1. Introduction

The phenomenon of evaporative cooling can be either used for cooling air or rejecting heat from processes, such as in chillers’ evaporative condensers and cooling towers. Compared to air-cooled condenser units, evaporative condensers and cooling towers can entrain large energy savings, but entail water consumption and the risk of Legionella disease. Adiabatic condensers, based on the use of evaporative cooling to precool the air before the condensing coils, can improve the energy efficiency of the chiller with less water consumption [

1]. Because the power generation also yields water consumption, better energy efficiencies of the system also indirectly imply a reduction in water consumption. This work is intended to evaluate the hypothesis that the use of adiabatic condensers versus air-cooled condensers may result in global water savings of chillers in certain climatic zones.

2. Materials and Methods

It is first necessary to gather information about different overall electricity mixes in the target countries, with which the water consumption associated with electricity generation has been estimated. Then, the chiller energy efficiency ratio (EER) is related to the condensing temperature, which enables the estimation of the electric energy consumption in terms of the climate conditions. The actual global water consumption is finally calculated through both the direct water use and the water derived from the generation of the electricity consumed. Eventually, the present document provides results of the case study.

Adiabatic condensers and air-cooled condensers were chosen because of their similarities. In essence, in adiabatic condensers, heat is removed into the environment by heat gain of the air flowing over the condenser, the same way as in air-cooled condensers. The only difference is that air gets pre-cooled before coming into contact with the condenser coils, almost reaching its wet bulb temperature.

Other types of devices, such as cooling towers or evaporative condensers, are not included in this work. Although they can be more efficient in energy consumption terms, their water consumption is higher and they imply larger risk of developing Legionella because of their high working temperatures.

Global water consumption in an adiabatic condenser includes both the direct consumption due to the humidification of the air through the adiabatic cooling pad previous to the condenser, and the indirect consumption of water in the generation of the power required to operate the chiller. To determine this second term, it is necessary to know the electricity mix of each country in Europe, as water consumption in electricity generation differs between different technologies.

3. Results and Discussion

3.1. European Electric Mix

To determine the indirect water consumption due to the electricity consumption, the electric mix from every European country has been collected [

2], noting that there are substantial disparities between countries that will have an impact on their indirect water consumption.

3.2. EER Evolution according to Condensing Temperature

One of the first steps is to relate the energy efficiency ratio (EER) of the chiller to the condensing temperature, which depends on the environmental temperature. This justifies the interest in reducing the condensing temperatures of the air-cooled condenser through adiabatic cooling of the air.

3.3. Indirect Water Consumption Due to Electricity Consumption

The published literature shows significant differences both in the methodology to obtain data and in the assumptions made about each generation technology [

3,

4,

5,

6,

7]. Moreover, this is a relatively unexplored field with scarce information available.

The gathering of reliable data about water consumption in every single power plant around the continent is a vast work, so some assumptions and approximations must be set. In summary, the values given in

Table 1 were determined [

3,

4,

5,

6,

7]:

For thermal power plants, it is assumed that they are located in river basins and their refrigeration systems are closed-loop. Other alternative power sources were disregarded in this study. We also did not take into account any specific countries’ legislation.

Energy transition to low-carbon power generation may result in an increase or decrease in indirect water consumption. It will depend on whether hydroelectric and biomass sources, which involve great consumption, are developed along with other renewable sources.

