1. Introduction

NorDan AB in Sweden is one of the leading window and door manufacturers in the Swedish building industry. The company has 350 employees, with three factories and five sales offices. It is a subsidiary of the NorDan Group, a family-owned company based in Norway with operations in 10 countries.

Since 2018, NorDan AB in Sweden (hereinafter NorDan) has worked on a holistic strategy focusing on sustainability, quality management and profitable growth. On the sustainability agenda, the company committed itself to working on the UN Sustainable Development Goals (hereinafter SDGs). It selected 7 of the 17 goals based on relevance to NorDan. Goal 8 and Goal 11 to address local values, Goal 3 and Goal 5 to focus on people, Goal 9 and Goal 12 to reduce consumption of resources as well as Goal 17 to involve customers and stakeholders in this important work. Throughout, NorDan has maintained a very practical and pragmatic approach toward sustainable development, focusing on improvements, innovations and working methods that make a positive contribution to a more sustainable company and product offering. It has also been driven by the wish to be at the forefront of sustainability developments within the Scandinavian building industry, and in many ways, to be a leading company within this area.

This paper discusses the strategic and operational approach that NorDan has taken to sustainability and how this, in a genuine and credible way, has given NorDan a clear sustainability profile. First, this paper presents how the strategic approach, including the SDGs, has helped NorDan become more sustainable. Second, NorDan’s approach to business excellence is described and how the SIQ Management Model has provided a useful framework for the company’s sustainability journey. Third, NorDan’s innovations in additive manufacturing and its connections to the SDGs are presented. The paper ends with some general takeaways from NorDan’s sustainability journey so far and reflections on future developments.

2. Strategic Approach to Sustainability

NorDan was first introduced to the concept of “Sustainability” by the company’s largest customer, NCC Construction Sweden AB (hereinafter NCC), at NCC’s sustainability supplier conference in April 2015. Here, NCC’s approach to sustainability was explained, together with a set of expectations for its supplier. As part of the presentation, sustainability was defined and presented to the participating suppliers, with reference to the Our Common Future report from 1987 by the World Commission on Environment and Development [

1] and the three pillars of sustainability: social, economic and environmental [

2,

3]. NCC was very clear on its strategic approach to sustainability and how it relied on suppliers to establish transparent supply chains and contribute to NCC’s goals for more sustainable buildings and cities. As a strategic supplier to NCC, NorDan started exploring theories, models and approaches to sustainability and how it was different and broader than the company’s current focus on the environment and its current systems for health, safety and environment (HSE).

In September 2015, the 17 Sustainable Development Goals (SDGs) were set by the international community as part of the UN 2030 Agenda for Sustainable Development [

4]. The Swedish government, with PM Stefan Löfven, took an active approach to embrace and support the SDGs [

5] and showed a clear determination to get companies involved and accountable [

6]. In 2016, the Swedish Government enacted a new law that made it mandatory for companies with more than 250 employees, from the fiscal year 2017, to publish a sustainability and equality report, either separately or as part of the annual financial report [

7]. This development was also related to the global reporting initiative (hereinafter GRI) that, in 2016, provided the first global standards for sustainability reporting, the GRI Standards [

8].

NorDan was inspired by the clear trend among customers to focus on sustainability as well as the strong political agenda for sustainability in Sweden. During the autumn of 2016, the management team started preparing NorDan´s first sustainability and equality report in accordance with the new regulations. In many areas of sustainability, NorDan already had good practices and working routines and systems due to the company’s historical development and product offering, as well as a clearly documented quality management system based on ISO 9001 [

9] and environmental management system based on ISO 14001 [

10]. Furthermore, the company had worked for more than 5 years with lean production [

11] through the company’s “NorDan Production System”. The analysis and documentation of the first sustainability and equality report made it clear to the management team of NorDan that whereas the environmental and economic pillars of sustainability were covered in a good way, the social pillar was rather weak.

In 2017, NorDan became a member of The Swedish Institute for Quality (hereinafter SIQ), the leading national centre for business excellence in Sweden [

12]. At that time, SIQ had conducted a major update and revision of its excellence model, the SIQ Management Model, and NorDan accepted the invitation to be one out of five pilot companies to test the new model [

13]. The most significant update to the model was that sustainability, with its three pillars, was fully incorporated. The self-assessment by the NorDan management team towards the criteria of the SIQ Management Model, as well as feedback from SIQ’s auditing team, revealed that the main improvement areas for NorDan were social sustainability, digitalisation and innovation.

