Experimental Study on the Effect of Convective Drying of Potato Slices with Sequentially Reducing Temperature †

Abstract

:1. Introduction

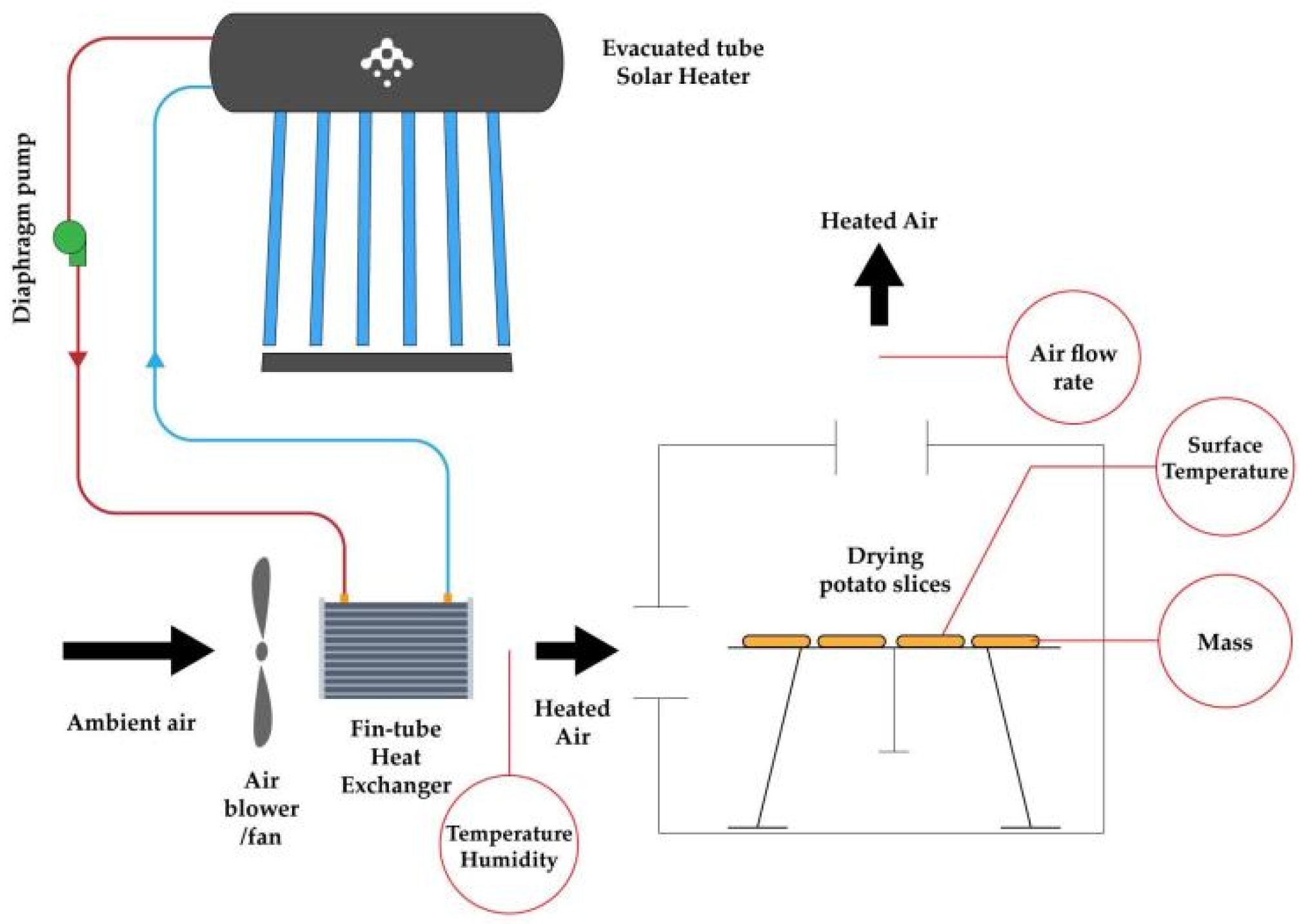

2. Methodology

3. Theoretical Model

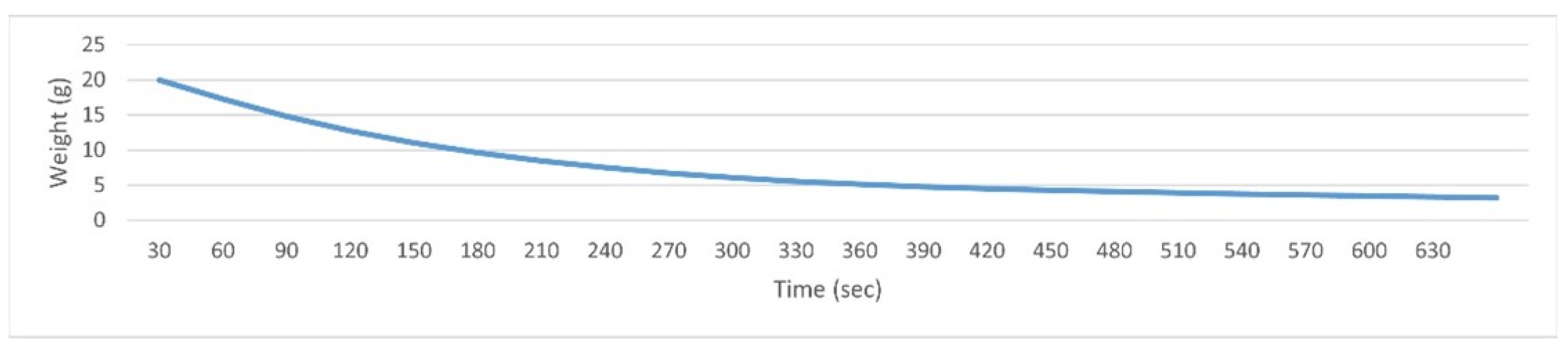

