Increased Velocity (INVELOX) Wind Delivery System: A Review of Performance Enhancement Advances

Abstract

1. Introduction

2. Theoretical Framework

2.1. Power Model

2.2. Turbulence Models

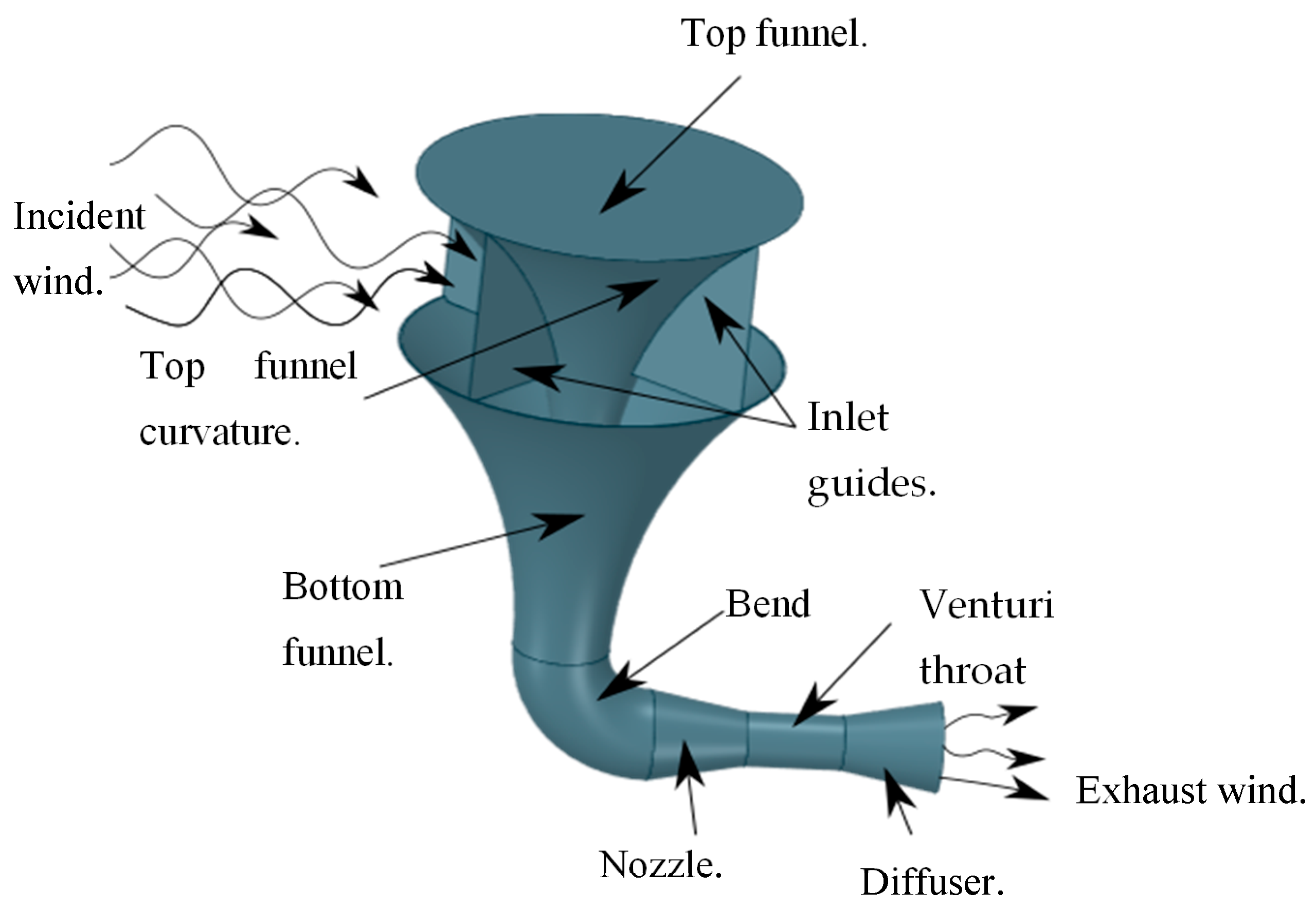

3. INVELOX Wind Delivery System

3.1. Geometric Properties of INVELOX

