Abstract

Mauritia flexuosa L.f. is a palm from the Amazon. Pulp and oil are extracted from its fruits, which have a high content of phenolic compounds and unsaturated fatty acids, respectively. In this study, two extraction processes were compared at an extraction volume of 2000 L: (a) conventional solvent extraction (CSE) with ethanol 80% for the recovery of phenolic-rich extracts, (b) and supercritical fluid extraction (SFE) followed by CSE to obtain oil and phenolic-rich extracts. According to the economic evaluation performed using SuperPro Designer 9.0, SFE+CSE was the most economically feasible process for obtaining bioactive compounds from M. flexuosa on an industrial scale.

1. Introduction

Mauritia flexuosa L.f. is a palm from the South American Amazon; it is distributed throughout Peru, Bolivia, Brazil, Colombia, Ecuador, Venezuela and Guyana [1]. The fruit of M. flexuosa is considered to be functional food due to its high content of phenolic compounds, carotenoids, essential fatty acids, vitamin E (tocopherols) and dietary fiber [2,3,4]. From the pulp, 20–30% (wt.) of oil can be extracted [5], which contains 89.81% and 10.19% of unsaturated and saturated fatty acids, respectively, as well as a high content of β-carotene (911.4 mg/kg) and tocopherol (800 mg/kg) [6,7]. Oleic acid, a monounsaturated fatty acid, is the most abundant (89.81%) of the oil, followed by palmitic acid and linoleic acid [7,8].

Conventionally, for the recovery of oil and phenolic-rich extracts from M. flexuosa, supercritical adsorption [5] and solid–liquid extraction [2,3,4] are used, respectively. In some of these processes, large volumes of petroleum-derived solvents are required, as well as a long extraction time, which could reduce the quality of the bioactive compounds obtained [9]. A strategy to reduce costs without affecting the quality of these products is the intensification of processes that allow efficient use of energy and capital while improving techno-economic parameters [10].

Using the concept of biorefinery and through the sequential integration of green extraction processes, the yield and recovery of bioactive compounds can be increased on an industrial scale for use as functional foods, as well as in the food and pharmaceutical industry [11]. The aim of this study was to compare the extraction yield and composition of each extract in both processes. Furthermore, an economic evaluation and sensitivity study was performed using SuperPro Designer 9.0 software at an extraction volume of 2000 L.

2. Materials and Methods

2.1. Sample Preparation

Fruits of M. flexuosa of the “Shambo” morphotype, acquired in the “Veinte de Enero” community of the Marañon River, Iquitos Region, Peru, were used in this study. The fruits were selected from their sanity and ripening stage and washed in water containing 25 ppm of sodium hypochlorite. Then, the pulp was obtained, which was lyophilized for subsequent assays as previously described [3].

2.2. Single-Stage Process and Two-Stage Sequential Process

Supercritical CO2 extraction equipment (Top Industrie, France) was used to obtain oil from M. flexuosa on a laboratory scale. Pressure, temperature and flow were set at 200 bar, 42 °C and 42 g CO2/min. Phenolic-rich extracts were obtained from supercritical fluid extraction (SFE)-defatted pulp or lyophilized pulp of M. flexuosa on a laboratory scale, as previously described [3]. During this study, a (a) single-stage process by conventional solvent extraction (CSE) for obtaining phenolic-rich extracts and a (b) two-stage sequential process using supercritical and conventional solvent extraction (SFE+CSE) for the recovery of oil and phenolic-rich extracts were evaluated. The extraction yields (EY) for both extraction processes were calculated as the ratio between the total mass of extract and the mass of raw material loaded in the extractor on a dry weight (dw) basis [12].

2.3. Total Phenolic and Flavonoid Content

The content of total phenolics and total flavonoids were measured using a modified Folin–Ciocalteu assay and aluminum chloride colorimetric method, respectively [3].

