1. Introduction

The consumption of dietary fibre has shown notable health benefits in terms of immunonutritional well-being and in the prevention of chronic conditions including obesity, type 2 diabetes, cardiovascular ailments, and cancer [

1,

2]. However, the current global intake of dietary fibre falls below the recommended daily amount of 25 g set by the WHO/FAO [

3].

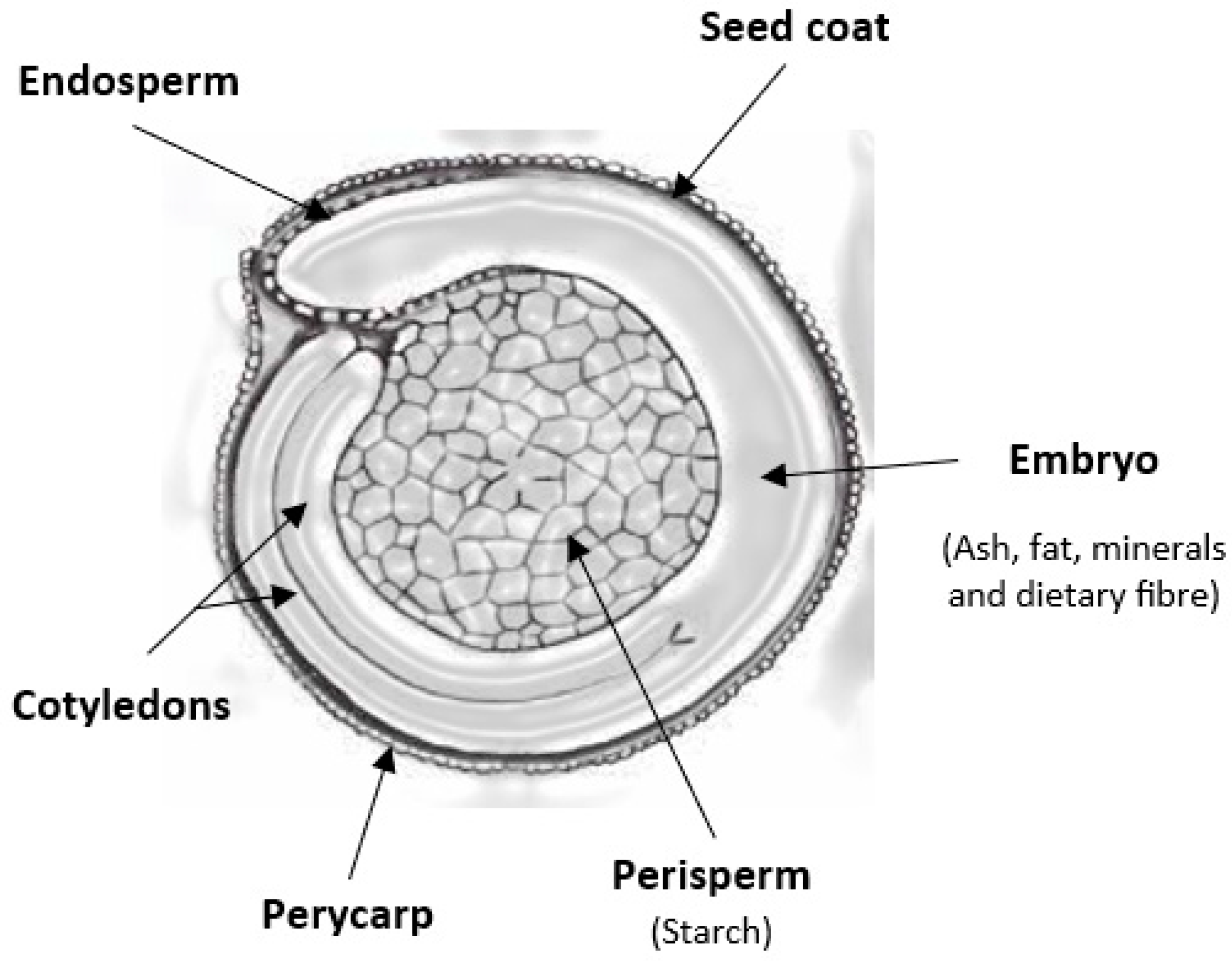

A remarkable reservoir of dietary fibre resides within the fibre-rich fractions of quinoa, which not only possesses high technological potential but also boasts considerable nutritional value and biological activity. These fibre-rich fractions can be efficiently extracted through the wet-milling process of quinoa. This method yields greater quantities and enhanced recovery of vital chemical components found in cereals and pseudocereals (as depicted in

Figure 1), while maintaining a higher level of purity compared to dry-milling techniques.

The primary aim of our study was to isolate fibre-rich fractions from different varieties of Bolivian quinoa—white, red, and black—utilizing wet-milling techniques. A comprehensive characterization was subsequently carried out, evaluating their potential as technofunctional ingredients in the development of cereal-based food products, including applications such as fresh pasta.

2. Materials and Methods

2.1. Materials

