Comparative Analysis of Gasification and Adiabatic Digestion of Corn for Practical Implementation in Conventional Gas Turbines

Abstract

1. Introduction

2. Materials and Methods

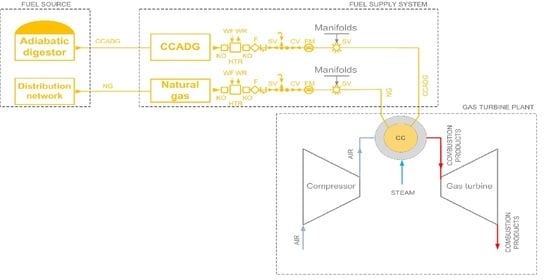

2.1. Numerical Model of a Physical Cycle

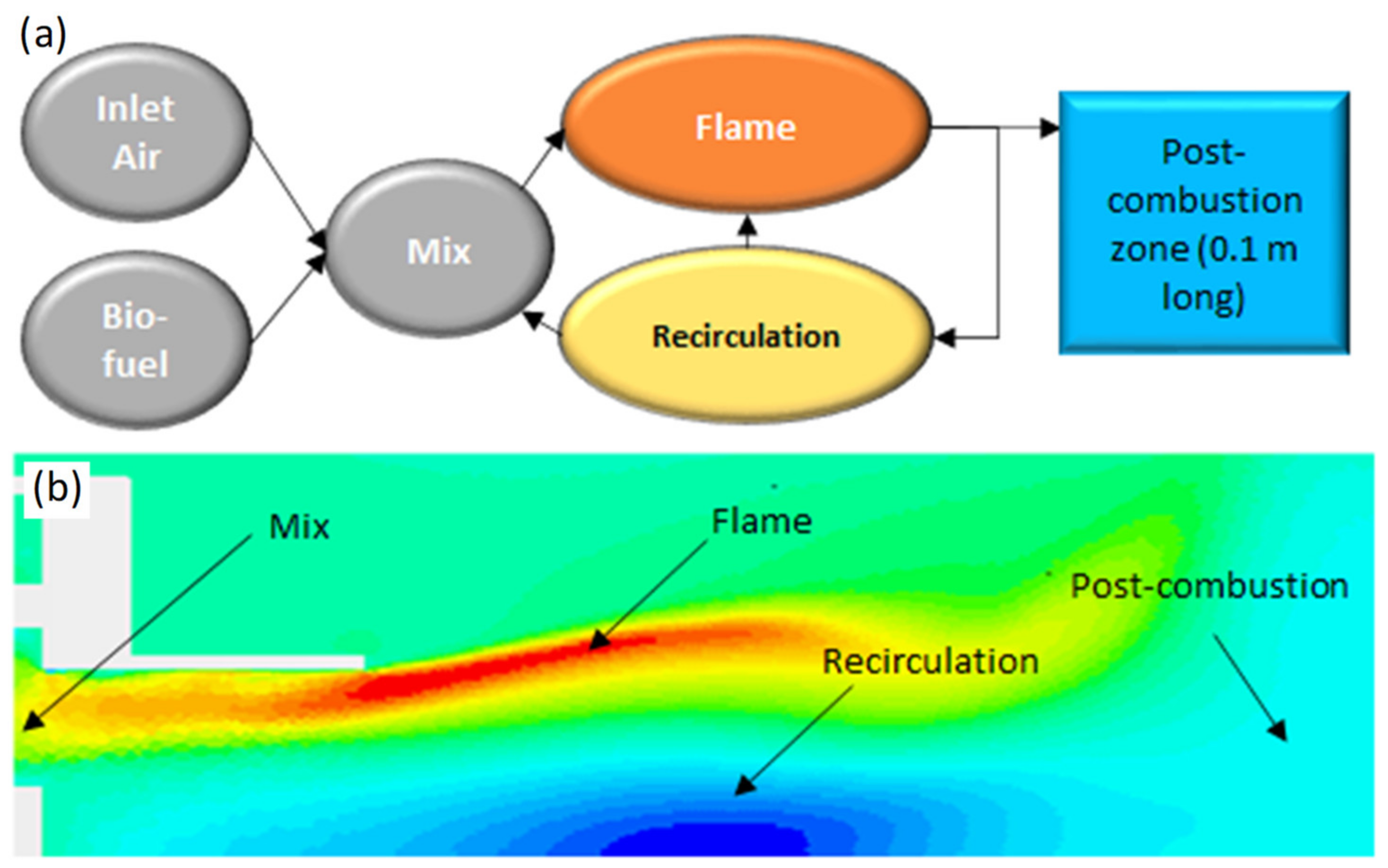

2.2. Gas Combustion Modeling

2.3. Fuel Selection

2.4. Types of Manifold Injection

3. Results and Discussion

