Study on the Aerodynamic Wind Pressure Behavior Characteristics of High-Speed Railway Sound Barriers

Abstract

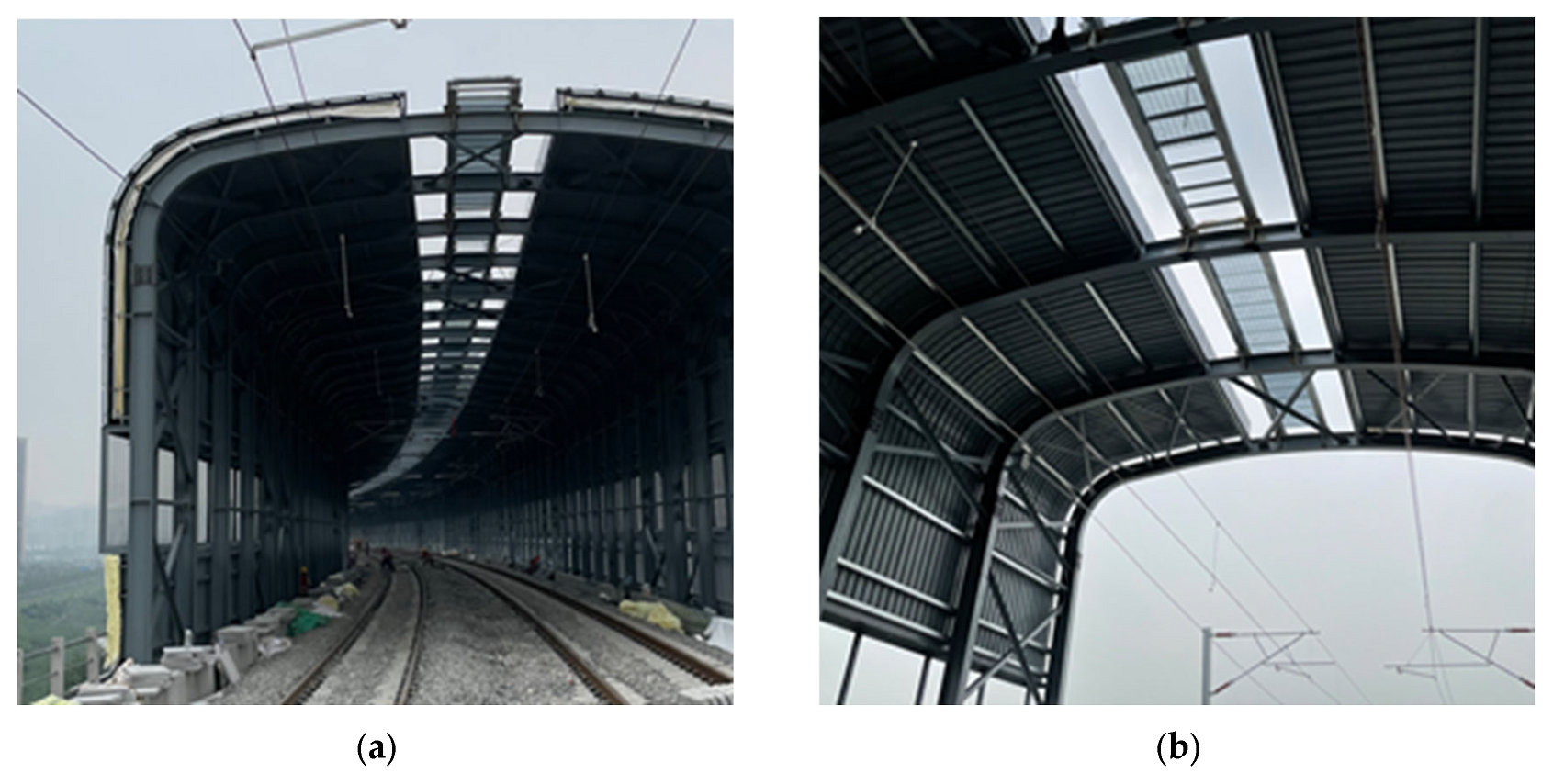

1. Introduction

2. Numerical Analysis Theory and Model

2.1. Computational Method

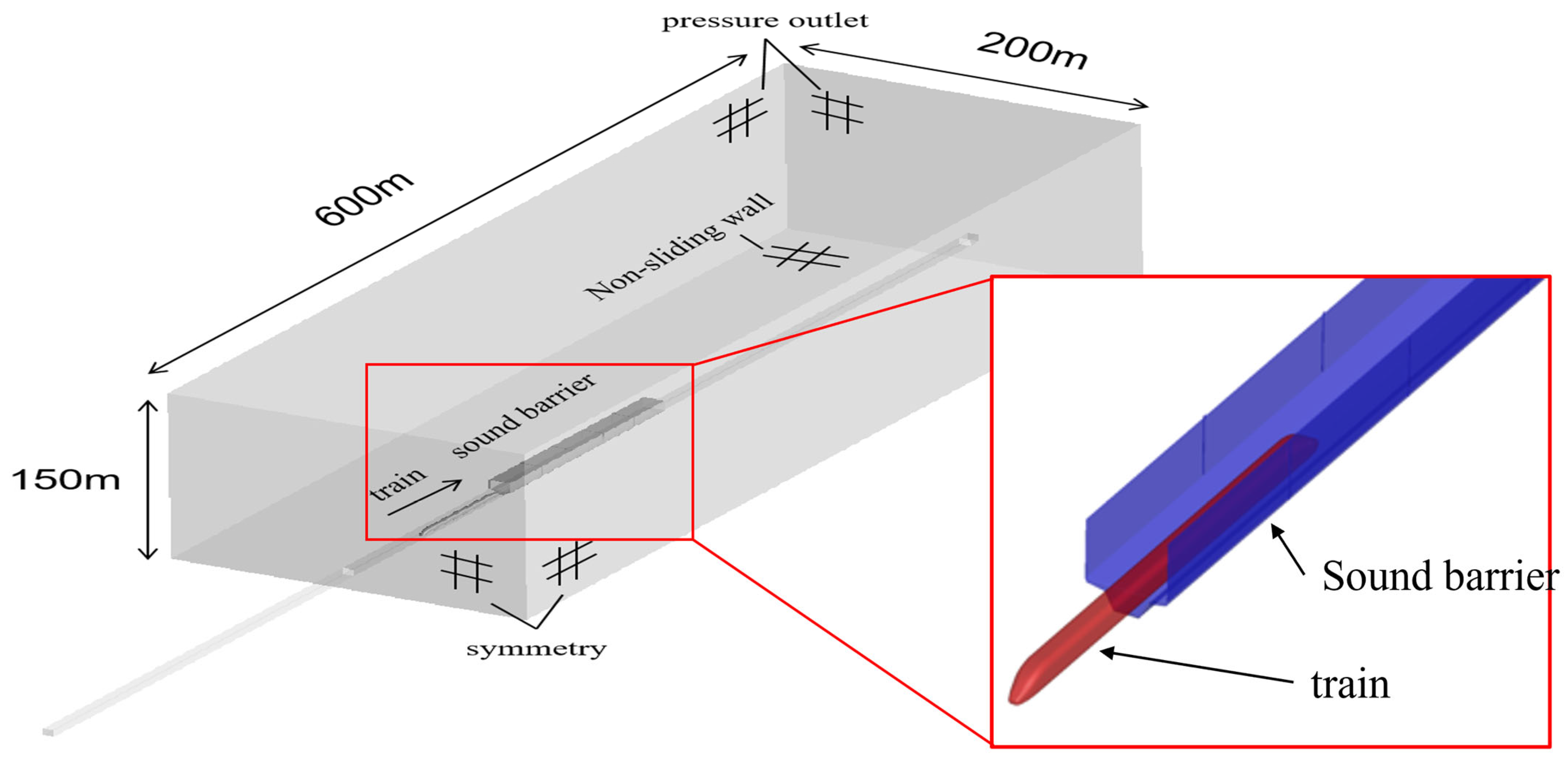

2.2. Computational Domain and Boundary Conditions

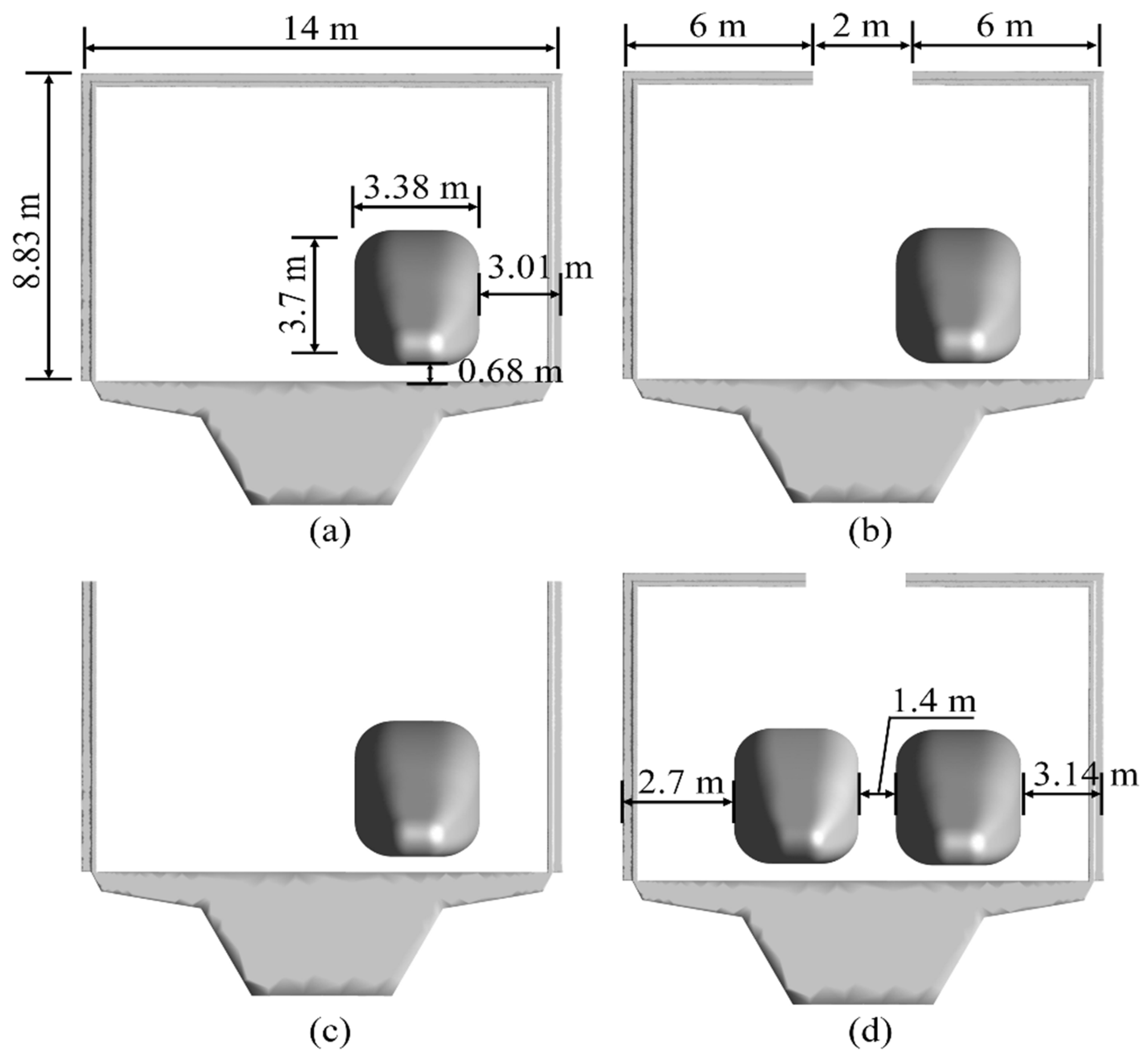

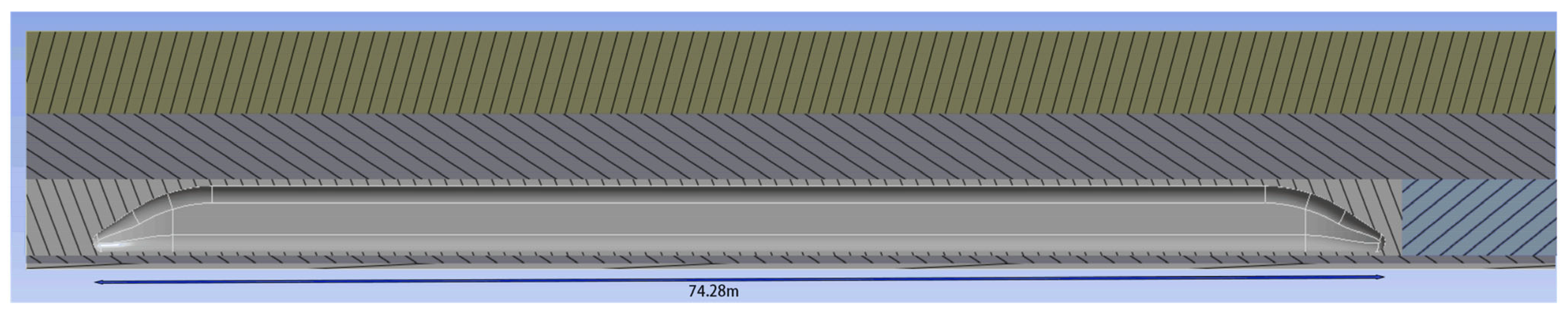

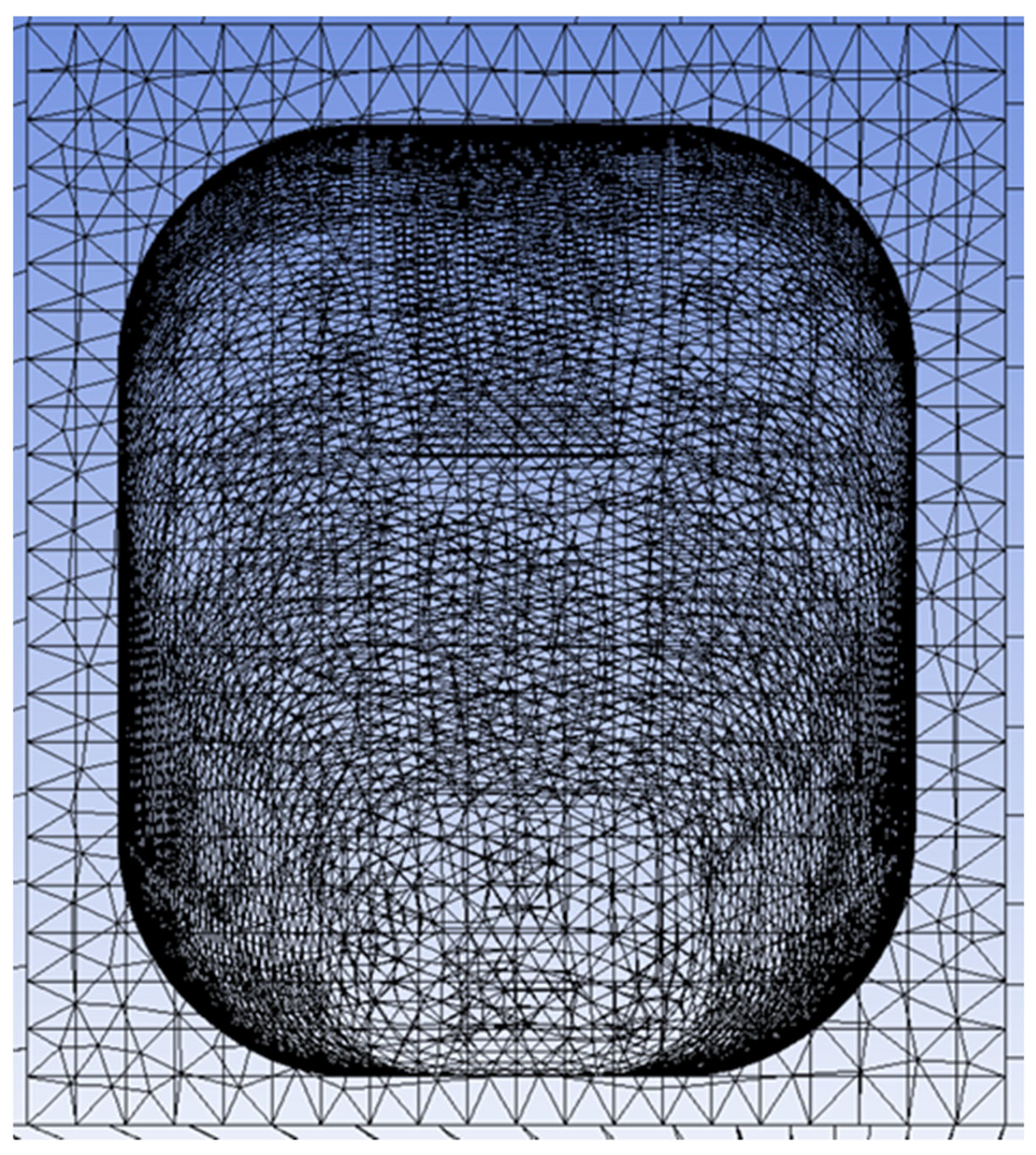

2.3. Geometry Model and Mesh

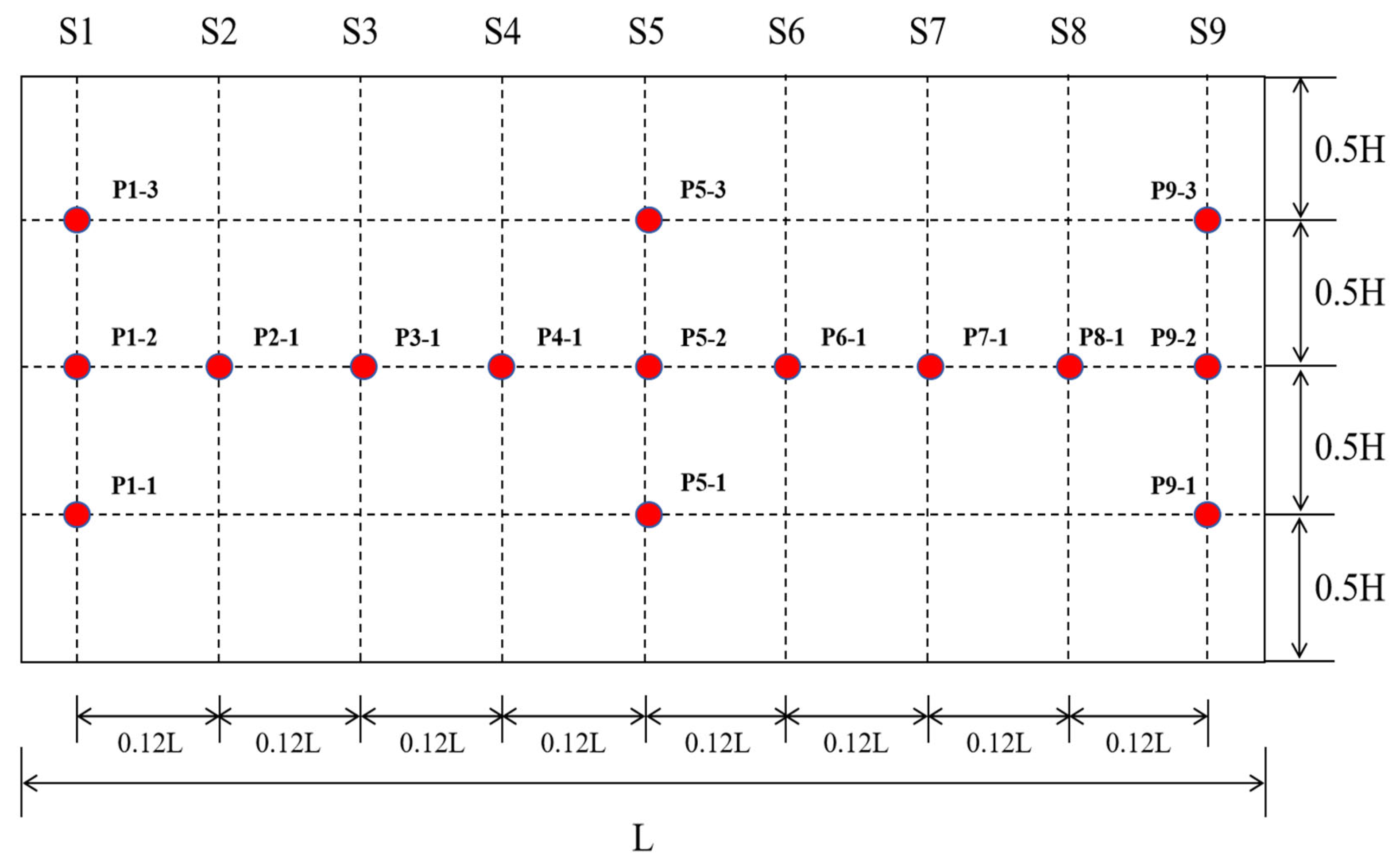

2.4. Arrangement of Measurement Points

3. Numerical Validations

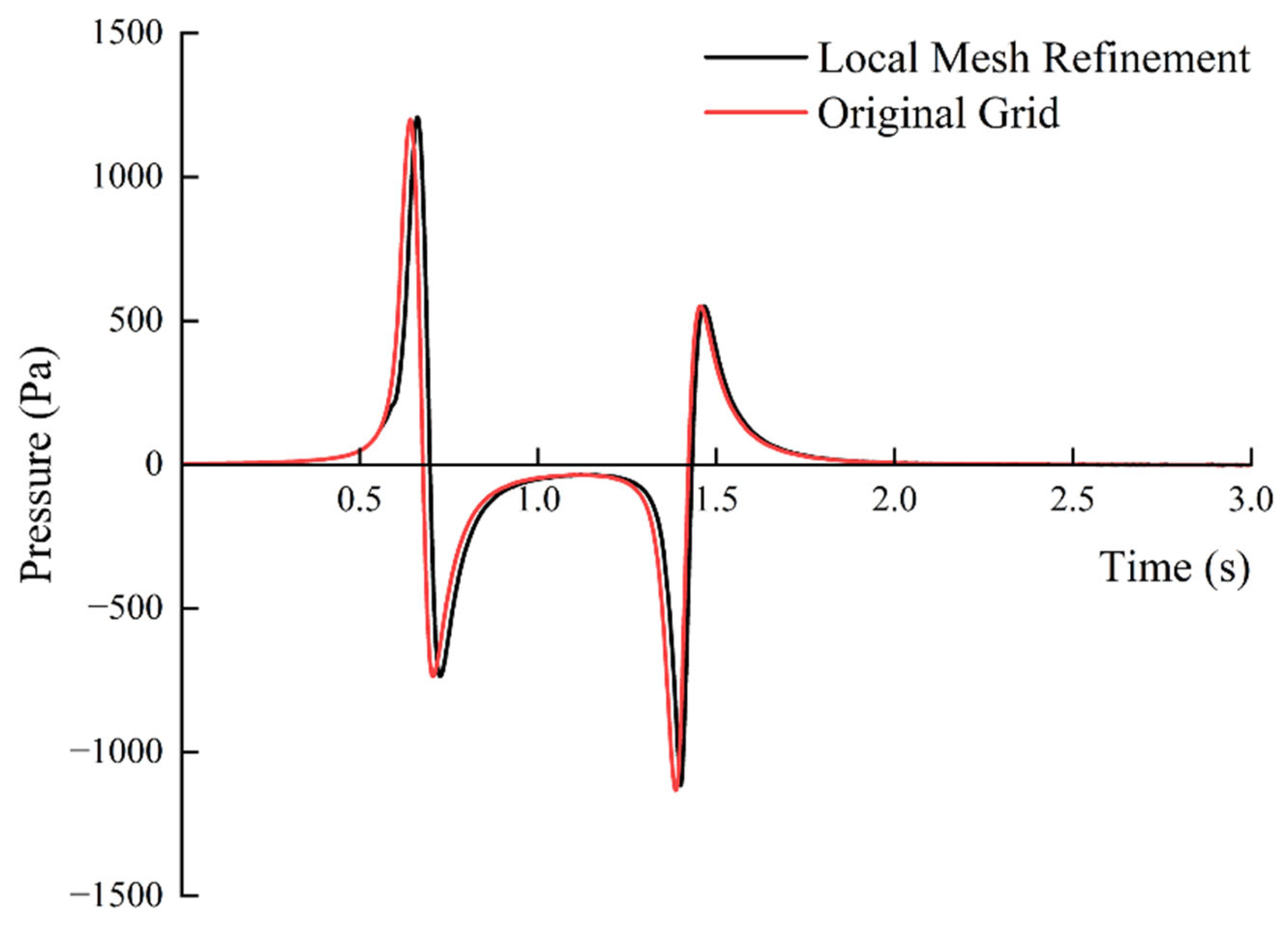

3.1. Grid Independence Verification

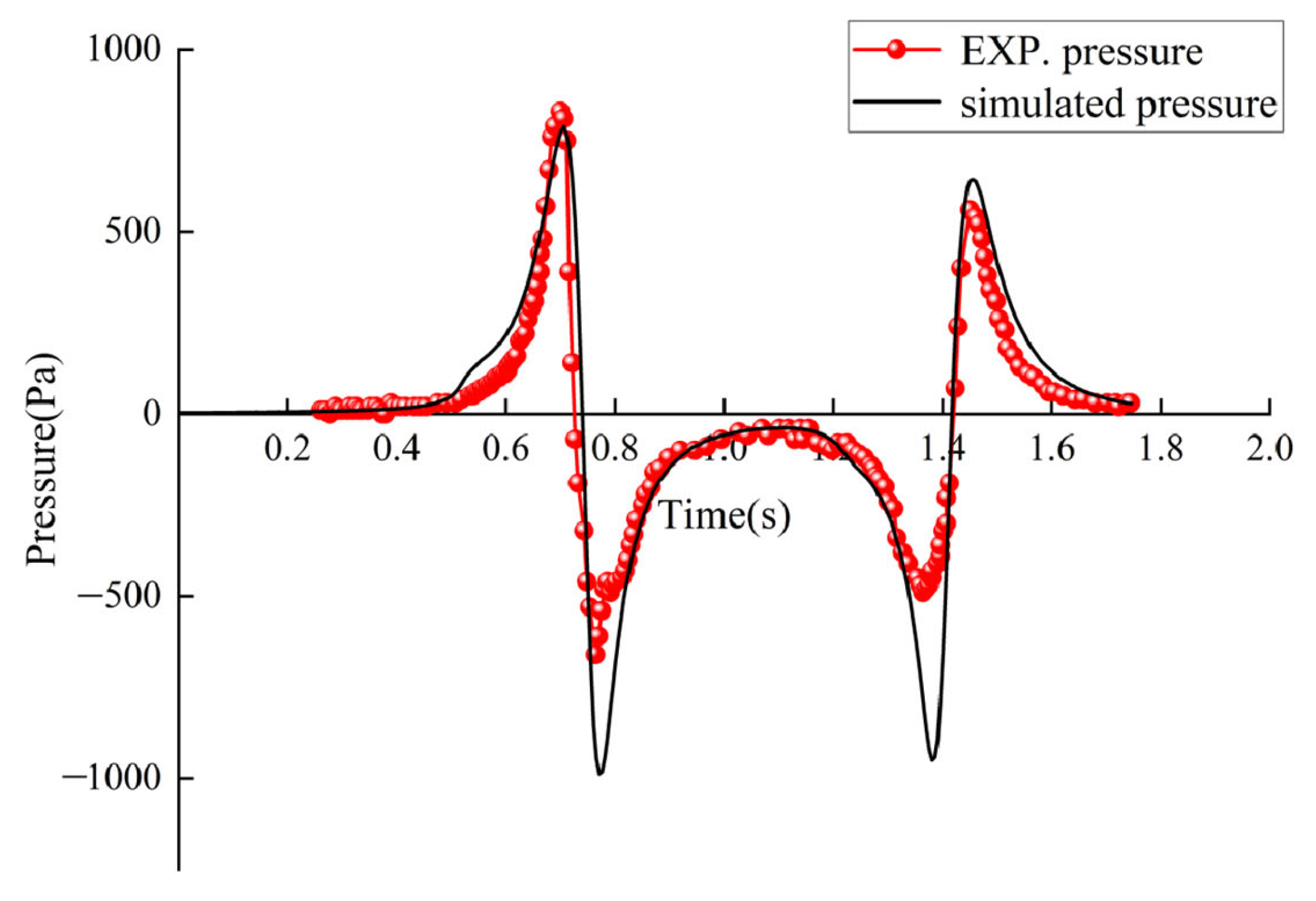

3.2. Comparison of Simulated and Measured Data

4. Numerical Results and Discussions

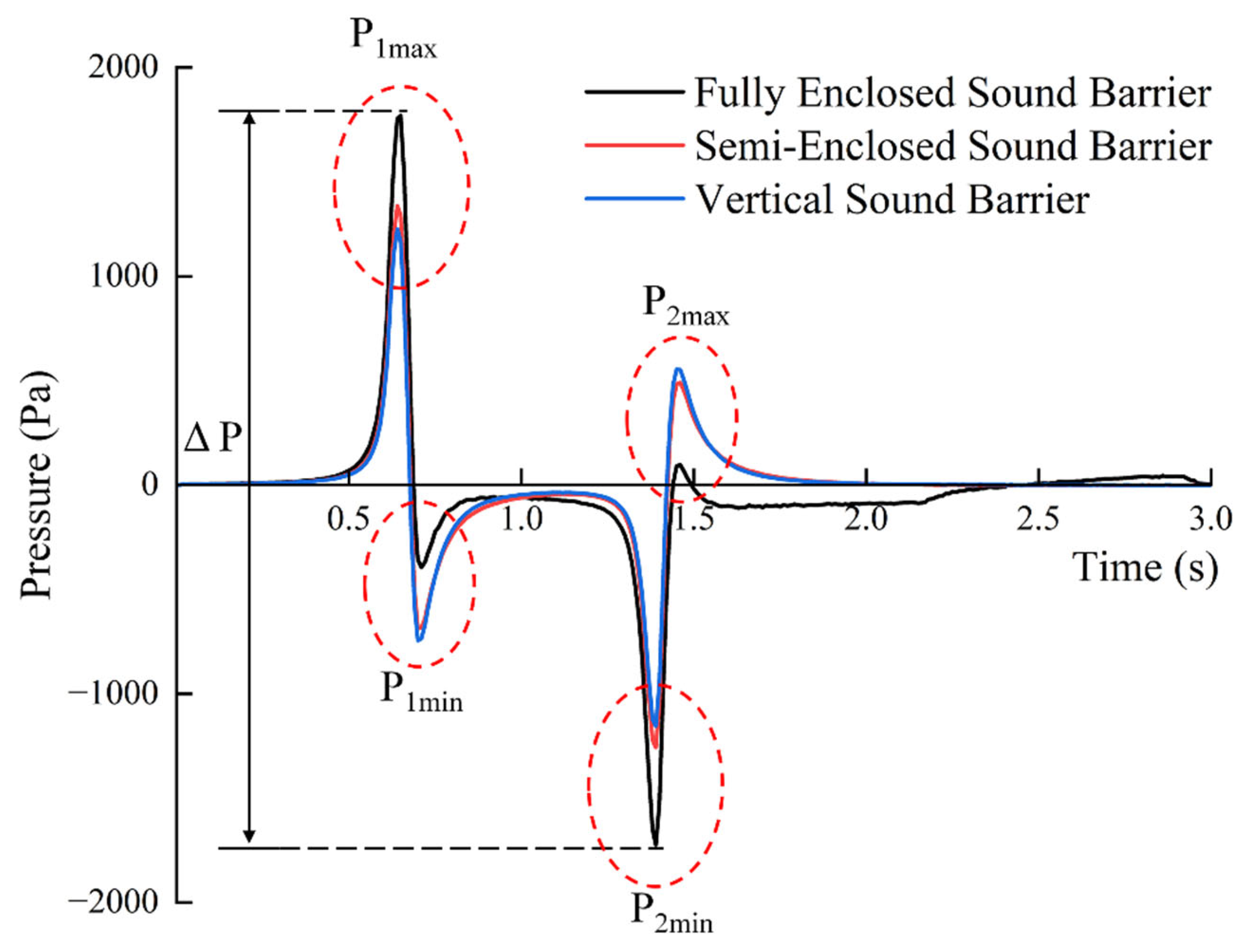

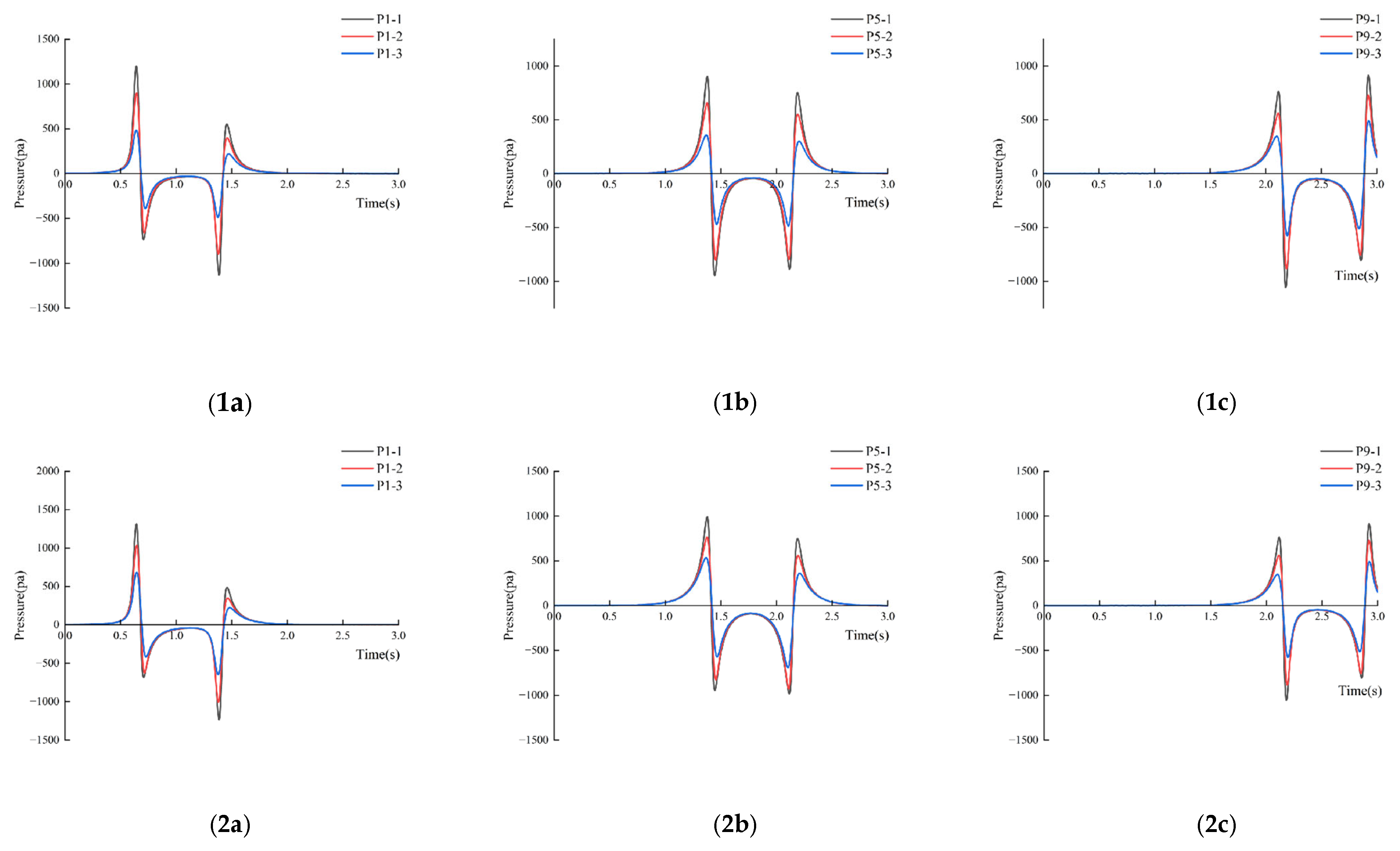

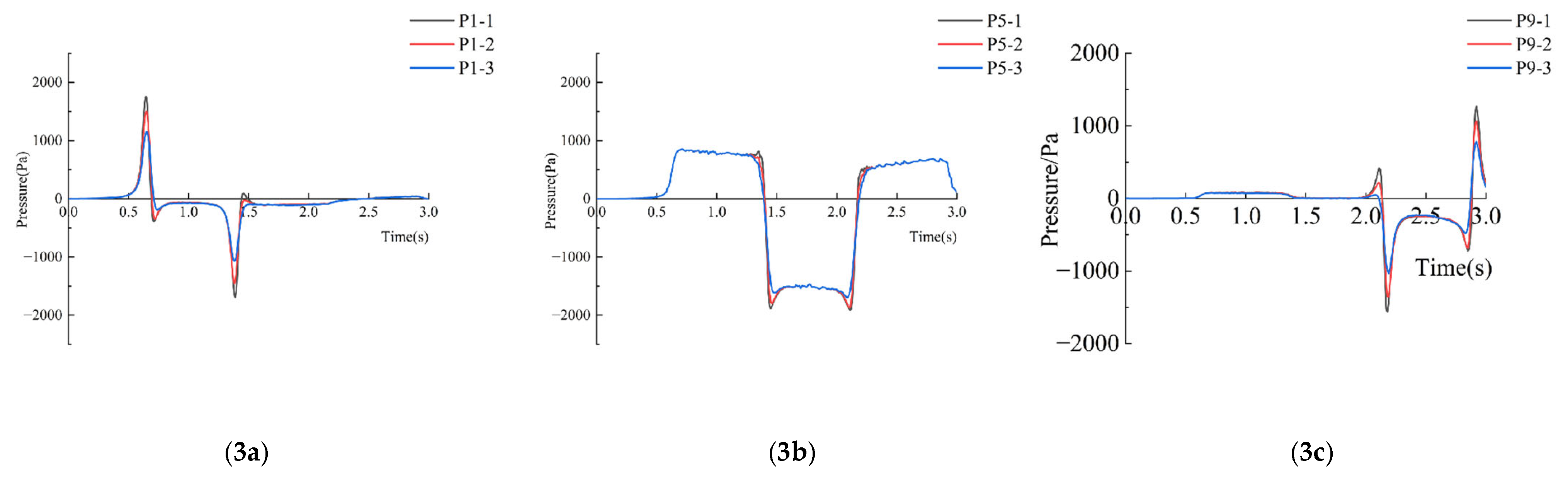

4.1. Fluctuating Wind Pressure on the Sound Barrier