Royal quinoa grains (white, red, and black) produced in Bolivia were obtained from Organic Quinoa Real

® (

Figure 2).

2.2. Methods

Wet-Milling

Quinoa seeds were steeped in a sodium bisulfite solution adjusted with lactic acid at pH 5.0, in a Biostat

® B plus fermenter from Sartorius BBI Systems. Wet-milling was performed according to the methodology recommended by Ballester-Sánchez et al. [

5], with some modifications (

Figure 3).

2.3. Chemical Composition

Moisture was determined via gravimetry, starch via the enzymatic/spectrophotometric micromethod [

6], protein via combustion Dumas (conversion factor N 5.7) [

7], lipids via Randall [

8], ash via ignition [

9,

10], and soluble dietary fibre (SDF) and insoluble dietary fibre (IDF) via the enzymatic/gravimetric method [

11,

12]. Minerals such as calcium, iron, and zinc and total phosphorous were determined via atomic absorption spectrophotometry [

13].

2.4. Fresh Pasta Production

Laboratory-scale tagliatelle were made using the Nina electric pasta machine from Springlane® (Düsseldorf, Germany). All formulations included wheat flour mixed with water and egg yolk. However, four different formulations were prepared: a control made with 100% wheat flour, and three types in which 6% of the wheat flour was replaced by the fibre fractions isolated via wet-milling of white, red, and black quinoa.