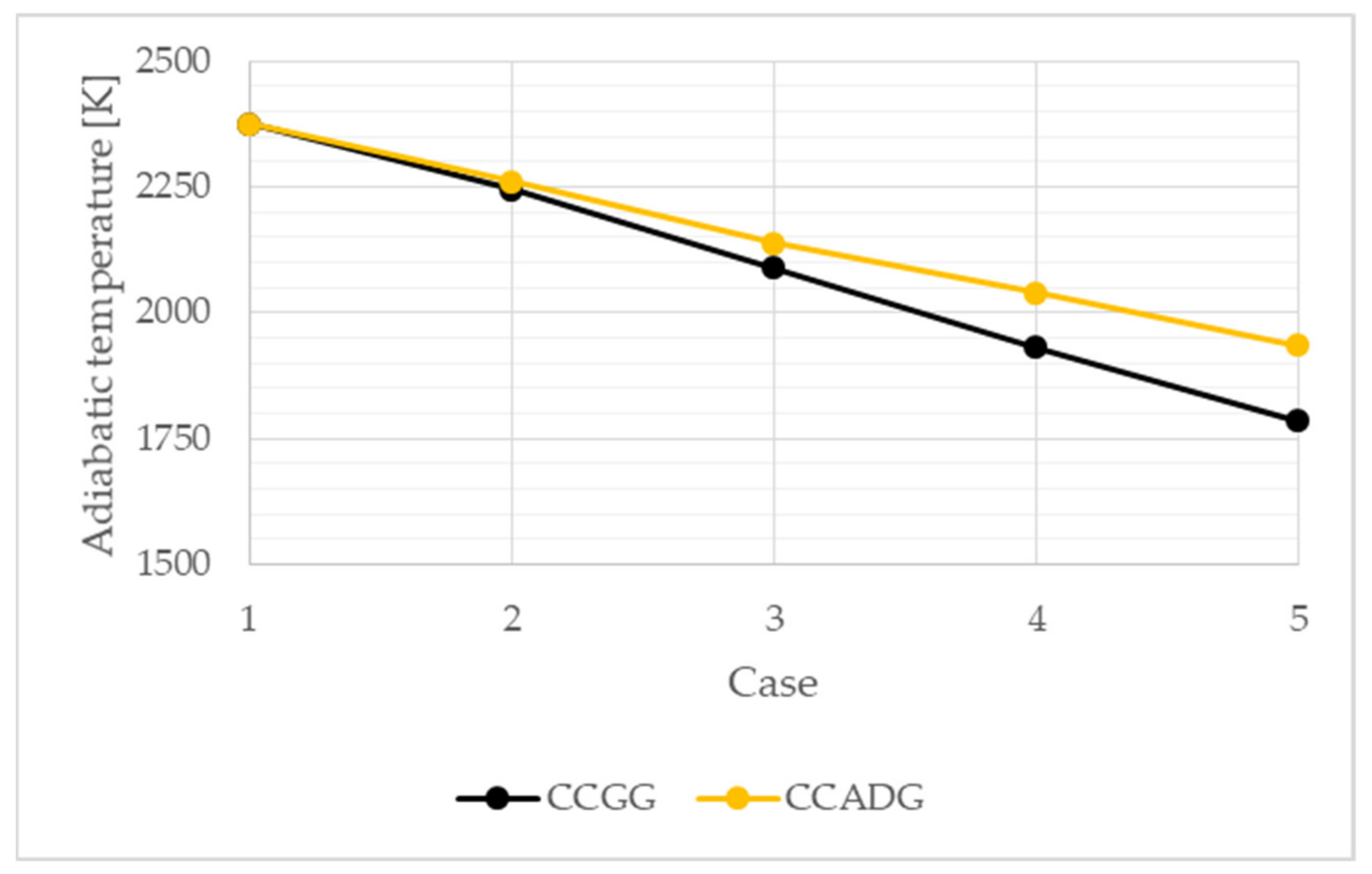

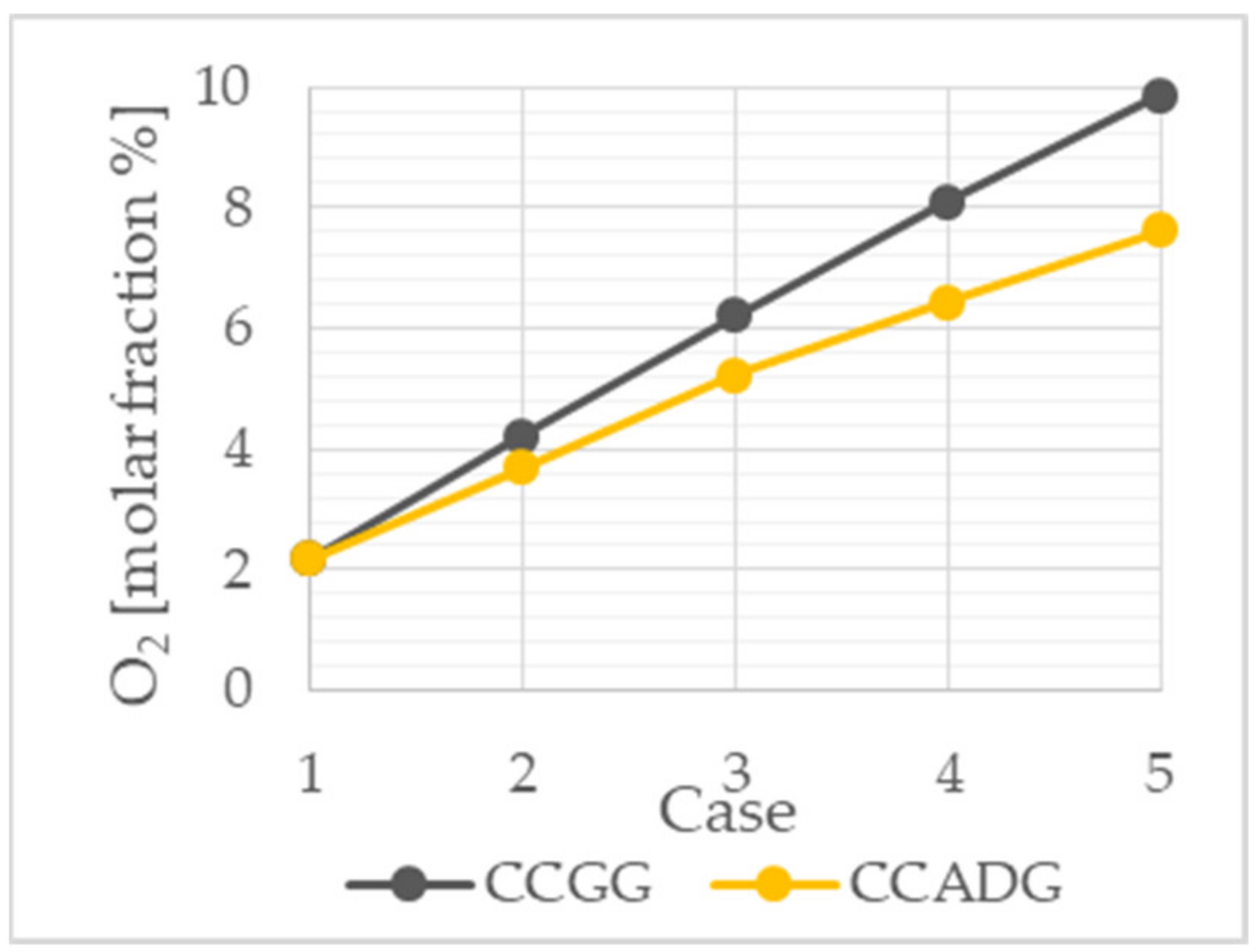

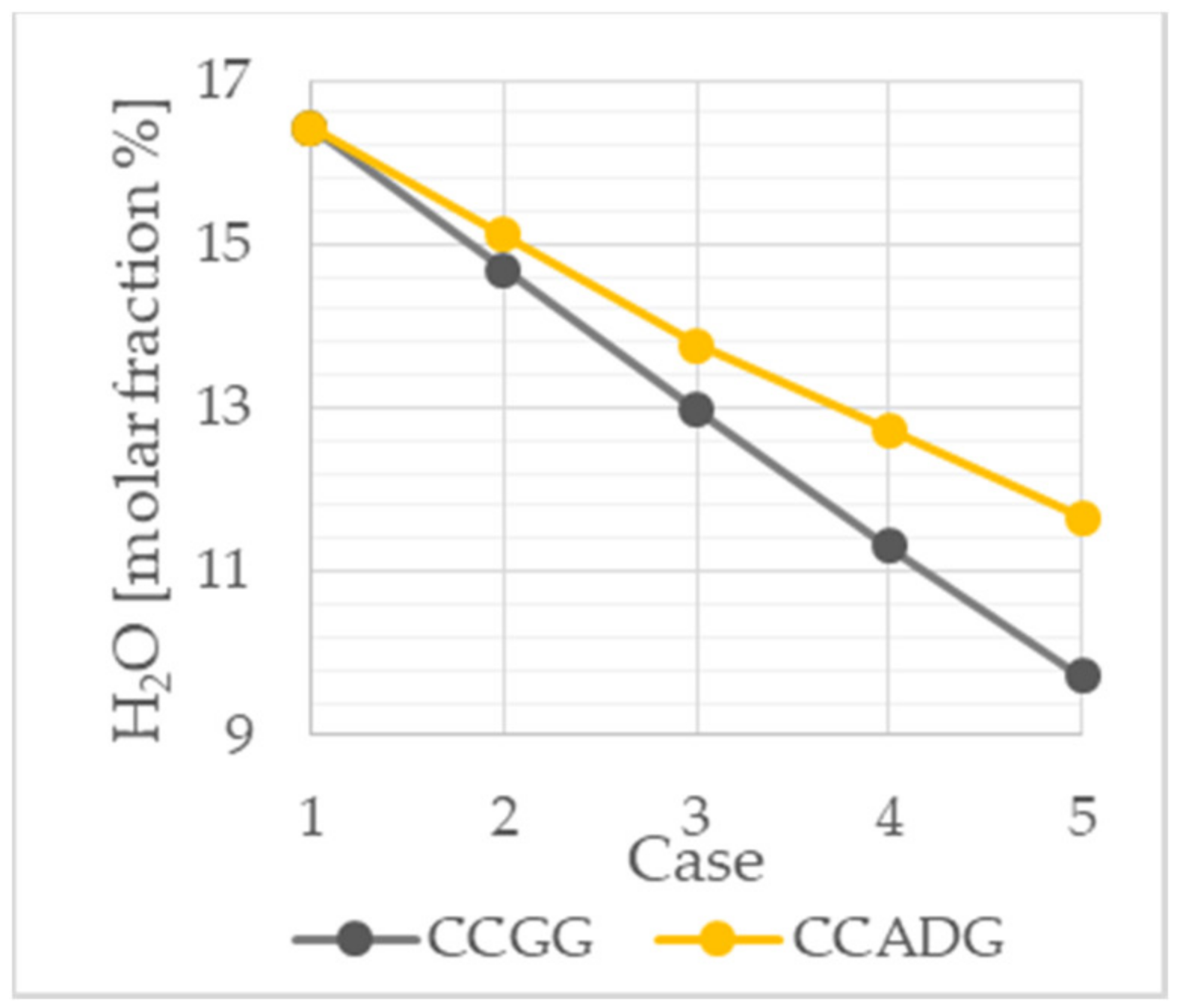

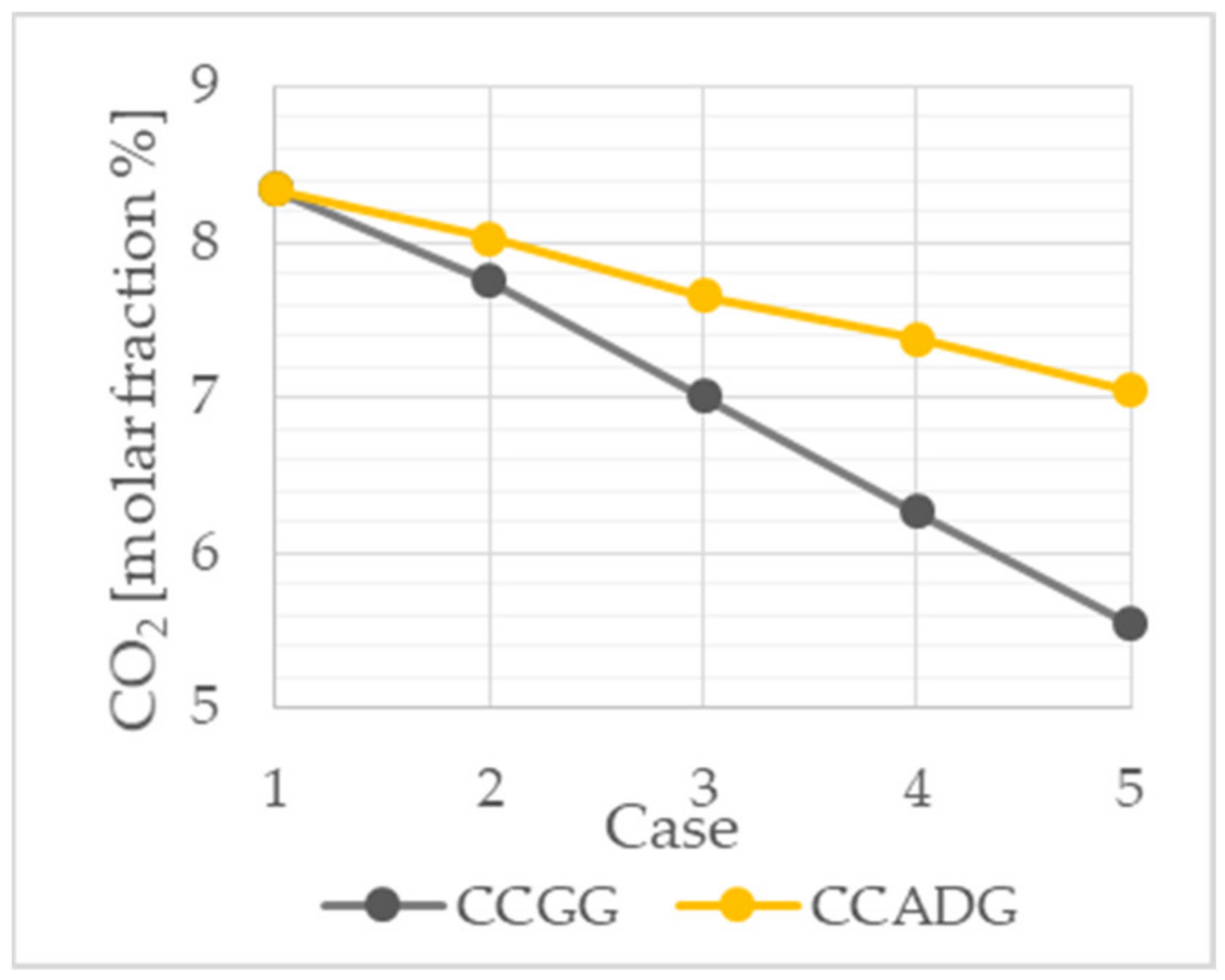

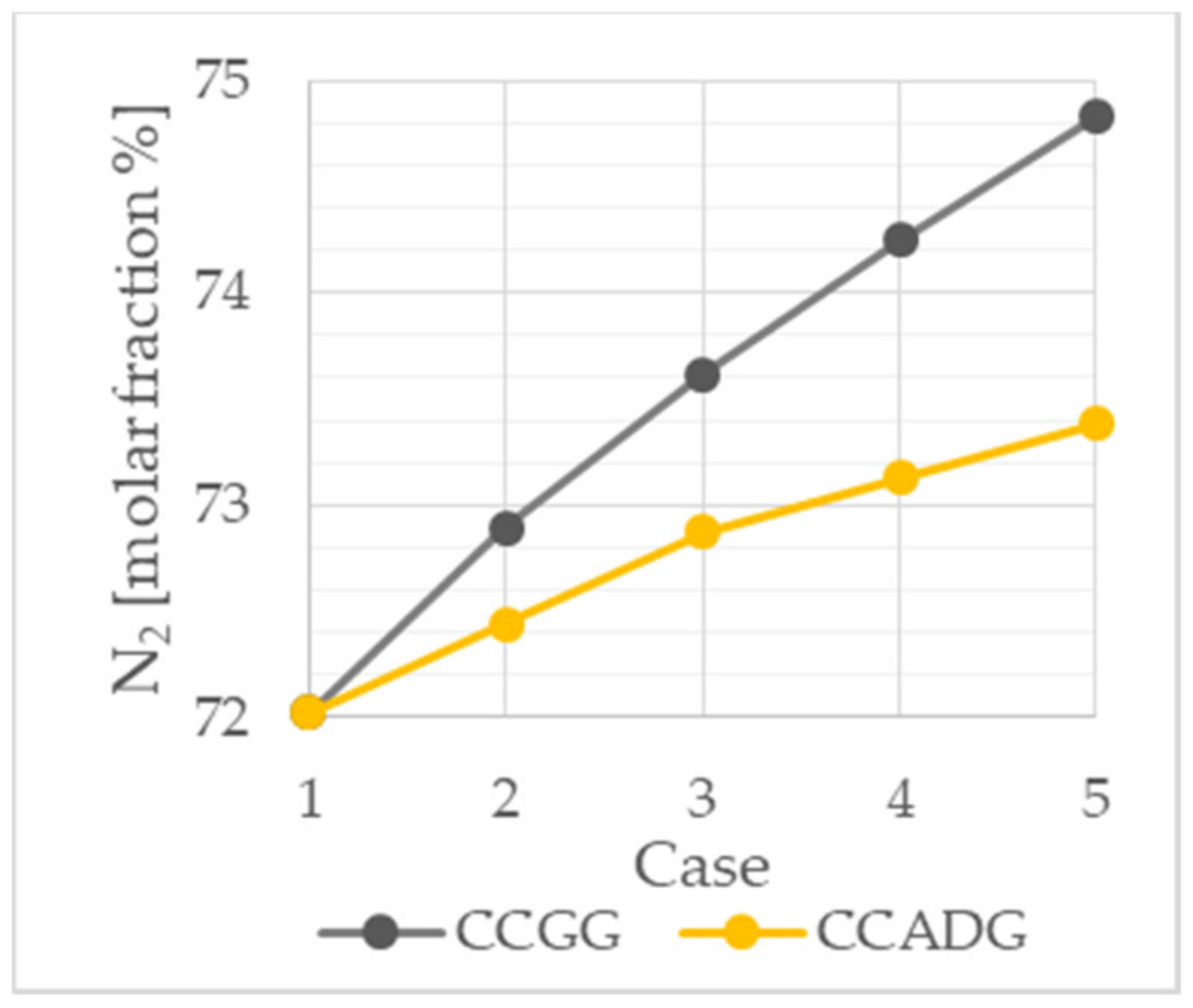

