Investigating Ageing Effects on Bored Pile Shaft Resistance in Cohesionless Soil Through Field Testing

Abstract

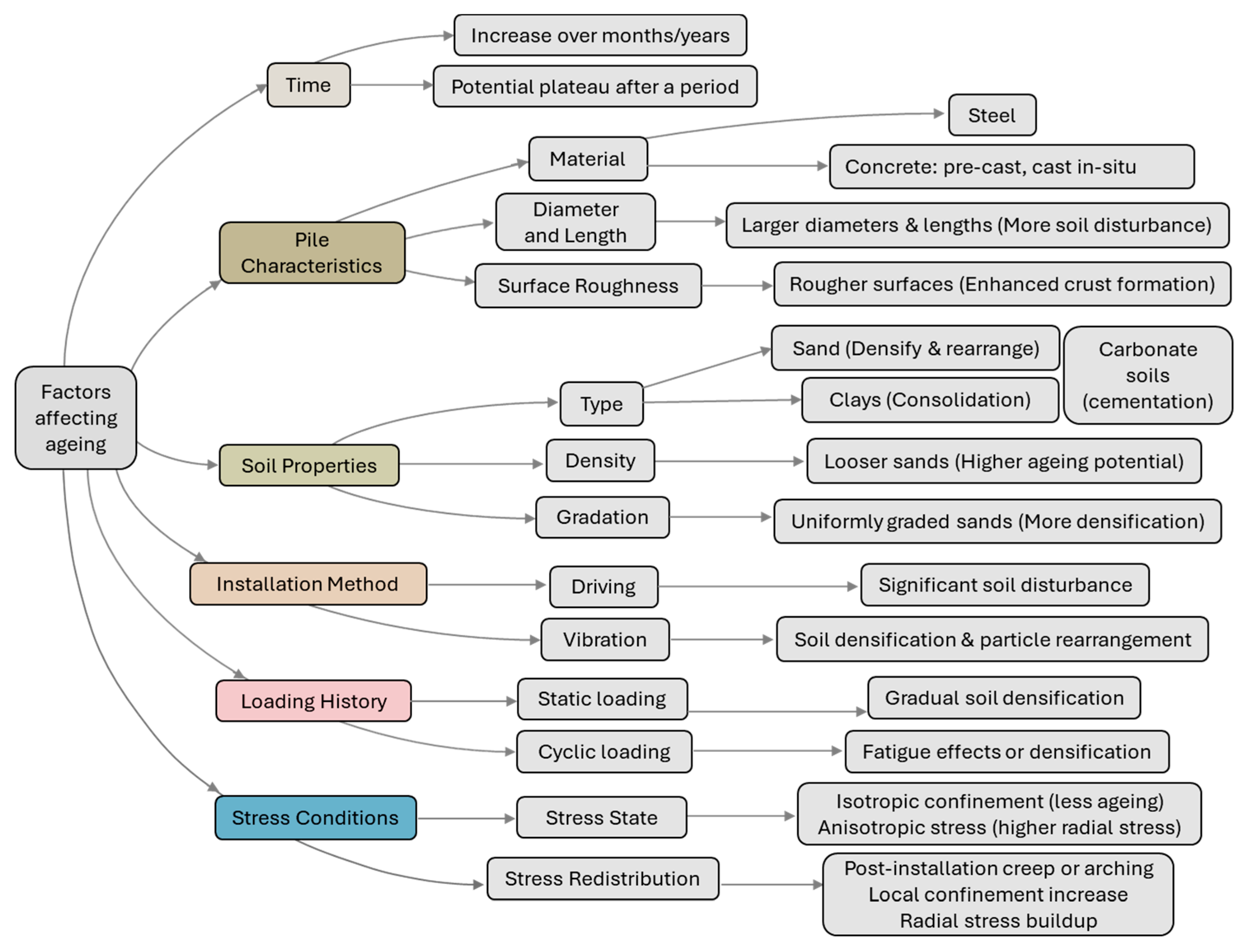

1. Introduction

2. Materials and Methods

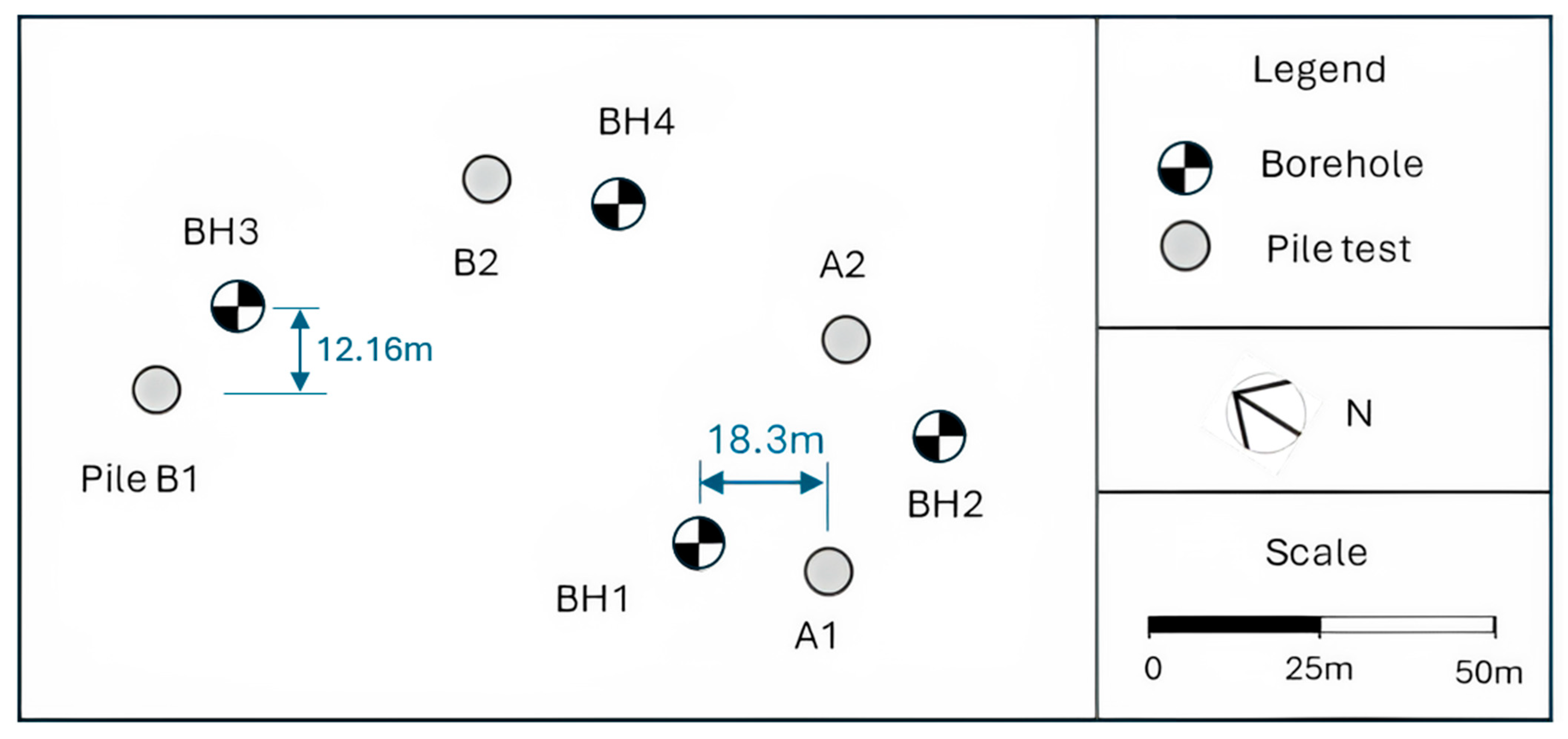

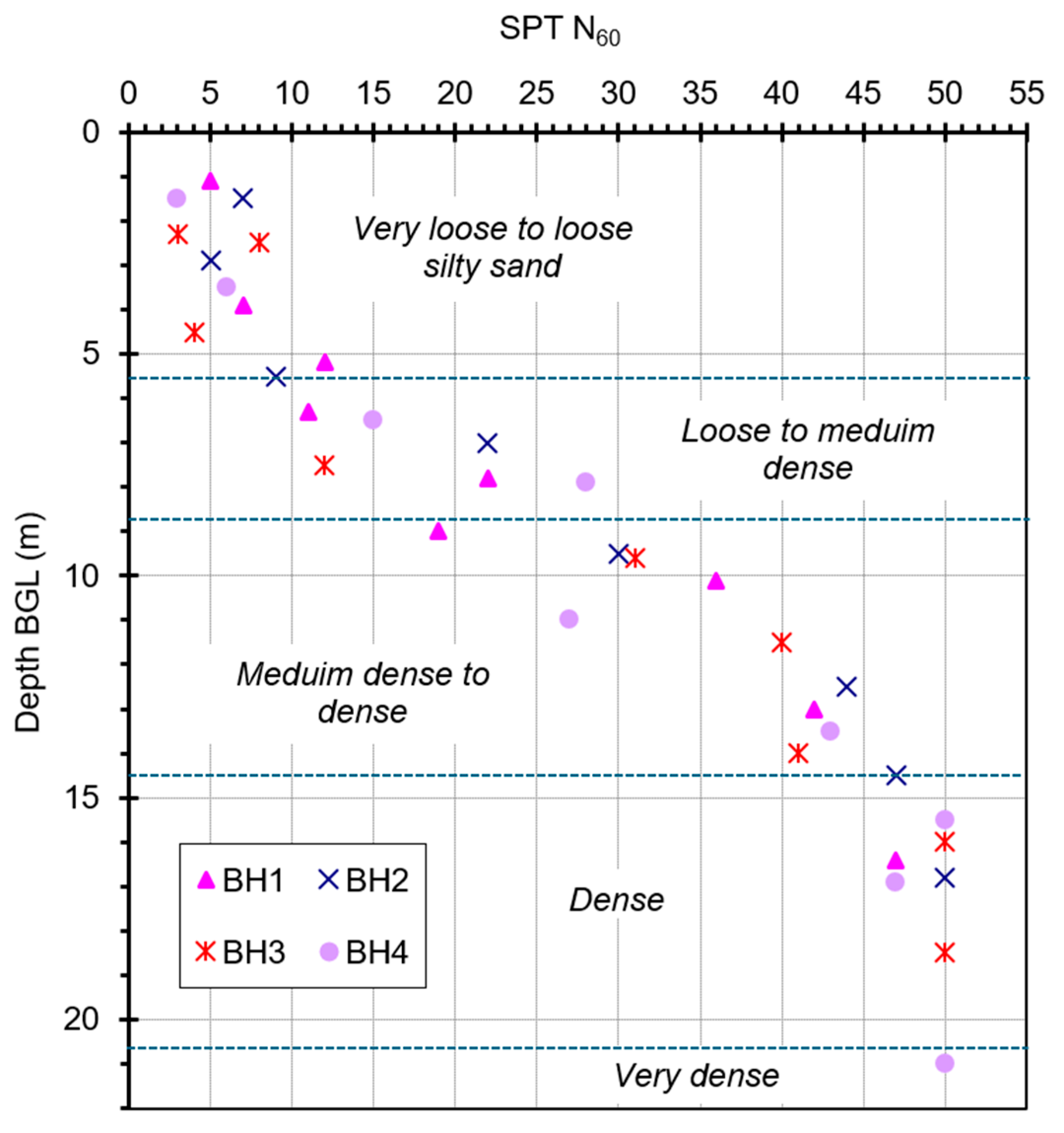

2.1. Site Description and Ground Investigation

2.2. Design and Scheduling of Uplift Tests

