Spatial Variability during Shrinkage Testing of Expansive Clays

Abstract

1. Introduction

2. Research Methodology

2.1. Site Investigation and Sample Selection

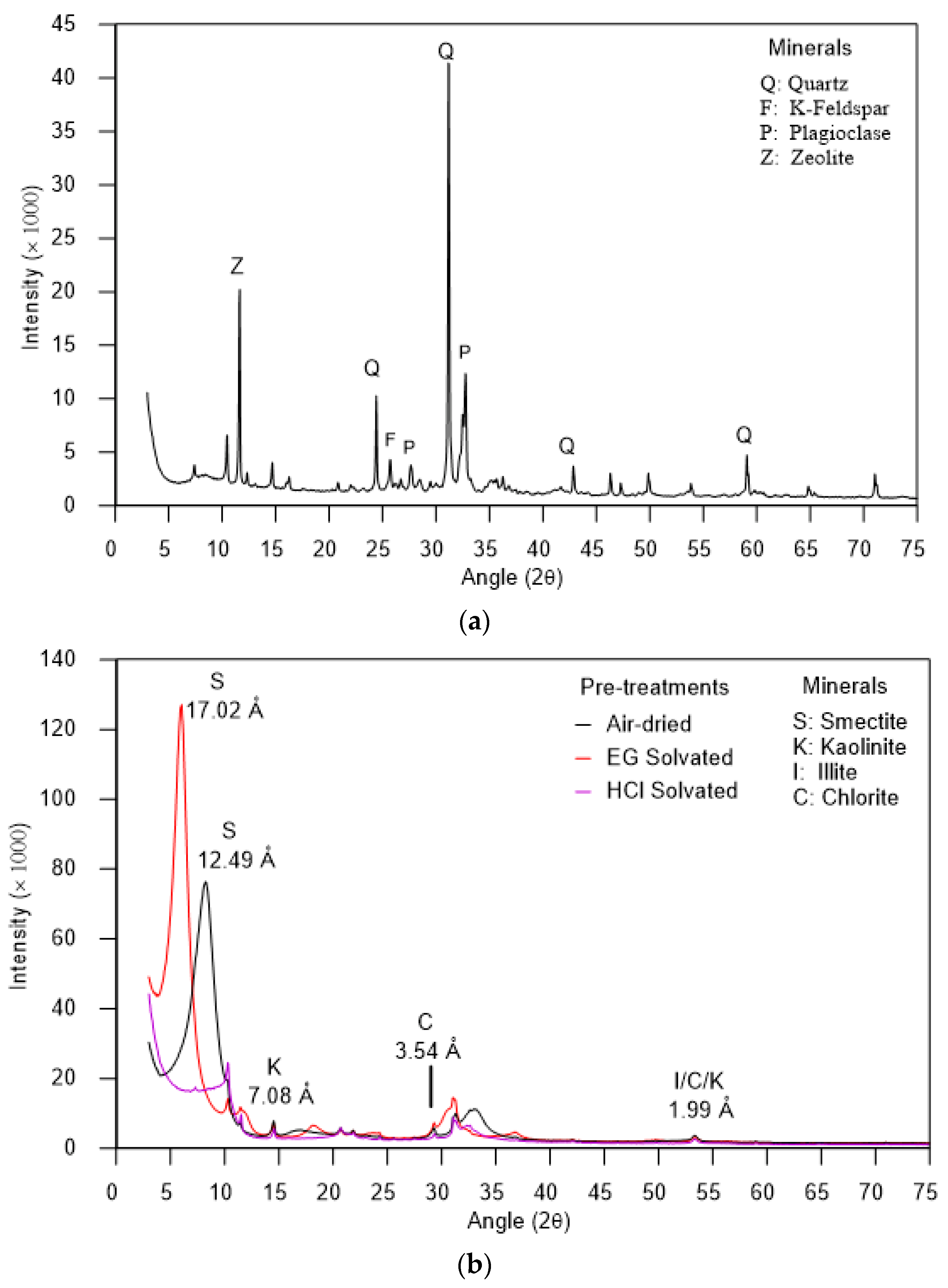

