Long-Term Monitoring Strategies for Increasing EPCs Reliability †

Abstract

:1. Introduction

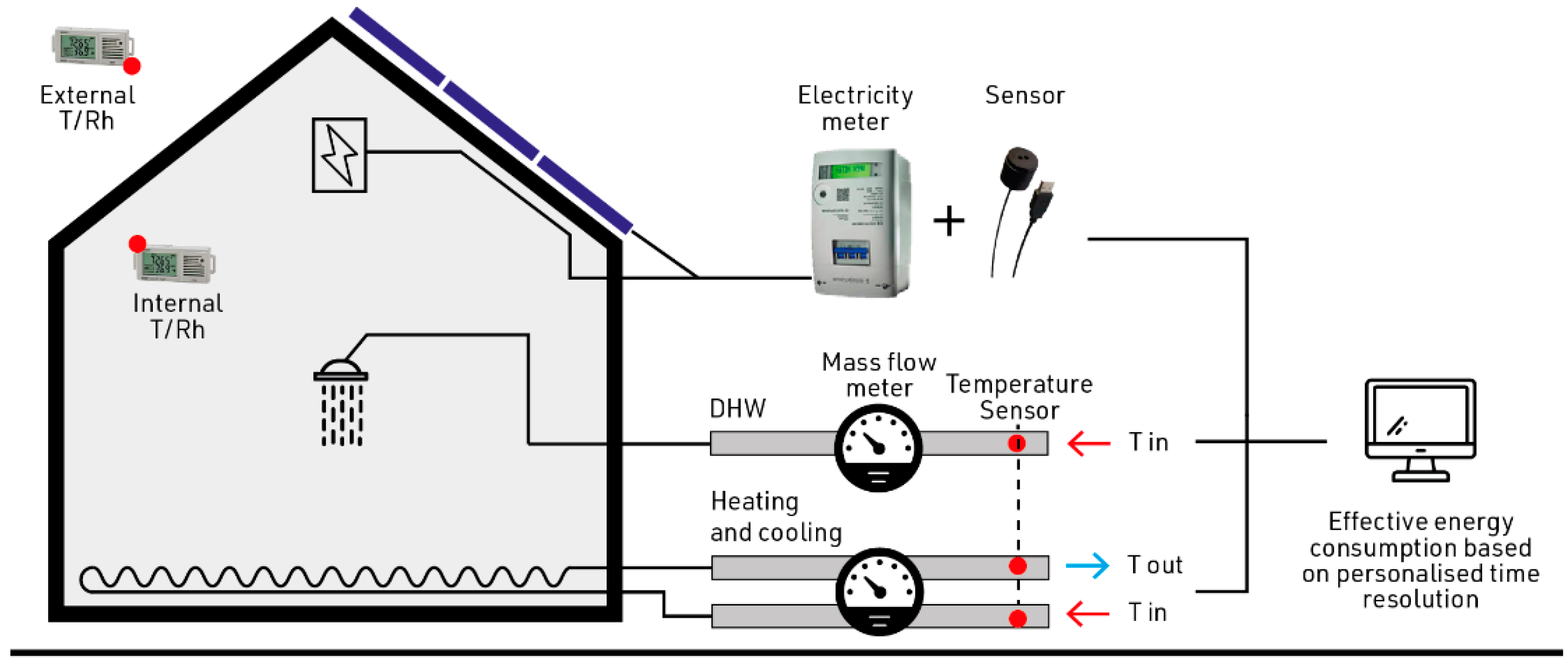

2. Materials and Methods

Monitoring Methods

- Utility meter monitoring, based on the measurement of the energy flow delivered to the building, collected either manually or via utility meters (e.g., gas or electricity);

- Sub-metering, used for centralized energy production systems: the energy flow absorbed for each dwelling must be gathered through dedicated sub-metering systems.

- Planning (i.e., set the monitoring goals, collect building data, identify boundaries and suitable sensors and data acquisition systems);

- Installation (i.e., assessment of the technical feasibility, and final plan and implementation);

- Operation (i.e., data quality check, data post-processing, and reporting).

- Spot measurement (up to one day of operation), to instantaneously detect the value of a metric or to quickly check the functioning of a subsystem;

- Short-time measurement (usually a week or month-based), to check the profile of metrics that vary with time;

- Long-time measurement (more than one year), to assess metrics that are influenced by variations in weather, occupants’ behavior, or other operating conditions.

- Measurement of energy consumption, using, for example, building meters, sub-metering, and plug-load measurements;

- Measurement of occupants’ comfort and activity, using temperature, occupancy, humidity, CO2, and air quality.

3. Monitoring Approach and Scenarios

3.1. Primary Energy Calculation Method

3.2. Application of the Approach on a Case Study (Lecco, IT)

4. Discussion and Conclusions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Directive 2002/91/CE of the European Parliament and of the Council of 16 December 2002 on the energy performance of buildings. Off. J. Eur. Communities 2002. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2010:153:0013:0035:EN:PDF (accessed on 24 November 2021).