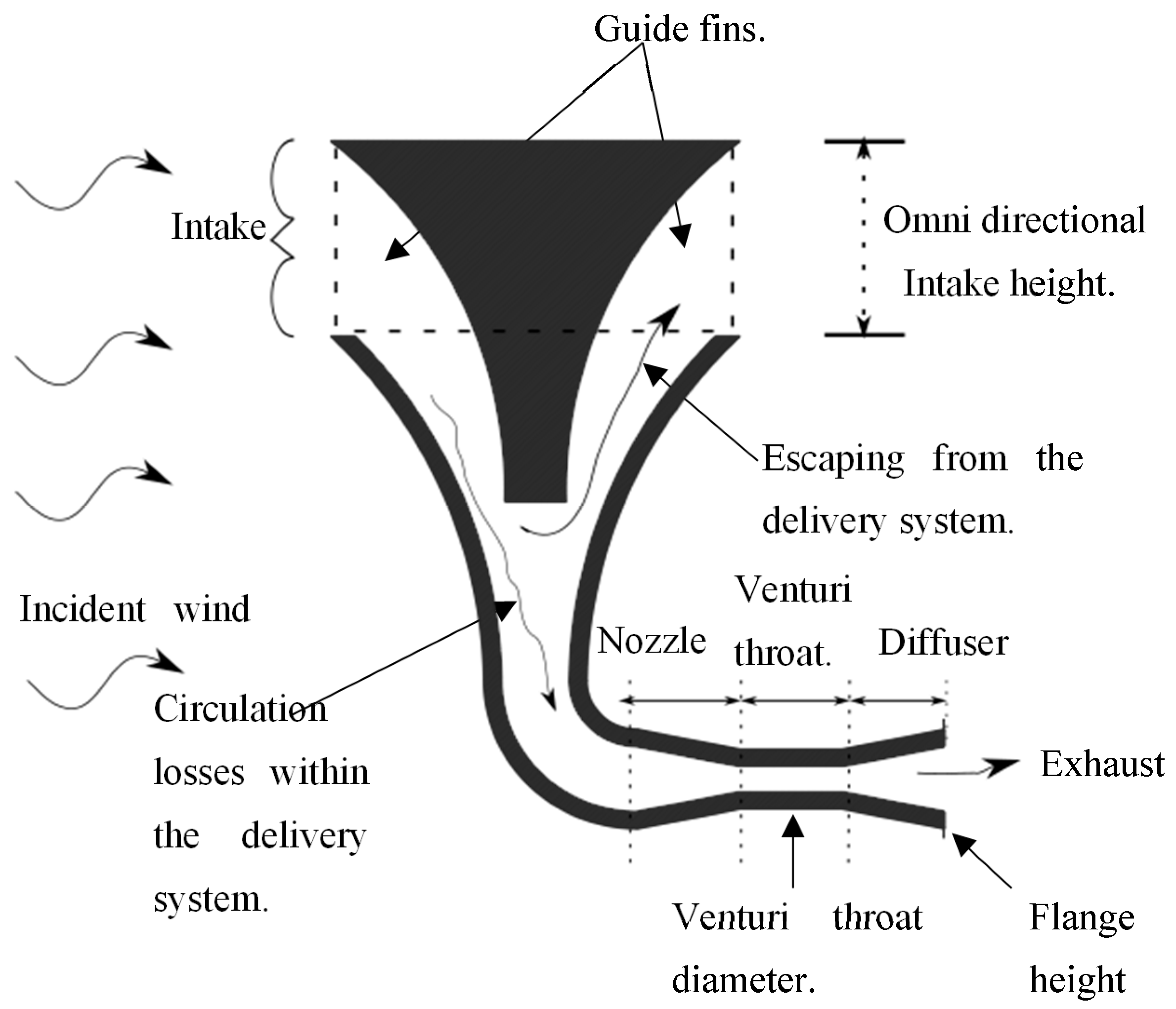

3.1.1. Wind Intake

3.1.2. Guide Fins

3.1.3. INVELOX Nozzle

3.1.4. Throat Diameter and Length

3.1.5. The Diffuser Sections

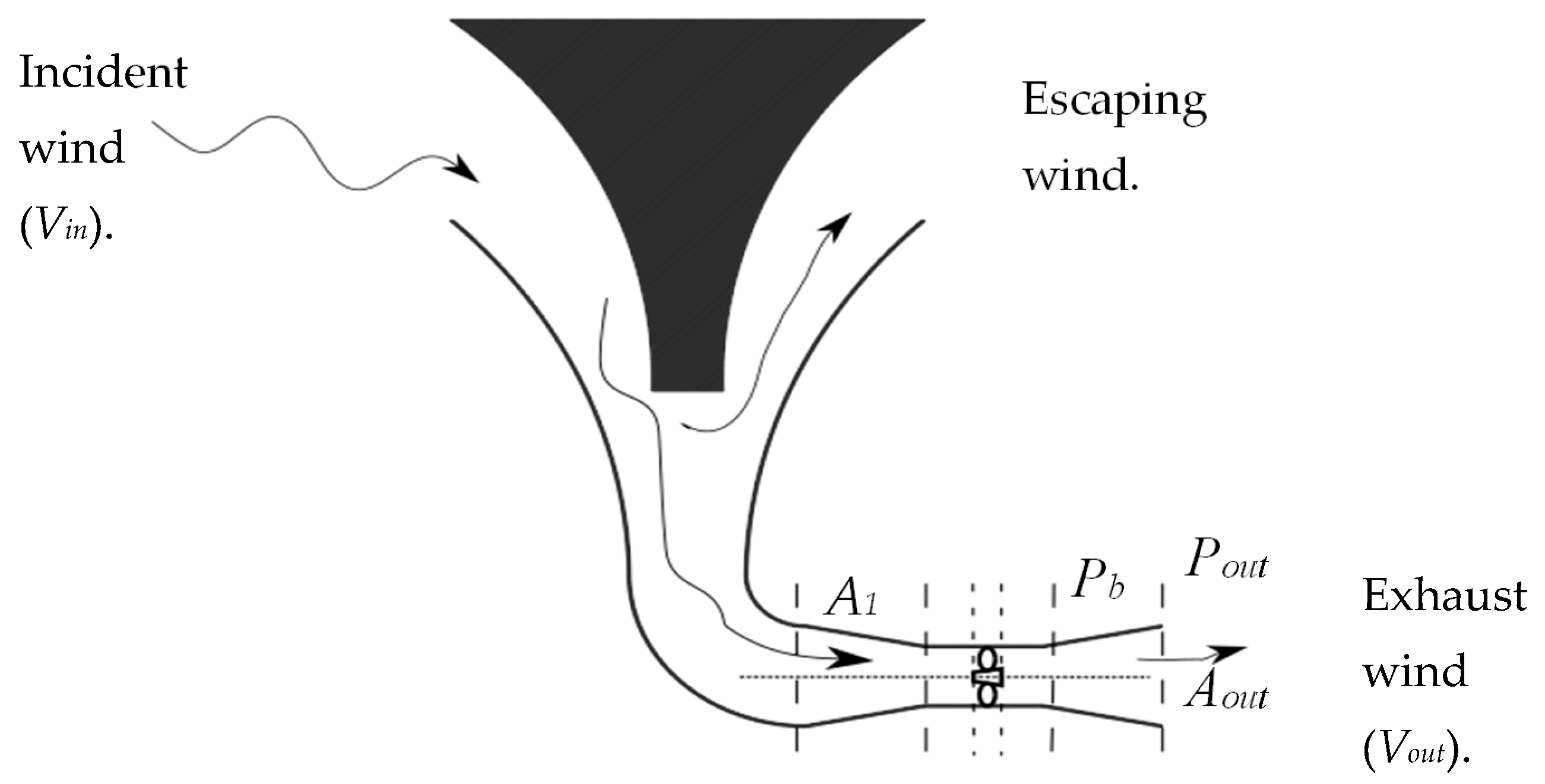

4. Operational Challenges of INVELOX

4.1. Wind Direction

4.2. Escaping Air

5. INVELOX Optimization

5.1. Nozzle–Diffuser Optimization

5.2. Entire INVELOX Optimization

6. Conclusions and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shonhiwa, C.; Makaka, G. Concentrator Augmented Wind Turbines: A Review. Renew. Sustain. Energy Rev. 2016, 59, 1415–1418. [Google Scholar] [CrossRef]

