Abstract

The construction industry’s current dependence on primary aggregates is unsustainable as these are non-renewable resources and the consumption of these materials has a high environmental impact. The global annual production of primary aggregates is estimated to be 50 billion tonnes. In Europe, where 2 billion tonnes of primary aggregates are produced annually, approximately 90% of aggregates are utilised by the construction industry, whilst over 1 Gt of waste are sent to landfill; in the UK, 44% of landfilled waste arises from the construction industry. The drive to adopt a circular economy necessitates changes in resource use (including non-renewable aggregates). Recycling wastes, such as aggregates, could help this situation; whilst this concept is not new, it does not appear to have been widely embraced in geotechnical engineering. The aim of this paper is to highlight the benefits of increasing the use of alternative aggregates as this would enable the reserves of primary aggregates to be better maintained and less material would be landfilled—a win-win situation and a contributing step towards developing a truly circular economy.

1. Introduction

It is well recognised that the overuse, or mismanagement, of a resource can lead to its depletion or exhaustion, which is unsustainable [1,2]; this situation is compounded by simultaneously sending wastes to landfill sites that could be recycled and reused in place of non-renewable resources, such as primary aggregate (PA). PA has been described as the most valuable non-fuel mineral commodity, and without it, life as we know it would be difficult to sustain [3]. The global consumption of PA combined with the extent of the landfilling of wastes that could act as aggregates is a case in point.

An estimated 50 billion tonnes of primary aggregate are currently produced annually worldwide, and this is predicted to increase 5% year after year [4]. The EU alone is estimated to consume 2 Gt of PA [5] whilst simultaneously sending over 1 Gt of waste (total weight, not just that which could be used as aggregates) to landfill sites annually [6].

The construction industry is a major consumer of aggregates and a contributor to landfilling (estimated to account for 35% of waste sent to a landfill globally, 44% in the UK [7]. Similarly, in the USA, approximately 1.4 billion tonnes of PA are consumed annually (58% of which are utilised within the road construction industry, and 90% of these aggregates are virgin materials) [8,9]. Millions of tonnes of CDW are generated by the construction industry globally each year; for example, an estimated 170 M tonnes are produced in the USA along with 860 M tonnes across the EU [10,11]. Therefore, successful management of CDW is critical to enable vast amounts of waste to be diverted from a landfill and precious resources to be conserved.

In order to enhance the utilisation of recycled and/or secondary aggregates (RA and SA) as alternatives to PA, it is imperative that industry practices are modified significantly. This may require a substantial reduction in the demand for PA or a step change in how recycled and secondary aggregates are both viewed and produced within the industry (both in quantities and range of techniques used to maximise uptake of available wastes, i.e., not just crushing materials but using additional processes to valorise previously unsuitable materials, such as accelerated carbonation to produce lightweight aggregates from ashes: [12,13,14].

In recent history, despite growing awareness of the need to act in a sustainable way, there has been some resistance to greater utilisation of alternative aggregates (AAs) over PA due to (but not limited to) concern regarding the availability of materials and potential issues with engineering performance [15,16,17,18,19]. There has been a vast amount of research into alternative aggregates for concrete, including materials such as municipal sludge ash, animal bones, human hair [20,21,22,23,24,25,26], but in comparison to uses within concrete, such studies are more limited for geotechnical applications. That said, there has been a considerable research effort to try to improve the understanding of the engineering performance of these alternative materials within geotechnical applications; however, in many cases, this is still poorly understood, and additional research is fundamental. This paper reflects the government’s stated need to embrace a circular economy and hence develop better resource/waste management practices and focuses on the need to reduce the reliance on PA for AAs. AAs have been considered, illustrating both potential and current gaps in understanding engineering performance.

The term ‘aggregate’ is used herein to describe potential materials for geotechnical applications, as this term is commonly used within the existing literature, although it is not used without reservation. The term aggregate seems evocative of ‘coarse-grained’ materials (used in railway and highway applications, where engineering properties must be stringent), which are not necessarily required for many geotechnical applications. Perhaps a better term would be ‘particles’, as the materials under review provide the solids for the placed soils (many of which form three-phase materials), although as noted above aggregate is used.

2. The Ethos of the Circular Economy as Motivation for the Use of Alternative Aggregates

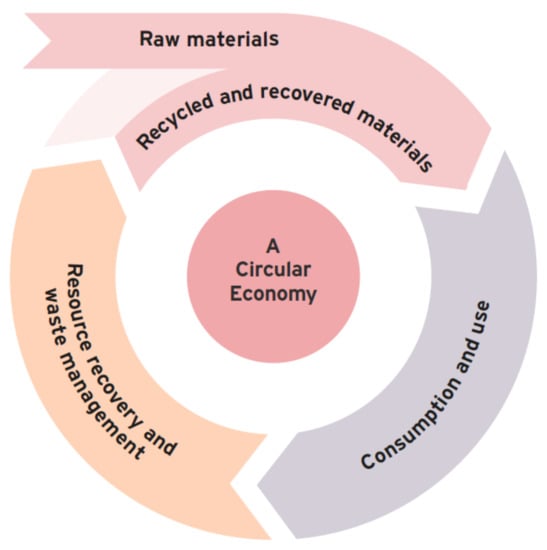

The preferred solution to waste management is to prevent waste generation in the first instance [27,28]. If that is impossible, the next goal is to minimise the waste generated and promote recycling, minimising landfilling/burning. These are the concepts underpinning the circular economy (CE) [20], shown in Figure 1. The concept of CE was first raised by Pearce and Turner (1990) and has since been gaining traction. Whilst there is not yet a clear definition of what a CE entails, it can broadly be described as a shift from a linear model of ‘take-make-dispose’ to an industrial economy that is restorative by intention, i.e., reducing the reliance of economic activity on finite resources and designing waste out of the system [29]. It has been argued that the CE concept has clearer objectives than the precursor (‘sustainable development’) and has had more resonance with the industry due to the view that CE offers operationalisation benefits [30,31,32,33]. For example, it was suggested that up to £130 million is accruable to the UK economy by reducing just 5% of its construction waste sent to landfill [34,35]; thus, there is not only an evironmental incentive to reduce waste and preserve resources but also a financial one.

Figure 1.

The circular economy for sustainable development. The win-win potential of circular economy [1].

This paper intends to draw on the concept of CE as motivation for the widespread use of RA/SA and to promote a change in attitudes towards the adoption of non-virgin materials rather than focusing on the concept of CE itself. For further information on the principals underpinning CE, the authors refer the reader to the following sources: [29,30,31,32].

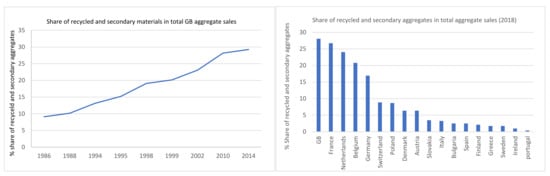

Achieving a CE is currently a political goal in many countries worldwide, including the UK, China, USA, Japan and the European Union [1,28,36]. Clearly, the construction industry must embrace change as part of wider societal and economic changes if this is to be achieved. However, recognising the need for change does not necessarily prompt change, and markets may require government intervention to stimulate action. For example, there have been calls for the use of alternative aggregates (AAs) in construction for decades [33,37,38]. Since the introduction of the landfill tax and aggregate levy in the UK, 1996 and 2002, respectively [39,40], there has been an increase in the amount of AAs consumed such that the UK now achieves the highest rate of recycled aggregates within the EU (Figure 2 shows an increase in the total AAs consumed from approximately 16% in 1996 to 29% by 2016 [41]. This is a step in the right direction but more needs to be carried out to reduce the reliance of the construction industry on PA [42].

Figure 2.

(Left) Share of recycled and secondary materials in GB aggregate sales and (Right) share of recycled and secondary materials in total aggregate sales (in 2018) (Mineral Products Association, 2019).

Germany, China, Japan and the EU have been amongst the first to enact the principles of a CE within Law [43,44]. Whilst the introduction of governmental regulations and legislation clearly has a positive effect on the reduction in waste generation and the adoption of AAs; a pilot CE study in a city in China reduced municipal waste by 17% over a 5-year period [43], whilst in Japan, 96% of CDW waste is recycled [45]. There remains the need for a greater societal change in attitudes towards the use of AAs [43]. Education, information, and encouragement to promote this change in attitude are required [43]. Typically, recycling has only taken place, by businesses at least, where there is an economic incentive. Attitudes need to be widened to ensure that recycling/re-use happens because it is socially desirable, not just financially desirable [46].

2.1. Primary, Recycled and Secondary Aggregates

PA can be defined as materials extracted directly from the earth, such as limestone, dolomite, sandstone, granite and terraced sands and gravels, that require little further processing. Within the UK, it is estimated that 300 Mt of aggregates and minerals were produced in 2014, and the construction industry consumes roughly 90% of these products [41]. Applications include: embankments, formation of road bases and subbase layers, placement of fills for infrastructure and construction purposes, the establishment of foundations (including stone columns) as well as being incorporated into concretes [17,47,48,49]. However, various studies [49,50,51,52,53] have shown that RA (defined herein as aggregates recycled from waste with minimal processing, such as crushing of demolition waste) and SA (defined herein as aggregates manufactured from waste via various processes, such as sintering or chemically stabilising them) can successfully be adopted in many of these applications if the engineering properties of these AAs are known.

