Random Forest-Based Machine Learning Model Design for 21,700/5 Ah Lithium Cell Health Prediction Using Experimental Data

Abstract

1. Introduction

2. Machine Learning-Based SOH Prediction Models Design

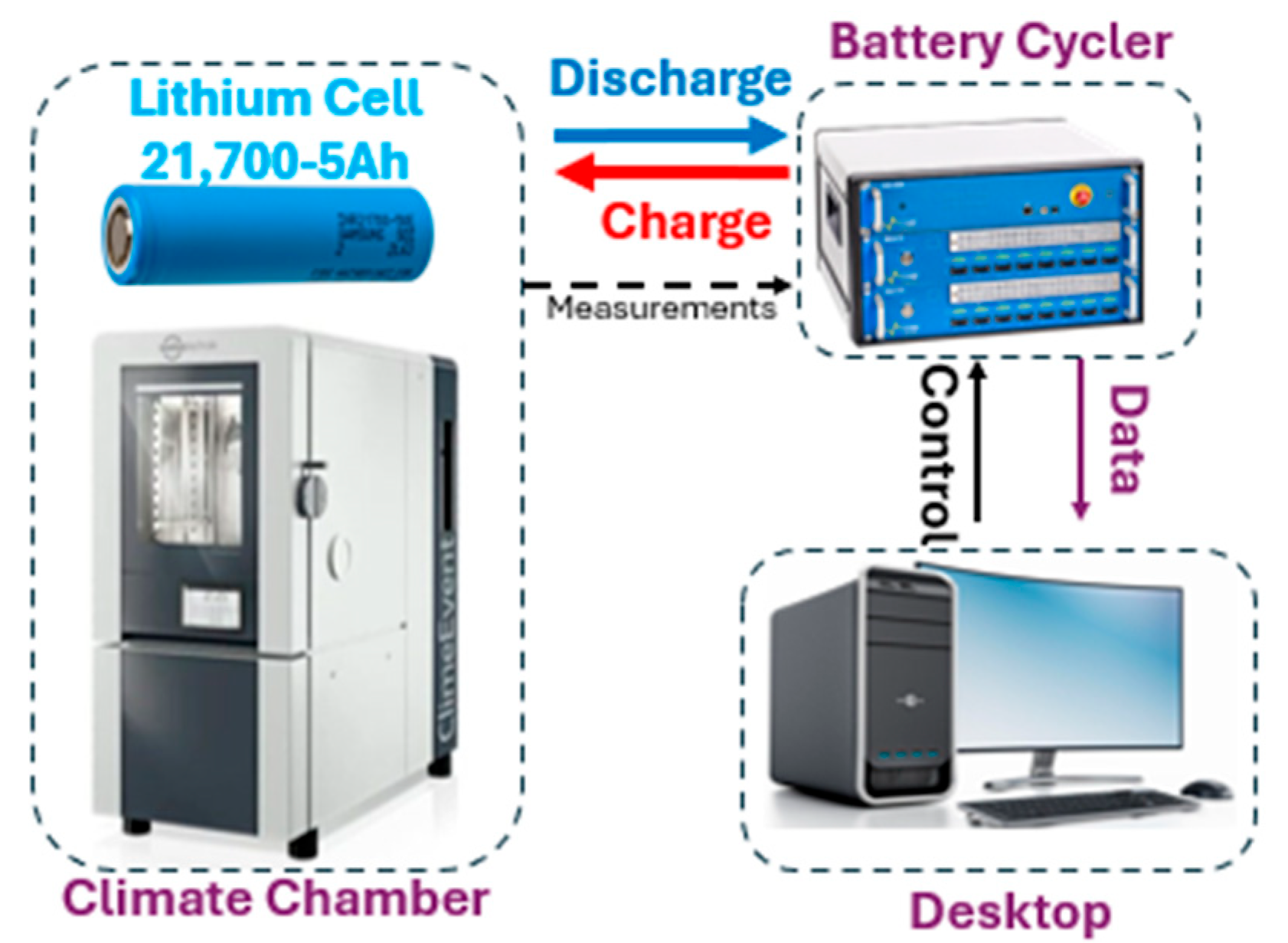

2.1. Data Collection

- ProDigitek battery cycler (BCS-800);

- Cell under test (Samsung INR21700-50S—5 Ah—3.6 V);

- Weiss Technik climate chamber;

- Desktop.

- Voltage (V): Measured at the battery terminals.

- Current (I): The charge and discharge currents.

- Temperature (T): Surface cell temperature.

- Capacity (C): The remaining capacity after each cycle.

- Ck is the capacity at the k-th cycle;

- Cinit is the initial capacity of the cell at the start of the test.