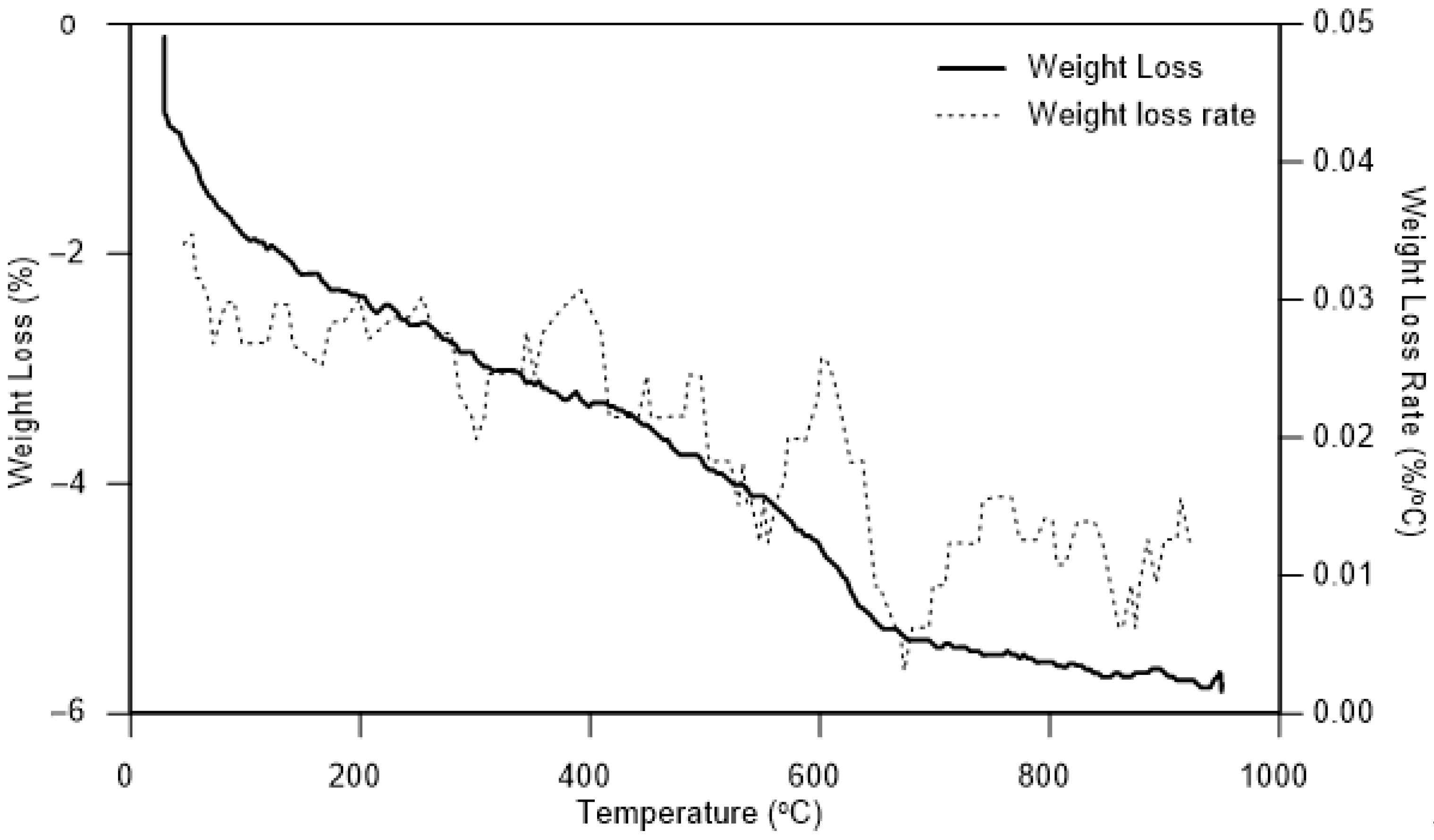

2.2. Soil and Water Composition

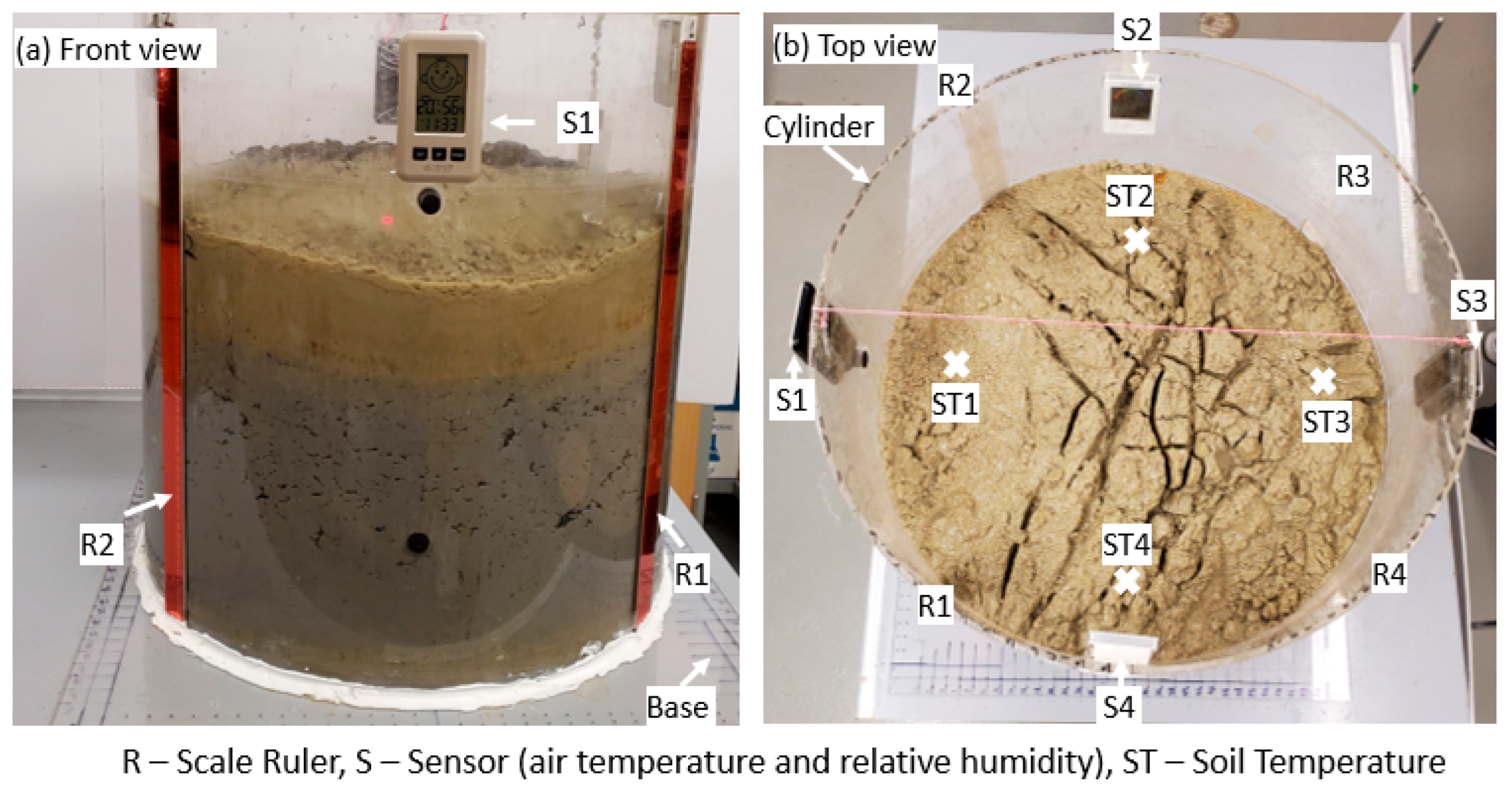

2.3. Shrinkage Monitoring and Sample Modeling

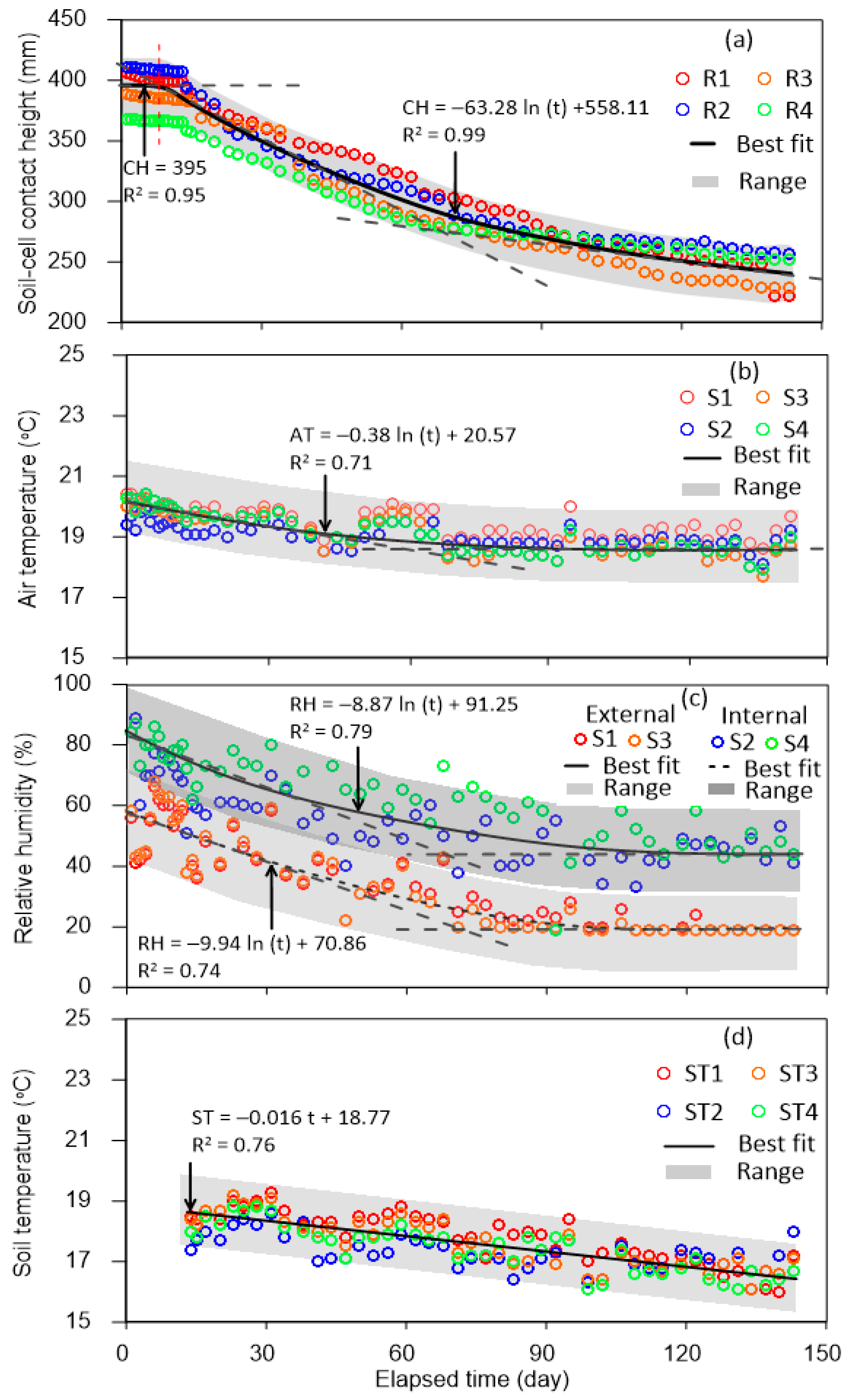

3. Results and Discussion

4. Summary and Conclusions

- The selected clay comprised expansive minerals, such as smectite (30%) and illite (14%), and the pore water mainly showed the presence of Na+ (695 mg/L) and SO42− (1150 mg/L). With a cation-exchange capacity of 42.5 cmol(+)/kg, the predominant exchange complex was found to be Na+-smectite, which is associated with a dispersive soil fabric.