2.1.1. Primary Aggregates

It seems an abstract question to ask if we can run out of rock; there certainly seems a large quantity on Earth, so why concern ourselves with alternatives? The Mineral Products Association (MPA) (2020) [54] states that, based on the 10-year average, the quantity of aggregates extracted and used each year exceeds the new reserves that have been granted planning permission, thus resulting in a long-term trend of reserve depletion. This is an issue that most urgently affects sand and gravel as there is only an estimated 8 years’ supply remaining in England [54]. However, crushed rock reserves are also of concern as only 75% of (compared to 63% of sand and gravel) reserves were replenished between 2009 and 2018 [54]. It is estimated that in the UK alone, over 5 billion tonnes of aggregates will be required (even when factoring in more efficient construction methods), and clearly, shortfalls are likely to occur in the near future unless alternative sources can be found [41,54].

Availability is not the only factor when assessing the viability of a resource, as there are clearly societal, environmental and economic considerations. The development of land has led to sand and gravel resources becoming inaccessible (leaving the accessible resources nearing exhaustion) and increasing the costs, both financial and energy, associated with extraction [16,39,41].

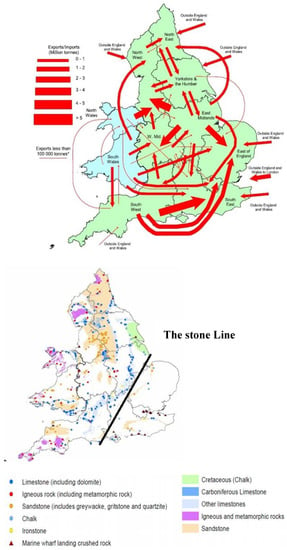

Since aggregate sources are located where Mother Nature placed them, and this does not always coincide with where it is required, there are large regions around the world where sources of PA are non-existent. This varying distribution of PA leads to additional pressure being placed upon areas of resource [55,56,57,58]. An example of this is the UK, where there is an imbalance in the areas of aggregate supply and demand in the: 70% of hard the rock sources lie within the south-west and East Midlands regions (of England and Wales) [38] (Figure 3) whereas the area of greatest development, i.e., the greatest demand for material, is located in the south-east [16,58,59,60,61]. This region has accounted for one-third of the total construction activity in the UK for at least the past twenty years [15,61]. In 2004, only 40% of aggregates could be sourced in the south-east; thus, materials were transported over 100 miles [62].

Figure 3.

(Top) Hard rock reserves in the UK (Reproduced with kind permission from the British Geological Survey (for supporting information see: [48]. (Bottom) Crushed rock inter-regional flows within England and Wales (2014) [17].

The cost of haulage is a major component of aggregate cost, both financial and environmental [27]. It is estimated that road transport dominates (90%), leading to increased carbon emissions [63,64], which further negatively impact the environment. Thomas et al. (2009) [62] suggested that carbon emissions (related to the use of aggregates) were reduced by one-third with the production (and utilisation) of RA via in situ recycling (i.e., crushing of demolition waste) when compared to trafficking in PA.

2.1.2. Recycled and Secondary Aggregates

The adoption of alternative aggregates diverts waste from landfill sites and can lead to large financial savings, especially since in the UK where RA and SA are not subject to the aggregate levy and in the case of hazardous waste streams where landfill gate fees are typically higher [63]. Furthermore, many of these waste streams are generated in, or comparatively near, urban settings (i.e., near the centres of demand for aggregates); hence, there is the potential for reduced transport distances (when compared to quarries).

Treating previously unsuitable wastes to produce SA offers benefits; for example, chemical treatment of hazardous materials can remove the potential to contaminate, producing aggregates from wastes with particles that would otherwise be too small to be workable (i.e., silt and clay-sized particle sizes), although these processes can be energy-intensive (in the case of sintering, etc.), so some techniques are not without cost. Examples of SA include lightweight products such as Lytag (sintering of pulverised fuel ash, PFA), carbonated ashes and cemented or thermally treated wastes [12,13,14,64].

2.1.3. End-of-Waste Status

The introduction of the revised Directive on Waste, Directive 2008/98/EC, intended to simplify the existing legislation on waste within Europe to promote the diversion of waste from landfills and to encourage lifecycle thinking, shifting the perception of waste from something to be disposed to a potentially valuable resource [31]. One of the important aspects of the revision was to clarify the definition of waste and the distinction between recovery and disposal [65,66], and the introduction of ‘End-of-Waste’ (EoW) criteria aimed to achieve this. In order for a waste to achieve EoW status, the following criteria must be met:

- the substance or object is commonly used for specific purposes;

- there is an existing market or demand for the substance or object;

- the use is lawful (substance or object fulfils the technical requirements for the specific purposes and meets the existing legislation and standards applicable to products);

- the use will not lead to overall adverse environmental or human health impacts.

There is some variation in EoW regulations across the EU. For some materials, such as for inert aggregates, each member state has their own quality criteria [66,67]. In the UK, the ‘Aggregates from inert waste’ quality protocol, set by the Environment Agency, indicates how compliance with EoW status can be demonstrated and gives guidance on matters such as storage and transportation of materials [68].

Another aim of the revised Directive is the promotion of reducing natural resource use [66,67]. This aspect is explicitly met by the diversion of wastes from landfills via their utilisation as aggregates (and has commercial benefits due to the simultaneous avoidance of the landfill and aggregate tax). However, there are more benefits to be gained during the production of the recycled/secondary aggregates, such as the sequestering of carbon dioxide during the accelerated carbonation of certain waste streams. In addition, research is currently being carried out into the extraction of valuable metals from waste streams prior to their treatment and subsequent production into aggregates [68,69], further preserving natural resources and adding to the commercial viability.

Compliance with EoW criteria requires the material to ‘fulfil the technical requirements for the specific purpose’, meaning that meeting the EoW criteria does not give widespread approval for the use of the waste material, and the application must be suitable, e.g., certain secondary aggregates may not meet leaching limits but would so if they were utilised in a bound capacity. In addition, so long as the EoW criteria are complied with, there is no limit to the number of times an RA/PA can be re-purposed. At the ‘end of life’ for one application, the material can simply be re-assessed against the EoW criteria and utilised, either in the same capacity or another more suitable application, enabling a truly circular economy. However, from a geotechnical viewpoint, it is clear that more research is required to understand the long-term performance of these materials (especially if exposed to cyclic loading after placement; or repeated cycles of removal and replacement with the recycling of these materials on a number of occasions over the life of the RA) to determine if/how the engineering parameters of these materials change.

2.2. Perceived Barriers to the Use of Recycled and Secondary Aggregates

Possible barriers to the widespread use of AAs have been identified by [25,68,69,70,71] and include: lack of confidence and/or perceived risk with the product (perception that they are inferior to PA, or there are issues with consistency: [49,55,72,73] a lack of suitable specifications and testing protocols (reliability and quality control issues for certain applications); and certification of the produced product. In addition, there may be a lack of awareness of AA products [69]), supply–demand and other market issues and waste management licensing regulations/environmental issues.

The construction industry has been characterised as being conservative [73,74,75,76]; thus, preference might be given to known materials (which they have experience of using), such as PA [69,76,77], over alternatives. Consequently, the desire to adopt AAs can be low whilst natural resources are still available (especially if lower in price than more sustainable alternatives), the benefits of AAs are poorly promoted, and there is uncertainty over appropriate testing to assess the properties of these materials [77]. Therefore, it is suggested that more research into material behaviour is required to help address both the negative perceptions of AAs but also raise awareness of these materials. Examples of research in this field are presented in the subsequent section.

2.2.1. Financial Aspects of AAs

It should be noted that the focus of this paper is on the geotechnical engineering performance of these materials and not on the economic or statuary considerations related to the use of these materials. This is not to say that these factors are considered of secondary importance to the engineering properties but a reflection of the authors’ area of expertise.

PA still represents an attractive option, even when compared to AA, due to the inherent low cost of the materials. This is perhaps a major reason that the uptake of AAs by contractors has not been more widespread. The introduction of the aggregate Levy in the UK (similar taxes apply in other European countries, such as Denmark and Sweden [78,79]) was designed to encourage the adoption of AAs, and the data shown in Figure 2 do indicate that the adoption of AAs is increasing (the UK currently has the greatest usage), but there is still scope for improvement. In order to consider AAs as a viable option, the whole cost of the material, including the transport costs (both financial and environmental) and other environmental aspects of recycling or reusing wastes (e.g., diverting waste from landfill), must be taken into account.

2.2.2. Appropriateness of Specification Testing When Assessing Suitability of an Aggregate for Geotechnical Applications

The revision of the European standards to incorporate the use of RA and SA can be viewed as a positive step, but the applicability of these tests to engineering applications have been called into question [43]. Traditionally, specifications for aggregates might be generalised as focusing upon aspects of crushing resistance, abrasion, shattering, etc. Clearly, these provide an indication of how the aggregate might perform during handling/placement, which is an important facet but does not necessarily describe the short and long-term behaviour of the placed fill (once the placed material has formed an equilibrium with the surrounding environment). Arguably, it is the behaviour, in the short and long term, of the placed material structure [48,79,80] rather than that of the individual particles, i.e., it is the response of the placed material to changing environmental and loading conditions, that is the key concern.