During the autumn of 2017, NorDan decided to build on the valuable input from customers, government and SIQ about the main improvement areas. Hence, NorDan embarked on a journey to become excellent in all three pillars of sustainability and be one of the leading companies in the Scandinavian building industry in sustainability and digitalisation. In 2018, NorDan introduced a new company strategy with three main elements: (1) sustainability, (2) quality management and (3) profitable growth. It also launched the ecoDigital ready™ initiative at Nordbygg 2018, the bi-annual trade show in the Swedish building industry. ecoDigital ready™ highlighted the company’s commitment to sustainability and digitalisation, with a clear outline of activities and customer promises.

The focus of NorDan was to change the way the company worked to truly become more sustainable and digitally mature, and to be at the forefront of these developments within the Scandinavian building industry. The management team also realised that the changes needed to be visible, both internally to employees and externally to customers, suppliers and other stakeholders. A lot of planning work was conducted to map the current strengths in order to capitalise on these moving forward and to identify additional improvements, innovations and changes necessary. Out of this strategic planning process, a range of development areas were identified and initiated, including:

Organise with a clear focus on sustainability and digitalisation;

Explore opportunities within additive manufacturing and modern materials;

Look at sponsorship opportunities with a clear social responsibility profile;

Evaluate potential of new business models in a circular economy;

Deliver digital solutions to the customers and the market;

Increase digital maturity level in all key processes;

Communicate the strategy and achievements to the market;

Reduce CO2 footprint of operations.

NorDan did not set a specific goal for CO

2 reduction at this early stage in the strategy. Instead, it realised that it was important to link the strategy and the many initiatives to the SDGs. The management team selected 7 out of the 17 goals that were most relevant to the business idea of NorDan: Goal 8 (Decent Work and Economic Growth) and Goal 11 (Sustainable Cities and Communities) under the heading “Local values”, Goal 3 (Good Health and Well-Being) and Goal 5 (Gender Equality) under the heading “People” and Goal 9 (Industry, Innovation and Infrastructure) and Goal 12 (Responsible Consumption and Production) under the heading “Reduce consumption of resources”. The company also decided on Goal 17 (Partnerships for the Goals) to actively involve suppliers, customers, universities and industry networks to enhance developments and innovations. The company posted the commitment to work on the SDGs on its homepage [

14] and made reference to the SDGs in internal and external communication.

Over the years, NorDan has been committed to this practical and pragmatic approach toward sustainable development, focusing on projects that make a positive contribution to a more sustainable company and product offering. Examples of successful projects and initiatives are:

Introducing 3D printed windows in bio-composite materials;

Launching advanced environmental product declarations;

Becoming a sustainability partner to Save the Children, Sweden;

Developing a solution for recycling used windows and doors;

Publishing numerous Building Information Modelling (BIM) models of products and developing a solution for the digital generation of quotations;

Sourcing green electricity;

Launching a digital showroom, including presentation of the SDGs;

Installing solar-PV plants at all three factories in Sweden.

As the company prepares for the strategic period 2022–2024, it continues its focus on sustainability and the SDGs. Social, economic and environmental sustainability can always be improved and further developed. Three main work areas that the management team has identified for the next years are: (1) achieve carbon neutrality by 2025, (2) maintain a strong sustainability profile within the Scandinavian building industry and (3) continue to embrace, learn from and adopt new developments within sustainability and digitalisation in an agile way.

3. Business Excellence Models

Interestingly, both the Our Common Future report by the World Commission on Environment and Development [

1] and the Malcolm Baldrige National Quality Award [

15] were introduced in 1987. The Baldrige Award, based on the Baldrige Excellence Framework, was the first business excellence model and national quality award in the western world, and it was inspired by the Japanese Deming Price ([

16], pp. 70–71). In Europe, the EFQM Excellence Award, based on the EFQM Excellence Model, and the Swedish Quality Award, based on the SIQ Management Model, were both introduced in 1992, and from then on, many other countries have launched their own business excellence models and quality awards [

17].

