-TFSI-SFS-F-PEDOT:PSS almost did not change, like other treatments [262], showing that treatment with F efficiently detached PSSH, leading to a rise in σ compared to the untreated PEDOT:PSS film [263]. In another study, Luo et al. employed UV−Vis absorption spectra to examine the interaction of a mixture of DMSO and 1−ethyl−3−methylimidazolium tetrafluoroborate (EMIMBF4) with PEDOT:PSS thin films (Figure 13B). Nevertheless, the PEDOT/PSS ratio for films treated by DMSO/EMIMBF4 was not clearly defined owing to the signal convergence [264]. Figure 13C also displays the UV-Vis absorption spectrum of acid-treated PEDOT:PSS films (PA) and acid and then rhodamine 101 (R101)-treated PEDOT:PSS films (PRA). The UV−Vis absorbance spectrum indicates the transformation of electrons from R101 into PEDOT:PSS (Figure 13C). The absorption peak band close to 900 nm is assigned to the polaron, while the absorption close to 600 nm is ascribed to the neutral state in PEDOT. The polaron peak band becomes more notable for PRA compared to PA, which is not owing to the R101 absorption [83]. Figure 13D displays the UV−Vis−NIR spectrum of the untreated/pristine, benzenesulfonic acid (BSA)-doped, and DMSO-treated, as well as hydrazine (HZ)-treated PEDOT:PSS films. Typically, PEDOT chains possess three oxidation states—including neutral, polaron, and bipolaron states—that resemble the absorption peaks at 600 nm, 900 nm, and 1400 nm, respectively. As displayed in Figure 13D, there was no noticeable absorption peak band in the 450 nm-to-1100 nm range in pristine/untreated, BSA-doped, and DMSO-treated films. Nevertheless, following dedoping by solutions of HZ, stronger absorption peak bands were observed at ca. 600 nm and ca. 900 nm. Such a shift showed a transformation from the bipolaron into polaron and neutral states following treatment with HZ [82]. Figure 13E shows the UV−Vis spectrum within the range of 400 to 1100 nm. As presented in the spectra, the pristine PEDOT:PSS film showed a wide absorption within the near-infrared region, showing the major role of PEDOT2+. While referring to the deep eutectic solvents (DESs) and choline chloride (ChCl)-treated film spectrum, the existence of ChCl introduced a polaron absorption near 900 nm, indicating the PEDOT chains dedoping from bipolaron state to polaron state. Comparatively, no detectable conversion was observed in the spectra of PEDOT:PSS film with ethylene glycol (EG) post-treatment [265].

Figure 13.

(A). UV-Vis spectrum for the PEDOT:PSS (pristine), F-PEDOT:PSS, SFS−F−PEDOT:PSS, and BMIM−TFSI−SFS−F−PEDOT:PSS films. Adapted with permission from ref. [263] Copyright 2020, Frontiers. (B) UV−Vis spectrum of PEDOT:PSS films with various fabrication circumstances. Adapted with permission from ref. [264] Copyright 2013, The Royal Society of Chemistry. (C) UV−Vis absorbance spectra of PA and PAR films [83] Copyright 2023, Wiley. (D) UV-Vis-NIR spectrum for the untreated PEDOT:PSS, BSA-doped, DMSO-treated, and HZ-treated PEDOT:PSS films. Adapted with permission from ref. [82] Copyright 2018, Wiley. (E). UV−Vis spectrum of (d) pristine/untreated and after post-treated with (c) EG, (b) ChCl, and (a) DES. Adapted with permission from ref. [265] Copyright 2015, Wiley. (F) Vis−NIR spectrum of PP, DBAP, and TDBAP. Adapted with permission from ref. [77] Copyright 2025, Wiley.

