1. Introduction

In the quest for more sustainable and environmentally friendly construction practices, the search for viable bio-based alternatives to traditional chemical admixtures in cementitious materials has gained significant momentum [

1,

2]. Among these alternatives, sugarcane molasses (SCM) has emerged as a promising eco-efficient additive, primarily due to its organic composition, wide availability, and economic value [

3]. SCM is a viscous, dark brown byproduct derived from the final stage of sugar extraction in the sugar refining industry [

4]. Chemically, SCM consists of approximately 76% dry matter, with major constituents including sucrose (42.4–55.2%), glucose (2.6–8%), fructose (5.3–10.9%), ash (10–16%), and smaller quantities of organic acids, polysaccharides, oligosaccharides, crude protein, potassium, and nitrogen compounds [

5]. This composition imparts multifunctional behavior, enabling SCM to serve as a water-reducing, set-retarding, or accelerating agent based on its dosage and interaction with cement hydration products [

6,

7,

8,

9].

Numerous studies have explored the performance of SCM in modifying fresh and hardened properties of mortar and concrete. At lower dosages, SCM acts predominantly as a dispersant and hydration modulator. For instance, Yousif et al. [

10] reported a 41.4% increase in 7-day compressive strength and a peak strength of 40 MPa at 28 days with 0.25% SCM. Weifeng et al. [

11] demonstrated a 12% strength improvement at 3 days with just 0.04% molasses, along with delayed C

3S hydration and enhanced fluidity. In another study, Ali et al. [

12] found that incorporating 0.25–0.50% sugarcane molasses into recycled aggregate concrete improved both workability and compressive strength, particularly at a 0.50 W/C ratio, reinforcing the efficacy of low SCM dosages for enhancing fresh and hardened properties. These enhancements are typically attributed to the presence of sugars and organic acids, which modulate the formation and growth of hydration products such as ettringite and calcium silicate hydrates.

The retarding effects of SCM have been extensively documented. Khan & Baradan [

13] found a setting time delay of up to 255 min with 0.04% molasses, a behavior that proves especially valuable in hot weather concreting. Yildrim and Altun examined three molasses types sourced from different factories and found that molasses significantly prolonged both the initial and final setting times of mortar [

14]. Similarly, Kassa observed increased setting times with 0.075–0.1% molasses, while a higher dosage of 0.3% led to a reduction in setting time [

15]. Conversely, Juneja et al. reported that molasses accelerates setting at lower dosages (up to 0.5%) but delays it when used at higher levels (0.75–2.0%) [

16]. Mohammed & Kadhim [

17] utilized SCM in lightweight concrete, achieving 42.2 MPa compressive strength with a 19.31% reduction in density, highlighting its effectiveness even in alternative aggregate systems. From a durability perspective, Akar & Canbaz [

18] reported an increase in 28-day strength by 20% and improved resistance to alkali-silica reaction when SCM was incorporated at optimal levels. Similar findings were echoed by Dias et al. [

19], who studied hydration chemistry alterations due to the presence of molasses. These benefits underscore SCM’s potential to improve both the service life and the mechanical performance of cement-based materials. Despite its advantages, the performance of SCM is highly dosage sensitive. Exceeding optimal limits can result in excessive retardation or adverse effects on early-age strength. For instance, Odal [

20] demonstrated that incorporating 1.5% sugarcane molasses by weight of cement resulted in a marked reduction in compressive strength and a prolonged final setting time of 270 min, emphasizing the detrimental effects of excessive SCM dosage on early-age performance. Thus, determining the optimal dosage is critical for balancing workability, setting time, and mechanical performance.