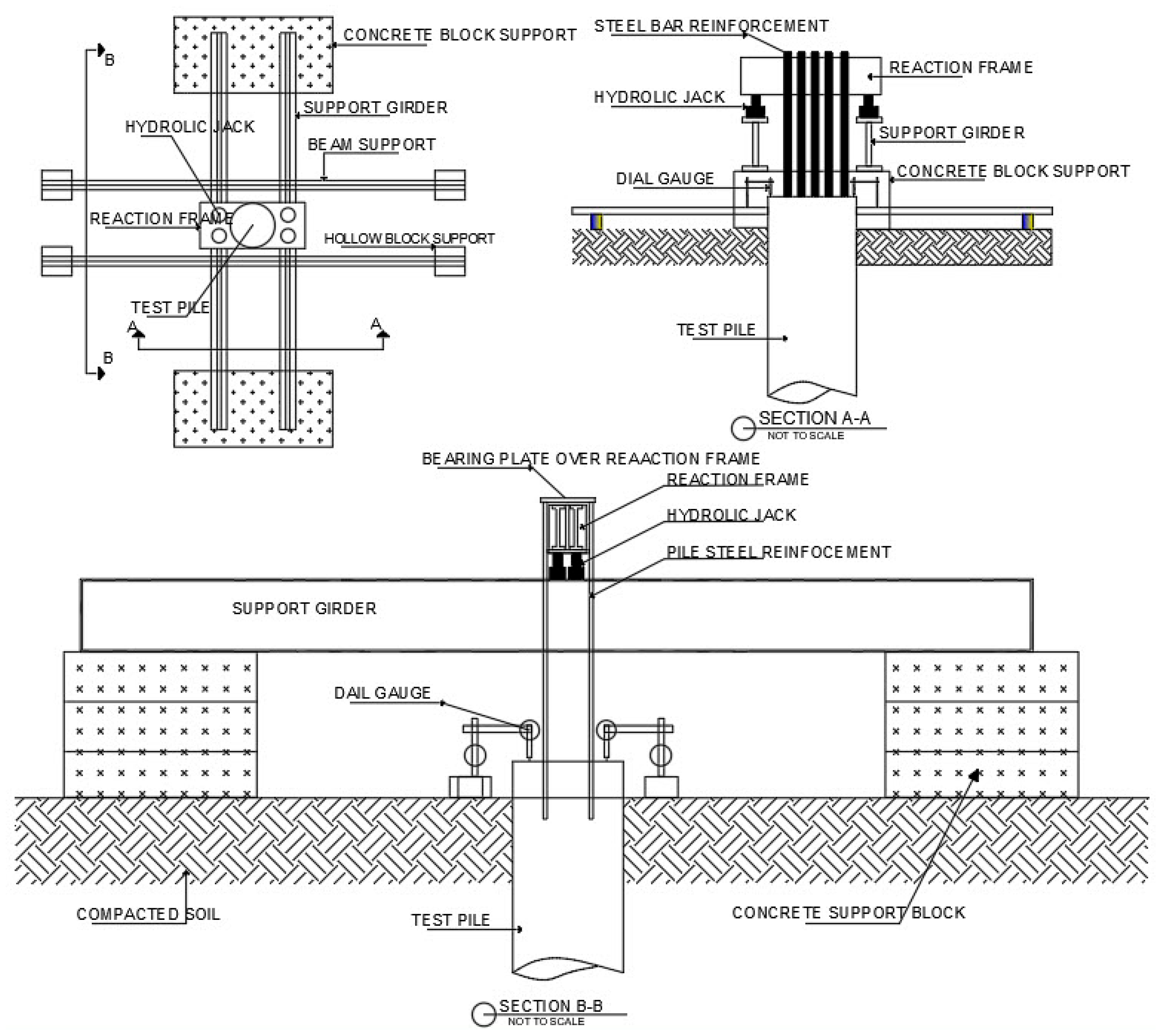

2.3. Pile Construction, Instrumentation and Loading Procedures

2.3.1. Pile Construction

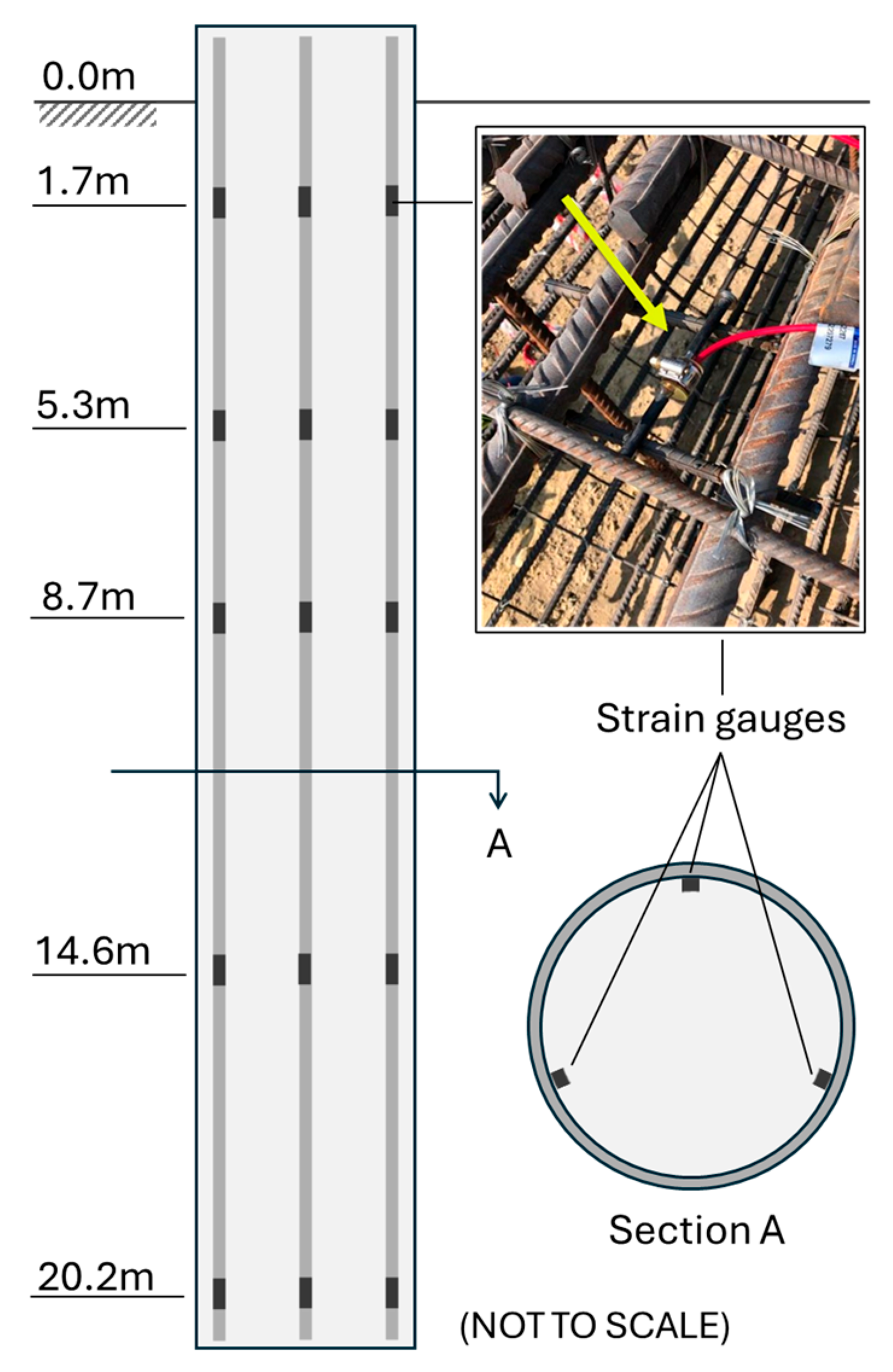

2.3.2. Experimental Setup and Pile Instrumentation

2.3.3. Loading Procedures

3. Results and Discussion

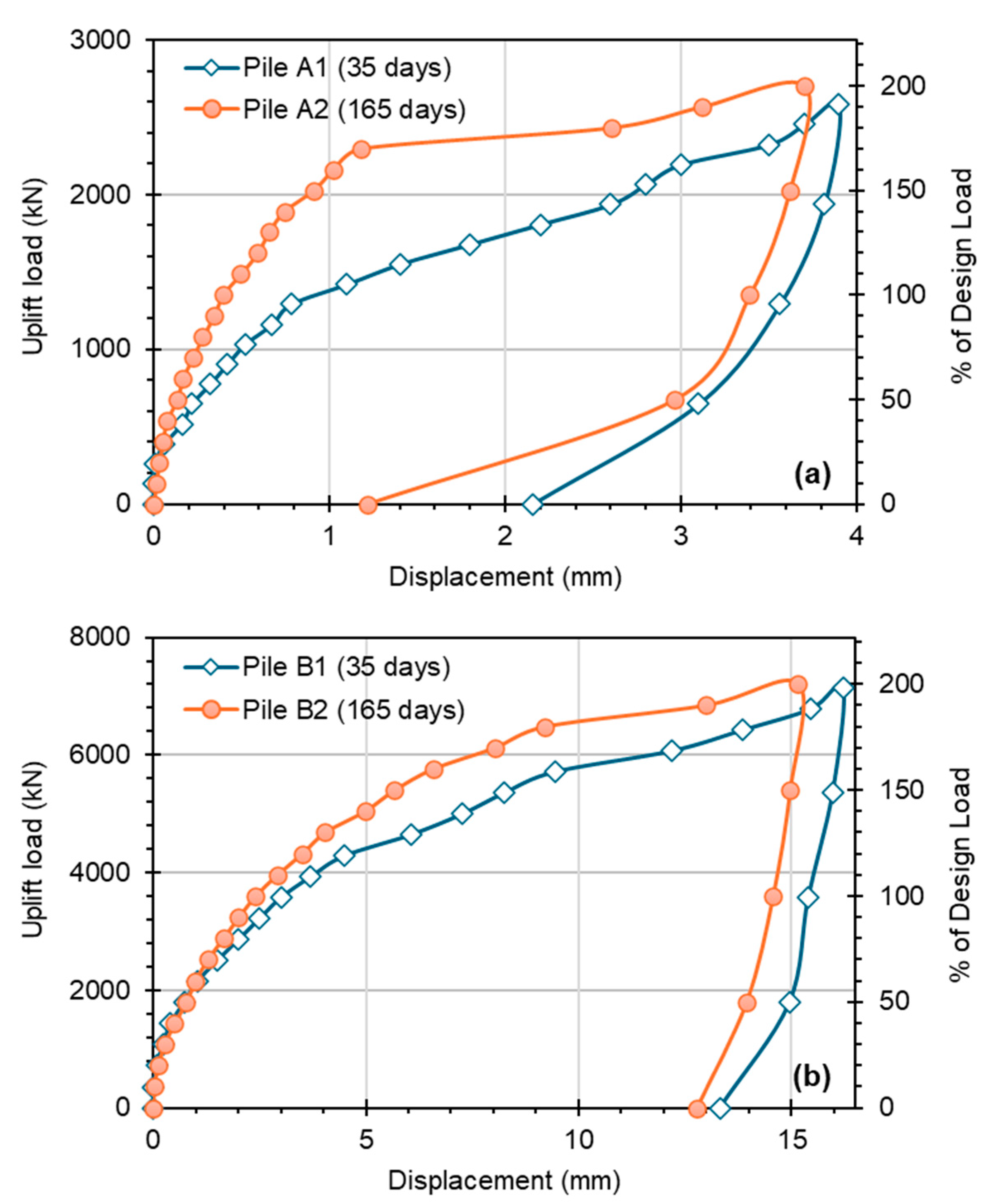

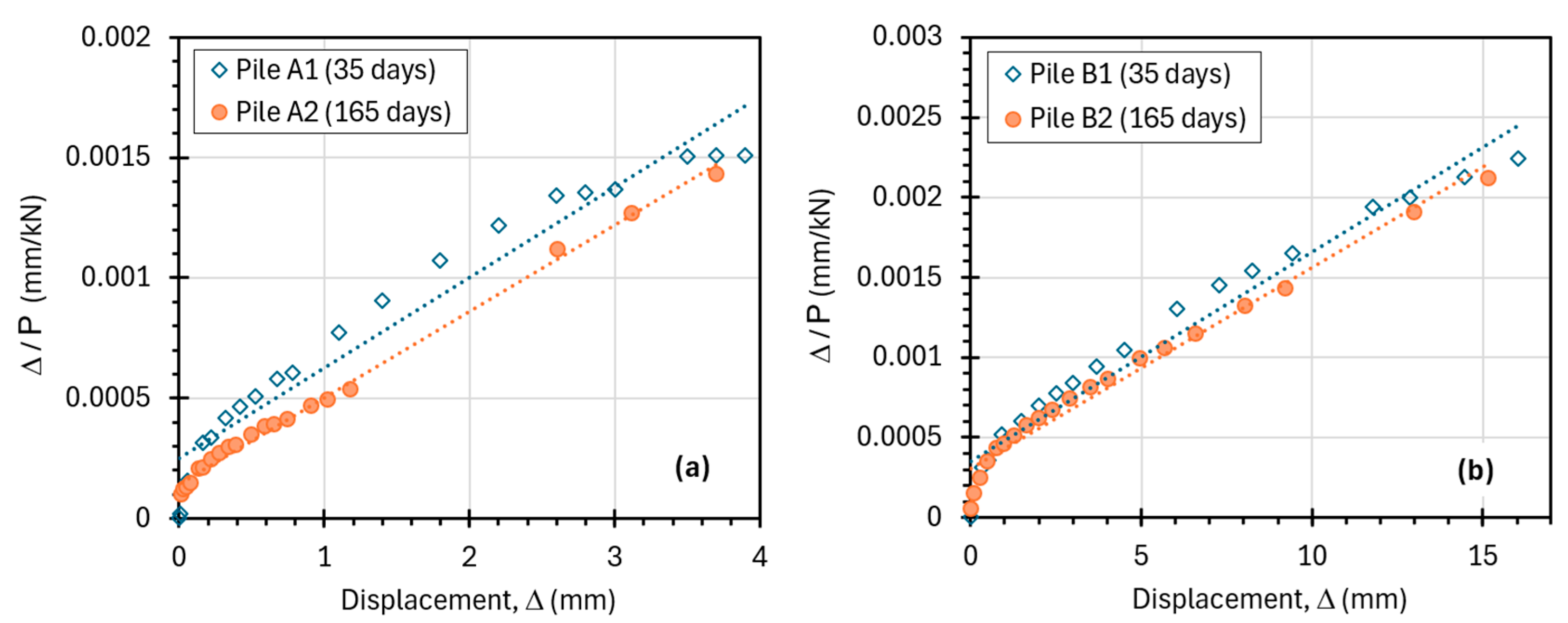

3.1. Load-Displacement Behaviour