More recently, Chen et al. [77] reported an enhanced PEDOT:PSS TE by treatment with tetrathiafulvalene (TTF). Figure 13F shows the Vis−NIR spectra for PEDOT:PSS (PP), - DBAP (acid and then base−DMSO) and acid–base–DMSO–tetrathiafulvalene (TDBAP) films. The absorption bands at 193 nm and 225 nm were mainly attributed to the benzene ring regions of rich PSS− or PSSH. The intensities of the two absorption peak bands dropped after the acid post-treatment as a result of the phase separation of the insulating PSSH shell from PEDOT:PSS. There was an apparent reduction in the intensity of the two absorption peak bands following post-treatment by TTF solution. This cannot be attributed to the TTF absorption. Apparently, TTF—as a weak reducing agent—may barely dedope DBAP. TTF comes to be TTF+ after the reduction, and then TTF+ and PSS− are rinsed away from PEDOT:PSS. In addition, some TTF molecules stayed in PEDOT:PSS, and they can possess a specific interaction with the conjugated PEDOT chains. The three bands at 1200, 900, and 600 nm were assigned to the neutral, polaron, and bipolaron states, respectively. The polaron band of DBAP was slightly weaker compared to the BAP film. This can be attributed to the rise in crystallinity, which can delocalize the holes and hence lower the values of the polaron density. After post-treatment with a solution of TTF with DBAP, a shoulder appears at approximately 600 nm. This was not because of the absorption of TTF, as TTF possesses no absorption within this range. The polaron absorption band of TDBAP is also remarkably stronger compared to that of DBAP. These conversions can be attributed to the slight reduction in PEDOT by using TTF. Furthermore, the peak position of the polar band was blue-shifted after the post-treatment with the TTF solution. It appeared at 1004 nm for DBAP and was shifted to 956 nm for TDBAP.

Generally, the explanation of the UV-Vis-NIR spectrum of PEDOT:PSS has been amended. For instance, Zozoulenko et al. [266] have interpreted according to the density functional theory calculations that the absorption peak at ca. 700−1000 nm may be ascribed to both polaronic and bipolaronic states, and that the peak in the NIR range may be attributed to polarons as well as bipolaron states originating from a higher oxidation state of PEDOT. Nevertheless, the summaries made here remain valid in light of these new views/explanations, since the decreasing/increasing tendency in the range of Vis−NIR helps the change from a higher to a lower oxidation level/state following post-treatment by solution.

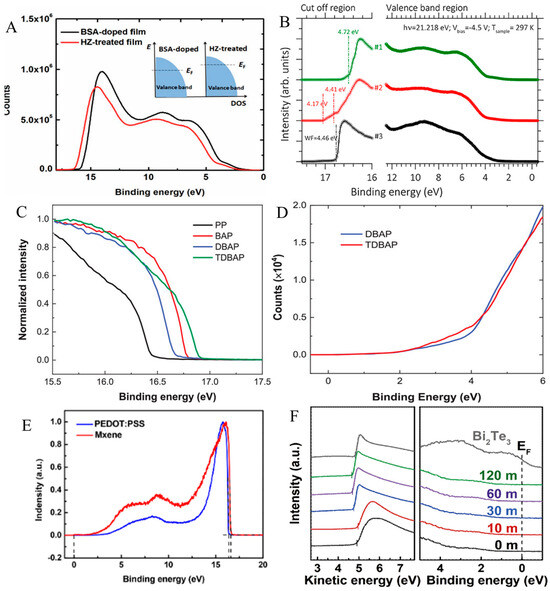

3.1.2. UPS

According to Mott’s theory, S is proportional to the slope of the electronic density of states (DOS) at the Fermi energy level [6,267]. The UPS study can be employed to scrutinize the transformation in slope. For instance, Wang et al. reported the UPS spectra of BSA and HZ-treated PEDOT:PSS films (Figure 14A). The authors showed that the HZ-treated film exhibited a somewhat lower work function (Φ) than that of the BSA-treated film. Based on band theory analysis, the Fermi level (EF) of PEDOT:PSS position was shifted deep into the interior of the valence band for the heavily doped PEDOT films. A lower value of Φ suggested the moving of EF to the top of the deep valence band, in which DOS varied abruptly; therefore, the S was boosted for HZ-treated PEDOT films [82].

