Abstract

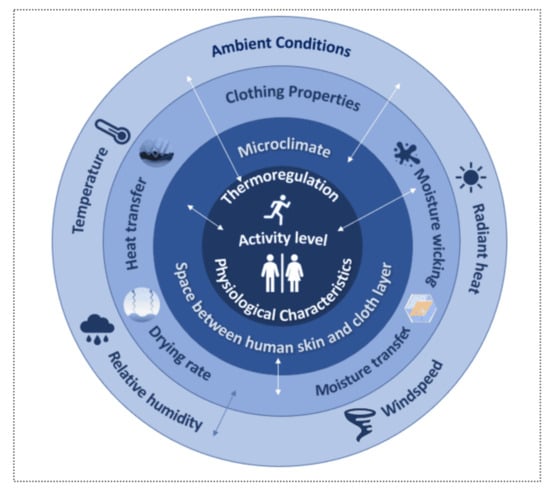

Thermophysiological comfort is a crucial aspect of human life, contributing to health and work performance. The current paper aims to enhance the understanding of current research, progress, and remaining challenges regarding clothing thermophysiological comfort from a textile science perspective. It provides a comprehensive review of several facets of clothing thermophysiological comfort, focusing on the history of thermophysiological comfort prediction models, heat and moisture transfer mechanisms in the skin–clothing–environment system, controlling factors of thermophysiological comfort, textile materials for superior thermophysiological comfort, and thermal comfort assessment techniques. The paper shows that previously developed thermophysiological comfort models were mainly based on the human thermoregulation process. However, the effect of the air gap size between the human skin and the cloth layer, i.e., the microclimate, on the heat and moisture transfer in the skin–clothing–environment system has been largely overlooked. In addition, thermophysiological comfort models of skin–clothing–environment systems generally only considered dry thermal resistance and evaporative resistance, yet many other fabric properties have effects on human thermophysiological comfort. Potential future directions are identified to fill some of the current gaps. A conceptual model of clothing comfort to contribute to a better understanding of thermophysiological comfort is also proposed.

1. Introduction

The term “thermophysiological comfort” is often used in textile science research to define the ability of a garment to maintain the thermal balance of a human body under various environmental conditions [1]. Human thermophysiological comfort is associated with the human body’s physiological characteristics and processes, clothing heat and moisture transport properties, and environmental conditions [2]. The air gap distance between the human skin and the cloth layer (referred to as the microclimate) is one of the dominant factors affecting thermophysiological comfort [3,4]. Parsons [1] identified seven factors that contribute to human thermophysiological comfort: metabolic heat production, adaptive responses (e.g., thermoregulation process), clothing insulation, air temperature, relative humidity, air velocity, and radiant temperature. It is important to note that the term “thermal comfort” is often used interchangeably with thermophysiological comfort in scholarly works, as the thermal properties of fabrics affect the human thermophysiological process [2].

Attaining thermophysiological comfort is essential to maintain the well-being of the human body [1,2]. Poor heat and moisture transfer properties of fabrics cause an increase in core body temperature in warm conditions, which can lead to heat strain [5,6,7]. The possible physiological responses associated with heat strain can be divided into three stages [8]: heat loss, temperature re-increase, and cardiac system failure. In ideal conditions, the amount of metabolic heat produced by the human body equals the amount of heat lost from the human body to the environment. This loss of heat may become lower than metabolic heat production, e.g., due to poor heat and moisture management properties of the clothing ensemble. As a result, an increase in core temperature occurs in the human body system. The first stage of heat stress causes vasodilation (i.e., the body expands the diameter of the blood vessels to increase the blood flow) and sweating in response to the rising core body temperature. This vasodilation and sweat evaporation foster initial heat loss. In the next stage, vital organs receive insufficient blood flow and the fatigue of the sweat glands generates less perspiration. This causes an increase in core body temperature, leading to heatstroke in the third stage.

A comparison of the level of heat strain generated by clothing made of a selectively permeable membrane (SPM) and a textile fabric with a similar level of heat and water vapor resistance evidenced a greater increase in core body temperature and heart rate over time with the SPM-based clothing, in addition to a higher amount of sweat production and accumulation in the clothing [9]. This was attributed to the poor air permeability and lower ventilation with the SPM-based clothing. In another study, Holmer [10] showed that the water vapor pressure in the microclimate increased more over time while wearing an impermeable overall compared to a microporous overall. The increase in the heart rate, rectal temperature, and skin temperature measured was attributed to the limited permeability of the fabric material under various ambient temperatures.

On the other hand, cold strain is caused by exposure to low temperatures while wearing garments with poor clothing insulation [11]. Even though physical activity increases metabolic heat generation, it might not be sufficient to mitigate the effect of cold weather conditions in the long run [12]. The human body responds to cold mainly in four ways: (a) vasoconstriction (i.e., reduction in the diameter of blood vessels, which reduces the blood flow to extremities and minimizes heat loss) [13], (b) shivering (i.e., systematic muscle contraction to increase metabolic heat production) [14], (c) non-shivering thermogenesis (i.e., heat production by the metabolism of brown fat) [15], and (d) piloerection [16]. Pisacane et al. [17] mentioned that long-term cold exposure can cause muscle hardening, heart fibrillation, unconsciousness, and cardiac and respiratory failure.

The study of thermophysiological comfort involves the use of thermophysiological comfort models, human subject assessment, and investigation of clothing heat and moisture transport properties [1]. Several models and indices have been developed to predict human thermophysiological comfort [18]. Among these, Fanger’s model [19], Gagge’s model [20], and Stolwijk’s model [21] are widely used in the construction, automotive, medical, and aerospace industries [22]. More sophisticated models have built upon these early thermophysiological comfort models to predict the local skin and core body temperature under various exposure conditions [23]. Models derived from Stolwijk’s model are Fiala’s model [24], UC Berkeley’s model [25], Tanabe’s model [26], and ThermoSEM [27].

Fanger’s and Fiala’s models are most frequently used by clothing comfort researchers because they can be combined with standard test methods of fabric/clothing to determine human thermophysiological comfort [1,18,28,29]. Fanger’s model is considered the first comprehensive model for thermophysiological comfort prediction [23]. It is based on a heat balance equation to estimate the net heat loss or gain in a skin–cloth–environment system (Section 2.1). Fanger’s model was adopted by the ASHRAE 55 [30] and ISO 7730 [31] standards to assess the thermophysiological comfort of the human body. On the other hand, Fiala’s model is based on Pennes’s bioheat equation, which includes heat conduction within nodes/tissue layers, metabolic heat generation, and heat transfer due to arterial blood flow [24]. Fiala’s model can be coupled with ISO 18640-1 [32] when determining the clothing thermophysiological comfort using a sweating cylindrical torso [29].

The existing problem with these thermophysiological comfort prediction models is that they include only two fabric properties: dry thermal and evaporative resistance [18,28]. However, other fabric properties may also affect human thermophysiological comfort, such as moisture wicking, drying rate, wet conduction, and heat of sorption [33,34,35,36]. Noman and Petru [37] indicated that the water vapor transmission rate, air permeability, moisture wicking, and thermal effusivity are the main thermophysiological comfort properties of fabrics. Hes [38] constructed a comfort index that listed nine different fabric properties that affect overall comfort perception. These fabric properties are dry thermal resistance, evaporative resistance, moisture absorptivity, dry thermal absorptivity, wet friction coefficient, dry friction coefficient, bending rigidity, shearing rigidity, and compression work.

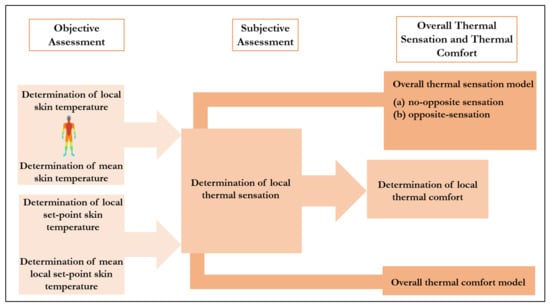

Another aspect of thermophysiological comfort is the assessment of the human body’s psychophysical (i.e., subjective) and physiological (i.e., objective) responses under various exposure conditions [39]. Subjective assessment requires human subjects to determine their comfort level using a rating scale, for example, a 7-point Likert scale [1]. Likert scales quantify comfort perception, functional effectiveness, preference, acceptance, and tolerance of a particular clothing system [40]. On the other hand, objective assessment measures human physiological responses, such as core body temperature, skin temperature, heart rate, and sweat loss [41]. These subjective and objective responses can then be associated with the heat and moisture management properties of fabrics (also referred to as the thermal comfort properties of fabrics) to construct the thermophysiological comfort model. Some common standard test methods for assessing the heat and moisture management properties of fabrics are dry thermal and evaporative resistance [42], water vapor transmission rate [43], liquid moisture management test [44], air permeability [45], and thermal effusivity [46].