Key parameters used to describe the behaviour of soils include: the angle of internal shearing resistance, apparent cohesion, coefficient of compressibility and coefficient of consolidation and are all based on the interactions between the two/three phases within the soil structure and not individual particle characteristics. To reiterate (for granular soils), it is the macro-parameters such as particle size distribution, particle shape, relative density, degree of saturation, etc., that are key to behaviour [48,69,81]. Tests, such as the fragmentation and abrasion (the Los Angeles value and micro Deval values), indicate the resistance of the individual particles [78], but they do not represent the overall interaction between the two/three phases encountered within soils (In addition Schouenborg, Aurstad and Pétursson (2004) [76] note that the LA test only utilises a certain size fraction of the aggregate sample (between 10–14 mm) and so cannot assess the performance of the entire grading which is particularly important for heterogeneous materials, which AAs often are). Clearly, the shattering of particles with placement, resulting in reducing the internal angle of shearing resistance, is a concern that cannot be dismissed as it can potentially influence the strength of placed material. AAs such as crushed masonry and (burnt) colliery spoil have been identified as potentially experiencing particle degradation with dynamic loading, although cases of PA shattering have also been identified.

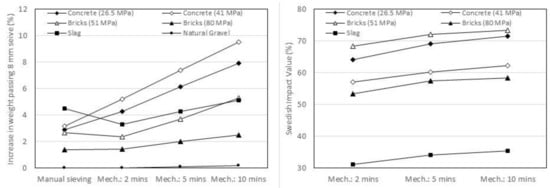

Schouenborg, Aurstad and Pétursson (2004) [76] demonstrated that many aggregates, including a PA, are sensitive to traditional test methods, such as mechanical sieving; the abrasive process of mechanical sieving can lead to unrepresentative particle size distribution and can influence other properties, such as aggregate impact value: a measure of resistance to sudden impact, see Figure 4 [79], and yet, demolition waste and colliery spoil have successfully been used in geotechnical applications previously [82,83]. This highlights the importance of understanding the material properties and selecting appropriate engineering applications together with suitable construction methods.

Figure 4.

(Left) Change in the amount of material passing the 8mm sieve due to different sieving procedures and (Right) change in Swedish Impact Values for the AAs post-sieving [78].

Whilst particle testing provides a basis for a comparison of the durability of the materials, it does not give any insight into the interaction between the particles when they are confined. Thus, it is the contention of the authors that this is the key consideration when assessing the suitability of AAs for geotechnical applications and that perhaps specified characteristic tests should be modified to reflect this.

2.2.3. Los Angeles Coefficient

The method for determining an aggregate’s resistance to fragmentation, as detailed in BS EN 1097-2:2010 [84], also known as the Los Angeles test, involves placing a sample (which passes the 14 mm sieve and is retained on the 10 mm sieve) into a drum with 11 400–445 g steel balls. The drum is then rotated 500 times, and the mass retained on a 1.6 mm sieve is recorded () [79].

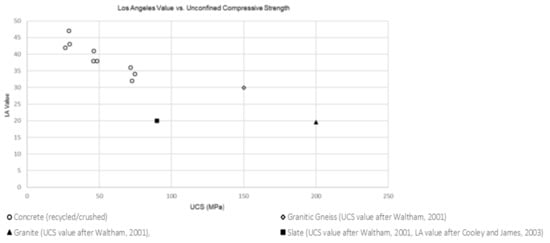

This method may be suitable to replicate the experience of aggregates in the wearing course of highways, but it does not necessarily reflect that of confined aggregates. This could mean that some AAs, which may look poor when assessed using LA values, will perform well in certain applications (see Figure 5). An example of this is crushed concrete. Whilst the AAs appear to have high LA and low UCS values (see Figure 5), these AAs have been a real success story [85,86,87].

Figure 5.

Los Angles vs. Compressive strength [79].

Koohmishi (2019) [88] notes that the main shortcoming of the LA test is that the extent of inter-particle abrasion is overshadowed by the force exerted by the steel balls on individual particles, potentially causing misleading results. In addition, Cooley and James (2003) [89] suggest that the nature of the test, i.e., steel balls dropped a distance up to the drum diameter, results in the aggregate particles being subject to large impact loads, which for some crystalline materials (such as granites), results in yielding artificially high loss values. Other lower-quality materials, such as slate, may actually reflect lower loss values as the structure enables impact loads to be better absorbed [89], again presenting a slightly skewed indication of their performance in engineering applications.

The LA values for natural gravel (see Table 1) and the two types of crushed brick, shown in Table 3, are comparable. Within the Manual of Contract Documents for Highways Works, Volume 1 [90], the upper limit of the Los Angeles coefficient is 50 for applications such as gabion filling, general fill, drainage layers, starter layer, and relaxes to 50 for capping layers [90], suggesting that despite concerns over friability, recycled crushed bricks may have many potential uses.

Table 1.

Published values of LA coefficients [53].

3. Examples of the Utilisation of Wastes as Alternative Aggregates in Geotechnical Engineering and an Alternative that Potentially Could Be Used

There are undoubtedly specific geotechnical applications where high-quality PA is fundamental and stringent requirements necessitate aggregates with exacting engineering properties (e.g., railway ballast). However, it is argued that there are undoubtedly lower-grade applications where AAs might be perfectly acceptable (for example, for bulk fills or drainage). This is reflected in the reported usage of AAs within the literature, where applications include hard standing, bulk fills and capping layers for haul roads [62,91,92,93]. However, there are calls for the use of AAs in higher grade applications, such as is in ground improvement [18,50,94] (8). For this to become a reality, a greater understanding of the behaviour of AAs is required to enable the appropriate end-use of the AAs to be selected [75]. Examples of research into this field are given below.

When determining if an AAs is suitable for use in geotechnical applications, there are a number of aspects to consider, summarised as [69,82,94]: availability, both in tonnage and location; existing precedent of usage in engineering applications; the chemico-physical properties of the material, the variability of these properties and the potential for these to change with time (i.e., through creep and leaching) and the cost of the material. Nowak and Gilbert (2015) [94] state that selected materials must not have the potential to cause harm to the environment and must be stable; for example, they should not be biodegradable, miscible, contain significant inter-particle weaknesses or flaws, be flammable or prone to degradation when encountering buried concrete or substances such as fuel.

This paper draws on the results of previous studies which have shown successful use of wastes as alternative aggregates. The materials discussed within only represent an overview of some of the most common types of AAs currently being produced/utilised. There are many more materials, including plastics, various industrial wastes, such as colliery spoil [48,63,95,96,97,98,99,100,101], and mineral wastes [18,38,51,52,53,54,55], which may have geotechnical applications and merit further research.

3.1. Scrap Tyres

The disposal of waste tyres is a global problem, with an estimated 1000 million tyres being discarded each year, and 50% of these are disposed of with no further treatment [57]. Regulations preventing the landfilling of tyres within the EU and further restrictions on the disposal of tires elsewhere around the world (2006 under the European Landfill Directive 1999/31/EC; [49,102]) has necessitated alternative uses for this waste. Tyres are fabricated using vulcanised rubber, which means that the material cannot be melted and re-set, so recycling/reusing is the only viable alternative to disposal. Research into the usage of tyre bales, tyre strips and rubber crumb in geotechnical applications [103,104,105,106,107] indicates that these AAs are lightweight, free draining, durable and offer good thermal insulation [108,109,110,111]. These properties make the material particularly suitable for applications, such as fill behind retaining structures (horizontal earth pressures acting on retaining structures were found to reduce by 50-60% by utilising a rubber shred–sand backfill [110] and highway embankments, particularly over weak or highly compressible soils [111]. The low cost of the material is a possible added benefit [112,113].

Utilising rubber strips (without soil infill) is not advised due to an incident where an embankment experienced auto combustion [108,114]. Mixing the tyres with soil appears to have reduced this risk and potentially improves the performance of the material [105,110,115]. The data shown in Table 2 reflects the increase in shear strength achieved through tyre–sand mixtures in comparison to pure tyre shreds. The optimal mix, in terms of shear strength (friction angle) and deformability (void ratio), has been found to comprise a 30/70% tyre-chip-to-sand ratio [112,116,117], where tyre content exceeds 30% the mixture behaves more as a tyre chip mass rather than a reinforced soil [117,118]. Research by Anbazhagan, Manohar and Rohit (2017) [116] show that the optimal size particle size (in terms of friction angle) is between 6 and 12 mm.

Table 2.

Properties of tyre chips and tyre–sand mixes.

In addition to acting as lightweight AAs, rubber crumb has also been used as a soil improver in clayey, silty, organic (e.g., peat) and expansive soils [107,111,118,119]. Additionally, the ability of sand-tyre mixes to retain high levels of permeability even under large vertical loads makes the material particularly suitable as drainage media [118,120].

3.2. Construction and Demolition Waste

Construction and Demolition Waste (CDW) describes several materials including, crushed brick, gypsum board, plastics, timber and crushed concrete (which typically accounts for much of this type of waste. The utilisation of CDW materials varies depending on both the waste and the location. For example, in Japan, 99% of concrete waste is recycled [43], and technologies have been developed to improve the qualities of the waste material, enabling it to be used in higher grade applications [64]. The recycling of CDW is also relatively high within the UK; in 2016, 91% of non-hazardous CDW was recovered [52,120,121,122,123]. However, in other parts of the world, such as Australia, where only approximately 40% is recycled (usually within low-grade applications), the situation is less positive [121].

Concerns over the stability (disintegration) and lack of understanding of engineering properties of RA and SA, such as crushed concrete, crushed brick and gypsum, have typically resulted in lower recycling rates.