2.4. Process Simulation Model

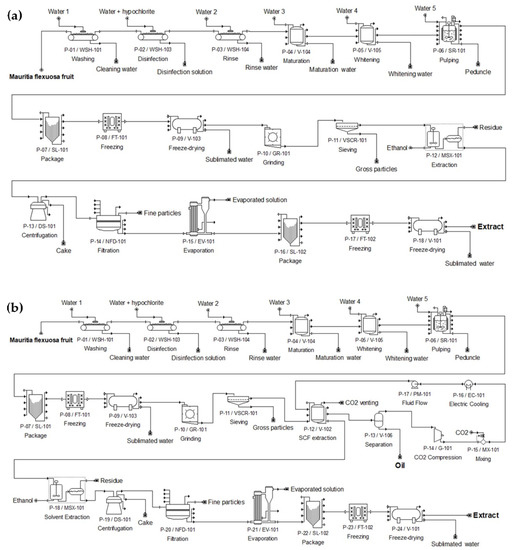

SuperPro Designer 9.0 was used to perform the simulations of the CSE and SFE+CSE. Direct costs (buildings, yard improvement, electrical facilities, insulation, instrumentation, installation) and indirect costs (administration rates, engineering, and construction, insurance, human resources for administration, cleaning services) are estimated by the simulator, and both are considered in the economic evaluation. In Figure 1, the flowsheets of the CSE and SFE+CSE are shown. For the scale-up process, it was assumed that the yield and composition obtained at the laboratory scale would be similar to those obtained at the industrial scale under the same processing conditions for each technology (pressure, temperature, extraction time, density) [13].

Figure 1.

Flowsheet of the (a) single-stage process by conventional solvent extraction (CSE) and (b) sequential two-stage process using supercritical and conventional solvent extraction (SFE+CSE), designed by the SuperPro Designer 9.0 software.

2.5. Economic Evaluation

The cost of the extraction plants for the CSE and SFE+ CSE was calculated using past quotes from vendors and previous reports [14]. In some cases, the quotes and detailed specifications of the equipment were of different capacities than those required [15]. Equation 1 was used to obtain the cost of each large-scale equipment based on the quote obtained for small-scale equipment.

where C1 is the cost of the equipment with capacity Q1, C2 is the known base cost for equipment with capacity Q2, and n is a constant depending on the equipment type. The values of n were collected from the literature [16,17]. The cost of the supercritical fluid equipment was calculated according to the specifications of [18]. For both extraction processes, the scale-up was carried out for a vessel with a volume of 2000 L.

Experimental data obtained at fixed operating conditions were used as inputs for the model. The manufacturing cost (COM) for the production of phenolic-rich extracts by the CSE, as well as the for production of oil and phenolic-rich extracts by SFE+CSE, was determined as the sum of three main components: direct costs, fixed costs, and general expenses. COM was estimated according to the methodology proposed by [17], by which the three main components are estimated in terms of four major costs: fixed capital investment (FCI), cost of raw material (CRM), cost of operational labor (COL), and cost of utilities (CUT). The FCI is related to expenses involved in the implementation of the production plant. CRM considers the cost of the raw material, including the costs of the extraction solvents. COL is related to required operators to perform all stages of extraction. CUT considers electricity requirements, steam, and treated water for the process. The cost of raw material (M. flexuosa) was quoted as USD 15.63/kg. The commercialization of phenolic-rich extracts obtained by the CSE and SFE+CSE was estimated at USD 100.00/kg and USD 180.00/kg, respectively. The commercialization of oil was estimated at USD 314.47/L. The value of COM was simulated in CSE and SFE+CSE, considering six different scenarios: (1) real value of COM, (2) plant at 50% the cost, (3) M. flexuosa at 50% the cost, (4) ethanol 50% recycled, (5) extract lyophilized 50% more expensive and (6) merging scenarios 2–5. The gross margin (GM), return over the investment (ROI), payback time (PBT), internal rate of return (IRR), and net present value (NPV) at 7% interest were also simulated, considering the above-mentioned selling prices of oil and phenolic-rich extracts.

3. Results and Discussion

3.1. Experimental Results

In the CSE, the extraction yield was 13.84 g extract/100 g M. flexuosa pulp (dry basis), while in the SFE+CSE, the extraction yield was 44.5 g oil/100 g M. flexuosa pulp (dry basis) and 13.84 g extract/100 g M. flexuosa pulp (dry basis). These results are in agreement with previous studies, showing an extraction yield of 8.04% for phenolic rich-extracts obtained from the pulp of M. flexuosa defatted by Sohxlet [19] and an oil extraction yield between 23.5 to 41.1 g oil/ 100 g M. flexuosa using SFE-CO2 [20]. In the SFE+CSE interaction, the total content of polyphenols and flavonoids were 8.4- and 2.4-fold higher, respectively, compared to the CSE results (p < 0.01). The levels of total polyphenols obtained by the CSE were similar to those reported by previous studies of methanol extracts from the M. flexuosa pulp [21,22]. However, these levels were significantly lower compared to those found from the pulp defatted by the SPE+CSE. This last method allows us to concentrate on the content of phenolic compounds, and therefore to increase the activity and the market value of these phenolic-rich extracts from M. flexuosa. Regarding the total flavonoid levels, the content obtained by both extraction methods in the present study was lower than that reported by previous studies [21,22].