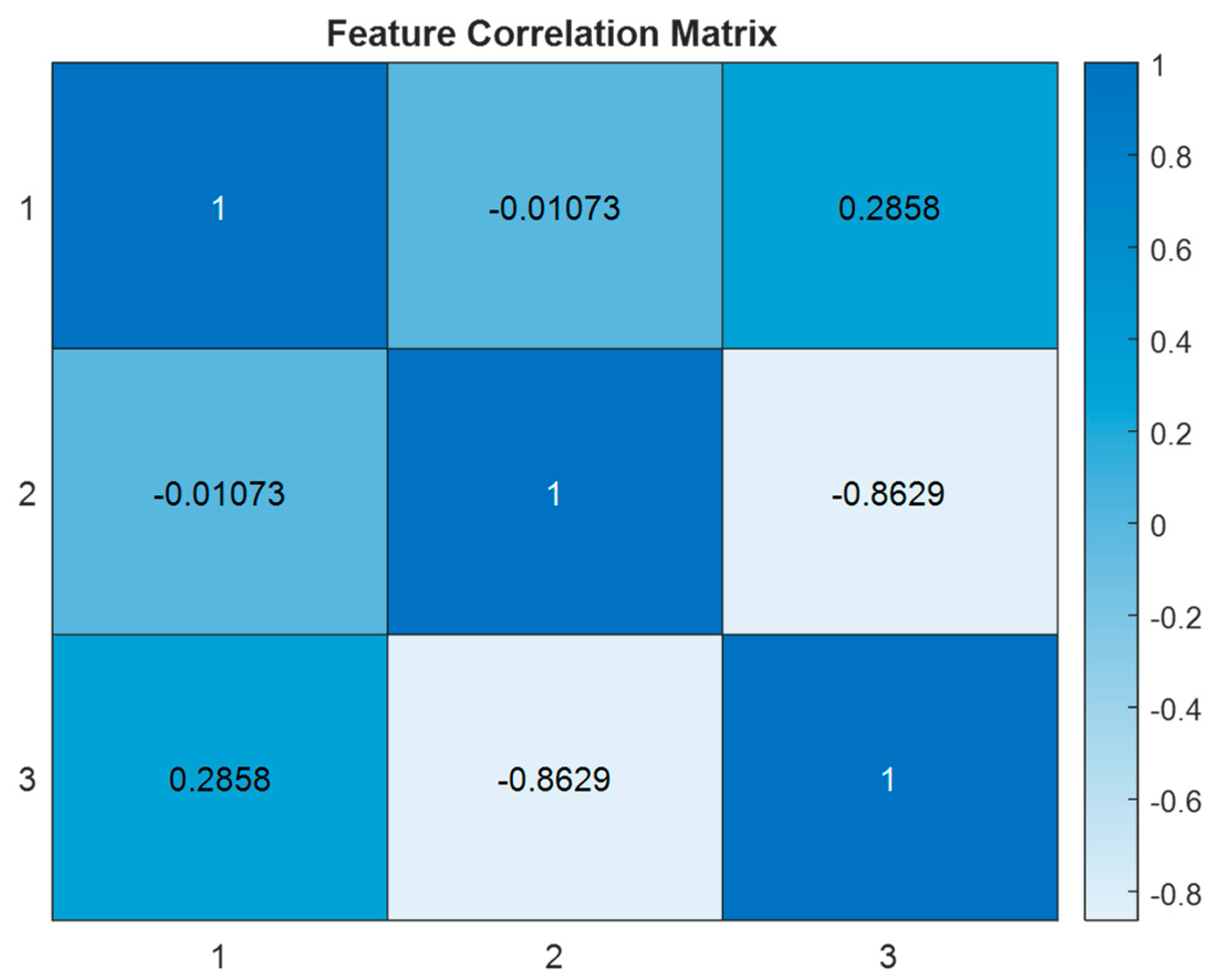

2.2. Data Preprocessing

- Outlier Removal:

- xi is the observed value;

- μ is the mean of the feature;

- σ is the standard deviation of the feature.

- 2.

- Normalization:

- x is the original feature value;

- min(x) and max(x) are the minimum and maximum values of the feature across the dataset;

- xnorm is the normalized value.

- 3.

- Feature Engineering:

- Vk is the voltage at cycle k;

- Vk+1 is the voltage at cycle k + 1.

2.3. Random Forest Model Design

| D: | The dataset; |

| Ntrees: | The number of decision trees in the forest; |

| Dmax: | The maximum depth of each tree; |

| Smin: | The minimum number of samples required to split a node; |

| Sleaf: | The minimum number of samples required to be in a leaf node. |

- is the prediction from the i-th tree;

- N is the total number of trees in the forest.

- M is the number of samples in the training dataset,

- yi is the true label for sample i;

- is the predicted label for sample i.

2.4. Support Vector Regression Model Design

- w and b are the parameters of the hyperplane;

- (xi) is the mapping function (kernel);

- ϵ is the error tolerance margin;

- ξi is the slack variable that allows for some errors in the model;

- C is the regularization parameter controlling the trade-off between a low error on the training data and a large margin.

Hyperparameter Tuning for SVR

- Regularization parameter C controls the trade-off between achieving a low training error and low model complexity. It regulates the margin of tolerance for classification errors in the training data. A smaller value of C allows more slack (tolerance for errors) in the model, potentially resulting in a smoother decision boundary with higher bias and lower variance. A larger value of C reduces the tolerance for errors, leading to a more complex model that might overfit (higher variance).

- Kernel Function: Radial Basis Function (RBF) kernel has been used; it is particularly suited for capturing complex non-linear relationships in the battery degradation data; this has been confirmed in recent studies focusing on battery performance prediction and degradation modeling [45]. The ability of the RBF kernel to transform data into higher-dimensional spaces makes it ideal for capturing the intricate behavior of battery systems over time [46]. Hyperparameter tuning is a critical step in ensuring that the SVR model performs optimally, as it directly influences the model’s generalization ability and prediction accuracy [13], where the kernel function is defined as (9):

- -

- x and x′ are input vectors (samples);

- -

- ||x − x′||2 is the squared Euclidean distance between x and x′;

- -

- σ is the bandwidth parameter, which controls the spread or “width” of the kernel, determining the locality of influence for each data point. A smaller σ value results in a more localized influence, whereas a larger value leads to a broader influence.

- Epsilon (ε) defines the margin of tolerance for error within which no penalty is applied. In other words, errors smaller than ϵ do not contribute to the loss function. The goal of SVR is to find a function f(x) that has at most ϵ deviation from the actual target values, while still being as flat as possible. This can be formulated as follows.

2.5. Performance Evaluation and Comparison

- R2 (Coefficient of Determination): This metric is used to measure the proportion of variance in the dependent variable that is predictable from the independent variables. It is calculated as (10):

- -

- are the actual values of the dependent variable for the i-th data point;

- -

- are the predicted values for the i-th data point;

- -

- is the mean of the actual values;

- -

- is the number of samples in the dataset.