The human thermophysiological comfort models thus depend on a wide variety of interconnected factors, which makes it difficult to predict the precise level of thermal comfort of an individual under a given condition [28]. The next sections describe several aspects of thermophysiological comfort modeling, including the conceptual ground for model development, the physics of heat and moisture transfer in the skin–clothing–environment system, factors controlling thermophysiological comfort, and assessment techniques.

2. Thermophysiological Comfort Prediction Models

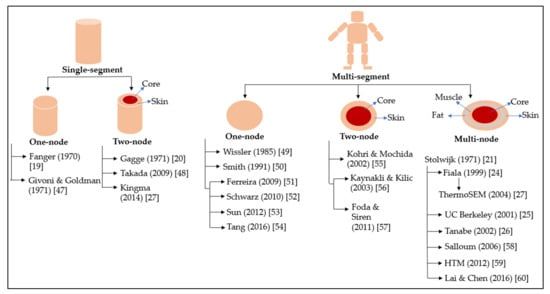

Thermophysiological comfort models can be classified into two main categories depending on the number of segments representing the body parts [18]: (a) single-segment and (b) multi-segment. The single-segment predictive model considers the entire human body as a whole. In contrast, the multi-segment model considers different body parts separately. Another way to classify thermophysiological comfort models is based on the number of concentric layers: (a) single-node, (b) two-node, and (b) multi-node. A single-node model only considers the core to represent the cross-section of a human body, whereas a two-node model considers the core and skin to represent the cross-section of the human body. In contrast, the multi-node model considers the core, muscles, fat, and skin layers separately. Figure 1 shows the chronology of the development of the different types of thermophysiological comfort prediction models.

Figure 1.

Chronology of the development of thermophysiological comfort models [19,20,21,24,25,26,27,47,48,49,50,51,52,53,54,55,56,57,58,59,60] (inspired by [18]).

Thermophysiological comfort prediction models are mainly constructed using physiological variables (e.g., heat and sweat generation within the human body, skin temperature, and core body temperature), clothing insulation properties, and environmental conditions [24,31,61]. For instance, Kang et al. [62] developed an advanced thermophysiological comfort model to predict the human core body and skin temperature. The model employed a three-dimensional approach and divided the human body into 15 different segments, mimicking the cylindrical geometry of the body parts. First, it determined the heat transfer inside a human body, which included basal metabolism, shivering, and external work as heat generation sources. The study calculated the thermal conductivity of the body segments, including when vasodilation and vasoconstriction occur, depending on the skin temperature. Next, the model determined the amount of convective and radiative heat transfer from the human body to the environment, assuming the human skin and cloth as a single layer (i.e., no air gap between the skin and clothing). The model also included evaporative heat dissipation (i.e., both for insensible and sensible sweating) to estimate the total evaporative heat loss from the human skin.

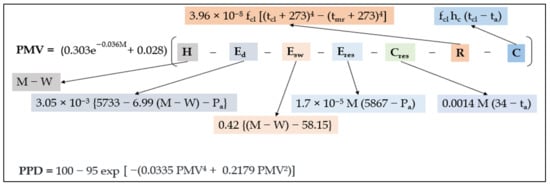

Fanger’s thermophysiological comfort prediction model consists of three steps [1]: (a) determination of the thermal stress level using the predicted mean vote (PMV) and predicted percentage of dissatisfied (PPD), (b) calculation of the equivalent temperature, and (c) evaluation of thermal comfort based on subjective assessment. The PMV and PPV indices are estimated from the basal metabolism (M), heat produced by work (W), clothing surface temperature (tcl), clothing insulation (Icl), clothing cover factor (fcl), air temperature (Ta), relative humidity of air (RHa), mean radiant temperature (Tmr), and convective heat transfer coefficient (hr). The PMV values range from −3 to +3, mimicking a 7-point Likert scale, where −3 represents very cold, −2 represents cold, −1 represents slightly cold, 0 represents neutral, 1 represents slightly warm, 2 represents warm, and 3 represents very warm. When the PMV is −0.5 to +0.5, the PPD is 10%. This indicates that 10% of the participants are in discomfort. It is to be noted that discrepancies have been documented between PMV results and thermal sensation from wear trials [63]. They are possibly due to issues with the determination of tcl.

Fiala et al. [24,64] developed a thermophysiological comfort prediction model for different environmental conditions considering the passive and active thermoregulatory systems. The passive system involves the functions of human body attributes (e.g., bone, muscle, fat, and skin), such as the basal metabolism, arterial blood flow, and metabolic heat. On the other hand, the active system includes human thermoregulatory responses like vasodilation, vasoconstriction, shivering, and sweating. The passive model was developed in three different steps: (a) modeling the human body, (b) modeling the heat transfer between the nodes or periphery, and (c) numerical simulation. First, the human body was divided into 15 segments and 7 tissue layers or nodes. Next, the heat transfer between the nodes was derived from Pennes’s bioheat equation. This step also includes heat exchange between the human body and the environment through clothing. In the third step, numerical simulations were performed to predict the tissue temperature. Fiala et al. [64] combined active thermoregulatory responses with the passive model [24] to construct an overall thermophysiological comfort prediction model. The simulation started by exposing the passive system to predefined boundary conditions when no active system was running. The active regulatory responses that had been obtained experimentally were then added to the model. The results of numerical simulations using the model were in good agreement with experimentally obtained results.

The thermophysiological comfort prediction models described above did not consider the effect of the air gap thickness between the human skin and the cloth, which is called the microclimate. However, studies investigating the effect of this air gap thickness on heat and moisture transport phenomena in the skin–cloth–environment system found that it significantly affects the amount of heat and moisture transfer from the human body to the environment through the cloth layer, which eventually contributes to the thermal balance of the human body [4,65]. Ding et al. [3] showed that an air gap distance greater than 12 mm between the sweating-guarded hot plate (i.e., simulating the human skin) and the clothing layer allowed the occurrence of natural convection in the microclimate. In contrast, when the air gap between the sweating-guarded hot plate and the cloth layer was lower than 12 mm, the heat transfer mechanism in the microclimate only involved conduction and radiation. Joshi [28] developed a thermophysiological comfort prediction model that included the effect of the air gap on heat and moisture transfer in a skin–clothing–environment system. Awais et al. [66] described a modeling and simulation procedure to predict the thermophysiological comfort of clothing ensembles for various values of the air gap. First, the physical, mechanical, and thermal properties of the fabrics were added to the simulation software Modaris (V8) for creating realistic clothing simulations. Next, human body scanned data were added to the Modaris software for conducting the fit simulation. Finally, these data were imported in finite-element software for thermophysiological comfort simulation of the clothing ensemble. The thermophysiological comfort simulations were conducted for different physical activities and air gap distributions.

2.1. Heat Balance Equation

Another aspect of thermophysiological comfort prediction models is the heat balance in the human body. Fanger [61] stated that thermophysiological comfort can be achieved by balancing the amount of heat produced within the human body and the amount of heat transferred from the human body to the environment through clothing. The heat balance equation was described as follows [1]:

H − Ed − Esw − Eres − Cres = K = R + C

Here, H is the internal heat production within the human body, Ed is the heat loss due to water-vapor diffusion through the skin, Esw is the heat loss due to sweat evaporation, Eres is the latent respiratory heat loss, Cres is the dry respiratory heat loss, K is the net heat loss by clothing, R is the radiative heat loss from the outer cloth surface, and C is the convective heat loss from the outer cloth surface. Fanger estimated the internal heat production by subtracting the mechanical energy spent in work (W) from the total metabolic heat production (M) [1]. Thus, H = M − W. However, W is considered to be 0 in most cases. Therefore, the expression can be written as H = M. Later, they developed another expression to estimate the metabolic heat production based on the human body surface area. The surface area of the human body (AD) was estimated using the Du Bois equation, where AD = 0.202 (weight)0.425 × (height)0.725. Fanger created a database of metabolic heat production for various physical activities in order to estimate the heat balance of the human body. For instance, the normalized metabolic rate estimated for seated people was 58.15 Wm−2. It gave a normalized metabolic rate of 116.3 W for a person with a body surface area of 2 m2.

Water vapor diffusion occurs through the skin due to the difference in vapor pressure at the interior skin and the outer air layer, which causes heat loss [1]. Mathematically, the heat loss due to water vapor diffusion through the skin (Ed) is related to the vapor diffusion coefficient (d) of the skin, the latent heat of vaporization (λ) at the skin temperature (tsk), and the difference between the interior skin vapor pressure (which is always wet) and the air layer vapor pressure (∆P) according to the following equation:

Ed = d · λ · ∆P

Heat loss also occurs at the outer surface of the skin due to the evaporation of sweat [1]. During extreme physical activity, the sweat rate increases. Research has shown that the evaporative heat loss (Esw.req) required to maintain thermophysiological comfort increases with increasing physical activity. Simultaneously, the required skin temperature (tsk.req) decreases with an increase in intensity of physical activity.