Crushed concrete aggregate (CCA), produced by crushing material recovered during demolition of structures, has been considered inferior with qualities such as lower strength and stiffness when compared to other primary materials. It is the case that CCA could be considered as poorer quality due to the stiff core particles being surrounded by weak layers of mortar [124]. However, the extensive research that has been carried out into the properties of CCA reflects that AAs can exhibit strength and stiffness equivalent or better than higher grade materials when utilised in applications where it is well-compacted [124].

Large quantities of gypsum plasterboard are produced around the world, particularly in Europe, the USA and Japan, which leads to the creation of 15 million tonnes of waste annually, which is disposed of in landfill sites [123]. Research carried out by Ahmed et al. (2015) [125] indicated that waste gypsum (mixed with a solidification agent) could potentially be successfully utilised within earthworks projects, providing a much-needed alternative to landfilling the material. Similarly, another study, which focused on brick dust, showed that the waste could be chemically treated to form a useful SA [126]. Going further, the Bermondsey Dive Under project, undertaken in the UK [53], illustrates that significant quantities of crushed masonry can be successfully adopted as AAs. This study is considered in more detail below as an example of how AAs can be used effectively in place of PA.

Bermondsey Dive Under

Crushed masonry has not typically been used as structural fill material due to concerns over the friability and long-term performance [52]. However, redevelopment work (the Bermondsey Dive Under: BDU) has successfully utilised this material. The BDU project comprised the demolition of 900 m of masonry viaduct together with the construction of 900 m of new structures, including five new bridges, reinforced earth structures and 100 m of retaining walls. In order to avoid the requirement for large amounts of demolition material, i.e., crushed masonry, to be removed from the site and to be replaced with imported fill, research was carried out into the performance of the crushed brick prior to the start of the project [52]. In this case, the financial gains were very clear as the cost of transporting and potentially sending to landfill, such a large amount of material would have had a huge impact on the project budget. The project team identified a number of barriers to the utilisation of recycled materials [52], which reflect general concerns cited previously, i.e., risk-averse (design, construction and client) teams or organisations; overly onerous ‘standard’ specifications; bespoke nature of projects; resistance to change, lack of motivation; weak leadership and lack of published data that would allow those with aspirational ideas to recycle masonry, to assess more confidently the basis of their designs and manage risk.

The successful use of crushed brick at the site was attributed to three main factors [52]: early introduction of the concept during project planning; motivation of the whole project team (client, engineering, project management, environmental and commercial) and the creation of a business case for the research study; and the design and build team’s (the main contractor in this case) willingness to take on and develop the proposals. These key factors illustrate a shift in approach, similar to the ethos of the circular economy, which is potentially achievable for all construction projects. Whilst the project had to incur the initial cost of planning and carrying out the laboratory testing for the waste masonry, this was likely to have been relatively small in comparison to the cost of removing all the waste material from the site. In addition, the project generated useful data that others are able to benefit from in the future (see Table 3).

Table 3.

Summary of brick properties compared to the requirements for fill material specifications.

Ellis et al. (2016) [52] highlighted one of the barriers to the adoption of crushed masonry as a lack of published data. This is a statement echoed by others [50,68,124]. Ellis et al. (2016) [52] went further to cite the need for academia and industry to forge better-working links in this area to disseminate research findings and promote greater uptake of alternative aggregates. Perhaps this is one explanation for the relatively low uptake of alternative aggregate sources despite various studies [49,125,126,127,128,129,130,131] proving their likely suitability; the authors concur with this call for better collaboration.

3.3. Recycled Crushed Glass

The production of glass is energy-intensive, requiring large amounts of non-renewable resources and energy [132,133]; hence, there is a ready market for (certain) recycled glass (Table 4). In the USA, the largest element of municipal solid waste is food and beverage bottles.

Table 4.

Container glass waste: reuse, recycle and landfill figures around the world [136].

Waste container glass cullet (WGC) (crushed glass created from waste glass bottles) is recycled within the glass manufacturing industry (i.e., to create new containers) where possible. This type of closed-loop recycling of WGA is the most energy-efficient use of material, potentially enabling reductions of 215–250 kg CO2/tonne and energy savings of greater than 1.5 GJ/tonnes to be achieved [134]. However, due to the prevalence of comingled glass collection schemes and the difficult task of separating all WGC back into colour streams (which is required for use in the container glass manufacture due to the differing chemical compositions of each glass colour [75]), significant quantities of waste glass are sent to landfill. Within the EU, this is estimated at 30%, but this figure is much larger in other parts of the world, see Table 4 [134]. The disposal of WGC in landfills is largely due to the lack of knowledge on the engineering properties of the material and the inclusion of contaminating material (non-recyclable glass) [127,129,131,132]. This is extremely wasteful, especially since studies have shown that recycled glass exhibits geotechnical properties similar to PA, such as sands and gravels [126,129], and research shows that recycled glass has some favourable characteristics, particularly when in finer fractions, such as an LA coefficient comparable to natural granite (see Table 5 and Table 6). In addition, effective angles of friction should be similar to sands and gravels. Evidence suggests the smaller the particle size (in the coarse-grained size range), the less susceptible to crushing the glass becomes [135]. However, the potential for particle crushing to occur should be considered when deciding on the application of the material, as clearly, this could lead to changes in behaviour [136].

Table 5.

Market share of glass production in the EU (data from 2007) [143].

Table 6.

Aggregate characteristics of recycled glass.

WGC has numerous possible applications, including drainage material, filter media or drainage blankets and load-bearing material in road pavements and asphalt aggregate projects [126,129,131,136]. Furthermore, waste glass is an inert material and non-biodegradable, thus staying in landfills for up to 1 million years [137], which is an obvious disadvantage in landfills but an advantage for AAs in geotechnical applications. Case studies of WCG being successfully used as pipe bedding material in Australia have been published, and many states in America and New Zealand have adopted the WGC-blends for use in road construction [138].

The varying chemical composition of waste glass, debris content and the ability to sort it by colour are limiting factors in the recycling rates of this material [128,132]. The recycling of flat glass (e.g., windows from buildings or vehicles) is substantially lower than cullet, which is largely due to the stricter quality requirements [138,139,140,141]. This is disappointing as it is possible to directly reuse windows (e.g., from buildings), but due to constraints that include: additional time and labour costs for glass removal, ease of damage during transportation and difficulties in matching supply with demand, much of this is landfilled [134,142,143].

3.4. Incinerated Waste By-Products

Unlike demolition waste, scrap tyres and waste glass, which can form RA with relatively little processing, there are wastes that, with processing, could produce AAs (i.e., SA). For example, deriving energy from waste (EfW) results in the formation of new wastes that could be processed into AAs. These wastes (e.g., municipal solid waste incinerator bottom and fly ashes: MSWIBA and MSWIFA, and air pollution control residue, APCr) can be hazardous and might require disposal in controlled landfill sites unless remediation ensures the End-of-Waste (EoW) status is achieved.

3.4.1. MSWIBA and MSWIFA

The volume of municipal waste incinerated for EfW is reduced by up to 80–90%, yet EfW plants still produce considerable amounts of ash that are currently either disposed of in landfills (MSWIFA is usually considered hazardous) or reused in relatively low-grade civil engineering applications (MSWIBA is considered potentially suitable for use) [144,145,146,147,148,149,150,151].

Coarser fractions of the ash are typically utilised as bulk fill for road building or drainage material. The finer fractions are more problematic due to variability of material and the potential for leaching (tends to be higher than for the coarser fractions), although it has been used in landfill liners [150]. For this reason, the process of sintering has been adopted to treat MSWIFA [148,151], producing lightweight aggregates.

Lightweight aggregates, defined as materials with a maximum loose bulk density of 1.2 Mg/m3, BS EN 13055:2016 [152], can present additional challenges (hence they are not suitable for all applications), but they do offer potential benefits (with comparatively low levels of loading on subsoils, etc.) [36,153,154].

Testing on lightweight aggregates formed from sintering PFA (produced as a dry material) indicated that upon contact with water, there was an initial period of rapid absorption that continued for over six to twelve months [155]. This behaviour can be attributed to the range and degree of porosity of the material produced as a result of the sintering process [156]. Gunning et al. (2011) [13] also reported water absorption of 21%, 30% and 29% for sintered PFA, expanded clay and APCr, respectively.

The response to water absorption above potentially calls into question the validity of the standard 24-h period of soaking in water (recommended for lightweight aggregates) under atmospheric pressure before determining the water absorption, freeze-thaw response, bearing capacity, etc., tests and for determination of thermal properties in moist or wet conditions [16,33,68].

3.4.2. Sewage Sludge Ash (SSA)

Each year millions of tonnes (approximately 1.6 Mt in the UK, 8.9 Mt within the EU [157,158,159] and 78 Mt- which accounts for 70% of industrial waste produced in Japan [43]) of sewage sludge waste are produced as a by-product of the wastewater treatment process sludge each year. Sewage Sludge Ash (SSA) is a by-product of the firing of sewage sludge, and whilst SSA is not classed as hazardous waste and is not subject to higher rates of taxation, alternatives to disposal in landfill are being sought due to the increasingly limited space available (as of 2016 the remaining landfill capacity the UK was 554,751,000 m3 [121]).

