3.2.1. Cement Mortars

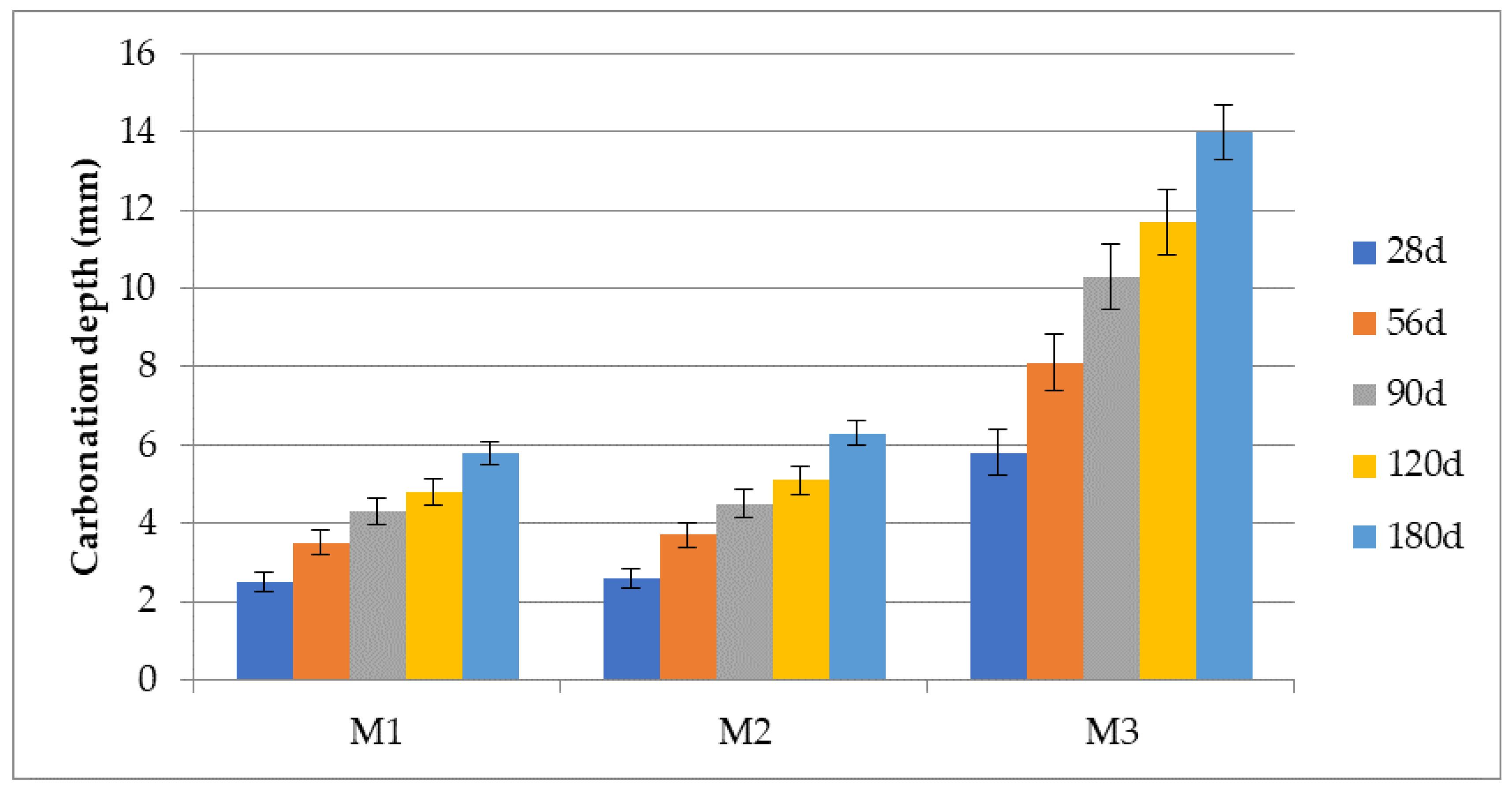

Mixtures M1 and M2, in which CEM I 42.5N and CEM II/A-M (P-LL) 42.5N cements were used, showed lower depths of accelerated carbonation penetration at all measurement ages.