3.2. Economic Evaluation of the Extraction Processes

The total investment for CSE and SFE+CSE was USD28,152,594.00 and USD183,712,894.00, respectively. These differences in the cost of the total investment are due to the use of a supercritical fluid equipment in the SPE+CSE, which allows researchers to obtain two by-products, such as oil and rich-phenolic extracts. For the CSE, the productivity was 731.1 tons extract/year; while for the SFE+CSE, the productivity was 335.9 tons oil/year and 405.8 tons extract/year. In the sensitivity study, for both extraction processes, no variation was observed in the productivity of oil and/or phenolic-rich extracts among all the evaluated scenarios. The differences in the COM and productivities of the by-products obtained by both extraction processes were related to the input data for the simulation, as well as the extraction yields and total investment cost of each process. The COM was 1.5 times higher in the SFE+CSE compared to the CSE; however, using the first process, two by-products were recovered.

3.3. Sensitivity Study and Comparison among Extraction Methods

The simulation was carried out considering an industrial scale, at an extraction volume of 2000 L. In addition to COM, to carry out the sensitivity study, GM, ROI, PBT, IRR and NPV were evaluated. As shown in Table 1, when the CSE was used, the COM of one kg of phenolic-rich extracts ranged between USD63.63 and USD126.47. CRM had the greatest influence on COM, with an impact of approximately 80–90%. This occurred because M. flexuosa is a biomass of large importance in the Peruvian market, as well as in the South American economy. When it is possible to purchase this raw material at half cost, the parameters of return indicate a feasibility of the process. For example, the GM, ROI and IRR were 26.94%, 33.46% and 42.42%, respectively. The PBT was 2.99 years, with an NPV of USD123,274,000.00. The best scenario for processing M. flexuosa by the CSE was achieved when merging scenarios 2–5. In the same trend, when the SFE+CSE was carried out, two by-products were obtained in each batch. The COM of one kg of oil + phenolic-rich extracts ranged from USD96.31 to USD193.38. Overall, the values of COM are a bit higher in SFE+CSE than CSE because the SFE equipment significantly increased the FCI cost. This itemized cost contributes to approximately 50% of the total cost of these by-products. In this process, both CRM and FCI significantly impact COM. Despite the values of COM being high, all scenarios for SFE+CSE presented positive return to the initial capital and operational investment. The best scenario to process M. flexuosa by SFE+CSE was achieved by merging scenarios 2–5. In such a scenario, the GM, ROI and IRR were 73.34%, 92.91% and 152.58%, respectively. The PBT was 1.08 years with an NPV of USD1,294,690,000.00 (Table 2).

Table 1.

Project indices of the single-stage process (CSE).

Table 2.

Project indices of the sequential two-stage process (SFE+CSE).

4. Conclusions

The scenario that individually impacted the economic parameters the most saw a reduction in the cost of raw materials by 50%. In this scenario, in the CSE and SFE+CSE methods, the COM decreased 1.7 and 1.4 times, respectively. However, in both extraction processes, the COM reached its lowest value when scenarios 2 to 5 were merged, decreasing the value of COM approximately 2-fold. Comparing both extraction processes, SFE+CSE was the most desirable economic process because it allowed researchers to obtain two by-products and the highest profit.

Author Contributions

Conceptualization, I.B. and L.O.-M.; methodology and investigation, I.B., L.O.-M., Z.C.-G., O.A.-C. and G.Z.; validation, I.B., L.O.-M. and G.Z.; writing—original draft preparation, I.B. and G.Z.; writing—review and editing, I.B., L.O.-M. and G.Z.; supervision, I.B.; funding acquisition, I.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Fund for Scientific, Technological Development and Technological Innovation (FONDECYT) of the National Council of Science, Technology and Technological Innovation (CONCYTEC) of Peru, Contract 007-2018-FONDECYT-BM, and Universidad San Ignacio de Loyola.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