Business excellence models are commonly regarded, in both industry and academia, as holistic and advanced management models that develop in accordance with leading management theory and can be applied by organisations across all industries and sectors ([

16], pp. 99–124, [

18,

19]). The purpose of these excellence models and the quality awards are twofold: (1) to provide a framework and model for business excellence that companies can use for self-assessment and (2) to recognise excellent organisations at a national level and share best practices [

20]. Analysing these business excellence models in the mid-1990s, the author of this paper found that it was possible to extract eight common criteria across the different national quality award models at that time: (1) Leadership, (2) Impact on Society, (3) Information and Analysis, (4) Strategic Planning, (5) Human Resource Management, (6) Processes, (7) Customer Focus and (8) Business Results [

21]. From a sustainability point of view, it can be interpreted that social and environmental sustainability are parts of “Impact on Society”, whereas economic sustainability is covered in “Business Results”. However, no clear reference was made in these excellence models to sustainability, as defined in the Our Common Future report from 1987, nor the three pillars of sustainability.

From 2015 to 2017, SIQ worked on a major revision of the Swedish business excellence model. One of the most notable changes was the integration of all three pillars of sustainability—social, economic and environmental. With the publication of the updated SIQ Management Model in 2018, sustainability is clearly visible in the results criteria and also in the working methods [

13],

Figure 1. The SIQ Management Model gives a detailed description of the criteria and sub-criteria in the model, including what is expected of excellent organisations. Organisations applying the model must complete a self-assessment with regards to current approaches in all criteria and also describe how it continuously improves, learns and develops within these criteria. This means that companies working with the SIQ Management Model actively address all three pillars of sustainability and develop these through continuous improvements and innovations. As part of the revised SIQ Management Model, the Swedish Quality Award logotype was also updated with a new headline, namely “Sustainable Success”.

For the management team at NorDan, it has been very important to use the SIQ Management Model as a framework to assess the current sustainability status, identify areas for improvement, and develop in a systematic and sustainable way. The SIQ Management Model has directed NorDan to the areas within sustainability where it already has systematic working methods and achieves good results, but also to areas where it needs to improve and develop. It has also been important to understand that in order to improve the result criteria of the SIQ Management Model, the company needs to focus more on the working methods by carrying out improvement projects and innovations.

4. Innovations in Additive Manufacturing

NorDan has gained significant international attention and recognition for its pioneering efforts in 3D printing, in which the company—in good cooperation with key suppliers—developed a production technique, material solution, product documentation and marketing concept for commercial sales of 3D printed windows in bio-composite materials. The product was launched in the Scandinavian market in October 2019 as the world’s first 3D printed window for commercial sales [

22].

The 3D printer project was one of the first large projects that NorDan initiated in the autumn of 2017 when it decided to become one of the leading companies in the Scandinavian building industry in the areas of sustainability and digitalisation. From the very start, the 3D printer project was driven by a clear overall goal, i.e., to be the first company in the world to start sales of 3D printed windows.

