The need for electrical energy by societies and individuals is continuously increasing. Although there are many reasons for this increase, the main reasons can be considered as the increase in the world population, the rapid development of the industrial sectors of countries, and the increase in the number of electrical devices used in homes due to developing technology. According to the 2022 report from the International Energy Agency (IEA), approximately 80% of the energy consumed in the world for decades has been met by fossil sources [

1]. The use of fossil fuels leads to numerous harmful effects on both the environment and human health. Additionally, the depletion of these resources is anticipated soon. Therefore, the generation of electricity through alternative sources has become an inevitable necessity.

RESs, which harness clean and limitless energy from natural sources, have significant potential to meet today’s energy needs. RESs, compared to fossil fuels, cause less harm to the environment while enabling sustainable energy generation. Due to these advantages, interest in RESs continues to grow. According to IEA’s 2022 data, global investments in clean energy increased by 40% compared to 2020 [

1].

In parallel with the global trend, there is also a growing inclination towards RESs in Türkiye. According to the data from the Turkish Electricity Transmission Corporation (TEİAŞ) [

2], Türkiye’s installed power in 2000 was 27,264.1 megawatts (MW), the total power of RESs was 11,221.6 MW, and its rate was 41.2%. In 2022, the country’s total installed power capacity increased to 103,809.3 MW, the total power of RES increased to 53,234.1 MW, and its rate increased to 53.3% (

Table 1).

As is seen in

Table 1, in the year 2000, energy production from renewable energy sources other than hydraulic power plants was either zero or very close to zero. However, significant increases have been observed in subsequent years (geothermal energy production increased by 96 times, wind by 602 times, biomass by 192 times). Türkiye’s industrial production value, which was 59.08 billion dollars in 2002, rose to 201.65 billion dollars in 2020 [

3]. This increase has led to a diversification of production sources due to the increased demand for energy, and the increased industrial waste has been utilized, resulting in a 192-fold increase in biomass energy production.

RESs, inherently unstable, cannot provide stable and regular energy generation. To overcome this problem, resources have begun to be used in a hybrid manner. Hybrid energy generation systems are systems that combine two or more energy sources to generate energy [

4]. These systems aim for more efficient energy generation by working in interaction with each other. In these systems, the void resulting from the inactivity of one energy source can be compensated for by other sources. Thus, these systems offer a more reliable and continuous approach to energy generation. Depending on the characteristics of the geographical location, the energy needs of the region, and technological possibilities, it is possible to achieve maximum efficiency with different combinations such as solar–wind, hydroelectric–wind–solar, and solar–bioenergy–hydrogen.

Below are summarized the key points regarding the importance of renewable-energy-based hybrid systems:

1.1. Literature Review

Researchers have conducted studies to enhance the efficiency and effectiveness of hybrid systems. Some of these studies are presented below.

Qiblawey et al. [

5] provided a comprehensive techno-economic assessment for increasing the use of RESs in the Canary Islands, specifically Tenerife and Gran Canaria. They claimed that with the system designed with the help of HOMER Pro software, the cost of electricity generation would decrease by 23% and 25.3% for both islands, respectively, and there would be a decrease of up to 70% in CO

2 emissions.

Ellabban and Alassi presented a hybrid microgrid design for mining applications with their study in 2021. In the study, three case studies in Australia were discussed, and optimizations of hybrid power plants were carried out using HOMER Pro software [

6].

In a study presented by Demirören and Yılmaz [

7], the authors investigated how electricity generation would be done with the help of RESs for Gökçeada, Türkiye’s largest island. The proposed system was composed of photovoltaic (PV) panels, wind turbines (WTs), and batteries (BSSs), designed using HOMER Pro software. The study revealed that, in terms of cost, wind energy systems were more suitable for Gökçeada.

Fikari et al. modeled and analyzed an independent hybrid power system for a rural area in Kenya with a population of 100. The microgrid, consisting of PV panels, a diesel generator (DG), BSSs, WT, basic loads, water pumping, and purification loads, was modeled with the help of MATLAB Simulink and simulated in terms of power management [

8].