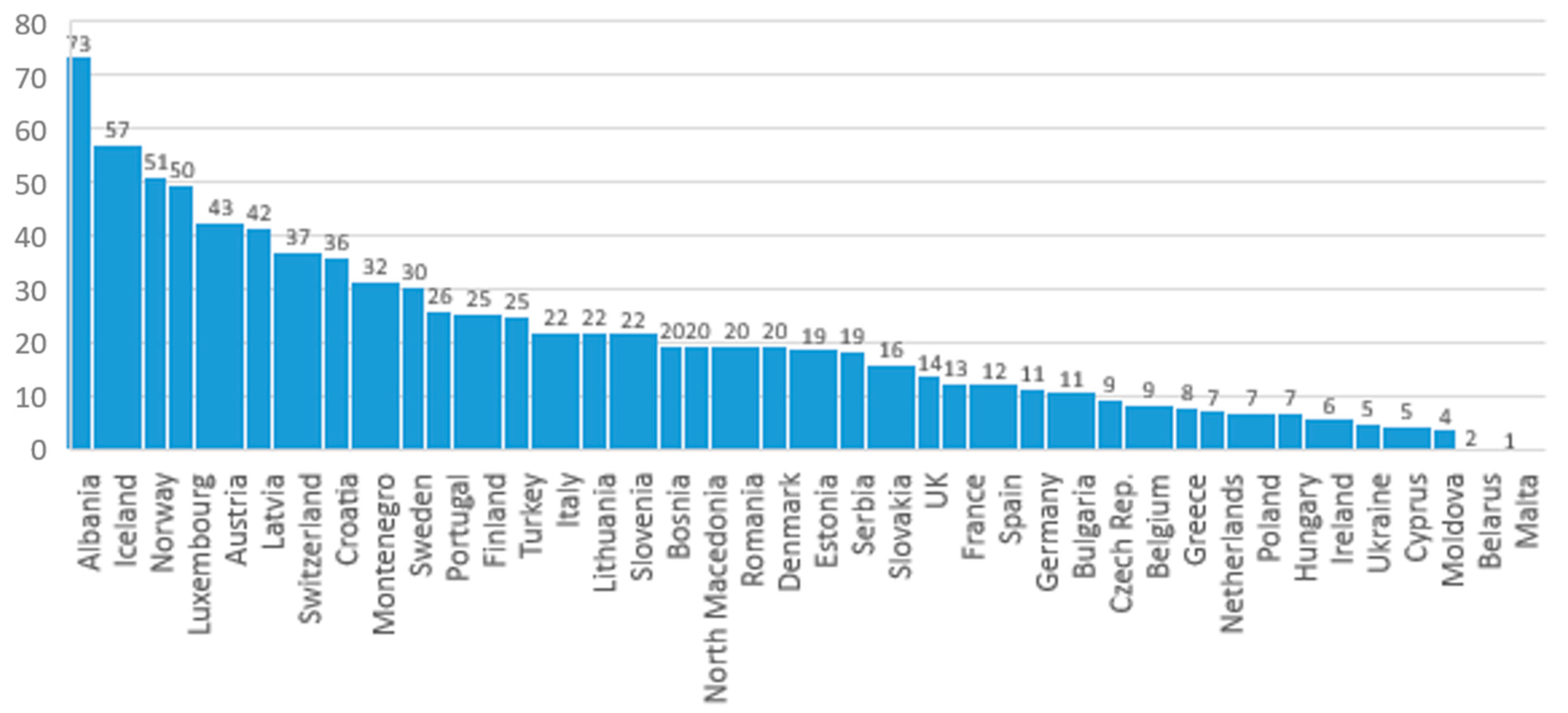

In countries whose electric mix is dominated by thermal power plants, water consumption in power generation is quite low. On the other hand, countries with a strong hydroelectric or with a significant biomass share have a much larger water consumption. That is to be found in mountainous countries such as Norway, Albania, Iceland or Switzerland (

Figure 1).

3.4. Case Study

In order to illustrate the comparison of the global water consumption in adiabatic condensers and air-cooled condensers, a particular case was studied. The facility consists of six air-cooled condensers with a total cooling power of 8400 kW. The air-cooled condensers are equipped with a structure to put evaporative cooling pads at the air inlet, to increase their energy efficiency. For a preliminary study, it is considered that during the summer season (from May to September), load varies between 50% and 75%. The EER is improved through the adiabatic precooling of air as given in

Table 2 [

1].

The predicted electric power consumed was calculated for each period, through the expression (1):

Water consumption in energy generation varies widely according to the electric mix. In this particular case in Spain, with the assumptions made, it can be estimated at 13 L/kWh. This yields 34,696 m3 and 26,553 m3 of water consumed indirectly by the air-cooled condenser and the adiabatic condenser, respectively, the former 8143 m3 being higher than that of the adiabatic condenser in the same summer conditions.