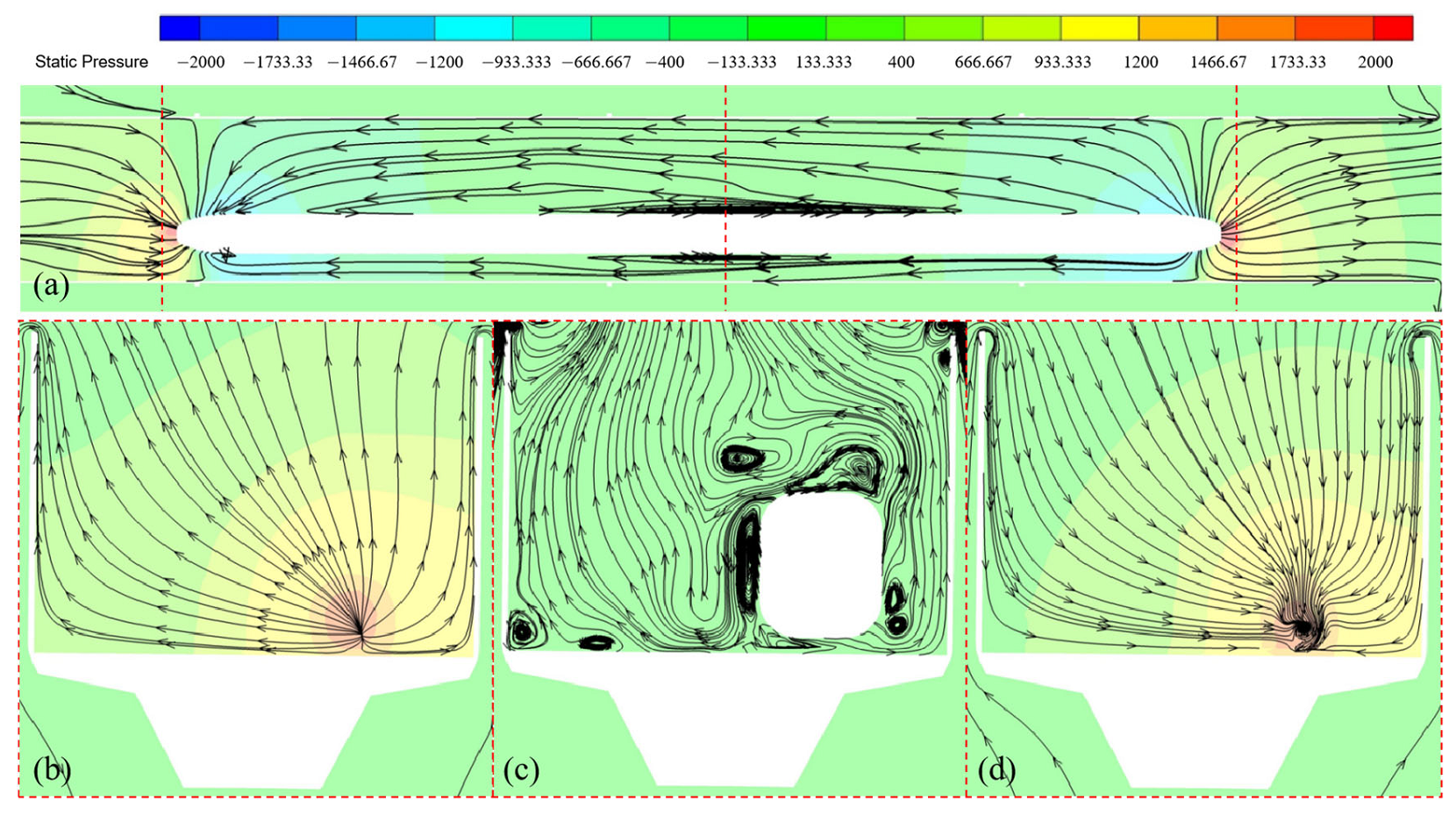

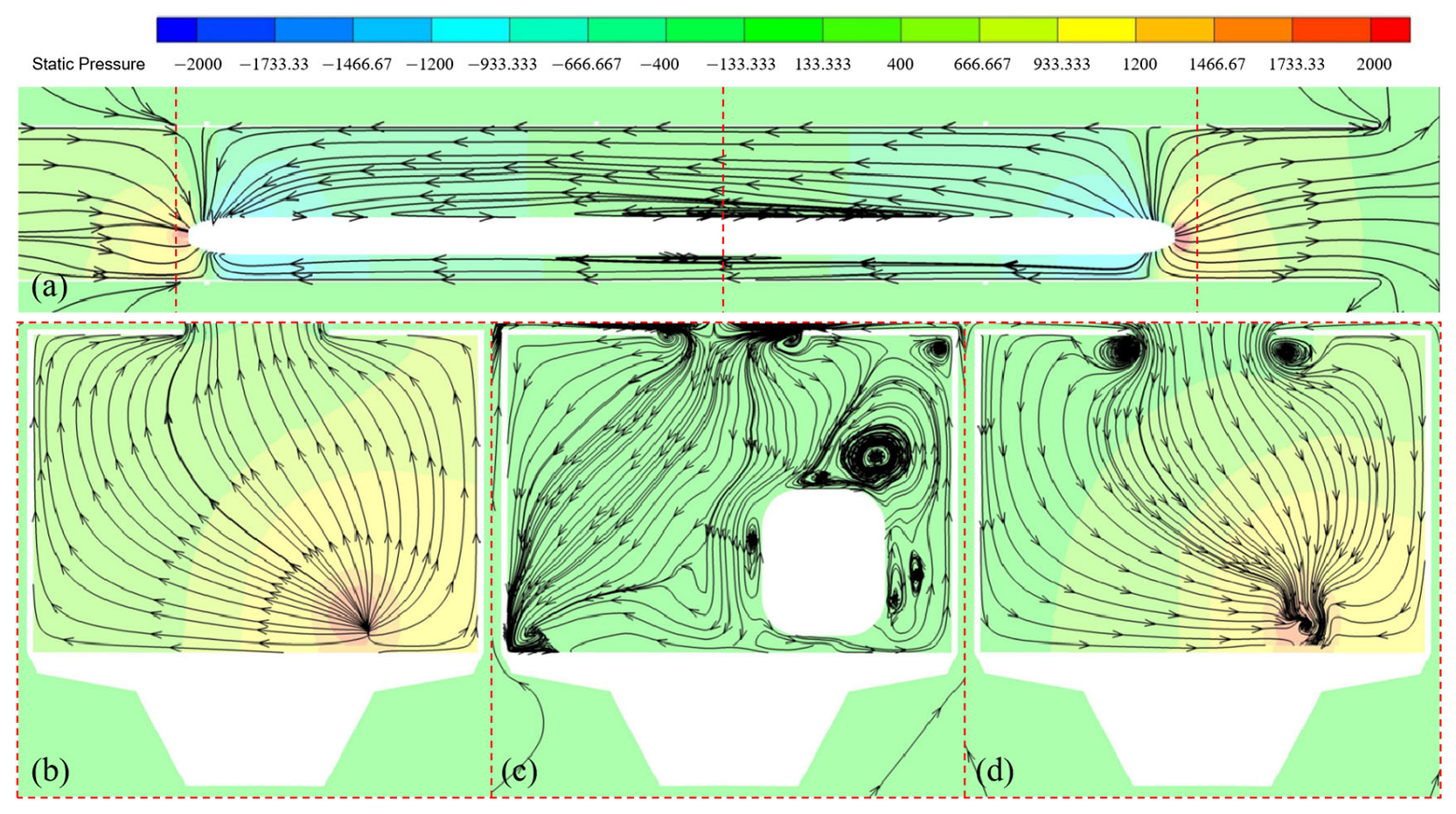

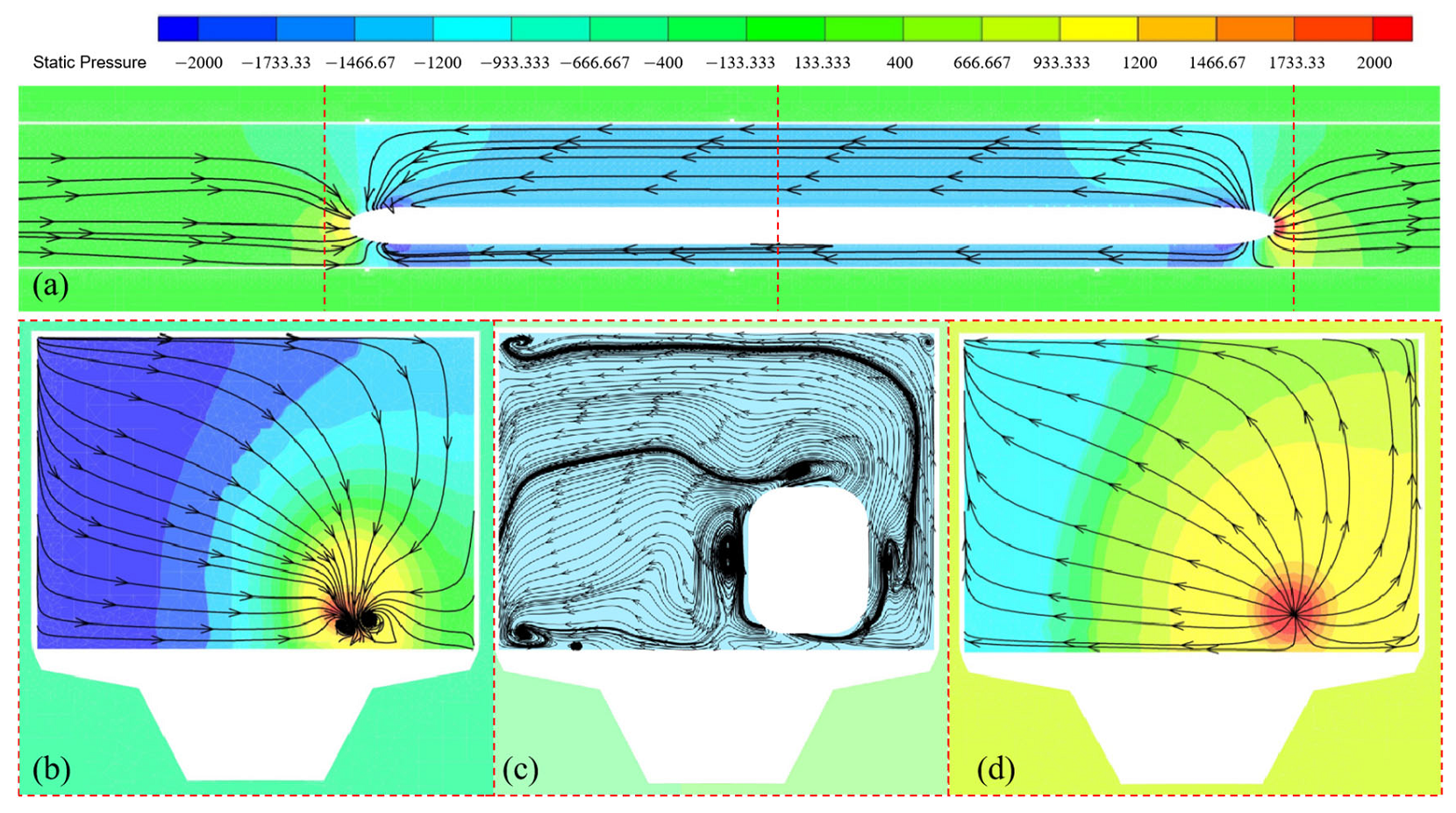

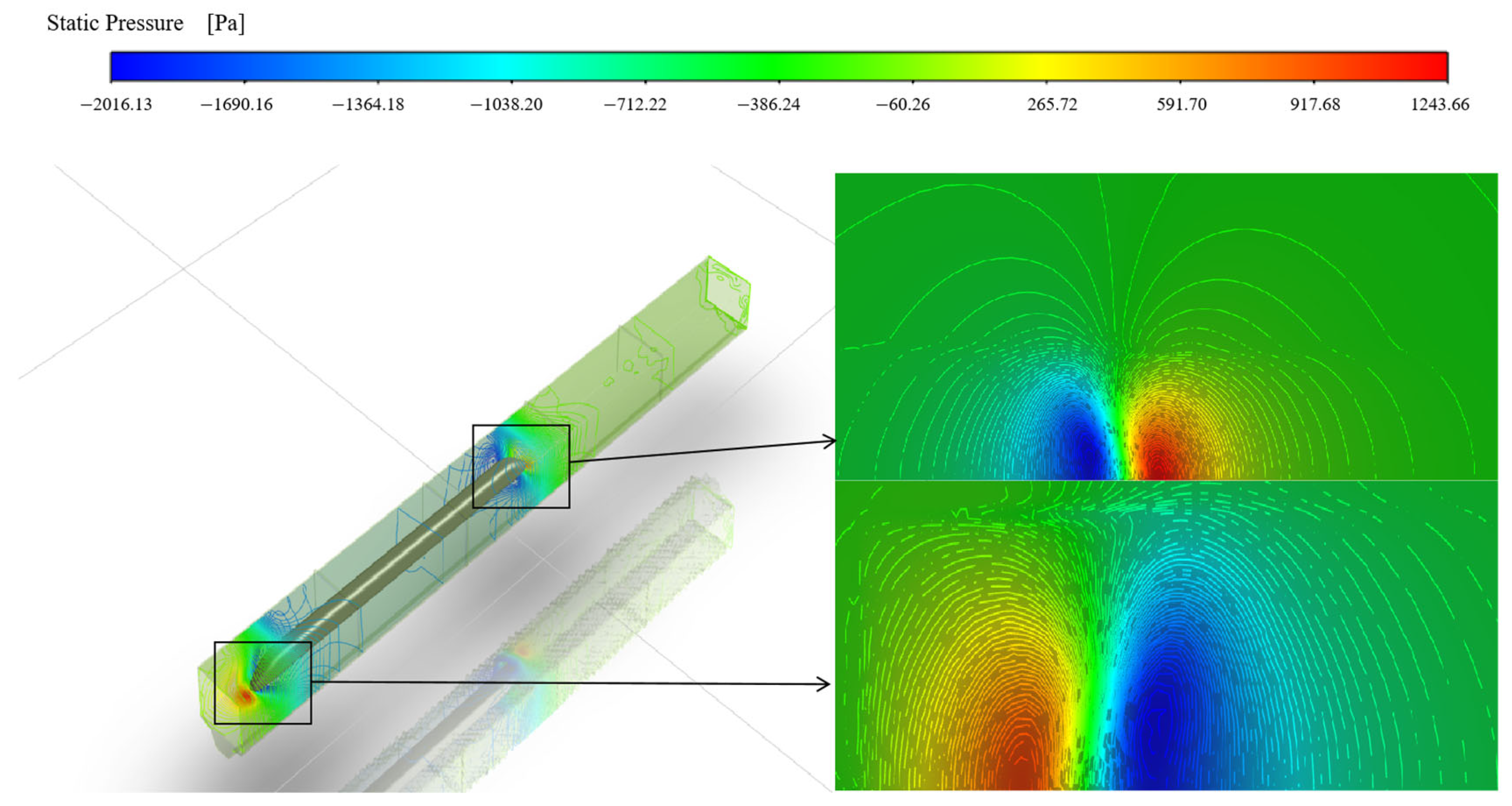

4.1.1. Global Distribution of the Pressure Induced by a Single Train

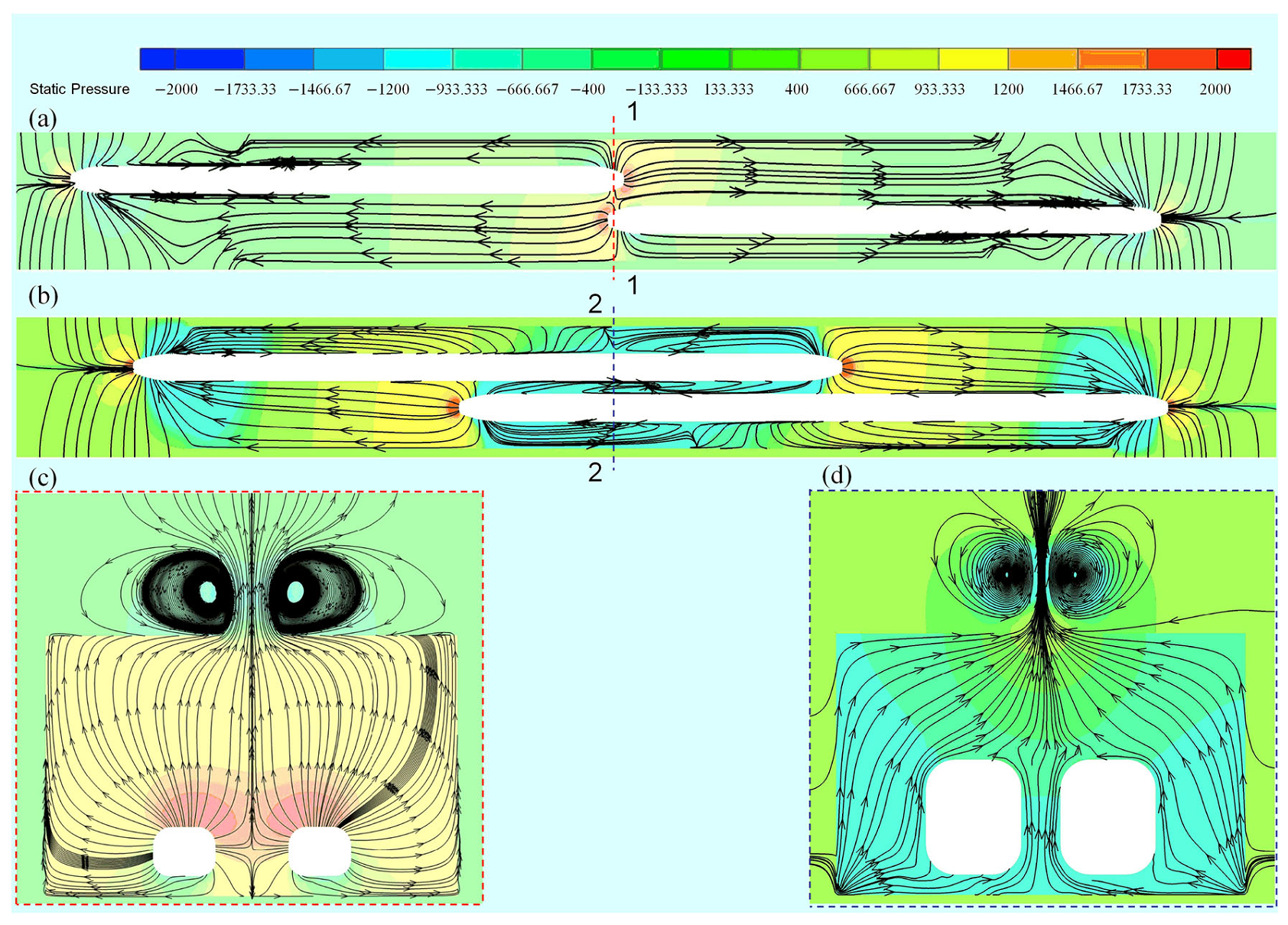

4.1.2. Global Distribution of the Pressure Induced by Double-Trains

4.1.3. Point Pressure (Point P1-1) Induced by a Single Train

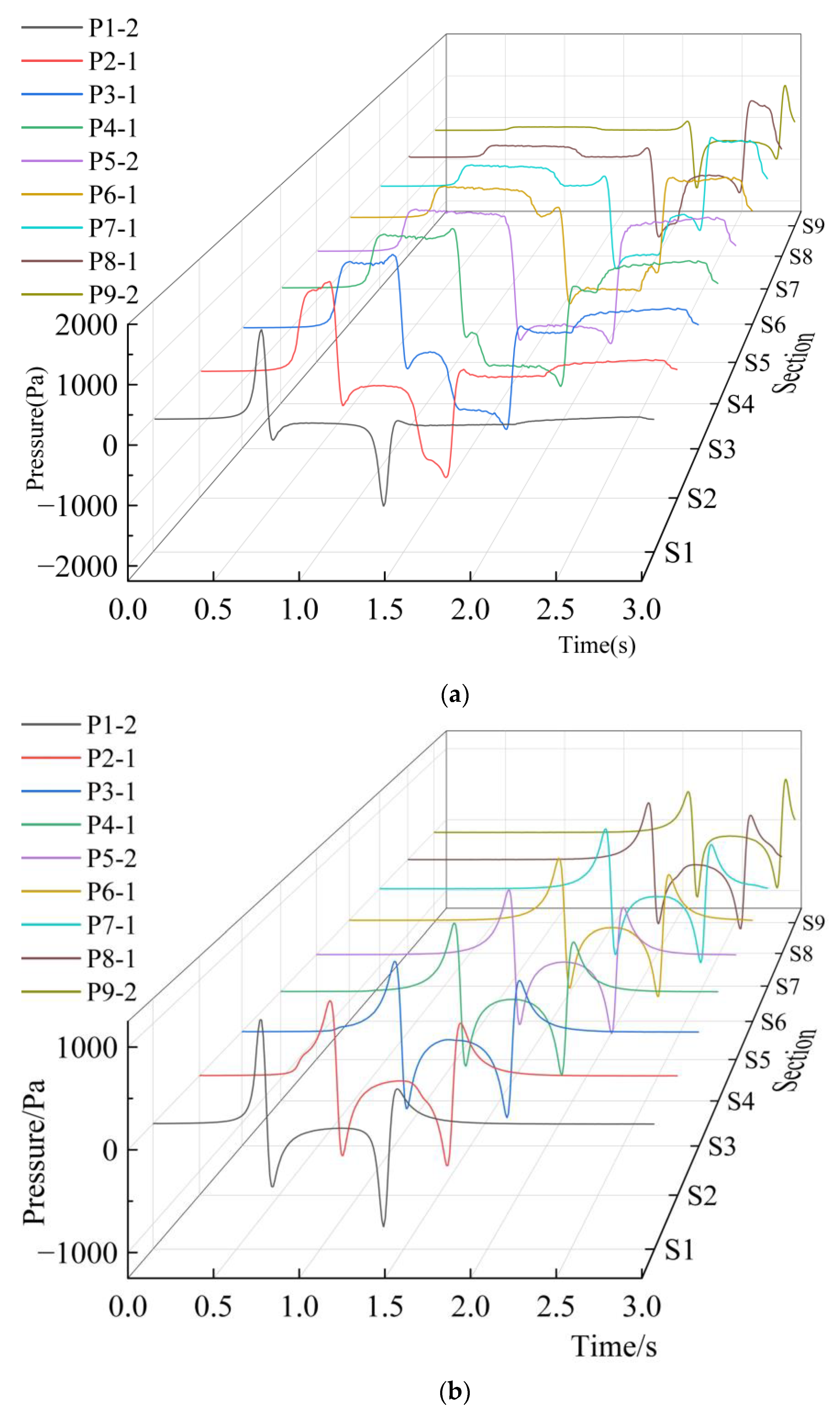

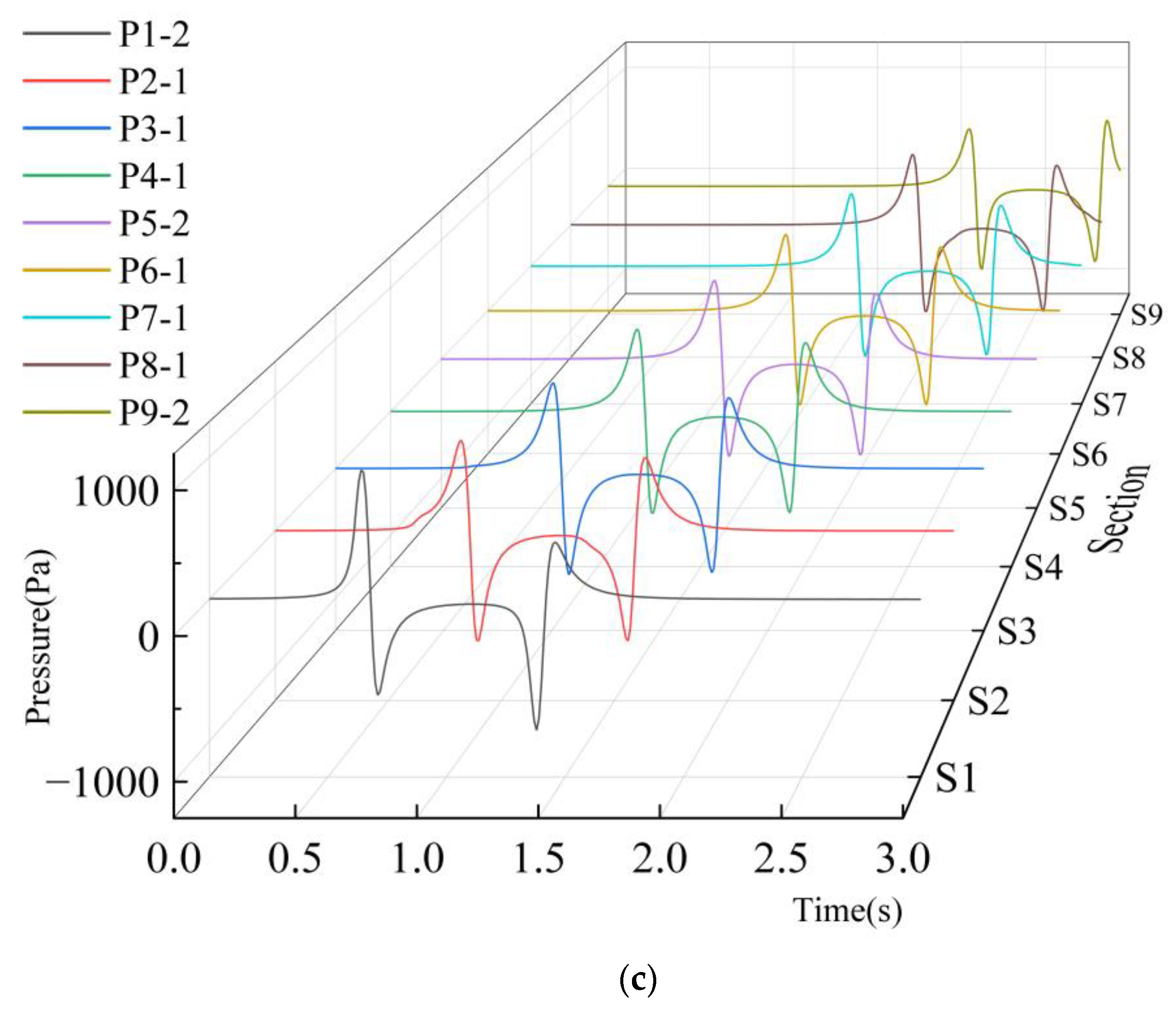

4.1.4. Line Pressure Induced by a Single Train

4.2. Variation in Aerodynamic Pressure Along the Height of the Sound Barrier

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, H.; Hu, Z.; Thompson, D. Effect of cavity flow control on high-speed train pantograph and roof aerodynamic noise. Railw. Eng. Sci. 2020, 28, 54–74. [Google Scholar]

- Wang, D.; Ge, J. Vibration and acoustic radiation of bogie area under random excitation in high-speed trains. J. Mod. Transp. 2019, 27, 120–128. [Google Scholar]