Heat loss from the human body also occurs due to breathing [1]. When a person inhales moist air from the ambient air, it travels through the lungs and respiratory tract. The temperatures of the lungs and respiratory tract are usually higher than the ambient temperature, which increases the temperature of the inhaled moist air. There might also be some heat gain due to the inhalation process itself, as the inhaled moisture vapor is condensed inside the body. On the other hand, when a person exhales, the moist air exhaled carries more heat and vapor than the inhaled moist air, which causes both evaporative and dry heat loss. In this case, heat transfer occurs via evaporation and convection. The evaporative heat loss depends on the difference between the water vapor concentrations in exhaled air (Dex) and inhaled air (Din) [1]. Conversely, convective heat transfer depends on the temperature difference between exhaled air (tex) and inhaled air (tin).

In the heat balance equation (Equation (1)), K refers to the net heat exchange between the human body and the environment through the cloth layer [1]. The estimation of K is complex, as many other factors are involved in this heat exchange process, such as the thickness of the air gap between the skin and the cloth, clothing contact area, the presence of uncovered body parts, and human body movement. The heat transfer mechanism in the skin–cloth–environment may involve conduction, convection, radiation, and evaporative cooling [4]. Fanger proposed that K can be estimated from the temperature difference between the skin (tsk) and the air layer adjacent to the outer fabric surface (ta) divided by the fabric’s dry thermal resistance (Rcl) [1]. The unit of dry thermal resistance is m2KW−1. This unit is generally used for the thermal resistance of fabrics. Gagge et al. [67] devised another unit, clo, for thermal resistance (called thermal insulation, Icl). The clo unit is generally used for the overall thermal resistance of the clothing based on how much area of the body is covered by the cloth [1]. The expression to estimate the heat transfer through the cloth is K = (tsk − ta)/Rcl and 1 clo = 0.155 m2KW−1. Thus, K= (tsk − ta)/0.155Icl. It is important to note that the dry thermal resistance value obtained from the sweating-guarded hot plate/manikin/torso corresponds to the total thermal resistance (Rct) of the fabric and the air layer adjacent to the outer fabric surface. Thus, Rct = Rcf + Rc0, with Rcf the thermal resistance of the fabric and Rc0 the thermal resistance of the air layer adjacent to the outer fabric surface. In the case of thermal insulation, the expression can be written as Icl = IT − Ia/fcl. Here, Icl refers to the clothing thermal resistance, IT is the total thermal resistance, Ia is the thermal resistance of the air layer, and fcl (=Acl/Abody) is the clothing cover factor. Ia is divided by fcl because the thermal insulation of the cloth is determined based on how much area of the body is covered by the cloth. Here, Acl is the surface area of the body that is covered by the cloth and Abody is the whole-body surface area.

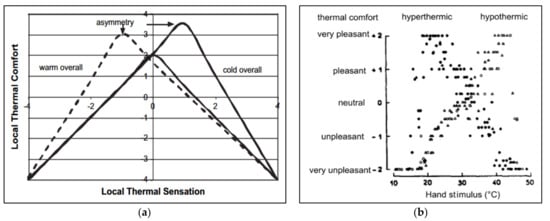

The outer surface of clothing loses heat to the environment through radiation and convection [1,68]. The radiative heat transfer depends on the difference in the fourth power of difference in temperature between the two surfaces. The heat loss by convection between the clothing’s outer surface and the environment can be categorized into (a) free or natural convection (when no external force is working on heat flow) and (b) forced convection (when an external force causes heat flow) [1]. An example of natural convection is when light warm air is substituted by heavier chilled air due to gravity acting on the air. On the other hand, forced convection may occur due to human body movement, heavy winds, etc. Fanger expressed the heat balance equation (Equation (1)) in terms of the PMV and PPD indices to predict the human thermophysiological comfort level (Figure 2).

Figure 2.

PMV and PPD equations based on the heat balance equation [1,69]. The different parameters are described in Section 2.

2.2. Thermoregulation in a Human Body

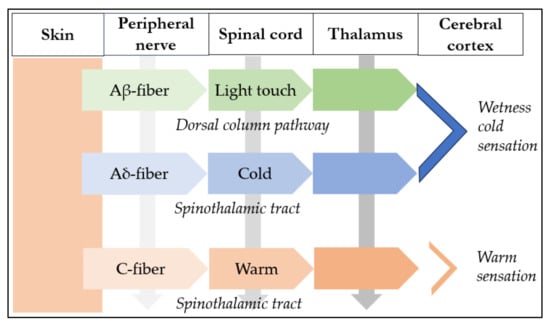

Human body thermophysiological comfort arises from the thermoregulation process [2]. Thermoregulation causes the generation of heat and sweat to maintain a constant core body temperature of 37.0 ± 0.5 °C under various exposure conditions [8]. The thermoregulation process is complex and depends on various physiological and environmental parameters. The main thermoregulation-controlling point of the human body is the hypothalamus [2]. It is a gland in the brain that receives signals from (a) peripheral nerves and (b) blood particles (due to their movement in the hypothalamus area) [8]. The peripheral nerves collect signals from warm and cold receptors of the cutaneous sensory layer. The warm and cold receptors can sense temperature changes as little as 0.007 °C and 0.012 °C, respectively.

When the human body is exposed to cold weather conditions, it begins to lose heat [2]. Concurrently, the hypothalamus in the brain receives signals about this temperature drop and attempts to counterbalance the effect of cold weather conditions by implementing vasoconstriction, shivering, and piloerection. The vasoconstriction process compresses the blood vessels and decreases blood flow, which lowers the amount of heat loss from the body. The shivering process generates heat in the body. Piloerection creates a thin insulating layer of air around the human skin, which helps to prevent the loss of body heat [16]. Unfortunately, all these processes cannot counter the effect of cold weather conditions forever if appropriate clothing ensembles are not worn. Thus, the human body’s core temperature might fall below the normal range, which causes hypothermia [70].

When the human body is exposed to hot weather conditions, the core body temperature starts to rise [2]. At the same time, the hypothalamus in the human brain receives signals about the temperature increase and attempts to counterbalance the effect of hot weather conditions by vasodilation and sweating. The vasodilation process increases the circumference of the blood vessels, which augments blood flow. Increased blood flow enhances heat loss to the environment, which helps lower the core temperature. In addition, the human body starts sweating. This sweat eventually evaporates into the environment and causes heat loss (known as evaporative cooling) [71]. When the thermoregulation processes (e.g., sweating and vasodilation) are unable to lower the core body temperature as needed, heat stress occurs.

3. Physics of Heat and Moisture Transfer in the Skin–Clothing–Environment System

3.1. Heat and Sweat Generation in the Human Body

The human body generates heat and sweat in response to the clothing worn, exposure to the environment, and level of physical activity [28]. Heat generation in the human body involves basal metabolism, shivering, and metabolic heat due to physical activity [24,62]. The total heat generation within human body parts or tissue layers can be estimated from Equation (3) in Table 1. Equation (3) assumes that there is a temperature variation along the radial directions of the tissue layer for the estimation of conductive heat transfer [24]. No angular heat flow within the tissues is considered. Even though there might be temperature variations in the angular direction, the total amount of angular heat transfer is considered to be negligible compared to the radial direction.

Table 1.

Heat and sweat generation within the human body.

The thermal conductivity (K) of tissue in a local body part takes the highest value (Kmax) of 2.8 Wm−1K−1 when TSkin ≥ 37 °C during the vasodilation process [62]. In contrast, the minimum thermal conductivity (Kmin) is achieved when the skin temperature falls below 27.9 °C. Different body parts have different values of Kmin [4]. Finally, when TSkin is between 27.9 and 37 °C, the thermal conductivity (K) of the tissue of a certain body part can be estimated from Equation (4) (Table 1). In this equation, the thermal conductivity of the tissue layer in a particular body segment is assumed to have a linear correlation with the skin temperature of that body segment [62].

The basal metabolic heat can be estimated from previous studies, such as Kang et al.’s [62] work, where they provided tables that contain the value of total basal metabolic heat (Qtbm) of different body parts. Equation (5) can be used to compute the local basal metabolic heat (Table 1).

Like the thermal conductivity of the tissue layer, heat generation by shivering (QSh) can be estimated from the body segment skin temperature [62]. When TSkin ≥ 36.4 °C, QSh is 0 Wm−3. Maximum shivering occurs when TSkin ≤ 34.1 °C. Eyolfson et al. [72] reported that the maximum shivering heat generation could become 3.9 times the basal metabolic heat generation when the core body temperature and mean skin temperature reach 35.2 °C and 22.1 °C, respectively. Therefore, at TSkin ≤ 34.1 °C, the shivering heat generation would be QSh = 3.9 × QBasic. Lastly, when the skin temperature is between 34.1 and 36.4 °C, the amount of shivering heat generation is estimated using Equation (6) (Table 1).

