Comparative Evaluation of Ultra-Low-Volume Nozzle Configurations for UAV Spraying in Mango Orchards Under Semi-Arid Conditions in Northern India †

Abstract

1. Introduction

- (i)

- Quantify spray coverage and canopy penetration across three vertical canopy layers,

- (ii)

- Assess the interaction between nozzle droplet spectrum and canopy density under tropical field microclimates,

- (iii)

- Perform principal-component analysis (PCA) to evaluate multivariate drivers of deposition patterns, and

- (iv)

- Estimate water and carbon savings from UAV spraying compared with conventional methods.

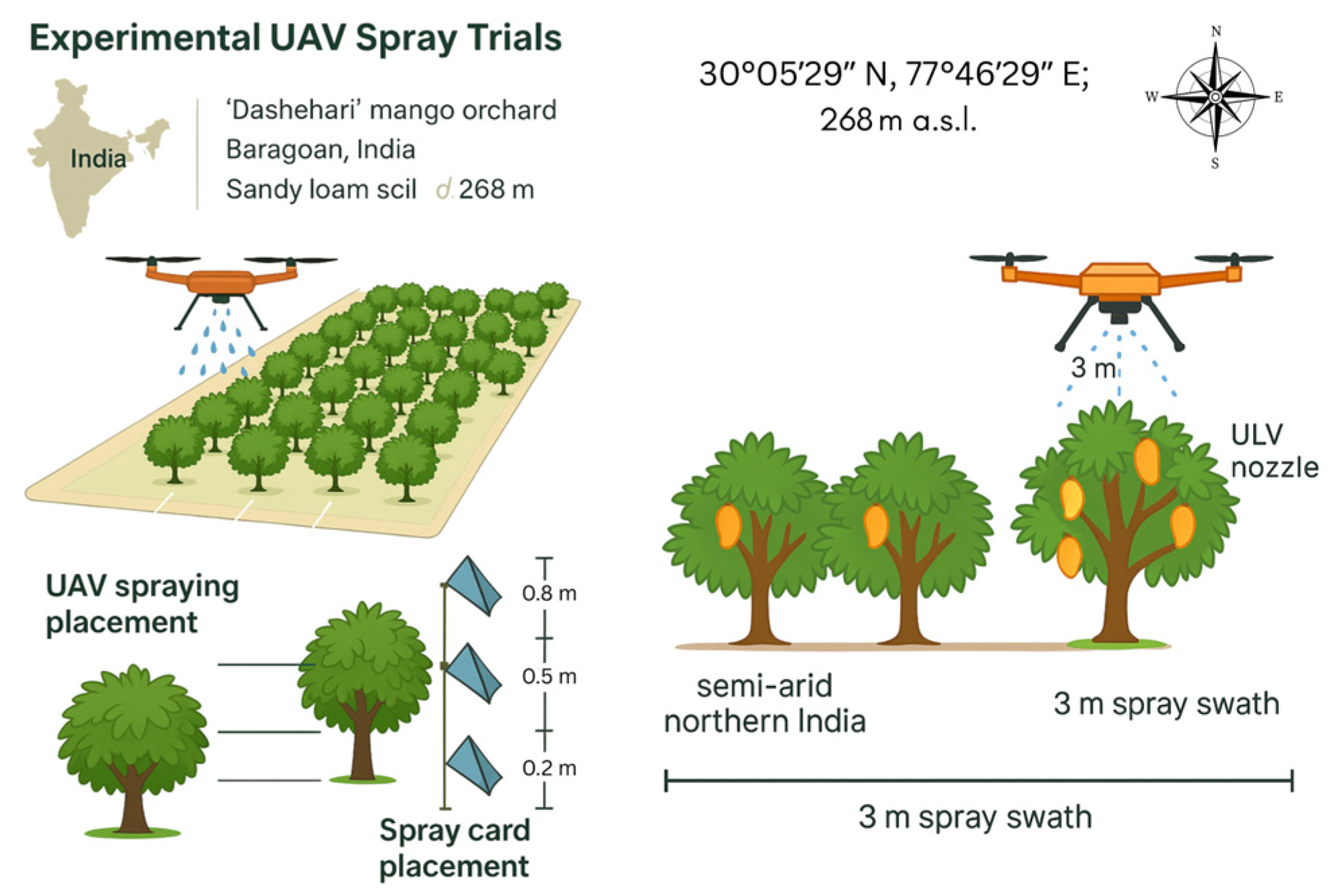

2. Materials and Methods

2.1. Study Site and Climatic Conditions

2.2. Drone Platform and Spraying Protocol

- TeeJet XR 11002VK hollow-cone nozzle (TeeJet Technologies, Springfield, IL, USA), operated at 3.0 bar with a VMD of139 ± 6 µm; and

- HYPRO ULV rotary atomiser (Pentair-HYPRO, New Brighton, MN, USA), operated at 2.2 bar and 6000 rpm with a VMD of 81 ± 5 µm.

