Abstract

The addition or substitution of various gel materials in cement-based composites has been proven to be an effective approach in enhancing the performance of concrete. Current research focuses mainly on enhancing the toughness of concrete, but lacks discussion on the performance of alternative gel materials. Therefore, this study aims to explore the effects of partially substituting cement with fly ash and slag powder as gel materials, while incorporating a high volume fraction of micro-steel fibers (6%), on the workability and mechanical properties of self-compacting concrete. By means of rigorous experimental investigation and meticulous analysis, we comprehensively assessed the workability characteristics of self-compacting concrete, encompassing critical aspects such as filling ability, cohesion, and permeability. Additionally, we conducted an extensive evaluation of the mechanical attributes of self-compacting concrete, encompassing vital parameters, such as compressive strength, axial compressive strength, splitting tensile strength, and flexural strength. Last but not least, through a holistic integration of workability and mechanical properties, we conducted a comprehensive performance evaluation of self-compacting concrete incorporating a synergistic blend of fly ash, slag powder, and micro steel fibers. The experimental results indicate that the composite addition of fly ash and slag powder in self-compacting concrete, while compatible with up to 6% micro-steel fibers, leads to a decrease in concrete workability and an increase in cohesiveness due to the addition of micro-steel fibers. Moreover, fly ash predominantly influences the tensile properties of concrete, while the addition of slag powder significantly affects the compressive and flexural properties of concrete. Additionally, the addition of micro-steel fibers significantly improves the overall mechanical properties of concrete.

1. Introduction

Self-compacting concrete (SCC) is a type of concrete that achieves uniform compaction solely through gravity, eliminating the need for vibration. It exhibits remarkable flowability, permeability, and resistance to segregation [1]. Owing to its superior performance, SCC finds extensive application in construction projects characterized by limited pouring spaces and intricate steel reinforcement arrangements. The material’s impressive flowability and anti-segregation properties enable even distribution [2], resulting in reduced voids and consistent strength, thus ensuring overall concrete integrity [3]. However, in the construction process, a substantial amount of concrete pouring is indispensable, a practice that not only escalates the production cost of concrete but also impacts its workability and durability [4]. Furthermore, concrete itself is inherently a brittle structure, losing functionality once the first crack forms [5]. Therefore, investigating the synergistic utilization of diverse materials to attain the optimum mixture design is the most effective approach to address these challenges.

Fibers can be capable of bridging the crack most appropriately [6], the characteristics of fibers can enhance the brittleness of concrete [7]. Steel fibers are commonly used in the combination with self-compacting concrete to improve its poor crack resistance and weak structural ductility [8,9,10,11,12]. However, the larger diameter of ordinary steel fibers limits their dosage, resulting in limited enhancement of the performance of self-compacting concrete [13,14,15,16,17]. Additionally, the inclusion of steel fibers can cause friction between materials, leading to a decrease in flowability and workability [18], increased weak areas [19], and consequent impact on the overall performance of the concrete. Furthermore, an excessive dosage of steel fibers can result in a reduced matrix, making the fibers more prone to fracture under stress concentration [20]. By comparing previous and other studies on steel fibers [21], it has also been discovered that the inclusion of a single gel material limits the dosage of steel fibers [22]. In addition to steel fibers, the significant inclusion of cement causes concerns, such as high hydration heat, significant autogenous shrinkage, and increased costs for self-compacting concrete [23]. Therefore, it is imperative to use alternative cementitious materials to improve the performance of steel fiber-reinforced self-compacting concrete. To investigate the impact of cement substitutes on concrete performance, researchers have explored the influence of various gel materials on steel fiber-reinforced self-compacting concrete (SFSCC). Gokhan Kaplan [24] and Rafat Siddique [25] introduced fly ash as an additive to steel fiber-reinforced concrete, resulting in a slump flow test of 67 cm, which represents a remarkable 173.3% increase compared to non-fly ash specimens. The incorporation of fly ash also led to pore refinement within the concrete matrix, enhanced the interfacial bonding strength of steel fibers, and improved the mechanical properties of the material. However, it should be noted that the average particle size of fly ash exceeds that of cement, thereby potentially impeding certain working properties of concrete. Abdulla M. Saba [26] et al. investigated the effect of silica fume addition on steel fiber-reinforced self-compacting concrete. Consequently, the slump flow test was reduced to 55 cm due to the high reactivity and inter-particle friction induced by silica fume. Nonetheless, the inclusion of silica fume contributed to an enhancement in the compressive strength of the concrete. However, it is crucial to recognize that the fluidity of the material exhibits an inverse relationship with its mechanical properties, thus hindering the ability to achieve optimal mechanical performance. Furthermore, Hassan M. Magpool [27] et al. incorporated volcanic pumice powder into steel fiber-reinforced self-compacting concrete, resulting in a diminished slump flow test of merely 49 cm, representing a 95.8% decrease when compared to concrete specimens without volcanic pumice. The decline in diameter can be attributed to the increased viscosity of the mixture caused by volcanic pumice powder, thus affecting fluidity. However, the mechanical properties of the concrete were significantly improved. These studies collectively highlight that the modification of concrete properties can be achieved by employing different admixtures. Nevertheless, it is difficult to address the diverse performance requirements of concrete solely through the addition of a single material.

Researchers, recognizing the limitations of using a single material, have attempted to achieve advantages through the complementary use of multiple materials. They have conducted tests on the performance of steel fiber-reinforced self-compacting concrete (SFSCC) by incorporating cement substitutes. For instance, Iman Ferdosian [28] and Jingjun Li [19] introduced silica fume and fly ash into SFSCC and found that the average slump flow test r reached 60 cm, showing improvement compared to specimens with only silica fume. The combination of silica fume and fly ash resulted in a denser structure, leading to an improvement in the mechanical properties of the concrete to some extent. However, it is worth noting that the combination did not achieve the desired state of concrete. Thamer Alomayri [29], Anıl Nis [30], Mehmet Eren Gülşan [31], and other research teams incorporated nanoparticles of silica, fly ash, and slag powder into steel fiber-reinforced self-compacting concrete. The average slump flow test reached 66 cm. Testing of the mechanical properties revealed that nanoparticles improved workability and impact resistance but had adverse effects on compressive strength and elastic modulus. The interaction between nanoparticles and steel fibers also negatively affected both workability and strength.