3. Results

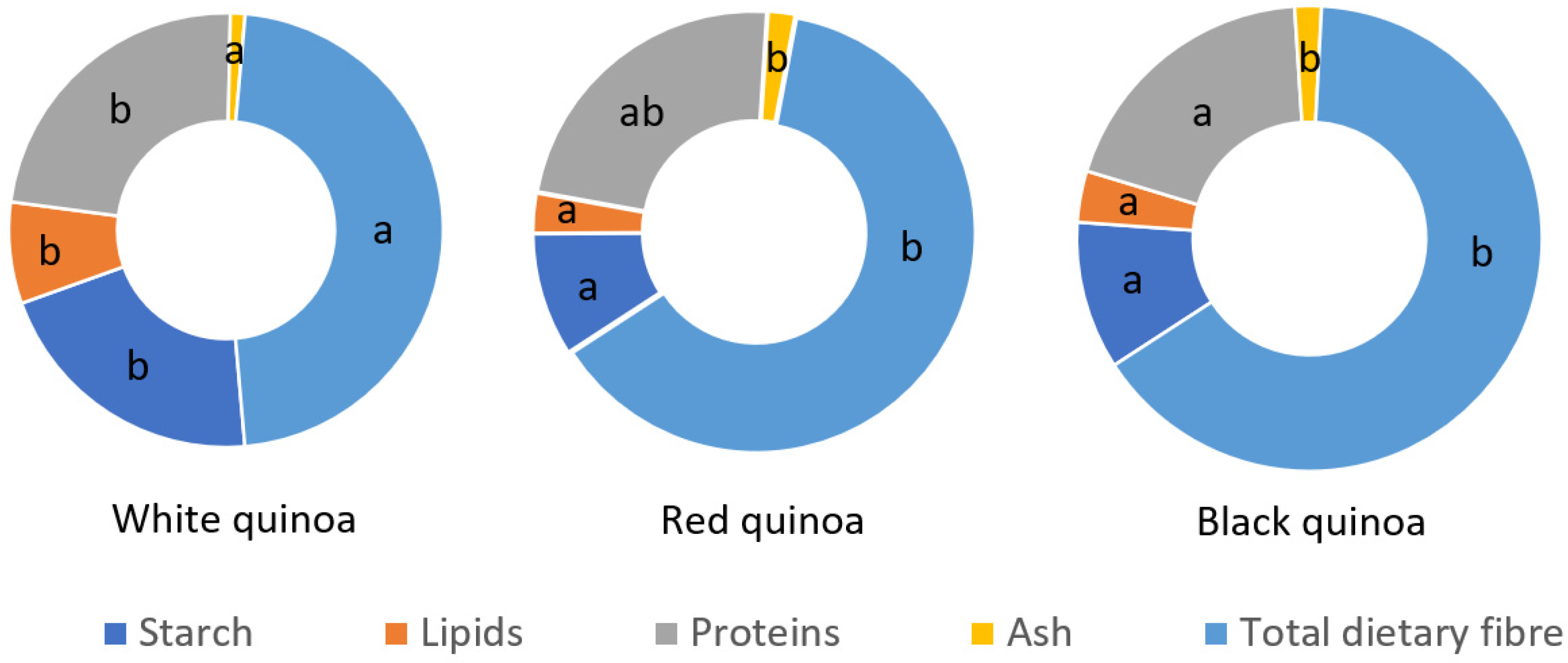

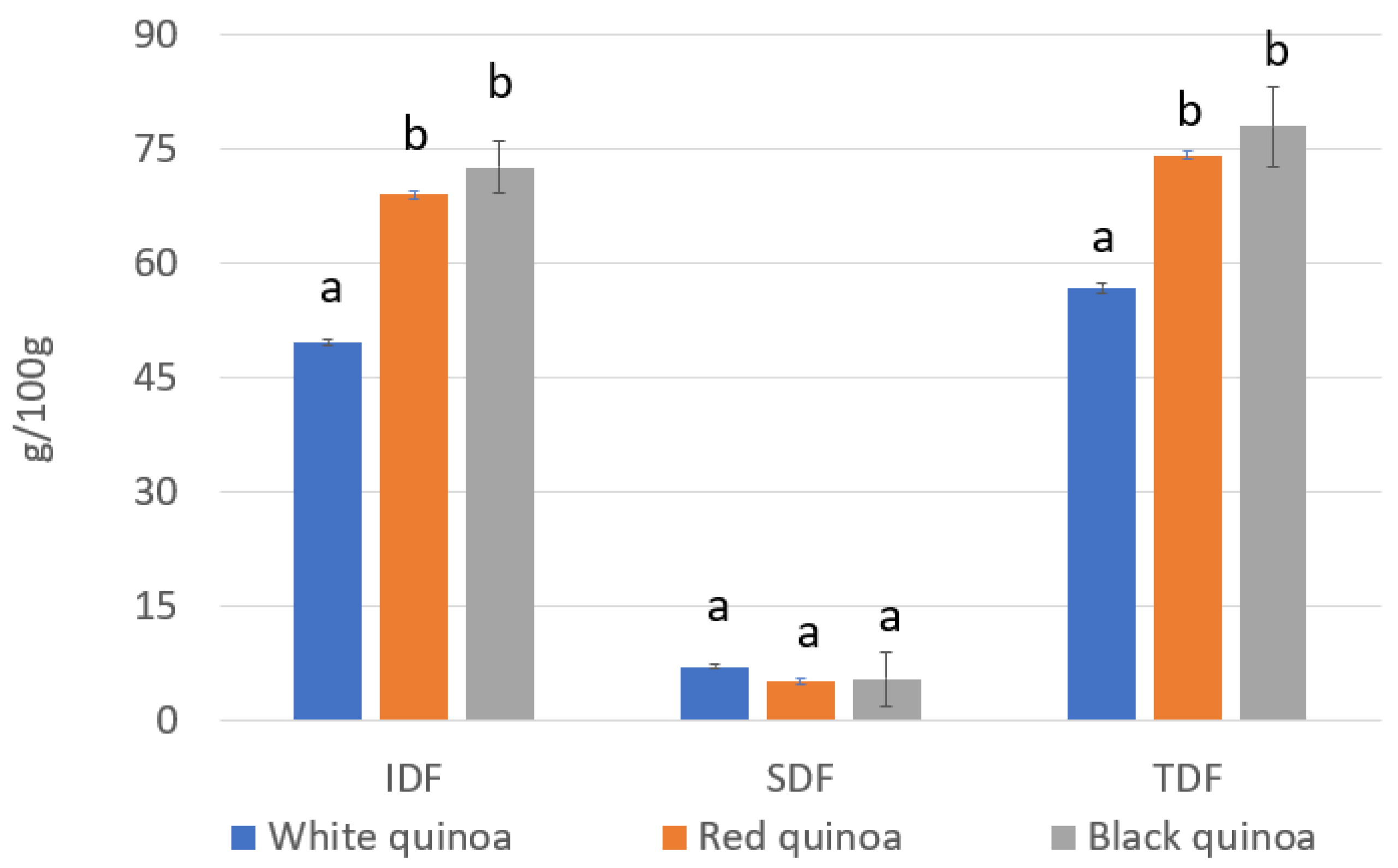

Extraction yield of the quinoa fibre fraction obtained via wet-milling was between 14 and 21% in dry matter. The proximate composition (protein, lipid, starch, ash, and total dietary fibre (TDF) content) is shown in

Figure 4. The fibre fractions show significant differences (

p < 0.05) with respect to the TDF, with black quinoa having the highest proportion, followed by red quinoa. However, no significant differences were observed in the percentages of SDF between the different fractions (

Figure 5). In terms of their technofunctional properties, the red quinoa fibre presented between 40 and 60% more water and oil retention capacity, as well as more swelling power than the rest of the fibres studied.

In general, the quinoa fibre showed high concentrations of minerals Ca, Fe, Zn, and P (

Figure 6). No significant differences were found in the phosphorus of the different dietary fibre fractions of the differently coloured quinoas. However, the high phosphorous could indicate a high phytate content, meaning mineral absorption may be compromised due to the formation of insoluble compounds with phytates.

