Kiln Process Fan Vibrations Prediction Based on Machine Learning Models: Application to the Raw Mill Fan †

Abstract

:1. Introduction

2. Kiln Process Fans

- Raw mill fan;

- Preheater fan;

- Kiln fan;

- Clinker cooler fan;

- Coal mill fan;

- Cement mill fan.

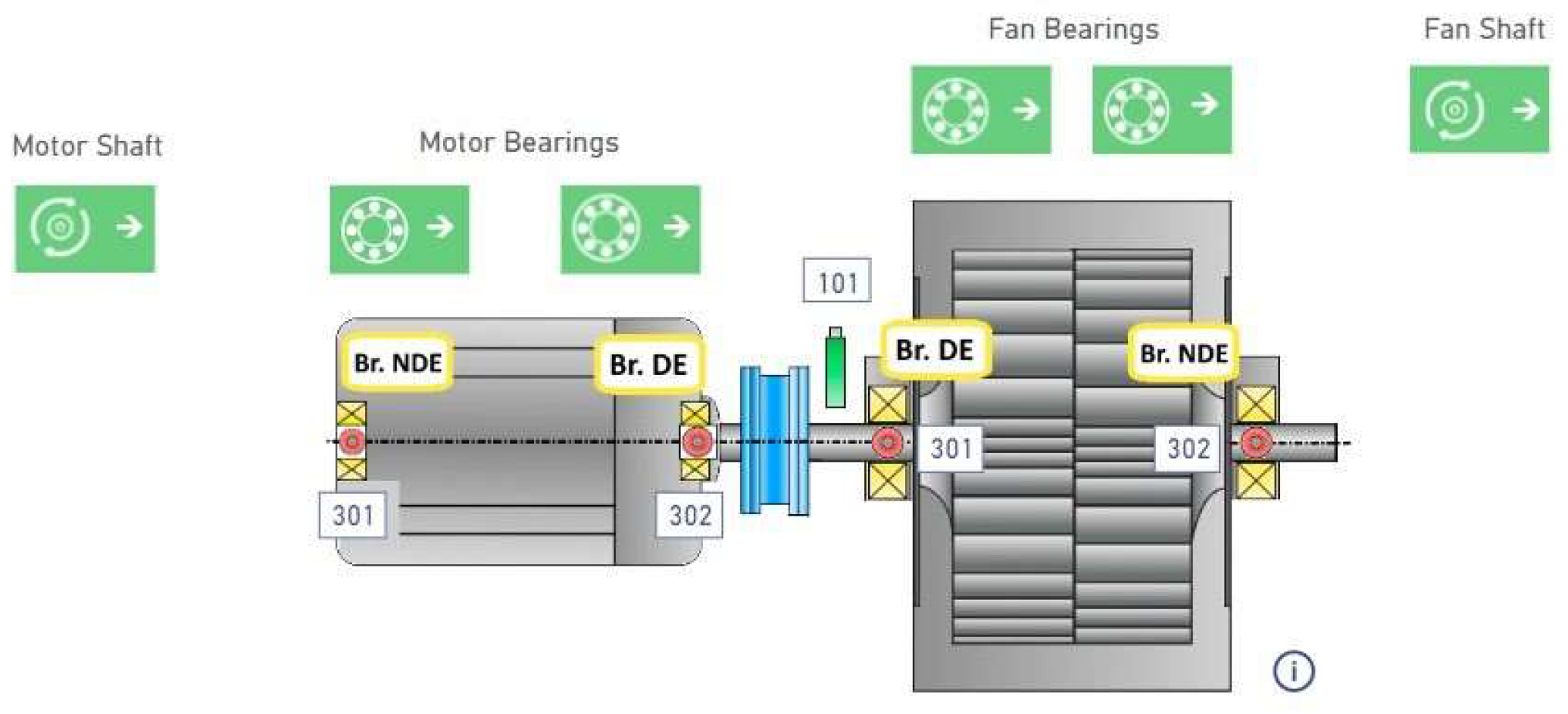

3. Process Fan Running Parameters

- Outlet gas temperature: the temperature of the gas air flow leaving the kiln;

- Fan speed: the speed of the fan that delivers the combustion air to the kiln;

- Stage DE temperature: drive-end fan bearing temperature;

- Stage NDE temperature: non-drive-end fan bearing temperature;

- Fan motor intensity: the amount of electrical power consumed by the fan motor;

- Draft fan airflow: the volume of air or air flow gas moved by the fan that creates the draft.

4. Process Fan Vibrations Acquisition

- Identify the location where the vibration data needs to be collected;

- Install the vibration sensors;

- Connect the sensors to the data acquisition system;

- Choose a database management system (DBMS) to store the vibration data;

- Configure data acquisition system to collect vibration data at the desired frequency and amplitude ranges, as well as to store the data in the database;

- Store data in the database in real-time.

5. Case Study

5.1. Data Presentation

5.2. Data Preprocessing

5.2.1. Data Cleaning

- Identify and handle missing values;

- Identify and handle outliers;

- Identify and handle inconsistent data.