Subsequently, G. Laxmi [32], Abhay V. Nakum [33], and others used only fly ash and slag powder in steel fiber-reinforced self-compacting concrete. This resulted in a range of slump flow tests from 65 cm to 75 cm, indicating excellent workability. The addition of fly ash and slag powder improved the flowability and compactness affected by steel fibers, thus positively affecting the mechanical properties of SFSCC. Research has shown that the use of fly ash and slag powder as substitutes for Portland cement in steel fiber-reinforced self-compacting concrete produces different effects. Fly ash improves the performance and workability of the mixture [34,35], while slag powder reduces the hydration heat within the concrete, reducing the chances of internal cracking. Combined with the crack resistance provided by steel fibers, the performance of the concrete is well preserved [36,37,38]. This suggests that the combined use of fly ash and slag powder is the best gel substitute material. The above studies indicate that the composite incorporation of different materials can improve the workability, strength, and durability of steel fiber-reinforced self-compacting concrete.

In conclusion, the replacement of cement with fly ash and slag powder can enhance the workability and improve the mechanical properties of steel fiber self-compacting concrete (SFSCC). However, building upon the findings of a previous phase of this study, which revealed nearly inadequate flowability, we aim to investigate the impact of alternative gel materials on the performance. Moreover, there is limited research discussing the performance of SFSCC incorporating the dual admixtures of fly ash and slag powder. Therefore, in this study, the dual admixtures of fly ash and slag powder were selected to replace cement, and smaller-sized micro-steel fibers were incorporated into self-compacting concrete to investigate the workability and mechanical properties. Additionally, a graded volume fraction of micro-steel fibers (0%, 1.5%, 3%, 5%, 6%) was used to systematically study and analyze the performance of high-content micro-steel fiber self-compacting concrete mixed with fly ash and slag powder. The findings from this study provide valuable insights for optimizing concrete mixture design and engineering applications.

2. Materials and Mix Proportion

2.1. Gel Material

The gel materials employed in this study included Portland cement, fly ash, and slag powder. The ordinary Portland cement, as indicated in Table 1, exhibited a density of 3.08 g/cm2 and a specific surface area of 346 m2/kg. Fly ash with a specific surface area of 480 m2/kg and slag powder with a specific surface area of 412 m2/kg were incorporated as alternative materials to substitute for Portland cement in the concrete mixture. Figure 1a,b visually represent the fly ash and slag powder used in the research.

Table 1.

Physical and mechanical properties of ordinary Portland cement.

Figure 1.

Cement replacement materials (a) Fly ash and (b) Slag powder.

The moisture content of fly ash was within the range of 0.85% to 1.0%, while its density was determined to be 2.55 g/cm3. The density of S95 grade slag powder was measured at 2.9 g/cm3, which is lower than the density of cement. Specific parameters can be found in Table 2.

Table 2.

Composition of gel materials.

2.2. Steel Fiber

Steel fibers employed in this study were manufactured through milling and subsequently treated with copper coating. This treatment facilitated their uniform dispersion within the concrete mixture, while also yielding a strength of 2869 MPa. This signifies their exceptional dispersibility, strength, and stability [39]. Figure 2 exhibits the micro steel fibers with a length of 6 mm, a diameter of 0.18 mm, and an aspect ratio of 70, which were utilized in the experiment. These fibers, owing to their small size, can achieve a high dosage in self-consolidating concrete.

Figure 2.

Copper-plated micro-steel fiber.

2.3. Aggregate

The fine aggregate utilized in this research consisted of ordinary medium sand with a fineness modulus of 2.6 and a clay content of 3.3%. The coarse aggregate was derived from crushed limestone, containing 9.7% needle-like particles. A 1:1 mass ratio was employed to blend the 5–10 mm and 10–16 mm coarse aggregates.

2.4. Additives

The water reducer used in this study was a standard polycarboxylic acid high-performance water reducer, with a solid content of 17.76% and a water reduction rate of 30%. The water reducer was prepared from BASF F10 polycarboxylic acid powder as raw material. After adding a water reducing agent, a completely non segregated gypsum mixture can be prepared. F10 can reduce mixing, quickly solidify, increase the fluidity of concrete, and improve slump [40]. After multiple experiments to determine the quality of the cementitious material, 0.18% was selected as the dosage. The water used was tap water from the laboratory of Chongqing Jiaotong University.

2.5. Mix Proportion

In this research, a combination of micro steel fibers, fly ash, and slag powder as blended supplementary materials was employed. A control group was established, and the total dosage of blended materials was set at 30% [41,42], comprising a mixture of the two mineral admixtures. The proportions of fly ash to slag powder were 20% + 10%, 15% + 15%, and 10% + 20%.

The dosage of micro steel fibers ranged from 0% to 6%, with incrementally selected volume ratios of 0%, 1.5%, 3%, 5%, and 6%. The objective was to analyze the variations in workability and mechanical properties of SCC containing steel fibers under different proportions of fly ash and slag powder.

As shown in Table 3, this study classified the mix proportions of self-compacting concrete into five groups, each with varying micro steel fiber dosages. Within each group, further subdivisions were made into three subclasses to consider different levels of fly ash and slag powder content. Consequently, a total of 15 distinct subclasses were investigated.

Table 3.

Mix proportions of self-compacting concrete with mixed fly ash and slag powder.

3. Testing Procedure

3.1. Workability Test

Fluidity, passing ability, and resistance to segregation are three fundamental aspects of SCC flowability. In this study, the filling ability is assessed through slump flow tests, cohesiveness is evaluated via V-funnel tests, and passing ability is determined by L-box tests. These testing procedures follow the guidelines provided by the Chinese standard for self-compacting concrete, JGJ/T283-2012 [43]. The tests and evaluations are conducted in accordance with the testing and standard values presented in Table 4.

Table 4.

Design requirements for working performance of SCC.