We thank the staff at the ICAN-USIL of the Universidad San Ignacio de Loyola for their valuable assistance in obtaining the samples of M. flexuosa.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pereira Freire, J.A.; Barros, K.B.; Lima, L.K.; Martins, J.M.; Araújo, Y.D.; da Silva Oliveira, G.L.; de Souza Aquino, J.; Ferreira, P.M. Phytochemistry Profile, Nutritional Properties and Pharmacological Activities of Mauritia flexuosa. J. Food Sci. 2016, 81, R2611–R2622. [Google Scholar] [CrossRef] [PubMed]

- Cândido, T.L.; Silva, M.R.; Agostini-Costa, T.S. Bioactive compounds and antioxidant capacity of buriti (Mauritia flexuosa L.f.) from the Cerrado and Amazon biomes. Food Chem. 2015, 177, 313–319. [Google Scholar] [CrossRef] [PubMed]

- Best, I.; Casimiro-Gonzales, S.; Portugal, A.; Olivera-Montenegro, L.; Aguilar, L.; Muñoz, A.M.; Ramos-Escudero, F. Phytochemical Screening and DPPH Radical Scavenging Activity of Three Morphotypes of Mauritia flexuosa L.f. from Peru, and Thermal Stability of a Milk-Based Beverage Enriched with Carotenoids from These Fruits. Heliyon 2020, 6, e05209. [Google Scholar] [CrossRef] [PubMed]

- Abreu-Naranjo, R.; Paredes-Moreta, J.G.; Granda-Albuja, G.; Iturralde, G.; González-Paramás, A.M.; Alvarez-Suarez, J.M. Bioactive Compounds, Phenolic Profile, Antioxidant Capacity and Effectiveness against Lipid Peroxidation of Cell Membranes of Mauritia flexuosa L. Fruit Extracts from Three Biomes in the Ecuadorian Amazon. Heliyon 2020, 6, e05211. [Google Scholar] [CrossRef]

- Cunha, M.A.; Neves, R.F.; Souza, J.N.; França, L.F.; Araújo, M.E.; Brunner, G.; Machado, N.T. Supercritical Adsorption of Buriti Oil (Mauritia flexuosa Mart.) in γ-Alumina: A Methodology for the Enriching of Anti-Oxidants. J. Supercrit. Fluids 2012, 66, 181–191. [Google Scholar] [CrossRef]

- Aquino, J.D.; Soares, J.K.; Magnani, M.; Stamford, T.C.; Mascarenhas, R.D.; Tavares, R.L.; Stamford, T.L. Effects of Dietary Brazilian Palm Oil (Mauritia flexuosa L.) on Cholesterol Profile and Vitamin A and E Status of Rats. Molecules 2015, 20, 9054–9070. [Google Scholar] [CrossRef] [PubMed]

- Faustino Pereira, Y.; do Socorro Costa, M.; Relison Tintino, S.; Esmeraldo Rocha, J.; Fernandes Galvão Rodrigues, F.; de Sá Barreto Feitosa, M.K.; de Menezes, I.R.; Douglas Melo Coutinho, H.; da Costa, J.G.; de Sousa, E.O. Modulation of the Antibiotic Activity by the Mauritia flexuosa (Buriti) Fixed Oil against Methicillin-Resistant Staphylococcus Aureus (MRSA) and Other Multidrug-Resistant (MDR) Bacterial Strains. Pathogens 2018, 7, 98. [Google Scholar] [CrossRef] [PubMed]

- Pérez, M.M.; Gonçalves, E.C.; Salgado, J.C.; Rocha, M.D.; Almeida, P.Z.; Vici, A.C.; Infante, J.D.; Guisán, J.M.; Rocha-Martin, J.; Pessela, B.C.; et al. Production of Omegas-6 and 9 from the Hydrolysis of Açaí and Buriti Oils by Lipase Immobilized on a Hydrophobic Support. Molecules 2018, 23, 3015. [Google Scholar] [CrossRef]

- More, P.R.; Arya, S.S. Intensification of Bio-Actives Extraction from Pomegranate Peel Using Pulsed Ultrasound: Effect of Factors, Correlation, Optimization and Antioxidant Bioactivities. Ultrason. Sonochem. 2020, 72, 105423. [Google Scholar] [CrossRef] [PubMed]

- Zabot, G.L.; Moraes, M.N.; Carvalho, P.I.; Meireles, M.A. New Proposal for Extracting Rosemary Compounds: Process Intensification and Economic Evaluation. Ind. Crops Prod. 2015, 77, 758–771. [Google Scholar] [CrossRef]