- 2.

- RMSE (Root Mean Squared Error): RMSE is used to measure the average magnitude of the errors between the predicted and actual values. It is given by (11):

- 3.

- MAE (Mean Absolute Error): MAE measures the average magnitude of the errors in a set of predictions, without considering their direction. It is calculated as (12):

3. Results and Discussion

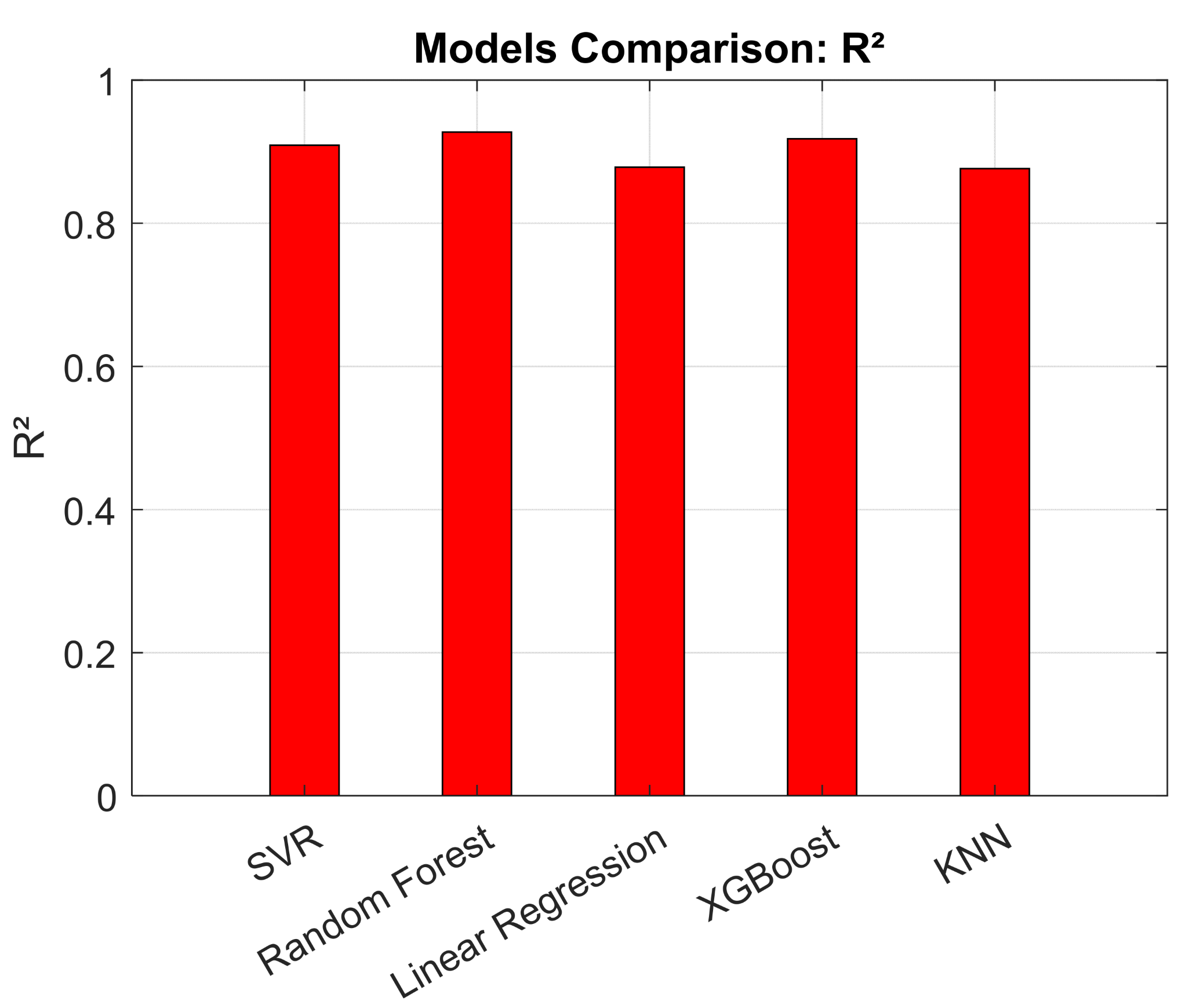

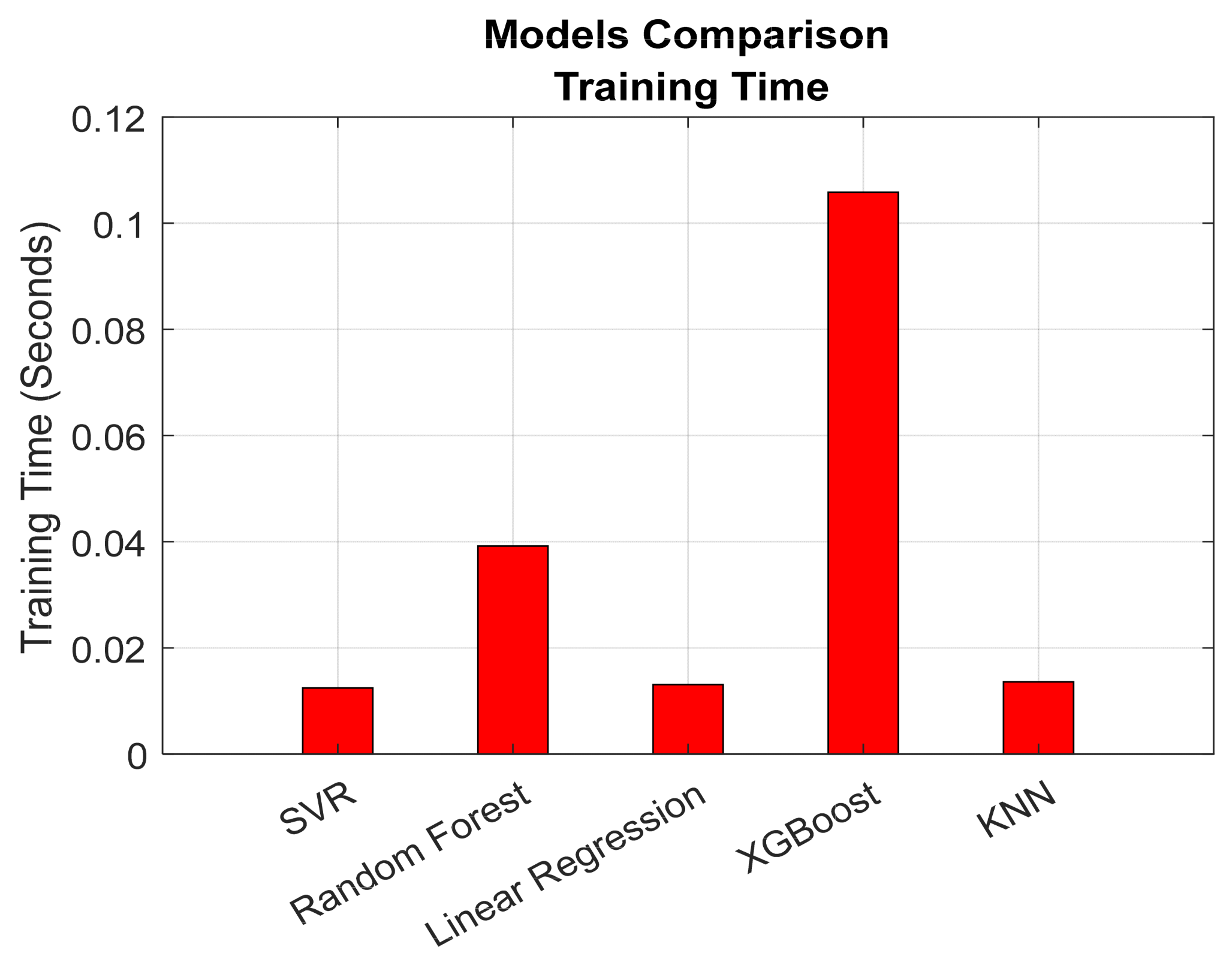

3.1. Different Models’ Metrics Performances

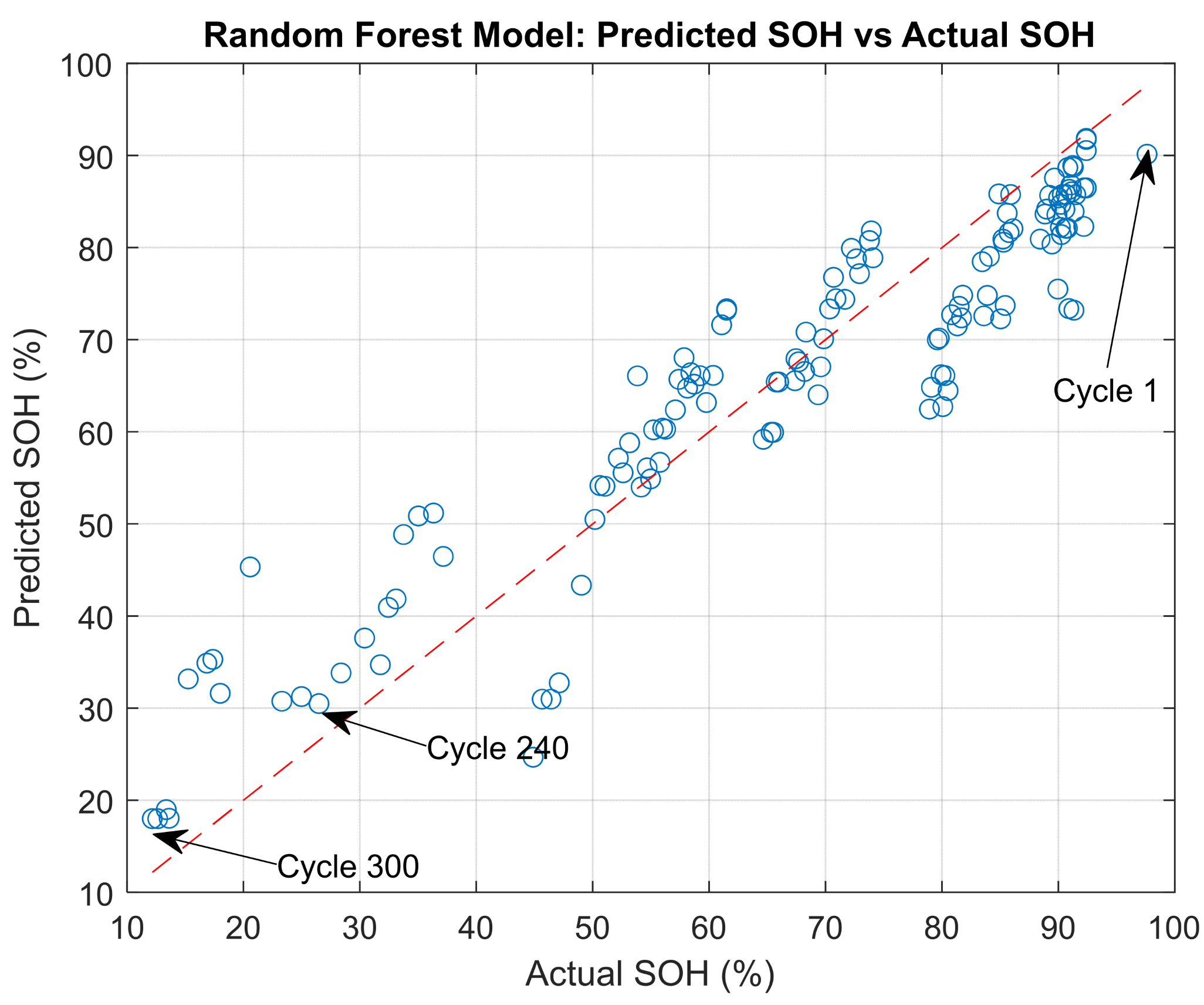

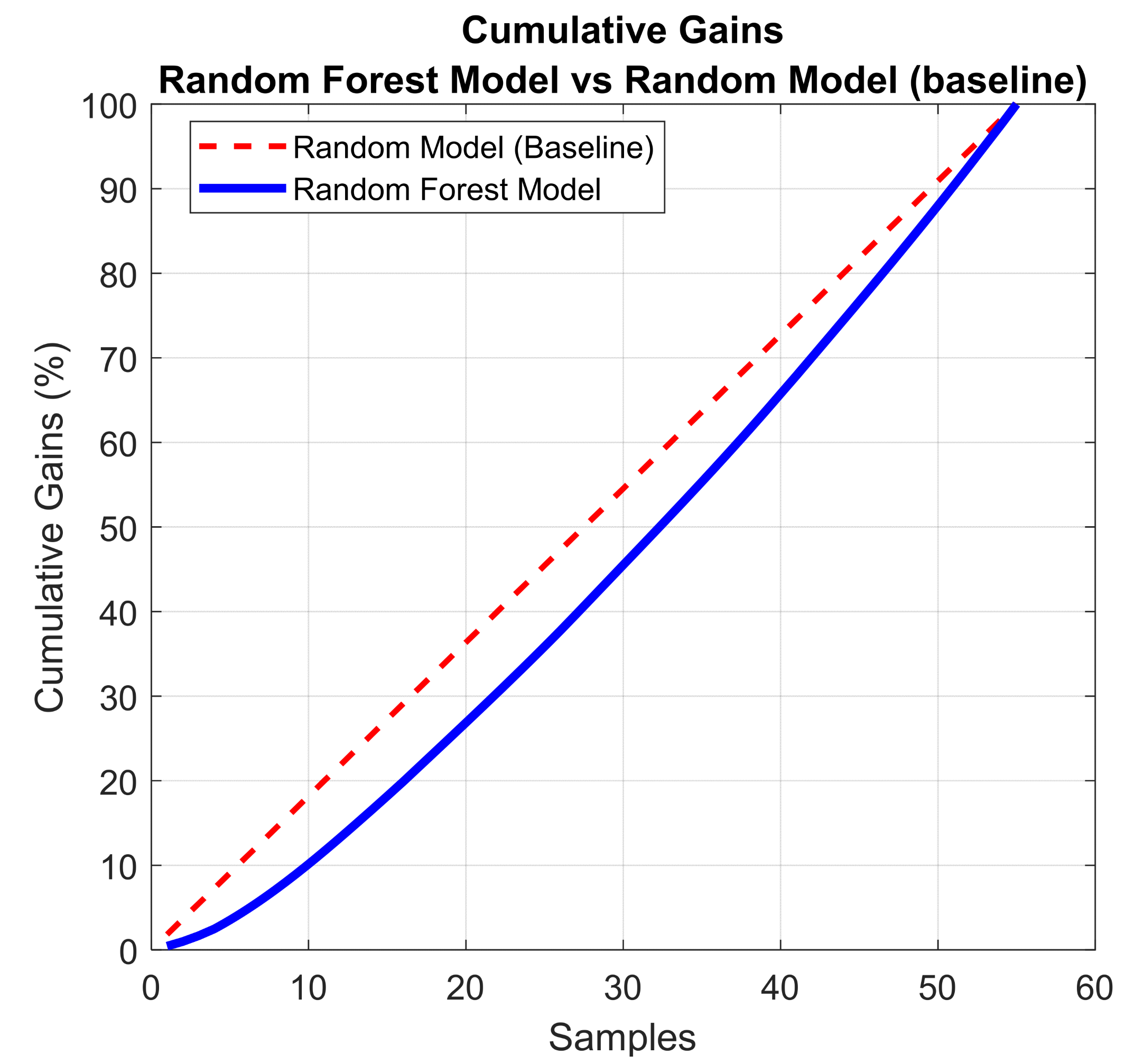

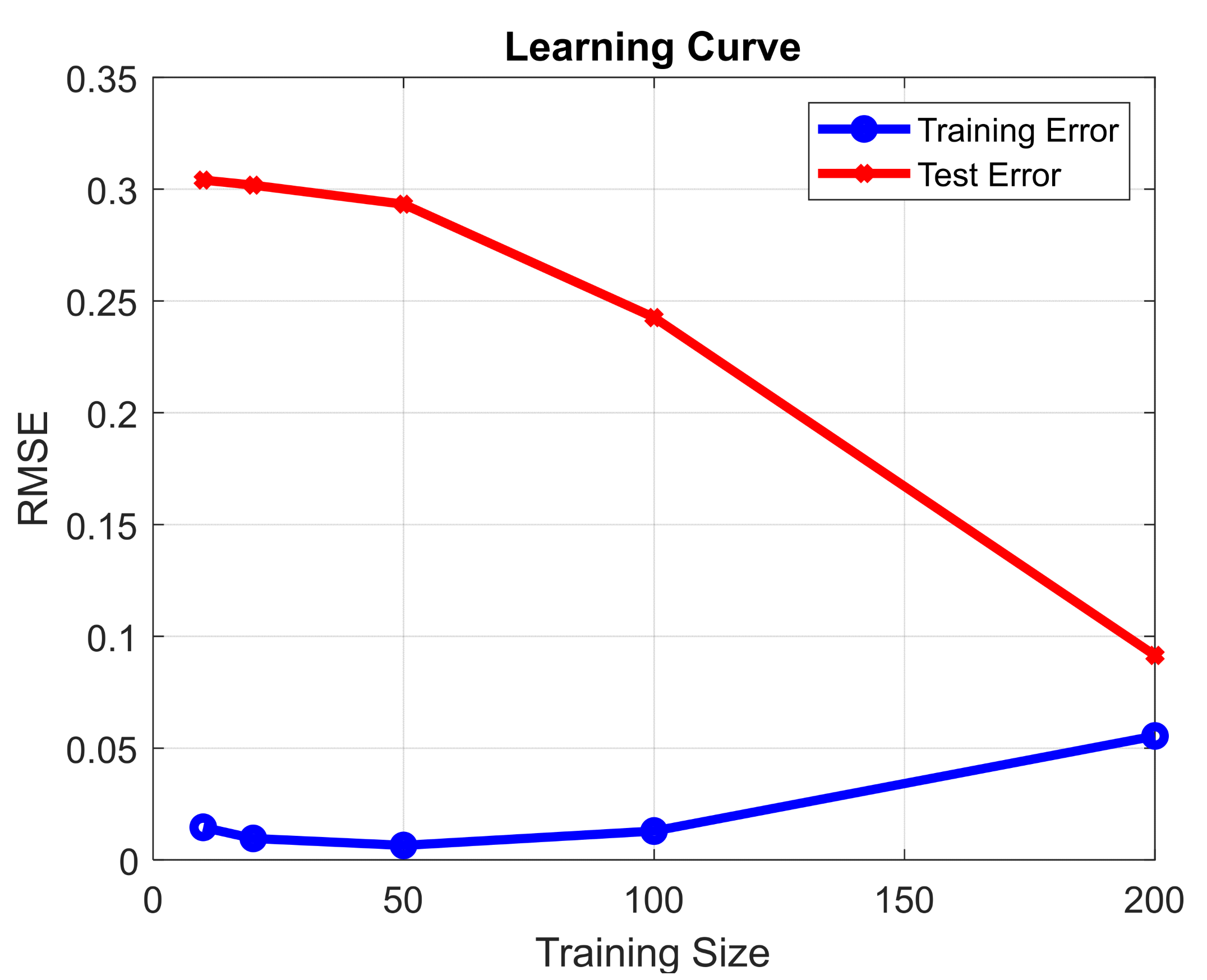

3.2. Random Forest Model Performance

3.3. Discussion

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kostenko, G.; Zaporozhets, A. Transition from Electric Vehicles to Energy Storage: Review on Targeted Lithium-Ion Battery Diagnostics. Energies 2024, 17, 5132. [Google Scholar] [CrossRef]