3.1.1. Slump Flow Test

The slump flow test is conducted on a horizontal surface. As shown in Figure 3a,b, the slump cone is filled with the fresh concrete mixture, and then the cone is lifted steadily and quickly along the vertical direction. The flow behavior of the concrete mixture is observed until the slump flow stabilizes, and the height is measured using a ruler when the flow ceases.

Figure 3.

Testing setup (a,b) is slump flow diameter, (c) V-funnel, (d) L-box ratio.

3.1.2. V-Funnel Tests

The concrete mixture is poured into the V-shaped funnel, as shown in Figure 3c, from the top of the funnel. After allowing the mixture to stand undisturbed for 1 min, the valve at the bottom of the funnel is opened. The flow time of the concrete, from the start of the flow until complete discharge, is measured using a stopwatch, with precision to 0.1 s. Simultaneously, any occurrence of blockage during the flow process is observed and recorded.

3.1.3. L-Box Tests

The prepared concrete mixture is poured into the vertical section of the box, as shown in Figure 3d. After allowing it to settle undisturbed for 1 min, the vertical and horizontal switch panels are lifted to initiate the flow of concrete. The time is recorded from the start of the concrete flow until it reaches the bottom of the horizontal section. Specifically, the time taken for the concrete to flow to the 200 mm and 400 mm marks in the horizontal section is recorded separately. After the flow ceases, the heights at the front and back ends of the horizontal section are measured to assess any potential height difference and determine the levelness of the concrete flow.

3.2. Mechanical Performance Test

The mechanical performance was evaluated through tests including compressive strength of cubic specimens, axial compressive strength tests, splitting tensile tests, and flexural strength tests. A total of 15 different mix ratios were tested. The compressive strength, axial compressive strength, and splitting tensile strength were measured using a universal testing machine, while the flexural strength of beam specimens was measured at three points using a flexural strength testing machine.

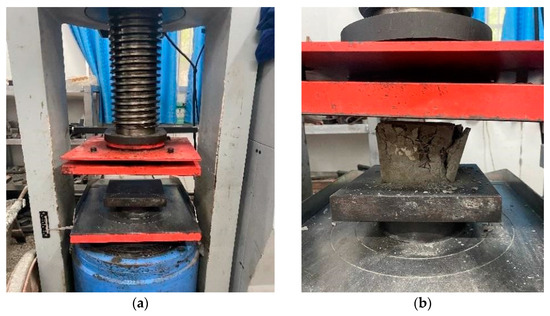

3.2.1. Cube Compression Test

Mechanical performance tests were conducted in accordance with the Chinese standard GB/T 50081-2019 [44], including cube compressive strength tests, prism axial compressive strength tests, splitting tensile tests, and flexural strength tests. A total of 15 different mix proportions were tested. For the compressive strength tests, both cube and prism specimens of different sizes were tested. This is because in concrete structures, concrete is often present in the form of columns or walls, and the stress state experienced by these structural elements may be different from that of cube specimens. Therefore, cube specimens can effectively reflect the overall compressive performance of concrete [45], while prism specimens can provide compressive strength data that is closer to actual conditions [46]. Simultaneously testing cube compressive strength and prism axial compressive strength allows for a comprehensive evaluation of the compressive performance of concrete. The universal testing machine is shown in Figure 4a.

Figure 4.

Cube compressive strength test (a) Universal testing machine, (b) Cube compressive loading process.

The compression result of the specimen is calculated using the following formula:

where is the compressive strength of the cube (MPa); is the failure load of the specimen (N); and is the compressive area of the cube specimen (mm2).

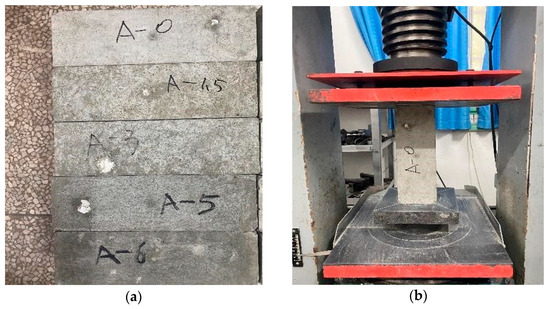

3.2.2. Axial Compressive Test

The axial compressive strength of concrete is similar to the compressive strength of cubes and is a key performance indicator of concrete’s compressive strength. However, for the axial compressive strength test, prismatic specimens, as shown in Figure 5a, are used instead of square cubes. The dimensions of the test specimens are 100 mm × 100 mm × 300 mm. The testing method for axial compressive strength is similar to that of cube compressive strength. According to the operating rules of the universal testing machine, the prism is positioned in the middle of the upper and lower platens, and then loaded until the specimen fails. The axial compressive strength test is illustrated in Figure 5b.

Figure 5.

Axial compressive strength test (a) Axial compressive specimen, (b) Axial compressive strength test.

The axial compressive strength value is calculated according to the following formula:

where is the axial compressive strength (MPa); is the failure load (N); and is the average bearing area of the specimen (mm2). The result should be accurate to 0.1 Mpa.

3.2.3. Splitting Tensile Strength Test

Traditional SCC without the addition of steel fibers exhibits a brittle behavior, causing the entire internal structure of the specimen to rupture from the middle when subjected to minimal tensile stress. Additionally, there is no excess deformation inside the specimen before failure. On the other hand, concrete with the addition of steel fibers does not undergo sudden rupture when subjected to tensile forces but rather exhibits a gradual and more complete form of failure. The splitting tensile strength reflects the concrete’s ability to resist cracking from certain aspects, making it an effective indicator of the research significance of the high-volume micro steel fiber SCC used in this study.

In this experiment, cubic specimens with dimensions of 100 mm × 100 mm × 100 mm were used to study the splitting tensile strength of the concrete. Steel plates and wooden spacer layers were simultaneously placed at the bottom and top of the cubic specimens. The steel plates were positioned to make contact with the upper and lower plates of the testing machine, while the wooden spacer layers were used to separate the specimen from the steel plates. This arrangement reduced the contact area and allowed for testing the tensile strength. The wooden spacer layers, as they deform and get damaged after being subjected to pressure, were only used once to avoid significant impact on the splitting tensile strength values. The loading procedure is illustrated in Figure 6.

