Current Technologies and Target Crops: A Review on Australian Protected Cropping

Abstract

:1. Introduction

2. Current Techniques and Technologies in Protected Cropping

2.1. New Technologies for Low-Tech Poly-Tunnels

2.2. Upgrading Medium-Tech Greenhouses with Innovations and New Technologies

2.3. Innovations of Science and Technology for High-Tech Greenhouses

2.4. Developing Vertical Farms for Future Needs

3. Target Crops in Protected Cropping

- Those that grow on vines or bushes (tomato, strawberry, raspberry, blueberry, cucumber, capsicum, grape, kiwifruit);

- High-value specialist crops (hops, vanilla, saffron, coffee);

- Medicinal and cosmetic crops (seaweed, Echinacea);

- Small trees (cherries, chocolate, mango, almonds) are other viable options [13].

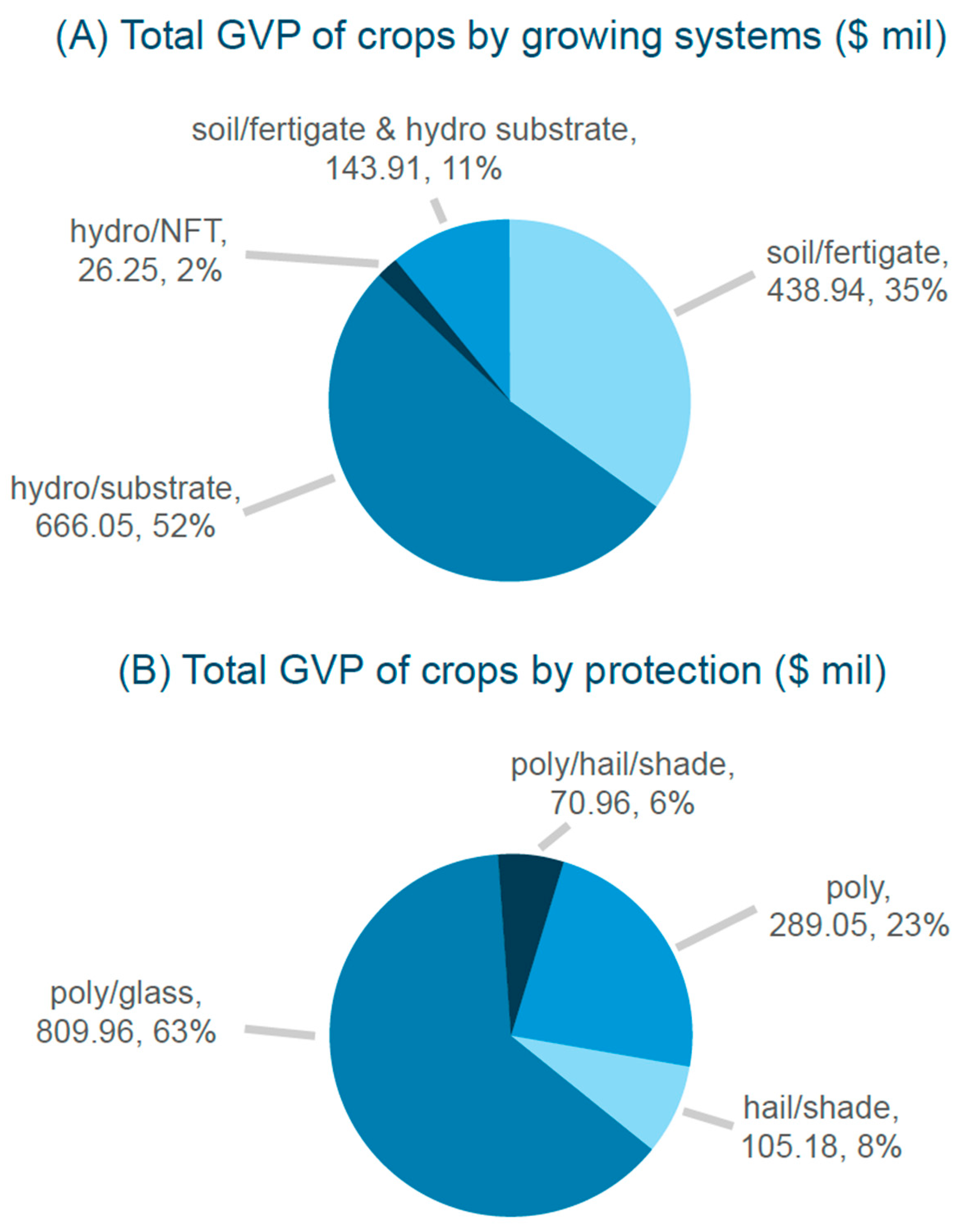

3.1. Existing Crops Grown in Low, Medium and High-Tech Facilities

3.2. Industry Survey: Where Do Participants’ Interests Lie?

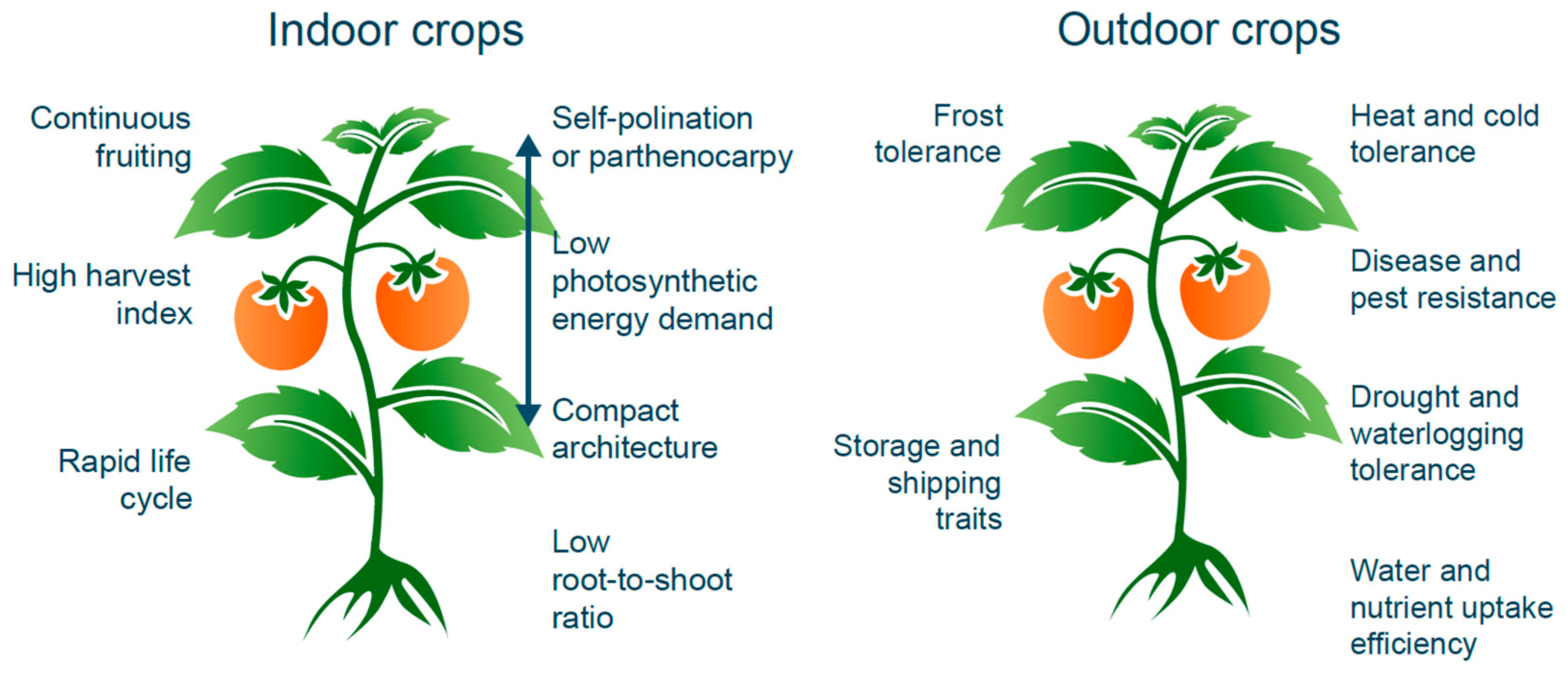

3.3. Breeding New Cultivars for Controlled-Environment Facilities

4. Challenges and Opportunities in Protected Cropping and Indoor Farming

- High capital costs, due to high land prices in inner-urban and peri-urban areas;

- High energy consumption;

- Demand for skilled labour;

- Disease management without chemical controls; and

- Development of nutritional quality indexes—to define and certify quality aspects of the produce—for crops grown indoors.