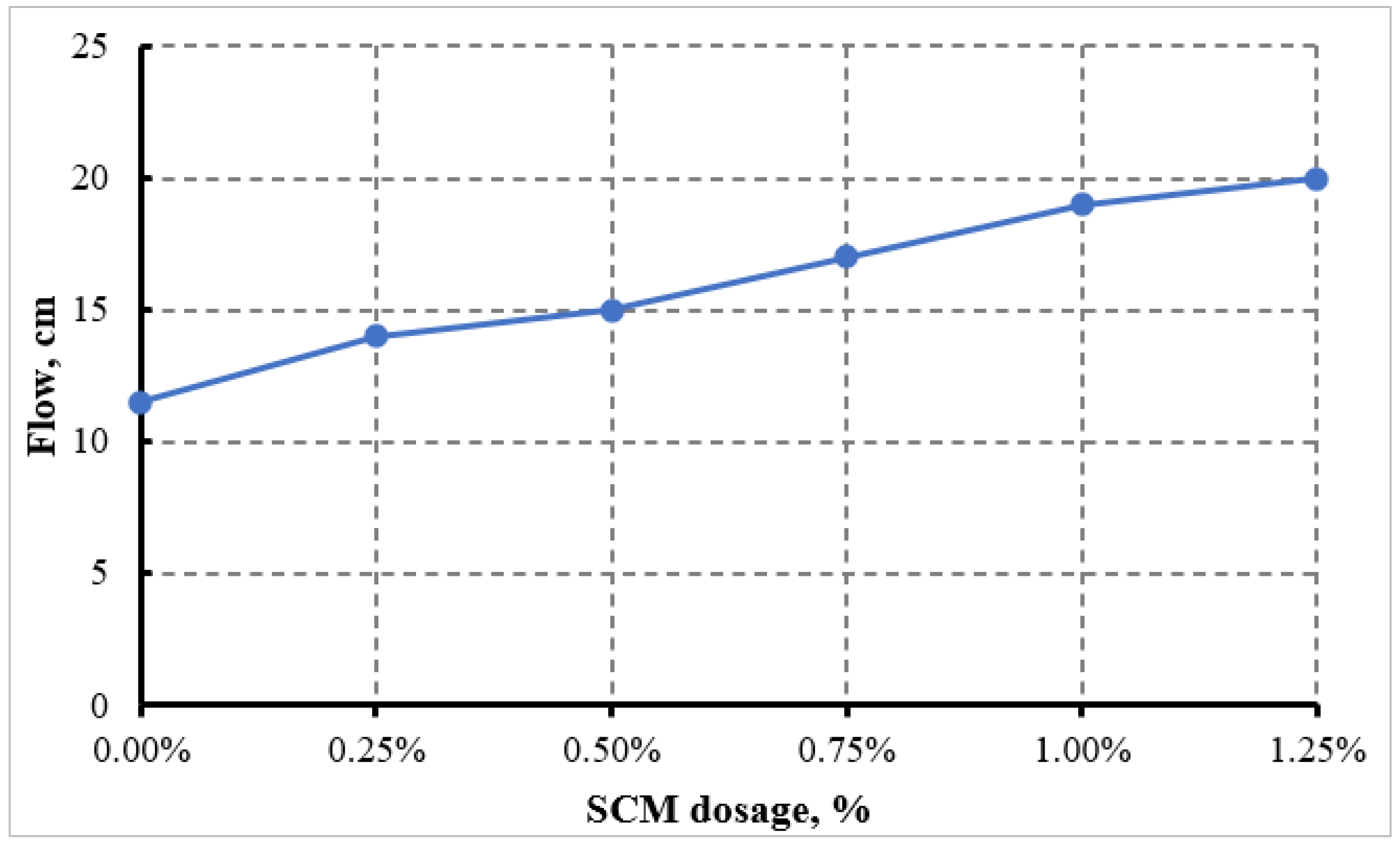

Given this context, the present study aims to systematically assess the performance of SCM as a bio-based additive in cement mortar. Five dosage levels of 0.25%, 0.50%, 0.75%, 1.00%, and 1.25% by weight of cement were selected to explore the dosage-dependent effects of SCM on both fresh and hardened properties. The experimental program encompasses the following: (i) workability characterization via flow table testing; (ii) mechanical evaluation through compressive strength testing at 7, 14 and 28 days, as well as flexural strength testing of prisms; and (iii) hydration behavior monitoring using embedded thermal sensors to capture real-time internal temperature evolution concerning ambient conditions. Additionally, the study investigates durability attributes, including water absorption and chloride ion penetration, alongside density measurements to assess the influence of SCM on pore structure and matrix compactness. Collectively, these assessments aim to deliver a comprehensive understanding of the role of SCM in influencing hydration kinetics, microstructural development, and performance outcomes in cement-based systems.