- Martínez, J.; de Aguiar, A.C.; Machado, A.P.; Barrales, F.M.; Viganó, J.; dos Santos, P. 2.51—Process Integration and Intensification. In Comprehensive Foodomics; Cifuentes, A., Ed.; Elsevier: Oxford, UK, 2021; pp. 786–807. ISBN 978-0-12-816396-2. [Google Scholar]

- Veggi, P.C.; Cavalcanti, R.N.; Meireles, M.A. Production of Phenolic-Rich Extracts from Brazilian Plants Using Supercritical and Subcritical Fluid Extraction: Experimental Data and Economic Evaluation. J. Food Eng. 2014, 131, 96–109. [Google Scholar] [CrossRef]

- Farías-Campomanes, A.M.; Rostagno, M.A.; Meireles, M.A. Production of Polyphenol Extracts from Grape Bagasse Using Supercritical Fluids: Yield, Extract Composition and Economic Evaluation. J. Supercrit. Fluids 2013, 77, 70–78. [Google Scholar] [CrossRef]

- Ochoa, S.; Durango-Zuleta, M.M.; Felipe Osorio-Tobón, J. Techno-Economic Evaluation of the Extraction of Anthocyanins from Purple Yam (Dioscorea Alata) Using Ultrasound-Assisted Extraction and Conventional Extraction Processes. Food Bioprod. Process. 2020, 122, 111–123. [Google Scholar] [CrossRef]

- de Aguiar, A.C.; Osorio-Tobón, J.F.; Viganó, J.; Martínez, J. Economic Evaluation of Supercritical Fluid and Pressurized Liquid Extraction to Obtain Phytonutrients from Biquinho Pepper: Analysis of Single and Sequential-Stage Processes. J. Supercrit. Fluids 2020, 165, 104935. [Google Scholar] [CrossRef]

- Peters, M.; Timmerhaus, K.; West, R.; Peters, M. Plant Design and Economics for Chemical Engineers; McGraw-Hill: New York, NY, USA, 2002; ISBN 978-0-07-239266-1. [Google Scholar]

- Turton, R. Analysis, Synthesis and Design of Chemical Processes; Pearson Education: London, UK, 2012. [Google Scholar]

- Rocha-Uribe, J.A.; Novelo-Pérez, J.I.; Araceli Ruiz-Mercado, C. Cost Estimation for CO2 Supercritical Extraction Systems and Manufacturing Cost for Habanero Chili. J. Supercrit. Fluids 2014, 93, 38–41. [Google Scholar] [CrossRef]

- Nobre, C.B.; Sousa, E.O.; Camilo, C.J.; Machado, J.F.; Silva, J.M.; Filho, J.R.; Coutinho, H.D.; Costa, J.G. Antioxidative Effect and Phytochemical Profile of Natural Products from the Fruits of “Babaçu” (Orbignia Speciose) and “Buriti” (Mauritia flexuosa). Food Chem. Toxicol. 2018, 121, 423–429. [Google Scholar] [CrossRef]

- Chañi-Paucar, L.O.; Yali, E.T.; Maceda Santivañez, J.C.; Garcia, D.A.; Jonher, J.C.; Angela, A.; Meireles, M. Supercritical Fluid Extraction from Aguaje (Mauritia flexuosa) Pulp: Overall Yield, Kinetic, Fatty Acid Profile, and Qualitative Phytochemical Profile. Open Food Sci. J. 2021, 13, 1–11. [Google Scholar] [CrossRef]

- Koolen, H.H.; da Silva, F.M.; Gozzo, F.C.; de Souza, A.Q.; de Souza, A.D. Antioxidant, Antimicrobial Activities and Characterization of Phenolic Compounds from Buriti (Mauritia flexuosa L.f.) by UPLC–ESI-MS/MS. Food Res. Int. 2013, 51, 467–473. [Google Scholar] [CrossRef]

- Pereira-Freire, J.A.; Oliveira, G.L.; Lima, L.K.; Ramos, C.L.; Arcanjo-Medeiros, S.R.; Lima, A.C.; Teixeira, S.A.; Oliveira, G.A.; Nunes, N.M.; Amorim, V.R.; et al. In Vitro and Ex Vivo Chemopreventive Action of Mauritia flexuosa Products. Evid.-Based Complement. Altern. Med. 2018, 2018, e2051279. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).