Finally, the metabolic heat due to physical activity can be estimated from Tanabe et al.’s model [26]. If wi is the heat distribution factor of labor work (value in [62]) and Qtotal is the total heat generation from Tanabe et al.’s model [26], then the metabolic heat loss due to physical activity (without considering shivering) can be estimated using Equation (7) (Table 1).

The skin sweat rate can also be estimated based on the tissue temperature [4]. When the core body temperature exceeds 37 °C, the human body starts to sweat. The sweat rate of a body segment (msw) can be theoretically calculated from Equation (8) (Table 1). In this equation, fsw is the sweat factor and fmin is the minimum sweat rate (value in [62]).

3.2. Heat and Moisture Transfer in the Skin–Clothing–Environment System

The heat transfer mechanism from the human body to the skin through clothing can be divided into two categories: (a) sensible heat transfer and (b) latent heat transfer [4]. Sensible heat transfer refers to the conductive, convective, and radiative heat transfer from human skin to the environment through the clothing layer. On the other hand, latent heat transfer refers to evaporative cooling that occurs due to sweat evaporation.

3.2.1. Sensible Heat Transfer

The sensible heat transfer (Qsensible) in the skin–clothing–environment system can be estimated from the difference between the skin temperature (Ts) and the air layer temperature (Ta) adjacent to the outer cloth surface divided by the total thermal resistance (Rct) of the skin–clothing–environment system (Equation (9)) [28]. Joshi et al. [4] reported that sensible heat transfer in the skin–clothing–environment system can be divided into three regions: (a) from the skin to the inner surface of the cloth, which can be termed the enclosed air layer (EAL), (b) through the cloth, and (c) from the outer surface of the cloth to the environment, which can be termed the boundary air layer (BAL). If the dry thermal resistance of the enclosed air layer, cloth layer, and boundary air layer are labeled REAL_cf, Rcf, and RBAL_cf, respectively, the sensible heat transfer in the skin–cloth–environment system can be written as the right side of Equation (9) [4].

Qsensible = (Ts − Ta)/Rct = (Ts − Ta)/(REAL_cf + Rcf + RBAL_cf)

Sensible Heat Transfer in the Enclosed Air Layer (or Microclimate)

The dominant sensible heat transfer mechanisms in the enclosed air layer between the skin and the cloth are conduction, convection, and radiation [68]. If the thickness of the microclimate or enclosed air layer is lower than a certain value, no convection occurs, and the heat transfer mechanisms in the microclimate solely involve conduction and radiation [3]. On the other hand, when the microclimate thickness surpasses the value that corresponds to the onset of natural convection, conduction becomes negligible, and the heat transfer in the microclimate is convection- and radiation-driven. The density of the air enclosed in the microclimate layer varies locally due to the temperature difference between the two boundaries of the microclimate layer [73]. If they defeat the viscous force of the fluid, the buoyancy force causes the upward movement of the less dense warm air, while gravity causes the downward movement of the heavier cool air. The moment when the buoyancy force overcomes the viscous resistance of the fluid corresponds to the onset of natural convection. Lord Rayleigh, who was particularly interested in the convection phenomenon in the early 20th century, developed a dimensionless parameter, the Rayleigh number, that characterizes the effect of the buoyancy force over the viscous force [74]. The Rayleigh number for heat transfers can be estimated from Equation (10) in Table 2 [68]. When the Rayleigh number value is greater than or equal to 1708, natural convection is observed [3]. On the other hand, when the value of the Rayleigh number is less than 1708 in a heat transfer system, the heat transfer is conduction-driven. The amount of sensible heat transfer in the enclosed air layer can be estimated using Equations (14) and (15) (Table 2).

Table 2.

Sensible heat transfer mechanisms in the enclosed air layer.

Sensible Heat Transfer through the Clothing Layer

The amount of heat transfer through the clothing layer can be obtained experimentally using advanced instruments, such as a sweating-guarded hot plate, sweating cylindrical torso, and thermal manikin [28]. The standard test method ISO 11092 requires direct contact between the skin-simulating hot surface and the fabric layer for the measurement of the dry thermal resistance of fabric (Rcf) (Equation (19)) [42].

Rcf = (TSkin − TAir)/Qcf

Here, TSkin is the surface temperature of the guarded hot plate, TAir is the air temperature inside the guarded hot plate chamber, and Qcf is the heat transfer through the fabric layer.

Sensible Heat Transfer in the Boundary Air Layer

The heat transfer from the outer surface of cloth to the environment involves convection and radiation [68]. Both natural and forced convection, i.e., mixed convection, may occur depending on the conditions. The radiative and mixed convective heat transfer from the outer surface of the clothing to the environment are calculated using Equation (20) to Equation (22) in Table 3.

Table 3.

Sensible heat transfer mechanisms in the boundary air layer.

3.2.2. Latent Heat Transfer

The latent heat transfer (Qlatent) in the skin–clothing–environment system can be estimated from the difference between the saturated vapor pressure at the skin (Ps) and the partial vapor pressure at the air layer adjacent to the outer cloth surface (Pa) divided by the total evaporative resistance (Ret) of the skin–clothing–environment system (Equation (24)) [28]. Like sensible heat transfer, the latent heat transfer in the skin–clothing–environment system can be divided into three regions: (a) the enclosed air layer between the skin and the inner surface of the cloth (EAL), (b) the cloth, and (c) the boundary air layer from the outer surface of the cloth to the environment (BAL) [4]. Thus, if the evaporative resistance of the enclosed air layer, cloth layer, and boundary air layer are labelled REAL_ef, Ref, and RBAL_ef, respectively, the latent heat transfer in the skin–cloth–environment system can be written as the right side of Equation (24) [4].

Qlatent = (Ps − Pa)/Ret = (Ps − Pa)/(REAL_ef + Ref + RBAL_ef)

The latent heat transfer in the skin–clothing–environment system due to sweat evaporation depends on the sweat vapor transmission of the vapor transfer medium (e.g., enclosed air layer and fabric) [68,76]. The sweat vapor transmission rate in the skin–clothing–environment system can be theoretically calculated using Fick’s law of vapor diffusion. For instance, if the vapor pressure at the inner surface of the fabric is C1, the vapor pressure at the outer surface of the fabric is C2, the fabric thickness is L, and the vapor diffusion coefficient fabric is D, the sweat vapor transmission rate through the fabric (mDiff) can be estimated using Equation (25) [75].

When the thickness of the vapor transfer medium (i.e., the microclimate) corresponds to a Rayleigh number less than 1708, the vapor transfer mechanism obeys Fick’s law of vapor diffusion [3,75]. On the other hand, when the Rayleigh number is equal to or greater than 1708, the vapor transfer mechanism is convection-driven. The convective vapor transfer (mcon) in a medium is calculated from Equation (26) [62]. The evaporative heat loss (QEVAP) due to sweat evaporation or moisture-vapor transfer (i.e., mDiff/mcon) is estimated from Equation (27) [28]. Here, λ is the latent heat of water vaporization (2257 J/g).

The evaporation rate or vapor transfer rate in the enclosed air layer depends on the difference between the saturated vapor concentration on the skin and the water vapor partial pressure at the inner surface of the clothing layer [75]. In this case, the vapor transfer mechanism can be either diffusion-driven or convection-driven. The evaporative heat transfer in the enclosed air layer can be estimated from either Equation (28) or Equation (29) (Table 4). The water vapor transmission rate for the enclosed air layer is determined from either Equation (30) or Equation (31) (Table 4). The evaporative resistance is computed according to Equation (32) or Equation (33) (Table 4). The evaporative resistance of the clothing layer can be experimentally obtained using advanced instruments, such as the sweating-guarded hot plate, sweating cylindrical torso, and thermal manikin (Equation (34) in Table 4). Parsons [8] showed an estimation of the evaporative heat loss from the boundary air layer using the Lewis ratio (LR) and vapor convection coefficient (). The evaporative heat transfer of the boundary air layer is calculated using Equation (35) in Table 4.

Table 4.

Latent heat transfer mechanisms in the skin–cloth–environment system.

4. Factors Controlling Thermophysiological Comfort

The discussion above identified five factors that affect human thermophysiological comfort. These factors are (a) the physiological characteristics and processes, (b) microclimate layer, (c) clothing properties, (d) ambient conditions, and (e) body motion. The current section describes the effect of these factors on thermophysiological comfort based on the information found in scholarly works.

4.1. Effect of the Physiological Characteristics and Processes

Human physiological characteristics (such as age, sex, and body composition) contribute to the variation in thermophysiological comfort [77,78]. Firstly, the thermoregulatory process of the human body varies with age. This variation results from structural changes in the body parameters (e.g., skin, muscles, bones, and blood flow) [79]. Blatteis [80] found that the thermoregulatory processes of humans decline with age due to the reduction in fitness. Fanger [61] observed a lower rate of metabolic heat production by older people. Hoof [81] reported that older people prefer higher temperatures compared to young people in order to perceive a similar level of thermal comfort.