2.3. Experimental Layout and Sampling

2.4. Deposition and Droplet Analysis

2.5. Micro-Climate and Environmental Covariates

2.6. Statistical and PCA

2.7. Life-Cycle Assessment (LCA)

3. Results

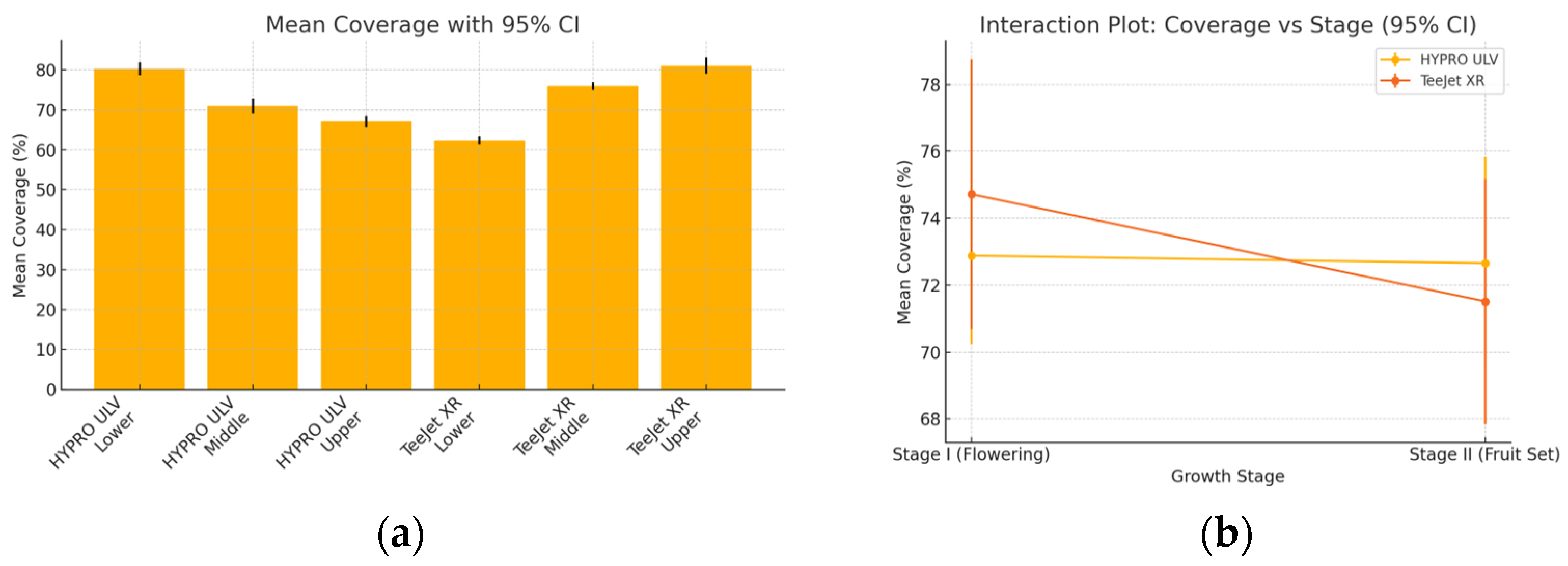

3.1. Spray Coverage

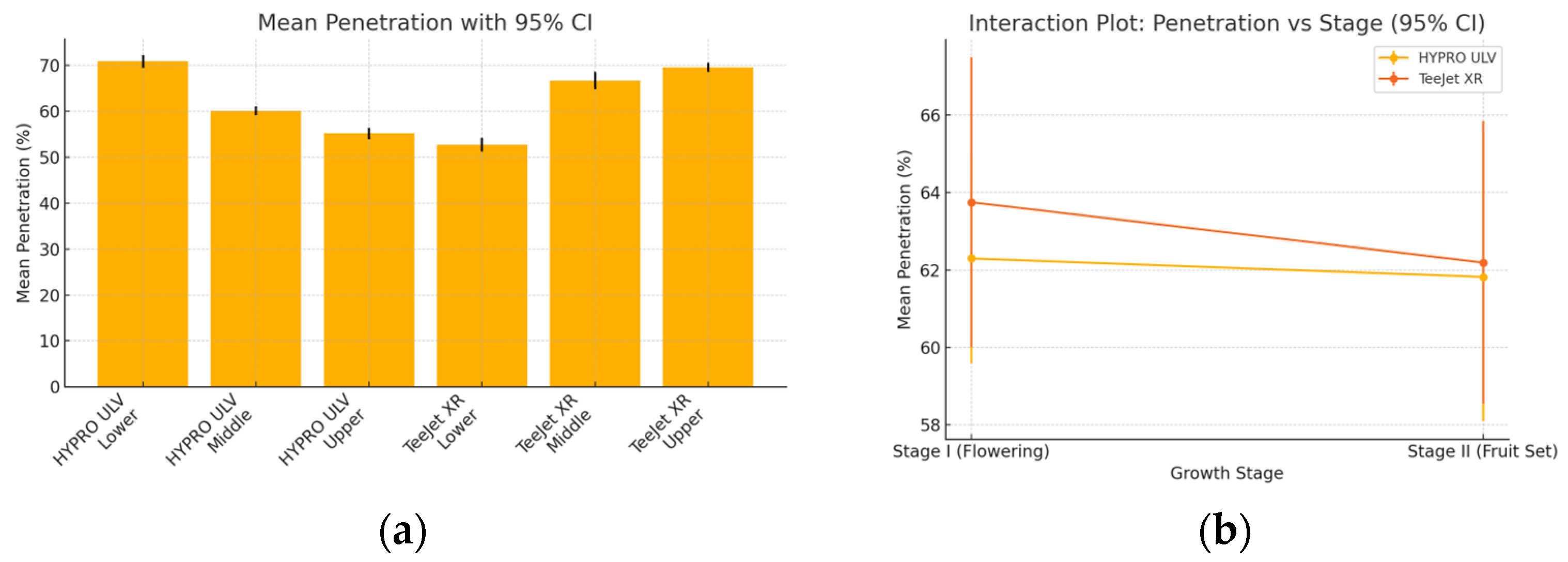

3.2. Canopy Penetration

3.3. Droplet Size Distribution

3.4. Environmental Covariate Effects

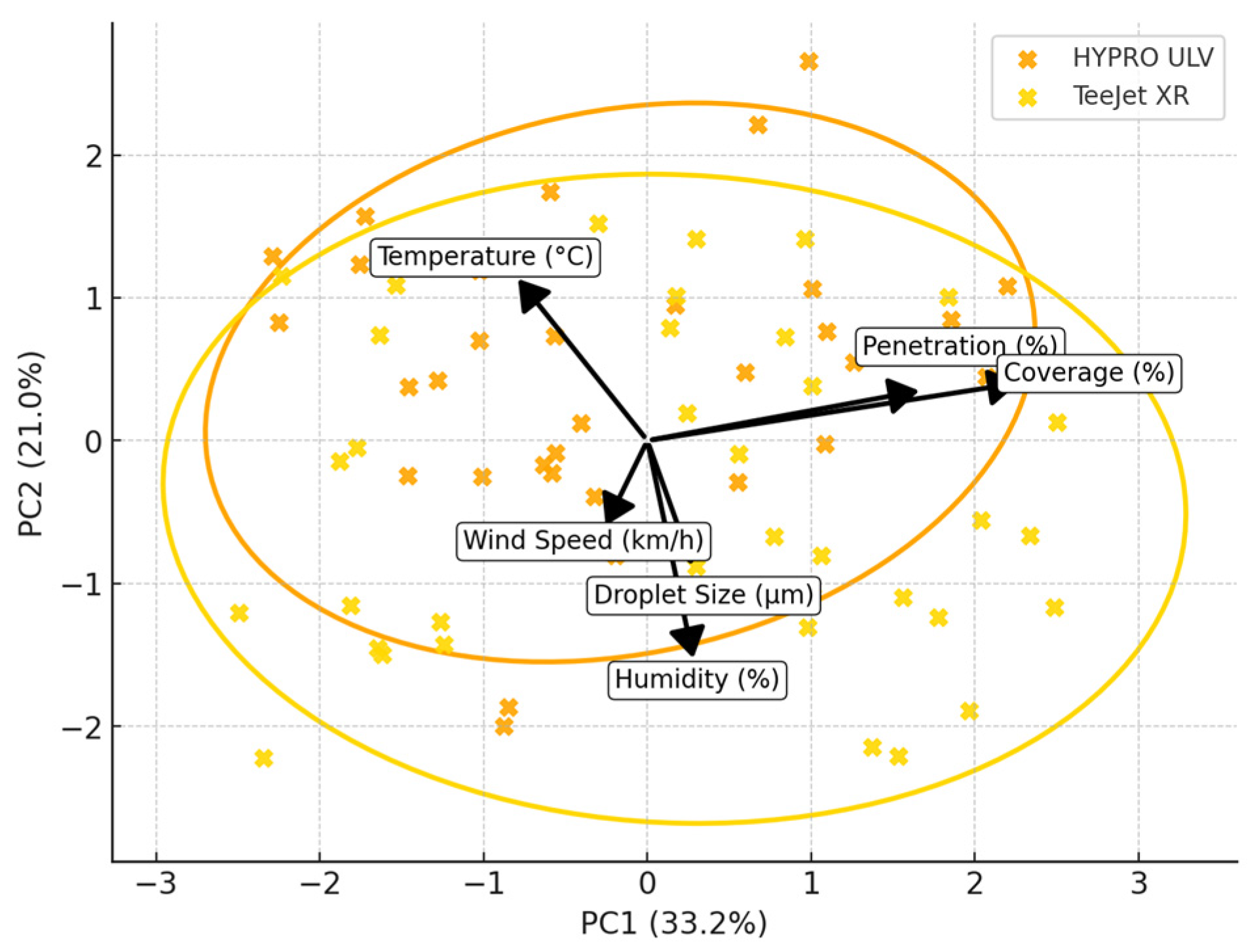

3.5. Principal Component Analysis

3.6. Sustainability Impact

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ministry of Food Processing Industries (MoFPI). Study on Infrastructure Gaps in the Mango Supply Chain in India; Government of India, Ministry of Food Processing Industries: New Delhi, India, 2020. Available online: https://www.mofpi.gov.in/sites/default/files/study_on_infrastructure_gaps_-_mango_0.pdf (accessed on 12 May 2025).