Research has shown that when SSA is sintered at temperatures 1040–1060 °C, a lightweight aggregate is formed. SSA has been used in brick and tile production, an aggregate for concrete and a material used within road bases and embankments [158]). The resulting aggregate is lightweight compared to PA, so the material lends itself to situations where a reduction in imposed load is important. The following benefits of SSA as SA (Table 7, compared to Lytag) were suggested by Cheeseman and Virdi (2005) [159] and Smol et al. (2015) [160]: cost of disposal of SSA in landfills is increasing; there is a shortage of readily available aggregates in some regions of the UK; incinerators tend to be located in urban areas, close to areas of high construction activity; and the process of sintering immobilises hazardous heavy metals and destroys pathogens making them safer to use.

Table 7.

Properties of SSA (with 1% clay) compared to commercially available lightweight aggregate, Lytag [159].

3.4.3. APCr

Sintering of ash requires significant energy input. However, an ambient-temperature (or a low temperature when compared to sintering) treatment using the process of accelerated carbonation (ACT) has been developed. ACT carbonates the waste by reacting carbon dioxide with calcium or magnesium [13,14,160,161,162] and produces AAs from wastes previously considered unsuitable (in their natural state are considered unusable as aggregates due to small particle size, little or no apparent cohesion, and potentially hazardous nature). This process consumes more quantities of carbon dioxide than is released during production [162], hence contributing to carbon sequestration/utilisation efforts whilst also consuming less energy than traditional methods [13,14]. The aggregates produced are lightweight (rounded) particles in the sand and gravel range (see Table 8) and have achieved End-of-Waste status. In the UK (at least), this SA is predominantly used in the manufacture of lightweight construction blocks [13].

Table 8.

Properties of carbonated wastes.

There is currently very little geotechnical information available on these materials, and the authors argue that they have the potential to act as AAs in geotechnical engineering applications and thus merit research in this area.

4. Conclusions

Despite numerous studies highlighting the potential of RA/SA, the construction industry, and by extension geotechnical engineering, still relies heavily on PA for applications that could adopt non-virgin materials. With sources of PA under pressure and landfilling being politically undesirable, now is the time to change the way in which resources are consumed, especially if the stated desire to adopt a circular economy is to be realised.

AAs have been produced from waste streams (such as scrap tyres, ashes, waste glass and demolition rubble) and have successfully been utilised in geotechnical solutions. Despite this, there are several barriers preventing the widespread use of waste materials, including the lack of confidence and perceived risk with product quality, lack of suitable specifications, financial concerns and a lack of awareness. Case studies, such as the BDU project, offer inspiration to others to utilise materials that initially may not seem suitable. In addition, various laboratory studies have been undertaken to further understand the engineering properties of AAs and consider their use in (somewhat limited) geotechnical engineering applications.

It is clear, however, that there is still much to do with regards to AAs before the barriers (or a number of influencing financial constraints is probably beyond the remit of such studies) preventing a much greater utilisation in geotechnical applications are addressed. This includes furthering the understanding of engineering behaviour in more geotechnical contexts (other than road base, etc.), assessing new materials as they become available (such as AAs from APCr) and addressing the required criteria for use (standards) in these applications. If this can be achieved, then greater uptake of AAs may be facilitated, improving the use of non-renewable resources, limiting the amount of waste sent to landfills and moving towards the desired circular economy.

Funding

This work is supported by the UK’s EPSRC.

Acknowledgments

The authors would like to gratefully acknowledge the financial support for this work provided by the UK’s EPSRC.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| AAs | alternative aggregates (comprising recycled and/or secondary aggregates) |

| ACT | accelerated carbonation treatment |

| APCr | air pollution control residue |

| BDU | Bermondsey Dive Under |

| CCA | crushed concrete aggregate |

| CDW | Construction and Demolition Waste |

| CE | circular economy |

| EfW | energy from waste |

| EoW | End of Waste |

| LA | Los Angeles coefficient |

| MSWIBA | municipal solid waste incinerator bottom ash |

| MSWIFA | municipal solid waste incinerator fly ash |

| PA | primary aggregate |

| PFA | pulverised fuel ash |

| RA | recycled aggregate |

| SA | secondary aggregate |

| SSA | sewage sludge ash |

| WGC | waste glass cullet |

References

- HM Government. Our Waste, Our Resource: A Strategy for England; Government of the United Kingdom: London, UK, 2018.

- Vieira, C.; Pereira, P.M. Use of recycled construction and demolition materials in geotechnical applications: A review. Resour. Conserv. Recycl. 2015, 103, 192–204. [Google Scholar] [CrossRef]

- Drew, L.J.; Langer, W.H.; Sachs, J.S. Environmentalism and Natural Aggregate Mining. Nat. Resour. Res. 2002, 11, 19–28. [Google Scholar] [CrossRef]

- Dhir, R.K.; de Brito, J.; Mangabhai, R.; Lye, C.Q. Introduction. In Sustainable Construction Materials; Woodhead Publishing: Sawston, UK, 2017; pp. 1–8. [Google Scholar]

- British Geological Survey. World Mineral Production 2008–2012; British Geological Survey: Nottingham, UK, 2017. [Google Scholar]

- Eurostat. Generation of Waste by Economic Activity. 2019. Available online: https://ec.europa.eu/eurostat/tgm/table.do?tab=table&init=1&plugin=1&language=en&pcode=ten00106 (accessed on 20 July 2020).

- Faleschini, F.; Zanini, M.A.; Pellegrino, C.; Pasinato, S. Sustainable management and supply of natural and recycled aggregates in a medium-size integrated plant. Waste Manag. 2016, 49, 146–155. [Google Scholar] [CrossRef] [PubMed]

- Carpenter, A.; Gardner, K.; Fopiano, J.; Benson, C.; Edil, T. Life cycle based risk assessment of recycled materials in roadway construction. Waste Manag. 2007, 27, 1458–1464. [Google Scholar] [CrossRef] [PubMed]

- U.S. Geological Society. Materials Flow. 2019. Available online: https://www.usgs.gov/centers/nmic/materials-flow (accessed on 10 September 2021).

- Silva, R.; de Brito, J.; Dhir, R. Availability and processing of recycled aggregates within the construction and demolition supply chain: A review. J. Clean. Prod. 2017, 143, 598–614. [Google Scholar] [CrossRef] [Green Version]

- Silva, R.; de Brito, J.; Dhir, R. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–207. [Google Scholar] [CrossRef]

- Gunning, P.J.; Hills, C.D.; Carey, P.J. Accelerated carbonation treatment of industrial wastes. Waste Manag. 2010, 30, 1081–1090. [Google Scholar] [CrossRef] [PubMed]

- Gunning, P.J.; Hills, C.D.; Carey, P.J.; Antemir, A. Secondary aggregate from waste treated with carbon dioxide. Proc. ICE Constr. Mater. 2011, 164, 231–239. [Google Scholar] [CrossRef]

- Gunning, P.J.; Hills, C.D.; Carey, P.J. Production of lightweight aggregate from industrial waste and carbon dioxide. Waste Manag. 2009, 29, 2722–2728. [Google Scholar] [CrossRef]

- Gunn, A.G.; Bate, R.; Jackson, N.E.; Ward, J.; Marker, B.R.; Brown, T.J.; Highley, D.E. Managing Aggregates Supply in England; Open Report; Geological Survey: Nottingham, UK, 2008. [Google Scholar]

- Bloodworth, A.; Scott, P.; McEvoy, F. Digging the backyard: Mining and quarrying in the UK and their impact on future land use. Land Use Policy 2009, 26, S317–S325. [Google Scholar] [CrossRef] [Green Version]

- Brown, T.; McEvoy, F.; Ward, J. Aggregates in England—Economic contribution and environmental cost of indigenous supply. Resour. Policy 2011, 36, 295–303. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Lo, C.Y.; Xiao, J. Bringing recycled aggregate to its full potential. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2013, 166, 128–136. [Google Scholar] [CrossRef]

- Dhir, R.K.; de Brito, J.; Silva, R.V.; Lye, C.Q. Availability of Recycled Aggregates. In Sustainable Construction Materials; Elsevier: Amsterdam, The Netherlands, 2019; pp. 35–56. [Google Scholar]

- Bhatty, J.I.; Reid, K.J. Moderate strength concrete from lightweight sludge ash aggregates. Int. J. Cem. Compos. Light Concrete 1989, 11, 179–187. [Google Scholar] [CrossRef]

- Khalaf, F.M.; Devenny, A.S. Recycling of Demolished Masonry Rubble as Coarse Aggregate in Concrete: Review. J. Mater. Civ. Eng. 2004, 16, 331–340. [Google Scholar] [CrossRef]

- Frigione, M. Recycling of PET bottles as fine aggregate in concrete. Waste Manag. 2010, 30, 1101–1106. [Google Scholar] [CrossRef]

- Cavalline, T.L.; Weggel, D.C. Recycled brick masonry aggregate concrete: Use of brick masonry from construction and demolition waste as recycled aggregate in concrete. Struct. Surv. 2013, 31, 160–180. [Google Scholar] [CrossRef]

- Jani, Y.; Hogland, W. Waste glass in the production of cement and concrete—A review. J. Environ. Chem. Eng. 2014, 2, 1767–1775. [Google Scholar] [CrossRef]

- Hassan, K.E.-G.; Reid, J.M.; Al-Kuwari, M.S. Recycled aggregates in structural concrete—A Qatar case study. Proc. Inst. Civ. Eng. Constr. Mater. 2016, 169, 72–82. [Google Scholar] [CrossRef]