The novelty of this study lies in the comprehensive evaluation of SCM’s performance across fresh, mechanical, durability, density and thermal properties. In contrast to the previous limited investigations, this study utilizes real-time thermal monitoring linking SCM dosage with hydration kinetics and performance results.

To support the scientific rationale and contextual relevance of this study,

Table 1 offers a chronological summary of key investigations into the use of SCM in cementitious systems. It provides a structured comparison of experimental approaches, dosage levels, testing protocols, and resultant performance metrics. This summary consolidates current understanding while highlighting areas where further research is needed, offering valuable context for the objectives and direction of the present study. It is worth mentioning that each of the studies mentioned in

Table 1 has its own unique SCM composition, however they do not vary drastically from the limits given earlier.

3. Testing Program

For compressive strength evaluation, The 50 mm cubes were tested at the ages of 7, 14, and 28 days according to ASTM C109/C109M [

28]. The specimens were demolded after 24 h and cured in lime-saturated water until the designated testing ages. Testing was performed using a TC-B001 universal testing machine with a compressive strength capacity of 3000 kN, operated at a constant loading rate of 0.3 MPa/s. For each age and dosage, three replicate samples were tested, and the average value was reported.

Flexural strength was determined on prism specimens (40 × 40 × 160 mm) at 7, 14, and 28 days according to ASTM C348 [