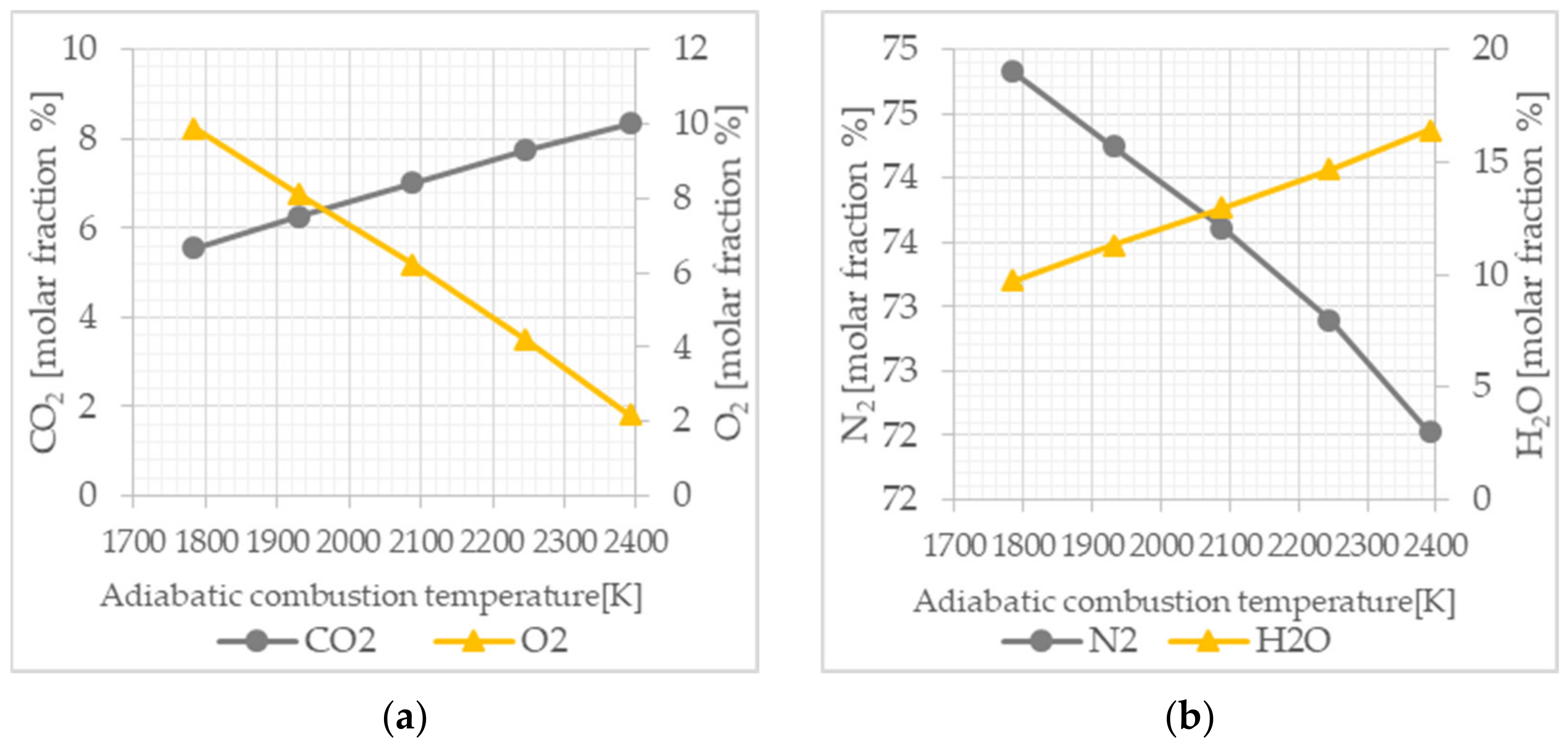

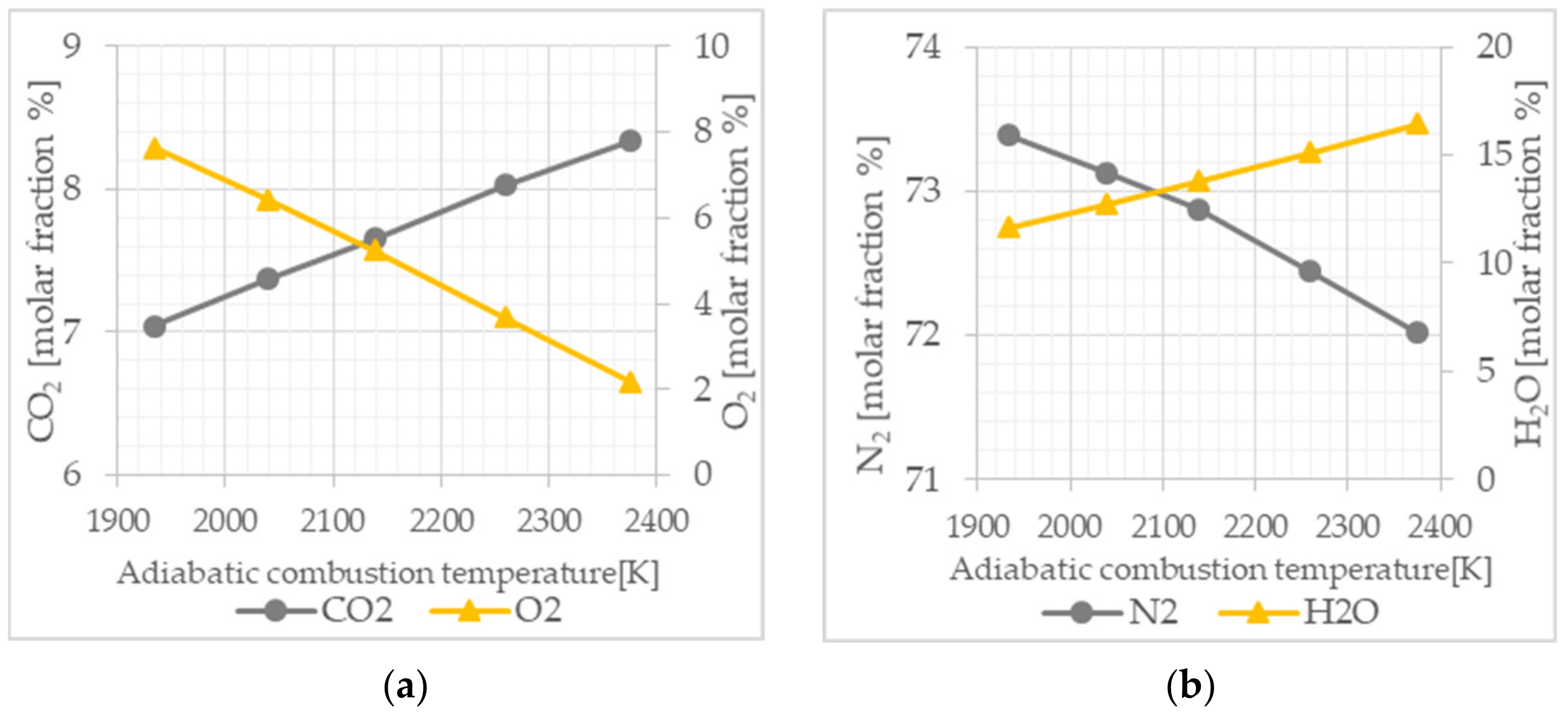

3.1. Reaction Modeling

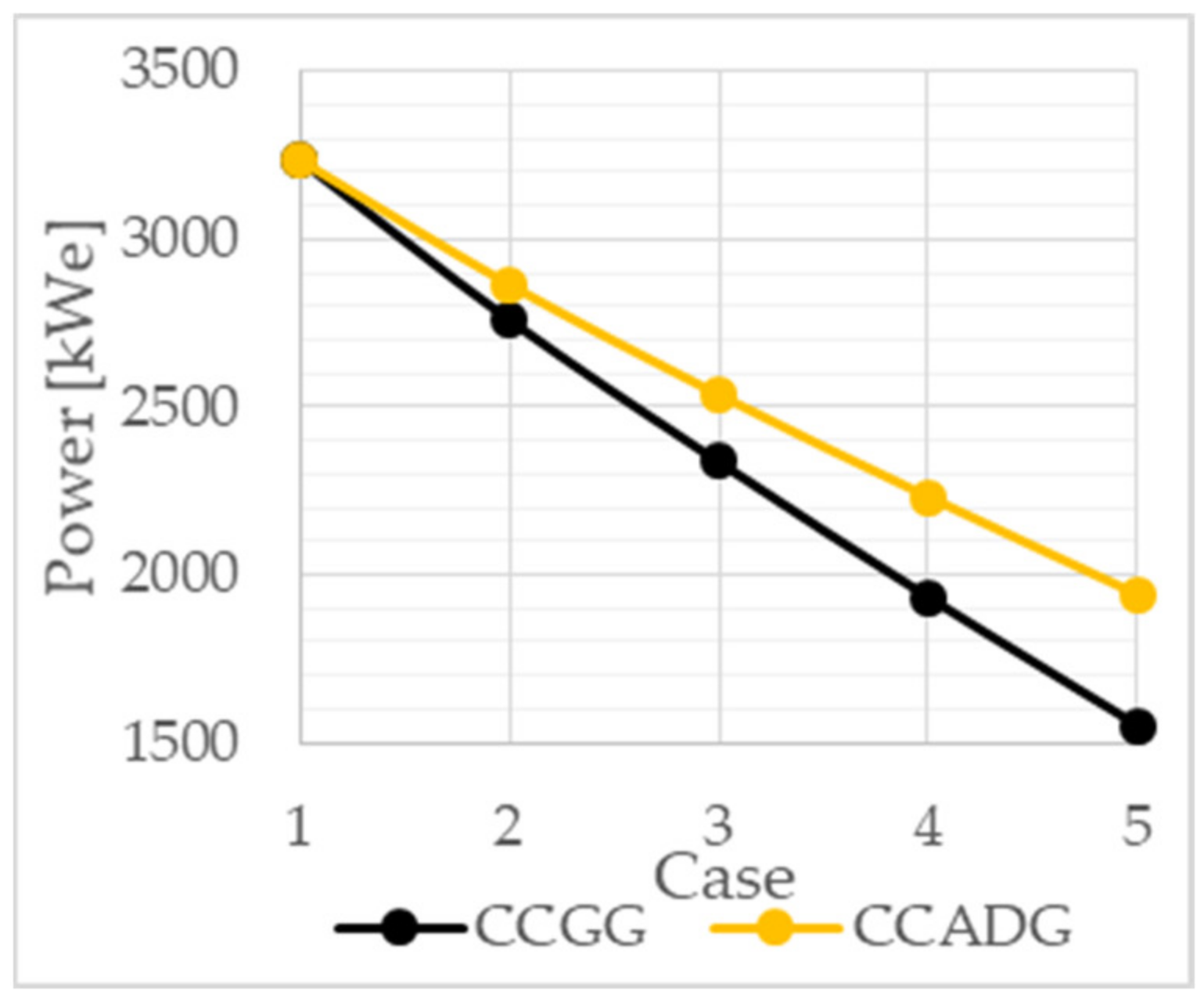

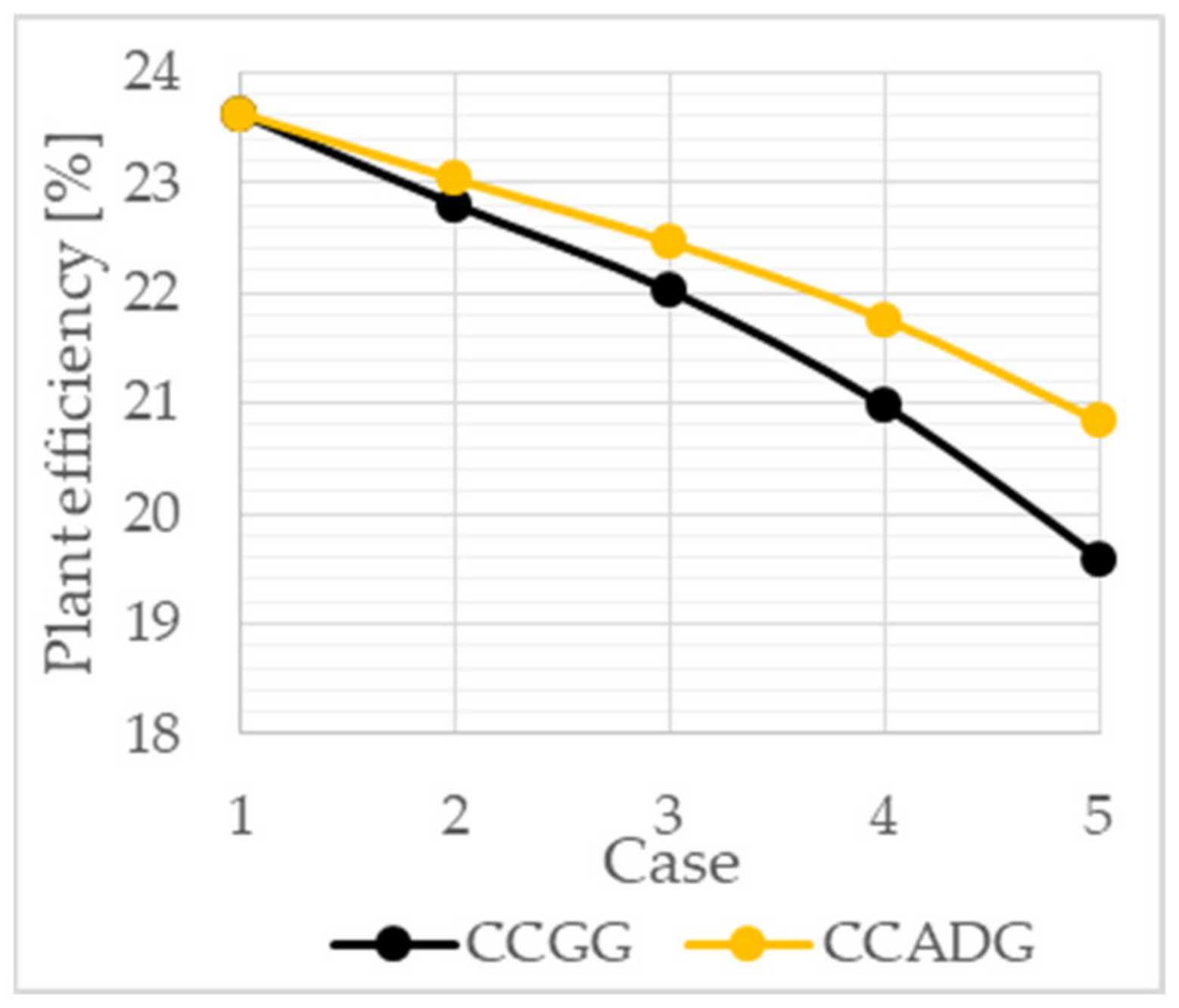