3.2. Strain Gauge Interpretation

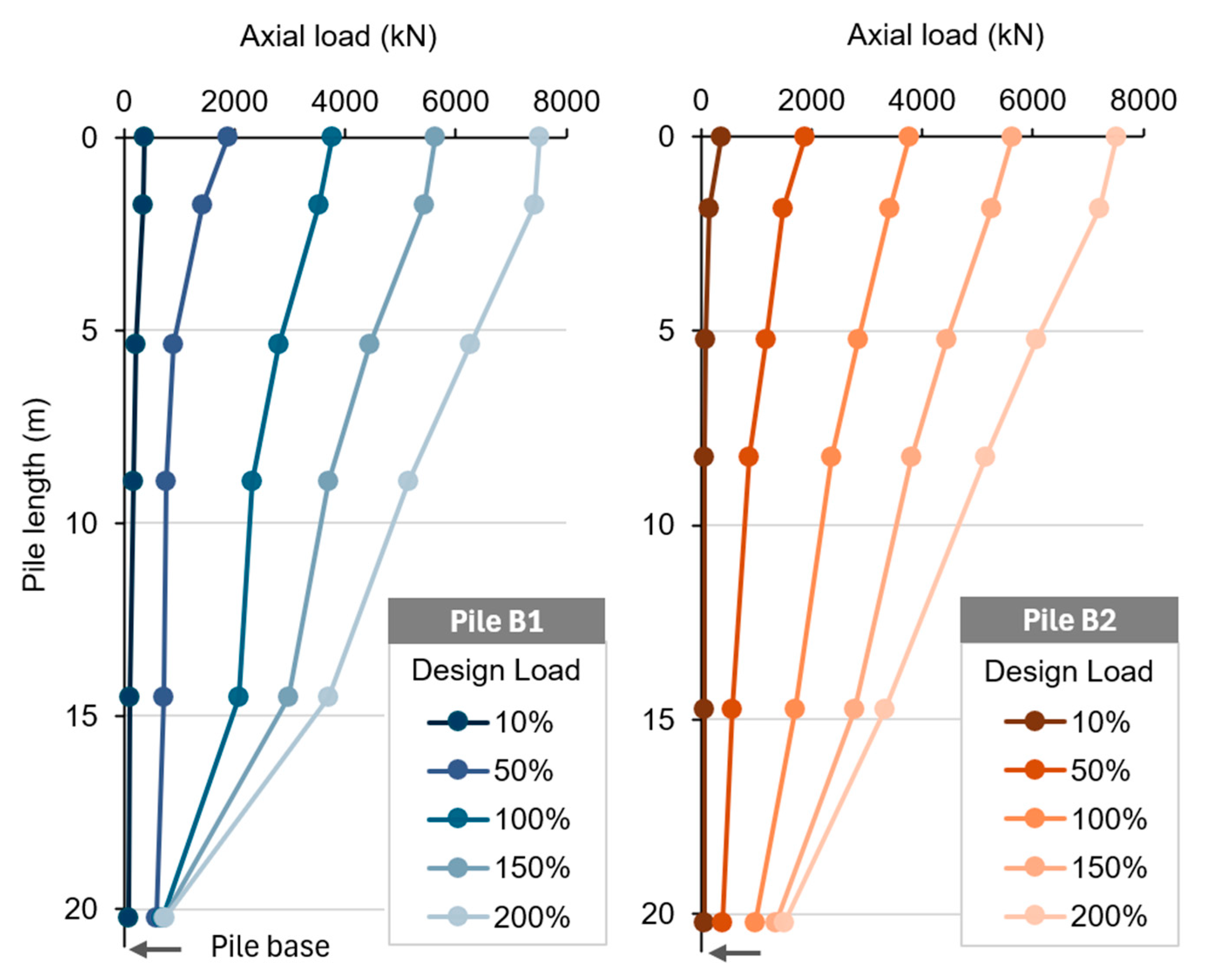

3.2.1. Distribution of Axial Load

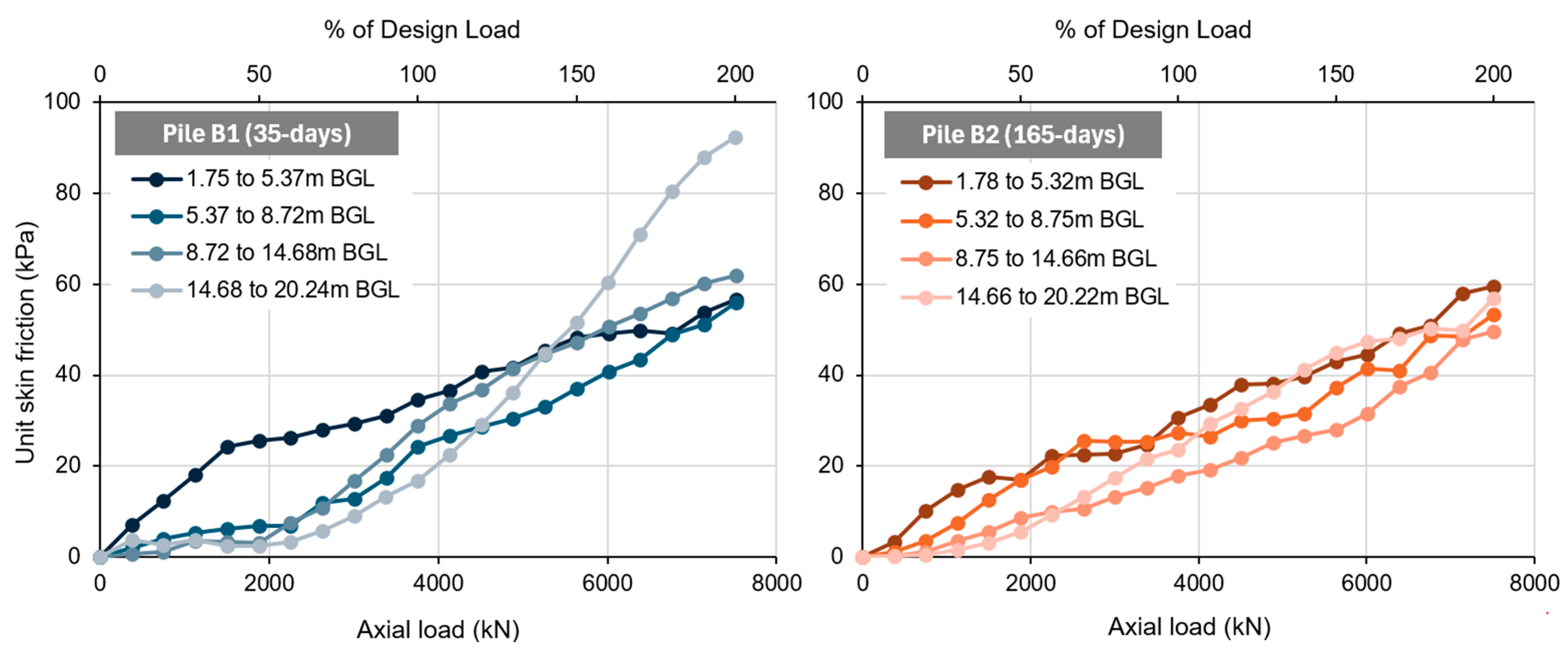

3.2.2. Distribution of Shaft Resistance

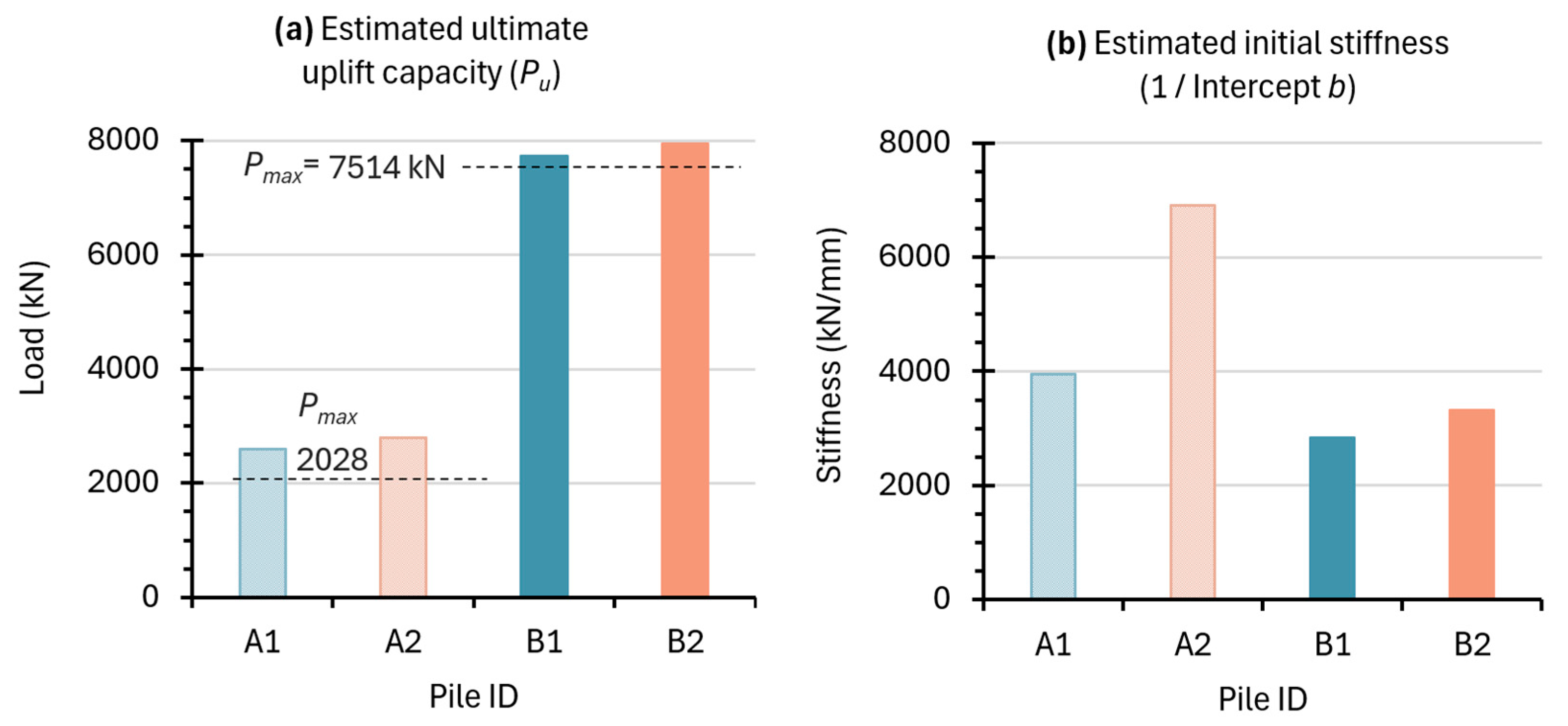

3.3. Estimation of Ultimate Uplift Load Capacity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Efstathopoulos, G.E.; Balomenos, G.P. Effects of Wave Load Models on the