- Prakash, O. Diseases and Disorders of Mango and Their Management. In Diseases of Fruits and Vegetables; Naqvi, S.A.M.H., Ed.; Springer: Dordrecht, The Netherlands, 2004; Volume I, pp. 511–619. [Google Scholar] [CrossRef]

- Rathnayake, A.P.; Khot, L.R.; Hoheisel, G.A.; Thistle, H.W.; Teske, M.E.; Willett, M.J. Downwind Spray Drift Assessment for Airblast Sprayer Applications in a Modern Apple Orchard System. Trans. ASABE 2021, 64, 601–613. [Google Scholar] [CrossRef]

- Nuyttens, D.; De Schampheleire, M.; Baetens, K.; Sonck, B. The influence of operator-controlled variables on spray drift from field crop sprayers. Trans. ASABE 2007, 52, 1479–1489. [Google Scholar] [CrossRef]

- Martinez-Guanter, J.; Agüera, P.; Agüera, J.; Pérez-Ruiz, M. Spray and economics assessment of a UAV-based ultra-low-volume application in olive and citrus orchards. Precis. Agric. 2020, 21, 226–243. [Google Scholar] [CrossRef]

- Zhang, C.; Kovacs, J.M. The application of small unmanned aerial systems for precision agriculture: A review. Precis. Agric. 2012, 13, 693–712. [Google Scholar] [CrossRef]

- Stateras, D.; Kalivas, D. Assessment of Olive Tree Canopy Characteristics and Yield Forecast Model Using High Resolution UAV Imagery. Agriculture 2020, 10, 385. [Google Scholar] [CrossRef]

- Zhang, C.; Valente, J.; Kooistra, L.; Guo, L.; Wang, W. Orchard Management with Small Unmanned Aerial Vehicles: A Survey of Sensing and Analysis Approaches. Precis. Agric. 2021, 22, 2007–2052. [Google Scholar] [CrossRef]

- Wang, B.; Geng, Z.; Pan, B.; Jiang, L.; Lin, Y. Effect of Vegetable Oil Adjuvant on Wetting, Drift, and Deposition of Pesticide Droplets from UAV Sprayers on Litchi Leaves. Agronomy 2025, 15, 293. [Google Scholar] [CrossRef]