Human thermophysiological comfort also varies depending on the sex of a person. Fanger [61] found that women produce less metabolic heat compared to men, which translates into a lower skin temperature and lower heat loss due to sweat evaporation. Other research studies suggested that women possess a higher surface-to-volume ratio, resulting in increased heat dissipation through the skin [77,82]. Hoof [81] found that women are more sensitive to temperature changes and feel colder than men in the same ambient conditions. Rupp et al. [83] reported that boys are sensitive to warm temperatures, whereas girls are sensitive to cold temperatures. This finding was later attributed to the metabolic rate of the corresponding sexes.

Body composition and fitness are also essential factors for thermophysiological comfort. The presence of fat in the subcutaneous region helps maintain the thermal balance of the human body in a colder environment [84]. The greater thickness of the fat layer provides more insulation to limit heat loss from the body. However, in hot conditions, the thermal insulation characteristic of the fat layer causes poor thermophysiological comfort due to the lack of heat transfer from the human body to the environment [85].

Like physiological characteristics, the human body’s physiological processes, such as vasodilation, vasoconstriction, shivering, breathing, and metabolism, also contribute to thermophysiological comfort. Heat and sweat generation in the human body due to the thermoregulation process have been described in Section 3.1.

4.2. Effect of the Microclimate Layer

The air gap distance between the human skin and the cloth layer impacts the heat and sweat transfer in the skin–clothing–environment system [4]. Ding et al. [3,86] studied the effect of different microclimate thicknesses on the heat and sweat transfer through firefighter fabric systems using both experimental methods and numerical simulation. They showed that the total dry thermal resistance (Rct) and total evaporative resistance (Ret) vary with the microclimate thickness and ambient temperature. The Rct and Ret increased with an increase in the microclimate thickness up to 12 mm at an ambient temperature of approximately 20 °C. Below 12 mm, the heat and water-vapor transfer mechanisms in the microclimate were considered to be conduction and diffusion, respectively, due to the absence of air movement. The poor thermal conductivity of immobile microclimate air caused an increase in the total dry thermal resistance. Similarly, water-vapor diffusivity in the immobile microclimate air was low, causing an increase in evaporative resistance. When the microclimate thickness was greater than 12 mm, Rct and Ret values started decreasing and appeared to eventually reach a plateau for a microclimate thickness greater than approximately 18 mm. This might have happened as the enclosed air in the microclimate had sufficient space to experience natural convection, which eventually increased the transfer of heat and sweat vapor in the microclimate. Radiative heat transfer was also present in the microclimate; however, it was not affected by the microclimate thickness or the movement of the microclimate air.

Ding et al. [86] also showed that the microclimate thickness for the onset of natural convection increased with the increase in the ambient temperature between −50 and 60 °C for Rct and between 0 and 30 °C for Ret. At higher ambient temperatures (i.e., TE > 60 °C for Rct and TE > 30 °C for Ret, approximately), the Rct and Ret values did not decrease at higher air gap thicknesses due to natural convection and appeared to follow a logarithmic curve. The Rct and Ret results obtained by Ding et al. [86] in their simulations were experimentally validated by Ding et al. [3] for air gap values of up to 12 mm.

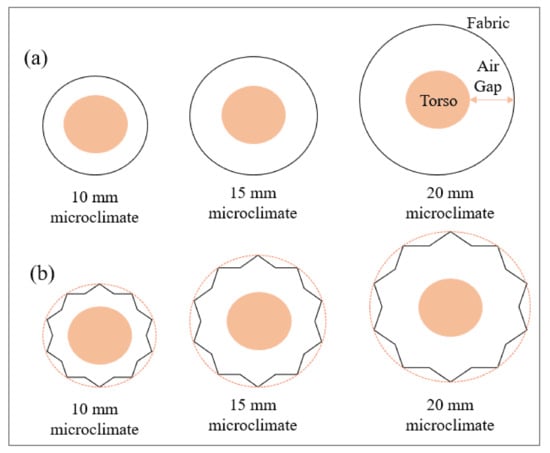

While the microclimate discussed in Ding et al.’s [3,86] work was horizontal and homogeneous, the microclimate formed between the human skin and the cloth layer is usually heterogeneous and vertical in orientation [28]. Mert et al. [65] investigated the total heat flux in the skin–cloth–environment system using a vertical microclimate. Both homogeneous and heterogeneous microclimates were created to conduct the study. In the case of the homogeneous vertical microclimate, the distance between the single-sector sweating cylindrical torso (i.e., skin) and the surrounding cloth layer was kept the same (Figure 3a). On the other hand, the heterogeneous air gap was created by folding the fabric at various frequencies (Figure 3b). The study found that the total heat of the system decreased with the increase in microclimate thickness. Neither their experimental results nor theoretical calculations showed any clear evidence of the onset of natural convection. Natural convection in a vertical microclimate starts when the buoyancy force overcomes the fluid resistance [75]. Mert et al.’s [65] study also found that the number of folds increased the amount of total heat loss in the skin–clothing–environment system. Santos et al. [87] developed a numerical heat transfer model in 2D cylindrical microclimates implementing forced convection from the ambient air to the cloth outer surface for a Reynold number of 3900. They suggested that the airflow inside the microclimate regime depended on the air velocity of the ambient air, a characteristic length corresponding to the microclimate thickness, and the porosity of the fabric. The airflow inside the microclimate was estimated to be laminar when the fabric porosity was such that it kept the microclimate air velocity < 0.16 m/s and the characteristic length of the fluid flow < 20 mm.

Figure 3.

Schematic representations of cross-sections of (a) homogeneous and (b) heterogeneous vertical microclimate (inspired by [65]).

4.3. Effect of Clothing Properties

The clothing properties that impact human thermophysiological comfort can be divided into three categories: (a) fiber, (b) yarn, and (c) fabric properties [11]. Fibers are small hair-like structures whose length is generally thousands of times greater than the width [88]. The final properties of textile materials partly depend on the chemical and structural features (i.e., crystallinity) of the fibers of which they are comprised [89,90]. Next, a yarn is a continuous strand-like form that is produced by twisting fibers together [88]. When a yarn is produced from filament fibers, it requires low twist/no twist to create the continuous strand [91]. The final properties of textile materials depend on the yarn fineness, number of twists per inch of yarn (TPI), cross-section, production technique, etc. [92,93]. Lastly, the fabric is a 3D structure produced by the interlacement or interloping of yarns or chemical and mechanical bonding of fibers [94]. The functionality of textile materials greatly depends on the fabric’s structural features, physical and mechanical properties, and surface finish [95]. The next sections describe the fiber, yarn, and fabric characteristics that contribute to human thermophysiological comfort.

4.3.1. Effect of the Fiber Properties

The fiber properties that can contribute to human thermophysiological comfort include their moisture absorption and transmission properties, heat of sorption, thermal conductivity, and specific heat capacity [11]. These properties mainly depend on the chemical and structural features (i.e., the fine structure of fiber) of the constituent fibers [36]. For instance, Fourt and Harrist [96] and Badr et al. [97] reported that the type of fibers in fabrics influences the water vapor transmission rate regardless of the fabric structure. When talking about fibers, the term “fine structure” refers to the way the fiber is formed by the linear arrangement of polymer chains, how the crystallites are oriented and ordered, the structure of the crystalline and amorphous regions, the degree of crystallinity, and the size of the crystallites [98].

Moisture is absorbed in textiles as either a liquid or vapor [1]. When moisture (both liquid and vapor phases) is absorbed by fibers, heat is either absorbed or released into the system [36]. This heat is called heat of sorption. A general tendency of molecules is to stay at a low chemical potential (i.e., the condition at which a substance stays at low energy). When moisture absorption occurs into the fiber, the fiber reaches a low chemical potential due to heat release. The water molecule absorbed by the fiber can be attached to the polymer structure either directly or indirectly, i.e., it can be directly attached to the polymer structure or attached to another water molecule connected to the polymer structure. Several studies reported that heat of sorption is released when moisture is absorbed by fibers, which keeps the microclimate warmer than when the moisture is not absorbed by the fibers [99,100].

The crystallinity of fibers plays a large role in moisture absorption [36]. For instance, cotton fibers absorb less moisture than regenerated cellulosic fibers (e.g., rayon and lyocell). The crystalline regions in cotton are tightly packed and experience no moisture absorption. On the other hand, the crystalline regions in rayon and lyocell are less compact, causing some level of moisture absorption in the crystalline region. Morton and Hearle [36] also reported that the moisture regain, a parameter that is used to describe the moisture-vapor absorption of fibers from the ambient air, largely depends on the degree of crystallinity of fibers. A high degree of crystallinity usually causes a low moisture regain and vice versa.

Some studies explored the effect of crystallinity on the water vapor transmission rate, but these studies mainly focused on polymer composites. For instance, Trifol et al. [101] investigated the effect of crystallinity on the water vapor transmission rate through a cellulose polymer matrix. The study found a higher water vapor transmission rate through amorphous specimens than crystalline specimens. Duan and Thomas [102] investigated the water vapor transmission rate of PLA (polylactic acid) specimens with different crystallinity percentages. The study showed a decline in the water vapor transmission rate with an increase in crystallinity percentage.

