Abstract

To address the issues of significant brittleness in self-compacting concrete (SCC), limited parameter ranges in existing steel fiber reinforcement studies, and incomplete performance evaluation systems, this study conducted mechanical performance tests on steel fiber-reinforced SCC (SFRSCC) with a wide range of volume fractions (1–3%) and multiple aspect ratios. A multi-indicator comprehensive evaluation model of compressive strength, flexural strength, and elastic modulus was established using an improved entropy-weighted TOPSIS method. Gray relational analysis was integrated to reveal nonlinear correlation patterns between fiber parameters (the volume fraction and aspect ratio) and mechanical responses. The experimental results demonstrated the following: (1) At a 3% fiber content, compressive and flexural strengths increased by 25.7% and 280%, respectively, compared to the control group; (2) the elastic modulus peaked at 2% fiber content, with excessive content (3%) causing an uneven fiber dispersion and diminishing performance gains; (3) short fibers (6 mm) achieved optimal compressive strength at 3% content and medium-length fibers (13 mm) significantly enhanced flexural strength, while long fibers (25 mm) maximized the elastic modulus at 2% content. The combined application of the improved entropy-weighted TOPSIS method and gray relational analysis identified that the high fiber content (3%) paired with medium-length fibers (13 mm) optimally balanced flexural strength and toughness, providing theoretical guidance for the application of SFRSCC in tensile- and crack-resistant engineering projects.

1. Introduction

Self-compacting concrete (SCC), with its high fluidity, moderate viscosity, and resistance to segregation, can achieve self-leveling and compacting without or with minimal vibration, significantly improving construction efficiency and avoiding defects such as honeycombing and voids caused by insufficient vibration in traditional methods []. However, the inherent brittleness of SCC limits its application in projects sensitive to tensile and cracking stresses. To address this, researchers have explored performance-enhancement strategies through fiber incorporation [,].

Commonly used fibers include steel fibers, basalt fibers, polyvinyl alcohol (PVA) fibers, polypropylene (PP) fibers, and carbon fibers [,,,]. Wang et al. [] investigated the mix proportion of basalt fiber-reinforced self-compacting concrete, revealing that the optimal basalt fiber content is 0.1%. Chen et al. [] incorporated rubber of varying volumes and particle sizes into SCC and conducted impact resistance tests. The results showed that rubberized SCC significantly enhanced dynamic peak strain and stress without compromising static compressive strength, with the optimal rubber particle size being 1–2 mm. Wang et al. [] experimentally and numerically studied the flexural fracture behavior of steel fiber-reinforced rubberized self-compacting concrete (SRSCC). The results demonstrated that the addition of steel fibers improved the flexural strength of rubberized SCC. Furthermore, incorporating rubber and steel fibers in SRSCC enhanced the post-peak residual load capacity. The inclusion of steel fibers also provided excellent bridging effects, effectively inhibiting crack propagation and improving crack resistance before peak load.

The incorporation of an appropriate amount of single-type steel fibers into self-compacting concrete (SCC) can effectively enhance its mechanical and durability properties [,,,,,]. Siddique and Kaur [] investigated the mechanical properties of SCC by adding steel fibers at volume fractions of 0.5%, 1.0%, and 1.5%. The experimental results showed that, compared to plain SCC, the tensile performance of steel fiber-reinforced SCC specimens improved by 11.6%, 32.1%, and 38.7%, respectively. Additionally, with a steel fiber volume fraction of 1.5%, the compressive and tensile strengths increased by 33% and 24%, respectively, compared to plain SCC without fibers. The inclusion of steel fibers prevented the formation of internal microcracks and inhibited further cracking in the concrete specimens, thereby enhancing their tensile performance. Khaloo et al. [] conducted experimental studies by incorporating steel fibers at four different volume fractions (0.5–2%) into SCC to explore their effects on the properties of SCC at different strength grades (40 MPa and 60 MPa). The results indicated that the addition of steel fibers reduced the workability of SCC, leading to a decrease in the compaction level of the vibrated concrete. Iqbal et al. [] added steel fibers at volume fractions of 0.5%, 0.75%, 1.0%, and 1.25% to SCC and conducted mechanical tests. The study revealed that the flexural strength of the SCC mixture significantly improved with increasing steel fiber content. Specifically, as the steel fiber content increased from 0.5% to 1.25%, the performance of SCC improved by approximately 18%. Athiyamaan V [] incorporated hooked-end micro steel fibers with an aspect ratio of 60 into SCC at volume fractions of 0.25%, 0.50%, and 0.75%. The results demonstrated that the addition of steel fibers enhanced the flexural strength of SCC, suppressed crack propagation, prevented brittle failure, and improved its strain capacity. Aghaee et al. [] found that incorporating a certain volume of steel fibers into SCC could improve its strength, with the optimal steel fiber content being 0.75%.

Previous studies have found [,] that adding steel fibers to self-compacting concrete (SCC) can improve the matrix’s tensile strength, toughness, durability, and impact resistance. However, the incorporation of steel fibers increases the specific surface area of the matrix, and the bridging effect between steel fibers hinders the flow of the paste, both of which negatively affect the fluidity of SCC [,]. For instance, Hai Ran et al. [], Saba et al. [], and Zhou Jiye [] all noted in their studies that the workability of SCC decreases with an increase in the volume fraction of steel fibers. Specifically, Hai Ran et al. [] observed that when the steel fiber volume fraction exceeds 0.75%, the fluidity of SCC rapidly declines. Since the addition of steel fibers significantly alters the properties of the original SCC [,], and when the single-type steel fiber volume fraction exceeds 1.4%, the concrete no longer satisfies the self-compacting requirements [,].