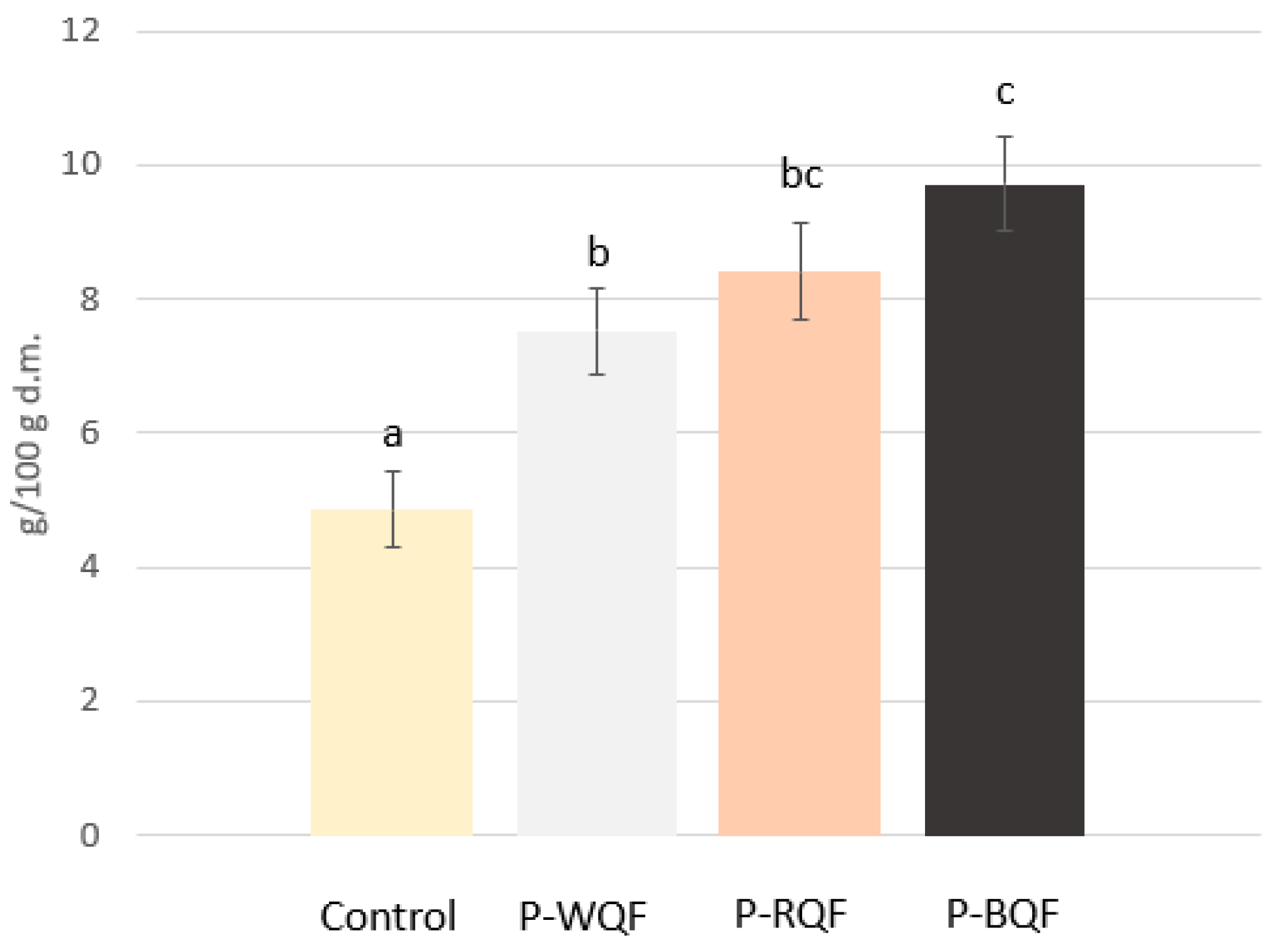

The intake of 100 g of pasta fortified with a 5–10% fraction of dietary fibre sourced from white, red, or black quinoa fibre can contribute approximately 35% of an adult’s daily fibre requirement (

Figure 7 and

Figure 8).

4. Conclusions

All fibre fractions obtained through the wet-milling process have the potential to serve as valuable food ingredients. Notably, the fibre-rich fraction extracted from black quinoa boasts the highest content of insoluble fibre. However, considering technological aspects, the fibre derived from red quinoa emerges as an optimal candidate for incorporation into food formulations. This is attributed to its capacity for water and oil retention, alongside its ability to swell.

Incorporating a modest proportion of dietary fibre sourced from quinoa can significantly enhance the nutritional value of cereal-based food products.