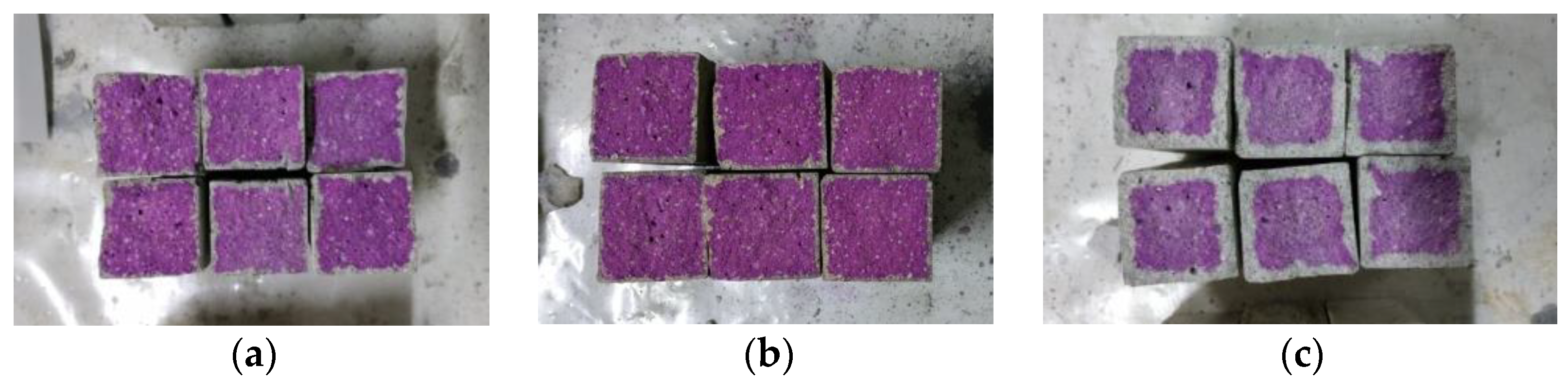

The examples in

Figure 8 show the difference in carbon dioxide penetration between mixtures M1, M2 and M3 at the same measurement age.

The above figure shows the negative effect of the use of 32.5 fineness cement in carbonation resistance. At all ages, the values of carbonation depth were significantly higher in the M3 mixture (c) than the values in the M1 and M2 mixtures whose carbonation depths were similar to each other (a,b).

According to Vanoutrive et al. [

40], specimens tested at 1% CO

2 are characterized by a lower carbonation depth when CEM II is used than specimens with CEM I. Nonetheless, the differences in carbonation depth between CEM I- and CEM II-based mortar were found to be non-significant, as was the case in this study. Singh and Singh [

44] observed that, in general, higher compressive strength implies higher carbonation resistance. This is in agreement with the results of the present research. Torre et al. [