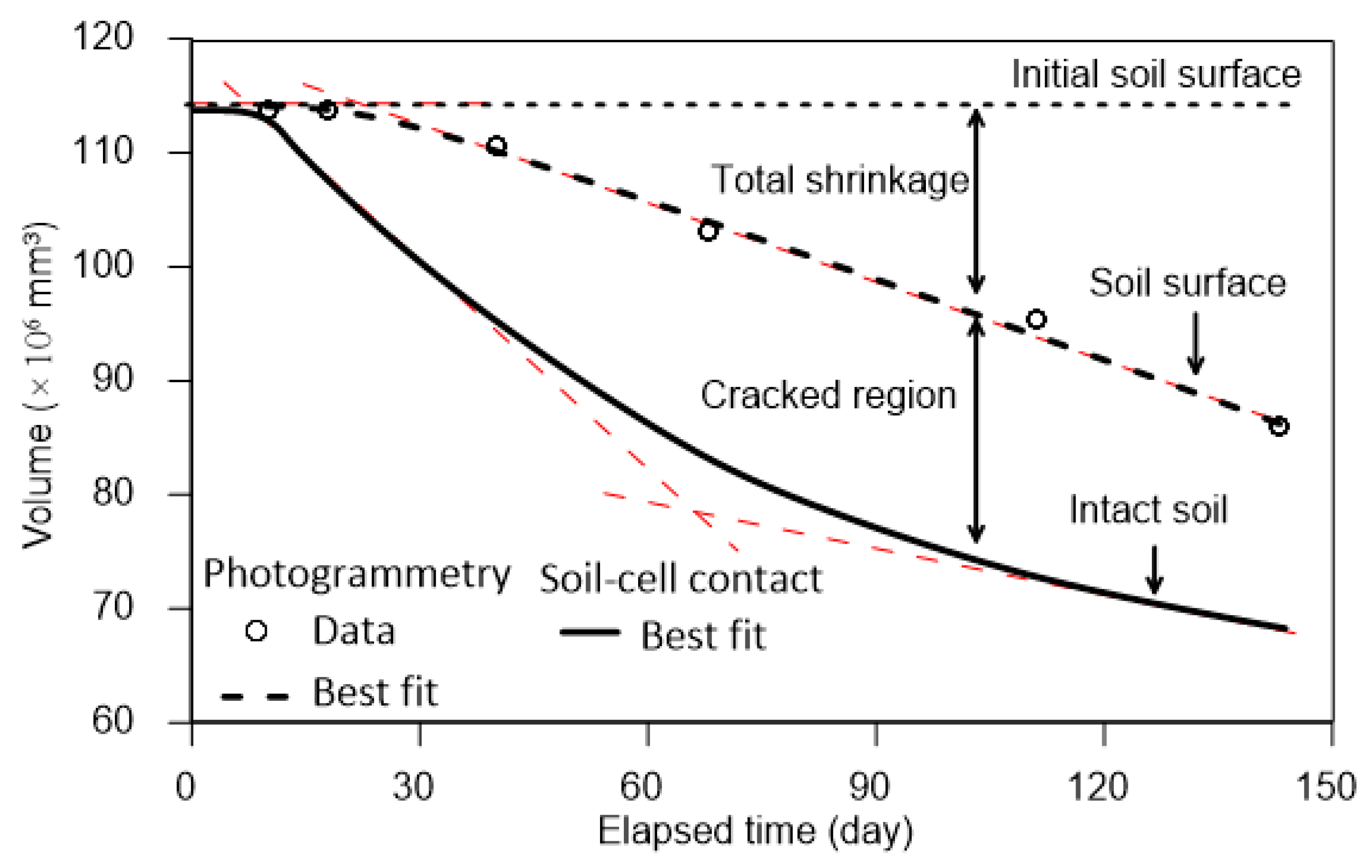

- The vertical shrinkage in the intact-soil portion was unchanged (remaining at 114 × 106 mm3) in the first 10 days because of pore-water expulsion, followed by a sharp decrease of up to 280 mm (80 × 106 mm3) over 68 days because of surface exposure and, subsequently, by a slow decrease down to 240 mm (68 × 106 mm3) over 145 days because of partial coverage by the upper soil.

- The shrinkage behavior of the investigated expansive clay corroborated well with the ambient environmental parameters during the five-month test duration. The soil temperature inside the cell was found to be 10% lower than the air temperature, whereas the relative humidity within the cell was found to be 30% higher than that outside the cell.

- The soil initially showed a prominent central ridge with a few cracks that gradually evolved to a distinct crack pattern with equal-sized and irregular soil chunks. The average soil surface showed no volume reduction up to 18 days and a subsequent linear volume reduction, reaching 25% of the initial value by the end of the test.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mishra, A.K.; Dhawan, S.; Rao, S.M. Analysis of Swelling and Shrinkage Behavior of Compacted Clays. Geotech. Geol. Eng. 2008, 26, 289–298. [Google Scholar] [CrossRef]

- Mitchell, J.K.; Soga, K. Fundamentals of Soil Behavior; John Wiley & Sons: New York, NY, USA, 2005. [Google Scholar]

- Ito, M.; Azam, S. Engineering Characteristics of a Glacio-Lacustrine Clay Deposit in a Semi-Arid Climate. Bull. Eng. Geol. Environ. 2009, 68, 551–557. [Google Scholar] [CrossRef]

- Hillel, D. Environmental Soil Physics: Fundamentals, Applications, and Environmental Considerations; Elsevier: Amsterdam, The Netherlands, 1998. [Google Scholar]

- Hu, Y.; Hubble, D.W. Failure Conditions of Asbestos Cement Water Mains in Regina. In Proceedings of the 1st CSCE Specialty Conference on Infrastructure Technologies, Management and Policy, Toronto, ON, Canada, 2–4 June 2005; pp. 2–4. [Google Scholar]

- Nelson, J.D.; Miller, D.J. Expansive Soils: Problems and Practice in Foundation and Pavement Engineering; John Wiley & Sons, Inc.: New York, NY, USA, 1992. [Google Scholar]

- Li, J.; Cameron, D.A.; Ren, G. Case Study and Back Analysis of a Residential Building Damaged by Expansive Soils. Comput. Geotech. 2014, 56, 89–99. [Google Scholar] [CrossRef]