4.1. Optimal Conditions for High Productivity and Efficient Resource Use

4.2. Pest and Disease Management

4.3. Crop Quality and Nutritional Values

4.4. Employment and Skilled-Labour Availability

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- United Nations Department of Economic and Social Affairs. Available online: https://www.un.org/development/desa/en/news/population/2018-revision-of-world-urbanization-prospects.html (accessed on 13 April 2022).

- United Nations Department of Economic and Social Affairs. Available online: https://www.un.org/development/desa/publications/world-population-prospects-2019-highlights.html (accessed on 13 April 2022).

- Binns, C.W.; Lee, M.K.; Maycock, B.; Torheim, L.E.; Nanishi, K.; Duong, D.T.T. Climate change, food supply, and dietary guidelines. Annu. Rev. Public Health 2021, 42, 233–255. [Google Scholar] [CrossRef] [PubMed]

- Valin, H.; Sands, R.D.; Van Der Mensbrugghe, D.; Nelson, G.C.; Ahammad, H.; Blanc, E.; Bodirsky, B.; Fujimori, S.; Hasegawa, T.; Havlik, P.; et al. The future of food demand: Understanding differences in global economic models. Agric. Econ. 2014, 45, 51–67. [Google Scholar] [CrossRef]

- Hughes, N.; Lu, M.; Ying Soh, W.; Lawson, K. Simulating the effects of climate change on the profitability of australian farms. In ABARES Working Paper; Australia Government: Canberra, Australia, 2021. [Google Scholar] [CrossRef]

- Rabbi, B.; Chen, Z.-H.; Sethuvenkatraman, S. Protected cropping in warm climates: A review of humidity control and cooling METHODS. Energies 2019, 12, 2737. [Google Scholar] [CrossRef] [Green Version]

- Benke, K.; Tomkins, B. Future Food-production systems: Vertical farming and controlled-environment agriculture. Sustain. Sci. Pract. Policy 2017, 13, 13–26. [Google Scholar] [CrossRef] [Green Version]

- Mougeot, L.J.A. Growing Better Cities: Urban Agriculture for Sustainable Development; IDRC: Ottawa, ON, Canada, 2006; ISBN 978-1-55250-226-6. [Google Scholar]

- Pearson, L.J.; Pearson, L.; Pearson, C.J. Sustainable urban agriculture: Stocktake and opportunities. Int. J. Agric. Sustain. 2010, 8, 7–19. [Google Scholar] [CrossRef]

- Tout, D. The horticulture industry of Almería province, Spain. Geogr. J. 1990, 156, 304–312. [Google Scholar] [CrossRef]

- Henry, R. Innovations in agriculture and food supply in response to the COVID-19 pandemic. Mol. Plant 2020, 13, 1095–1097. [Google Scholar] [CrossRef]

- O’Sullivan, C.; Bonnett, G.; McIntyre, C.; Hochman, Z.; Wasson, A. Strategies to improve the productivity, product diversity and profitability of urban agriculture. Agric. Syst. 2019, 174, 133–144. [Google Scholar] [CrossRef]

- O’Sullivan, C.A.; McIntyre, C.L.; Dry, I.B.; Hani, S.M.; Hochman, Z.; Bonnett, G.D. Vertical farms bear fruit. Nat. Biotechnol. 2020, 38, 160–162. [Google Scholar] [CrossRef]

- Cuesta Roble Releases. Global Greenhouse Statistics. 2019. Available online: https://www.producegrower.com/article/cuesta-roble-2019-global-greenhouse-statistics/ (accessed on 13 April 2022).

- Hadley, D. Controlled Environment Horticulture Industry Potential in NSW; University of New England: Armidale, Australia, 2017; p. 25. [Google Scholar]

- World Vegetable Map. 2018. Available online: https://research.rabobank.com/far/en/sectors/regional-food-agri/world_vegetable_map_2018.html (accessed on 13 April 2022).