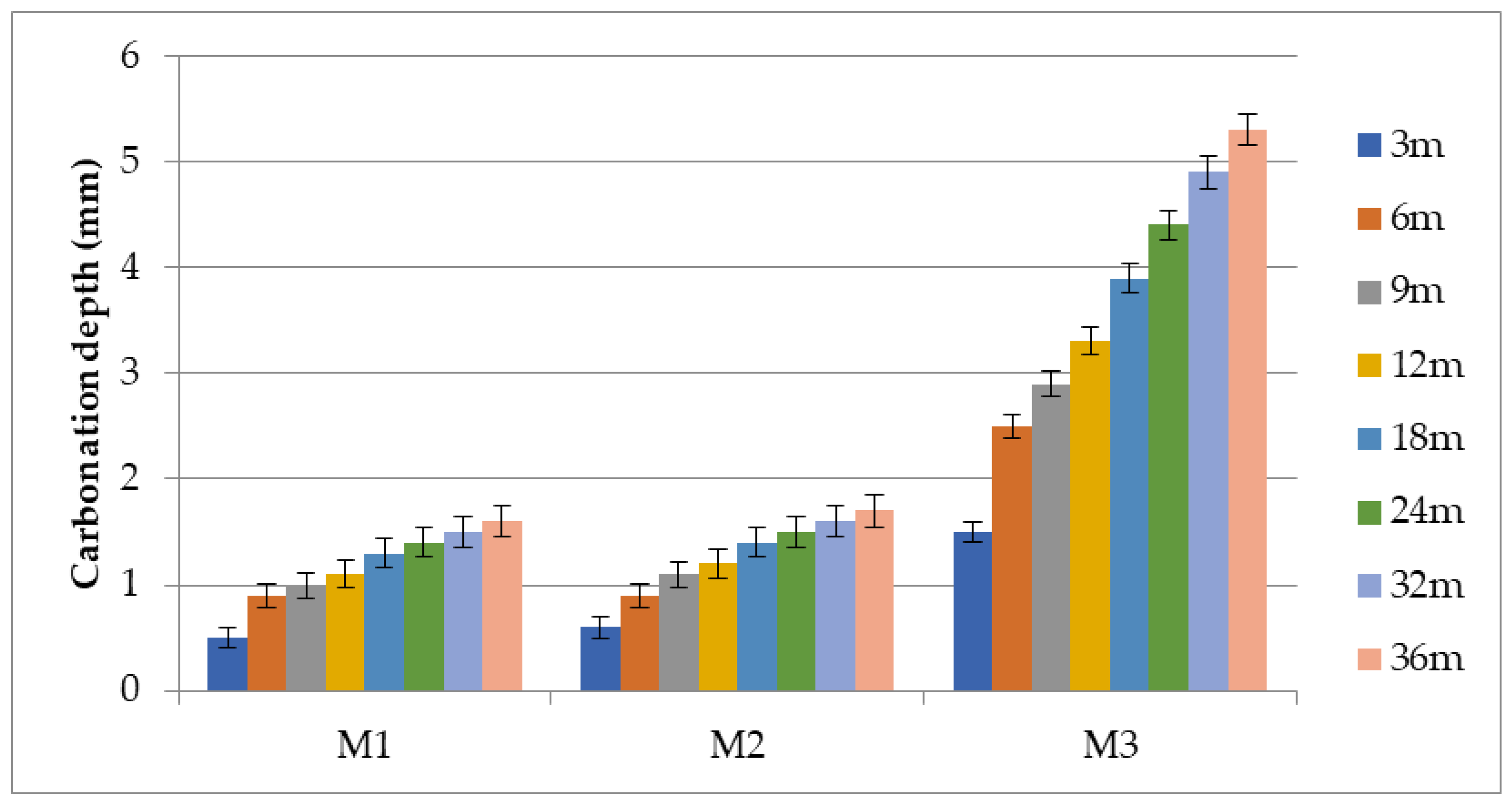

45] found that there were differences in the carbonation speed and depth of cement mortars with Portland cement made by different companies, a fact that shows the possibility of diversity in the results found in the literature. Depth of natural carbonation and standard deviation of mortar mixtures exposed in Xanthi is shown in

Table 9 and

Figure 9.

Table 9.

Depth (mm) of natural carbonation and standard deviation of mortar mixtures exposed in Xanthi.

Table 9.

Depth (mm) of natural carbonation and standard deviation of mortar mixtures exposed in Xanthi.

| (mm) | M1 | M2 | M3 |

|---|

| 3m | 0.5 (0.50) | 0.6 (0.52) | 1.5 (0.55) |

| 6m | 0.9 (0.57) | 0.9 (0.55) | 2.5 (0.54) |

| 9m | 1.0 (0.61) | 1.1 (0.58) | 2.9 (0.57) |

| 12m | 1.1 (0.58) | 1.2 (0.56) | 3.3 (0.54) |

| 18m | 1.3 (0.58) | 1.4 (0.63) | 3.9 (0.59) |

| 24m | 1.4 (0.63) | 1.5 (0.62) | 4.4 (0.60) |

| 30m | 1.5 (0.61) | 1.6 (0.64) | 4.9 (0.63) |

| 36m | 1.6 (0.60) | 1.7 (0.61) | 5.3 (0.63) |

The overall picture of the results of the mixtures exposed outdoors in the Xanthi area is similar to that of accelerated carbonation. The mixtures Μ1 and M2, in which CEM I 42.5N and CEM II/A-M (P-LL) 42.5N cements were used, also showed lower depths of carbonation penetration at all measurement ages up to 3 years. The volume of pores and the number of microcracks of these specimens were lower, this being a decisive factor in their reduced carbonation level [

36].