- Hu, Y.; Vu, H.Q.; Lotfian, K. Instrumentation of a Section of AC Pipe in Expansive Soil. In Pipelines 2008: Pipeline Asset Management: Maximizing Performance of Our Pipeline Infrastructure; Curran Associates, Inc.: New York, NY, USA, 2008; pp. 1–10. [Google Scholar]

- Paranthaman, R.; Azam, S. Coupled Hydraulic-Thermal Model for Soils under Extreme Weather in Cold Regions. J. Environ. Inform. Lett. 2022, 7, 90–102. [Google Scholar] [CrossRef]

- Azam, S.; Shah, I.; Raghunandan, M.E.; Ito, M. Study on Swelling Properties of an Expansive Soil Deposit in Saskatchewan, Canada. Bull. Eng. Geol. Environ. 2013, 72, 25–35. [Google Scholar] [CrossRef]

- Julina, M.; Thyagaraj, T. Quantification of Desiccation Cracks Using X-Ray Tomography for Tracing Shrinkage Path of Compacted Expansive Soil. Acta Geotech. 2019, 14, 35–56. [Google Scholar] [CrossRef]

- Ito, M.; Azam, S.; Clifton, W. Suction-Based Model for Predicting Cyclic and Transient Volume Changes in Expansive Clays Using a Material Property Function. Eng. Geol. 2022, 296, 106491. [Google Scholar] [CrossRef]

- Morris, P.H.; Graham, J.; Williams, D.J. Cracking in Drying Soils. Can. Geotech. J. 1992, 29, 263–277. [Google Scholar] [CrossRef]

- Cordero, J.A.; Prat, P.C.; Ledesma, A. Experimental Analysis of Desiccation Cracks on a Clayey Silt from a Large-Scale Test in Natural Conditions. Eng. Geol. 2021, 292, 106256. [Google Scholar] [CrossRef]

- Ito, M.; Azam, S. Relation between Flow through and Volumetric Changes in Natural Expansive Soils. Eng. Geol. 2020, 279, 105885. [Google Scholar] [CrossRef]

- Bordoloi, S.; Hussain, R.; Gadi, V.K.; Bora, H.; Sahoo, L.; Karangat, R.; Garg, A.; Sreedeep, S. Monitoring Soil Cracking and Plant Parameters for a Mixed Grass Species. Géotech. Lett. 2018, 8, 49–55. [Google Scholar] [CrossRef]

- Cameron, D.A. The Extent of Soil Desiccation near Trees in a Semi-Arid Environment. In Unsaturated Soil Concepts and Their Application in Geotechnical Practice; Toll, D.G., Ed.; Springer: Dordrecht, The Netherlands, 2001; pp. 357–370. ISBN 978-94-015-9775-3. [Google Scholar]

- Kleiner, Y.; Rajani, B. Considering Time-Dependent Factors in the Statistical Prediction of Water Main Breaks. In Proceedings of the American Water Works Association Infrastructure Conference, Baltimore, MD, USA, 12–15 March 2000. [Google Scholar]

- Yu, F.; Zhang, M.; Lai, Y.; Liu, Y.; Qi, J.; Yao, X. Crack Formation of a Highway Embankment Installed with Two-Phase Closed Thermosyphons in Permafrost Regions: Field Experiment and Geothermal Modelling. Appl. Therm. Eng. 2017, 115, 670–681. [Google Scholar] [CrossRef]

- Puppala, A.J.; Katha, B.; Hoyos, L.R. Volumetric Shrinkage Strain Measurements in Expansive Soils Using Digital Imaging Technology. Geotech. Test. J. 2004, 27, 547–556. [Google Scholar]

- ASTM D4318-17; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. Annual Book of ASTM Standards: West Conshohocken, PA, USA, 2017.

- TxDOT. Test Procedure for Determining the Bar Linear Shrinkage of Soils; Texas Department of Transportation: Austin, TX, USA, 1999. [Google Scholar]

- Tripathy, S.; Rao, K.S.; Fredlund, D.G. Water Content-Void Ratio Swell-Shrink Paths of Compacted Expansive Soils. Can. Geotech. J. 2002, 39, 938–959. [Google Scholar] [CrossRef]

- ASTM D4943-18; Standard Test Method for Shrinkage Factors of Cohesive Soils by the Water Submersion Method. Annual Book of ASTM Standards: West Conshohocken, PA, USA, 2018.