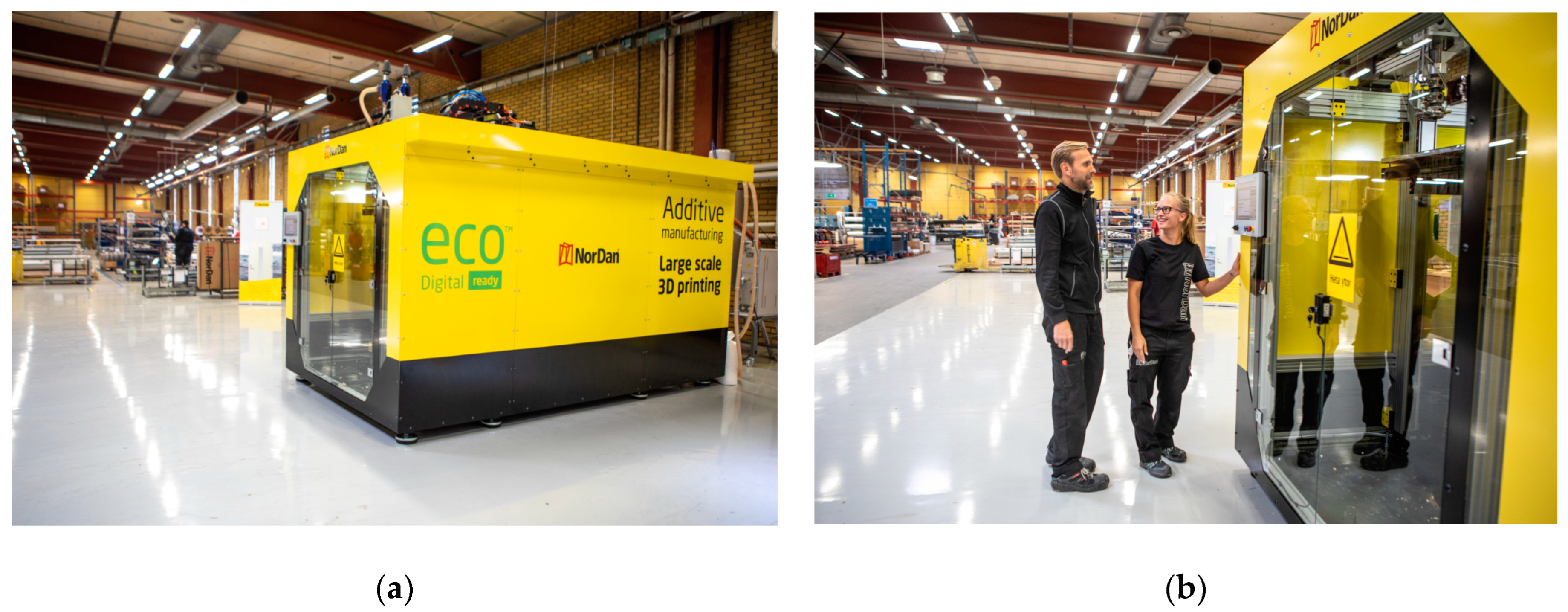

When searching for manufacturers of 3D printers—large enough to print full-sized windows and doors for NorDan—the options were very few in 2017. After some months, NorDan got in touch with a Swedish start-up company with interesting prototype technology for large 3D printers. The company, BLB Industries AB, designed a unique large-scale 3D printer for NorDan, which could print windows and doors up to 1.5 m in width and 2.5 m in height. NorDan decided to make the investment, and the 3D printer was delivered in 2018 (

Figure 2). The 3D printer uses granular materials for printing, which is much more affordable and industrially viable for large-scale commercial 3D printing compared to expensive filament material.

During the innovation project, NorDan explored many options for printing materials, which included the likes of acrylonitrile butadiene styrene (ABS) and polypropylene (PP). If NorDan had decided to continue with those readily available materials in the market, the project would have been completed much earlier. However, NorDan’s focus on sustainability directed the innovation project to focus on finding the most sustainable material possible so that the 3D-printed windows would contribute to the SDGs (in particular Goal 9 and Goal 12) and remain in alignment with the other products in NorDan’s timber range. Because of this, the company decided to work with Stora Enso for material testing and development of a bio-composite granular material (

Figure 3), aiming to achieve a high wood content and excellent recycling properties. Stora Enso’s competence centre and factory for bio-composites are located in Smaaland, Sweden, in the same region as NorDan’s factory for entrance doors and BLB Industries. A unique innovation project cooperation between NorDan, BLB Industries and Stora Enso was established, and Goal 17 (Partnerships for the Goals) was clearly evident throughout the project.

To ensure that the performance of the 3D printed windows in a building façade was maintained, product tests were performed at the Research Institutes of Sweden (RISE), using the same testing parameters as practised with traditionally manufactured windows in timber. The test results were very good, and the 3D printed windows were granted approval. The first products to be 3D printed were shaped windows (e.g., circular and half-circular), as these are amongst the most expensive and difficult to produce within the window industry. NorDan’s innovation in 3D printing had very visible success in terms of digitalisation (additive manufacturing), sustainability (material and recycling properties) and effectiveness (reduced lead times, cycle times and costs).