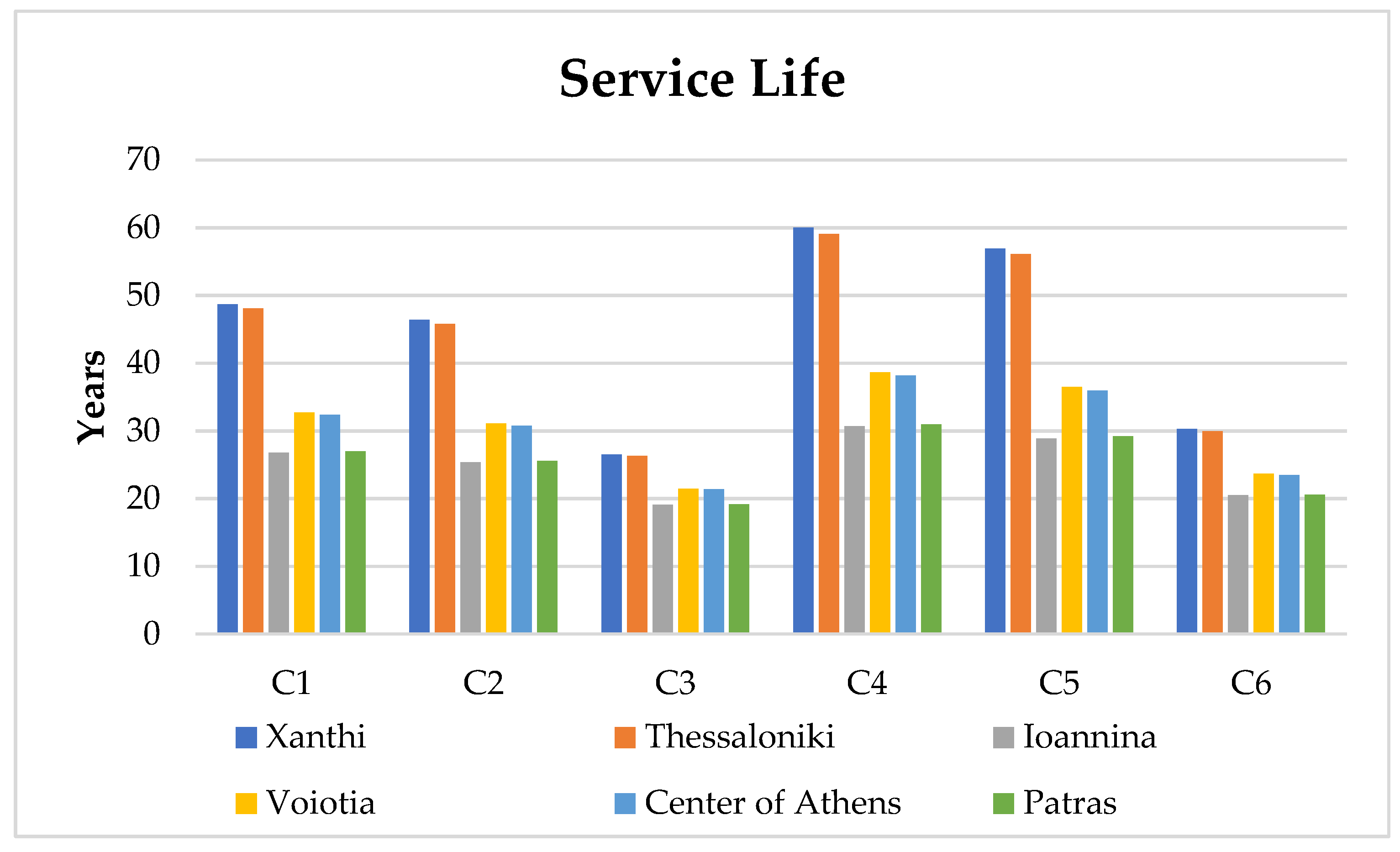

Table 10 presents the values of natural carbonation depth in the selected regions of Greece at 36 months of age.

Table 10.

Depth (mm) of natural carbonation and standard deviation at 36 months of age.

Table 10.

Depth (mm) of natural carbonation and standard deviation at 36 months of age.

| | M1 | M2 | M3 |

|---|

| Xanthi | 1.6 (0.67) | 1.7 (0.59) | 5.3 (0.64) |

| Thessaloniki | 1.6 (0.62) | 1.7 (0.65) | 5.4 (0.62) |

| Ioannina | 2.4 (0.72) | 2.6 (0.68) | 6.1 (0.67) |

| Voiotia | 1.9 (0.70) | 2.0 (0.74) | 5.4 (0.72) |

| Center of Athens | 1.9 (0.81) | 2.1 (0.75) | 5.3 (0.85) |

| Patras | 2.3 (0.75) | 2.5 (0.84) | 5.9 (0.80) |

All the results of natural carbonation from all selected areas confirm the results of accelerated carbonation and reinforce the conclusion that the use of CEM I 42.5N and CEM II/A-M (P-LL) 42.5N cements has a beneficial effect on carbonation resistance. The effect of cement strength class on carbonation can also be investigated at the microlevel. The difference between the properties of cements with various strength classes is due to differences between their constituent compounds, especially the main components in the hydration products [

39,

40]. This difference in the microstructure level leads to changes in both volume of pores and structure of the specimens, which are factors that affect compressive strength [

36]. The volume of pores and the number of microcracks for samples with 42.5 cement are lower compared to samples of 32.5 cement [

39,

40,

46].