- Arvidsson, T.; Bergström, L.; Kreuger, J. Spray drift as influenced by meteorological and technical factors. Pest Manag. Sci. 2011, 30, 273–279. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Fu, Y.; Guo, Q.; Huang, H.; Tan, Z.; Luo, S. Numerical Simulation of the Spatial and Temporal Distributions of the Downwash Airflow and Spray Field of a Co-Axial Eight-Rotor Plant Protection UAV in Hover. Comput. Electron. Agric. 2023, 206, 107634. [Google Scholar] [CrossRef]

- Nicolò, B.F.; De Salvo, M.C.; Ramirez-Sanz, C.; Estruch, V.; Sanjuan, N.; Falcone, G.; Strano, A. Life cycle assessment applied to different citrus farming systems in Spain and Italy. Agroecol. Sustain. Food Syst. 2018, 42, 1092–1105. [Google Scholar] [CrossRef]

- FAO. Guidelines on the Use of Drones in Agriculture; Food and Agriculture Organization of the United Nations: Rome, Italy, 2021. [Google Scholar]

- Razzaq, A.; Naseer, M.A.U.R.; Ahmed, M.; Ahmad, S.; Raza, M.Y.; Naqvi, S.A.H. Water Management Strategies for Sustainable Mango Cultivation in a Changing Climate. In Climate Change and Mango Production; Naqvi, S.A.H., Ahmad, S., Ahmed, M., Eds.; Springer: Cham, Switzerland, 2025. [Google Scholar] [CrossRef]

- Verma, A.; Singh, M.; Parmar, R.; Bhullar, K. Feasibility Study on Hexacopter UAV-Based Sprayer for Application of Environment-Friendly Biopesticide in Guava Orchard. J. Environ. Biol. 2022, 43, 97–104. [Google Scholar] [CrossRef]

- Rajan, S.; Tiwari, D.; Singh, V.K.; Saxena, P.; Singh, S.; Reddy, Y.T.N.; Upreti, K.K.; Burondkar, M.M.; Bhagwan, A.; Kennedy, R. Application of extended BBCH scale for phenological studies in mango (Mangifera indica L.). J. Appl. Horticulture. 2011, 13, 108–114. [Google Scholar] [CrossRef]

- Indian Council of Agricultural Research. Vision 2050: Central Soil Salinity Research Institute; ICAR-CSSRI: Karnal, India, 2019. [Google Scholar]

- India Meteorological Department. Climatological Tables of Observatories in India 1991–2020; Government of India, Ministry of Earth Sciences: New Delhi, India, 2023.

- Naik, S.K.; Das, B.; Kumar, S.; Bhatt, B.P. Evaluation of Major and Micronutrient Status of Acid Soils of Different Mango Orchards. Int. J. Fruit Sci. 2014, 15, 10–25. [Google Scholar] [CrossRef]

- Directorate General of Civil Aviation (DGCA). Civil Aviation Requirements: Section 3—Air Transport Series F Part 1; DGCA: New Delhi, India, 2022.

- ASABE. S572.3: Spray Nozzle Classification by Droplet Spectra; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2023. [Google Scholar]

- Ranabhat, S.; Price, R. Effects of Flight Heights and Nozzle Types on Spray Characteristics of Unmanned Aerial Vehicle (UAV) Sprayer in Common Field Crops. AgriEngineering 2025, 7, 22. [Google Scholar] [CrossRef]

- Delgado, P.; Aranguren González, M.; Reig, C.; Fernández Galván, D.; Mesejo, C.; Martínez Fuentes, A.; Galán Saúco, V.; Agustí, M. Phenological Growth Stages of Mango (Mangifera indica L.) According to the BBCH Scale. Sci. Hortic. 2011, 130, 536–540. [Google Scholar] [CrossRef]

- Hoffmann, W.C.; Hewitt, A.J. Comparison of three imaging systems for water-sensitive paper droplet analysis. Appl. Eng. Agric. 2005, 21, 961–964. [Google Scholar] [CrossRef]

- Malvern-Panalytical. Spraytec Instrument Manual (v1.5); Malvern-Panalytical Ltd.: Malvern, UK, 2022. [Google Scholar]

- ASTM E104-20; Standard Practice for Maintaining Constant Relative Humidity by Means of Aqueous Solutions. ASTM International: West Conshohocken, PA, USA, 2020.

- ISO 22866; Equipment for Crop Protection—Methods for the Field Measurement of Spray Drift. ISO: Geneva, Switzerland, 2020.