Direct consumption refers to the on-site water use, which is zero in air-cooled condensers and relatively high in adiabatic condensers [

8]. It can be calculated with the following expression (2):

where

is the inlet mass flow of air and Δx is the specific humidity increase at the outlet of the evaporative cooling pads.

First, dry bulb temperature (DBT) and relative humidity (RH) were calculated for each period by taking the average of the twelve warmest hours of each day in the city. Then, assuming an ideal adiabatic humidification efficiency that reaches the wet bulb temperature (WBT), the final conditions were obtained. Initial and final temperature and relative and specific humidity conditions are shown in

Table 3.

From this data, the predicted direct water consumption with an evaporative pad during a summer season is 16,341 m3. Comparing this value with the previously calculated indirect consumption, the seasonal global water consumption would be 8198 m3 higher than with the air-cooled condensers.

4. Conclusions

Global water consumption differs greatly from country to country according to their climate and mix. This is due to the fact that electric mix varies largely among countries, and also because the EER of the chillers is heavily reliant on temperature. The present preliminary study predicts that global consumption can be generally higher in adiabatic condensers, but in some specific circumstances of air temperature or electric mix, it may be higher in air-cooled condensers. Possible larger electricity consumption in air-cooled condensers, particularly at high temperatures, implies additional water use in power generation systems. Harsher climate conditions imply less indirect water consumption in adiabatic rather than air-cooled condensers, but also more direct water consumption. For this case study in Spain, global water consumption with adiabatic condensers was only 24% higher than with air-cooled condensers. Countries with a high dependence on hydroelectricity or biomass energy and located in hot climates, such as Albania and Turkey, could show higher global water consumption with air-cooled condensers. An increase in temperature due to climate change may have a negative influence in the EER of the chillers, especially affecting air-cooled condensers.

Author Contributions

Conceptualization, A.T.-G.; methodology, A.T.-G. and J.I.-R.; investigation and formal analysis, J.I.-R. and M.A.-C.; data curation, J.I.-R.; writing—original draft preparation, J.I.-R.; writing—review and editing, A.T.-G. and M.A.-C.; visualization, J.I.-R.; supervision, A.T.-G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Martínez, F.J.R.; Alonso, J.F.S.J.; Gómez, E.V.; González, A.T.; Esquivias, P.M.; Hernández, J.M.R. Energy consumption reduction of a chiller plant by adding evaporative pads to decrease condensation temperature. Energies 2020, 13, 2218. [Google Scholar] [CrossRef]

- International Energy Agency. Countries and Regions—IEA. Available online: https://www.iea.org/countries (accessed on 22 April 2022).

- Pistochini, T.; Modera, M. Water-use efficiency for alternative cooling technologies in arid climates. Energy Build. 2011, 43, 631–638. [Google Scholar] [CrossRef]

- Krarti, M.; Aldubyan, M. Mitigation analysis of water consumption for power generation and air conditioning of residential buildings: Case study of Saudi Arabia. Appl. Energy 2021, 290, 116767. [Google Scholar] [CrossRef]

- Torcellini, P.; Long, N.; Judkoff, R. Consumptive Water Use for U.S. Power Production. 2003. Available online: http://www.osti.gov/bridge (accessed on 29 August 2022).

- Macknick, J.; Newmark, R.; Heath, G.; Hallett, K.C. Operational water consumption and withdrawal factors for electricity generating technologies: A review of existing literature. Environ. Res. Lett. 2012, 7, 045802. [Google Scholar] [CrossRef]

- Jin, Y.; Behrens, P.; Tukker, A.; Scherer, L. Water use of electricity technologies: A global meta-analysis. Renew. Sustain. Energy Rev. 2019, 115, 109391. [Google Scholar] [CrossRef]

- Sohani, A.; Sayyaadi, H. Thermal comfort based resources consumption and economic analysis of a two-stage direct-indirect evaporative cooler with diverse water to electricity tariff conditions. Energy Convers. Manag. 2018, 172, 248–264. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).