Chromatic Dispersion of Chalcogenide Glass-Based Photonic Crystal Fiber with Ultra-High Numerical Aperture †

Abstract

1. Introduction

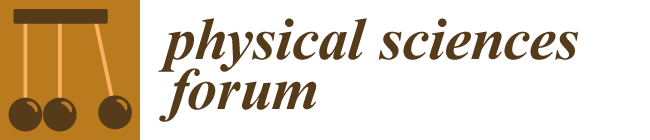

2. Proposed Design and Fabrication Techniques

3. Results and Discussion

3.1. Chromatic Dispersion

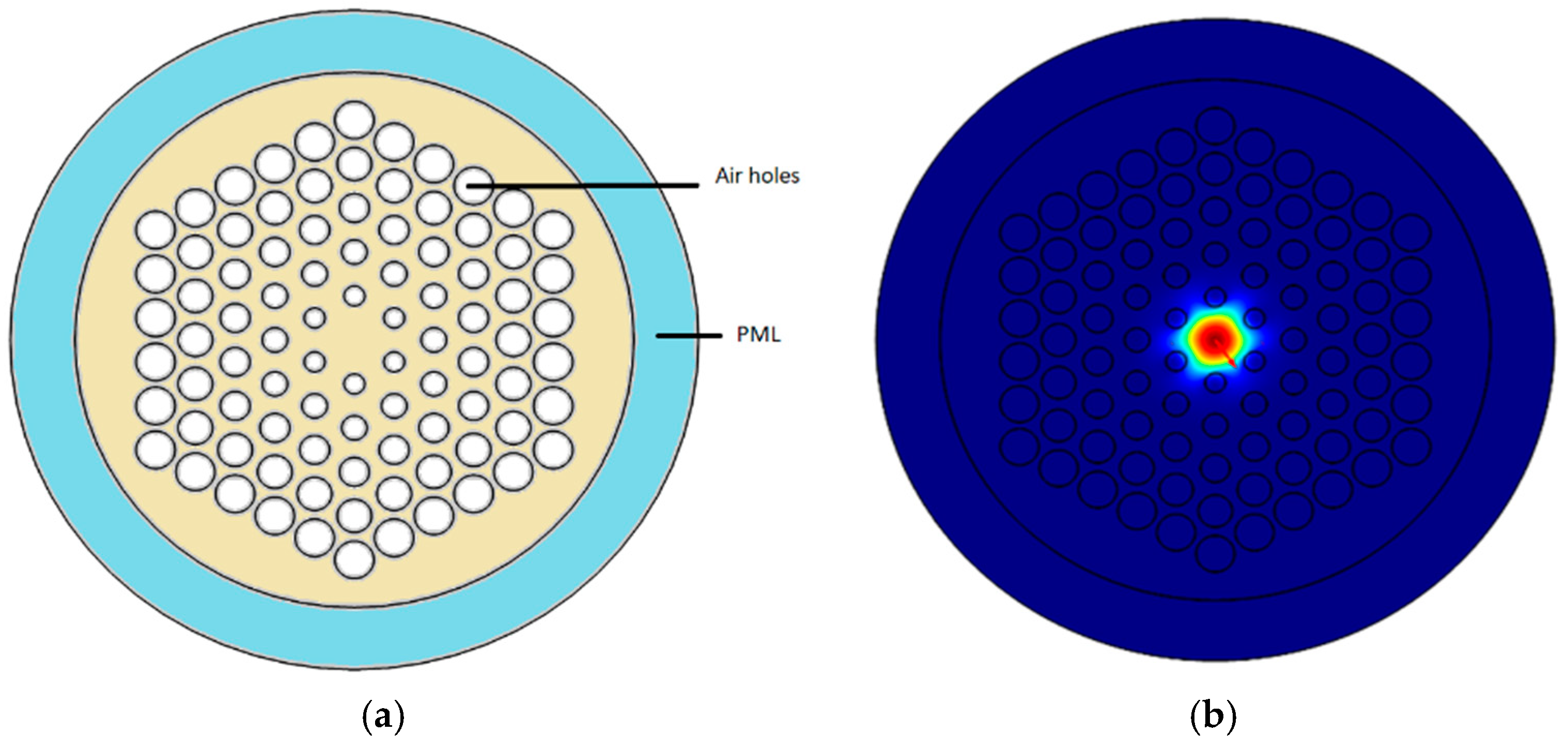

3.2. Numerical Aperture

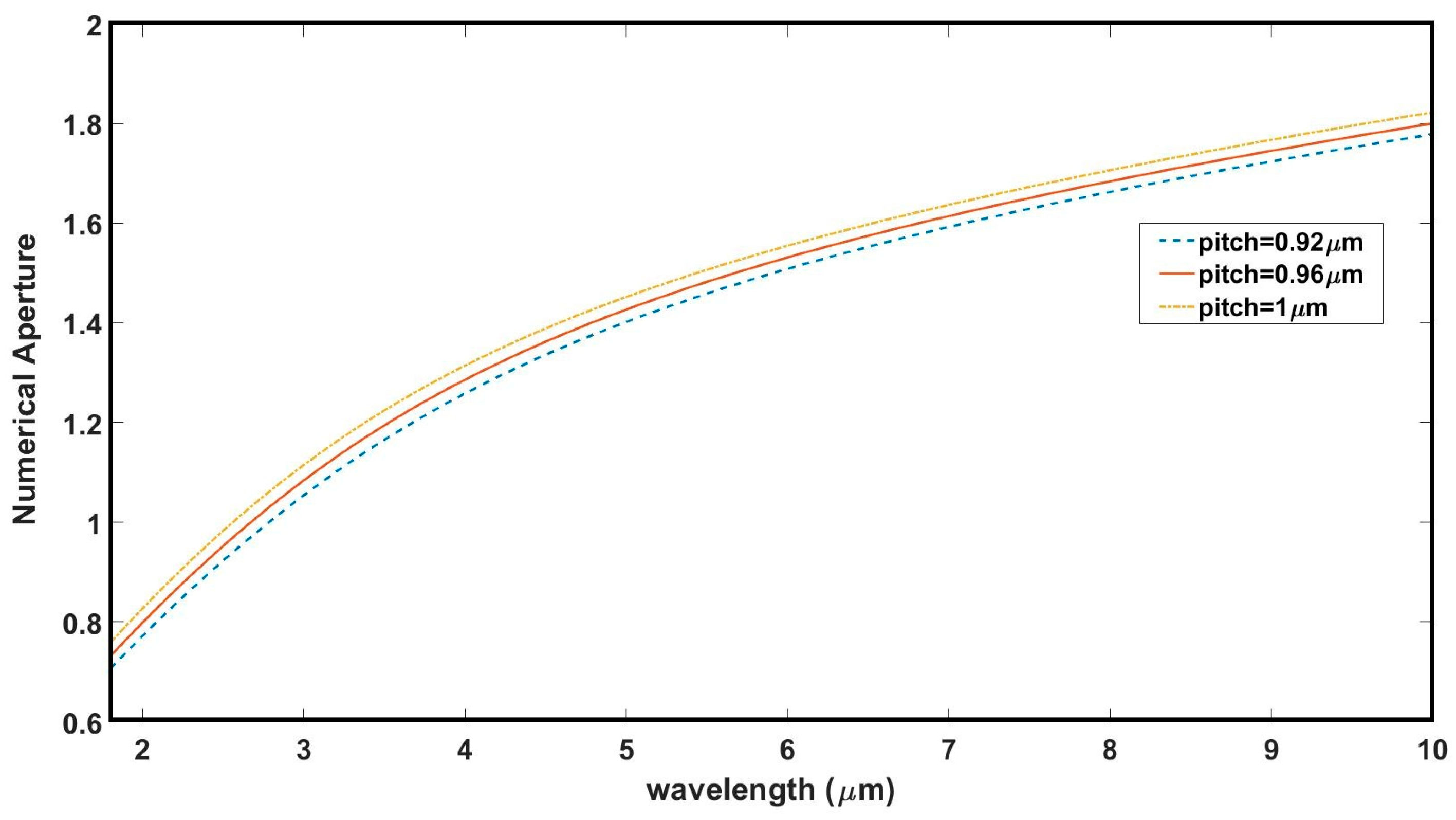

3.3. Confinement Loss

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Russell, P. Photonic crystal fibers. Science 2003, 299, 358–362. [Google Scholar] [CrossRef]