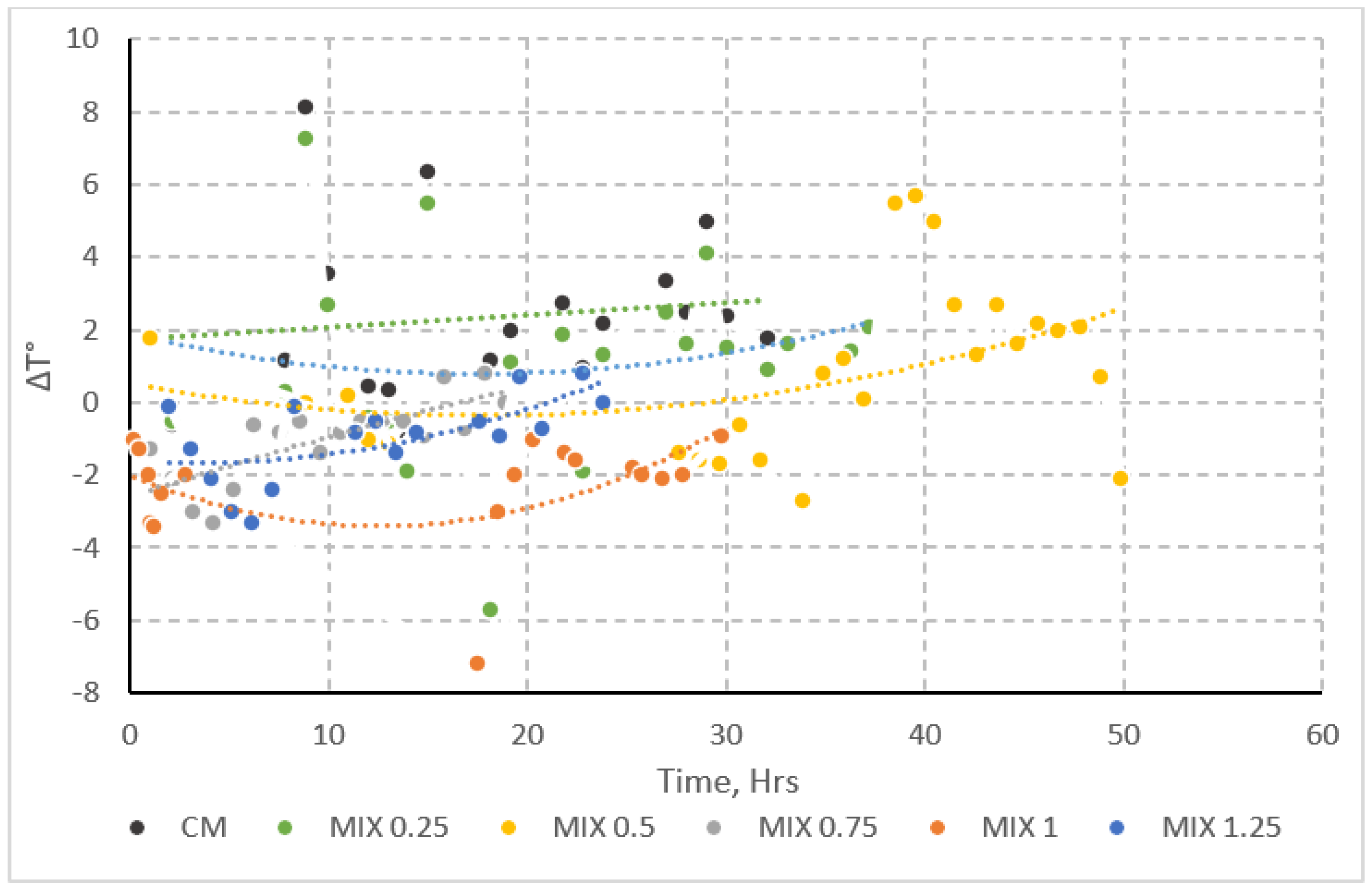

30]. The specimens were tested under three-point loading with a span length of 100 mm, and the applied load was recorded until failure. Similarly to compressive testing, the mean of three prisms was calculated for each age and SCM dosage. Thermal behavior during hydration was monitored by embedding calibrated electronic temperature sensors at the center of selected mortar cubes. Temperature readings were automatically logged at hourly intervals for the first 72 h of hydration, along with simultaneous ambient temperature measurements.

Figure 4 illustrates the thermometer and sensor arrangement. These measurements allowed for assessing the internal exothermic activity associated with hydration reactions and the influence of SCM dosage. Additional testing included flow table measurements for workability assessment (ASTM C230) [

31], water absorption (ASTM C642) [

32], and rapid chloride ion penetration (ASTM C1202) [

33]. Density was determined by oven-drying the specimens at 105 ± 5 °C to constant mass and dividing by their respective volumes. Each test was performed in triplicate, and averages are reported to ensure consistency and reliability.

5. Statistical Insight

To complement the experimental findings, regression and ANOVA analyses were conducted using Minitab 17 to statistically validate the effect of sugarcane molasses (SCM) dosage on cement mortar performance. The null hypothesis (H

0) assumed that no significant differences exist among the tested dosage levels, while the alternative hypothesis (H

1) posited that SCM content produces measurable changes in fresh, mechanical, thermal, durability, and density properties. A 95% confidence level was adopted, whereby a

p-value < 0.05 necessitates rejection of H

0, confirming that the observed variations are statistically significant. As summarized in

Table 7, the results demonstrated clear evidence of significance across multiple parameters. Compressive strength at 28 days showed a strong negative correlation with dosage (

p = 0.027), confirming that higher SCM levels reduce strength beyond random variation. Similarly, flexural strength decreased systematically with dosage (

p = 0.015), reflecting the same sensitivity. Workability, on the other hand, improved markedly with increasing SCM, and the regression model explained nearly all the variance (R

2 = 98.8%,

p < 0.001), highlighting a consistent and statistically robust trend. Durability indicators also reached significance: water absorption rose with dosage (

p = 0.009), and chloride ion penetration correlated strongly with SCM content (

p = 0.026), underscoring the negative durability implications of overdosing. Finally, density exhibited the most significant response, with R

2 = 99.8% and

p < 0.001, confirming that the observed reductions cannot be attributed to chance.

Overall, the statistical analyses conducted in Minitab 17 provide robust evidence that SCM dosage exerts a decisive effect on mortar performance. With all key performance indicators returning p-values below 0.05, the null hypothesis was consistently rejected. These findings reinforce the experimental observations and confirm that dosage optimization is critical: while low SCM levels enhance workability without major performance penalties, higher dosages significantly compromise strength, durability, and density. This statistical validation therefore justifies restricting SCM incorporation to ≤0.25% by cement weight for practical applications, beyond which adverse effects become both experimentally evident and statistically significant.