Hafez and Bhattacharya designed microgrids for four different scenarios—diesel-only, fully renewable-based, diesel–renewable hybrid, and externally grid-connected—to compare their economies, operational performances, and environmental emissions. HOMER Pro software was used for modeling hybrid renewable energy systems [

9].

In their study, Islam et al. presented a case analysis for providing electricity to rural unelectrified areas in the northern region of Bangladesh through a hybrid mini-grid. Three different alternative models were developed for electricity generation with different combinations of solar energy, biomass generator, DG, and BSS storage resources. HOMER Pro software was used to perform techno-economic analysis and determine the optimum off-grid system configuration. It was found that the proposed hybrid system would produce 75% less CO

2 than existing methods [

10].

In their study, He et al. presented techno-economic analyses for various renewable-energy-based microgrid scenarios, both off-grid and grid-connected, in a residential area in Beijing. They used HOMER Pro software to evaluate the physical, operational, and economic performance of system components and to obtain the most cost-effective configuration model. The proposed renewable-energy-based microgrid was shown to meet at least 90% of the electricity demand [

11].

Sigalo et al. designed a hybrid system consisting of PV, DG, and a backup grid for the Rivers State University Faculty of Engineering building using HOMER Pro software and performed its economic analysis [

12].

In their study, by Shezan et al. designed the optimal quantity and size of a hybrid energy system comprising PV, WT, BSSs, and DG to meet load requirements. Various optimization techniques were developed and applied for this purpose. Additionally, a control method incorporating proportional-integral-derivative (PID) and fuzzy logic controllers (FLC) to manage voltage and frequency was implemented using MATLAB Simulink [

13].

Odetoye et al. presented the design of a multi-source independent renewable-energy-based microgrid for a rapidly commercializing rural region in Nigeria. The design and techno-economic analyses of the proposed model were performed using HOMER Pro software. The results show that up to 7540 tons of CO

2 can be saved per year thanks to the proposed system [

14].

In their study, Mbasso et al. aimed to design an independent hybrid renewable energy system for Manoka Island, where fish farming is the primary activity. The daily electricity consumption of the considered residence averages 9.28 kWh, with a peak demand of 0.88 kW. HOMER Pro software was used to investigate the most suitable energy generation model to sustain the fish farming industry and meet the energy requirements of the selected building [

15].

In the study conducted by Peláez-Peláez et al., a CHP system consisting of PV-FC was designed and analyzed. The analysis results indicated that while the system was not economically feasible, it was technically feasible [

16].