- Konstantinidis, E.I.; Botsaris, P.N. Wind Turbines: Current Status, Obstacles, Trends and Technologies. IOP Conf. Ser. Mater. Sci. Eng. 2016, 161, 012079. [Google Scholar] [CrossRef]

- Anbarsooz, M.; Hesam, M.S.; Moetakef-Imani, B. Numerical Study on the Geometrical Parameters Affecting the Aerodynamic Performance of INVELOX. IET Renew. Power Gener. 2017, 11, 791–798. [Google Scholar] [CrossRef]

- Ahmed, M. Elsayed Design Optimization of Diffuser Augmented Wind Turbine. CFD Lett. 2021, 13, 45–59. [Google Scholar] [CrossRef]

- Farokhzade, A.; Maghrebi, M.J. Inlet Parameters Effects of INVELOX on the Aerodynamic Performance Using Numerical Simulation. J. Appl. Fluid Mech. 2021, 14, 1511–1520. [Google Scholar] [CrossRef]

- Watanabe, K.; Ohya, Y. A Simple Theory and Performance Prediction for a Shrouded Wind Turbine with a Brimmed Diffuser. Energies 2021, 14, 3661. [Google Scholar] [CrossRef]

- Heyru, B.; Bogale, W. Flow Field Analysis and Testing of Curved Shroud Wind Turbine with Different Flange Angle. Cogent Eng. 2022, 9, 2095951. [Google Scholar] [CrossRef]

- Allaei, D.; Andreopoulos, Y. INVELOX: Description of a New Concept in Wind Power and Its Performance Evaluation. Energy 2014, 69, 336–344. [Google Scholar] [CrossRef]

- Allaei, D.; Tarnowski, D.; Andreopoulos, Y. INVELOX with Multiple Wind Turbine Generator Systems. Energy 2015, 93, 1030–1040. [Google Scholar] [CrossRef]

- Bussel, D.G.J.W.V. The Science of Making More Torque from Wind: Diffuser Experiments and Theory Revisited. J. Phys. Conf. Ser. 2007, 75, 012010. [Google Scholar] [CrossRef]

- Ding, L.; Guo, T. Numerical Study on the Power Efficiency and Flow Characteristics of a New Type of Wind Energy Collection Device. Appl. Sci. 2020, 10, 7438. [Google Scholar] [CrossRef]

- Ding, L. Study of INVELOX Wind Turbine Considering Atmospheric Boundary Layer: Based on Numerical Simulation. J. Phys. Conf. Ser. 2020, 1600, 012063. [Google Scholar] [CrossRef]

- Ghorani, M.M.; Karimi, B.; Mirghavami, S.M.; Saboohi, Z. A Numerical Study on the Feasibility of Electricity Production Using an Optimized Wind Delivery System (Invelox) Integrated with a Horizontal Axis Wind Turbine (HAWT). Energy 2023, 268, 126643. [Google Scholar] [CrossRef]

- Wibowo, T.T.; Daulay, F.H.; Suryopratomo, K.; Budiarto, R. Numerical Study of the Effect of Geometry Variation on the Performance of Innovative Design Wind Speed Enhancer. E3S Web Conf. 2018, 42, 01013. [Google Scholar] [CrossRef]

- Akour, S.N.; Bataineh, H.O. Design Considerations of Wind Funnel Concentrator for Low Wind Speed Regions. AIMS Energy 2019, 7, 728–742. [Google Scholar] [CrossRef]

- Billah, S.M.B.; Qasim, S. Development of MATLAB Simulink Model of INVELOX to Analyze the Impact of Inlet Height on Speed Ratio. In Proceedings of the 2019 International Conference on Energy and Power Engineering (ICEPE), Dhaka, Bangladesh, 14–16 March 2019; IEEE: New York, NY, USA; pp. 1–5. [Google Scholar]

- Ravichandra; Shasindra. Subira Effects of Geometric Design Parameters on Discharge Rate of a Funnel Based Wind Tunnel. Available online: https://www.bing.com/search? (accessed on 14 November 2023).