Uplift Fragility Assessment of Pile-Supported Wharves and Piers Exposed to Storm Surge and Waves. Eng. Struct. 2023, 290, 116372. [Google Scholar] [CrossRef]

- Taghavi, A.; McVay, M.; Niraula, L.; Davidson, M.; Patil, A. Axial and Lateral Resistance Coupling in the Analysis of Large-Diameter Drilled Shafts. Eng. Struct. 2020, 206, 110160. [Google Scholar] [CrossRef]

- Chow, F.C.; Jardine, R.J.; Nauroy, J.F.; Brucy, F. Time-Related Increases in the Shaft Capacities of Driven Piles in Sand. Geotechnique 1997, 47, 353–361. [Google Scholar] [CrossRef]

- Abushama, K.; Hawkins, W.; Pelecanos, L.; Ibell, T. Minimising the Embodied Carbon of Reinforced Concrete Piles Using a Multi-Level Modelling Tool with a Case Study. Structures 2023, 58, 105476. [Google Scholar] [CrossRef]

- Hamza, O.; Abogdera, A.; Zoras, S. Emissions-Based Options Appraisal for Modular Building Foundations: A Case Study. Proc. Inst. Civ. Eng. Sustain. 2023, 177, 162–173. [Google Scholar] [CrossRef]

- Mihálik, J.; Gago, F.; Vlček, J.; Drusa, M. Evaluation of Methods Based on CPTu Testing for Prediction of the Bearing Capacity of CFA Piles. Appl. Sci. 2023, 13, 2931. [Google Scholar] [CrossRef]