NorDan has received much media attention and has been awarded international prices for 3D-printed windows in bio-composites, including the Quality Innovation Award 2019 [

24], the Quality Sustainability Award 2020 [

25] and the Most Sustainable Product 2020 on BIMobject. The company continues to explore the possibilities within additive manufacturing and the application of bio-composite materials. It is currently working on the high-volume production of profiles for windows and doors in bio-composites, including the use of recycled plastics in the composite fraction. In addition, additive manufacturing has the potential to enable flexible production closer to the end-market and construction sites. Furthermore, given that the technology is based on additive manufacturing using bio-composite material, it opens for sustainable production of many kinds of products within the building industry and beyond. Recently NorDan has been invited to deliver 3D printed windows and doors to the first 3D printed house in Sweden [

26].

5. Lead by Example and Dare to Share

Very often, it is the large enterprises within an industry that have the resources, initiatives and strategies in place to credibly claim they are working with sustainability in a strategic way and make a positive impact. NorDan is a small and medium-sized enterprise (SME) with 350 employees, which normally should not have a big impact nor get any attention. However, NorDan decided early to “lead by example” and to “dare to share” in the area of sustainability. It is also how the management of NorDan has understood the UN’s work on the SDGs, Agenda 2030 and carbon neutrality by 2050, namely that everyone can and must contribute at a national, regional and local level for the joint efforts of nations, governments, businesses and individuals to be successful [

27].

The strategic focus on sustainability by NorDan has made the company better and more mindful. With the many successfully completed projects within sustainability, NorDan has, for some time, been able to communicate its work on sustainability and the SDGs in a credible way to the market. Some examples are 3D printed products in modern biomaterial, solar PV plants at factories, sustainability partner for Save the Children Sweden and reduced CO2 footprint. This credibility is very important and works in a self-enforcing loop as more projects are added and new levels of development within sustainability are reached. It also gives NorDan a competitive advantage in the market, as the company is regarded to be working very well with sustainability. NorDan applies both standard project methods and more agile ways of working to achieve improvements and innovations, depending on the nature of the project and the complexity.

Customers, suppliers and other stakeholders frequently give positive feedback to NorDan about its progress in, and focus on, sustainability. The company views this as good recognition of the work done so far and also as an inspiration to continue on the sustainability journey. In May 2021, the Swedish Federation of Wood and Furniture Industry—Trä- och Möbelföretagen (TMF), put sustainable development on the agenda when it published a guideline document for all members [

28]. TMF is the national trade and employers’ association of the wood processing and furniture industry in Sweden, representing some 700 member companies and more than 30,000 employees. This development is welcomed by NorDan and shows that the Swedish building industry is starting to join forces to make progress towards a circular and sustainable building industry.

Management representatives from NorDan have also actively taken board member positions in industry networks which focus on one or more sustainability aspects both within the building industry and across industries. In this way, the company is involved in development trends and can directly enhance sustainability topics and put them on the agenda. NorDan is also working actively with academia and research institutions. In 2021, the company is involved in two large applications for funding research projects on sustainable development together with leading Swedish universities. The progress of NorDan within sustainability has also inspired other NorDan subsidiaries to work on the SDGs, and the

ecoDigital ready™ initiative has been adopted by all subsidiaries [

29].

Overall, the development within NorDan described above is very much in line with the reasoning and developments described within “Quality 5.0” [

30], where the purpose of organisations is firstly to focus on customers and stakeholders but also at the same time support development and societal satisfaction and contribution.

6. Conclusions

Over the last five years, NorDan has worked actively with sustainability at a strategic and operational level. The company has focused on the UN SDGs and on running improvement projects to enhance sustainable development in a pragmatic, collaborative and project-driven way. It discovered the advantages of linking sustainability and digitalisation in some areas and how these two mega trends complement each other well. Furthermore, in order to change quickly enough and make breakthrough improvements, it is necessary to also focus on innovations and work in agile ways.

The SDGs and the SIQ Management Model have been very helpful for NorDan in its sustainable development journey so far. The SIQ Management Model fully incorporates all three pillars of sustainability and offers organisations a strong and practical framework to assess current status in sustainability, identify areas for improvement and develop in a systematic and sustainable way. More research and work should be directed into how business excellence models around the world can more clearly encompass sustainability and the three pillars of sustainability, thereby supporting more organisations on their sustainable development journey.

The work on sustainability by NorDan has already changed the company for the better and reduced its CO2 footprint. Furthermore, it has formed the basis and inspiration for continued work on sustainability and the SDGs in the years to come.