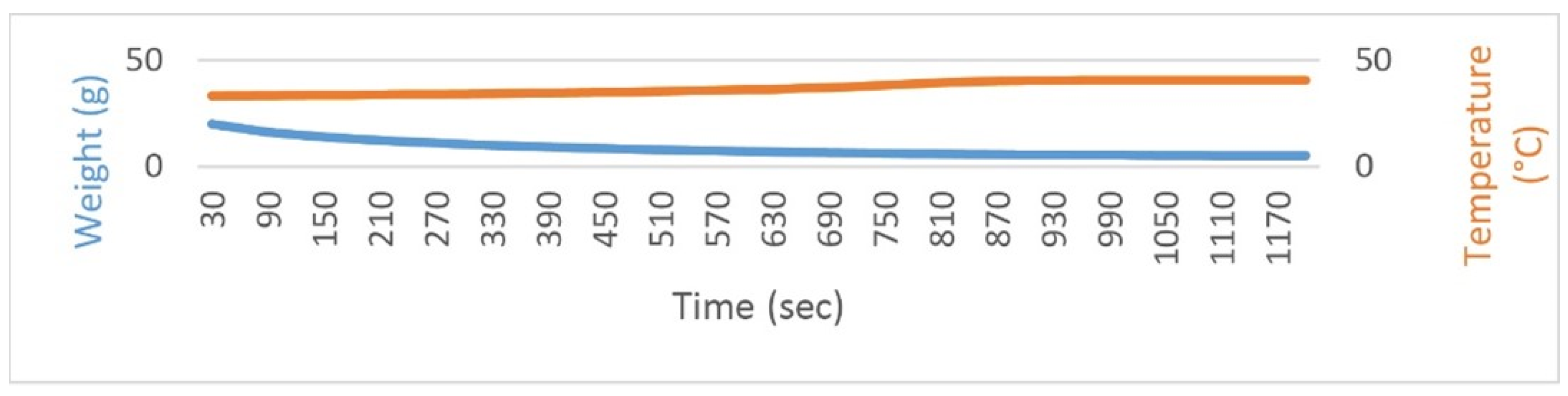

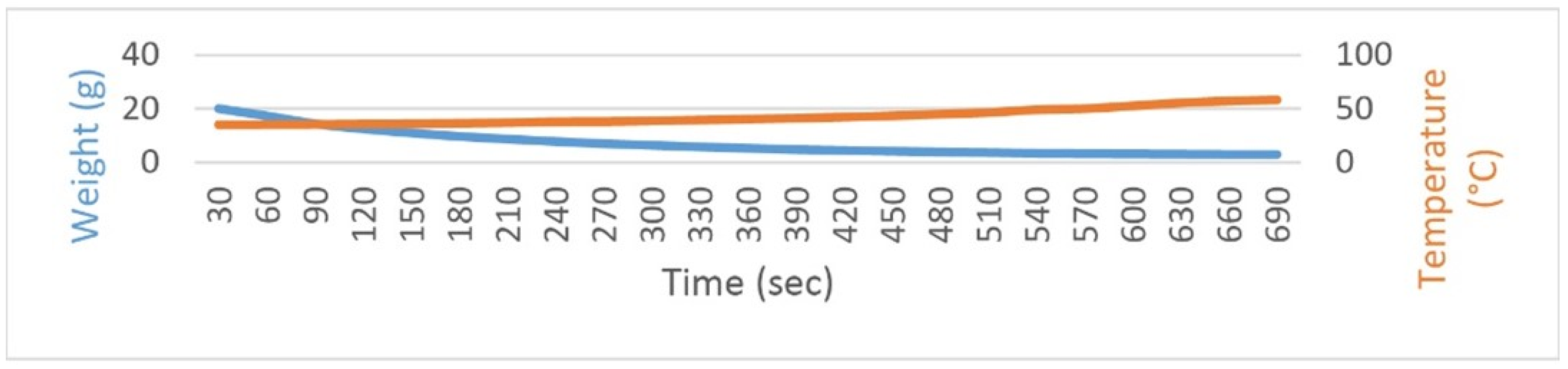

4. Results

5. Conclusions

5.1. Drying Rate

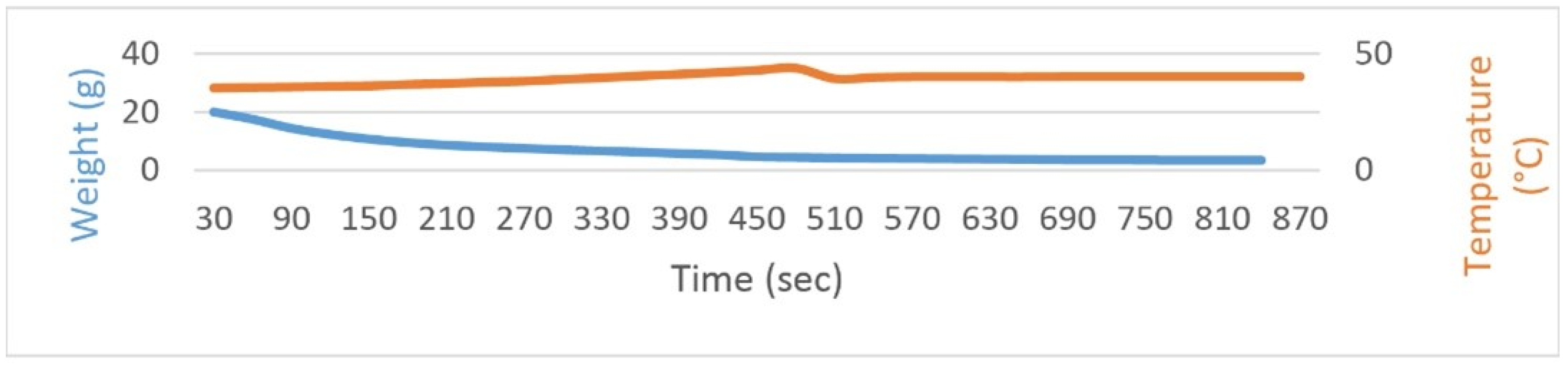

- The drying rate was found to observe an exponential decay for all experiments. This is due to the rate of evaporation at the surface being higher towards the beginning and reducing over time. The moisture that is removed further through the drying process is located further away from the surface.