Another study by Yemata and colleagues reported that, along with increasing the TE properties of the PEDOT:PSS films, the ionic liquid (IL) treatment of the films affected other behaviors of PEDOT:PSS films, which are relevant to the operation of the device, like Φ. They showed that UPS was a key method to measure the surface Φ by determining the secondary-electron cut-off (Ec). The impact of valence band and Φ on the pristine and treated PEDOT:PSS thin films was estimated by applying UPS tests (Figure 14B) [263]. In fact, based on the UPS tests, the Φ can be estimated using Φ = hv – Ec, where hv is the photon energy (hv ≤ 21.2 eV) of the UPS light source, and the Ec of the spectral width is found from the energy gap between the Fermi edge and inelastic secondary-electron emission (SEE) cut-off [268,269]. The authors discovered that treatment of the film by IL resulted in a reduction in the Φ from 4.7 eV to 4.4 eV (Figure 14B). They also indicated that Φ ranging from 4.7 eV to 5.4 eV was reported in the literature for PEDOT:PSS thin films [270,271], which is in good agreement with the results exhibited in Figure 14B. The variation in the value of Φ is suggested to be associated with the top-layer differences, which may contain an excess of the PSS shell [269,272]. The top layer with rich PSS chains can be altered using the inclusion of higher-boiling solvents [273] and other processing conditions [274].

In the more recent method, the Φ of the sequential acid (H2SO4), base (NaOH), DMSO, and tetrathiafulvalene (TTF)-treated PEDOT:PSS films was investigated by UPS (Figure 14C,D). As exhibited in Figure 14C,D, treatment with DMSO or TTF solution shifted the cut-off edge of the spectra imaged with the UPS. The ϕ was determined in terms of the binding cut-off energy (E cut-off) and the photon energy (21.2 eV) using a cut-off of ϕ = 21.2-E. The ϕ of PP was 4.78 eV, and it decreased to 4.47 eV for BAP. This can arise by the dedoping of PEDOT:PSS using NaOH, which shifted up the Fermi level. The ϕ of DBAP was also 4.57 eV for DBAP, and it reduced to 4.33 eV for TDBAP, suggesting the shifting up of the Fermi level by treatment with TTF solution [77].

Guan et al. also employed UPS to study the Φ for MXene (Ti3C2Tx) (two-dimensional (2D) n-type material), which was mixed with PEDOT:PSS. As displayed in Figure 14E, the Φ values of MXene and PEDOT:PSS were 4.61 and 4.84 eV, respectively. They showed that the PEDOT:PSS Fermi level was lower compared to that of MXene. Hence, the electrons close to the MXene Fermi level were transferred from MXene to PEDOT:PSS until the Fermi levels were aligned. As both PEDOT:PSS and MXene possess a metallic electronic configuration, the transfer of charge can occur only in a narrow range. The authors concluded that this cannot be observed through XPS, RS, or UV−Vis absorbance spectroscopy [275].

Kim et al. applied UPS spectra to investigate the effect of polar solvent vapor annealing (PSVA) treatment in the Φ values for PEDOT:PSS/Bi2Te3 NWs composite film by employing DMSO as a polar solvent (Figure 14F). The treatment by PSVA enables altering the Φ value of the PEDOT:PSS and tuning the barrier energy between Bi2Te3 NWs and PEDOT:PSS [276]. The untreated PEDOT:PSS film and the PSVA-treated PEDOT:PSS films (shorter duration) showed higher Φ compared to that of Bi2Te3 NWs (Φ = 4.83 eV), whereas all the other specimens—including PSVA-treated films (long duration)—showed lower Φ compared to that of Bi2Te3 NWs, confirming the successful tuning of the Φ of PDOT:PSS by simply changing the PSVA duration [276].

Figure 14.

(A). UPS spectra for HZ (red) and BSA (black)-treated PEDOT:PSS films. Here, the inset sketch is the DOS for BSA- and HZ-treated PEDOT:PSS. Adapted with permission from ref. [82] Copyright 2018, Wiley. (B). UPS spectra of untreated, SFS−F−PEDOT:PSS and BMIM−TFSI−SFS−F−PEDOT:PSS films obtained by employing He I photon (21.22 eV): (#1) untreated, (#2) SFS-F-PEDOT:PSS, and (#3) BMIM−TFSI−SFS−F−PEDOT:PSS. Adapted with permission from ref. [263] Copyright 2020, Frontiers. (C). The cut-off edge and (D) Fermi level of the UPS spectra for PP, BAP, DBAP, and TDBAP films. Adapted with permission from ref. [77] Copyright 2025, Wiley. (E). UPS spectra of pure PEDOT:PSS and neat MXene. Adapted with permission from ref. [275] Copyright 2020, American Chemical Society. (F). UPS observations for pure Bi2Te3 NWs or powder and composite films based on short or long PSVA duration. Adapted with permission from ref. [276] Copyright 2020, Elsevier.