- Graeme Smith Consulting—General Industry Information. Available online: https://www.graemesmithconsulting.com/index.php/information/general-industry-information (accessed on 13 April 2022).

- Davis, J. Growing Protected Cropping in Australia to 2030; Protected Cropping Australia: Perth, Australia, 2020; p. 15. [Google Scholar]

- Agrilyst. State of Indoor Farming; Agrilyst: Brooklyn, NY, USA, 2017. [Google Scholar]

- Indoor Soilless Farming: Phase I: Examining the Industry and Impacts of Controlled Environment Agriculture|Publications|WWF. Available online: https://www.worldwildlife.org/publications/indoor-soilless-farming-phase-i-examining-the-industry-and-impacts-of-controlled-environment-agriculture (accessed on 13 April 2022).

- Emmott, C.J.M.; Röhr, J.A.; Campoy-Quiles, M.; Kirchartz, T.; Urbina, A.; Ekins-Daukes, N.J.; Nelson, J. Organic photovoltaic greenhouses: A unique application for semi-transparent PV? Energy Environ. Sci. 2015, 8, 1317–1328. [Google Scholar] [CrossRef]

- Marucci, A.; Zambon, I.; Colantoni, A.; Monarca, D. A combination of agricultural and energy purposes: Evaluation of a prototype of photovoltaic greenhouse tunnel. Renew. Sustain. Energy Rev. 2018, 82, 1178–1186. [Google Scholar] [CrossRef]

- Torrellas, M.; Antón, A.; López, J.C.; Baeza, E.J.; Parra, J.P.; Muñoz, P.; Montero, J.I. LCA of a tomato crop in a multi-tunnel greenhouse in Almeria. Int. J. Life Cycle Assess. 2012, 17, 863–875. [Google Scholar] [CrossRef]

- Caponetto, R.; Fortuna, L.; Nunnari, G.; Occhipinti, L.; Xibilia, M.G. Soft computing for greenhouse climate control. IEEE Trans. Fuzzy Syst. 2000, 8, 753–760. [Google Scholar] [CrossRef] [Green Version]

- Guo, D.; Juan, J.; Chang, L.; Zhang, J.; Huang, D. Discrimination of plant root zone water status in greenhouse production based on phenotyping and machine learning techniques. Sci. Rep. 2017, 7, 8303. [Google Scholar] [CrossRef] [Green Version]

- Hassabis, D. Artificial intelligence: Chess match of the century. Nature 2017, 544, 413–414. [Google Scholar] [CrossRef] [Green Version]

- Hemming, S.; de Zwart, F.; Elings, A.; Righini, I.; Petropoulou, A. Remote control of greenhouse vegetable production with artificial intelligence—Greenhouse climate, irrigation, and crop production. Sensors 2019, 19, 1807. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Taki, M.; Abdanan Mehdizadeh, S.; Rohani, A.; Rahnama, M.; Rahmati-Joneidabad, M. Applied machine learning in greenhouse simulation; new application and analysis. Inf. Processing Agric. 2018, 5, 253–268. [Google Scholar] [CrossRef]

- Shamshiri, R.R.; Hameed, I.A.; Thorp, K.R.; Balasundram, S.K.; Shafian, S.; Fatemieh, M.; Sultan, M.; Mahns, B.; Samiei, S. Greenhouse Automation Using Wireless Sensors and IoT Instruments Integrated with Artificial Intelligence; IntechOpen: Rijeka, Croatia, 2021; ISBN 978-1-83968-076-2. [Google Scholar]

- Subeesh, A.; Mehta, C.R. Automation and digitization of agriculture using artificial intelligence and internet of things. Artif. Intell. Agric. 2021, 5, 278–291. [Google Scholar] [CrossRef]

- Lehnert, C.; McCool, C.; Sa, I.; Perez, T. A sweet pepper harvesting robot for protected cropping Environments. arXiv 2018, arXiv:1810.11920. [Google Scholar]

- Lehnert, C.; McCool, C.; Corke, P.; Sa, I.; Stachniss, C.; Henten, E.J.V.; Nieto, J. Special issue on agricultural robotics. J. Field Robot. 2020, 37, 5–6. [Google Scholar] [CrossRef]

