Abstract

Movement–process collaborative compound robots are an important part of intelligent factory logistics systems, and they usually have two control systems located in the movement platform and the process platform. Interaction between the two platforms often requires the central logistics execution system to work. This paper proposes a compound robot control system architecture that integrates movement control and process action control. Its hardware can be an industrial computer with movement- and process-related sensor interfaces, and its software with multi-process management completes the internal collaboration and external data exchange. This architecture can greatly reduce the cost of compound robots and the scheduling load on the central logistics system server, simplify the development of logistics control programs, improve real-time collaboration between movement and process control, and provide strong support for the realization of massive logistics devices’ collaborative management and control.

1. Introduction

In the last few years, the market demand for multifunctional AGVs and AMRs has been very strong. Movement–process collaborative compound robots (MPCCRs) are an important direction for this kind of integrated innovative application and product development. Such robots include two key parts: a movement platform (an AGV or an AMR) and a process platform (traditional standard series/parallel industrial robots or a special process non-standard machinery arm with an end effector). The movement platform has the functions of intelligent navigation, driving, and transfer, and the process platform has the functions of intelligent positioning, identification, grasping, lifting, turning, and even hole making, riveting, tightening, grinding, and other process collaboration functions. The combination of the two parts can execute complex procedures in smart factories, which is one of the core execution units of intelligent logistics system [1,2,3,4].

However, most of the control systems of MPCCRs are separated, that is, the movement platform is controlled by an AGV or AMR controller, and the process platform is controlled by a series or parallel robot controller. There are usually few interactions between the two controllers (there may be an interaction with the action interlocking signal), and the completion of the task also requires the central logistics server to schedule and handle the effect of movement and process coordination. The work efficiency of such robots is low, the two controllers are difficult to cooperate, the control program is complicated, and the two sets of control logic are prone to confusion and errors. When the number of robots is large, the scheduling pressure of the central logistics server will be very high. At the same time, in order to meet the needs of efficient logistics transportation and production cycles in modern workshops, MPCCRs have strict operation monitoring standards, maintenance point inspection specifications, and safe operation requirements on site.

In addition, during the operation of MPCCRs, the movement data and process data are usually not fully collected, and problems such as data loss and inability to reproduce faults often occur in the context of wireless network fluctuations. However, various types of driving data logs are large and abnormal action processes are difficult to trace, requiring frequent inspection, export, and maintenance by inspection personnel. Therefore, how to ensure that an MPCCR’s movement and process data are completely recorded and how to reduce maintenance costs have become problems to be solved at present.

2. The Hardware Part of the MPCCR Control System

Aimed at current problems such as complex MPCCR action coordination, long development cycles, high scheduling pressure, the easy loss of operating data, incomplete collection, and difficult fault traceback, this paper provides an MPCCR control system. In view of the universality of the movement platform and the diversity of the process platform, the hardware uses an industrial computer as the main control, which can simultaneously perform standard movement control and multi-axis serial and parallel control, and is based on Ethernet, RS 485, RS 232, USB, Wi-Fi, 4G/5G, Bluetooth, and other interfaces, which are connected to various networked sensors and can be extended to connect various non-standard machinery arm control devices for process control; the software is based on multi-process pool management, achieving the linkage operation of four modules: data collection, data processing and control, data reporting, and data presentation. It adopts asynchronous storage of real-time and historical data, avoiding overall communication congestion and data loss caused by individual collection devices or line failures. It adopts multi-process compression and decompression to improve the performance of historical data access and reduce the occupation of historical data storage space.

Rich network interfaces such as Ethernet, RS 485, RS 232, USB, Wi-Fi, 4G/5G, and Bluetooth can be connected to various networked sensors and drive connections, can communicate with extended control devices, and can insert an SD card or an SSD solid state hard drive for local data storage; HDMI, DP, VGA, and other multimedia interfaces can be connected to independent display screens or integrated display screens to achieve integrated monitoring.

The hardware part of the MPCCR control system includes an industrial computer (IPC), a laser navigator (LN), a thermal imaging camera (TIC), an ultrasonic obstacle avoidance device (UOAD), a contact pressure sensor (CPS), a non-standard process action control device (NPACD), a battery management system (BMS), a motor drive device, and sensors related to motor status, etc. Detailed information is shown in Table 1.

Table 1.

The hardware parts of the MPCCR control system.

The motor drive device includes servo drivers and frequency converters, which are used to receive speed given control commands issued by IPC or NPACD to drive the motor to run. Sensors related to the motor status include encoders, temperature and torque sensors, etc. It can provide feedback to IPC on the actual operating speed, temperature rise status, and wheel torque of the motor. The server and frequency converter are usually provided by third-party equipment manufacturers to convert the speed values provided by IPC into the input power of the motor. The server is usually used for small MPCCRs with high-speed and high-precision positioning, while the frequency converter is not suitable for installation in a narrow space with other devices due to electromagnetic compatibility issues and is usually used for large MPCCRs with certain energy-saving needs. When high-precision position detection and motion control feedback are required, the encoder can be directly installed on the motor rotating shaft, and the movement of the rotating shaft can be used to drive the encoder to rotate; If the encoder needs to be protected in a special environment, it can be fixed next to the rotating shaft and transmitted to the encoder through mechanical structures such as couplings or gear drives.