3.2. Functional Groups Analysis

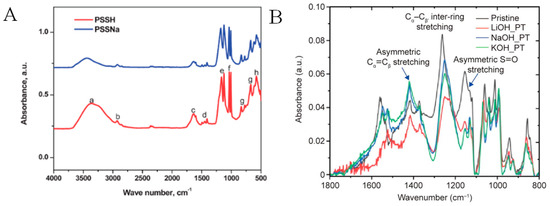

3.2.1. ATR-FTIR Spectroscopy

ATR-FTIR spectroscopy can be employed to examine the impact of the various treatments on the chemical structures of PEDOT:PSS films. For instance, Alemu et al. employed ATR-FTIR to confirm the washing away of PSS chains for methanol (MeOH)-treated PEDOT:PSS film. After PEDOT:PSS film treatment through the dipping technique, the solution of MeOH was vaporized to increase the concentration of the removed PSS, and the ATR-FTIR tests were performed by dropping the MeOH on the infrared (IR) cell. Figure 15A shows the IR spectrum for a solution of MeOH obtained after MeOH vaporization—and it exhibited a characteristic PSSH spectrum. The absorbance peaks at 1005, 1035, 1125, and 1165 cm−1 were assigned to the sulfonate (SO3−) group vibration of the PSS. Moreover, the authors compared the PSSH spectrum of a commercial product of poly(sodium 4-styrenesulfonate) (PSSNa) (solid pellet)—and they observed a similar spectrum. This observation verified that the PSS chain was cleansed from the PEDOT:PSS film by treatment with MeOH without any chemical alteration. The authors also discussed that MeOH (with the highest dielectric constant (ε)) induced a charge screening effect between the PSS (negatively charged) and PEDOT (positively charged), resulting in Coulombic interaction reduction between them. This can lead to a significant phase segregation/separation of PEDOT and rich PSS on the nanometer scale, which can be depicted by segregation of the rich PSS phase. Further, the hydrophilic site of MeOH can easily dissolve and enhance the hydrophilic phase separation of PSS and then facilitate its wash away from the PREDOT:PSS film [277].

Figure 15.

(A). ATR-FTIR spectra of PSSH and PSSNa: (h). Ring in-plane deformation vibrations (615 cm−1 region); (g) out-of-plane C=H deformation vibrations (833 cm−1, 776 cm−1, and 670 cm−1 regions); (f) symmetric stretch of SO3− (1035 and 1005 cm−1regions); (e) SO3− asymmetric stretching vibrations (1165 and 1125 cm−1 regions); (d) C=C stretching vibrations (aromatic): 1410, 1450, 1495, and 1600 cm−1 regions); (c) bending vibrations of O−H (1640 cm−1 region); (b) alkyl C-H stretch vibration (2925 cm−1 region); and (a) stretching vibration of O-H (3700–2965 cm−1 regions). Adapted with permission from ref. [277] Copyright 2012, The Royal Society of Chemistry. (B). ATR-FTIR spectra for pristine, LiOH-, NaOH-, and KOH-treated PEDOT:PSS films. Adapted with permission from ref. [278] Copyright 2019, The authors.