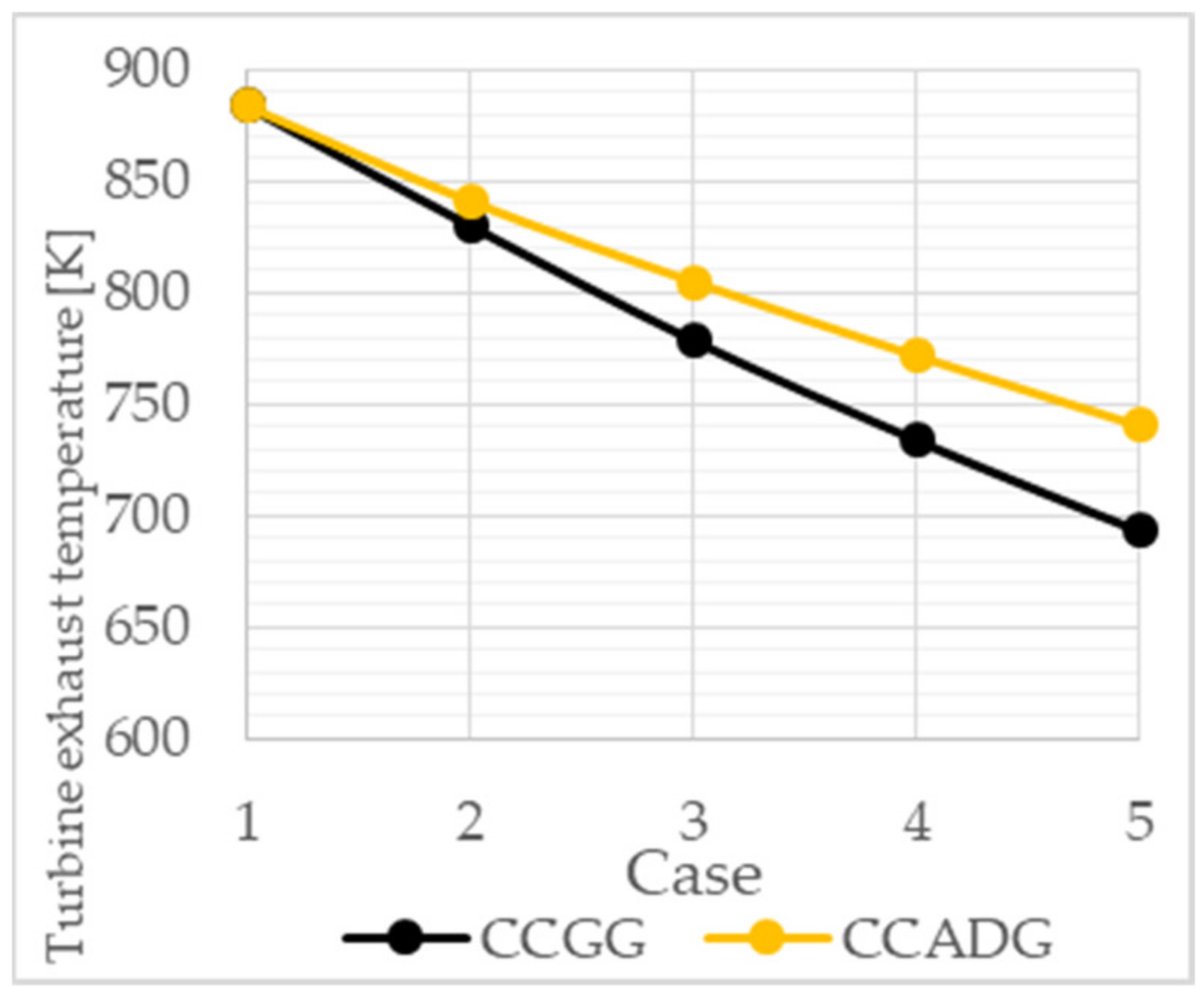

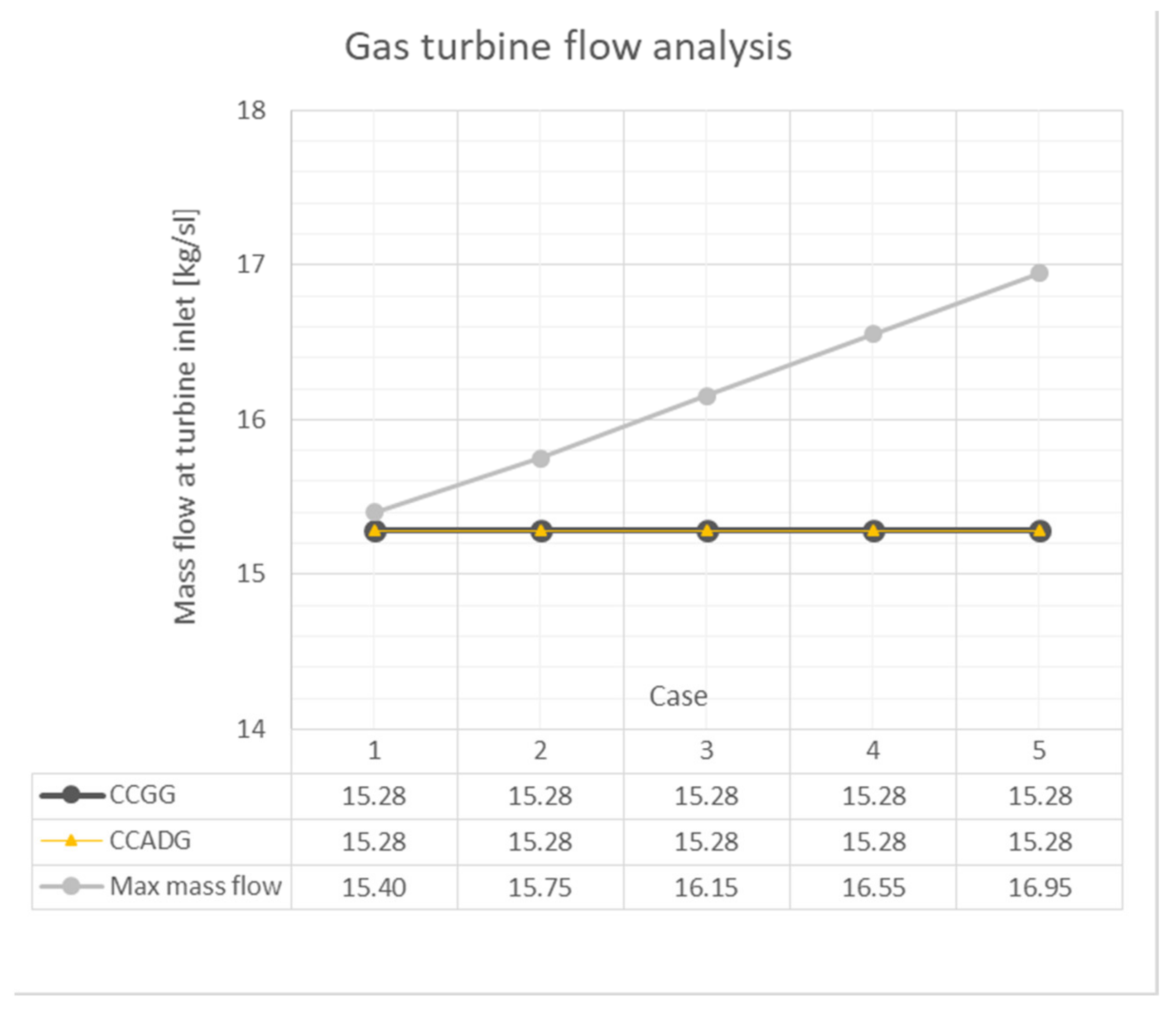

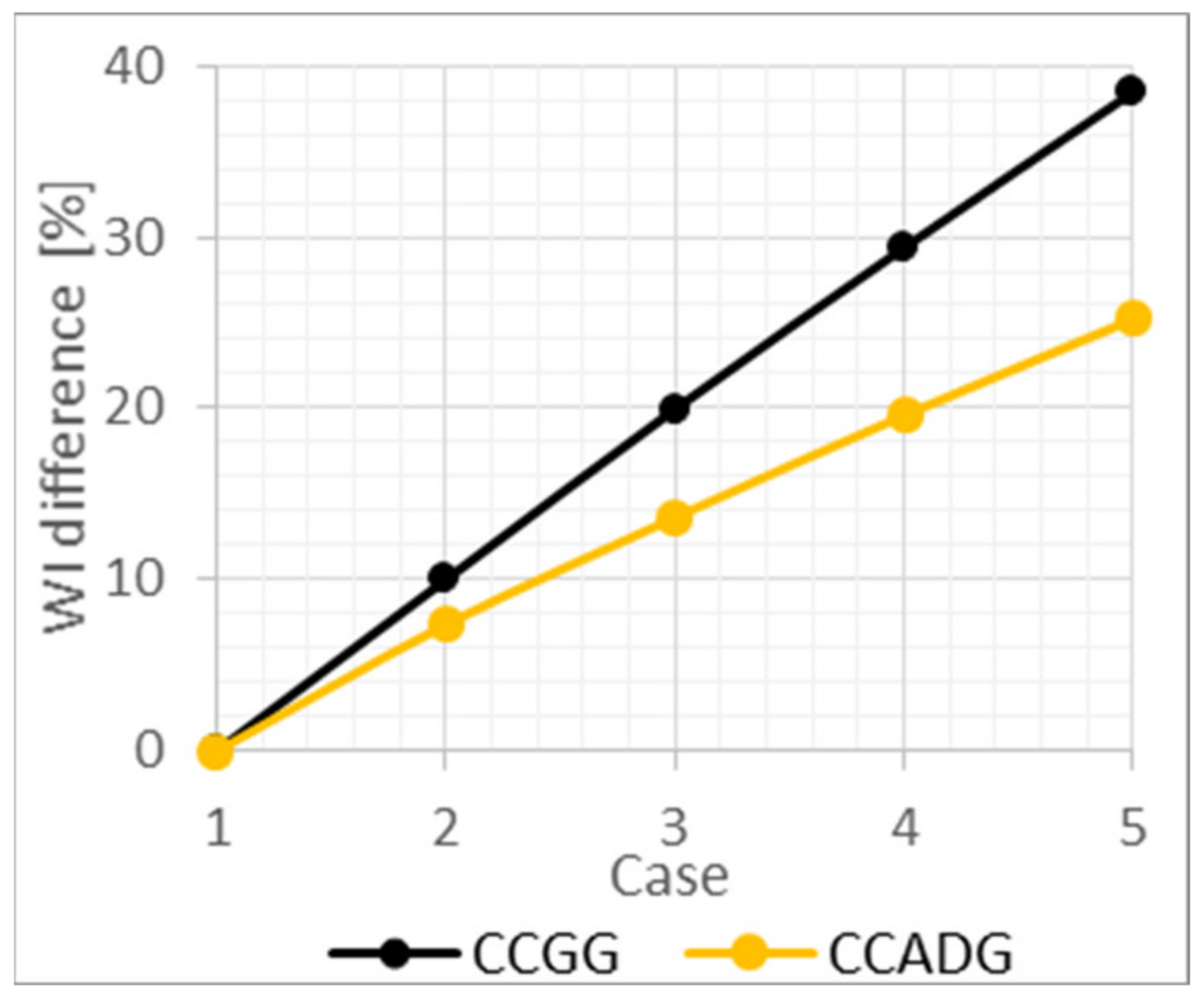

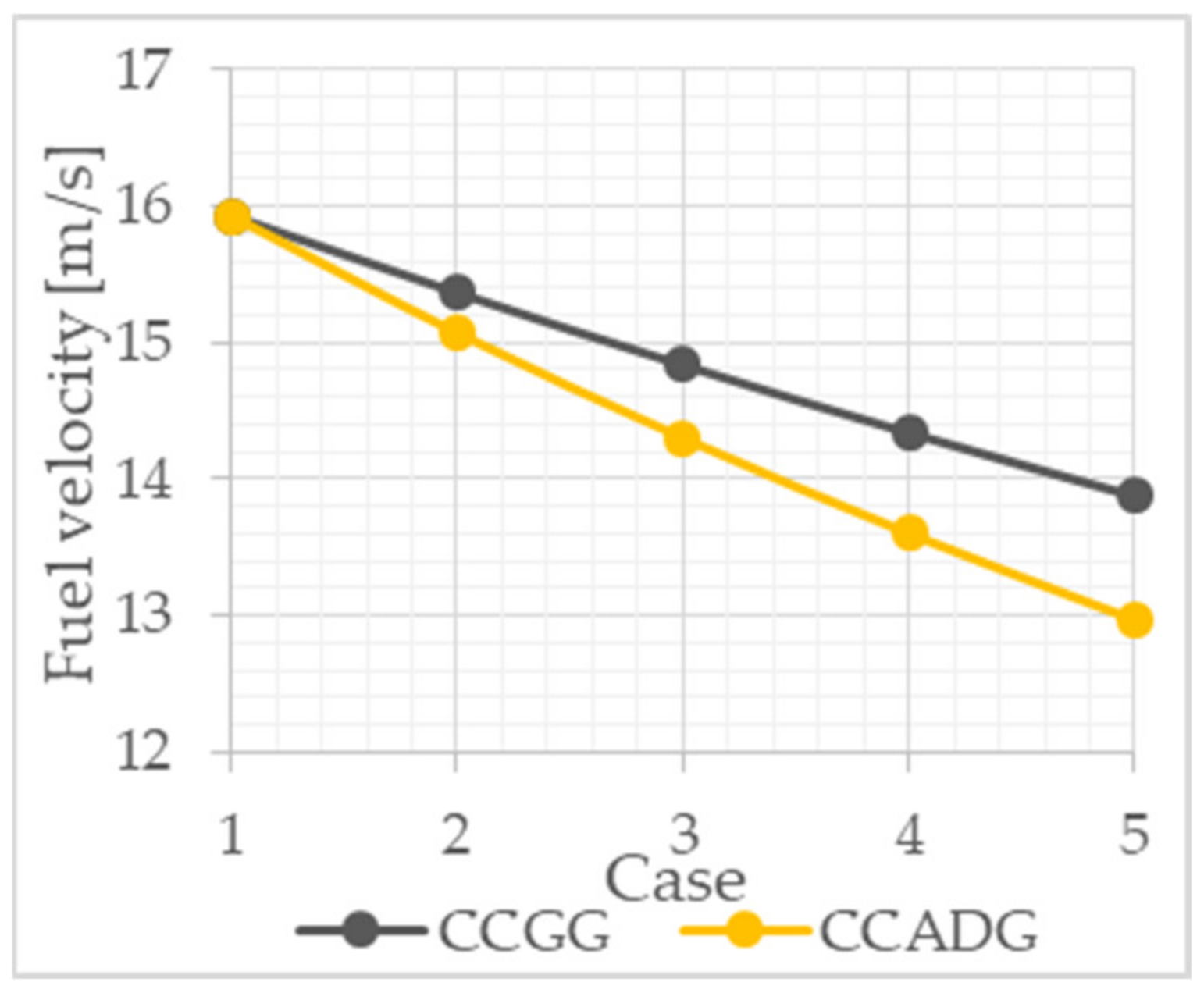

3.2. Gas Turbine Simulation