Author Contributions

Conceptualization, C.M.H.; Funding acquisition, C.M.H.; Investigation, A.A.-Á. and C.M.H.; Methodology, A.A.-Á. and C.M.H.; Project administration, C.M.H.; Supervision, C.M.H.; Writing—original draft, A.A.-Á. and C.M.H.; Writing—review and editing, C.M.H. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by grants Ia ValSe-Food-CYTED (Iberoamerican Valuable Seeds—119RT0567) and Food4ImNut (PID2019-107650RB-C21) of the Ministry of Science and Innovation (MICINN-Spain).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to their privacy.

Acknowledgments

The contract of Andrea Alonso-Álvarez from INVESTIGO Program within the framework of the Recovery, Transformation and Resilience Plan—Government of Spain, in the Generalitat Valenciana, is gratefully acknowledged. The authors sincerely thank Ana Belén Romero Alonso for her important collaboration in generating some of the results presented in this publication.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Slavin, J. Fiber and Prebiotics: Mechanisms and Health Benefits. Nutrients 2013, 5, 1417–1435. [Google Scholar] [CrossRef] [PubMed]

- Nohra, E.; Bochicchio, G.V. Management of the Gastrointestinal Tract and Nutrition in the Geriatric Surgical Patient. Surg. Clin. 2015, 95, 85–101. [Google Scholar] [CrossRef] [PubMed]

- Jones, J.M. CODEX-aligned dietary fiber definitions help to bridge the ‘fiber gap’. Nutr. J. 2014, 13, 34. [Google Scholar] [CrossRef] [PubMed]

- Prego, I.; Maldonado, S.; Otegui, M. Seed Structure and Localization of Reserves in Chenopodium quinoa. Ann. Bot. 1998, 82, 481–488. [Google Scholar] [CrossRef]

- Ballester-Sánchez, J.; Gil, J.V.; Fernández-Espinar, M.T.; Haros, C.M. Quinoa wet-milling: Effect of steeping conditions on starch recovery and quality. Food Hydrocoll. 2019, 89, 837–843. [Google Scholar] [CrossRef]

- AOAC Official Method 996.11, Starch (Total) in Cereal Products. Amyloglucosidase-α-Amylase Method First Action 1996, AOAC-AACC Method. Available online: http://www.aoacofficialmethod.org/index.php?main_page=product_info&products_id=1546 (accessed on 15 July 2023).

- ISO/TS 16634-2:2016; Food Products—Determination of the Total Nitrogen Content by Combustion According to the Dumas Principle and Calculation of the Crude Protein Content—Part 2: Cereals, Pulses and Milled Cereal Products. ISO: Geneva, Switzerland, 2016.

- Cereals and Grains Association. 30-25.01 Crude Fat in Wheat, Corn, and Soy Flour, Feeds, and Mixed Feeds. In AACC Approved Methods of Analysis, 11th ed.; Cereals and Grains Association: St. Paul, MN, USA, 2000. [Google Scholar]

- ISO 2171:1980; Cereals, Pulses and Derived Products—Determination of Ash. ISO: Geneva, Switzerland, 1980.

- ICC 104/1; Determination of Ash in Cereals and Cereal Products. ICC: Vienna, Austria, 1990.

- AOAC Official Method 991.43 Total, Soluble, and Insoluble Dietary Fibre in Foods. 1996. Available online: https://acnfp.food.gov.uk/sites/default/files/mnt/drupal_data/sources/files/multimedia/pdfs/annexg.pdf (accessed on 6 August 2023).

- Cereals and Grains Association. 32-07.01 Soluble, Insoluble, and Total Dietary Fiber in Foods and Food Products. In AACC Approved Methods of Analysis, 11th ed.; Cereals and Grains Association: St. Paul, MN, USA, 2000. [Google Scholar]

- Miranda-Ramos, K.; Millán-Linares, M.C.; Haros, C.M. Effect of Chia as Breadmaking Ingredient on Nutritional Quality, Mineral Availability, and Glycemic Index of Bread. Foods 2020, 9, 663. [Google Scholar] [CrossRef] [PubMed]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).