Dong et al. also used ATR-FTIR spectrum for the analysis of PEDOT:PSS/DMSO films after post-treatment with various bases, including lithium hydroxide (LiOH), sodium hydroxide (NaOH), and potassium hydroxide (KOH), as shown in Figure 15B. The peak (i.e., at ca. 1155 cm−1) was greatly diminished after treatment with base. This signal was ascribed to an asymmetric stretching of PSS (S=O groups) in the form of a proton, showing the conversion of SO3H into SO3−. The peak at ca. 1524 cm−1 was assigned to the symmetrical stretching of (Cα=Cβ) thiophene ring, while the reduction in the peak ca. 1557 cm−1 (i.e., shifted to 1547 cm−1) was ascribed to the asymmetric stretching (Cα=Cβ) vibration, together indicating a conversion from a more quinoid structure to a more benzoid structure. In addition, a redshift from 1263 cm−1 to 1249 cm−1 (inter-ring Cα−Cα′ stretching) appeared—indicating that the Cα−Cα′ bond varied from a quinoid to benzoid structure. All these conversions can also support the dedoping process induced by base treatment. Notably, LiOH-treated PEDOT:PSS films showed a noticeable shoulder at ca. 1220 cm−1. This peak was assigned to the S=O groups that stretch from SO3−Li+, showing a strong interaction of Li+ and PSS− [278].

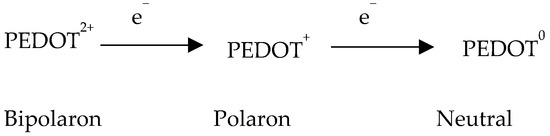

3.2.2. RS

In addition to UV−Vis−NIR spectra, RS can be employed to elucidate whether the various treatment techniques change the doping level of PEDOT:PSS films. Hence, to explain the influence of pre- or post-treatment on S, interest is directed to the structure PEDOT chains. It has already been verified that the oxidation level/state is vital for the S of PEDOT [279]. Acid/base chemistry, chemical dedoping engineering, and the electrochemical dedoping process can be employed for the transformation of the oxidation state/level [85,279]. It was also pointed out that upon the dedoping engineering, PEDOT can undergo three levels/states, as described in Scheme 1 [264]. The bipolaron level/state in PEDOT chains can be slowly dedoped into a polaron and then a neutral (doped) level. Through dedoping engineering, the σ is reduced whilst the S shows a boosting trend. These three PEDOT states exhibit absorbance at various wavelengths (PEDOT in the bipolaron level/state exhibits a broad absorbance in the near-infrared region (NIR, 700–900 nm) [280]; chains in the polaron state exhibit absorbance close to 900 nm [280]; and the neutral polymer PEDOT chains exhibit absorbance near 600 nm [280,281]).

Scheme 1.

Different redox levels of PEDOT showing the transformation of PEDOT from bipolaron level to polaron, and then neutral level upon dedoping [264].

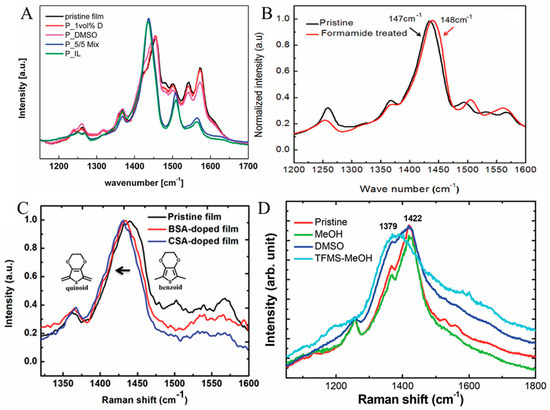

For instance, Luo et al. employed Raman spectra to elucidate the PEDOT:PSS films treated with various DMSO concentrations and a mixture of DMSO and EMIMBF4, as illustrated in Figure 16A. The absorbance of the untreated PEDOT:PSS film indicated a broad absorbance in the NIR region. There was no clear noticeable transformation in the DMSO-treated film. In contrast, EMIMBF4 treatment introduced a polaron absorption band, indicating the dedoping of PEDOT. In comparison with the partially dedoped PEDOT to the neutral state (600 to 700 nm referencing absorbance), EMIMBF4 only dedoped PEDOT from the bipolaron state to the polaron state. The authors confirmed that along with UV−Vis spectra and XPS analysis, it was confirmed that the EMIM cations dedoped the PEDOT and raised the density of polaron, as it was verified through the enhancement of S and reduction in σ. As displayed in Figure 16A, the spectra of DMSO-treated films appear like that of the untreated PEDOT:PSS film. Nevertheless, EMIMBF4-treated PEDOT:PSS films reveal a narrower band near 1436 cm−1, which was shifted to a smaller wavenumber region in contrast to the untreated PEDOT:PSS film. An additional peak was also observed at ca. 1510 cm−1. The alterations in Raman spectra verified the dedoping of PEDOT chains upon EMIMBF4 treatment [264].