- Yarimca, G.; Cetkin, E. Review of Cell Level Battery (Calendar and Cycling) Aging Models: Electric Vehicles. Batteries 2024, 10, 374. [Google Scholar] [CrossRef]

- Baazouzi, S.; Feistel, N.; Wanner, J.; Landwehr, I.; Fill, A.; Birke, K.P. Design, Properties, and Manufacturing of Cylindrical Li-Ion Battery Cells—A Generic Overview. Batteries 2023, 9, 309. [Google Scholar] [CrossRef]

- Gong, J.; Xu, B.; Chen, F.; Zhou, G. Predictive Modeling for Electric Vehicle Battery State of Health: A Comprehensive Literature Review. Energies 2025, 18, 337. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, Q.; Zhang, Y.; Wang, J.; Stimming, U.; Lee, A.A. Identifying degradation patterns of lithium ion batteries from impedance spectroscopy using machine learning. Nat. Commun. 2020, 11, 1706. [Google Scholar] [CrossRef]

- Ouyang, M.; Feng, X.; Han, X.; Lu, L.; Li, Z.; He, X. A dynamic capacity degradation model and its applications considering varying load for a large format Li-ion battery. Appl. Energy 2016, 165, 48–59. [Google Scholar] [CrossRef]

- Barré, A.; Deguilhem, B.; Grolleau, S.; Gérard, M.; Suard, F.; Riu, D. A review on lithium-ion battery ageing mechanisms and estimations for automotive applications. J. Power Sources 2013, 241, 680–689. [Google Scholar] [CrossRef]

- Sylvestrin, G.R.; Maciel, J.N.; Amorim, M.L.M.; Carmo, J.P.; Afonso, J.A.; Lopes, S.F.; Ando, O.H., Jr. State of the Art in Electric Batteries’ State-of-Health (SoH) Estimation with Machine Learning: A Review. Energies 2025, 18, 746. [Google Scholar] [CrossRef]

- Park, J.; Jin, Y.; Kam, W.; Han, S. A practical semi-empirical model for predicting the SoH of lithium-ion battery: A novel perspective on short-term rest. J. Energy Storage 2024, 96, 12659. [Google Scholar] [CrossRef]

- Ren, Z.; Du, C. A review of machine learning state-of-charge and state-of-health estimation algorithms for lithium-ion batteries. Energy Rep. 2023, 9, 2993–3021. [Google Scholar] [CrossRef]

- Chen, L.; Wang, H.; Liu, B.; Wang, Y.; Ding, Y.; Pan, H. Battery state-of-health estimation based on a metabolic extreme learning machine combining degradation state model and error compensation. Energy 2021, 215, 119078. [Google Scholar] [CrossRef]

- Shen, S.; Sadoughi, M.; Li, M.; Wang, Z.; Hu, C. Deep convolutional neural networks with ensemble learning and transfer learning for capacity estimation of lithium-ion batteries. Appl. Energy 2020, 260, 114296. [Google Scholar] [CrossRef]