Figure 6.

Splitting tensile test.

The calculation method for the splitting tensile strength of concrete cubes is as follows:

where is the splitting tensile strength of the concrete cube (MPa); is the maximum load failure force (N); and is the stress area of the cube (mm2).

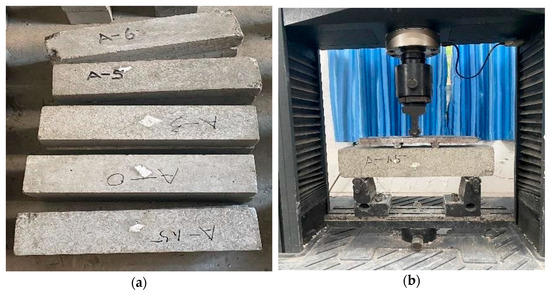

3.2.4. Bending Resistance Test

The flexural strength of concrete is studied using cube beam specimens with dimensions of 100 mm × 100 mm × 400 mm. The experiment employs the flexural strength testing machine at the Road Engineering Laboratory of Chongqing Jiaotong University. The concrete specimens and testing machine for flexural strength testing are shown in Figure 7a,b. The three-point bending method is used to test the specimens, with two loading points placed on the upper part of the specimen. The testing is conducted by controlling the testing machine until the specimen fails, at which point the test is terminated.

Figure 7.

Bending test (a) Bending test piece, (b) Bending strength testing machine.

The flexural strength of concrete test blocks shall be calculated according to the following equation:

where is the flexural strength of the small beam specimen (MPa), is the load at which the small beam specimen fails (N), is the support span (mm), is the height of the cube small beam (mm), and is the width of the cube small beam (mm).

4. Results and Discussion

4.1. Fresh Properties

The workability testing results for five different mix proportions are displayed in Table 5. The subsequent sections will provide separate analyses of the filling ability, cohesion, and permeability of voids.

Table 5.

Workability results.

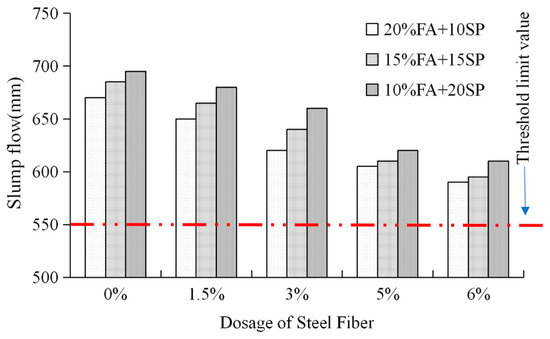

4.1.1. Filling Ability

The slump flow test evaluates the ability of a concrete mixture to flow freely, which is an indicator of its workability and filling ability. Experimental results indicate that the minimum flow diameter of the mixture is 590 mm when the steel fiber dosage is 6%, which meets the minimum standard limit of 550 mm specified in JGJ/T283-2012 [43].

The variation in slump flow with increasing micro steel fiber content from 0% to 6% for the three combinations of fly ash and slag powder is shown in Figure 8. As the steel fiber content increased, the slump flow of different proportions of blended mixtures showed a decreasing trend. The mixture with a 20% slag powder content exhibited higher slump flow compared to the other two mix proportions. The overall flowability was poorer when using an equal combination of fly ash and slag powder, while the mixture with a higher proportion of fly ash showed the poorest flowability. This variation can be attributed to the influence of slag powder content on flowability. When the slag powder content was 20%, the highest slump flow value achieved was 695 mm, while the fly ash content of 20% resulted in a slump flow of only 670 mm. The difference between the highest and lowest values was approximately 4%, and throughout the entire trend, mixtures with a higher proportion of slag powder exhibited better flowability than other mix proportions. This phenomenon indicates that with an increase in slag powder content, the flowability of the mixture improves to some extent.

Figure 8.

Effect of dosage ratio on slump expansion.

4.1.2. Cohesiveness

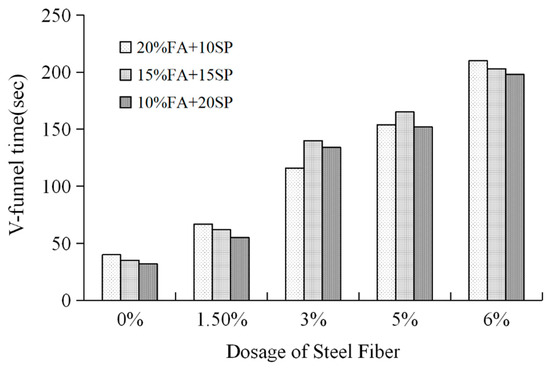

The cohesion performance of the concrete mixture was evaluated based on the flow time through a V-shaped funnel, as shown in Figure 9. A longer flow time indicates better cohesion performance, but an excessively long time suggests poor flowability of the mixture.

Figure 9.

Effect of mixing ratio on passing time of V-shaped funnel.

Overall, the group with a higher proportion of fly ash exhibited a longer flow time, while the group with a higher proportion of slag powder showed a shorter flow time. When the steel fiber content was 0%, the group with a higher proportion of slag powder had the shortest flow time, which was 32 s, whereas the group with a higher proportion of fly ash had the longest flow time, which required 40 s. This indicates that, in the absence of steel fibers, the group with a higher proportion of slag powder demonstrated better cohesion performance. When the steel fiber content was 6%, the group with a higher proportion of fly ash required 210 s, the group with an equal proportion of fly ash and slag powder required 203 s, and the group with a lower proportion of fly ash required 198 s for flow time. It can be observed that as the steel fiber content increased, all three mix proportions of blended materials exhibited significantly enhanced cohesion performance, and the overall integrity of the mixture flowing out of the funnel was improved.

For fly ash and slag powder, a higher proportion of fly ash resulted in lower flowability, indicating better cohesion performance of the mixture.