Current research still faces the following limitations [,,,]: (1) Existing studies predominantly focus on a single aspect ratio or a narrow range of fiber volume fractions (≤1.5%), lacking systematic analysis of high volume fractions and the synergistic effects of multiple aspect ratios. (2) Most mechanical tests rely on single-indicator comparisons, lacking a comprehensive evaluation system that considers the coupled effects of multiple parameters.

To address these research gaps, this study conducts mechanical performance tests on steel fiber-reinforced SCC (SFRSCC) with a wide range of volume fractions (1–3%) and multiple aspect ratios. An improved entropy-weighted TOPSIS method is employed to construct a comprehensive evaluation model incorporating indicators such as compressive strength, flexural strength, and elastic modulus. Combined with gray relational analysis, the nonlinear mapping relationships between fiber parameters (volume fraction and aspect ratio) and mechanical responses are revealed. This study aims to identify the optimal fiber volume fraction and provide theoretical support for the mix design of high-toughness SCC in engineering applications.

2. Materials and Methods

2.1. Raw Materials

Cement: The cement used is P·O42.5 ordinary Portland cement produced by Chongqing Lafarge Baseway Cement Plant, with a density of 3.1 g/cm3. Fly Ash: low-calcium Class F fly ash provided by Chongqing Hualuo Fly Ash Company was used. Fine aggregate: manufactured limestone sand with a fineness modulus of 3.2, a fine powder content of 3%, an apparent density of 2.7 g/cm3, and a bulk density of 1.5 g/cm3. Coarse aggregate: crushed stone with a size range of 5–10 mm, an apparent density of 2.78 g/cm3, and a bulk density of 1.45 g/cm3. The water-reducing agent is a high-efficiency polycarboxylic acid water-reducing agent master batch with solid content (mass fraction) of 50~60% and is used in 6.5-fold dilution, tap water is used in the laboratory of Chongqing Jiaotong University, the steel fibers are used in the concrete, three kinds of steel fibers with different aspect ratios are added into the concrete for testing, as shown in Figure 1.

Figure 1.

Steel fiber with different aspect ratios.

2.2. Specimen Preparation

According to the Technical Specification for the Application of Self-Compacting Concrete (JGJ/T283-2012) [] and the Specification for the Design of Normal Concrete Proportions (JGJ/T55-2011) [], the baseline self-compacting concrete proportion with a strength class of C30 was determined. Table 1 records the steel fiber self-compacting concrete mix ratios for 1 m3 with different steel fiber volume admixtures.

Table 1.

Steel fiber self-compacting concrete specimen mix ratio (1 m3/kg).

2.3. Experimental Preparation

Prior to the commencement of performance research experiments on self-compacting concrete, it is requisite to initially conduct fluidity tests and passing ability tests [] thereon, with the aim of determining the slump flow diameters and J-ring slump flow diameters of self-compacting concrete of different volume contents. The specific testing procedures are as follows: The concrete mixture is loaded into a standard conical slump cone in accordance with the stipulated methodology. Upon completion of filling and leveling, the cone is lifted vertically upwards and then removed to the side. Owing to its self-weight, the concrete mixture undergoes a slumping phenomenon. Subsequently, the dimension of the downward slump is measured, and this measured dimension (expressed in millimeters) represents the slump value. The J-ring slump flow diameter is defined as the average value of the two mutually perpendicular diameters of the expanded surface of the concrete mixture after the termination of its slump flow, as shown in Figure 2.

Figure 2.

Slump flow and J-ring tests.

2.4. Loading Methods

According to existing research, the addition of fibers can improve the compressive strength of concrete; however, excessive fiber content may lead to discontinuities in the internal structure of the concrete, thereby reducing compressive strength. At the same time, varying dosages can be used to assess the economic feasibility of different fiber content levels, providing a basis for the cost–benefit analysis of the project.

In this study, the mechanical properties of self-compacting concrete are characterized by compressive strength, flexural strength, and modulus of elasticity; thus, cubic specimens and beam specimens are prepared for the corresponding tests. In this experiment, 10 groups of specimens of self-compacting concrete and self-compacting concrete with different aspect ratios of steel fibers at 1%, 2%, and 3% admixture were used for the preliminary experimental study to compare and analyze the effect of steel fibers on the properties of self-compacting concrete. The number of specimens in each group of the program is 60 for the cubic compressive strength test, flexural test, and bending and tensile test, respectively. The total number of specimens is 180. The dimensions and number of specimens are summarized in Table 2.

Table 2.

Specimen size and quantity.

2.4.1. Cubic Compressive Strength Test

The primary indicators used for assessing the strength of concrete materials are compressive strength and flexural strength []. The 100 mm × 100 mm × 100 mm cubic specimens were used; three identical specimens were prepared for each group, the mold was dismantled after 24 h of molding, and the specimens were taken out after 28 days of curing in a curing box, and the surface of the specimens was cleaned up. The tests were conducted on an MTS universal testing machine, and the specimen axis and the center of the lower pressure plate placed perpendicular to the upper pressure plate were adjusted to the upper surface of the specimen, close but not touching. The test machine was started with pre-pressure, pre-pressure loading speed of 0.5 MPa/s, physical alignment adjustment, and pressure stability adjustment. After the pre-compression was completed, the specimen was loaded at a uniform speed of 2 KN/s until the specimen was damaged, and then it was unloaded slowly, as shown in Figure 3.

Figure 3.