Figure 16.

(A). Raman spectra of pristine and treated PEDOT:PSS films by various post-treatment techniques. Reproduced with permission from ref. [264] Copyright 2013, The Royal Society of Chemistry. (B). The Raman spectra of the untreated and formamide-treated PEDOT:PSS (Dip + Drop)2 films. Reproduced with permission from ref. [70] Copyright 2017, Wiley. (C) Normalized Raman spectra of the pristine, BSA-doped, and CSA-doped PEDOT:PSS films. Adapted with permission from ref. [82] Copyright 2018, Wiley. (D) Raman spectra of the untreated, MeOH-, DMSO-, and TFMSA−MeOH-treated PEDOT:PSS films. Adapted with permission from ref. [282] Copyright 2018, The Royal Society of Chemistry.

In another study, Kyaw et al. employed RS along with Vis−NIR spectra to explore whether formamide-treated PEDOT:PSS films change the doping states of PEDOT:PSS. As shown in Figure 16B, the Raman peak near 1447 cm−1, which emerged from the five-membered thiophene ring (symmetric Cα=Cβ groups stretching), often shifted to a smaller wavenumber region along with a narrower bandwidth as the doping state diminished from the bipolaron level to the polaron state or neutral level. An insignificant shift in wavenumber (approximately 1 cm−1) and the bandwidth variation in the symmetric Cα=Cβ group stretching indicated that the formamide post-treatment did not alter the doping state noticeably, indeed accounting for a small variation in S value [70].

Wang et al. [82] also applied Raman spectra to study the transformation in untreated camphorsulfonic acid (CSA), as well as BSA-doped PEDOT:PSS films, as illustrated in Figure 16C. The authors pointed out that strong Raman bands were observed between 1400 cm−1 and 1500 cm−1, which were ascribed to the symmetric Cα=Cβ group stretching of PEDOT thiophene rings. The Raman peak appeared at 1441 cm−1 for the pristine film. The redshift in the Raman peak was detected for both CSA- and BSA-doped films, showing a resonant structure transformation from a benzoid to a quinoid configuration, as portrayed in the inset of Figure 16C. This conformational transformation provides the facilitation of long conjugated length and offers mobility of charge carriers. Another study by Wang and colleagues [282] applied Raman spectra to scrutinize untreated, MeOH, DMSO, and trifluoromethanesulfonic acid (TFMS)−MeOH-treated PEDOT:PSS films, as presented in Figure 16D. They showed that the MeOH and DMSO treatment did not cause a noteworthy transformation in its Raman band at about 1421 cm−1, which was ascribed to the stretching vibrations of the Cα=Cβ groups. On the other hand, the Raman band at 1421 cm−1 was downshifted to 1387 cm−1 by TFMS−MeOH treatments—switching from the benzoid configuration to the quinoid configuration in PEDOT chains.