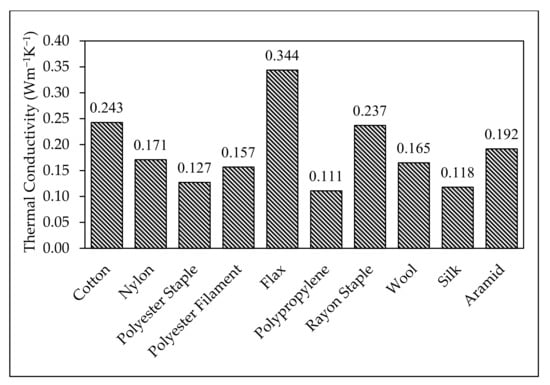

The crystallinity of fibers also affects their thermal properties, such as thermal conductivity, specific heat capacity, and heat of sorption [36]. The heat transfer through the crystalline regions of a fiber occurs through crystal lattice vibrations [103]. For the amorphous regions, the conductive heat transfer mainly involves the intrachain axial conduction mechanism [104]. A polymer with a higher degree of crystallinity exhibits a higher thermal conductivity than a polymer with a lower degree of crystallinity [105]. For instance, the thermal conductivity of polyester fibers is usually lower than that of cotton, which has been attributed to the lower degree of crystallinity of the PET polymer [36]. In addition, the free volume in the amorphous regions of low-density polymers causes their low thermal conductivity. Figure 4 provides a comparison of the thermal conductivity of different textile fibers.

Figure 4.

Thermal conductivity of different fibers [106].

The presence of amorphous regions in the fiber structure increases the thermal insulation of textile materials [36]. The specific heat capacity refers to the amount of heat that can be stored per unit mass and the associated change in the temperature of fibers [62]. The specific heat capacity thus has a negative correlation with the crystallinity percentage [107]. However, the number of studies that have analyzed the relationship between the thermal conductivity or specific heat capacity of fibers and their crystalline structure is limited.

The chemical groups present in the polymer, both side groups and the backbone, also affect the moisture absorption behavior of fibers [36]. Based on the chemical groups present, textile fibers can be categorized into two classes: (a) hydrophilic and (b) hydrophobic. Hydrophilic fibers contain polar groups (such as -OH, -NH3, -COO−, and -CO-NH2) in their chemical structure, resulting in higher moisture absorption. On the other hand, hydrophobic fibers contain relatively inert groups and have poor moisture absorption. For instance, the chemical composition of polyester includes a benzene ring, —CH2—, and —CO.O—. None of these groups has a strong affinity toward water molecules. As a result, polyester fiber is considered a hydrophobic fiber.

4.3.2. Effect of Yarn Properties

Yarn characteristics that affect thermophysiological comfort include the yarn linear density, yarn fiber content, yarn twist, and yarn tightness [92,108,109]. The term “linear density” (sometimes called yarn count/numbering) expresses the fineness of the yarn [88]. Özdil et al. [92] investigated the thermal resistance of 1 × 1 rib structures manufactured in a 28-gauge and 30-inch circular knitting machine using 100% cotton yarns with different linear densities. The thermal resistance of rib fabrics decreased with the decrease in linear density (i.e., finer yarns). The authors attributed this decrease to the fact that finer yarns might trap less air in their structure compared to bulkier yarns, causing low thermal resistance of fabrics. Conversely, the water-vapor permeability of fabrics increased with the increase in yarn fineness, as finer yarns create more open channels in fabric structures for moisture-vapor transport.

Yarn fiber content plays an important role in human thermophysiological comfort [110]. Hydrophilic and hydrophobic fiber types function differently in terms of heat (e.g., the heat of sorption) and moisture (e.g., moisture regain and wicking) management. Therefore, several studies suggested fiber blending techniques to create yarns that give better performance in warm and sweaty conditions [111,112]. Prakash and Ramakrishnan [113] investigated the thermal comfort properties of fabrics made of yarns produced by blending cotton and bamboo-based regenerated fibers. The study found an increase in air permeability and water-vapor permeability of fabrics with the increase in bamboo fiber content in the yarn. In contrast, the thermal conductivity of fabrics had a decreasing trend with the increasing proportion of bamboo fibers in the yarn.

There are two types of yarns: (a) staple and (b) filament [88]. Staple yarns are produced from short fibers by twisting them together, whereas filament yarns are produced with little or no twist. The level of twist applied to fibers or filaments to create yarns significantly impacts the thermal comfort properties of fabrics [114]. A higher number of twists per unit length of yarn decreases the volume of void spaces in the yarn, causing a decrease in the thermal resistance of the corresponding fabric. Özdil et al. [92] also showed that the thermal resistance of fabrics decreased with the increase in the yarn twist while the water-vapor permeability increased. Similarly, Atalie et al. [114] reported that as the number of twists per unit length in the weft yarn increased, the thermal resistance of a 100% cotton fabric decreased.

The spinning technique used is also one of the determinants of the contribution of yarns to the thermal comfort properties provided by the fabric. The ring-spinning process produces the finest yarns compared to all other techniques [88]. Indeed, it involves multiple steps to remove short and unnecessary fibers and creates slivers with parallel fibers using the combing process [115]. On the other hand, other yarn manufacturing techniques, such as the air jet technique, focus on quick production and do not have multiple refining steps [116]. The air jet spinning technique applies twists on the slivers using a pneumatic air flow mechanism, which provides a bulky cross-section to the final yarn. The bulkiness in the yarn cross-section traps air and increases the thermal insulation of the final product [117]. Moreover, the texturization process is used in the filament yarn production to improve the bulkiness and elasticity of yarns. The bulkiness in the texturized yarns influences the thermal insulation and moisture transport properties of fabrics [109].

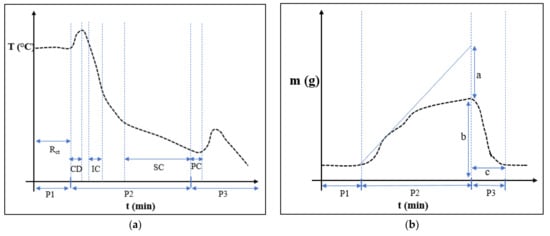

4.3.3. Effect of Fabric Properties

Fabric physical properties (thickness, weight, count, structure, porosity, etc.) and surface properties (e.g., surface finish) can affect thermophysiological comfort [11]. First, the fabric thickness impacts its thermal resistance and water-vapor transmission rate [28]. As the fabric’s dry thermal resistance is given by the fabric thickness divided by its thermal conductivity, the thermal resistance of the fabric increases with the fabric thickness for the same thermal conductivity. On the other hand, the water-vapor transmission rate through a fabric structure (J) is equal to the product of the water-vapor diffusion coefficient (DF) and the water-vapor concentration difference (ΔC) between both sides of the fabric, divided by the fabric thickness (L), as described by Fick’s law [75]. If DF and ΔC are kept constant, the water-vapor transmission rate will decrease with the increase in fabric thickness. An experimental study by Stoffberg et al. [118] found that the fabric thickness had a positive correlation with the dry thermal resistance and a negative correlation with the water-vapor transmission rate. In another study, Dalbaşı et al. [119] reported an increase in fabric dry thermal resistance with the number of washing cycles due to an increase in the fabric thickness. In addition, fabric weight and thickness are positively correlated when the fabric density remains constant [75]. Fabric weight (or mass per unit area) thus also affects thermal comfort properties [11]. Guan et al. [33] investigated the sweat absorption behaviors of cloth using a sweating cylindrical torso. The results showed that fabrics with higher weight and thickness absorb more sweat than lighter and thinner fabrics.

Fabric count, structure, and porosity are interrelated fabric parameters [120]. Fabric count refers to the number of threads per unit length in the longitudinal direction and transverse direction of the fabric [88]. When the fabric count is low, the fabric structure is loose and has high porosity [121,122]. Several studies have reported how fabric count, structure, and porosity impact thermal comfort properties [95,123]. Limeneh et al. [124] investigated the thermal comfort properties of different weave structures (i.e., plain, twill, and satin) made of 100% cotton yarns. The fabrics had the same fabric count and yarn linear density. The results showed that the satin and twill structures exhibited higher water-vapor permeability, water absorption rate, and air permeability than the plain structure. This result was attributed by the authors to the amount of yarn interlacements in the fabric structure. They suggested that, since the satin structure has a lower number of interlacements, the length of void channels through the fabric structure where air and water vapor can travel increases. On the other hand, the plain structure had the highest number of interlacements, which caused poor moisture vapor and air transport properties through the fabric.