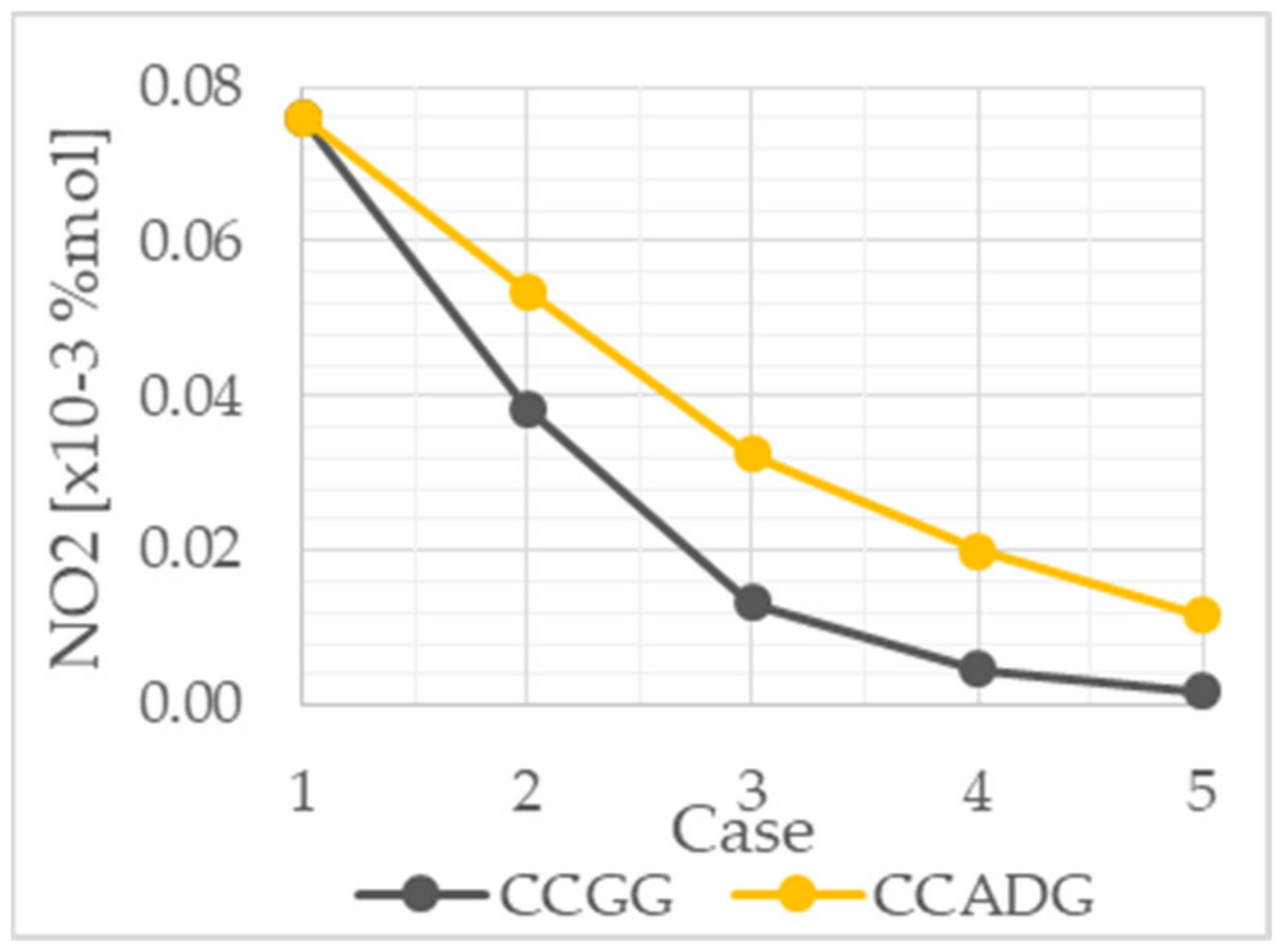

3.3. NOx Emissions

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jankes, G. Biomass gasification–annual report. Fac. Tech. Sci. Mech. Fac. 2009. [Google Scholar]