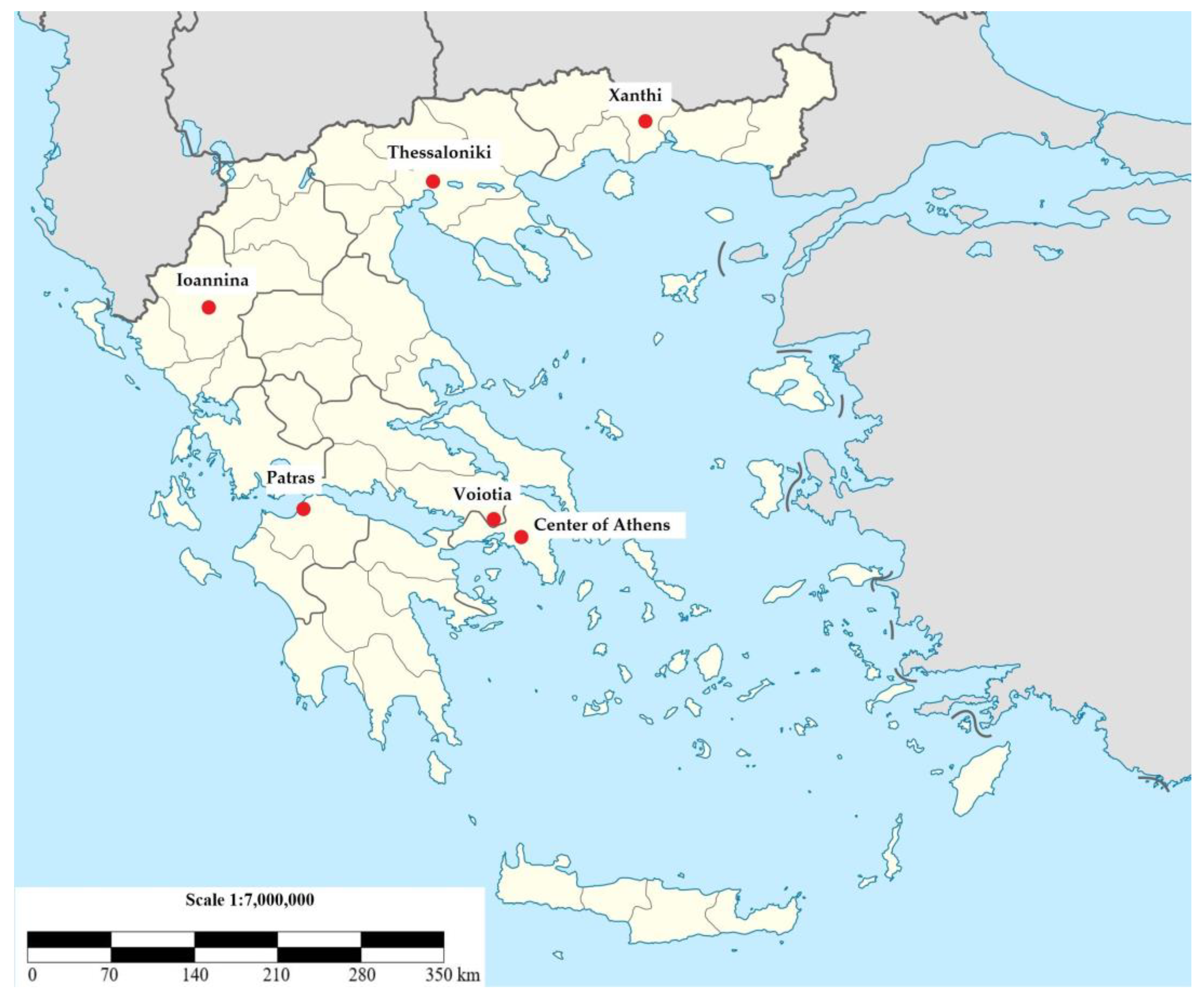

At the same time, studying the variations of the results between the selected areas points to the fact that the exposure environment greatly influences the penetration of carbonation. Mortars exposed in areas such as Patras and Ioannina showed increased depths of carbonation compared to mortars exposed in other areas. For this reason, the correlation of carbonation evolution of each cement mortar with the meteorological data of the exposure areas was investigated.

Most papers in the literature generally report on carbonation depth after a specific time of exposure. However, the resistance to carbonation used for service life prediction modeling is mostly expressed as a coefficient, which is the relation between the carbonation depth and time of exposure [

42]. Several analytical models are used to describe the relationship between carbonation depth (x) and concrete age (t). The most widely used is the analytic solution of Fick’s first law in the form:

where x is the carbonation front depth, t is the exposure time and k is the carbonation coefficient. This coefficient depends on environmental conditions such as CO

2 concentration and humidity, and concrete characteristics such as

w/

c ratio and type of cement, and therefore varies significantly from one structure to another [

47].

During the evolution of the experiments, a convergence of the k coefficient to specific values was observed with the addition of each new measurement, as was a simultaneous reduction of the standard deviation of the results. This fact is confirmed by Vanoutrive et al. [

40], who concluded that carbonation rates based on carbonation depths at greater exposure ages show lower deviation; therefore, these values are considered to serve as a good estimate of the potential resistance to carbonation of the tested mixtures. Based on this conclusion, in the present paper, five values were used until the 180 days of exposure for accelerated carbonation (ages of 28, 56, 90, 120 and 180 days) and eight values for up to 3 years of exposure for natural carbonation (ages of 3, 6, 9, 12, 18, 24, 30 and 36 months) in order to achieve more stable and reliable results. In

Table 11, the values of the k coefficient for the cement mortars tested in accelerated carbonation are presented.

Table 11.

k coefficient of cement mortars exposed to accelerated carbonation.

Table 11.

k coefficient of cement mortars exposed to accelerated carbonation.

| | M1 | M2 | M3 |

|---|

| k (mm/day 1/2) | 0.431 | 0.466 | 1.050 |

| R2 | 0.127 | 0.078 | 0.153 |

Table 12 presents the values of the k coefficient for all cement mortars that were exposed to natural carbonation in the selected areas.

Table 12.

k coefficient (mm/day 1/2) and coefficient of determination R2 of cement mortars exposed in the selected areas.

Table 12.

k coefficient (mm/day 1/2) and coefficient of determination R2 of cement mortars exposed in the selected areas.

| | M1 | M2 | M3 |

|---|

| | k | R2 | k | R2 | k | R2 |

|---|

| Xanthi | 0.861 | 0.978 | 0.903 | 0.972 | 1.916 | 0.969 |

| Thessaloniki | 1.020 | 0.967 | 1.071 | 0.966 | 2.240 | 0.963 |

| Ioannina | 1.599 | 0.969 | 1.679 | 0.970 | 3.392 | 0.969 |

| Voiotia | 1.296 | 0.948 | 1.361 | 0.947 | 2.774 | 0.945 |

| Center of Athens | 1.302 | 0.951 | 1.362 | 0.948 | 2.796 | 0.944 |

| Patras | 1.508 | 0.962 | 1.582 | 0.964 | 3.253 | 0.959 |

Table 13 shows average annual temperature (T), relative humidity (RH), annual rainfall (mm) and rainfall higher than 25 mm (days) in the exposure areas for the three years of exposure (2019–2021).