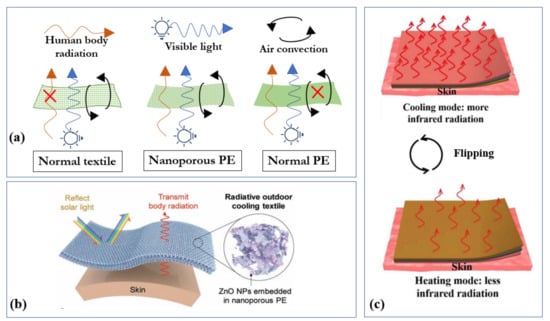

Lastly, the surface finish of the fabric may also affect the thermal comfort properties of clothing [11,109]. Surface-finishing techniques can be either (a) chemical or (b) mechanical. Chemical surface finishes can enhance the cool touch feeling, radiative cooling, and solar heat reflection of fabrics [125]. Dalbaşı et al. [119] treated fabrics made of regenerated bamboo fibers and regenerated bamboo–cotton blends with softeners made of poly-amino siloxane to improve the fabrics’ cool touch or thermal absorptivity. The experimental results showed higher thermal absorptivity in the treated fabrics compared to the untreated fabrics. The use of a solar radiation-reflective chemical finish on the outer surface of cloth limits the penetration of solar radiation through the fabric and keeps the body cool [126]. In addition, hydrophilic finishes improve the moisture-wicking performance of clothes [11]. On the other hand, water-repellent finishes prevent the wetting of fabrics by water and block its penetration through the fabric. When a fabric is wet, its thermal conductivity increases, which can cause excessive heat loss from the human body [28]. For their part, mechanical finishes are applied to enhance the warmth, bulkiness, and smoothness of the fabric surface [11,88]. Raising and shearing are two mechanical finishing techniques that cut the loops from one side of the fabric and create a fleecy surface. The fleecy surface improves the thermal insulation property of fabrics [88].

4.4. Effect of Ambient Conditions

Human body thermophysiological comfort depends also on environmental parameters [8]. Previous scholarly works identified four essential environmental parameters of thermophysiological comfort: air temperature, air velocity, relative humidity, and mean radiant temperature [2]. Sometimes, the air temperature is different from the “feels like” temperature because the sensation of warmth and coolness also depends on air velocity, relative humidity, and mean radiant temperature at the same time. This feel-like temperature is referred to as the apparent temperature [127].

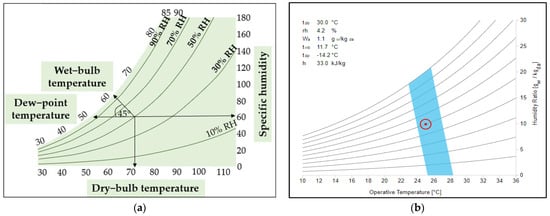

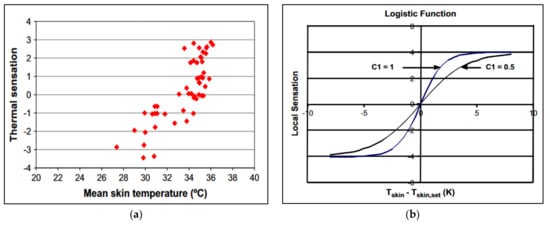

The psychometric chart is a graphical representation of moisture air thermal and physical (i.e., amount of vapor present in air) properties [128]. The vertical axis of the psychometric chart on the right side is the specific humidity, the bottom horizontal axis is the dry-bulb temperature, and the curvature on the left side indicates the dew-point temperature (Figure 5a). The dry-bulb temperature is the actual air temperature in dry conditions [8,129]. The dew-point temperature is the temperature at which moisture vapor starts condensing—the air is at full saturation. The specific humidity is different from the relative humidity and can be defined as the amount of vapor per unit mass of dry air. The wet-bulb globe temperature and relative humidity are derived from the dry bulb temperature, specific humidity, and dew-point temperature (Figure 5a). The wet-bulb temperature is the minimum temperature at which water evaporates in the atmosphere and cools air at a steady pressure [8]. It is measured using a wet wick wrapped around the bulb of the thermometer. The wet-bulb globe temperature is positioned along the curve of the dew-point temperature in the top-left corner (Figure 5a). The wet-bulb globe temperature is determined by drawing a diagonal line along the top-left corner direction, which creates a 45-degree angle (approximately) from the perpendicular crossing point of dry-bulb temperature and specific humidity. When the specific humidity is extended in the exact opposite direction horizontally (from right to left), it can determine the dew-point temperature. The curvature lines inside the graph represent different relative humidity values.

Figure 5.

(a) Schematic diagram of a psychometric chart (inspired by [129]), and (b) CBE thermal comfort tool (reproduced from [130], available through the Creative Commons license: http://creativecommons.org/licenses/by/4.0/ (accessed on 8 July 2023).

Tartarini et al. [130] developed a thermal comfort prediction tool (called CBE thermal comfort tool) using a psychometric chart. The tool uses the operative temperature, air velocity, relative humidity, metabolic rate, and clothing insulation as inputs to predict whether the human subject is within or outside the comfort zone (Figure 5b). The red point located within the blue comfort zone in Figure 5b indicates the operative temperature (which depends on the dry-bulb temperature, mean radiant temperature, and air velocity) and relative humidity of the environment. Teitelbaum et al. [131] applied contour shading in the psychometric chart to define the comfort zone using comfort parameters, such as mean radiant temperature, air velocity, metabolism, skin wetness, and physical activity of occupants.

Based on the discussion above, it is evident that human thermophysiological comfort depends on multiple environmental parameters. Huang and Chen [132] investigated the effect of air temperature, air velocity, and relative humidity on the water-vapor transmission rate through the fabric structure. They found that the water-vapor transmission of the fabric increased with the air temperature and velocity, while it had a negative correlation with the relative humidity of the air flowing over the fabric surface. The numerical simulation of the heat transfer in a 2D cylindrical microclimate showed that the ambient air velocity increased the convective heat transfer coefficient from the outside of the fabric to the ambient [87]. Guan et al. [110] investigated the radiant heat gain (RHG) with or without the presence of a radiant heat source, including a continuous sweat supply at different rates. The study found that the hygroscopic fabrics tested exhibited a high RHG compared to the hydrophobic fabrics. The study also showed that RHG increased with the incident radiation intensity.

4.5. Effect of Body Movement

Several researchers explored the effect of human body movement on human thermophysiological comfort [28,133,134,135]. Belding et al. [133] investigated the effect of different levels of physical activities (e.g., sitting, standing, and walking) on the human body’s thermal energy balance and clothing insulation while closing the opening at the wrists, ankles, waist, etc. The results showed that the lower-level activities (i.e., sitting and standing) produced a metabolic heat of 50 to 70 cal·m−2·h−1, while the higher-level activities produced 300 to 500 cal·m−2·h−1. The heat loss from the human body at a lower level of physical activity occurs by convection and radiation through the cloth layer. On the contrary, at a higher level of physical activity, the heat-loss mechanism includes sweat evaporation and other external mechanisms. In the case of clothing insulation, the study found that the clothing insulation varied depending on the intensity of the physical activity. The thermal insulation of the same clothing ensemble at standing, walking at 2.25 m/h, and running at 6 m/h were 2.7 clo, 1.6 clo, and 1.2 clo, respectively. The reduction in clothing thermal insulation was caused by the forced convection of air in the enclosed microclimate caused by human movement.

The forced convection caused by human movement in the enclosed microclimate between the human body and the cloth layer is sometimes referred to as the pumping effect [28]. Vogt et al. [134] investigated the influence of the pumping effect on the thermal insulation of the cloth layer. The authors assumed that the pumping effect would be minimal when the mean skin temperature and ambient air temperature have the same value. In this situation, most of the heat transfer is through radiation in addition to forced convection. On the other hand, when the mean skin temperature and mean radiant temperature (temperature of the chamber wall) are the same, the pumping effect is expected to be maximal. The results showed up to 75% of loss in the thermal insulation of the cloth layer was due to the pumping effect. Nielsen et al. [135] analyzed the effect of various physical activities, body shapes, sex, and air velocity on the thermal insulation of clothing. The study found that the clothing insulation is maximum in the standing position compared to a seated position, bicycling, and walking. The clothing insulation decreased by 8–18% in a seated position and 30–50% while bicycling and walking. An air velocity of 1.1 ms−1 decreased the thermal insulation of clothing by 18% in a standing position, while it did not affect the thermal insulation of clothing in a seated position. The decline in clothing insulation was higher for male participants compared to female participants due to a higher pumping effect.

Another way to lose body heat through movements is called ventilation. Ventilation occurs when the garment openings are not sealed and fabric pores are large so that they allow the movement of microclimate air through the fabric structure [136]. External wind and human body motion cause the ventilation effect in the clothing system [137]. Zhu et al. [138] reported that fabrics’ air permeability significantly increased with the porosity, which causes the ventilation of air through the fabric structure due to human body movement [139]. However, there are a limited number of studies that have explored the ventilation effect due to pore structure and garment openings.