- Thompson, D.J.; Iglesias, E.L.; Liu, X.; Zhu, J.; Hu, Z. Recent developments in the prediction and control of aerodynamic noise from high-speed trains. Int. J. Rail Transp. 2015, 3, 119–150. [Google Scholar]

- Iglesias, E.L.; Thompson, D.J.; Smith, M.; Kitagawa, T.; Yamazaki, N. Anechoic wind tunnel tests on high-speed train bogie aerodynamic noise. Int. J. Rail Transp. 2017, 5, 87–109. [Google Scholar]

- Jiang, L.; Kang, J. Combined acoustical and visual performance of noise barriers in mitigating the environmental impact of motorways. Sci. Total Environ. 2016, 543, 52–60. [Google Scholar]

- Luo, W.; Chen, J. Study on the contribution of frequency characteristics of sound-absorbing sound barriers to noise reduction. Urban Mass Transit 2017, 20, 171–173. [Google Scholar]

- Luo, W.; Li, H.; Chen, J. Comparison of noise reduction effects of various sound-absorbing sound barriers. Urban Mass Transit 2017, 20, 101–103+116. [Google Scholar]

- Li, X.; Yang, D.W.; Gao, W.; Luo, Y.K. Study on Vibration and Noise Reduction of Semi-or Fully Enclosed Noise Barriers of High Speed Railways. Noise Vib. Control 2018, 38 (Suppl. S1), 8–13. [Google Scholar]

- Li, X.; Zhao, Q.; Zhang, X.; Yang, D. Field Test and Analysis of Noise Reduction Performance of High-speed Railway Semi-closed Sound Barriers. J. Southwest Jiaotong Univ. 2018, 53, 755. [Google Scholar]

- Wen, W.; Lei, K.; Yang, D.; Li, X. Full-scale Model Test Study on Noise Reduction Characteristics of Fully Enclosed Sound Barriers for High-speed Railways. J. China Railw. Soc. 2021, 43, 193–199. [Google Scholar]

- Xin, S.; Zhang, S.; Wang, X. Study on Noise Reduction Effect of Fully Enclosed Sound Barriers on the Beijing-Xiong’an Intercity Railway. Railw. Stand. Des. 2022, 66, 163–168. [Google Scholar]

- Song, Y.; Zhang, M.; Iseth, O.; Rnnquist, A. Wind deflection analysis of railway catenary under crosswind based on nonlinear finite element model and wind tunnel test. Mech. Mach. Theory 2022, 168, 104608. [Google Scholar] [CrossRef]