- Van Rossum, G.; Drake, F.L. Python 3 Reference Manual; CreateSpace: Scotts Valley, CA, USA, 2009. [Google Scholar]

- McDonald, J.H. Handbook of Biological Statistics, 3rd ed.; Sparky House Publishing: Baltimore, MD, USA, 2014. [Google Scholar]

- Field, A.P. Discovering Statistics Using Python; Sage Publications: London, UK, 2018. [Google Scholar]

- Pajula, T.; Behm, K.; Vatanen, S.; Saarivuori, E. Managing the life cycle to reduce environmental impacts. In Dynamics of Long-Life Assets: From Technology Adaptation to Upgrading the Business Model; Grösser, S.N., Reyes-Lecuona, A., Granholm, G., Eds.; Springer International Publishing AG: Cham, Switzerland, 2017; pp. 93–113. [Google Scholar] [CrossRef]

- IEA. Global Solar Photovoltaic Supply Chain Report 2023; International Energy Agency: Paris, France, 2023. [Google Scholar]

- Wang, G.; Li, Z.; Jia, W.; Ou, M.; Dong, X.; Zhang, Z. A Review on the Evolution of Air-Assisted Spraying in Orchards and the Associated Leaf Motion During Spraying. Agriculture 2025, 15, 964. [Google Scholar] [CrossRef]

- Yang, S.; Xu, P.; Jiang, S.; Zheng, Y. Downwash Characteristics and Analysis from a Six-Rotor Unmanned Aerial Vehicle Configured for Plant Protection. Pest Manag. Sci. 2022, 78, 1707–1720. [Google Scholar] [CrossRef] [PubMed]

- Lan, Y.; Wang, G.; Hussain, M.; Yan, Y.; Wang, H.; Yu, X.; Shan, C.; Wang, B.; Song, C. Evaluation of Droplet Deposition and Spray Distribution in Citrus Orchards by Plant-Protection Drones. Front. Plant Sci. 2023, 14, 1303669. [Google Scholar] [CrossRef]

- Safaeinejad, M.; Ghasemi-Nejad-Raeini, M.; Taki, M. Reducing Energy and Environmental Footprint in Agriculture: A Study on Drone Spraying vs. Conventional Methods. PLoS ONE 2025, 20, e0323779. [Google Scholar] [CrossRef] [PubMed]

| Nozzle | VMD (µm) ± SD | Span |

|---|---|---|

| TeeJet XR | 139 ± 6 | 1.25 |

| HYPRO ULV | 81 ± 5 | 1.05 |

| Variable | Coverage | Penetration | Droplet Size |

|---|---|---|---|

| Wind speed | −0.27 * | −0.18 | +0.05 |

| Relative humidity | +0.14 | +0.11 | −0.08 |

| Temperature | −0.21 | −0.25 * | +0.02 |

| Parameter | Conventional | UAV ULV | Saving | % |

|---|---|---|---|---|

| Water (L) | 700 | 20 | 680 | 97.1 |

| Energy | 0.9 L diesel | 0.25 kWh PV | - | - |

| CO2-eq (kg) | 2.41 | 0.013 | 2.40 | 99.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramteke, S.V.; Varadwaj, P.K.; Tiwari, V. Comparative Evaluation of Ultra-Low-Volume Nozzle Configurations for UAV Spraying in Mango Orchards Under Semi-Arid Conditions in Northern India. Biol. Life Sci. Forum 2025, 47, 4. https://doi.org/10.3390/blsf2025047004

Ramteke SV, Varadwaj PK, Tiwari V. Comparative Evaluation of Ultra-Low-Volume Nozzle Configurations for UAV Spraying in Mango Orchards Under Semi-Arid Conditions in Northern India. Biology and Life Sciences Forum. 2025; 47(1):4. https://doi.org/10.3390/blsf2025047004

Chicago/Turabian StyleRamteke, Shefali Vinod, Pritish Kumar Varadwaj, and Vineet Tiwari. 2025. "Comparative Evaluation of Ultra-Low-Volume Nozzle Configurations for UAV Spraying in Mango Orchards Under Semi-Arid Conditions in Northern India" Biology and Life Sciences Forum 47, no. 1: 4. https://doi.org/10.3390/blsf2025047004

APA StyleRamteke, S. V., Varadwaj, P. K., & Tiwari, V. (2025). Comparative Evaluation of Ultra-Low-Volume Nozzle Configurations for UAV Spraying in Mango Orchards Under Semi-Arid Conditions in Northern India. Biology and Life Sciences Forum, 47(1), 4. https://doi.org/10.3390/blsf2025047004