Concrete cubic specimen compression damage pattern.

The compressive strength results of the test block were calculated according to the following formula:

where —the compressive strength of steel fiber concrete cube (MPa); F—ultimate load (N); A—average value of compressed area above and below the specimen (mm2).

2.4.2. Flexural Strength Test

The size of the steel fiber concrete specimen block was 100 mm × 100 mm × 400 mm. The test was carried out on a hydraulic universal testing machine. The long axis of the specimen was perpendicular to the supporting circular axis, the specimen was loaded at a uniform speed of 50 N/s until the specimen was destroyed, and the oil tank of the machine was turned off. After 28 days of maintenance, specimen in the maintenance box was taken out; the surface was cleaned up; the surface of the test piece was checked; the specimen was placed on the test machine; and for the long axis of the test piece and support the vertical column, the distance between the lower two cylindrical supports was 0.3 m, with constraints using a fixed hinge and universal rolling hinge support. The test machine was opened. First of all, the test piece of pre-pressure had a loading force of 1 kN. The test piece was placed in a flat location in order to ensure the specification and safety of the test. The loading was continued, and the specimen did not produce initial damage before a loading rate of 0.06 MPa/s. Once the specimen cracked, it changed the loading method. Displacement control was used, loading until the specimen was destroyed, and then slowly unloading. As shown in Figure 4, the flexural strength of the specimen was expressed in MPa and was calculated according to the following formula:

where —flexural strength of steel fiber concrete, MPa; P—destructive load applied to the middle of the specimen at the time of fracture (N); L—spacing of support (mm); b—height of the specimen (mm); h—width of the specimen (mm).

Figure 4.

Concrete flexural damage pattern.

2.4.3. Modulus of Elasticity Test

The static modulus of elasticity of concrete is the main index reflecting the deformation properties of concrete. In accordance with GB/T50081-2019 “Standard for Test Methods of Physical and Mechanical Properties of Concrete” [], this test is conducted using four-point bending test, taking 1/2 of the average value of the flexural and tensile ultimate load as the load standard for flexural and tensile elasticity modulus test F0.5 and loading at a stress of 10 KN and a speed of 0.2 mm/min, then calculating to obtain the flexural and tensile elastic modulus of concrete tensile modulus of elasticity of concrete.

The modulus of elasticity of concrete against bending and tension was calculated using the following formula:

Eq: —modulus of elasticity of concrete against bending and tension (MPa);

—final and initial loads (N);

—corresponding and micrometer reading (mm);

L—distance between the supports of the specimen (L = 450 mm);

J—moment of inertia of the specimen section (mm). J = 1/12 bh3 (mm4).

3. Results and Analysis

3.1. Results of Workability Performance Tests

The experimental data are shown in Table 3.

Table 3.

The slump flow diameter and J-ring flow spread of steel fiber self-compacting concrete under different steel fiber dosages.

It can be observed from the obtained results that, under the condition of a constant steel fiber content, with the augmentation of the steel fiber length, certain trends emerge in the slump flow diameter and the J-ring slump flow diameter. When the steel fiber content remains unchanged, the J-ring slump flow diameter decreases linearly with the increment in the fiber length, signifying that alterations in the steel fiber length exert an impact on the fluidity and passing ability of the concrete. For steel fibers of identical length, as the steel fiber content rises, both the slump flow diameter and the J-ring slump flow diameter generally exhibit a downward tendency. For instance, in the case of a fiber length of 6 mm, when the steel fiber content escalates from 1% to 2%, the slump flow diameter declines from 830 mm to 770 mm, and the J-ring slump flow diameter drops from 690 mm to 670 mm; upon further increasing the content to 3%, the slump flow diameter plummets to 660 mm, and the J-ring slump flow diameter diminishes to 500 mm. This phenomenon indicates that the elevation of the steel fiber content augments the internal friction within the concrete, consequently diminishing its fluidity and passing ability.

The slump flow diameter of SCC is required to range from 550 mm to 850 mm. If it exceeds this range on the upper end, the paste and the aggregate will experience segregation; if it falls short on the lower end, the fluidity of the mixture fails to meet the self-compacting requirements. The experimental outcomes reveal that the slump flow diameters of the SFRSCC test groups lie between 560 mm and 830 mm, thus fulfilling the filling performance requisites. As the steel fiber content amplifies, the fluidity of the concrete wanes, and the slump flow diameter progressively decreases. When the steel fiber content is 3%, the filling ability of the mixture is the weakest, and the dosage of the water-reducing agent needs to be increased to improve the filling ability.

3.2. Influence of Fiber Length on the Mechanical Properties of Self-Compacting Concrete

The failure modes of the specimens are shown in Figure 5.

Figure 5.

Failure modes of specimens.