- For step-reduction of temperature done in Experiment—3, it was found that the slope of the drying rate reduces on each temperature reduction step.

5.2. Surface Temperature

- The surface temperature was found to exponentially converge to the temperature of the hot air. This is because the moisture at the surface acts as a phase-change coolant that depletes over time. Thus, the rate of evaporative cooling at the surface approaches zero as the drying process continues.

- For Experiment—3, the temperature curve was identical to that obtained with constant temperature drying at 60 °C for the first 210 seconds. The slope of the curve reduced to zero as the temperature change became linear after the first step-reduction. The second step-reduction caused a sudden drop in temperature following which it approached and stagnated at 40 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Samykano, M. Progress in one-dimensional nanostructures. Mater. Charact. 2021, 179, 111373. [Google Scholar] [CrossRef]

- Giri, S.K.; Prasad, S. Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms. J. Food Eng. 2007, 78, 512–521. [Google Scholar] [CrossRef]

- Asnaz, M.S.K.; Dolcek, A.O. Comparative performance study of different types of solar dryers towards sustainable agriculture. Energy Rep. 2021, 7, 6107–6118. [Google Scholar] [CrossRef]

- Tulej, W.; Głowacki, S. Modeling of the Drying Process of Apple Pomace. Appl. Sci. 2022, 12, 1434. [Google Scholar] [CrossRef]

- Hasan, M.U.; Malik, A.U.; Ali, S.; Imtiaz, A.; Munir, A.; Amjad, W.; Anwar, R. Modern drying techniques in fruits and vegetables to overcome postharvest losses: A review. J. Food Process. Preserv. 2019, 43, e14280. [Google Scholar] [CrossRef]

- Semai, H.; Bouhdjar, A.; Amari, A. An improved protocol for natural convective drying of pumpkin. Food Feed. Res. 2021, 48, 29–39. [Google Scholar] [CrossRef]

| No. | Inlet Temperature (°C) | Air Speed (m/s) | Initial Mass (g) | Final Mass (g) | Drying Time (min) | Color Retention (%) |

|---|---|---|---|---|---|---|

| 1 | 40 | 1 | 20 | 5.1 | 33 | 44.9 |

| 2 | 60 | 1 | 20 | 3.9 | 21 | 41.2 |

| 3 | 60–50–40 | 1 | 20 | 4.6 | 26 | 61.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Usama, M.; Hayyat, M.K.; Ahmed, A.; Ali, M.; Ali, Z.; Iqbal, A. Experimental Study on the Effect of Convective Drying of Potato Slices with Sequentially Reducing Temperature. Environ. Sci. Proc. 2022, 23, 10. https://doi.org/10.3390/environsciproc2022023010

Usama M, Hayyat MK, Ahmed A, Ali M, Ali Z, Iqbal A. Experimental Study on the Effect of Convective Drying of Potato Slices with Sequentially Reducing Temperature. Environmental Sciences Proceedings. 2022; 23(1):10. https://doi.org/10.3390/environsciproc2022023010

Chicago/Turabian StyleUsama, Muhammad, Muhammad Khizar Hayyat, Ammar Ahmed, Muhammad Ali, Zaib Ali, and Aashir Iqbal. 2022. "Experimental Study on the Effect of Convective Drying of Potato Slices with Sequentially Reducing Temperature" Environmental Sciences Proceedings 23, no. 1: 10. https://doi.org/10.3390/environsciproc2022023010

APA StyleUsama, M., Hayyat, M. K., Ahmed, A., Ali, M., Ali, Z., & Iqbal, A. (2022). Experimental Study on the Effect of Convective Drying of Potato Slices with Sequentially Reducing Temperature. Environmental Sciences Proceedings, 23(1), 10. https://doi.org/10.3390/environsciproc2022023010