- Schuitema, G.; Aravena, C.; Denny, E. The psychology of energy efficiency labels: Trust, involvement, and attitudes towards energy performance certificates in Ireland. Energy Res. Soc. Sci. 2020, 59, 101301. [Google Scholar] [CrossRef]

- Hjortling, C.; Björk, F.; Berg, M.; Klintberg, T. Energy mapping of existing building stock in Sweden—Analysis of data from Energy Performance Certificates. Energy Build. 2017, 153, 341–355. [Google Scholar] [CrossRef]

- Noussan, M. Performance indicators of District Heating Systems in Italy—Insights from a data analysis. Appl. Therm. Eng. 2018, 134, 194–202. [Google Scholar] [CrossRef]

- Hardy, A.; Glew, D. An analysis of errors in the Energy Performance certificate database. Energy Policy 2019, 129, 1168–1178. [Google Scholar] [CrossRef] [Green Version]

- Directive (eu) 2018/2002 of the European Parliament and of the Council—of 11 December 2018—Amending Directive 2012/27/EU on Energy Efficiency. 2002. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv%3AOJ.L_.2018.328.01.0210.01.ENG (accessed on 24 November 2021).

- European Commission For a Sustainable, Safer and More Competitive Europe Good Practice in Energy Efficiency Clean Energy for All Europeans. 2017. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/good_practice_in_ee_-web.pdf (accessed on 24 November 2021).

| Level of Monitoring | Energy Generation | Thermal Energy Assessment | Electrical Energy Assessment |

|---|---|---|---|

| Basic Level (BL) | Independent | Utility bills | Utility bills |

| Medium Level (ML) | Independent | Utility bills/Metering 1 | Utility bills/Metering 1 |

| Advanced Level (AL) | Only partially centralized | Metering 1 + Sub-metering | Metering 1 + Sub-metering |

| Centralized | Sub-metering | Sub-metering |

| Building Configuration | Energy Monitoring | Environmental Monitoring | ||||

|---|---|---|---|---|---|---|

| Heating (H) | Cooling (C) | Domestic Hot Water (DHW) | Electricity (E) | Indoor RH/T | Outdoor RH/T | |

| Configuration n.1 Independent systems: H, C, DHW, E Centralized systems: - Electricity meter: Electromechanical/Smart Gas meter: Electromechanical/Smart | 1.a—Utility bills (gas) | 1.a—Utility bills (electricity) | Utility bills (gas) | Utility bills (electricity) | Metering | |

| 1.b—Utility bills (electricity) | ||||||

| Building Configuration | Energy Monitoring | Environmental Monitoring | ||||

|---|---|---|---|---|---|---|

| Heating (H) | Cooling (C) | Domestic Hot Water (DHW) | Electricity (E) | Indoor RH/T | Outdoor RH/T | |

| Configuration n.2 Independent systems: H, C, DHW, E Centralized systems: - Electricity meter: Smart Gas meter: Smart | 2.a—Metering (gas) | 2.a—Metering (electricity) | Metering (gas) | Metering (electricity) | Metering | |

| 2.b—Metering (electricity) | ||||||

| Building Configuration | Energy Monitoring | Environmental Monitoring | ||||

|---|---|---|---|---|---|---|

| Heating (H) | Cooling (C) | Domestic Hot Water (DHW) | Electricity (E) | Indoor RH/T | Outdoor RH/T | |

| Configuration n.3 Independent systems: C, DHW, E Centralized systems: H Electricity meter: Smart Gas meter: Smart | 3.a—Sub-metering (energy) | Metering (electricity) | Metering (gas) | Metering (electricity) | Metering | |

| 3.b—Sub-metering (temperature + mass flow) | ||||||

| Configuration n.4 Independent systems: C, E Centralized systems: H, DHW Electricity meter: Smart Gas meter: Smart | 4.a—Sub-metering (energy) | Metering (electricity) | Sub-metering (temperature + mass flow) | Metering (electricity) | Metering | |

| 4.b—Sub-metering (temperature + mass flow) | ||||||

| Configuration n.5 Independent systems: DHW, E Centralized systems: H, C Electricity meter: Smart Gas meter: Smart | Sub-metering (temperature + mass flow) | Sub-metering (temperature + mass flow) | Metering (gas) | Metering (electricity) | Metering | |

| Configuration n.6 Independent systems: H, C, DHW Centralized systems: E Electricity meter: Smart Gas meter: Smart | Sub-metering (temperature + mass flow) | Sub-metering (temperature + mass flow) | Sub-metering (temperature + mass flow) | Metering (electricity) | Metering | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salvalai, G.; Sesana, M.M. Long-Term Monitoring Strategies for Increasing EPCs Reliability. Environ. Sci. Proc. 2021, 11, 16. https://doi.org/10.3390/environsciproc2021011016

Salvalai G, Sesana MM. Long-Term Monitoring Strategies for Increasing EPCs Reliability. Environmental Sciences Proceedings. 2021; 11(1):16. https://doi.org/10.3390/environsciproc2021011016

Chicago/Turabian StyleSalvalai, Graziano, and Marta Maria Sesana. 2021. "Long-Term Monitoring Strategies for Increasing EPCs Reliability" Environmental Sciences Proceedings 11, no. 1: 16. https://doi.org/10.3390/environsciproc2021011016

APA StyleSalvalai, G., & Sesana, M. M. (2021). Long-Term Monitoring Strategies for Increasing EPCs Reliability. Environmental Sciences Proceedings, 11(1), 16. https://doi.org/10.3390/environsciproc2021011016