- Petrounias, P.; Rogkala, A.; Giannakopoulou, P.P.; Lampropoulou, P.; Xanthopoulou, V.; Koutsovitis, P.; Koukouzas, N.; Lagogiannis, I.; Lykokanellos, G.; Golfinopoulos, A. An Innovative Experimental Petrographic Study of Concrete Produced by Animal Bones and Human Hair Fibers. Sustainability 2021, 13, 8107. [Google Scholar] [CrossRef]

- Petrounias, P.; Giannakopoulou, P.P.; Rogkala, A.; Lampropoulou, P.; Tsikouras, B.; Rigopoulos, I.; Hatzipanagiotou, K. Petrographic and Mechanical Characteristics of Concrete Produced by Different Type of Recycled Materials. Geosciences 2019, 9, 264. [Google Scholar] [CrossRef] [Green Version]

- Lazarevic, D.; Buclet, N.; Brandt, N. The application of life cycle thinking in the context of European waste policy. J. Clean. Prod. 2012, 29-30, 199–207. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector. A literature review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Lederer, J.; Trinkel, V.; Fellner, J. Wide-scale utilization of MSWI fly ashes in cement production and its impact on average heavy metal contents in cements: The case of Austria. Waste Manag. 2017, 60, 247–258. [Google Scholar] [CrossRef]

- O’Mahony, M.M.; Milligan, G.W.E. Use of recycled materials in subbaselayers. Transp. Res. Rec. 1991, 1310, 73–80. [Google Scholar]

- BRE. Construction and Demolition Waste: Good Buildings Guide Part 1; Building Research Establishment: Garston, UK, 2003. [Google Scholar]

- Ajayi, S.O.; Oyedele, L.O. Policy imperatives for diverting construction waste from landfill: Experts’ recommendations for UK policy expansion. J. Clean. Prod. 2017, 147, 57–65. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.-D.; Zeng, C.-C.; Liu, J.; Diao, H. Measured Settlement of Highways Improved by Lightweight Backfilling Without Road Closure. Arab. J. Sci. Eng. 2016, 41, 3889–3896. [Google Scholar] [CrossRef]

- Ellis, S.J. Recycling in Transportation. Transportation geotechnics. In Proceedings of the Symposium Transportation Geotechnics, Nottingham, UK, 11 September 2003. [Google Scholar]

- Thompson, A.; Harris, K.; Knapman, D.; Marker, B.; Poole, J.; Higgs, J. Reasons for the Decline in Aggregate Reserves in England; Capita Symonds Ltd.: East Grinstead, UK, 2008. [Google Scholar]

- HMSO. The Aggregates Levy (General) Regulations; HMSO: Richmond, UK, 2002; Volume 761, pp. 1–20. [Google Scholar]

- Mineral Products Association. The Mineral Products Industry at a Glance—2016 Edition. 2016. Available online: Contribution_of_Recycled_and_Secondary_Materials_to_Total_Aggs_Supply_in_GB (accessed on 15 October 2021).

- Tangtinthai, N.; Heidrich, O.; Manning, D.A. Role of policy in managing mined resources for construction in Europe and emerging economies. J. Environ. Manag. 2019, 236, 613–621. [Google Scholar] [CrossRef]

- Sas, W.; Głuchowski, A.; Radziemska, M.; Dziecioł, J.; Szymański, A. Environmental and geotechnical assessment of the steel slags as a material for road structure. Materials 2015, 8, 4857–4875. [Google Scholar] [CrossRef] [PubMed]

- Sakai, S.I.; Yano, J.; Hirai, Y.; Asari, M.; Yanagawa, R.; Matsuda, T.; Yoshida, H.; Yamada, T.; Kajiwara, N.; Suzuki, G.; et al. Waste prevention for sustainable resource and waste management. J. Mater. Cycles Waste Manag. 2017, 19, 1295–1313. [Google Scholar] [CrossRef] [Green Version]

- Ministry of Land, Infrastructure, Transport and Tourism. White Paper on Land, Infrastructure, Transport and Tourism in Japan. 2019. Available online: https://www.mlit.go.jp/en/statistics/white-paper-mlit-2019.html (accessed on 20 July 2020).

- Andersen, M.S. An introductory note on the environmental economics of the circular economy. Sustain. Sci. 2007, 2, 133–140. [Google Scholar] [CrossRef]

- Mankelow, J.M.; Bide, T.P.; Sen, M.A.; Raycraft, E.; Cameron, D.G. Collation of the Results of the 2014 Aggregate Minerals Survey for England and Wales; British Geological Survey Commissioned Report; British Geological Survey: Nottingham, UK, 2016; pp. 1–160. [Google Scholar]

- Royal, A.; Jefferson, I. Use of Wastes, Recycled Aggregates and Secondary Aggregates in Geotechnical Engineering Applications. NexGen Technol. Min. Fuel Ind. 2017, 1, 719. [Google Scholar]

- Poulikakos, L.; Papadaskalopoulou, C.; Hofko, B.; Gschösser, F.; Falchetto, A.C.; Bueno, M.; Arraigada, M.; Sousa, J.; Ruiz, R.; Petit, C.; et al. Harvesting the unexplored potential of European waste materials for road construction. Resour. Conserv. Recycl. 2017, 116, 32–44. [Google Scholar] [CrossRef]

- Serridge, C.J. Achieving sustainability in vibro stone column techniques. Proc. Inst. Civ. Eng. Eng. Sustain. 2005, 158, 211–222. [Google Scholar] [CrossRef]

- Mohajerani, A.; Vajna, J.; Cheung, T.H.H.; Kurmus, H.; Arulrajah, A.; Horpibulsuk, S. Practical recycling applications of crushed waste glass in construction materials: A review. Constr. Build. Mater. 2017, 156, 443–467. [Google Scholar] [CrossRef]

- Ellis, S.; Goodwin, A.; Laycock, E.; Hurst, C. Use of crushed brick in reinforced earth railway structures. Proc. Inst. Civ. Eng. Constr. Mater. 2016, 169, 93–105. [Google Scholar] [CrossRef] [Green Version]

- Reddy, S.B.; Krishna, A.M.; Reddy, K. Sustainable Utilization of Scrap Tire Derived Geomaterials for Geotechnical Applications. Indian Geotech. J. 2017, 48, 251–266. [Google Scholar] [CrossRef]

- Mineral Products Association. Profile of the Mineral Products Industry—2020 Edition. 2020. Available online: Profile_of_the_UK_Mineral_Products_Industry_2020_Spread.pdf(mineralproducts.org) (accessed on 15 October 2021).

- Ismail, S.; Hoe, K.W.; Ramli, M. Sustainable Aggregates: The Potential and Challenge for Natural Resources Conservation. Procedia Soc. Behav. Sci. 2013, 101, 100–109. [Google Scholar] [CrossRef] [Green Version]

- Langer, W.H. Managing and Protecting Aggregate Resources; USGS: Reston, VI, USA, 2002.

- Baker, D.; Hendy, R. Planning for sustainable construction aggregate resources in Australia. In Proceedings of the QUT Research Week, Brisbane, Australia, 4–5 July 2005. [Google Scholar]

- Hossain, U.; Poon, C.S.; Lo, I.M.C.; Cheng, J.C. Comparative environmental evaluation of aggregate production from recycled waste materials and virgin sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Zuo, C.; Birkin, M.; Clarke, G.; McEvoy, F.; Bloodworth, A. Reducing carbon emissions related to the transportation of aggregates: Is road or rail the solution? Transp. Res. Part A Policy Pr. 2018, 117, 26–38. [Google Scholar] [CrossRef] [Green Version]

- Cowell, R.; Owens, S. Suitable Locations: Equity and Sustainability in the Minerals Planning Process. Reg. Stud. 1998, 32, 797–811. [Google Scholar] [CrossRef]

- Mankelow, J.M.; Oyo-Ita, D.; Birkin, M. Assessing the carbon footprint of transporting primary aggregates. In Proceedings of the 15th Extractive Industry Geology Conference; Scott, P.W., Walton, G., Eds.; EIG Conferences Ltd.: Warwick, UK, 2010; pp. 41–45. [Google Scholar]

- Thomas, A.; Lombardi, D.R.; Hunt, D.; Gaterell, M. Estimating carbon dioxide emissions for aggregate use. Proc. Inst. Civ. Eng. Eng. Sustain. 2009, 162, 135–144. [Google Scholar] [CrossRef]

- Tranter, R.; Jefferson, I.; Ghataora, G. The Use of Recycled Aggregate in Vibro-Stone Columns—A UK Perspective. In Proceedings of the GeoCongress, New Orleans, LA, USA, 9–12 March 2008; pp. 630–637. [Google Scholar] [CrossRef]

- Padfield, A.M.; Carey, P.J.; Hills, C.D.; Poole, A.B. Reuse of quarry fines in production of secondary aggregates. In Engineering Sustainability; ICE: London, UK, 2004; pp. 3–8. [Google Scholar]

- Nash, H.A. The Revised Directive on Waste: Resolving Legislative Tensions in Waste Management? J. Environ. Law 2008, 21, 139–149. [Google Scholar] [CrossRef]

- Velzeboer, I.; Van Zomeren, A. End of Waste Criteria for Inert Aggregates in Member States; ECN: Petten, The Netherlands, 2017; p. 43. [Google Scholar]

- Environment Agency. Aggregates from Inert Waste: End of Waste Briteria for the Production of Aggregates from Inert Waste; WRAP: Banbury, UK, 2013; pp. 1–24. [Google Scholar]

- Styring, P.; Wilson, I.A.G.; Brun, T.; Knippels, H.; Armstrong, K.; Travaly, Y.; Kramer, D.; Saussez, G.; Bolscher, H. A Vision for Smart CCU Transformations in Europe: Using CO2 as a Resource; Smart CO2 Transformation: Ebook-; 2015. Available online: https://co2-utilization.net/fileadmin/user_upload/SCOT_Vision.pdf (accessed on 15 October 2021).