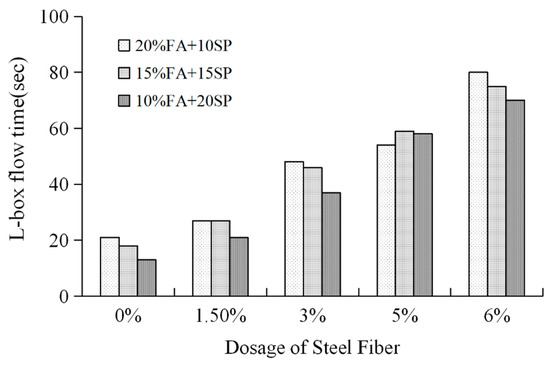

4.1.3. Passing Ability

The permeability performance is evaluated by the time it takes for the mixture to pass through an L-shaped box and the difference in height before and after the horizontal trough. As shown in Figure 10, under different proportions of additives, when the steel fiber content was 0%, the time for the mixtures from each group to reach the bottom of the horizontal trough through the outlet was 21 s, 18 s, and 13 s, respectively. The difference between the three groups was not significant, but the group with a higher slag powder content exhibited slightly better permeability performance. When the steel fiber content was 6%, the time for the three mixtures to pass through was 80 s, 75 s, and 70 s, respectively, with the mixture containing a higher fly ash content showing slightly poorer permeability performance. Upon observation of the mixtures, it was found that as the steel fiber content increased, the speed of the mixture passing through the steel rebar slowed down significantly, greatly affecting the permeability performance.

Figure 10.

Effect of mixing ratio on passing time.

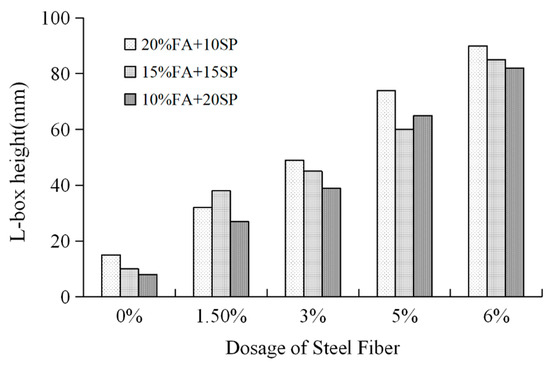

The height difference between the front and rear troughs after the mixture stopped flowing was measured as for Figure 11, and a larger height difference indicates poorer permeability performance of the mixture. Test results showed that when the steel fiber content was 0%, the height differences for the three blended mix proportions were 15 mm, 10 mm, and 8 mm, respectively. When the steel fiber content was 6%, the height differences for the respective groups were 90 mm, 85 mm, and 82 mm, with little difference in permeability performance among the three proportions. By comparing the permeability performance at different steel fiber contents, it was found that the increase in steel fiber content greatly affected the ability of the mixture to pass through complex rebar areas. A steel fiber content of 6% has already reached the limit for incorporating steel fibers in this experiment.

Figure 11.

Effect of mixing ratio on height difference of L-box.

4.2. Mechanical Properties

Different sizes of test specimens were subjected to compressive strength tests, axial compressive strength tests, splitting tensile tests, and flexural strength tests. Three specimens were taken for each test from each mix proportion, and the arithmetic average of the test results was taken as the final strength value. The analysis results are as follows.

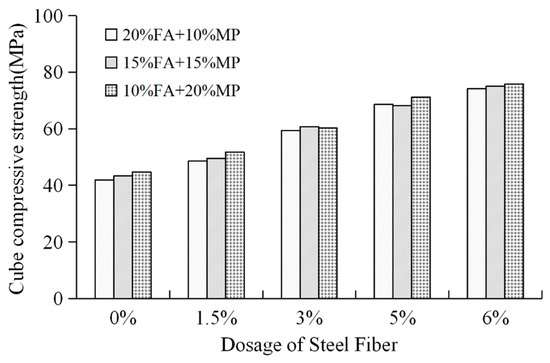

4.2.1. Cube Compressive Strength

The experimental data results were plotted in Figure 12. The test results indicate that when the steel fiber content is 0%, among the three mix proportions, the highest compressive strength value of 44.7 MPa is achieved when the slag powder content is 20%, while the lowest compressive strength of 41.9 MPa is obtained when the fly ash content is 20%. The difference between the two is approximately 7%. Clearly, when the slag powder content is higher, there is a certain improvement in the strength of the concrete.

Figure 12.

Cube compressive strength in different proportions.

As the steel fiber content increases, the strength of the three groups of specimens greatly improves. When the steel fiber content is 6%, the mix with a higher slag powder content achieves the highest compressive strength of 75.8 MPa, showing a significant improvement of 69.6%. The mix with a higher fly ash content exhibits the largest overall improvement of 76.8%. However, at this point, the difference among the three is small. By analyzing the reason, when the fiber content is very high, the influence of fly ash and slag powder on concrete diminishes.

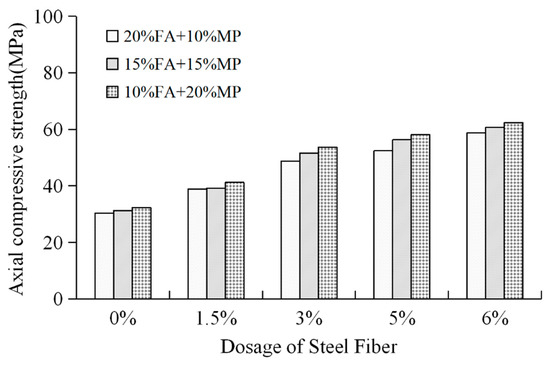

4.2.2. Axial Compressive Strength

Based on the experimental data results in Figure 13, it can be observed that when the steel fiber content is 0%, slag powder has the greatest influence on the axial compressive strength of the specimens. The specimen with a higher proportion of slag powder achieves the highest axial compressive strength value of 32.3 MPa, while the strength is lowest when the fly ash content is high, at 30.4 MPa. The difference between the two groups is 6%. As the steel fiber content increases, the axial compressive strength values of the three groups all increase. When the steel fiber content is 6%, the strength values of the concrete specimens with different admixtures increase by approximately 100%, with the highest axial compressive strength reaching 62.4 MPa. The maximum improvement for each group exceeds 90%, with the highest increase of 93.9% observed when the proportion of fly ash and slag powder is equivalent. At the highest steel fiber content, the axial compressive strength of the three groups is almost the same.