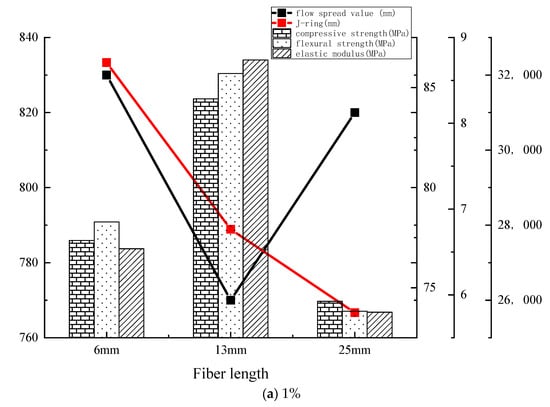

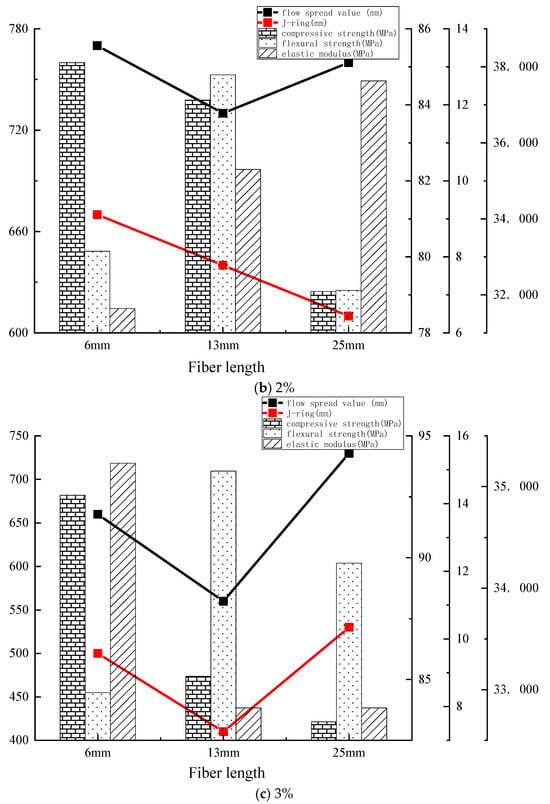

The test results of the mechanical properties of self-compacting concrete under different fiber lengths are shown in Figure 6.

Figure 6.

The influence of different fiber length of SFRSCC performance.

As can be seen in the above chart, with the increase in the length of steel fibers, the slump flow diameter and the J-ring slump flow diameter of self-compacting concrete generally show a trend of first decreasing and then increasing. This is because fibers that are too long or too short affect the fluidity of the concrete mixture, and medium-length fibers have a greater hindrance to fluidity. Relatively short fibers increase the friction between the internal particles of the concrete to a lesser extent, resulting in better fluidity, while overly long fibers are difficult to disperse in the concrete and are prone to intertwine with each other. Instead, they reduce the negative impact on fluidity to a certain extent.

When the fiber content is 1%, the concrete with 13 mm-long fibers has a relatively high compressive strength; when the fiber content is 2%, the concrete with 6 mm-long fibers has a relatively high compressive strength; when the fiber content is 3%, the concrete with 25 mm-long fibers shows outstanding compressive strength. This indicates that under different fiber contents, an appropriate fiber length can work better in coordination with the concrete, preventing the expansion of internal cracks in the concrete and thus increasing the compressive strength. With the increase in the length of steel fibers, the flexural strength generally shows a downward trend. Shorter steel fibers can be more evenly distributed in the concrete matrix, effectively preventing the generation and expansion of cracks and improving the flexural performance of the concrete, while longer fibers are prone to agglomeration and become stress concentration points when subjected to force, reducing flexural strength.

3.3. Influence of Fiber Content on the Mechanical Properties of Self-Compacting Concrete

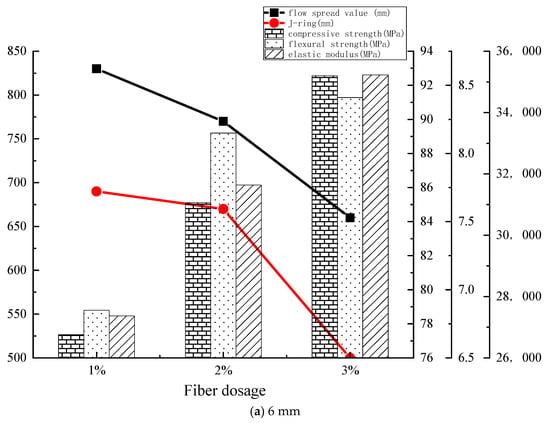

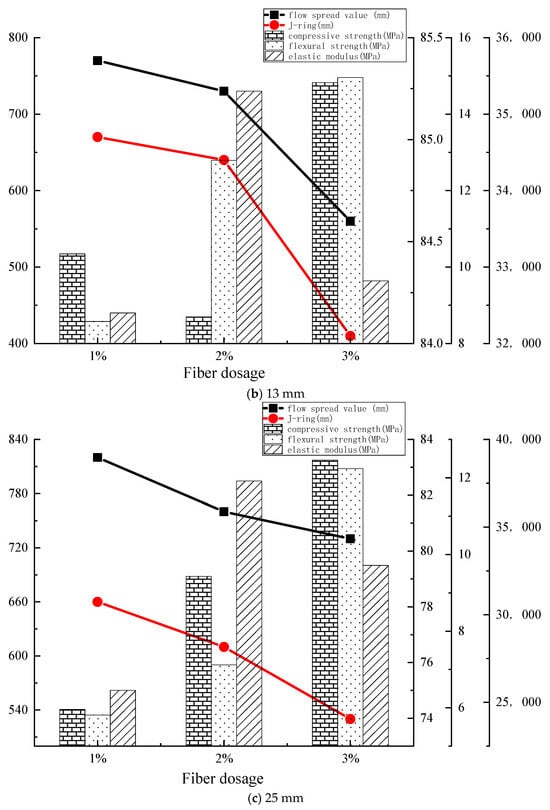

The test results of the mechanical properties of self-compacting concrete under different fiber contents are shown in Figure 7.

Figure 7.

The influence of different fiber dosages on the performance of SFRSCC.