- Sotoudeh, F.; Kamali, R.; Mousavi, S.M. Field Tests and Numerical Modeling of INVELOX Wind Turbine Application in Low Wind Speed Region. Energy 2019, 181, 745–759. [Google Scholar] [CrossRef]

- Shayestehnezhad, S.; Kargar, S.; Nichkoohi, A.L. A Numerical Study of INVELOX Wind Turbine Considering the Inlet Shape Design. In Proceedings of the 7th Iran Wind Energy Conference (IWEC2021), Shahrood, Iran, 17–18 May 2021; IEEE: New York, NY, USA; pp. 1–5. [Google Scholar]

- Anbarsooz, M.; Amiri, M.; Rashidi, I. A Novel Curtain Design to Enhance the Aerodynamic Performance of INVELOX: A Steady-RANS Numerical Simulation. Energy 2019, 168, 207–221. [Google Scholar] [CrossRef]

- Golozar, A.; Shirazi, F.A.; Siahpour, S.; Khakiani, F.N.; Gaemi Osguei, K. A Novel Aerodynamic Controllable Roof for Improving Performance of INVELOX Wind Delivery System. Wind Eng. 2021, 45, 477–490. [Google Scholar] [CrossRef]

- Siahpour, S.; Khakiani, F.N.; Fazlollahi, V.; Golozar, A.; Shirazi, F.A. Morphing Omni-Directional Panel Mechanism: A Novel Active Roof Design for Improving the Performance of the Wind Delivery System. Energy 2021, 217, 119400. [Google Scholar] [CrossRef]

- Hosseini, S.R.; Ganji, D.D. A Novel Design of Nozzle-Diffuser to Enhance Performance of INVELOX Wind Turbine. Energy 2020, 198, 117082. [Google Scholar] [CrossRef]

- Abe, K.; Ohya, Y. An Investigation of Flow Fields around Flanged Diffusers Using CFD. J. Wind Eng. Ind. Aerodyn. 2004, 92, 315–330. [Google Scholar] [CrossRef]

- Ohya, Y.; Karasudani, T.; Sakurai, A.; Abe, K.; Inoue, M. Development of a Shrouded Wind Turbine with a Flanged Diffuser. J. Wind Eng. Ind. Aerodyn. 2008, 96, 524–539. [Google Scholar] [CrossRef]

- Ramayee, L.; Supradeepan, K.; Ravinder Reddy, P.; Karthik, V. Design of Shorter Duct for Wind Turbines to Enhance Power Generation: A Numerical Study. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 160. [Google Scholar] [CrossRef]

- Bontempo, R.; Di Marzo, E.M.; Manna, M. Diffuser Augmented Wind Turbines: A Critical Analysis of the Design Practice Based on the Ducting of an Existing Open Rotor. J. Wind Eng. Ind. Aerodyn. 2023, 238, 105428. [Google Scholar] [CrossRef]

- Mostafa Radwan Behery. Optimization of Flanged Diffuser for Small-Scale Wind Power Applications. CFD Lett. 2024, 16, 54–70. [Google Scholar] [CrossRef]

- Sorribes-Palmer, F.; Figueroa-Gonzalez, A.; Pindado, S. Wind Turbine Diffuser Aerodynamic Study with OpenFOAM. In OpenFOAM®: Selected Papers of the 11th Workshop; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Maftouni, N.; Barghi, Y. An Innovative Design of INVELOX Wind Turbine: A Numerical Study on the Effects of Implementing Long Flange and Venturi Holes. Trans. Can. Soc. Mech. Eng. 2023, 47, 162–174. [Google Scholar] [CrossRef]