In the study presented by Kalamaras et al. [

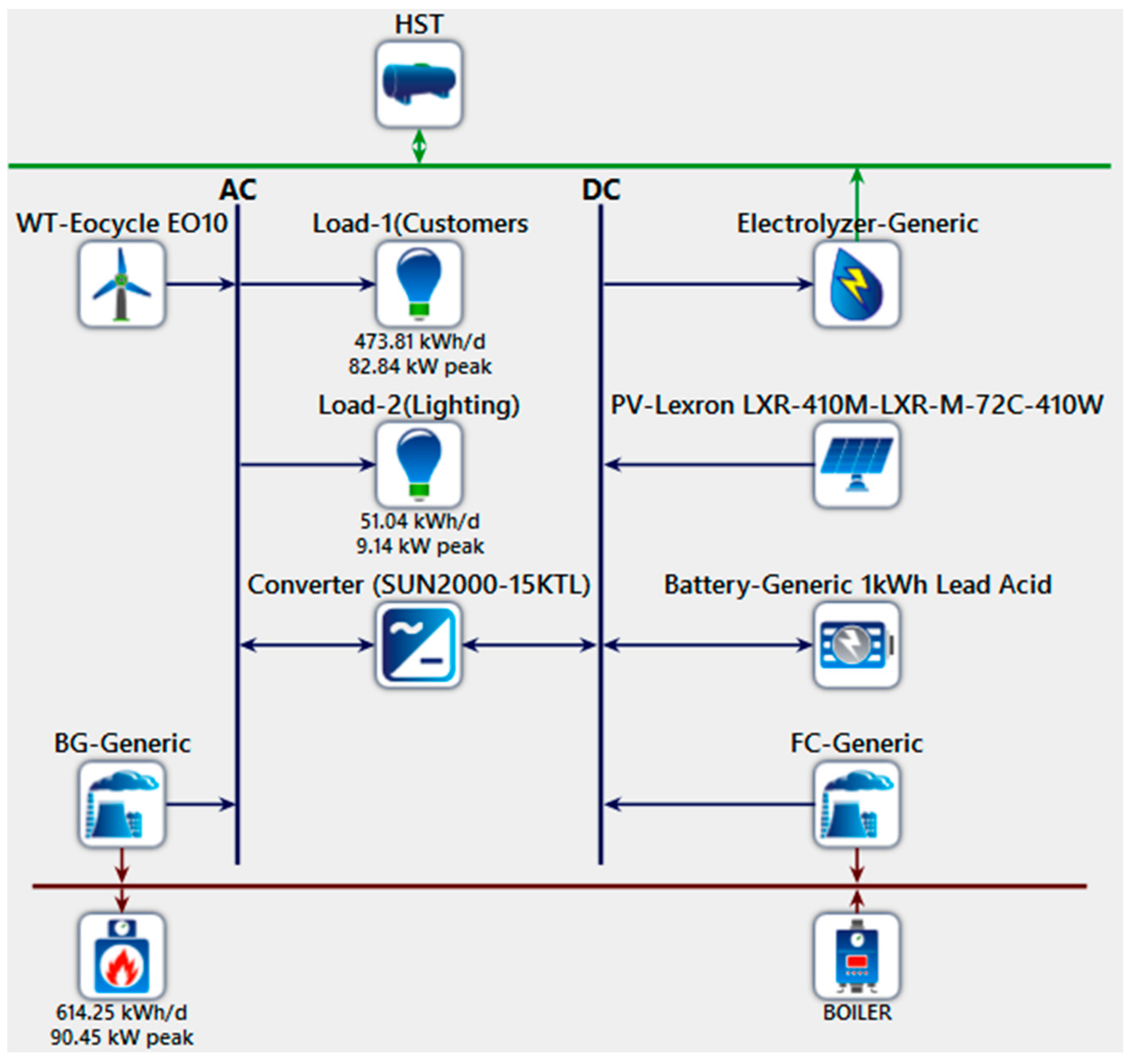

17], an off-grid system based on RESs was designed and optimized using HOMER Pro to meet the heat and electricity needs of a household. The results indicated that a system consisting of a 3 kW WT, a 3.35 kW PV panel, a 2.9 kW FC, a 6 kW BSS, a 4.2 kW electrolyzer, and a 40 kg HTS can meet a household’s electricity and thermal energy demands throughout the year.

In their study, Jahangiri et al. designed a CHP system for a household in the Abadan region of Iran using HOMER Pro, incorporating WT, PV, BG, FC, and BSS components. It was stated that the most significant advantage of the proposed system is the ability to recover the heat energy generated in BG and FC. According to the analysis results, the LCOE value was calculated to be USD 1.16/kWh [

18].

Studies in the literature, some of which are presented above, show that researchers are focusing on modeling renewable-energy-based hybrid systems for a wide range of different objectives for almost all rural areas around the world. This focus highlights the importance of hybrid systems in addressing diverse energy needs.

1.2. Aim of the Study

Since many parameters are considered in modeling hybrid systems, the process is complex and difficult. As mentioned above, RESs are inherently uncertain. For example, a sudden stop of the wind or the disappearance of the sun due to cloudiness will cause sudden generation decreases. During these transitional periods, the system must quickly decide which generation resources will be put into use. Another difficulty is balancing generation and consumption values. If the generation amount does not meet consumption, energy shortages will occur. If the generation value exceeds consumption, it may result in unnecessary excess energy. To overcome this problem, adding storage units to the system can be a good solution. Thus, when energy generation is high, the remaining energy will be stored and can be used when generation is insufficient. However, storage units both increase the cost of the system and cause losses.