With the increase in the content of steel fibers, both the slump flow diameter and the J-ring slump flow diameter of self-compacting concrete show a downward trend. This is because the addition of steel fibers increases the internal friction and cohesion of the concrete mixture, hindering the flow of the concrete. Moreover, the higher the fiber content, the more obvious this hindering effect is, resulting in poorer fluidity of the concrete.

Under different fiber lengths, as the content of steel fibers increases, the compressive strength of the concrete generally shows an upward trend. This indicates that the steel fibers play a reinforcing role in the concrete. They can effectively prevent the expansion of internal micro-cracks and share the external load, thereby improving the compressive capacity of the concrete. As the content of steel fibers increases, the flexural strength first rises and then falls. When the fiber length is 6 mm, the flexural strength increases when the steel fiber content increases from 1% to 2% but decreases when it further increases to 3%. The same situation occurs when the fiber lengths are 13 mm and 25 mm. An appropriate amount of steel fibers can effectively prevent crack expansion when the concrete is subjected to bending, improving the flexural performance. However, an excessive amount of steel fibers may lead to agglomeration, forming weak areas and reducing the flexural strength.

As the content of steel fibers increases, the elastic modulus fluctuates to a certain extent. The addition of steel fibers changes the internal structure and stress characteristics of the concrete, thus affecting the elastic modulus. The patterns of this influence vary under different fiber lengths.

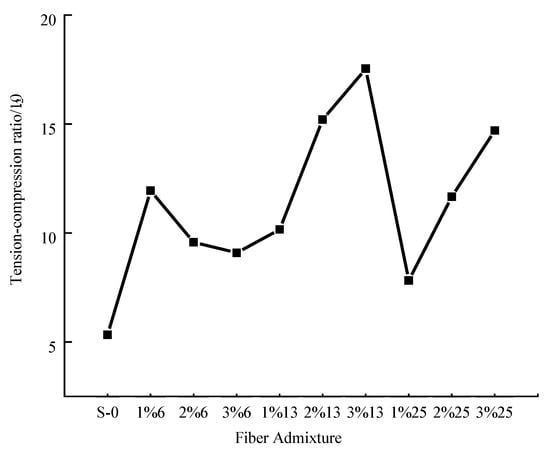

3.4. Tension–Compression Ratio

To conduct an in-depth exploration of the influence exerted by steel fibers on the strength of concrete, this study undertakes a further analysis of the data obtained from the experiments described in the previous sections, thereby deriving the tension-to-compression ratio of the test specimens. Subsequently, a line graph is constructed, with the steel fiber content designated as the x-axis and the tension-to-compression ratio as the y-axis, as presented in Figure 8. The values on the y-axis signify the ratio of the flexural strength to the compressive strength of the specimens. Evidently discernible from the graph, the incorporation of steel fibers leads to a notable enhancement in the tension-to-compression ratio of self-compacting concrete.

Figure 8.

Self-compacting steel fiber concrete tensile/compression ratio vs. volume of steel fiber admixture.

As shown in the figure, when the fiber aspect ratio is 6 mm, the tensile-to-compressive strength ratio of self-compacting steel fiber-reinforced concrete decreases with an increase in fiber dosage. As the aspect ratio increases, the tensile-to-compressive strength ratio increases with higher dosages. The possible reasons for this include an uneven distribution of steel fibers or insufficient bonding between the steel fibers and the concrete matrix, leading to unstable reinforcement effects. The volume effect of steel fibers at high dosages may cause discontinuities in the internal structure of the concrete, reducing performance. Overall, the addition of steel fibers can enhance the tensile strength and toughness of concrete; however, excessive dosages may decrease the workability and uniformity due to reduced flowability. Therefore, the dosage of steel fibers significantly impacts the tensile-to-compressive strength ratio, with an optimal dosage range existing beyond which the volume effect may impair performance. In practical applications, the optimal dosage of steel fibers should be determined based on specific engineering requirements and material characteristics.

4. Mechanical Property Analysis of Fiber-Reinforced Self-Compacting Concrete

4.1. Solution of Positive and Negative Ideal Sequences of the TOPSIS Method Improved Using the Entropy Weight Method

The TOPSIS method improved by the entropy weight method is a multi-attribute decision-making method. It introduces the entropy weight method on the basis of the traditional TOPSIS method, which can better solve the problem of uncertain attribute weights. The entropy weight method is used to obtain the weights of multiple indicators of the mechanical properties of self-compacting concrete, and the objective influence weights of the compressive strength, flexural strength, and elastic modulus on the mechanical properties are obtained through information entropy.

- (1)

- Normalize the positive indicator values according to Equation (4) and the negative indicator values according to Equation (5) to obtain the standardized matrix B = (m × n).

- (2)

- Calculate the proportion of the i—the sample index value under the j—the index according to Equation (6) to obtain the matrix F = (m × n).

- (3)

- The entropy weight method is adopted to calculate the index weights. Calculate the information entropy value according to Equation (7). The larger the information entropy value is, the greater the information entropy of the j—the index is. Calculate the weights according to Equation (8). The larger the index coefficient calculated by the entropy value method is, the greater the weight is, and the greater the contribution to the result is.

- (4)

- Apply the weights obtained using the entropy weight method to the solution of the positive and negative ideal sequences in the TOPSIS method. Construct the normalized decision making matrix , as shown in Equation (9), based on the index weights. Determine the optimal scheme and the worst scheme according to Equation (10) and Equation (11), respectively. Calculate the distance from the positive ideal solution and the distance from the negative ideal solution according to Equation (12) and Equation (13), respectively. Finally, calculate the score of the i-th group of tests according to Equation (14).