- Shamshiri, R.; Weltzien, C.; Hameed, I.A.; Yule, I.J.; Grift, T.E.; Balasundram, S.K.; Pitonakova, L.; Ahmad, D.; Chowdhary, G. Research and development in agricultural robotics: A perspective of digital farming. Int. J. Agric. Biol. Eng. 2018, 11, 1–14. [Google Scholar] [CrossRef]

- Balendonck, J. Sweeper robot picks first peppers. Greenh. Int. Mag. Greenh. Grow. 2017, 6, 37. [Google Scholar]

- Yuan, T.; Zhang, S.; Sheng, X.; Wang, D.; Gong, Y.; Li, W. An autonomous pollination robot for hormone treatment of tomato flower in greenhouse. In Proceedings of the 2016 3rd International Conference on Systems and Informatics (ICSAI), Shanghai, China, 19–21 November 2016; pp. 108–113. [Google Scholar]

- Meharg, A.A. Perspective: City farming needs monitoring. Nature 2016, 531, S60. [Google Scholar] [CrossRef] [PubMed]

- Thomaier, S.; Specht, K.; Henckel, D.; Dierich, A.; Siebert, R.; Freisinger, U.B.; Sawicka, M. Farming in and on urban buildings: Present practice and specific novelties of zero-acreage farming (ZFarming). Renew. Agric. Food Syst. 2015, 30, 43–54. [Google Scholar] [CrossRef] [Green Version]

- Ghannoum, O. The Green Shoots of Recovery. Openforum. 2020. Available online: https://www.openforum.com.au/the-green-shoots-of-recovery/ (accessed on 13 April 2022).

- Despommier, D. Farming up the city: The rise of urban vertical farms. Trends Biotechnol. 2013, 31, 388–389. [Google Scholar] [CrossRef]

- Yang, J.; Liu, M.; Lu, J.; Miao, Y.; Hossain, M.A.; Alhamid, M.F. Botanical internet of things: Toward smart indoor farming by connecting people, plant, data and clouds. Mob. Netw. Appl. 2018, 23, 188–202. [Google Scholar] [CrossRef]

- Samaranayake, P.; Liang, W.; Chen, Z.-H.; Tissue, D.; Lan, Y.-C. Sustainable protected cropping: A case study of seasonal impacts on greenhouse energy consumption during capsicum production. Energies 2020, 13, 4468. [Google Scholar] [CrossRef]

- Lin, T.; Goldsworthy, M.; Chavan, S.; Liang, W.; Maier, C.; Ghannoum, O.; Cazzonelli, C.I.; Tissue, D.T.; Lan, Y.-C.; Sethuvenkatraman, S.; et al. A novel cover material improves cooling energy and fertigation efficiency for glasshouse eggplant production. Energy 2022, 251, 123871. [Google Scholar] [CrossRef]

- Samaranayake, P.; Maier, C.; Chavan, S.; Liang, W.; Chen, Z.-H.; Tissue, D.T.; Lan, Y.-C. Energy minimisation in a protected cropping facility using multi-temperature acquisition points and control of ventilation settings. Energies 2021, 14, 6014. [Google Scholar] [CrossRef]

- FAO. Good Agricultural Pratices for Greenhouse Vegetable Crops: Principles for Mediterranean Climate Areas; FAO Plant Production and Protection Paper; FAO: Rome, Italy, 2013; ISBN 978-92-5-107649-1. [Google Scholar]

- Hort Innovation Protected Cropping—Review of Research and Identification of R&D Gaps for Levied Vegetables (VG16083). Available online: https://www.horticulture.com.au/growers/help-your-business-grow/research-reports-publications-fact-sheets-and-more/project-reports/vg16083-1/vg16083/ (accessed on 13 April 2022).