- Ramayee, L.; Supradeepan, K. Performance Evaluation of Cowl-Augmented Wind Turbine. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 42. [Google Scholar] [CrossRef]

- Ramayee, L.; Supradeepan, K. Numerical Study on Flow Characteristics of Shroud with and without Flap for Wind Turbine Applications. Wind Eng. 2023, 47, 546–563. [Google Scholar] [CrossRef]

- Matsushima, T.; Takagi, S.; Muroyama, S. Characteristics of a Highly Efficient Propeller Type Small Wind Turbine with a Diffuser. Renew. Energy 2006, 31, 1343–1354. [Google Scholar] [CrossRef]

- Chaker, R.; Kardous, M.; Chouchen, M.; Aloui, F.; Ben Nasrallah, S. Vortices’ Characteristics to Explain the Flange Height Effects on the Aerodynamic Performances of a Diffuser Augmented Wind Turbine. J. Sol. Energy Eng. 2016, 138, 061013. [Google Scholar] [CrossRef]

- Kassab, S.Z.; Abdulaziz, A.O.; Abdelrazek, A.M. Influence of the Flange Height on the Performance of a Flanged Diffuser Augmented Wind Turbine Structure. Int. J. Mech. Eng. 2022, 7, 1928–1938. [Google Scholar]

- Kardous, M.; Chaker, R.; Aloui, F.; Nasrallah, S.B. On the Dependence of an Empty Flanged Diffuser Performance on Flange Height: Numerical Simulations and PIV Visualizations. Renew. Energy 2013, 56, 123–128. [Google Scholar] [CrossRef]

- El-Zahaby, A.M.; Kabeel, A.E.; Elsayed, S.S.; Obiaa, M.F. CFD Analysis of Flow Fields for Shrouded Wind Turbine’s Diffuser Model with Different Flange Angles. Alex. Eng. J. 2017, 56, 171–179. [Google Scholar] [CrossRef]

- Taghinezhad, J.; Abdoli, S.; Silva, V.; Sheidaei, S.; Alimardani, R.; Mahmoodi, E. Computational Fluid Dynamic and Response Surface Methodology Coupling: A New Method for Optimization of the Duct to Be Used in Ducted Wind Turbines. Heliyon 2023, 9, e17057. [Google Scholar] [CrossRef] [PubMed]

- Shambira, N.; Makaka, G.; Mukumba, P. Velocity Augmentation Model for an Empty Concentrator-Diffuser-Augmented Wind Turbine and Optimisation of Geometrical Parameters Using Surface Response Methodology. Sustainability 2024, 16, 1707. [Google Scholar] [CrossRef]

- Alkhalidi, A.; Ahmad, B.D.; Khawaja, M.K. Novel INVELOX Design with Unique Intake to Improve Wind Capturing Mechanism. Results Eng. 2022, 16, 100780. [Google Scholar] [CrossRef]

- Ayaz, A.; Israr, A.; Khan, M.Z. Numerical and Experimental Investigation of Geometric Parameters Influence on Power Generation of INVELOX Wind Turbine. Energy Sustain. Dev. 2023, 77, 101329. [Google Scholar] [CrossRef]

- Kumar, K.R.; Selvaraj, M. Investigations on Integrated Funnel, Fan and Diffuser Augmented Unique Wind Turbine to Enhance the Wind Speed. J. Appl. Fluid Mech. 2023, 16, 575–589. [Google Scholar] [CrossRef]

- Kumar, K.R.; Selvaraj, M. Novel Deep Learning Model for Predicting Wind Velocity and Power Estimation in Advanced INVELOX Wind Turbines. J. Appl. Fluid Mech. 2023, 16, 1256–1268. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Salehi, F. Analyzing Overlap Ratio Effect on Performance of a Modified Savonius Wind Turbine. Phys. Fluids 2023, 35, 125131. [Google Scholar] [CrossRef]

- Narendrabhai, P.S.; Desmukh, T.S. Numerical Simulation of Flow through Invelox Wind Turbine System. Int. J. Renew. Energy Res. 2018, 8, 291–301. [Google Scholar] [CrossRef]