The calculation results of the entropy weight method are as follows: the weight of compressive strength is 32.05%, the weight of flexural strength is 25.37%, and the weight of elastic modulus is 42.59%. The calculation results of the TOPSIS evaluation method improved using the entropy weight method are shown in Table 4.

Table 4.

Calculation results of the TOPSIS evaluation method improved using the entropy weight method.

According to the calculation results of the entropy weight method, among the mechanical performance indexes of the compressive strength, flexural strength, and elastic modulus of the self-compacting concrete, the elastic modulus has the largest weight, indicating that its relative importance is high; the flexural strength has a smaller weight, indicating that its relative importance is low.

From the perspective of the comprehensive score results, the steel fiber self-compacting concrete with a steel fiber content of 3% and a fiber length of 13 mm (i.e., 3% 13) has the highest comprehensive score, indicating that in this calculation and evaluation, the comprehensive performance of the concrete under this combination is relatively better. Overall, it is not the case that the higher the fiber content or the longer the fiber length, the higher the enhancement effect on the mechanical properties of SCC. This shows that the influence of fiber length and content on the performance of concrete is interrelated.

4.2. Analysis of the Mechanical Properties of Fiber-Reinforced Self-Compacting Concrete Based on Gray Relational Analysis

Based on the gray relational analysis method, the compressive strength, flexural strength, and elastic modulus are taken as the mother sequences, and the data sequences of fiber characteristic parameters, which are the factors influencing the system behavior, are taken as the sub-sequences for analysis. The results are shown in Table 5.

Table 5.

Analysis results of the gray relational method.

In the gray relational analysis, a larger correlation degree indicates a stronger correlation between variables. The correlation degree between fiber characteristic parameters and the working performance of self-compacting concrete can be analyzed based on the correlation degree. As can be seen in the above table, both the fiber dosage and fiber length have an impact on the compressive strength, flexural strength, and elastic modulus of self-compacting concrete. Among them, the fiber dosage has a relatively high correlation with the mechanical properties of self-compacting concrete. To ensure that self-compacting concrete has good mechanical properties, the fiber length and fiber dosage should be controlled.

Overall, when ranking the correlation degrees of different performance indicators for different fiber characteristic parameters, the following order can be obtained: flexural strength > elastic modulus > compressive strength. This indicates that as the fiber dosage increases, the fibers are more densely distributed in the concrete, which can disperse and transfer stress to a greater extent, significantly improving the concrete’s ability to resist flexural failure. At the same time, fibers of appropriate length can better play their bridging role, effectively transferring stress when the concrete is bent and preventing the further expansion of cracks.

The compressive strength and elastic modulus are also affected by fiber characteristics, but their correlation degrees are lower than that of the flexural strength. This shows that the fibers have an effect on these two performance indicators, but the degree of influence is relatively weak. One should not overly rely on fibers to improve the compressive strength but rather mainly optimize the concrete mix proportion.

5. Discussion

In order to prove the reliability of this study, this article selects three similar studies from previous years for comparative analysis. By selecting similar types of steel fibers and fiber-reinforced self-compacting concrete (SFRSCC), this analysis examines the research conducted by previous researchers on SFRSCC. In 2024, researchers such as Mukilan [] found that steel fiber enhanced ductile failure by providing early indications (cracks) and preventing sudden failure. However, a higher dose of steel fiber (more than 1.5%) reduced the SCC performance due to a lack of flowability. Mechanical improvement was observed at a 1.25% addition of hooked-end fiber steel fiber, which shows 14.4% compressive strength. Ghorbani (2020) [] added steel fibers with a volumetric content of 0~1.65% to self-compacting concrete for research. The results showed that the performance of self-compacting concrete is optimal when the content is 1.65%.

In Table 6, it can be seen that the studies by Mukilan and Ghorbani mainly focus on the compressive strength of steel fiber-reinforced self-compacting concrete. This study, through various mechanical tests, investigates the impact of different volumes and dosages of steel fibers on the mechanical properties of self-compacting concrete. It further demonstrates that within the 0–3% range of steel fiber dosage, there is a significant positive effect on the mechanical properties of concrete, particularly in the improvement in flexural strength and the elastic modulus.

Table 6.

Comparison of experimental data.

6. Conclusions

This study systematically investigates the influence of different fiber parameters (the volume fraction and aspect ratio) on the mechanical properties of steel fiber-reinforced self-compacting concrete (SFRSCC) through experimental and theoretical analyses. The results demonstrate that fiber parameters significantly affect the compressive strength, flexural strength, and elastic modulus of SFRSCC, and these effects exhibit nonlinear correlation patterns.

- (1)

- With the increase in the steel fiber volume fraction, the compressive and flexural strengths of SFRSCC are significantly enhanced. When the volume fraction reaches 3%, the compressive and flexural strengths increase by 25.7% and 280%, respectively, compared to the reference group. However, the elastic modulus peaks at a volume fraction of 2%, and further increasing the fraction to 3% leads to uneven fiber dispersion, resulting in a slowdown in performance improvement.

- (2)

- Steel fibers with different aspect ratios exhibit varying enhancement effects on the mechanical properties of SCC. Short fibers (6 mm) demonstrate optimal compressive strength at a 3% volume fraction; medium-length fibers (13 mm) significantly improve flexural strength; and long fibers (25 mm) achieve the highest elastic modulus at a 2% volume fraction.

- (3)

- By employing an improved entropy-weighted TOPSIS method and gray relational analysis, this study constructs a multi-criteria comprehensive evaluation model, revealing the nonlinear correlation patterns between fiber parameters and mechanical properties. The results indicate that a combination of a high volume fraction (3%) and medium-length fibers (13 mm) achieves a balance between flexural strength and toughness, providing a theoretical basis for the engineering application of high-toughness SFRSCC.