- Moharamian, A.; Soltani, S.; Rosen, M.A.; Mahmoudi, S.M.S.; Morosuk, T. A comparative thermoeconomic evaluation of three biomass and biomass-natural gas fired combined cycles using organic Rankine cycles. J. Clean. Prod. 2017, 161, 524–544. [Google Scholar] [CrossRef]

- Mondal, P.; Ghosh, S. Exergo-economic analysis of a 1-MW biomass-based combined cycle plant with externally fired gas turbine cycle and supercritical organic Rankine cycle. Clean Technol. Environ. Policy 2017, 19, 1475–1486. [Google Scholar] [CrossRef]

- Guteša, M.M.; Gvozdenac-Urošević, B.D.; Grković, V.R. Energy and economic effects of CHP with combined technologies of corn cobs gasification and gas turbines. Therm. Sci. 2016, 20, 343–354. [Google Scholar] [CrossRef]

- Bazooya, B.; Darabkhani, H.G. Design procedure and performance analysis of a microturbine combustor working on biogas for power generation. In Proceedings of the ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition, Phoenix, AZ, USA, 17–21 June 2019. Code 154121. [Google Scholar]

- Neilson, C.E. LM2500 Gas Turbine Modifications for Biomass Fuel Operation. Biomass Bioenergy 2010, 15, 269–273. [Google Scholar] [CrossRef]

- Franco, A.; Giannini, N. Perspectives for the use of biomass as fuel in combined cycle power plants. Int. J. Therm. Sci. 2005, 44, 163–177. [Google Scholar] [CrossRef]

- Datta, A.; Mondal, S.; Gupta, S.D. Perspectives for the direct firing of biomass as a supplementary fuel in combined cycle power plants. Int. J. Energy Resour. 2008, 32, 1241–1257. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Manna, D.; Paul, B.; Datta, A. Biomass integrated gasification combined cycle power generation with supplementary biomass firing: Energy and exergy-based performance analysis. Energy 2011, 36, 2599–2610. [Google Scholar] [CrossRef]

- Kang, D.W.; Kim, T.S.; Hur, K.B.; Park, J.K. The effect of firing biogas on the performance and operating characteristics of simple and recuperative cycle gas turbine combined heat and power systems. Appl. Energy 2012, 93, 215–228. [Google Scholar] [CrossRef]

- Adouane, B.; Hoppesteyn, P.; de Jong, W.; van der Wel, M.; Hein, K.R.G.; Spielthoff, H. Gas turbine combustor for biomass derived LCV gas, a first approach towards fuel-NOx modelling and experimental validation. Appl. Therm. Eng. 2002, 22, 959–970. [Google Scholar] [CrossRef]

- Guteša Božo, M.; Valera-Medina, A.; Syred, N.; Bowen, P.J. Fuel quality impact analysis for practical implementation of corn cob gasification gas in conventional gas turbine power plants. Biomass Bioenergy 2019, 122, 221–230. [Google Scholar] [CrossRef]

- Sansaniwala, S.K.; Pala, K.; Rosenb, M.A.; Tyagia, S.K. Recent advances in the development of biomass gasification technology: A comprehensive review. Renew. Sustain. Energy Rev. 2017, 72, 363–384. [Google Scholar] [CrossRef]

- Guteša Božo, M.; Guteša, M. Design and Development of the Anaerobic Digestion Facilities for Production of the Biogas from Agricultural Biomass Waste in Province Vojvodina Serbia; Internal Company Data from Project Documentation; Termoinzinjering, D.O.O.: Novi Sad, Serbia, 2021. [Google Scholar]

- Vindis, P.; Mursec, B.; Janzekovic, M.; Stajnko, D.; Cus, F. Anaerobic digestion of maize hybrids for methane production. J. Achiev. Mater. Manuf. Eng. 2010, 40, 87–94. [Google Scholar]

- Walter, A.; Llagostera, J. Feasibility analysis of co-fired combined-cycles using biomass-derived gas and natural gas. Energy Convers. Manag. 2007, 48, 2888–2896. [Google Scholar] [CrossRef]

- Liu, K.; Sanderson, V. The influence of changes in fuel calorific value to combustion performance for Siemens SGT-300 dry low emission combustion system. Fuel 2013, 103, 239–246. [Google Scholar] [CrossRef]

- Bharathirajaa, B.; Sudharsanaa, T.; Jayamuthunagaib, J.; Praveenkumarc, R.; Chozhavendhand, S.; Iyyappana, J. Biogas production–A review on composition, fuel properties, feed stock and principles of anaerobic digestion. Renew. Sustain. Energy Rev. 2018, 90, 570–582. [Google Scholar] [CrossRef]

- Van Foreest, F. Perspectives for Biogas in Europe; Oxford Institute for Energy Studies: Oxford, UK, 2012. [Google Scholar]

- Nishio, N.; Nakashimada, Y. Recent development of anaerobic digestion processes for energy recovery from wastes. J. Biosci. Bioeng. 2007, 103, 105–112. [Google Scholar] [CrossRef] [PubMed]

- Caposciutti, G.; Baccioli, A.; Ferrari, L.; Desideri, U. Impact of ambient temperature on the effectiveness of inlet air cooling in a co-digestion biogas plant equipped with a mGT. Energy Convers. Manag. 2020, 216, 112874. [Google Scholar] [CrossRef]

- Zare, A.; Saray, R.K.; Mirmasoumi, S.; Bahlouli, K. Optimization strategies for mixing ratio of biogas and natural gas co-firing in a cogeneration of heat and power cycle. Energy 2019, 181, 635–644. [Google Scholar] [CrossRef]

- Amiri Rad, E.; Kazemiani-Najafabadi, P. Introducing a novel optimized Dual Fuel Gas Turbine (DFGT) based on a 4E objective function. J. Clean. Prod. 2019, 206, 944–954. [Google Scholar] [CrossRef]

- Flores, R.; Brouwer, J. Optimizing natural gas combined cycle part load operation. In Proceedings of the ASME 2019 Power Conference, POWER 2019, Salt Lake City, UT, USA, 15–18 July 2019. Code 155466. [Google Scholar]

- Darabadi Zareh, A.; Khoshbakhti Saray, R.; Mirmasoumi, S.; Bahlouli, K. Extensive thermodynamic and economic analysis of the cogeneration of heat and power system fueled by the blend of natural gas and biogas. Energy Convers. Manag. 2018, 164, 329–343. [Google Scholar] [CrossRef]

- Hoda, A.; Rahman, T.M.R.; Asrar, W.; Khan, A.K. A Comparative Study of Natural Gas and Biogas Combustion in A Swirling Flow Gas Turbine Combustor. Combust. Sci. Technol. 2021, 1–28. [Google Scholar] [CrossRef]

- Somehsaraei, H.N.; Majoumerd, M.M.; Assadi, M. Performance assessment of a micro gas turbine cycle with exhaust gas recirculation fueled by biogas for post-combustion carbon capture application. In Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, GT 2018, Oslo, Norway, 11–15 June 2018. Code 138886. [Google Scholar]

- Mohammadpour, M.; Houshfar, E.; Ashjaee, M.; Mohammadpour, A. Energy and exergy analysis of biogas fired regenerative gas turbine cycle with CO2 recirculation for oxy-fuel combustion power generation. Energy 2021, 220, 119687. [Google Scholar] [CrossRef]

- Jenifer, L.; Annie Elisabeth Jebaseeli, E. Anaerobic digestion based modeling and simulation of bio gas fuel system. J. Green Eng. 2020, 10, 1–12. [Google Scholar]

- Al-Rasheda, A.A.A.A.; Masoud, A. Multi-criteria exergoeconomic optimization for a combined gas turbine-supercritical CO2 plant with compressor intake cooling fueled by biogas from anaerobic digestion. Energy 2021, 223, 119997. [Google Scholar] [CrossRef]

- Guteša, M.; Al-Doboon, A.; Valera-Medina, A.; Syred, N.; Bowen, P. CARSOXY (CO2-Argon-Steam-OxyFuel) Combustion in Gas Turbines for CCS Systems. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar] [CrossRef]