3.3. Elemental Composition Analysis

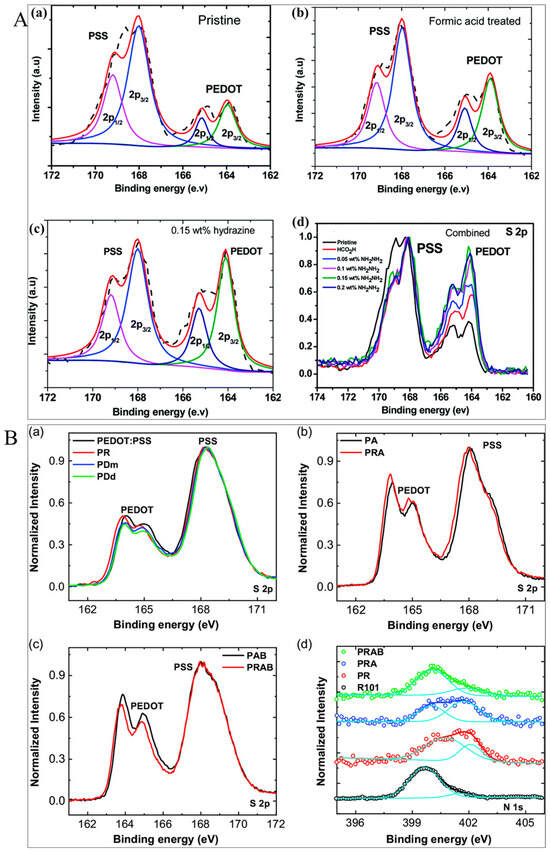

XPS

The S2p XPS can be employed to investigate the impact of pre- or post-treatment and the interaction of pre- or post-treatments with PEDOT:PSS thin films. The loss of PSS chains from the PEDOT:PSS thin film following treatment can also be verified by using the XPS spectra of the PEDOT:PSS films. The two XPS bands with B.E between 166 eV and 172 eV are due to the S2p band of the sulfur atoms from PSS, while the two doublet XPS bands with B.E between 162 eV and 166 eV originate from the S2p band of the sulfur atoms from the PEDOT chain [283,284,285,286,287]. The S2p XPS band increased for PEDOT compared to that of PSS for PEDOT:PSS films following various treatments, suggesting the removal of rich PSS chains from the PEDOT:PSS films by the treatment.

For instance, Yemata et al. employed XPS spectra for formic acid-, sequential formic acid-, and HZ-treated PEDOT:PSS films. They noticed that the S2p intensity of the PEDOT boosted as compared to that of PSS due to the loss of the rich PSS chains, as illustrated in Figure 17A (i.e., deconvoluted S2p XPS spectra). The B.E values of 165.3 and 164.1 eV, belonging to S2p1/2 and S2p3/2, in the S(2p) core level spectra for PEDOT treated by formic acid were shifted to the low B.E at 164.9 eV and 163.7 eV, belonging to S2p1/2 and S2p3/2 for PEDOT treated by 0.15 wt.% HZ, correspondingly, indicating that the reduction in doping state/level following HZ treatment resulted in a decrease in B.E. These sulfur atoms in the PEDOT were shifted to low energy after the HZ treatment, confirming the dedoping of PEDOT [69].

Figure 17.

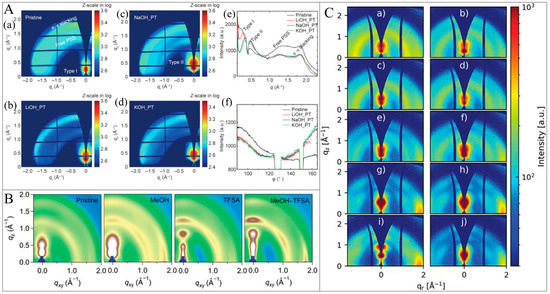

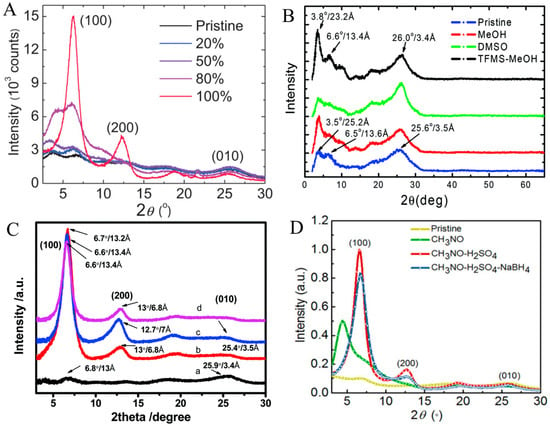

(A). XPS spectrum of (a) untreated, (b) formic acid, (c) HZ (0.15 wt.%), and (d) normalized combination of untreated, formic acid-, HZ (various concentrations)-treated PEDOT:PSS films. Adapted with permission from ref. [69] Copyright 2020, The Royal Society of Chemistry. (B). S2p XPS spectra for (a) PEDOT:PSS films treated by different zwitterions; (b) PRA and PA; (c) PRAB and PAB; and (d) N1s XPS spectra of PRAB, PRA, PR, and R101. Adapted with permission from ref. [83] Copyright 2023, Wiley.