Figure 13.

Axial compressive strength under different proportions.

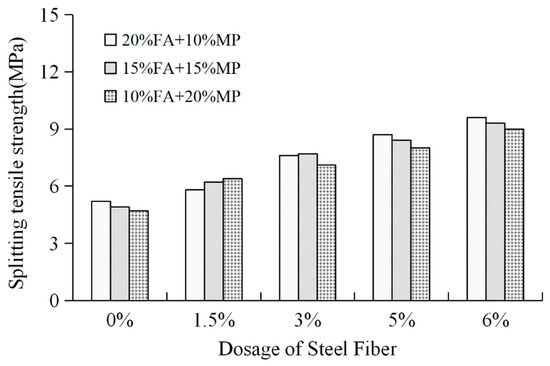

4.2.3. Splitting Tensile Strength

According to the experimental data in Figure 14, it can be observed that when the steel fiber content is 0%, the specimen with a higher fly ash content has the highest tensile strength value, reaching 5.2 MPa. As the fly ash content decreases, the tensile strength values also decrease, with the group having a lower fly ash content exhibiting the lowest value of 4.7 MPa. The range between the maximum and minimum values is 10%.

Figure 14.

Splitting tensile strength under different proportions.

As the steel fiber content increases, the tensile strength of each group shows a linear upward trend. The group with a steel fiber content increasing from 0% to 1.5% achieves the largest improvement. When the steel fiber content is 6%, the highest tensile strength value reaching 9.6 MPa.

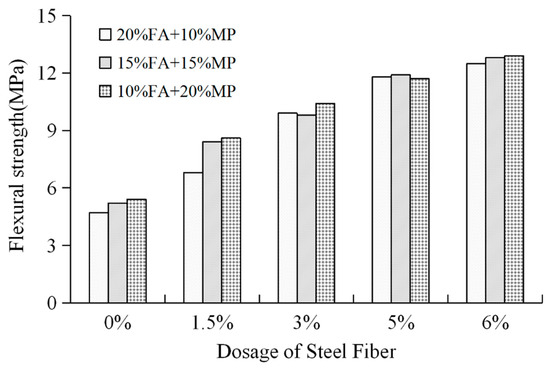

4.2.4. Flexural Strength

The test data for the flexural strength of concrete, as shown in Figure 15, indicates that when the steel fiber content is 0%, the specimen with 20% slag powder exhibits the highest flexural strength of 5.4 MPa, while the specimen with 20% fly ash has the lowest strength, measuring 4.7 MPa. The difference between the maximum and minimum values is 15%. It can be observed that when the total amount of admixture is 30%, a higher slag powder content leads to a higher flexural strength.

Figure 15.

Flexural strength at different proportions.

As the steel fiber content increases, the maximum increase in flexural strength exceeds 100% for all groups. When the steel fiber content reaches 6%, the specimen with 20% fly ash content experiences the highest improvement, reaching 165.9%. At this point, the flexural strength value is 12.5 MPa. The specimen with 20% slag powder content achieves the highest flexural strength of 12.9 MPa. With an increase in steel fiber content, the difference in flexural strength among the various proportions decreases. It can be deduced that at high steel fiber content, the impact on flexural strength is greater than that of admixtures.

5. Conclusions

This study primarily examines the comprehensive influence of workability on SCC with high dosage of micro steel fibers under the influence of fly ash and slag powder. The following conclusions are drawn:

- (1)

- The results of the workability tests indicate the following: with an increase in slag powder content, the flowability of the concrete mix improves, while the cohesion performance decreases, and the impact on passing ability through voids is minimal. With an increase in steel fiber content, all groups of concrete mixes experience a significant loss in flowability and an increase in cohesion. At lower steel fiber contents, the chemical mechanisms resulting from the interaction of mineral admixtures have a pronounced influence on the flowability of the concrete mix. However, at higher steel fiber contents, the flowability of the mix is primarily determined by the steel fiber content.

- (2)

- In terms of the influence on mechanical properties, a higher steel fiber content results in better and more stable mechanical performance. At lower steel fiber contents, the fly ash content is directly proportional to the splitting tensile strength value, while the slag powder content has a dominant effect on compressive strength and flexural strength. As the steel fiber content increases, the mechanical properties of the concrete improve significantly but reduces the influence of admixtures on concrete performance. Eventually, there is not a substantial difference in the values of various mechanical properties of the concrete.

- (3)

- Typically, the dosage of regular fibers in steel fiber SCC is less than 2%. However, in the mix design used in this study, which involves the combined effect of fly ash and slag powder, the steel fiber dosage in the concrete can reach a maximum of 6%. When the dosage of micro steel fibers is 6% and different mineral admixtures are added, the maximum improvement in 28-day compressive strength of cubic specimens is 84.8%, axial compressive strength is 93.9%, splitting tensile strength is 116.3%, and flexural strength is 165.9%. Additionally, the concrete can maintain good self-compaction properties while exhibiting significant improvements in compressive strength, splitting tensile strength, and flexural strength.

- (4)

- Based on a comprehensive analysis and comparison of three different mineral admixture addition forms, it is observed that when the total amount of mineral admixtures does not exceed 30% and is combined with a low dosage of mild steel fibers, slag powder is more beneficial for improving the overall workability of the concrete mixture. However, a high dosage of slag powder can lead to excessive bleeding of the mixture. Furthermore, after 28 days, the inclusion of slag powder enhances the compressive strength and flexural strength. On the other hand, fly ash is more advantageous for improving the tensile strength. When the dosage of mild steel fibers is relatively high, their influence on the workability and mechanical properties of SCC becomes more significant than that of the mineral admixtures.

In summary, the incorporation of micro steel fibers in self-compacting concrete with copious additions of fly ash and slag powder has achieved a high dosage of steel fiber, fulfilling the intended economic and superior design objectives. This research has also provided robust and reliable data support for the subsequent research plans.