- Jafari, S.; Kim, J.; Choi, W.; Byun, Y.-C. Integrating Multilayer Perceptron and Support Vector Regression for Enhanced State of Health Estimation in Lithium-Ion Batteries. IEEE Access 2025, 13, 11463–11478. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, D.; Du, J.; Sun, H.; Li, L.; Wang, L.; Wang, K. A Review of SOH Prediction of Li-Ion Batteries Based on Data-Driven Algorithms. Energies 2023, 16, 3167. [Google Scholar] [CrossRef]

- Jorkesh, S.; Ahmed, R.; Habibi, S.; Hosseininejad, R.; Xu, S. Battery State of Charge and State of Health Estimation Using a New Hybrid Deep Neural Network Approach. IEEE Access 2025, 13, 12566–12580. [Google Scholar] [CrossRef]

- Ramezani, S.B.; Cummins, L.; Killen, B.; Carley, R.; Amirlatifi, A.; Rahimi, S.; Seale, M.; Bian, L. Scalability, Explainability and Performance of Data-Driven Algorithms in Predicting the Remaining Useful Life: A Comprehensive Review. IEEE Access 2023, 11, 41741–41769. [Google Scholar] [CrossRef]

- Çetinus, B.; Oyucu, S.; Aksöz, A.; Biçer, E. The Role of Machine Learning in Enhancing Battery Management for Drone Operations: A Focus on SoH Prediction Using Ensemble Learning Techniques. Batteries 2024, 10, 371. [Google Scholar] [CrossRef]

- Manoharan, A.; Begam, K.M.; Aparow, V.R.; Sooriamoorthy, D. Artificial Neural Networks, Gradient Boosting and Support Vector Machines for electric vehicle battery state estimation: A review. J. Energy Storage 2022, 55, 105384. [Google Scholar] [CrossRef]

- Choi, H.; Son, H.; Choi, Y.H.; Youn, B.D.; Lee, G. Reliability-based design optimization of a pouch battery module using Gaussian process modeling in the presence of cell swelling. Struct. Multidiscip. Optim. 2023, 66, 227. [Google Scholar] [CrossRef]

- Liu, Z.; Tang, L.; Wang, H.; Huang, Z. Capacity Prediction Method of Lithium-Ion Battery in Production Process Based on Improved Random Forest. Energy Technol. 2024, 12, 2300891. [Google Scholar] [CrossRef]

- Wang, G.; Lyu, Z.; Li, X. An Optimized Random Forest Regression Model for Li-Ion Battery Prognostics and Health Management. Batteries 2023, 9, 332. [Google Scholar] [CrossRef]

- Yang, N.; Hofmann, H.; Sun, J.; Song, Z. Remaining Useful Life Prediction of Lithium-Ion Batteries with Limited Degradation History Using Random Forest. IEEE Trans. Transp. Electrif. 2024, 10, 5049–5060. [Google Scholar] [CrossRef]

- Garse, K.M.; Bairwa, K.N.; Roy, A. Hybrid Random Forest Regression and Artificial Neural Networks for Modelling and Monitoring the State of Health of Li-Ion Battery. J. Electr. Syst. 2024, 20, 2231–2243. [Google Scholar] [CrossRef]

- Wang, X.; Hu, B.; Su, X.; Xu, L.; Zhu, D. State of Health estimation for lithium-ion batteries using Random Forest and Gated Recurrent Unit. J. Energy Storage 2024, 76, 109796. [Google Scholar] [CrossRef]

- Li, Y.; Zou, C.; Berecibar, M.; Nanini-Maury, E.; Chan, J.C.-W.; Bossche, P.v.D.; Van Mierlo, J.; Omar, N. Random forest regression for online capacity estimation of lithium-ion batteries. Appl. Energy 2018, 232, 197–210. [Google Scholar] [CrossRef]

- Quinn, J.B.; Waldmann, T.; Richter, K.; Kasper, M.; Wohlfahrt-Mehrens, M. Energy Density of Cylindrical Li-Ion Cells: A Comparison of Commercial 18650 to the 21700 Cells. J. Electrochem. Soc. 2018, 165, A3284–A3291. [Google Scholar] [CrossRef]

- Waldmann, T.; Scurtu, R.-G.; Richter, K.; Wohlfahrt-Mehrens, M. 18650 vs. 21700 Li-ion cells—A direct comparison of electrochemical, thermal, and geometrical properties. J. Power Sources 2020, 472, 228614. [Google Scholar] [CrossRef]

- Tian, J.; Li, S.; Liu, X.; Wang, P. Long-short term memory neural network based life prediction of lithium-ion battery considering internal parameters. Energy Rep. 2022, 8 (Suppl. S10), 81–89. [Google Scholar] [CrossRef]

- Venugopal, P. State-of-Health Estimation of Li-ion Batteries in Electric Vehicle Using IndRNN under Variable Load Condition. Energies 2019, 12, 4338. [Google Scholar] [CrossRef]

- Bulla, M.; Schmandt, C.; Kolling, S.; Kisters, T.; Sahraei, E. An Experimental and Numerical Study on Charged 21700 Lithium-Ion Battery Cells under Dynamic and High Mechanical Loads. Energies 2023, 16, 211. [Google Scholar] [CrossRef]

- Petz, D.; Baran, V.; Park, J.; Schökel, A.; Kriele, A.; Kornmeier, J.R.; Paulmann, C.; Koch, M.; Nilges, T.; Müller-Buschbaum, P.; et al. Heterogeneity of Lithium Distribution in the Graphite Anode of 21700-Type Cylindrical Li-Ion Cells during Degradation. Batteries 2024, 10, 68. [Google Scholar] [CrossRef]