- Baker, C.; Jones, J.; Lopez-Calleja, F.; Munday, J. Measurements of the cross wind forces on trains. Wind. Eng. Ind. Aerodyn. 2004, 92, 547–563. [Google Scholar] [CrossRef]

- Wang, D.; Wang, B.; Chen, A. Vehicle-induced aerodynamic loads on highway sound barriers part 2: Numerical and theoretical investigation. Wind. Struct. Int. J. 2013, 17, 479–494. [Google Scholar] [CrossRef]

- Lichtneger, P.; Ruck, B. Full scale experiments on vehicle induced transient pressure loads on roadside walls. J. Wind. Eng. Ind. Aerodyn. J. Int. Assoc. Wind Eng. 2018, 174, 451–457. [Google Scholar] [CrossRef]

- Yao, S.; Li, R.; Kang, J. Strength calculation of the noise barrier under the wind loads caused by train on high speed railway. Transp. Eng. Inf. 2015, 13, 39–44. [Google Scholar]

- Belloli, M.; Pizzigoni, B.; Ripamonti, F.; Rocchi, D. Fluid-structure interaction between trains and noise-reduction barriers: Numerical and experimental analysis. WIT Trans. Built Environ. 2009, 105, 49–60. [Google Scholar]

- He, X.; Guo, K.; Yang, B. Numerical simulation study of 840 m fully enclosed sound barrier barometric load of high-speed railway. China Railw. Sci. 2020, 41, 137–144. [Google Scholar]

- He, X.; Ji, X.; Jing, H.; Ge, H.; Zhang, J. Numerical Simulations of the Pressure Waves and Micro Pressure Waves Generated by a High-speed Train Passing through an Enclosed Sound Barrier. Acta Aerodyn. Sin. 2021, 39, 142–150. [Google Scholar]

- Long, L.; Zhao, L.; Liu, L. Study on Air Pulsating Force of Train-induced Sound Barrier Structure. Eng. Mech. 2010, 27, 246–250. [Google Scholar]

- Han, J.; Pan, X.; Ji, X. Study on the time-varying characteristics of pulsating wind pressure of semi-enclosed sound barrier of 350 km/h high-speed railway. Railw. Stand. Des. 2025, 69, 191–197. [Google Scholar]

- Jing, H.; Peng, T.; He, X.; Zhou, J.; Zhang, S.; Zhang, H. Experimental Study on Wind Pressure Load of Enclosed Sound Barriers for High-speed Railways. J. Railw. Sci. Eng. 2021, 18, 1960–1967. [Google Scholar]