Author Contributions

Conceptualization, Q.Y. and H.W.; methodology, Q.Y. and H.W.; software, H.W., L.Z., L.G., J.C. and R.X.; formal analysis, H.W.; investigation, Q.Y., H.W., L.Z., L.G., J.C. and R.X.; resources, Q.Y.; data curation, H.W., L.Z., L.G., J.C. and R.X.; writing—original draft, H.W.; writing—review and editing, Q.Y. and H.W.; visualization, H.W.; supervision, Q.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bethmont, S.; D’Aloia Schwartzentruber, L.; Stefani, C.; Tailhan, J.L.; Rossi, P. Contribution of granular interactions to self compacting concrete stability: Development of a new device. Cem. Concr. Res. 2009, 39, 30–35. [Google Scholar] [CrossRef]

- Etli, S. Evaluation of the effect of silica fume on the fresh, mechanical and durability properties of self-compacting concrete produced by using waste rubber as fine aggregate. J. Clean. Prod. 2023, 384, 135590. [Google Scholar] [CrossRef]

- Kalyana Chakravarthy, P.R.; Namratha, K. Strength and durability properties of high strength self compacting concrete. Mater. Today Proc. 2022, 69, 896–900. [Google Scholar] [CrossRef]

- Ramkumar, K.B.; PR, K.R.; Gunasekaran, K. Performance of hybrid steel fiber-reinforced self-compacting concrete RC beam under flexure. Eng. Sci. Technol. Int. J. 2023, 42, 101432. [Google Scholar]

- Zamri, N.F.; Mohamed, R.N.; Awalluddin, D.; Abdullah, R. Experimental evaluation on punching shear resistance of steel fibre reinforced self-compacting concrete flat slabs. J. Build. Eng. 2022, 52, 104441. [Google Scholar] [CrossRef]

- Ahmad Wani, T.; Ganesh, S. Study on fresh properties, mechanical properties and microstructure behavior of fiber reinforced self compacting concrete: A review. Mater. Today Proc. 2022, 62, 6663–6670. [Google Scholar] [CrossRef]

- Vedhasakthi, K.; Chithra, R. Strength attributes and microstructural characterization of basalt fibre incorporated self-compacting concrete. J. Build. Eng. 2023, 78, 107592. [Google Scholar] [CrossRef]

- Buratti, N.; Mazzotti, C.; Savoia, M. Post-cracking behaviour of steel and macro-synthetic fibre-reinforced concretes. Constr. Build. Mater. 2011, 25, 2713–2722. [Google Scholar] [CrossRef]

- Mai, H.T.; Nguyen, M.H.; Ly, H. Development of machine learning methods to predict the compressive strength of fiber-reinforced self-compacting concrete and sensitivity analysis. Constr. Build. Mater. 2023, 367, 130339. [Google Scholar] [CrossRef]

- Mu, R.; Chen, J.; Chen, X.; Diao, C.; Wang, X.; Qing, L. Effect of the orientation of steel fiber on the strength of ultra-high-performance concrete (UHPC). Constr. Build. Mater. 2023, 406, 133431. [Google Scholar] [CrossRef]

- Turk, K.; Bassurucu, M.; Bitkin, R.E. Workability, strength and flexural toughness properties of hybrid steel fiber reinforced SCC with high-volume fiber. Constr. Build. Mater. 2021, 266, 120944. [Google Scholar] [CrossRef]

- Aslani, F.; Hamidi, F.; Valizadeh, A.; Dang, A.T. High-performance fibre-reinforced heavyweight self-compacting concrete: Analysis of fresh and mechanical properties. Constr. Build. Mater. 2020, 232, 117230. [Google Scholar] [CrossRef]

- Naik, B.; Chaubey, A.K.; Mustakim, S.M.; Paul, S.; Barua, A.; Jeet, S. Synthesis and characterization of ladle furnace slag on the mechanical properties of self-compacting concrete. Mater. Today Proc. 2023, 74, 673–680. [Google Scholar] [CrossRef]

- Kavyateja, B.V.; Guru Jawahar, J.; Sashidhar, C. Effectiveness of alccofine and fly ash on mechanical properties of ternary blended self compacting concrete. Mater. Today Proc. 2020, 33, 73–79. [Google Scholar] [CrossRef]

- Jain, A.; Choudhary, S.; Gupta, R.; Chaudhary, S.; Gautam, L. Effect of granite industry waste addition on durability properties of fly ash blended self-compacting concrete. Constr. Build. Mater. 2022, 340, 127727. [Google Scholar] [CrossRef]

- Ortiz, J.A.; de la Fuente, A.; Mena Sebastia, F.; Segura, I.; Aguado, A. Steel-fibre-reinforced self-compacting concrete with 100% recycled mixed aggregates suitable for structural applications. Constr. Build. Mater. 2017, 156, 230–241. [Google Scholar] [CrossRef]

- Yang, Z.; Li, Q.; Liu, M.; Xue, N.; Yu, L.; Xu, L.; Wu, K. Efflorescence inhibition and microstructure evolution of Portland cement-based artificial stone induced by mineral additives. Case Stud. Constr. Mater. 2022, 17, e1509. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Siddique, R. Recent advances in understanding the role of supplementary cementitious materials in concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Li, J.; Chen, J.; Wan, C.; Niu, J. Flexural toughness and evaluation method of steel fiber reinforced self-compacting lightweight aggregate concrete. Constr. Build. Mater. 2021, 277, 122297. [Google Scholar] [CrossRef]

- Benedetty, C.A.; Krahl, P.A.; Goes, C.M.W.; de Almeida, L.C.; Trautwein, L.M.; Silva, F.A. Effects of fiber content, inclination angle, and casting point on the fiber-matrix interaction of High-Strength Fiber-Reinforced Self Compacting Concrete. Constr. Build. Mater. 2023, 398, 132537. [Google Scholar] [CrossRef]

- Yang, Q.; Ru, N.; He, X.; Peng, Y. Mechanical behavior of refined SCC with high admixture of hybrid micro- and ordinary steel fibers. Sustainability 2022, 14, 5637. [Google Scholar] [CrossRef]

- Kesavamoorthi, R.; Mohan Ganesh, G. Impact resistance of micro and macro crimped steel fibre reinforced self-compacting concrete with SCM. Case Stud. Constr. Mater. 2023, 19, e2452. [Google Scholar] [CrossRef]