Researchers have developed empirical models to estimate the heat and moisture transfer due to the movement of body parts [68,136]. However, these models exhibit limited predictability in terms of estimating the thermophysiological comfort of any local body parts due to the complex nature of the fabric draping and human movement with different garment fits. Moreover, very few thermophysiological comfort prediction models have incorporated the pumping effect with realistic microclimate air gap values.

5. Materials and Advanced Technologies for Superior Thermophysiological Comfort

Techniques have been developed by researchers and garment manufacturers to improve the thermophysiological comfort of fabrics and garments. The next four sections cover the strategies based on fiber selection and engineering, moisture management finishes, radiative cooling and heating, and the use of smart textiles.

5.1. Fiber Selection and Engineering

Evidence of the use of textile fibers, namely, flax, has been found dating back to 35,000 BC [140]. Natural fibers (e.g., flax, cotton, wool, and silk) were the major sources for clothing applications until the nineteenth century. Hydrocarbon-based and regenerated cellulose fibers were invented throughout the late nineteenth century and twentieth century [141]. Advances in textile fibers in the late twentieth century and early twenty-first century were motivated by considerations related to sustainability and improved functionality [142]. Fibers used in clothing for superior thermophysiological comfort include cotton, wool, polyester, nylon, regenerated cellulose (rayon, modal, lyocell), elastane, channeled-cross-section fibers (e.g., Coolmax®), and fibers containing phase-change materials (e.g., Outlast®). They are described in the sections below, with the exception of fibers containing phase-change materials which are covered in Section 5.4. Table 5 provides the chemical nature, structural features, and functionality of some commercial fibers that have been used in clothing application for superior thermophysiological comfort.

Table 5.

Commercial fibers for superior thermophysiological comfort properties [143,144].

Cotton fiber has been widely used in the clothing industry for centuries as it has excellent thermal conductivity and moisture absorption properties [36]. The high thermal conductivity of cotton fibers comes from their polymeric structure [145]. The polymeric structure of cotton is highly crystalline, which makes it possible to transfer heat easily. On the other hand, the tightly packed crystalline structure of cotton makes cotton fiber less permeable to water vapor [36]. However, due to the presence of hydrophilic groups at the polymer backbone of the cellulose polymer, cotton fibers show excellent water absorbency. Studies have shown that the use of cotton fibers reduces the damp feeling of the wearer due to superior moisture absorption ability [99,146]. However, cotton fabrics show poor moisture-wicking ability, which leads to long drying times [147,148]. Plante et al. [146] explored the moisture dampness perception of clothing with varying fiber contents (i.e., cotton, wool, polyester, and a wool/cotton blend) in different RH values. The moisture dampness perception had a negative correlation with fiber hygroscopicity at 25% RH; the difference in dampness perception with different fiber contents decreased with the increase in ambient RH. Kim and Spivak [99] investigated the dynamic moisture-vapor transfer through bilayer fabrics made of cotton (C) and polyester (P) in various combinations, such as C/C, P/C, C/P, and P/P. The study found that the partial moisture-vapor pressure at the inner surface of the hydrophilic fiber-containing layer was lower due to the high absorption of moisture vapor, while for the hydrophobic fiber-containing inner layer, the partial moisture-vapor pressure was higher at the inner surface due to low absorption rate. Moreover, the inner surface temperature of the hydrophilic inner layer was higher compared to the hydrophobic inner layer because of the heat released during moisture absorption, which provided a warm feeling. Cotton fiber is usually blended with other fibers (i.e., moisture-wicking fibers) to improve the overall wicking performance of the fabric [111,112,149].

Wool fiber is extracted from the fur of sheep, camels, goats, rabbits, etc. [150,151]. Wool is well known for its thermal insulation, hygroscopic (i.e., moisture-vapor absorption) ability, air permeability, and water-vapor transmission. The concentric layer in the wool cross-section (from outer to inner) includes the cuticle layers (endocuticle, exocuticle, and epicuticle) layers, cortical cell, macro-fibrils, matrix, micro-fibrils, and twisted chains of proteins [152]. The epicuticle layer has microscopic pores that act as channels for water-vapor diffusion. Due to this, water vapor is easily absorbed by wool. However, the wool fiber surface usually repeals water droplets that come into contact and takes time to absorb liquid water. Wool is considered a hydrophilic fiber, as its monomer (a protein) contains (-COOH) carboxylic and (-NH2) on the ends [36]. As a result, wool fabrics dry slowly [153]. The scaly surface of the fiber helps to trap air in the fabric as well as provide a passage for moisture vapor to be transported [154]. Merino wool is one of the finest sheep wools and exhibits excellent thermal resistance and moisture absorption behaviors [155]. Merino wool forms natural crimps in the fabric structure, which improve the bulkiness and thermal insulation of the fabrics [156]. Kumar et al. [154] explored the thermal resistance and water-vapor transmission rate of fabrics made of merino wool, silk, and bamboo fibers with different fabric structures. The study found that fabrics with merino wool exhibited a higher thermal resistance and water-vapor transmission rate than fabrics made of silk and bamboo fibers, owing to the bulkiness of the wool fabrics.

Polyester fiber is produced from the reaction between ethylene glycol and terephthalic acid [145]. Polyester fibers are hydrophobic and usually more amorphous than cotton [36]. Thus, polyester fiber has a lower thermal conductivity than cotton [106]. On the other hand, the poor moisture absorption behavior of polyester may increase the moisture-wicking rate in polyester fabrics [157]. However, the wicking rate also depends on the yarn structure, fabric structure, and surface finish [158,159,160]. As polyester lacks moisture absorption properties, it minimizes the release of the heat of water sorption in the microclimate and causes a lower temperature at the inner fabric surface [99]. However, this process leaves the human skin wet, which causes discomfort [100]. The thermal properties of polyester fabrics can be improved by playing with the fiber fineness and cross-section. Varshney et al. [161] investigated the thermophysiological comfort of polyester fabrics with varying degrees of fiber fineness and different cross-sections (i.e., circular, triangular, four-channel propeller, and tetrakelion). The study found that the thermal resistance and air permeability of fabrics increased with the fiber fineness, while the wicking rate of fabrics with fibers with round cross-sections was lower than the other three types of cross-sections displaying receding or outward acute angles. Different commercial products have been developed where the cross-section of polyester fibers is deliberately altered to create capillary wicking channels along the fiber, such as Coolmax® and Octa® [144].

Nylon fiber (nylon 6,6) was invented in 1930 by Wallace H. Carothers, who was looking for a synthetic alternative to silk fibers [162]. Nylon is a polyamide fiber typically produced by the polymerization reaction of adipic acid and hexamethylenediamine; it contains the amide linkage (-CO-NH-) in its polymer structure [163]. The polymer backbone of the nylon fiber contains the hydrophilic -NH2 group, which leads to a high moisture absorption ability [36]. Moreover, nylon is less crystalline than cotton, which makes nylon fiber a good candidate for thermally insulating fabric [106,163]. Adamu and Gao [164] investigated the thermal comfort properties of woven fabrics made of cotton, nylon, and cotton–nylon blends. The results showed that the fabrics’ wicking increased with the proportion of nylon in the cotton–nylon blend, whereas the air permeability and moisture-vapor transmission rate decreased. The study also found that coarser yarns with the cotton–nylon blend increased the vertical and horizontal wicking rate. Anas et al. [165] explored the thermal comfort properties of weft-knitted fabrics made of nylon, polyester, cotton, and acrylic fibers. The results showed that fabrics made of nylon and polyester blends had higher air permeability than cotton and acrylic blends.

Rayon, modal, and lyocell fibers are man-made cellulose fibers or regenerated cellulose fibers [36]. These fibers are produced using wood pulp or other sources of cellulose. However, their production processes are slightly different, which affects the final thermal and moisture absorption behavior. The first generation of regenerated cellulose fiber is called viscose rayon and was invented in 1938 to replace silk [166]. The viscose rayon manufacturing process is complex, involves NaOH and CS2 solvent treatments, and generates a large amount of toxic chemical waste. Because the cellulose polymer is regenerated in a chemical process, the resulting viscose rayon has a lower crystallinity than cotton, which affects the final strength and thermal comfort behavior of fibers [163]. Viscose rayon fiber is comparatively less strong and shows superior moisture absorption [163,167] and thermal insulation [168] compared to cotton because of its reduced crystallinity. Prakash et al. [169] explored the moisture management behavior of a blend of cotton and regenerated cellulose fibers from bamboo. The study found that when the proportion of regenerated bamboo fibers increased, the wetting time and maximum wetted radius decreased, and the moisture absorption rate increased.

The second generation of regenerated cellulose fiber is called modal rayon or HWM rayon for “high wet modulus” [170]. It was developed to improve the wet strength of viscose rayon, which was a great concern for the dyeing process. However, the manufacturing process of modal fibers is still somewhat similar to the viscose process. The degree of crystallinity is moderate in modal fibers, which causes comparatively less moisture absorption than viscose rayon, but still more than cotton [171].