- Al-Doboon, A.; Guteša, M.; Valera-Medina, A.; Syred, N.; Ng, J.-H.; Chong, C.T. CO2-argon-steam oxy-fuel (CARSOXY) combustion for CCS inert gas atmospheres in gas turbines. Appl. Therm. Eng. 2017, 122, 350–358. [Google Scholar] [CrossRef]

- Müller, K.J. Grundzüge der Thermischen Turbomaschinen, Vorlesung Turbomaschinen und Energieanlagen; Institut für Thermische Turbomaschinen und Energieanlagen, Universität Wien: Vienna, Austria, 1991. [Google Scholar]

- Guteša, M. The Numerical Simulation Model of Gas Turbine Facility for Biomass Gasification Gas Application. Ph.D. Thesis, University of Novi Sad, Faculty of Technical Sciences, Novi Sad, Serbia, 2017. (In Serbian). [Google Scholar]

- Shmakov, A.G.; Korobeinichev, O.P.; Rybitskaya, I.V.; Cherno, A.A.; Knyazko, D.A.; Bolshova, T.A.; Konnov, A.A. Formation and consumption of NO in H2 + O2 + N2 flames doped with NO or NH3 at atmospheric pressure. Combust. Flame 2010, 157, 556–565. [Google Scholar] [CrossRef]

- Duynslaegher, C.; Jeanmart, H.; Vandooren, J. Ammonia Combustion at Elevated Pressure and Temperature Conditions. Fuel 2010, 89, 3540–3545. [Google Scholar] [CrossRef]

- Duynslaegher, C.; Contino, F.; Vandooren, J.; Jeanmart, H. Modelling Ammonia Combustion at Low Pressure. Combust. Flame 2012, 159, 2799–2805. [Google Scholar] [CrossRef]

- Rutar, T.; Malte, P.C. NOx Formation in High–Pressure Jet–Stirred Reactors with Significance to Lean–Premixed Combustion Turbines. J. Eng. Gas Turbines Power 2002, 124, 776–783. [Google Scholar] [CrossRef]

- Syred, N. A review of oscillation mechanisms and the role of the processing vortex core (PVC) in Swirl Combustion systems. Prog. Energy Combust. Sci. 2006, 32, 93–161. [Google Scholar] [CrossRef]

- Valera–Medina, A.; Syred, N.; Bowen, P. Central recirculation zone visualization in confined swirl combustors for terrestrial energy. J. Propuls. Power 2013, 29, 195–204. [Google Scholar] [CrossRef]

- Valera–Medina, A.; Marsh, R.; Runyon, J.; Pugh, D.; Beasley, P.; Hughes, T.; Bowen, P. Ammonia–methane combustion in tangential swirl burners for gas turbine power generation. Appl. Energy 2016, 185, 1362–1371. [Google Scholar] [CrossRef]

- Reaction Design. CHEMKIN Tutorials Manual CHEMKIN® Software.10112/15112; Reaction Design: Livermore, CA, USA, 2011; pp. 1–274. [Google Scholar]

- Rowen, W.I. Design Considerations for Gas Turbine Fuel Systems; GE Company: Schenectady, NY, USA, 1991; Volume 28, pp. 1–17. [Google Scholar]

- Meier, G.J.; Hung, W.S.Y.; Sood, V.M. Development and Application of Industrial Gas Turbines for Medium–Btu Gaseous Fuels. J. Eng. Gas Turbines Power 1986, 108, 182–190. [Google Scholar] [CrossRef]

- Strelec, V. Dokumentacija Izvanrednih Izdanja Transfera Tehnologije; Interprogres: Zagreb, Croatia, 1980. [Google Scholar]

- Chacartegui, R.; Sánchez, D.; Muñoz de Escalona, J.M.; Muñoz, A.; Sánchez, T. Gas and steam combined cycles for low calorific syngas fuels utilization. Appl. Energy 2013, 101, 81–92. [Google Scholar] [CrossRef]

| Dry CCGG | Wet CCGG | CCADG | |

|---|---|---|---|

| N2 [vol%] | 43.01 | 47.09 | 0–5 |

| CO2 [vol%] | 10.42 | 11.41 | 15–60 |

| CO [vol%] | 19.40 | 21.24 | - |

| H2 [vol%] | 16.67 | 18.26 | Traces |

| CH4 * [vol%] | 1.83 | 2.00 | 40–75 |

| H2O [vol%] | 8.70 | - | 1–5% |

| H2S [vol%] | - | - | - |

| O2 [vol%] | - | - | <2 |

| LHV [MJ/m3] | 4.90 | 5.37 | 21.48 |

| LHV [MJ/kg] | 5.26 | 5.77 | 30.00 |

| Composition [Molar Fraction] | 0% CCGG | 10% CCGG | 20% CCGG | 30% CCGG | 40% CCGG |

|---|---|---|---|---|---|

| CH4 | 0.9247 | 0.8342 | 0.7438 | 0.6533 | 0.5628 |

| C2H6 | 0.0350 | 0.0315 | 0.0280 | 0.0245 | 0.0210 |

| C3H8 | 0.0132 | 0.0119 | 0.0106 | 0.0092 | 0.0079 |

| C4H10 | 0.0022 | 0.0019 | 0.0018 | 0.0015 | 0.0013 |

| C5H12 | 0.0006 | 0.0005 | 0.0006 | 0.0004 | 0.0004 |

| N2 | 0.0175 | 0.0588 | 0.1000 | 0.1413 | 0.1825 |

| H2 | 0.0000 | 0.0167 | 0.0333 | 0.0500 | 0.0667 |

| CO | 0.0000 | 0.0194 | 0.0388 | 0.0582 | 0.0776 |

| H2O | 0.0000 | 0.0087 | 0.0174 | 0.0261 | 0.0348 |

| CO2 | 0.0068 | 0.0165 | 0.0263 | 0.0360 | 0.0458 |

| Composition [Molar Fraction] | 0% CCADG | 10% CCADG | 20% CCADG | 30% CCADG | 40% CCADG |

|---|---|---|---|---|---|

| CH4 | 0.9247 | 0.8922 | 0.8598 | 0.8273 | 0.7948 |

| C2H6 | 0.0350 | 0.0315 | 0.0280 | 0.0245 | 0.0210 |

| C3H8 | 0.0132 | 0.0119 | 0.0106 | 0.0092 | 0.0079 |

| C4H10 | 0.0022 | 0.0019 | 0.0018 | 0.0015 | 0.0013 |

| C5H12 | 0.0006 | 0.0005 | 0.0005 | 0.0004 | 0.0004 |

| N2 | 0.0175 | 0.0158 | 0.0140 | 0.0123 | 0.0105 |

| CO2 | 0.0068 | 0.0461 | 0.0854 | 0.1248 | 0.1641 |

| Case | Inlet Data—Mass Flows and ER | Pressure | |||||

|---|---|---|---|---|---|---|---|

| mfuel [kg/s] | mair [kg/s] | ER CCGG [-] | ER CCADG [-] | pfuel [bar] | pair [bar] | pcombustion [bar] | |

| 1 | 0.29 | 14.47 | 0.89 | 0.89 | 11.22 | 9.69 | 9.69 |

| 2 | 0.29 | 14.47 | 0.78 | 0.81 | 11.22 | 9.69 | 9.69 |

| 3 | 0.29 | 14.47 | 0.68 | 0.73 | 11.22 | 9.69 | 9.69 |

| 4 | 0.29 | 14.47 | 0.58 | 0.67 | 11.22 | 9.69 | 9.69 |

| 5 | 0.29 | 14.47 | 0.49 | 0.61 | 11.22 | 9.69 | 9.69 |

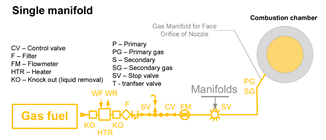

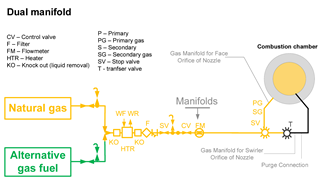

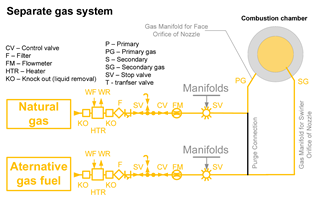

| Type | ΔWI | Field of Application | Graphical Scheme |

|---|---|---|---|

| Single manifold fuel system | ~5% | one type of fuel |  |

| Dual manifold fuel system | 5% (or 10%) to 25% | two types of fuels |  |

| Separate gas fuel systems | greater than 50% | two types of fuels |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guteša Božo, M.; Valera-Medina, A. Comparative Analysis of Gasification and Adiabatic Digestion of Corn for Practical Implementation in Conventional Gas Turbines. Gases 2021, 1, 92-105. https://doi.org/10.3390/gases1020008

Guteša Božo M, Valera-Medina A. Comparative Analysis of Gasification and Adiabatic Digestion of Corn for Practical Implementation in Conventional Gas Turbines. Gases. 2021; 1(2):92-105. https://doi.org/10.3390/gases1020008

Chicago/Turabian StyleGuteša Božo, Milana, and Agustin Valera-Medina. 2021. "Comparative Analysis of Gasification and Adiabatic Digestion of Corn for Practical Implementation in Conventional Gas Turbines" Gases 1, no. 2: 92-105. https://doi.org/10.3390/gases1020008

APA StyleGuteša Božo, M., & Valera-Medina, A. (2021). Comparative Analysis of Gasification and Adiabatic Digestion of Corn for Practical Implementation in Conventional Gas Turbines. Gases, 1(2), 92-105. https://doi.org/10.3390/gases1020008