- Randolph, M.F.; Wroth, C.P. An Analytical Solution for the Consolidation around a Driven Pile. Int. J. Numer. Anal. Methods Geomech. 1979, 3, 217–229. [Google Scholar] [CrossRef]

- Bullock, P.J.; Schmertmann, J.H.; McVay, M.C.; Townsend, F.C. Side Shear Setup. I: Test Piles Driven in Florida. J. Geotech. Geoenviron. Eng. 2005, 131, 292–300. [Google Scholar] [CrossRef]

- Jardine, R.J.; Standing, J.R.; Chow, F.C. Some Observations of the Effects of Time on the Capacity of Piles Driven in Sand. Géotechnique 2006, 56, 227–244. [Google Scholar] [CrossRef]

- Skov, R.; Denver, H. Time-Dependence of Bearing Capacity of Piles. In Proceedings of the Third International Conference on the Application of Stress-Wave Theory to Piles, Ottawa, ON, Canada, 25–27 May 1988; pp. 25–27. [Google Scholar]

- Ng, E.; Briaud, J.L.; Tucker, L.M. Field Testing of 5 Axially Loaded Single Piles in Sand at Hunter’s Point; Research Report to FHWA; Geo Resource Consultants Inc.: San Francisco, CA, USA, 1988. [Google Scholar]

- Fellenius, B.H.; Riker, R.E.; O’Brien, A.J.; Tracy, G.R. Dynamic and Static Testing in Soil Exhibiting Set-Up. J. Geotech. Eng. 1989, 115, 984–1001. [Google Scholar] [CrossRef]

- Gavin, K.G.; Igoe, D.J.P.; Kirwan, L. The Effect of Ageing on the Axial Capacity of Piles in Sand. Proc. Inst. Civ. Eng. 2013, 166, 122–130. [Google Scholar] [CrossRef]

- Karlsrud, K.; Jensen, T.G.; Lied, E.K.W.; Nowacki, F.; Simonsen, A.S. Significant Ageing Effects for Axially Loaded Piles in Sand and Clay Verified by New Field Load Tests. In Proceedings of the Offshore Technology Conference, OTC, Houston, TX, USA, 5–8 May 2014; p. D041S045R001. [Google Scholar]

- Carroll, R.; Carotenuto, P.; Dano, C.; Salama, I.; Silva, M.; Gavin, K.; Jardine, R. Field Studies on the Axial Capacity of Small Diameter Piles and Ageing Effects in Sands. In Offshore Site Investigation Geotechnics 8th International Conference Proceeding; Society for Underwater Technology: London, UK, 2017; pp. 1160–1169. [Google Scholar]

- Buckley, R.M.; Jardine, R.J.; Kontoe, S.; Lehane, B.M. Effective Stress Regime around a Jacked Steel Pile during Installation Ageing and Load Testing in Chalk. Can. Geotech. J. 2018, 55, 1577–1591. [Google Scholar] [CrossRef]

- Carroll, R.; Carotenuto, P.; Dano, C.; Salama, I.; Silva, M.; Rimoy, S.; Gavin, K.; Jardine, R. Field Experiments at Three Sites to Investigate the Effects of Age on Steel Piles Driven in Sand. Géotechnique 2020, 70, 469–489. [Google Scholar] [CrossRef]

- Igoe, D.; Gavin, K. Investigation of Cyclic Loading of Aged Piles in Sand. J. Geotech. Geoenviron. Eng. 2021, 147, 02451. [Google Scholar] [CrossRef]

- Bittar, E.M.; Lehane, B.M. An Experimental Study on Factors Affecting the Ageing of Shaft Friction on Steel Displacement Piles in Sand. Géotechnique 2024, 75, 348–361. [Google Scholar] [CrossRef]

- ISO 19901-4; Oil and Gas Industries Including Lower Carbon Energy—Specific Requirements for Offshore Structures Part 4: Geotechnical Design Considerations. ISO: Geneva, Switzerland, 2025.

- Manthey, S.; Vogt, S.; Cudmani, R.; Kidane, M. Experimental Study on the Time-Dependent Bearing Resistance of Open-Ended Steel Piles in Sand. Géotechnique 2024, 4, 985–1006. [Google Scholar]

- Taheri, A. Investigation of the Pile Aging Effect of a Fixed Offshore Platform Located in Persian Gulf Using Nonlinear Soil-Pile Interactions. Int. J. Marit. Technol. 2017, 8, 59–64. [Google Scholar] [CrossRef][Green Version]

- Karlsson, M.; Yannie, J.; Dijkstra, J. Modeling Aging of Displacement Piles in Natural Soft Clay. J. Geotech. Geoenviron. Eng. 2019, 145, 4019070. [Google Scholar] [CrossRef]

- Gavin, K.; Igoe, D. A Field Investigation into the Mechanisms of Pile Ageing in Sand. Géotechnique 2021, 71, 120–131. [Google Scholar] [CrossRef]

- Korff, M.; Mair, R.J.; Van Tol, F.A.F. Pile-Soil Interaction and Settlement Effects Induced by Deep Excavations. J. Geotech. Geoenviron. Eng. 2016, 142, 4016034. [Google Scholar] [CrossRef]

- Zhang, M.; Sang, S.; Wang, Y.; Bai, X. Factors Influencing the Mechanical Characteristics of a Pile–Soil Interface in Clay Soil. Front. Earth Sci. 2020, 7, 364. [Google Scholar] [CrossRef]

- Lehane, B.M.; Jardine, R.J.; Bond, A.J.; Frank, R. Mechanisms of Shaft Friction in Sand from Instrumented Pile Tests. J. Geotech. Eng. 1993, 119, 19–35. [Google Scholar] [CrossRef]

- Randolph, M.F. Science and Empiricism in Pile Foundation Design. Géotechnique 2003, 53, 847–875. [Google Scholar] [CrossRef]

- Tra, T.H.; Nguyen, T.T.; Huynh, T.Q.; Ishikawa, T. Load Transfer Behaviour of Super Long Piles in Multi-Layer Soft Soil through Field Testing and Numerical 3D FEM Modelling. Soils Found. 2025, 65, 101627. [Google Scholar] [CrossRef]

- Rocha de Albuquerque, P.J. Uplift Behavior of Bored Piles in Tropical Unsaturated Sandy Soil. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France, 2–6 September 2013. [Google Scholar]

- Guner, S.; Chiluwal, S. Cyclic Load Behavior of Helical Pile-to-Pile Cap Connections Subjected to Uplift Loads. Eng. Struct. 2021, 243, 112667. [Google Scholar] [CrossRef]

- Al-Mhaidib, A.I.; Edil, T.B. Model Tests for Uplift Resistance of Piles in Sand. Geotech. Test. J. 1998, 21, 213–221. [Google Scholar] [CrossRef]

- Xu, W.; Miao, H.; Chen, Y. Pull-out Behavior and Damage Assessment of Core Concrete of Full-Scale Prestressed High-Strength Hollow Square Piles. Structures 2023, 51, 1906–1918. [Google Scholar] [CrossRef]

- Buckley, R.M.; Jardine, R.J.; Kontoe, S.; Parker, D.; Schroeder, F.C. Ageing and Cyclic Behaviour of Axially Loaded Piles Driven in Chalk. Géotechnique 2018, 68, 146–161. [Google Scholar] [CrossRef]

- ASTM D2488; Standard Practice for Description and Identification of Soils (Visual-Manual Procedures). ASTM: West Conshohocken, PA, USA, 2017.