- Cardoso, R.; Silva, R.V.; de Brito, J.; Dhir, R. Use of recycled aggregates from construction and demolition waste in geotechnical applications: A literature review. Waste Manag. 2016, 49, 131–145. [Google Scholar] [CrossRef]

- Tam, V.W. On the effectiveness in implementing a waste-management-plan method in construction. Waste Manag. 2008, 28, 1072–1080. [Google Scholar] [CrossRef] [Green Version]

- Bolden, J.; Abu-Lebdeh, T.; Fini, E. Utilization of recycled and waste materials in various construction applications. Am. J. Environ. Sci. 2013, 9, 14–24. [Google Scholar] [CrossRef]

- Reid, J.M.; Chandler, J.W.E. Recycling in Transport Infrastructure; Transport Research Laboratory: Berks, UK, 2001. [Google Scholar]

- Winch, G.M. How innovative is construction? Comparing aggregated data on construction innovation and other sectors—A case of apples and pears. Construction. Manag. Econ. 2003, 21, 651–654. [Google Scholar] [CrossRef]

- Tangkar, M.; Arditi, D. Innovation in the construction industry. Civ. Eng. Dimens. 2000, 2, 96–103. [Google Scholar]

- Oyedele, L.O.; Ajayi, S.O.; Kadiri, K.O. Use of recycled products in UK construction industry: An empirical investigation into critical impediments and strategies for improvement. Resour. Conserv. Recycl. 2014, 93, 23–31. [Google Scholar] [CrossRef]

- Schouenborg, B. Standardisation in Europe: Still Some Barriers to Overcome Before a Routine Use of Recycled Aggregates and Aggregates from Secondary Sources Can be Achieved? In Proceedings of the 7th International Conference on the Bearing Capacity of Roads, Railways and Airfields, Trondheim, Norway, 25–27 June 2005; p. 4. [Google Scholar]

- Schouenborg, B.; Aurstad, J.; Pétursson, P. Test methods adapted to alternative aggregates. In Proceedings of the International RILEM Conference on the Use of Recycled Materials in Buildings and Structures, Barcelona, Spain, 9–11 November 2004. [Google Scholar]

- Söderholm, P. Resources, Conservation and Recycling Taxing virgin natural resources: Lessons from aggregates taxation in Europe. Resour. Conserv. Recycl. 2011, 55, 911–922. [Google Scholar] [CrossRef]

- Transport Research Laboratory. Final Report for Publication Alt-Mat Contract No.: RO-97-SC.2238; Transport Research Laboratory: Berks, UK, 2001; pp. 1–190. [Google Scholar]

- Steele, D.P. Ground Engineering as Potential End Uses for Recycled and Secondary Aggregates; Waste and Resources Action Programme: Banbury, UK, 2004. [Google Scholar]

- Mitchell, J.; Soga, K. Fundamentals of Soil Behavior, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2005; p. 85. [Google Scholar]

- Gomes Correia, A.; Winter, M.G.; Puppala, A.J. A review of sustainable approaches in transport infrastructure geotechnics. Transp. Geotech. 2016, 7, 21–28. [Google Scholar] [CrossRef] [Green Version]

- Skarzynska, K.M. Reuse of Coal-Mining Wastes in Civil Engineering. 2. Utilization of Minestone. Waste Manag. 1995, 15, 83–126. [Google Scholar] [CrossRef]

- Britsh Standards. Tests for Mechanical and Physical Properties of Aggregates, Part 2: Methods for the Determination of Resistance to Fragmentation; Britsh Standards: London, UK, 2010. [Google Scholar]

- Tam, V.W.; Tam, C.M. A review on the viable technology for construction waste recycling. Resour. Conserv. Recycl. 2006, 47, 209–221. [Google Scholar] [CrossRef] [Green Version]

- Arulrajah, A.; Piratheepan, J.; Aatheesan, T.; Bo, M.W. Geotechnical Properties of Recycled Crushed Brick in Pavement Applications. J. Mater. Civ. Eng. 2011, 23, 1444–1452. [Google Scholar] [CrossRef]

- Rahman, A.; Imteaz, M.; Arulrajah, A.; Disfani, M.M. Suitability of recycled construction and demolition aggregates as alternative pipe backfilling materials. J. Clean. Prod. 2014, 66, 75–84. [Google Scholar] [CrossRef]

- Koohmishi, M. Drainage potential of degraded railway ballast considering initial gradation and intrusion of external fine materials. Soils Found. 2019, 59, 2265–2278. [Google Scholar] [CrossRef]

- Cooley, L.A.; James, R.S.; Cooley, J.L.A. Micro-Deval Testing of Aggregates in the Southeast. Transp. Res. Rec. J. Transp. Res. Board 2003, 1837, 73–79. [Google Scholar] [CrossRef]

- Highways England. Manual of Contract Documents for Highway Works; Specification for Highway Works Series 600; Highways England: Birmingham, UK, 2016; Volume 1. [Google Scholar]

- Winter, M.G. A conceptual framework for the recycling of aggregates and other wastes. Proc. Inst. Civ. Eng. Munic. Eng. 2002, 151, 177–187. [Google Scholar] [CrossRef]

- Zukri, A.; Nazir, R. Sustainable materials used as stone column filler: A short review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 342, 012001. [Google Scholar] [CrossRef]

- Dhir, R.K.; Dyer, T.D.; Paine, K.A. Dismantling barriers: Roles for research in realising markets for construction and demolition wastes. In Proceedings of the 1st International Conference on Sustainable Construction: Waste Management, Singapore, 10–12 June 2004; pp. 1–22. [Google Scholar]

- Nowak, P.; Gilbert, P. Earthworks: A Guide, 2nd ed.; ICE Publishing: London, UK, 2015. [Google Scholar]

- Graettinger, A.J.; Johnson, P.W.; Sunkari, P.; Duke, M.C.; Effinger, J. Recycling of plastic bottles for use as a lightweight geotechnical material. Manag. Environ. Qual. Int. J. 2005, 16, 658–669. [Google Scholar] [CrossRef]

- Baic, I.; Koziol, W.; Machniak, L. Aggregates from mineral wastes. E3S Web Conf. 2016, 8, 1068. [Google Scholar] [CrossRef] [Green Version]

- González-Corrochano, B.; Alonso-Azcárate, J.; Rodas, M. Production of lightweight aggregates from mining and industrial wastes. J. Environ. Manag. 2009, 90, 2801–2812. [Google Scholar] [CrossRef] [PubMed]

- Perera, S.; Arulrajah, A.; Wong, Y.C.; Horpibulsuk, S.; Maghool, F. Utilizing recycled PET blends with demolition wastes as construction materials. Constr. Build. Mater. 2019, 221, 200–209. [Google Scholar] [CrossRef]

- Amrani, M.; Taha, Y.; Elghali, A.; Benzaazoua, M.; Kchikach, A.; Hakkou, R. An experimental investigation on collapsible behavior of dry compacted phosphate mine waste rock in road embankment. Transp. Geotech. 2021, 26, 100439. [Google Scholar] [CrossRef]

- Amrani, M.; Taha, Y.; El Haloui, Y.; Benzaazoua, M.; Hakkou, R. Sustainable Reuse of Coal Mine Waste: Experimental and Economic Assessments for Embankments and Pavement Layer Applications in Morocco. Minerals 2020, 10, 851. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C.; Panicker, V.J. Recycling of waste tire rubber as aggregate in concrete: Durability-related performance. J. Clean. Prod. 2016, 112, 504–513. [Google Scholar] [CrossRef]

- Ramarad, S.; Khalid, M.; Ratnam, C.; Chuah, A.L.; Rashmi, W. Waste tire rubber in polymer blends: A review on the evolution, properties and future. Prog. Mater. Sci. 2015, 72, 100–140. [Google Scholar] [CrossRef]

- Cecich, V.; Gonzales, L.; Hoisaeter, A.; Williams, J.; Reddy, K. Use of Shredded Tires as Lightweight Backfill Material for Retaining Structures. Waste Manag. Res. 1996, 14, 433–451. [Google Scholar] [CrossRef]

- Ahn, I.-S.; Cheng, L. Tire derived aggregate for retaining wall backfill under earthquake loading. Constr. Build. Mater. 2014, 57, 105–116. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Sharma, J.P.; Yadav, J.S. Geotechnical Properties of Dune sand-Waste Tires Composite. Mater. Today Proc. 2017, 4, 9851–9855. [Google Scholar] [CrossRef]

- Ayothiraman, R.; Soumya, S. Model tests on the use of tyre chips as aggregate in stone columns. Proc. Inst. Civ. Eng. Ground Improv. 2015, 168, 187–193. [Google Scholar] [CrossRef]