Table 13.

Average annual temperature (T), relative humidity (RH), annual rainfall (mm) and rainfall higher than 25 mm (days) in exposure areas [

48].

Table 13.

Average annual temperature (T), relative humidity (RH), annual rainfall (mm) and rainfall higher than 25 mm (days) in exposure areas [

48].

| City | T (°C) | RH (%) | Rainfall (mm) | Rainfall > 25 mm (Days) |

|---|

| Xanthi | 14.2 | 67.7 | 462 | 30 |

| Thessaloniki | 15.9 | 66.6 | 448 | 40 |

| Ioannina | 19.6 | 69.2 | 1080 | 80 |

| Voiotia | 18.4 | 59.1 | 395 | 11 |

| Center of Athens | 17.8 | 61.3 | 411 | 23 |

| Patras | 18.6 | 66.3 | 793 | 57 |

An increase in the carbonation coefficient k was observed in this study for cement mortars that were exposed in areas with higher average annual temperatures and higher average relative humidity for all three types of cement used. Haque and Khaiat [

49] studied about 50 buildings located from 0.5 to 18 km from the coast of Kuwait. They found that the coastal structures exposed to higher temperatures showed higher values of carbonation depth than the near-coastal structures. The same paper recommends that concrete structures situated in hot dry coastal regions should be built with a compressive strength at least in the range of 30–50 MPa, in order to avoid premature durability problems. Monteiro et al. [

47] investigated 47 samples from existing concrete structures with ages up to 99 years and found that k = 3.76 mm/year

0.5. Ta et al. [

50] concluded that the carbonation coefficient depends on many influencing parameters such as compressive strength, ambient temperature and relative external humidity.

Taking into account that, in large urban centers such as Athens and Thessaloniki, the concentration of carbon dioxide is greater (420–450 ppm in Athens and Thessaloniki during the testing period, while the relevant values in Xanthi, Ioannina and Patra were 380–410 ppm) [

48], the conclusion is strengthened that the combination of high temperature, humidity and precipitation had a negative effect on the carbonation of the specimens, as Ioannina and Patras are not the largest and most densely populated cities that were examined, but nevertheless presented the highest coefficient k.