3. The Software Part of the MPCCR Control System

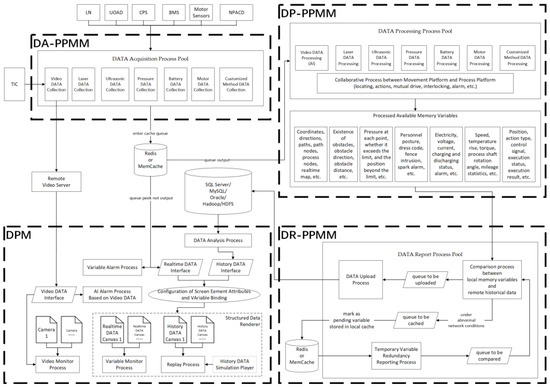

The software of the MPCCR control system includes a data acquisition process pool management module (DA-PPMM) running on an IPC, a data processing process pool management module (DP-PPMM), a data reporting process pool management module (DR-PPMM), a data presentation module (DPM), a standard movement control module (SMCM), a standard process action control module (SPACM), and a non-standard machinery arm control module (NMACM) running on an NPACD.

The data acquisition process pool management module (DA-PPMM) is used for the high-speed parallel acquisition of variable data from multiple sensors or expansion devices. DA-PPMM can cache the data queue in the state of network failure and use industrial-grade temporary storage device redundancy to maintain real-time data for a certain period. At the same time, based on the communication configuration, it can restart the process by itself until the network is restored. That is, when the three modules of DP-PPMM, DR-PPMM, and DPM fail, real-time data will not be lost, and DA-PPMM will not stop working.

The data processing process pool management module (DP-PPMM) is used for parsing positioning data, parsing video stream data, variable project conversion, variable HMI screen conversion, data compression and decompression, control command parsing and packaging, etc.

The data reporting process pool management module (DR-PPMM) is used to store and read real-time and historical data from the system and report it to the local rendering end or remote monitoring end in a specified format and time period. It supports RESTful, Web Services, and MQTT publishing.

The data presentation module (DPM) is used for real-time, multi-dimensional data display and abnormal variable alarm on terminal monitoring equipment, as well as the animation playback of the operation process based on historical data.

4. The Applications

The system architecture designed in this paper has been successfully applied in an automobile assembly factory and a ship outfitting workshop, as shown in Figure 1 and Figure 2. In the actual application scenario, each MPCCR uses an IPC as the main control, based on the multi-process pool management strategy, receives the scheduling instructions of the central logistics centralized management and control system, accesses various sensor data, and collects data from the on-board battery pack management system, carries out movement control and process control logic calculations, and then outputs motion control commands to the driver. At the same time, the IPC will store the movement and process execution data in the cache in real time and then report them asynchronously and completely to the remote server. This solution improves the industry’s mainstream dual-controller solution, improves the efficiency of movement and process collaboration, and reduces the pressure on server scheduling.

Figure 1.

The application case of the MPCCR control system.

Figure 2.

The multi-process pool management of the MPCCR control system.

5. Summary

MPCCRs are characterized by having a movement platform and a process platform at the same time. The movement platform realizes the functions of the AGV or AMR, and the process platform realizes various operation functions of multi-axis robotic arms on conventional workstations. The integration between the two platforms is not high due to multi-brand and multi-manufacturer reasons. Most of the data interaction depends on the central logistics system server for scheduling and transfer. The logic is complex, which leads to excessive pressure on the server when the number of robots is large, poor real-time coordination between the movement of the movement platform and the process platform, and a long control program development cycle. The MPCCR control system architecture proposed in this paper has a high degree of integration, which only needs a set of hardware. Using an IPC instead of traditional controllers, the central logistics system server does not need to schedule and coordinate the movement and process. The software modules on the IPC realize the movement control and process action control of the robot. This architecture simplifies the hardware configuration of the control part, reduces the overall cost of the robot, and reduces the scheduling load on the central logistics system server to meet the high-efficiency and high-availability operation requirements of the MPCCR. At the same time, its control system is easier to develop and maintain, and the data on the operation process and control process are also fully recorded and traceable.

Author Contributions

Conceptualization, L.X. and Q.L.; methodology, Z.C.; software, L.X.; validation, L.X. and Q.L.; writing—original draft preparation, writing—review and editing, Q.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data is unavailable due to privacy or ethical restrictions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wagner, T.; Herrmann, C.; Thiede, S. Industry 4.0 Impacts on Lean Production Systems. Procedia CIRP 2017, 63, 125–131. [Google Scholar] [CrossRef]

- Kehoe, B.; Patil, S.; Abbeel, P.; Goldberg, K. A survey of research on cloud robotics and automation. Autom. Sci. Eng. 2015, 12, 398–409. [Google Scholar] [CrossRef]

- Yao, F.; Keller, A.; Ahmad, M.; Ahmad, B.; Harrison, R.; Colombo, A.W. Optimizing the Scheduling of Autonomous Guided Vehicle in a Manufacturing Process. In Proceedings of the IEEE 16th International Conference on Industrial Informatics (INDIN), Porto, Portugal, 18–20 July 2018; pp. 264–269. [Google Scholar]

- Sanneman, L.; Fourie, C.; Shah, J.A. The State of Industrial Robotics: Emerging Technologies, Challenges, and Key Research Directions. Found. Trends® Robot. 2021, 8, 225–306. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).