- Hussain, Y.; Uagoda, R.; Borges, W.; Prado, R.; Hamza, O.; Cárdenas-Soto, M.; Havenith, H.-B.; Dou, J. Detection of Cover Collapse Doline and Other Epikarst Features by Multiple Geophysical Techniques, Case Study of Tarimba Cave, Brazil. Water 2020, 12, 2835. [Google Scholar] [CrossRef]

- Peck, R.B.; Hanson, W.E.; Thornburn, T.H. Foundation Engineering; Wiley: New York, NY, USA, 1974; Volume 10. [Google Scholar]

- Jardine, R.J.; Buckley, R.M.; Kontoe, S.; Barbosa, P.; Schroeder, F.C. Behaviour of Piles Driven in Chalk. In Engineering in Chalk: Proceedings of the Chalk 2018 Conference, Proceedings of the Chalk 2018 Conference, London, UK, 17–18 September 2018; ICE Publishing: London, UK, 2018; pp. 33–51. [Google Scholar]

- Kalaga, S.; Yenumula, P. Design of Electrical Transmission Lines: Structures and Foundations; CRC Press: Boca Raton, FL, USA, 2016; ISBN 1315755688. [Google Scholar]

- O’Neil, M.W.; Reese, L.C. Drilled Shafts: Construction Procedures and Design Methods; Federal Highway Administration; Office of Infrastructure: Washington, DC, USA, 1999.

- Reese, L.C.; Isenhower, W.M.; Wang, S.-T. Analysis and Design of Shallow and Deep Foundations; John Wiley & Sons: Hoboken, NJ, USA, 2005; Volume 10, ISBN 0471431591. [Google Scholar]

- ACI 318-19(22); Building Code Requirements for Structural Concrete and Commentary. ACI: Farmington Hills, MI, USA, 2022.

- ASTM-C39/C39M; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2001.

- ASTM C469; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM: West Conshohocken, PA, USA, 2014; Volume 4.

- ASTM D3689-07; Standard Test Methods for Deep Foundations Under Static Axial Tensile. ASTM: West Conshohocken, PA, USA, 2020; Volume 7.

- Shlash, A. Experimental Study of Ultimate Uplift Resistance of Roughened Model Piles in Sand; The University of Wisconsin-Madison: Madison, WI, USA, 1994; ISBN 9798597006949. [Google Scholar]

- Jardine, R.; Chow, F.; Overy, R.; Standing, J. ICP Design Methods for Driven Piles in Sands and Clays; Thomas Telford London: London, UK, 2005; Volume 112. [Google Scholar]

- Chin, F.K. Estimation of the Ultimate Load of Piles from Tests Not Carried to Failure. In Proceedings of the 2nd Southeast Asian Conference on Soil Engineering, Singapore, 11–15 June 1970. [Google Scholar]

| Ave Depth BGL (m) | Bulk Density (kg/m3) | SPT (N60) | Peak Friction Angle * (°) | Description of Density of the Silty Sand |

|---|---|---|---|---|

| 0–5.3 | 1426–1688 | 3–8 | 28–33 | Very loose to loose |

| 5.3–8.5 | 1688–1791 | 8–28 | 33–38 | Loose to medium dense |

| 8.5–14.4 | 1791–1972 | 28–45 | 38–40 | Medium dense to dense |

| 14.4–20.8 | 1972–2060 | >45 | 40–42 | Dense |

| from 20.8 | 2060–2171 | >50 | 42–45 | Dense to very dense |

| Pile Information | Pile Set A | Pile Set B | ||

|---|---|---|---|---|

| A1 | A2 | B1 | B2 | |

| Targeted structure | Suspension tower | Heavy-angle tower | ||

| Axial uplift design load (kN) | 1014 | 3757 | ||

| Design pile length & Dia (m) | 16.0 & 1.0 | 21.0 & 1.8 | ||

| Pile age after installation (days) | 35 | 165 | 35 | 165 |

| Max. applied uplift load (kN) | 2028 | 2028 | 7514 | 7514 |

| Embedded strain gauges | No | No | Yes | Yes |

| Pile ID | Maximum Applied Uplift Load, Pmax (kN) | Slope α (1/kN) | Intercept b (mm/kN) | Estimated Ultimate Uplift Capacity, Pu (kN) |

|---|---|---|---|---|

| A1 | 2028 | 0.000384172 | 0.000252971 | 2603 |

| A2 | 2028 | 0.000358551 | 0.000144846 | 2789 |

| B1 | 7514 | 0.000129199 | 0.000353511 | 7740 |

| B2 | 7514 | 0.000125838 | 0.000302043 | 7947 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hamza, O.; Mawas, A. Investigating Ageing Effects on Bored Pile Shaft Resistance in Cohesionless Soil Through Field Testing. Geotechnics 2025, 5, 59. https://doi.org/10.3390/geotechnics5030059

Hamza O, Mawas A. Investigating Ageing Effects on Bored Pile Shaft Resistance in Cohesionless Soil Through Field Testing. Geotechnics. 2025; 5(3):59. https://doi.org/10.3390/geotechnics5030059

Chicago/Turabian StyleHamza, Omar, and Abdulhakim Mawas. 2025. "Investigating Ageing Effects on Bored Pile Shaft Resistance in Cohesionless Soil Through Field Testing" Geotechnics 5, no. 3: 59. https://doi.org/10.3390/geotechnics5030059

APA StyleHamza, O., & Mawas, A. (2025). Investigating Ageing Effects on Bored Pile Shaft Resistance in Cohesionless Soil Through Field Testing. Geotechnics, 5(3), 59. https://doi.org/10.3390/geotechnics5030059