In conclusion, the appropriate selection of fiber parameters (the volume fraction and aspect ratio) can significantly improve the mechanical properties of self-compacting concrete, offering new insights and methods for its application in tension- and crack-sensitive engineering projects. Future research could further explore the effects of fiber parameters on the long-term performance and environmental durability of SFRSCC to promote its application in a wider range of engineering fields.

Author Contributions

Conceptualization, Y.Z. (Yu Zhao); Methodology, Y.Z. (Yu Zhao); Software, Y.Z. (Yu Zhao), N.R. and Y.L.; Validation, J.W. and Y.Z. (Yi Zhou); Resources, Y.Z. (Yi Zhou); Data curation, J.W. and Y.L.; Writing—review & editing, N.R.; Supervision, N.R.; Project administration, J.W., Y.L. and Y.Z. (Yi Zhou). All authors have read and agreed to the published version of the manuscript.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

Author Yu Zhao is employed by the company Chengdu Jiaotou Construction Industrialization Co., Ltd. Author Jun Wang is employed by the company Chengdu Jiaotou Transportation Construction Management Group Co., Ltd. Author Yong Li and Yi Zhou is employed by the company Chengdu Road & Bridge Operation and Management Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Ashish, D.K.; Verma, S.K. An overview on mixture design of self-compacting concrete. Struct. Concr. 2019, 20, 371–395. [Google Scholar] [CrossRef]

- Wang, E.; Li, G.; Chai, Y.; Zhang, H.; Li, Y.; Wang, Y. Fracture performance of steel-sisal hybrid fiber recycled aggregate concrete. Bull. Chin. Ceram. Soc. 2023, 42, 2754–2763. [Google Scholar]

- Revilla-Cuesta, V.; Skaf, M.; Faleschini, F.; Manso, J.M.; Ortega-López, V. Self-compacting concrete manufactured with recycled concrete aggregate: An overview. J. Clean. Prod. 2020, 262, 121362. [Google Scholar] [CrossRef]

- Lv, Y.; Yang, Y. Experimental study on freeze-thaw performance of hybrid fiber reinforced self-compacting concrete. China Concr. Cem. Prod. 2020, 11, 52–56. (In Chinese) [Google Scholar]

- Kathirvel, P.; Murali, G.; Vatin, N.I.; Abid, S.R. Experimental study on self-compacting fibrous concrete comprising magnesium sulphate solution treated recyeled aggregates. Materials 2022, 15, 340. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Zhang, Y.; Nian, X. Experimental study on stress-strain curves for high-strength steel fiber reinforced concrete under monotonic and repeated compressive loadings. J. Build. Struct. 2017, 38, 135–143. [Google Scholar]

- Xu, L.; Li, B.; Chi, Y.; Huang, B. Experimental investigation on stress-strain relation of steel-polypropylene hybrid fiber reinforced concrete subjected to uniaxial cyclic compression. J. Build. Struct. 2018, 39, 140–152. [Google Scholar]

- Wang, L.; Yang, Y.; Chen, J.; Li, J.W. Research on the proportion of self-compacting early-strength concrete with basafiber. Highway 2020, 65, 256–259. (In Chinese) [Google Scholar]

- Chen, J.; Zhuang, J.; Shen, S.; Dong, S. Experimental investigation on the impact resistance of rubber self-compacting concrete. Structure 2022, 39, 691–704. [Google Scholar] [CrossRef]

- Wang, J.Q.; Dai, Q.L.; Si, R.Z. Experimental and numerical investigation of fracture behaviors of steel fiber-reinforced rubber self-compacting concrete. J. Mater. Civ. Eng. 2021, 34, 04021379. [Google Scholar] [CrossRef]

- Chen, Q.; Xu, L.; Wu, F.; Zeng, Y.; Liang, X. Experimental investigation on strength of steel-polypropylene hybrid fiber reinforced ultra high performance concrete. Bull. Chin. Ceram. Soc. 2020, 39, 740–748+755. [Google Scholar]

- Luo, S.R.; Zheng, J.L.; Wang, G.J. Study and Application of Mechanical Properties of Self-Compacting High-Performance Concrete. Eng. Mech. 2005, 22, 164–169. (In Chinese) [Google Scholar]

- Zhao, G.F. Development and Application of Concrete and Its Reinforcement Materials. J. Build. Mater. 2000, 3, 1–6. (In Chinese) [Google Scholar]

- Cao, Q.; Cheng, Y.L.; Wang, X.F. A Review of Fiber-Reinforced Self-Compacting Concrete. Concrete 2016, 1, 123–126. (In Chinese) [Google Scholar]

- Song, P.S.; Huang, S. Mechanical properties of high-strength steel fiber-reinforced concrete. Constr. Build. 2004, 18, 669–673. [Google Scholar] [CrossRef]

- Pereira, E.N.B.; Barros, J.A.O.; Camoes, A. Steel fiber rein forced self-compacting concrete: Experimental research and numerical simulation. J. Struct. Eng. 2008, 134, 1310–1321. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Cao, C.J.; Sun, L.; Huo, H.Y. Experimental Study on Axial Compressive Stress-Strain Curve of Steel Fiber-Reinforced Concrete. Concrete 2013, 5, 24–27. [Google Scholar]