- Han, Y.; Yao, S. Scale effect analysis in aerodynamic performance of high-speed train. J. Zhejiang Univ. Eng. Sci. 2017, 51, 2383–2391. (In Chinese) [Google Scholar]

- EN14067-6; Railway Applications-Aerodynamics. Part 6: Requirements and Test Procedures for Cross Wind Assessment. European Committee for Standarization (CEN): Bressels, Belgium, 2018.

- Chen, X. Research on the Aerodynamic Pressure Characteristics of the Fully Enclosed Sound Barrier for High-Speed Railway Trains. Ph.D. Thesis, Shijiazhuang Tiedao University, Shijiazhuang, China, 2023. [Google Scholar]

- Li, Y.; Chen, X. Study on Aerodynamic Load of Fully Enclosed Sound Barriers for High-speed Railways Induced by Train Operation. Railw. Eng. 2023, 63, 81–88. [Google Scholar]

- Qin, X.; Li, X.; Zheng, J.; Wang, M. Fluctuating wind pressure on vertical sound barrier during two high-speed trains passing each other. Int. J. Rail Transp. 2023, 11, 111–128. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, R.; Yang, Q.; Li, H.; Zhang, D.; Zheng, S.; Yang, S. Study on the Aerodynamic Wind Pressure Behavior Characteristics of High-Speed Railway Sound Barriers. Dynamics 2025, 5, 14. https://doi.org/10.3390/dynamics5020014

Zhang R, Yang Q, Li H, Zhang D, Zheng S, Yang S. Study on the Aerodynamic Wind Pressure Behavior Characteristics of High-Speed Railway Sound Barriers. Dynamics. 2025; 5(2):14. https://doi.org/10.3390/dynamics5020014

Chicago/Turabian StyleZhang, Rui, Qingyuan Yang, Hui Li, Dazheng Zhang, Siyu Zheng, and Shengyou Yang. 2025. "Study on the Aerodynamic Wind Pressure Behavior Characteristics of High-Speed Railway Sound Barriers" Dynamics 5, no. 2: 14. https://doi.org/10.3390/dynamics5020014

APA StyleZhang, R., Yang, Q., Li, H., Zhang, D., Zheng, S., & Yang, S. (2025). Study on the Aerodynamic Wind Pressure Behavior Characteristics of High-Speed Railway Sound Barriers. Dynamics, 5(2), 14. https://doi.org/10.3390/dynamics5020014