- Knight, J.C.; Birks, T.A.; Russell, P.S.J.; De Sandro, J.P. Properties of photonic crystal fiber and the effective index model. JOSA A 1998, 15, 748–775. [Google Scholar] [CrossRef]

- Varshney, S.K.; Singh, M.P.; Sinha, R.K. Propagation Characteristics of Photonic Crystal Fibers. J. Opt. Commun. 2003, 24, 192–198. [Google Scholar] [CrossRef]

- Dabas, B.; Sinha, R.K. Dispersion characteristic of hexagonal and square lattice chalcogenide As2Se3 glass photonic crystal fiber. Opt. Commun. 2010, 283, 1331–1337. [Google Scholar] [CrossRef]

- Boyland, A.J.; Webb, A.S.; Yoo, S.; Mountfort, F.H.; Kalita, M.P.; Standish, R.J.; Sahu, J.K.; Richardson, D.J.; Payne, D.N. Optical Fiber Fabrication Using Novel Gas-Phase Deposition Technique. J. Light. Technol. 2011, 29, 912–915. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, Z.F.; Tam, H.Y.; Tao, X. Multifunctional Smart Optical Fibers: Materials, Fabrication, and Sensing Applications. Photonics 2019, 6, 48. [Google Scholar] [CrossRef]

- Chauhan, J.; Kalra, Y.; Sinha, R.K. Chalcogenide glass-based Low Loss Graded Index Photonic Crystal Fiber for non-linear applications in the Mid-IR regime. Results Opt. 2023, 12, 100431. [Google Scholar] [CrossRef]

- Liu, S.; Li, S.-G.; Zhang, X.-X. Numerical analysis of the As2Se3 chalcogenide glass multi-ring photonic crystal fiber. Infrared Phys. Technol. 2012, 55, 427–430. [Google Scholar]

- Nguyen, T.T.; Hoang, T.D.; Le, T.B.T. Dispersion and nonlinearity properties of small solid-core photonic fibers with As2Se3 substrate. Hue Univ. J. Sci. Nat. Sci. 2022, 130, 55–64. [Google Scholar] [CrossRef]

- Sharma, D.K.; Tripathi, S.M.; Sharma, A. Modal analysis of high-index core tellurite glass microstructured optical fibers in infrared regime. J. Non-Cryst. Solids 2019, 511, 147–160. [Google Scholar] [CrossRef]

- Xu, H.; Wang, X.; Kong, Q.; Peng, D. High numerical aperture photonic crystal fiber with silicon nanocrystals core for optical coherence tomography. Optik 2020, 219, 165000. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chauhan, J.; Kalra, Y.; Sinha, R.K. Chromatic Dispersion of Chalcogenide Glass-Based Photonic Crystal Fiber with Ultra-High Numerical Aperture. Phys. Sci. Forum 2024, 10, 8. https://doi.org/10.3390/psf2024010008

Chauhan J, Kalra Y, Sinha RK. Chromatic Dispersion of Chalcogenide Glass-Based Photonic Crystal Fiber with Ultra-High Numerical Aperture. Physical Sciences Forum. 2024; 10(1):8. https://doi.org/10.3390/psf2024010008

Chicago/Turabian StyleChauhan, Jyoti, Yogita Kalra, and Ravindra Kumar Sinha. 2024. "Chromatic Dispersion of Chalcogenide Glass-Based Photonic Crystal Fiber with Ultra-High Numerical Aperture" Physical Sciences Forum 10, no. 1: 8. https://doi.org/10.3390/psf2024010008

APA StyleChauhan, J., Kalra, Y., & Sinha, R. K. (2024). Chromatic Dispersion of Chalcogenide Glass-Based Photonic Crystal Fiber with Ultra-High Numerical Aperture. Physical Sciences Forum, 10(1), 8. https://doi.org/10.3390/psf2024010008