- Hiwasa-Tanase, K.; Ezura, H. Molecular breeding to create optimized crops: From genetic manipulation to potential applications in plant factories. Front. Plant Sci. 2016, 7, 539. [Google Scholar] [CrossRef] [Green Version]

- Kozai, T. Why LED lighting for urban agriculture? In LED Lighting for Urban Agriculture; Kozai, T., Fujiwara, K., Runkle, E.S., Eds.; Springer: Singapore, 2016; pp. 3–18. ISBN 978-981-10-1848-0. [Google Scholar]

- Kwon, S.; Lim, J. Improvement of energy efficiency in plant factories through the measurement of plant bioelectrical potential. In Informatics in Control, Automation and Robotics; Tan, H., Ed.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 641–648. [Google Scholar]

- Cocetta, G.; Casciani, D.; Bulgari, R.; Musante, F.; Kołton, A.; Rossi, M.; Ferrante, A. Light use efficiency for vegetables production in protected and indoor environments. Eur. Phys. J. Plus 2017, 132, 43. [Google Scholar] [CrossRef]

- Jones, M. New Breeding Technologies and Opportunities for the Australian Vegetable Industry; Horticulture Innovation Australia Limited: Sydney, Australia, 2016. [Google Scholar]

- Tüzel, Y.; Leonardi, C. Protected cultivation in mediterranean region: Trends and needs. Ege Üniversitesi Ziraat Fakültesi Derg. 2009, 46, 215–223. [Google Scholar]

- Bergougnoux, V. The history of tomato: From domestication to biopharming. Biotechnol. Adv. 2014, 32, 170–189. [Google Scholar] [CrossRef] [PubMed]

- Taher, D.; Solberg, S.Ø.; Prohens, J.; Chou, Y.; Rakha, M.; Wu, T. World vegetable center eggplant collection: Origin, composition, seed dissemination and utilization in breeding. Front. Plant Sci. 2017, 8, 1484. [Google Scholar] [CrossRef] [PubMed]

- Hasan, M.M.; Bashir, T.; Ghosh, R.; Lee, S.K.; Bae, H. An overview of LEDs’ effects on the production of bioactive compounds and crop quality. Molecules 2017, 22, 1420. [Google Scholar] [CrossRef] [Green Version]

- Piovene, C.; Orsini, F.; Bosi, S.; Sanoubar, R.; Bregola, V.; Dinelli, G.; Gianquinto, G. Optimal red:blue ratio in led lighting for nutraceutical indoor horticulture. Sci. Hortic. 2015, 193, 202–208. [Google Scholar] [CrossRef]

- Kwon, C.-T.; Heo, J.; Lemmon, Z.H.; Capua, Y.; Hutton, S.F.; Van Eck, J.; Park, S.J.; Lippman, Z.B. Rapid customization of solanaceae fruit crops for urban agriculture. Nat. Biotechnol. 2020, 38, 182–188. [Google Scholar] [CrossRef]

- Shamshiri, R.R.; Jones, J.W.; Thorp, K.R.; Ahmad, D.; Man, H.C.; Taheri, S. Review of optimum temperature, humidity, and vapour pressure deficit for microclimate evaluation and control in greenhouse cultivation of tomato: A review. Int. Agrophys. 2018, 32, 287–302. [Google Scholar] [CrossRef]

- Chavan, S.G.; Maier, C.; Alagoz, Y.; Filipe, J.C.; Warren, C.R.; Lin, H.; Jia, B.; Loik, M.E.; Cazzonelli, C.I.; Chen, Z.H.; et al. Light-limited photosynthesis under energy-saving film decreases eggplant yield. Food Energy Secur. 2020, 9, e245. [Google Scholar] [CrossRef]

- Timmermans, G.H.; Douma, R.F.; Lin, J.; Debije, M.G. Dual thermal-/electrical-responsive luminescent ‘smart’ window. Appl. Sci. 2020, 10, 1421. [Google Scholar] [CrossRef] [Green Version]

- Yin, R.; Xu, P.; Shen, P. Case study: Energy savings from solar window film in two commercial buildings in Shanghai. Energy Build. 2012, 45, 132–140. [Google Scholar] [CrossRef]

- Kim, H.-K.; Lee, S.-Y.; Kwon, J.-K.; Kim, Y.-H. Evaluating the effect of cover materials on greenhouse microclimates and thermal performance. Agronomy 2022, 12, 143. [Google Scholar] [CrossRef]