- Peron, H.; Hueckel, T.; Laloui, L.; Hu, L. Fundamentals of Desiccation Cracking of Fine-Grained Soils: Experimental Characterisation and Mechanisms Identification. Can. Geotech. J. 2009, 46, 1177–1201. [Google Scholar] [CrossRef]

- Vogel, H.-J.; Hoffmann, H.; Leopold, A.; Roth, K. Studies of Crack Dynamics in Clay Soil: II. A Physically Based Model for Crack Formation. Geoderma 2005, 125, 213–223. [Google Scholar] [CrossRef]

- Cuadrado, A.; Encalada López, D.A.; Ledesma Villalba, A.; Prat Catalán, P. Soil Surface Boundary Condition in Desiccating Soils. In Proceedings of the Conference Proceedings on Geotechnical Engineering, Foundation of the Future, Reykjavík, Iceland, 1–7 September 2019; The Icelandic Geotechnical Society (IGS): Reykjavík, Iceland; pp. 1–8. [Google Scholar]

- Lakshmikantha, M.R.; Prat, P.C.; Ledesma, A. Boundary Effects in the Desiccation of Soil Layers with Controlled Environmental Conditions. Geotech. Test. J. 2018, 41, 675–697. [Google Scholar] [CrossRef]

- Khan, F.S.; Azam, S. Spatial Variability in Swelling of Aggregated Expansive Clays. Innov. Infrastruct. Solut. 2016, 1, 11. [Google Scholar] [CrossRef]

- Suchan, J.; Azam, S. Controlled Photogrammetry System for Determination of Volume and Surface Features in Soils. MethodsX 2021, 8, 101368. [Google Scholar] [CrossRef]

- Imumorin, P.; Azam, S. Effect of Precipitation on the Geological Development of Badlands in Arid Regions. Bull. Eng. Geol. Environ. 2011, 70, 223–229. [Google Scholar] [CrossRef]

- Paranthaman, R.; Azam, S. Effect of Composition on Engineering Behavior of Clay Tills. Geosciences 2021, 11, 427. [Google Scholar] [CrossRef]

- Azam, S.; Khan, F. Geohydrological Properties of Selected Badland Sediments in Saskatchewan, Canada. Bull. Eng. Geol. Environ. 2014, 73, 389–399. [Google Scholar] [CrossRef]

- Khan, F.S.; Azam, S. Determination of the Desiccation Behavior of Clay Slurries. Int. J. Min. Sci. Technol. 2017, 27, 981–988. [Google Scholar] [CrossRef]

- Holtz, R.D.; Kovacs, W.D.; Sheahan, T.C. An Introduction to Geotechnical Engineering, 2nd ed.; Prentice-Hall: Englewood Cliffs, NJ, USA, 2011; Volume 733. [Google Scholar]

- Moore, D.M.; Reynolds, R.C. X-Ray Diffraction and the Identification and Analysis of Clay Minerals; Oxford University Press (OUP): Oxford, UK, 1989. [Google Scholar]

- Hendershot, W.H.; Lalande, H.; Duquette, M. Chapter 18. Ion Exchange and Exchangeable Cations. In Soil Sampling and Methods of Analysis; Canadian Society of Soil Science: Pinawa, MB, Canada; CRC Press: Boca Raton, FL, USA, 2008; pp. 173–178. [Google Scholar]

- Khan, F.S.; Azam, S. Determination of Swelling Potential of a Fissured Expansive Clay in a Large Cell. In Proceedings of the 67th Canadian Geotechnical Conference, Regina, SK, Canada, 30 September 2014. [Google Scholar]

- Gottardi, G. The Genesis of Zeolites. Eur. J. Mineral. 1989, 1, 479–488. [Google Scholar] [CrossRef]

- Wilson, M.J.; Deer, W.A.; Howie, R.A.; Zussman, J. Rock-Forming Minerals. 3C: Sheet Silicates. Clay Minerals; Geological Soc.: London, UK, 2013. [Google Scholar]

- Khan, F.M. Engineering Properties of Badlands in Semi-Arid Regions. Master’s Thesis, The University of Regina (Canada), Regina, SK, Canada, 2012. [Google Scholar]

- Azam, S. Solid-Liquid Separation of Laterite Slurries. Ph.D. Thesis, Faculty of Graduate Studies and Research, University of Alberta, Edmonton, AB, Canada, 2003. [Google Scholar]

- Azam, S.; Abduljauwad, S.N.; Al-Shayea, N.A.; Al-Amoudi, O.B. Effects of Calcium Sulfate on Swelling Potential of an Expansive Clay. Geotech. Test. J. 2000, 23, 389–403. [Google Scholar]