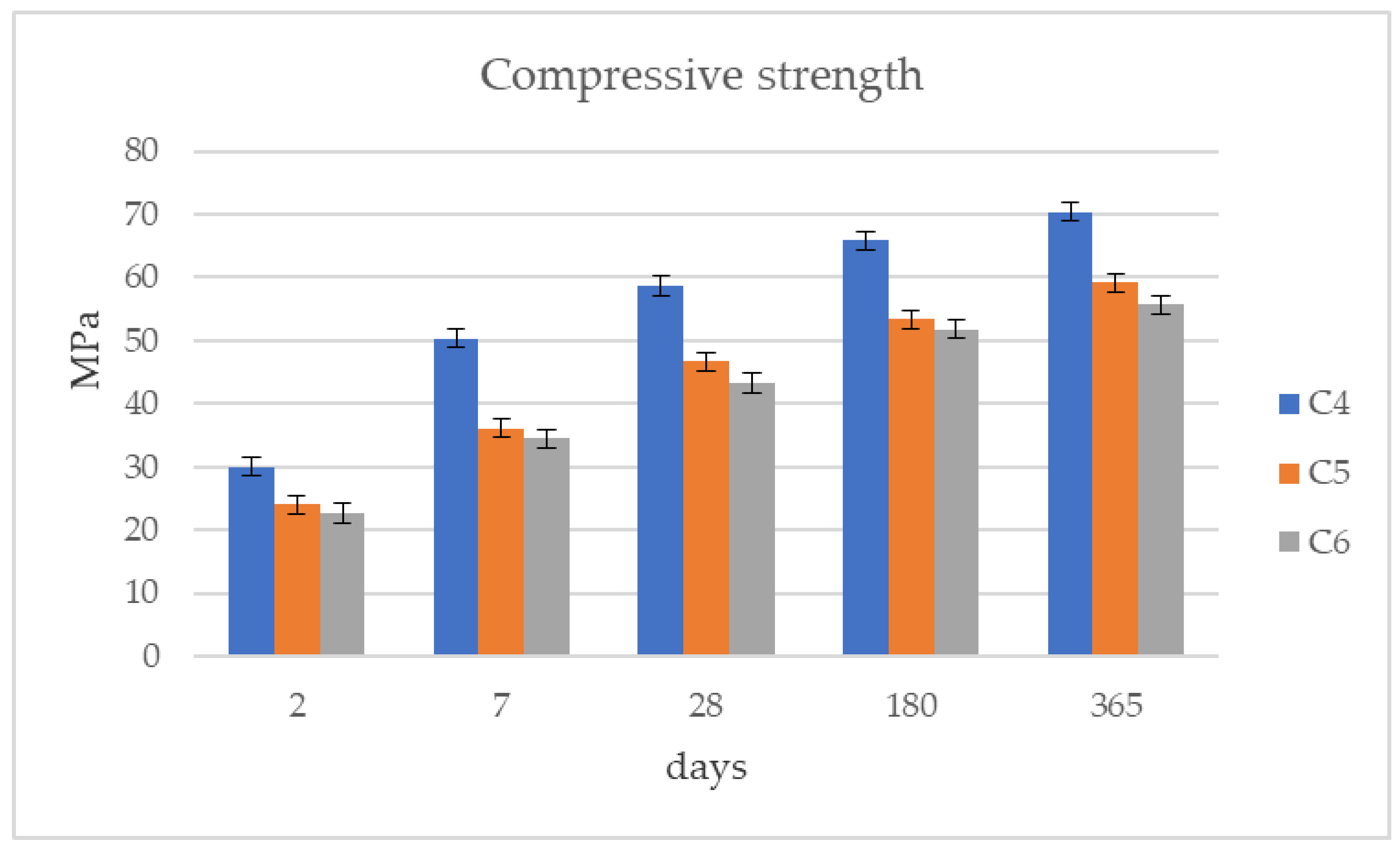

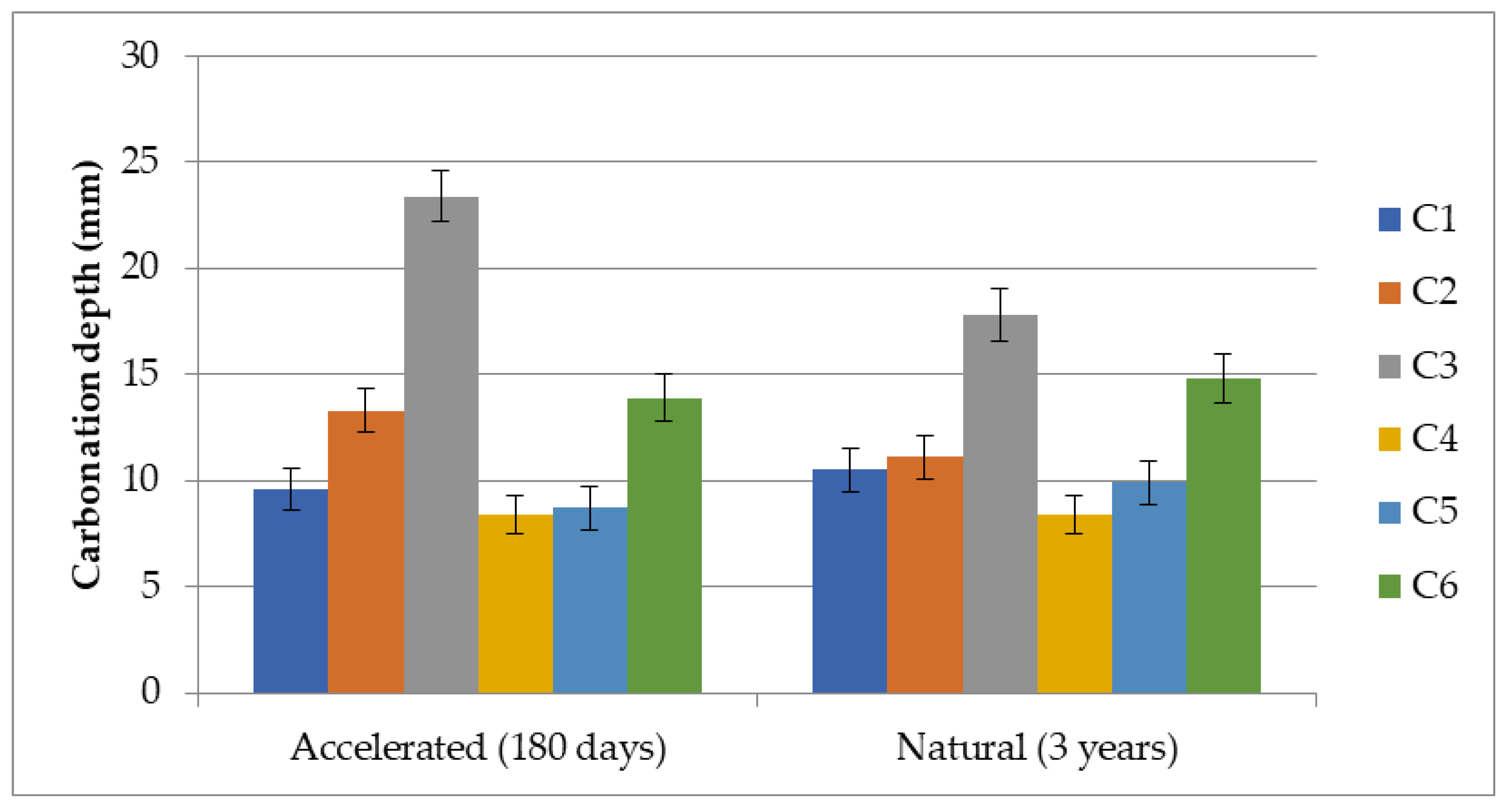

3.2.2. Concretes

Carbonation depth due to accelerated exposure was measured after 28, 56, 90 and 180 days and natural carbonation depth was measured after 3, 6, 9, 12, 18, 24, 30 and 36 months of exposure. A freshly broken surface sprayed with a phenolphthalein indicator [

35] is shown in

Figure 10.

The final values of carbonation depth for all mixtures in accelerated and natural carbonation are shown in

Table 14 and

Table 15, and are represented graphically in

Figure 11.

Table 14.

Carbonation depth and standard deviation of C25/30 strength class mixtures.

Table 14.

Carbonation depth and standard deviation of C25/30 strength class mixtures.

| (mm) | C1 | C2 | C3 |

|---|

| Accelerated (180 days) | 9.6 | 13.3 | 23.4 |

| s | 1.02 | 1.14 | 1.27 |

| Natural (3 years) | 10.5 | 11.1 | 17.8 |

| s | 0.99 | 0.94 | 1.18 |

The above figure shows the positive effect of the use of CEM I cement on carbonation resistance in concrete. All mixtures of both strength classes have lower values of carbonation depth in both accelerated and natural carbonation. In

Table 16 and

Table 17 are presented k coefficient of C25/30 and C30/37 strength class concretes.

Concrete structures that come into contact with atmospheric air are always subjected to carbonation; therefore, this category of durability is particularly important for the sustainability of construction projects in areas such as Greece and the Mediterranean, where the phenomenon of carbonation is more intense due to local climatic conditions [

51,

52]. For this reason, it is extremely useful to have a means of predicting carbonation in Greece. For this purpose, in the present study, the results of carbonation of cement mortars were combined and compared with concrete results in order to find a correlation between them. Carbonation testing is often executed on a mortar scale, which is then assumed to be representative of the concrete scale [

42]. The ratios of the k values between cement mortars and concretes were calculated, showing high homogeneity, and are presented in

Table 18 for accelerated carbonation. In the tables that follow, k

nat-concrete is the k coefficient for natural carbonation of concrete, k

acc-concrete is the k coefficient for accelerated carbonation of concrete, k

nat,mortar is the k coefficient for natural carbonation of mortar and k

acc-mortar is the k coefficient for accelerated carbonation of mortar.

Vanoutrive et al. [

42] concluded that the carbonation coefficient of concrete was 1.18 times that of mortar in accelerated carbonation. Papadakis et al. [