- Shonhiwa, C.; Makaka, G.; Mukumba, P.; Shambira, N. Investigation of Wind Power Potential in Mthatha, Eastern Cape Province, South Africa. Appl. Sci. 2023, 13, 12237. [Google Scholar] [CrossRef]

- Chitura, A.G.; Mukumba, P.; Lethole, N. Enhancing the Performance of Savonius Wind Turbines: A Review of Advances Using Multiple Parameters. Energies 2024, 17, 3708. [Google Scholar] [CrossRef]

| Reference | Turbulence Model Used | Domain Size | Grid Choice for Simulation | Improvement Achieved |

|---|---|---|---|---|

| [30] | k-ԑ turbulence model | 50 Dv × 40 Dv × 40 Dv | 1.5 million cells y+ range = 33–56.8 | Maximum throat velocity of 12.6 m/s. |

| [5] | k-ԑ turbulence model | 50 Dv × 40 Dv × 40 Dv | 1.5 million cells | Velocity improved by 3.6%. |

| [34] | k-ԑ Realizable turbulence model | 50 Dv × 40 Dv × 40 Dv | 3.79 million cells, GCIndex of 0.4% | Speed ratio improvement of 42%. |

| [40] | k-ԑ Realizable turbulence model | 122 m × 73 m × 68 m | 6 million cells. | Speed ratio improvement 2.77 times. |

| [3] | SST k-ω turbulence model | 100 m × 75 m × 75 m | 1.27 million cells | Speed ratio improvement 2.77 times. |

| [16] | SST k-ω turbulence model | 300 m × 160 m × 200 m | 3 million cells, y+ = 1 on all surfaces of INVELOX. | Power output improvement of 47%. |

| [37] | k-ԑ RNG turbulence model | 60 Dv × 60 Dv × 40 Dv | 1.7 million cells 5 mm first layer 1.2 growth ration, y+ = 35. | Throat velocity increased by 6% |

| [44] | SST k-ω turbulence model | 120 m × 72 m × 72 m | 1.83 million cells. y+ = 1–5 | Speed ratio improvement 1.67 times. Throat velocity increased to 5.77 m/s |

| [11] | k-ԑ turbulence model | 120 m × 72 m × 72 m | 10 layers on venturi section. 3 mm first layer, 1.2 growth rate, 2.2 million cells, y+ = 35 | Speed ratio improvement by 48%. |

| [12] | k-ԑ Standard turbulence model | 91 m × 60 m × 45 m | Mesh quality Skewness = 0.24 Orthogonality = 0.85 | 21.5% velocity increase by varying funnel gap. 24.2% velocity increase by varying throat diameter. |

| [15] | k-ԑ turbulence model | 120 m × 77 m × 67 m | 252,908 cells | Speed ratio improvement 2.3 times. |

| [17] | k-ԑ turbulence model | 120 m × 72 m × 72 m | 2 million cells y+ = 37–153 | Efficiency improvement by 20%. |

| [45] | k-ԑ Standard turbulence model | 60 m × 91 m × 45 m | 2.2 million cells. | Speed ratio improvement 1.72 times. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chitura, A.G.; Mukumba, P.; Shambira, N. Increased Velocity (INVELOX) Wind Delivery System: A Review of Performance Enhancement Advances. Wind 2025, 5, 19. https://doi.org/10.3390/wind5030019

Chitura AG, Mukumba P, Shambira N. Increased Velocity (INVELOX) Wind Delivery System: A Review of Performance Enhancement Advances. Wind. 2025; 5(3):19. https://doi.org/10.3390/wind5030019

Chicago/Turabian StyleChitura, Anesu Godfrey, Patrick Mukumba, and Ngwarai Shambira. 2025. "Increased Velocity (INVELOX) Wind Delivery System: A Review of Performance Enhancement Advances" Wind 5, no. 3: 19. https://doi.org/10.3390/wind5030019

APA StyleChitura, A. G., Mukumba, P., & Shambira, N. (2025). Increased Velocity (INVELOX) Wind Delivery System: A Review of Performance Enhancement Advances. Wind, 5(3), 19. https://doi.org/10.3390/wind5030019