- Smykatz, K. Differential Thermal Analysis. Application and Results in Mineralogy; Springer: Berlin/Heidelberg, Germany, 1974. [Google Scholar]

- Lehmann, P.; Merlin, O.; Gentine, P.; Or, D. Soil Texture Effects on Surface Resistance to Bare-Soil Evaporation. Geophys. Res. Lett. 2018, 45, 10–398. [Google Scholar] [CrossRef]

- Bedient, P.B.; Huber, W.C.; Vieux, B.E. Hydrology and Floodplain Analysis, 5th ed.; Pearson Education Limited: Edinburgh, UK, 2013. [Google Scholar]

- Yang, F.; Su, D.; Ma, Y.; Feng, C.; Yang, A.; Wang, M. Refraction Correction of Airborne LiDAR Bathymetry Based on Sea Surface Profile and Ray Tracing. IEEE Trans. Geosci. Remote Sens. 2017, 55, 6141–6149. [Google Scholar] [CrossRef]

- Tommasi, P.; Boldini, D.; Caldarini, G.; Coli, N. Influence of Infiltration on the Periodic Re-Activation of Slow Movements in an Overconsolidated Clay Slope. Can. Geotech. J. 2013, 50, 54–67. [Google Scholar] [CrossRef]

- Ting, L.; Chaosheng, T.; Dan, X.U.; Yunsheng, L.I.; Yan, Z.; Kan, W.; Bin, S.H.I. Advance on the engineering geological characteristics of expansive soil. J. Eng. Geol. 2018, 26, 112–128. [Google Scholar] [CrossRef]

- Udukumburage, R.S.; Gallage, C.; Dawes, L. Oedometer Based Estimation of Vertical Shrinkage of Expansive Soil in a Large Instrumeted Soil Column. Heliyon 2019, 5, e02380. [Google Scholar] [CrossRef]

- Umezaki, T.; Kawamura, T. Shrinkage and Desaturation Properties during Desiccation of Reconstituted Cohesive Soil. Soils Found. 2013, 53, 47–63. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Minerals (%) * | Coarse (47) |

| Quartz (14), Zeolite (20), Plagioclase (7), | |

| K-Feldspar (3), Others (3) | |

| Clay (53) | |

| Smectite (30), Illite (14), Chlorite (7), Kaolinite (2) | |

| Exchangeable cations (cmol(+)/kg) | Na+ (22.7), K+ (1.2), Ca2+ (17.2), Mg2+ (1.2) |

| Cation-exchange capacity (cmol(+)/kg) | 42.5 |

| Dissolved ions (mg/L) | Na+ (695), K+ (4.3), Ca2+ (21.2), Mg2+ (3.1), HCO3−(561), CO32−(44), Cl−(50.8), NO3−(2.2), SO42−(1150) |

| Total dissolved solids (mg/L) | 2250 |

| Sodium-absorption ratio † | 37.3 |

| Days | Elevation of Soil Surface in the Middle (cm) | Elevation of Cracked Soil in the Middle (cm) | Maximum Crack Depth (cm) |

|---|---|---|---|

| 10 (Figure 7a) | 46 (red) | 43 (yellow) | 3 |

| 18 (Figure 7b) | 46 (red) | 41 (light green) | 5 |

| 40 (Figure 7c) | 45 (red) | 39 (green) | 6 |

| 68 (Figure 7d) | 42 (red) | 35 (dark purple) | 7 |

| 111 (Figure 7e) | 40 (red) | 29 (light purple) | 11 |

| 143 (Figure 7f) | 38 (red) | 29 (green) | 9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paranthaman, R.; Suchan, J.; Azam, S. Spatial Variability during Shrinkage Testing of Expansive Clays. Geotechnics 2023, 3, 43-56. https://doi.org/10.3390/geotechnics3010004

Paranthaman R, Suchan J, Azam S. Spatial Variability during Shrinkage Testing of Expansive Clays. Geotechnics. 2023; 3(1):43-56. https://doi.org/10.3390/geotechnics3010004

Chicago/Turabian StyleParanthaman, Rajeevkaran, Jared Suchan, and Shahid Azam. 2023. "Spatial Variability during Shrinkage Testing of Expansive Clays" Geotechnics 3, no. 1: 43-56. https://doi.org/10.3390/geotechnics3010004

APA StyleParanthaman, R., Suchan, J., & Azam, S. (2023). Spatial Variability during Shrinkage Testing of Expansive Clays. Geotechnics, 3(1), 43-56. https://doi.org/10.3390/geotechnics3010004