- He, X.; Maier, C.; Chavan, S.G.; Zhao, C.-C.; Alagoz, Y.; Cazzonelli, C.; Ghannoum, O.; Tissue, D.T.; Chen, Z.-H. Light-altering cover materials and sustainable greenhouse production of vegetables: A review. Plant Growth Regul. 2021, 95, 1–17. [Google Scholar] [CrossRef]

- Timmermans, G.H.; Hemming, S.; Baeza, E.; Thoor, E.A.J.V.; Schenning, A.P.H.J.; Debije, M.G. Advanced optical materials for sunlight control in greenhouses. Adv. Opt. Mater. 2020, 8, 2000738. [Google Scholar] [CrossRef]

- Zisis, C.; Pechlivani, E.M.; Tsimikli, S.; Mekeridis, E.; Laskarakis, A.; Logothetidis, S. Organic photovoltaics on greenhouse rooftops: Effects on plant growth. Mater. Today Proc. 2019, 19, 65–72. [Google Scholar] [CrossRef]

- Aroca-Delgado, R.; Pérez-Alonso, J.; Callejón-Ferre, Á.-J.; Díaz-Pérez, M. Morphology, yield and quality of greenhouse tomato cultivation with flexible photovoltaic rooftop panels (Almería-Spain). Sci. Hortic. 2019, 257, 108768. [Google Scholar] [CrossRef]

- He, X.; Chavan, S.G.; Hamoui, Z.; Maier, C.; Ghannoum, O.; Chen, Z.-H.; Tissue, D.T.; Cazzonelli, C.I. Smart glass film reduced ascorbic acid in red and orange capsicum fruit cultivars without impacting shelf Life. Plants 2022, 11, 985. [Google Scholar] [CrossRef]

- Zhao, C.; Chavan, S.; He, X.; Zhou, M.; Cazzonelli, C.I.; Chen, Z.-H.; Tissue, D.T.; Ghannoum, O. Smart glass impacts stomatal sensitivity of greenhouse capsicum through altered light. J. Exp. Bot. 2021, 72, 3235–3248. [Google Scholar] [CrossRef]

- Pilkington, L.J.; Messelink, G.; van Lenteren, J.C.; Le Mottee, K. “Protected biological control”—Biological pest management in the greenhouse industry. Biol. Control 2010, 52, 216–220. [Google Scholar] [CrossRef]

- Sonneveld, C.; Voogt, W. Plant nutrition in future greenhouse production. In Plant Nutrition of Greenhouse Crops; Sonneveld, C., Voogt, W., Eds.; Springer: Dordrecht, The Netherlands, 2009; pp. 393–403. ISBN 978-90-481-2532-6. [Google Scholar]

- Treftz, C.; Omaye, S.T. Nutrient analysis of soil and soilless strawberries and raspberries grown in a greenhouse. Food Nutr. Sci. 2015, 6, 805–815. [Google Scholar] [CrossRef] [Green Version]

- Offering Further Education Opportunities to Veg Industry Members. AUSVEG. 2020. Available online: https://ausveg.com.au/articles/offering-further-education-opportunities-to-veg-industry-members/ (accessed on 13 April 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chavan, S.G.; Chen, Z.-H.; Ghannoum, O.; Cazzonelli, C.I.; Tissue, D.T. Current Technologies and Target Crops: A Review on Australian Protected Cropping. Crops 2022, 2, 172-185. https://doi.org/10.3390/crops2020013

Chavan SG, Chen Z-H, Ghannoum O, Cazzonelli CI, Tissue DT. Current Technologies and Target Crops: A Review on Australian Protected Cropping. Crops. 2022; 2(2):172-185. https://doi.org/10.3390/crops2020013

Chicago/Turabian StyleChavan, Sachin G., Zhong-Hua Chen, Oula Ghannoum, Christopher I. Cazzonelli, and David T. Tissue. 2022. "Current Technologies and Target Crops: A Review on Australian Protected Cropping" Crops 2, no. 2: 172-185. https://doi.org/10.3390/crops2020013

APA StyleChavan, S. G., Chen, Z.-H., Ghannoum, O., Cazzonelli, C. I., & Tissue, D. T. (2022). Current Technologies and Target Crops: A Review on Australian Protected Cropping. Crops, 2(2), 172-185. https://doi.org/10.3390/crops2020013