- Siddique, R.; Kaur, G. Strength and permeation properties of self-compacting concrete containing fly ash and hooked steel fibres. Constr. Build. Mater. 2016, 103, 15–22. [Google Scholar] [CrossRef]

- Palacio, A.J.; Raggiotti, B.B.; Rougier, V.C. Development and experimental verification of a design method for steel fibre-reinforced high strength lightweight self-compacting concrete. Constr. Build. Mater. 2024, 453, 139012. [Google Scholar] [CrossRef]

- Iqbal, S.; Ali, A.; Holschemacher, K.; Bier, T.A. Effect of change in micro steel fiber content on properties of high strength steel fiber reinforced lightweight self-compacting concrete (HSLSCC). Procedia Eng. 2015, 122, 88–94. [Google Scholar] [CrossRef]

- Athiyamaan, V.G. Mohan Ganesh1. Analysis of the Alignment of Micro-Steel Fibers in Admixture-Based Self-Compacting Concrete (MSFR-SCC) using NDT and Evaluation of Its Effect on the Modulus of Rupture. Int. J. Technol. 2019, 10, 5–15. [Google Scholar] [CrossRef]

- Aghaee, K.; Yazdi, M.A.; Tsavdaridis, K.D. Investigation into the mechanical properties of structural lightweight concrete reinforced with waste steel wires. Mag. Concr. Res. 2015, 67, 197–205. [Google Scholar] [CrossRef]

- Ou, Y.C.; Tsai, M.S.; Liu, K.Y.; Chang, K.C. Compressive behavior of steel fiber-reinforced concrete with a high reinforcing index. J. Mater. Civ. Eng. 2012, 24, 207–215. [Google Scholar] [CrossRef]

- Gordon, B.; Birkimer, D.; Mckee, D. Sate of the ant report on fiber reinforced concrete. Farmington Hills Mich. ACI Commite 1973, 544, 536. [Google Scholar]

- Khaloo, A.; Raisi, E.M.; Hosseini, P.; Tahsiri, H. Mechanical performance of self-compacting concrete reinforced with steel fibers. Constr. Build. Mater. 2014, 51, 179–186. [Google Scholar] [CrossRef]

- Nis, A. Mechanical properties of steel fiber reinforced self-compacting concrete. Int. J. Eng. Technol. 2018, 4, 33–40. [Google Scholar] [CrossRef]

- Hai, R.; Liu, P.; Yang, Y.M.; Liu, J. Mechanical properties of steel fiber reinforced fly ash self-compacting concrete. J. Build. Mater. 2021, 24, 87–92. (In Chinese) [Google Scholar]

- Saba, A.M.; Khan, A.H.; Akhtar, M.N.; Khan, N.A.; Koloor, S.S.R.; Petrů, M.; Radwan, N. Strength and flexural behavior of steel fiber and silica fume incorporated self-compacting concrete. J. Mater. Res. Technol. 2021, 12, 1380–1390. [Google Scholar] [CrossRef]

- Zhou, J.Y. Experimental Study and Numerical Simulation of the Properties of Fiber Self-Compacting Concrete. Master’s Thesis, Tianjin University, Tianjin, China, 2018. (In Chinese). [Google Scholar]

- da Silva, G.C.; Christ, R.; Pacheco, F.; de Souza, C.F.; Gil, A.M.; Tutikian, B.F. Evaluating steel fiber-reinforced self-consolidating concrete performance. Struct. Concr. 2020, 21, 448–457. [Google Scholar] [CrossRef]

- Jen, G.; Trono, W.; Ostertag, C.P. Self-consolidating hybrid fiber reinforced concrete: Development, properties and composite behavior. Constr. Build. Mater. 2016, 104, 63–71. [Google Scholar] [CrossRef]

- Pajak, M. Investigation on flexural properties of hybrid fibre reinforced self-compacting concrete. Procedia Eng. 2016, 161, 121–126. [Google Scholar] [CrossRef]

- Zhang, H. Early capability and damage analysis of self-compacting, steel-fiber-reinforced lightweight aggregate concrete. Mater. Rep. 2017, 31, 124–128. [Google Scholar]

- Tao, H. Study on Physical and Mechanical Properties of Steel Fiber High Strength Self-Compacting Concrete. Master’s Thesis, Zhongyuan University of Technology, Zhengzhou, China, 2022. [Google Scholar]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.N. Effect of Steel Fiber on Engineering Properties of Geopolymer Concrete. ACI Mater. J. 2020, 117, 29–40. [Google Scholar]

- Al Rifai, M.M.; Sikora, K.S.; Hadi, M.N. Effect of micro steel fibers volume fraction on behavior of high-strength self-compacting concrete. Constr. Build. Mater. 2024, 450, 138709. [Google Scholar] [CrossRef]

- JGJ/T 283-2012; Technical Specification for Application of Self-Compacting Concrete. China Architecture & Building Press: Beijing, China, 2012.

- JGJ 55-2011; Standard for Mix Proportion Design of Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2011.

- Karuppasamy, M.; Balakrishnan, B.; Chandran, K.; Gheisari, M.; Rezaeiye, P.P.; Andrievsky, B. Analysis of mechanical properties in self-compacting concrete enhanced with steel fibres. Micro Nano Lett. 2024, 19, e12203. [Google Scholar] [CrossRef]

- Ghorbani, S.; Sharif, S.; Rokhsarpour, H.; Shoja, S.; Gholizadeh, M.; Rahmatabad, M.A.D.; de Brito, J. Effect of magnetized mixing water on the fresh and hardened state properties of steel fibre reinforced self-compacting concrete. Constr. Build. Mater. 2020, 248, 118660. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).