53] found a factor of 1.1 between the mortar and concrete scales. The findings of the present study estimate this factor values from 1.46 to 1.67, depending on the different design of each mixture.

The ratios of the k values between accelerated and natural carbonation were calculated and are shown in

Table 19 for concrete mixtures

The ratios of the k values between cement mortars and concretes were calculated, showing high homogeneity, and are presented in

Table 20 for natural carbonation.

The ratios of the k values between accelerated and natural carbonation were calculated and are shown in

Table 21 for mortar mixtures for the six areas of exposure.

The high homogeneity of the results and their verification show the capability of empirically predicting the carbonation depth of concrete constructions at least in the six selected regions, and possibly even in regions with climatic conditions that are closely similar to those of the tested areas. Using the k coefficient ratios of

Table 18,

Table 19,

Table 20 and

Table 21, according to the sequence presented in

Figure 12, a general empirical rule is deduced for the prediction of concrete carbonation in the selected areas.

As already stated, the aim of the present research is the prediction of natural carbonation of concrete starting from the accelerated carbonation of mortar. According to

Figure 12, the way to correlate these two values is through the natural carbonation of mortars, specifically by using the ratios of k coefficients of

Table 20 and

Table 21.

For the most effective use of the empirical model, the following equation was formulated:

where k

nat-concrete is the required k coefficient for natural carbonation of concrete, k

acc-mortar is the given k coefficient for accelerated carbonation of mortar, enp is the environmental parameter according to

Table 22, scp is the

w/

c ratio parameter according to

Table 23, cemp is the cement parameter according to

Table 24, rp is the rainfall parameter according to

Table 25 and acurp is the curing parameter according to

Table 26 [

54].

Equation (2) was used to calculate k coefficients for concretes in the selected areas, as presented in

Table 27.

Table 28 presents a comparison of the results of k

nat-concrete coefficient due to real exposure and the same results according to Equation (2). The differences between them are also shown in the table.

The differences in the knat-concrete coefficient between real exposure in Xanthi and the prediction model range from 2.7–7.6%, with these percentages being considered low, providing that the prediction model shows high reliability.