- Amamra, S.-A.; Tripathy, Y.; Barai, A.; Moore, A.D.; Marco, J. Electric Vehicle Battery Performance Investigation Based on Real World Current Harmonics. Energies 2020, 13, 489. [Google Scholar] [CrossRef]

- Sudarshan, M.; Gautam, R.; Singh, M.; García, R.E.; Tomar, V. A comparative analysis of the influence of data-processing on battery health prediction by two machine learning algorithms. J. Energy Storage 2024, 104, 114524. [Google Scholar] [CrossRef]

- Kim, T.; Kang, D.; Oh, C.-Y.; Kim, M.; Baek, J. Efficient On-Board Health Monitoring for Multicell Lithium-Ion Battery Systems Using Gaussian Process Clustering. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018; pp. 5604–5609. [Google Scholar] [CrossRef]

- Liu, P.; Liu, C.; Wang, Z.; Wang, Q.; Han, J.; Zhou, Y. A Data-Driven Comprehensive Battery SOH Evaluation and Prediction Method Based on Improved CRITIC-GRA and Att-BiGRU. Sustainability 2023, 15, 15084. [Google Scholar] [CrossRef]

- Mohammadrezaei, M.; Maleki, Z.; Tabesh, A.; Khajehoddin, S.A. A Framework for Normalizing Physical Features of Li-Ion Batteries to Form a Generic Health Estimation Model. IEEE Trans. Transp. Electrif. 2024, 10, 6880–6892. [Google Scholar] [CrossRef]

- Piao, C.; Sun, R.; Chen, J.; Liu, M.; Wang, Z. A feature extraction approach for state-of-health estimation of lithium-ion battery. J. Energy Storage 2023, 73, 108871. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, C.; Meng, X.; Zhang, L.; Li, X.; Zhang, W. A Novel Feature Engineering-Based SOH Estimation Method for Lithium-Ion Battery with Downgraded Laboratory Data. Batteries 2024, 10, 139. [Google Scholar] [CrossRef]

- Maures, M.; Capitaine, A.; Delétage, J.-Y.; Vinassa, J.-M.; Briat, O. Lithium-ion battery SoH estimation based on incremental capacity peak tracking at several current levels for online application. Microelectron. Reliab. 2020, 114, 113798. [Google Scholar] [CrossRef]

- Andriunas, I.; Milojevic, Z.; Wade, N.; Das, P.K. Impact of solid-electrolyte interphase layer thickness on lithium-ion battery cell surface temperature. J. Power Sources 2022, 525, 231126. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, C.; Zhang, L.; Su, X.; Zhang, W.; Li, X.; Du, J. A novel aging characteristics-based feature engineering for battery state of health estimation. Energy 2023, 273, 127169. [Google Scholar] [CrossRef]

- Huang, S.-C.; Tseng, K.-H.; Liang, J.-W.; Chang, C.-L.; Pecht, M.G. An Online SOC and SOH Estimation Model for Lithium-Ion Batteries. Energies 2017, 10, 512. [Google Scholar] [CrossRef]

- Wang, R.; Xu, X.; Zhou, Q.; Zhang, J.; Wang, J.; Ye, J.; Wu, Y. State of Health Estimation for Lithium-Ion Batteries Using Enhanced Whale Optimization Algorithm for Feature Selection and Support Vector Regression Model. Processes 2025, 13, 158. [Google Scholar] [CrossRef]

- Li, Q.; Li, D.; Zhao, K.; Wang, L.; Wang, K. State of health estimation of lithium-ion battery based on improved ant lion optimization and support vector regression. J. Energy Storage 2022, 50, 104215. [Google Scholar] [CrossRef]

- Feng, R.; Wang, S.; Yu, C.; Hai, N.; Fernandez, C. High precision state of health estimation of lithium-ion batteries based on strong correlation aging feature extraction and improved hybrid kernel function least squares support vector regression machine model. J. Energy Storage 2024, 90, 111834. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; Chen, W.; Han, W. Holistic Comparison of Different Kernel Functions for Support Vector Regression Based on State-of-health Prediction of Lithium-ion Battery. In Proceedings of the 2020 11th International Conference on Prognostics and System Health Management (PHM-2020 Jinan), Jinan, China, 23–25 October 2020; pp. 40–46. [Google Scholar] [CrossRef]

- Gong, D.; Gao, Y.; Kou, Y.; Wang, Y. State of health estimation for lithium-ion battery based on energy features. Energy 2022, 257, 124812. [Google Scholar] [CrossRef]

- Xu, J.; Liu, B.; Zhang, G.; Zhu, J. State-of-health estimation for lithium-ion batteries based on partial charging segment and stacking model fusion. Energy Sci. Eng. 2023, 11, 383–397. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amamra, S.-A. Random Forest-Based Machine Learning Model Design for 21,700/5 Ah Lithium Cell Health Prediction Using Experimental Data. Physchem 2025, 5, 12. https://doi.org/10.3390/physchem5010012

Amamra S-A. Random Forest-Based Machine Learning Model Design for 21,700/5 Ah Lithium Cell Health Prediction Using Experimental Data. Physchem. 2025; 5(1):12. https://doi.org/10.3390/physchem5010012

Chicago/Turabian StyleAmamra, Sid-Ali. 2025. "Random Forest-Based Machine Learning Model Design for 21,700/5 Ah Lithium Cell Health Prediction Using Experimental Data" Physchem 5, no. 1: 12. https://doi.org/10.3390/physchem5010012

APA StyleAmamra, S.-A. (2025). Random Forest-Based Machine Learning Model Design for 21,700/5 Ah Lithium Cell Health Prediction Using Experimental Data. Physchem, 5(1), 12. https://doi.org/10.3390/physchem5010012