- Pelisser, F.; Vieira, A.; Bernardin, A.M. Efficient self-compacting concrete with low cement consumption. J. Clean. Prod. 2018, 175, 324–332. [Google Scholar] [CrossRef]

- Kaplan, G.; Bayraktar, O.Y.; Memis, S. Effect of high volume fly ash and micro-steel fiber on flexural toughness and durability properties in self-compacting lightweight mortar (SCLM). Constr. Build. Mater. 2021, 307, 124877. [Google Scholar] [CrossRef]

- Basu, P.; Thomas, B.S.; Chandra Gupta, R.; Agrawal, V. Strength, permeation, freeze-thaw resistance, and microstructural properties of self-compacting concrete containing sandstone waste. J. Clean. Prod. 2021, 305, 127090. [Google Scholar] [CrossRef]

- Saba, A.M.; Khan, A.H.; Akhtar, M.N.; Khan, N.A.; Rahimian Koloor, S.S.; Petrů, M.; Radwan, N. Strength and flexural behavior of steel fiber and silica fume incorporated self-compacting concrete. J. Mater. Res. Technol. 2021, 12, 1380–1390. [Google Scholar] [CrossRef]

- Magbool, H.M.; Zeyad, A.M. The effect of various steel fibers and volcanic pumice powder on fracture characteristics of Self-Compacting concrete. Constr. Build. Mater. 2021, 312, 125444. [Google Scholar] [CrossRef]

- Ferdosian, I.; Camões, A. Mechanical performance and post-cracking behavior of self-compacting steel-fiber reinforced eco-efficient ultra-high performance concrete. Cem. Concr. Compos. 2021, 121, 104050. [Google Scholar] [CrossRef]

- Alomayri, T.; Raza, A.; Shaikh, F. Effect of nano SiO2 on mechanical properties of micro-steel fibers reinforced geopolymer composites. Ceram. Int. 2021, 47, 33444–33453. [Google Scholar] [CrossRef]

- Niş, A.; Eren, N.A.; Çevik, A. Effects of nanosilica and steel fibers on the impact resistance of slag based self-compacting alkali-activated concrete. Ceram. Int. 2021, 47, 23905–23918. [Google Scholar] [CrossRef]

- Gülşan, M.E.; Alzeebaree, R.; Rasheed, A.A.; Niş, A.; Kurtoğlu, A.E. Development of fly ash/slag based self-compacting geopolymer concrete using nano-silica and steel fiber. Constr. Build. Mater. 2019, 211, 271–283. [Google Scholar] [CrossRef]

- Laxmi, G.; Patil, S.; Hossiney, N.; Thejas, H.K. Effect of hooked end steel fibers on strength and durability properties of ambient cured geopolymer concrete. Case Stud. Constr. Mater. 2023, 18, e2122. [Google Scholar] [CrossRef]

- Nakum, A.V.; Arora, N.K. Fresh and mechanical characterization of fly ash/slag by incorporating steel fiber in self-compacted geopolymer concrete. Constr. Build. Mater. 2023, 368, 130481. [Google Scholar] [CrossRef]

- Velandia, D.F.; Lynsdale, C.J.; Provis, J.L.; Ramirez, F. Effect of mix design inputs, curing and compressive strength on the durability of Na2SO4-activated high volume fly ash concretes. Cem. Concr. Compos. 2018, 91, 11–20. [Google Scholar] [CrossRef]

- Amer, I.; Kohail, M.; El-Feky, M.S.; Rashad, A.; Khalaf, M.A. A review on alkali-activated slag concrete. Ain Shams Eng. J. 2021, 12, 1475–1499. [Google Scholar] [CrossRef]

- Huyen Vu, T.; Dang, L.C.; Kang, G.; Sirivivatnanon, V. Chloride induced corrosion of steel reinforcement in alkali activated slag concretes: A critical review. Case Stud. Constr. Mater. 2022, 16, e1112. [Google Scholar] [CrossRef]

- Fu, Q.; Bu, M.; Zhang, Z.; Xu, W.; Yuan, Q.; Niu, D. Hydration characteristics and microstructure of Alkali-Activated slag concrete: A review. Engineering 2023, 20, 162–179. [Google Scholar] [CrossRef]

- Mo, K.H.; Chin, T.S.; Alengaram, U.J.; Jumaat, M.Z. Material and structural properties of waste-oil palm shell concrete incorporating ground granulated blast-furnace slag reinforced with low-volume steel fibres. J. Clean. Prod. 2016, 133, 414–426. [Google Scholar] [CrossRef]

- Afshoon, I.; Miri, M.; Mousavi, S.R. Comprehensive experimental and numerical modeling of strength parameters of eco-friendly steel fiber reinforced SCC containing coarse copper slag aggregates. Constr. Build. Mater. 2023, 367, 130304. [Google Scholar] [CrossRef]

- Joshi, R.; Singh, A.; Resatoglu, R.; Zain, M.; Singh, P. Effect of elevated temperature on Portland Pozzolona cement based concrete using Sulphonated naphthalene formaldehyde and Polycarboxylic ether as superplasticizer. Mater. Today Proc. 2023, 3, 483. [Google Scholar] [CrossRef]

- Ge, Z.; Wang, Y.; Sun, R.; Wu, X.; Guan, Y. Influence of ground waste clay brick on properties of fresh and hardened concrete. Constr. Build. Mater. 2015, 98, 128–136. [Google Scholar] [CrossRef]

- Shao, J.; Gao, J.; Zhao, Y.; Chen, X. Study on the pozzolanic reaction of clay brick powder in blended cement pastes. Constr. Build. Mater. 2019, 213, 209–215. [Google Scholar] [CrossRef]

- JGJ/T283-2012; Technical Specification for Application of Self-Compacting Concrete. China Architecture & Building Press: Beijing, China, 2012. (In Chinese)

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019. (In Chinese)

- GB 50010-2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2010. (In Chinese)

- GB/T 50152-2012; Standard for Test Method of Concrete Structures. China Architecture & Building Press: Beijing, China, 2012. (In Chinese)

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).