5.2.2. Data Integration

5.3. Modeling and Evaluation

- Root Mean Squared Error (RMSE)

- R-squared (R2)

5.4. Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gunnarsson, A.; Andersson, K.; Adams, B.R.; Fredriksson, C. Full-scale 3dmodelling of the radiative heat transfer in rotary kilns with a present bed material. Int. J. Heat Mass Transf. 2020, 147, 118924. [Google Scholar] [CrossRef]

- Behera, S.; Choubey, A.; Kanani, C.S.; Patel, Y.S.; Misra, R.; Sillitti, A. Ensemble trees learning based improved predictive maintenance using iiot for turbofan engines. In Proceedings of the 34th ACM/SIGAPP Symposium on Applied Computing, Limassol, Cyprus, 8–12 April 2019. [Google Scholar]

- Afkhami, B.; Akbarian, B.; Beheshti, N.; Kakaee, A.; Shabani, B. Energy consumption assessment in a cement production plant. Sustain. Energy Technol. Assess. 2015, 10, 84–89. [Google Scholar] [CrossRef]

- Jamil, I.A.; Abedin, M.I.; Sarker, D.K.; Islam, J. Vibration data acquisition and visualization system using mems accelerometer. In Proceedings of the 2014 International Conference on Electrical Engineering and Information & Communication Technology, Dhaka, Bangladesh, 10–12 April 2014. [Google Scholar]

- Lu, P.; Liu, H.; Serratella, C.; Wang, X. Assessment of data-driven, machine learning techniques for machinery prognostics of offshore assets. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 2017. [Google Scholar]

- Liu, R.; Yang, B.; Zio, E.; Chen, X. Artificial intelligence for fault diagnosis of rotating machinery: A review. Mech. Syst. Signal Process. 2018, 108, 33–47. [Google Scholar] [CrossRef]

- Liu, R.; Meng, G.; Yang, B.; Sun, C.; Chen, X. Dislocated time series convolutional neural architecture: An intelligent fault diagnosis approach for electric machine. IEEE Trans. Ind. Inform. 2017, 13, 1310–1320. [Google Scholar] [CrossRef]

| Active Parameters | Unit |

|---|---|

| BC outlet gas temperature | °C |

| BC fan speed | RPM |

| Stage DE Temperature | °C |

| Stage NDE Temperature | °C |

| Fan motor intensity | AMP |

| Draft fan airflow | Nm3/h |

| Date (nbr) | Outlet Gaz Temp | Fan Speed | DE Bearing Temp | NDE Bearing Temp | Motor Intensity | Fan Air Flow | |

|---|---|---|---|---|---|---|---|

| 0 | 43,956.375000 | 73.12 | 916.34 | 33.16 | 44.91 | 1202.36 | 228,393.15 |

| 1 | 43,956.416667 | 74.69 | 916.34 | 34.11 | 48.83 | 1201.62 | 226,188.93 |

| 2 | 43,956.458333 | 74.64 | 916.34 | 35.35 | 51.85 | 1190.90 | 225,487.57 |

| 3 | 43,956.500000 | 74.85 | 916.26 | 36.36 | 53.62 | 1182.79 | 224,862.90 |

| 4 | 43,956.541667 | 75.01 | 916.13 | 37.60 | 54.57 | 1186.48 | 225,946.48 |

| mm/s | G | gE | Date (nbr) | |

|---|---|---|---|---|

| 0 | 0.513 | 0.0460 | 0.022 | 44,208.328368 |

| 1 | 0.432 | 0.0455 | 0.023 | 44,208.222396 |

| 2 | 8.596 | 1.2947 | 1.091 | 44,208.087373 |

| 3 | 28.783 | 4.9991 | 2.361 | 44,208.086366 |

| 4 | 24.697 | 5.1883 | 2.142 | 44,208.082905 |

| Date (nbr) | Outlet Gaz Temp | Fan Speed | DE Bearing Temp | NDE Bearing Temp | Motor Intensity | Fan Air Flow | Vibration mm/s | Vibration G | Vibration gE | |

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 43,956.375000 | 73.12 | 916.34 | 33.16 | 44.91 | 1202.36 | 228,393.15 | 0.513 | 0.0460 | 0.022 |

| 1 | 43,956.416667 | 74.69 | 916.34 | 34.11 | 48.83 | 1201.62 | 22,6188.93 | 0.432 | 0.0455 | 0.023 |

| 2 | 43,956.458333 | 74.64 | 916.34 | 35.35 | 51.85 | 1190.90 | 22,5487.57 | 8.596 | 1.2947 | 1.091 |

| 3 | 43,956.500000 | 74.85 | 916.26 | 36.36 | 53.62 | 1182.79 | 22,4862.90 | 28.783 | 4.9991 | 2.361 |

| 4 | 43,956.541667 | 75.01 | 916.13 | 37.60 | 54.57 | 1186.48 | 22,5946.48 | 24.697 | 5.1883 | 2.142 |

| R2 | RMSE | |

|---|---|---|

| Linear Regression | 46.77% | 1.62 |

| kNN | 64.88% | 1.36 |

| Random Forest | 72.38% | 1.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benchekroun, M.T.; Zaki, S.; Hezzem, B.; Laacha, H. Kiln Process Fan Vibrations Prediction Based on Machine Learning Models: Application to the Raw Mill Fan. Comput. Sci. Math. Forum 2023, 6, 6. https://doi.org/10.3390/cmsf2023006006

Benchekroun MT, Zaki S, Hezzem B, Laacha H. Kiln Process Fan Vibrations Prediction Based on Machine Learning Models: Application to the Raw Mill Fan. Computer Sciences & Mathematics Forum. 2023; 6(1):6. https://doi.org/10.3390/cmsf2023006006

Chicago/Turabian StyleBenchekroun, Mohammed Toum, Smail Zaki, Brahim Hezzem, and Hicham Laacha. 2023. "Kiln Process Fan Vibrations Prediction Based on Machine Learning Models: Application to the Raw Mill Fan" Computer Sciences & Mathematics Forum 6, no. 1: 6. https://doi.org/10.3390/cmsf2023006006

APA StyleBenchekroun, M. T., Zaki, S., Hezzem, B., & Laacha, H. (2023). Kiln Process Fan Vibrations Prediction Based on Machine Learning Models: Application to the Raw Mill Fan. Computer Sciences & Mathematics Forum, 6(1), 6. https://doi.org/10.3390/cmsf2023006006