- Al-Bared, M.A.M.; Marto, A.; Latifi, N. Utilization of Recycled Tiles and Tyres in Stabilization of Soils and Production of Construction Materials—A State-of-the-Art Review. KSCE J. Civ. Eng. 2018, 22, 3860–3874. [Google Scholar] [CrossRef]

- Moo-Young, H.; Sellasie, K.; Zeroka, D.; Sabnis, G. Physical and Chemical Properties of Recycled Tire Shreds for Use in Construction. J. Environ. Eng. 2003, 129, 921–929. [Google Scholar] [CrossRef]

- Hazarika, H.; Yasuhara, K.; Kikuchi, Y.; Karmokar, A.K.; Mitarai, Y. Multifaceted potentials of tire-derived three dimensional geosynthetics in geotechnical applications and their evaluation. Geotext. Geomembr. 2010, 28, 303–315. [Google Scholar] [CrossRef]

- Reddy, S.B.; Krishna, A.M. Recycled Tire Chips Mixed with Sand as Lightweight Backfill Material in Retaining Wall Applications: An Experimental Investigation. Int. J. Geosynth. Ground Eng. 2015, 1, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Cetin, H.; Fener, M.; Gunaydin, O. Geotechnical properties of tire-cohesive clayey soil mixtures as a fill material. Eng. Geol. 2006, 88, 110–120. [Google Scholar] [CrossRef]

- Pierce, C.; Blackwell, M. Potential of scrap tire rubber as lightweight aggregate in flowable fill. Waste Manag. 2003, 23, 197–208. [Google Scholar] [CrossRef]

- Reddy, S.B.; Kumar, P.D.; Krishna, A.M. Evaluation of the Optimum Mixing Ratio of a Sand-Tire Chips Mixture for Geoengineering Applications. J. Mater. Civ. Eng. 2016, 28, 6015007. [Google Scholar] [CrossRef]

- Nightingale, D.; Green, W. An unresolved riddle: Tire chips, two roadbeds, and spontaneous reactions. In Testing Soil Mixed with Waste or Recycled Materials ASTM STP 1275; Wasemiller, M., Hoddinot, K., Eds.; American Society for Testing and Materials: West Conshohocken, PA, USA, 1997; pp. 265–285. [Google Scholar]

- Edil, T.B. A Review of Mechanical and Chemical Properties pof Shredded Tires and Soil Mixtures. In Proceedings of the ASCE Civil Engineering Conference and Exposition, Baltimore, MA, USA, 19–21 October 2004; pp. 1–21. [Google Scholar]

- Anbazhagan, P.; Manohar, D.R.; Rohit, D. Influence of size of granulated rubber and tyre chips on the shear strength characteristics of sand–rubber mix. Géoméch. Geoengin. 2017, 12, 266–278. [Google Scholar] [CrossRef]

- Foose, G.J.; Benson, C.H.; Bosscher, P.J. Sand Reinforced with Shredded Waste Tires. J. Geotech. Eng. 1996, 122, 760–767. [Google Scholar] [CrossRef]

- Edil, T.B.; Fox, P.J.; Ahl, S.W. Hydraulic conductivity and compressibility of waste tire chips. In Proceedings of the 15th Annual Madison Waste Conference, Madison, WI, USA, 23–24 September 1992; pp. 49–61. [Google Scholar]

- Akbulut, S.; Arasan, S.; Kalkan, E. Modification of clayey soils using scrap tire rubber and synthetic fibers. Appl. Clay Sci. 2007, 38, 23–32. [Google Scholar] [CrossRef]

- Tweedie, J.; Humphrey, D.N.; Sandford, T.C. Tyre Chips as Lightweight Backfill for Retaining Walls—Phase II; New England Transportation Consortium: Augusta, ME, USA, 1998. [Google Scholar]

- Tam, V.W. Comparing the implementation of concrete recycling in the Australian and Japanese construction industries. J. Clean. Prod. 2009, 17, 688–702. [Google Scholar] [CrossRef]

- DEFRA. UK Statistics on Waste. Governmental Statistical Service, (September). 2019; pp. 1–10. Available online: https://www.gov.uk/government/collections/waste-and-recycling-statistics (accessed on 15 October 2021).

- Jefferson, I.; Gaterell, M.; Thomas, A.M.; Serridge, C.J. Emissions assessment related to vibro stone columns. Proc. Inst. Civ. Eng. Ground Improv. 2010, 163, 71–77. [Google Scholar] [CrossRef]

- Tatsuoka, F.; Tomita, Y.-I.; Iguchi, Y.; Hirakawa, D. Strength and stiffness of compacted crushed concrete aggregate. Soils Found. 2013, 53, 835–852. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, A.; Ugai, K.; Kamei, T. Investigation of recycled gypsum in conjunction with waste plastic trays for ground improvement. Constr. Build. Mater. 2011, 25, 208–217. [Google Scholar] [CrossRef]

- Mueller, A.; Schnell, A.; Ruebner, K. The manufacture of lightweight aggregates from recycled masonry rubble. Constr. Build. Mater. 2015, 98, 376–387. [Google Scholar] [CrossRef] [Green Version]

- Chidiroglou, I.; O’Flaherty, O.; Goodwin, A. Shear behaviour of crushed concrete and bricks. Constr. Mater. 2009, 162, 141–149. [Google Scholar] [CrossRef] [Green Version]

- Disfani, M.; Arulrajah, A.; Bo, M.; Hankour, R. Recycled crushed glass in road work applications. Waste Manag. 2011, 31, 2341–2351. [Google Scholar] [CrossRef]

- Ali, M.M.Y.; Arulrajah, A. Potential Use of Recycled Crushed Concrete-Recycled Crushed Glass Blends in Pavement Subbase Applications. In Proceedings of the GeoCongress, Oakland, CA, USA, 25–29 March 2012; pp. 3662–3671. [Google Scholar]

- Arulrajah, A.; Piratheepan, J.; Disfani, M.M.; Bo, M.W. Geotechnical and Geoenvironmental Properties of Recycled Construction and Demolition Materials in Pavement Subbase Applications. J. Mater. Civ. Eng. 2013, 25, 1077–1088. [Google Scholar] [CrossRef]

- Disfani, M.M.; Arulrajah, A.; Ali, M.M.Y.; Bo, M.W. Fine recycled glass: A sustainable alternative to natural aggregates. Int. J. Geotech. Eng. 2011, 5, 255–266. [Google Scholar] [CrossRef]

- Arulrajah, A.; Ali, M.M.Y.; Disfani, M.M.; Horpibulsuk, S. Recycled-Glass Blends in Pavement Base/Subbase Applications: Laboratory and Field Evaluation. J. Mater. Civ. Eng. 2014, 26, 7. [Google Scholar] [CrossRef]

- Disfani, M.M.; Arulrajah, A.; Bo, M.; Sivakugan, N. Environmental risks of using recycled crushed glass in road applications. J. Clean. Prod. 2012, 20, 170–179. [Google Scholar] [CrossRef]

- Testa, M.; Malandrino, O.; Sessa, M.R.; Supino, S.; Sica, D. Long-Term Sustainability from the Perspective of Cullet Recycling in the Container Glass Industry: Evidence from Italy. Sustainability 2017, 9, 1752. [Google Scholar] [CrossRef] [Green Version]

- Butler, J.H.; Hooper, P. Glass Waste. Waste 2011, 151–165. [Google Scholar] [CrossRef]

- Ooi, P.S.K.; Li, M.M.W.; Sagario, M.L.Q.; Song, Y. Shear Strength Characteristics of Recycled Glass. Transp. Res. Rec. J. Transp. Res. Board 2008, 2059, 52–62. [Google Scholar] [CrossRef]

- Amiri, S.T.; Nazir, R.; Dehghanbanadaki, A. Experimental Study of Geotechnical Characteristics of Crushed Glass Mixed with Kaolinite Soil. Int. J. Geomate 2018, 14, 170–176. [Google Scholar] [CrossRef]

- Majdinasab, A.; Yuan, Q. Post-consumer cullet and potential engineering applications in North America. Resour. Conserv. Recycl. 2019, 147, 1–9. [Google Scholar] [CrossRef]

- WRAP. Realising the Value of Recovered Glass: An Update; WRAP: Banbury, UK, 2008. [Google Scholar]

- Heriyanto; Pahlevani, F.; Sahajwalla, V. From waste glass to building materials—An innovative sustainable solution for waste glass. J. Clean. Prod. 2018, 191, 192–206. [Google Scholar] [CrossRef]

- Cuelho, E.; Mokwa, R.; Obert, K.; Miller, A. Comparative Analysis of Micro-Deval, LA Abrasion, and Sulfate Soundness Tests. Transp. Res. Board 2008, 1638, 1–17. [Google Scholar]

- Vieitez, E.R.; Eder, P.; Villanueva, A.; Saveyn, H. End-of-Waste Criteria for Glass Cullet: Technical Proposals; JRC Scientific and Technical Reports; European Commission: Geneva, Switzerland, 2011; 124p. [Google Scholar]

- Guthrie, P.; Coventry, S.; Woolveridge, C.; Hillier, S.; Collins, R. The Reclaimed and Recycled Construction Materials Handbook; CIRIA: London, UK, 1999. [Google Scholar]

- Landris, T.L. Recycled Glass and Dredged Materials; Engineer Research and Development Center: Vicksburg, MS, USA, 2007; Volume 12, Available online: https://books.google.com/books?id=K1qdNwAACAAJ&pgis=1 (accessed on 15 October 2021).