System cost is one of the most critical parameters to consider when modeling. Two parameters are important in cost measurement: NPC and LCOE. NPC represents the value obtained by subtracting the present value of all expenditures for the installation and operation of system components over the project’s duration (25 years) from the present value of all earned revenues during this period. LCOE is the average cost of producing 1 kWh of useful energy in the system (excluding losses) over its lifetime.

The installation cost of the designed system depends on the resource selection made during system creation. Operating costs depend on which source will generate how much at any given time. All these issues make the design of hybrid systems difficult.

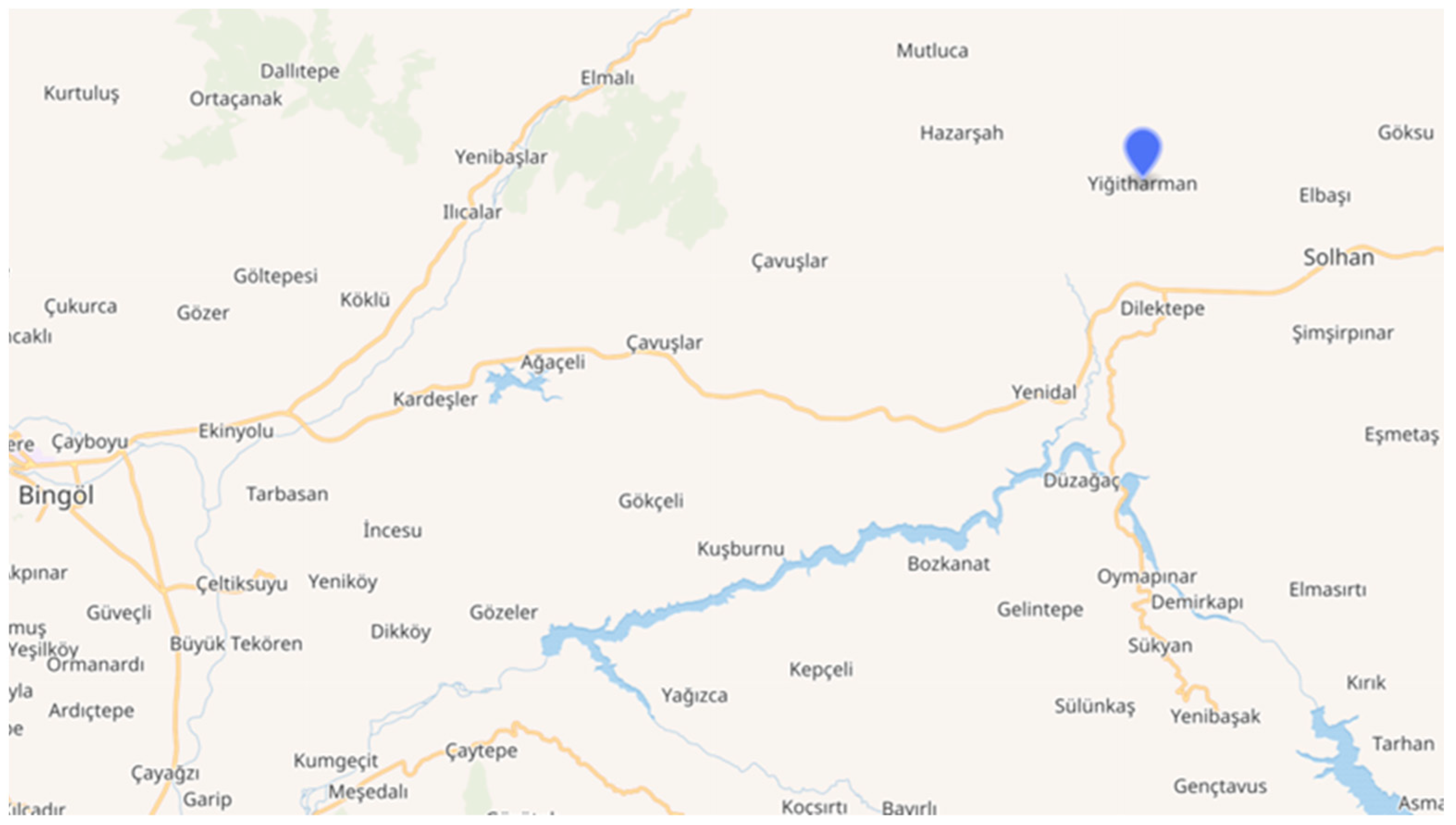

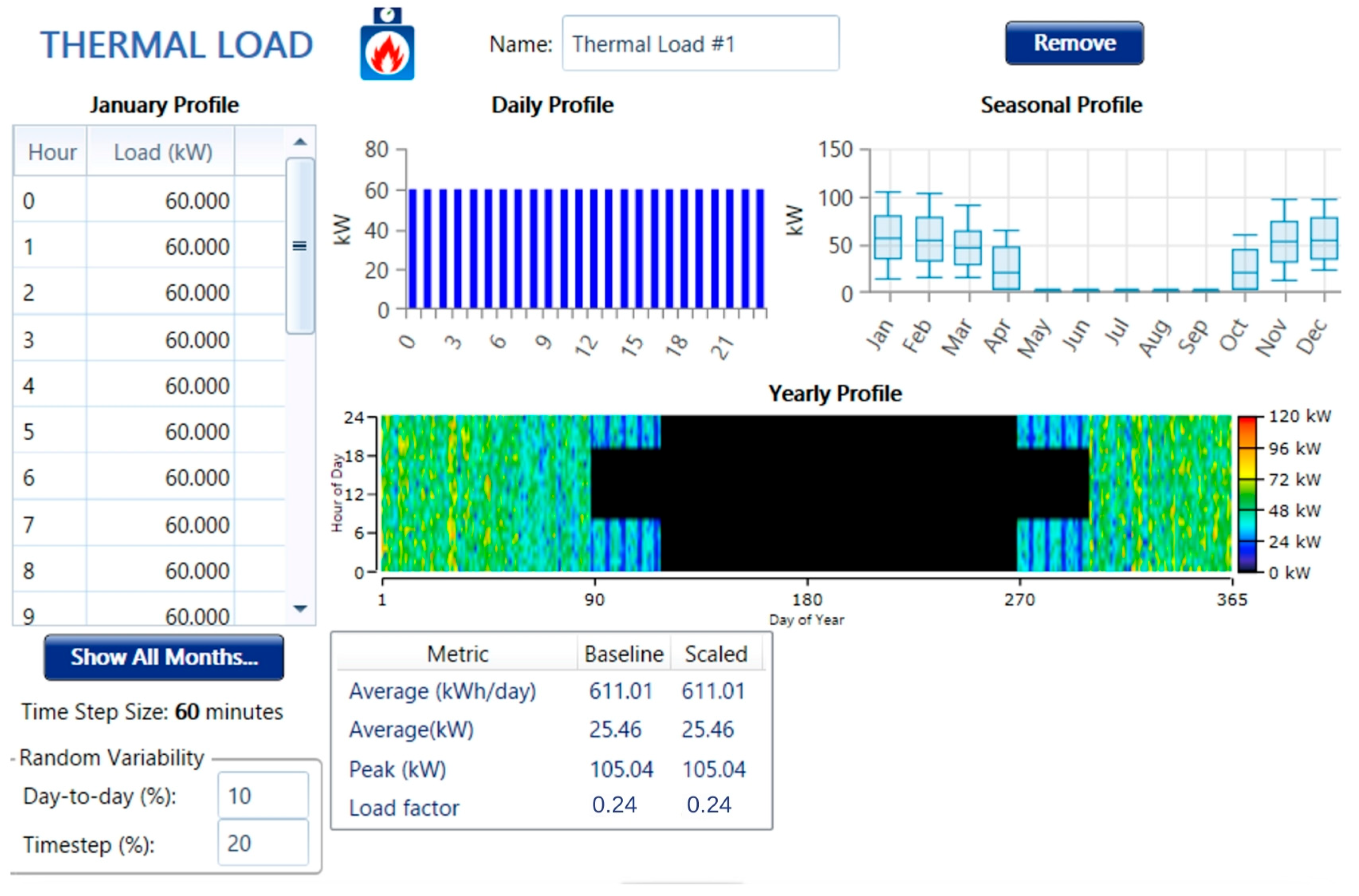

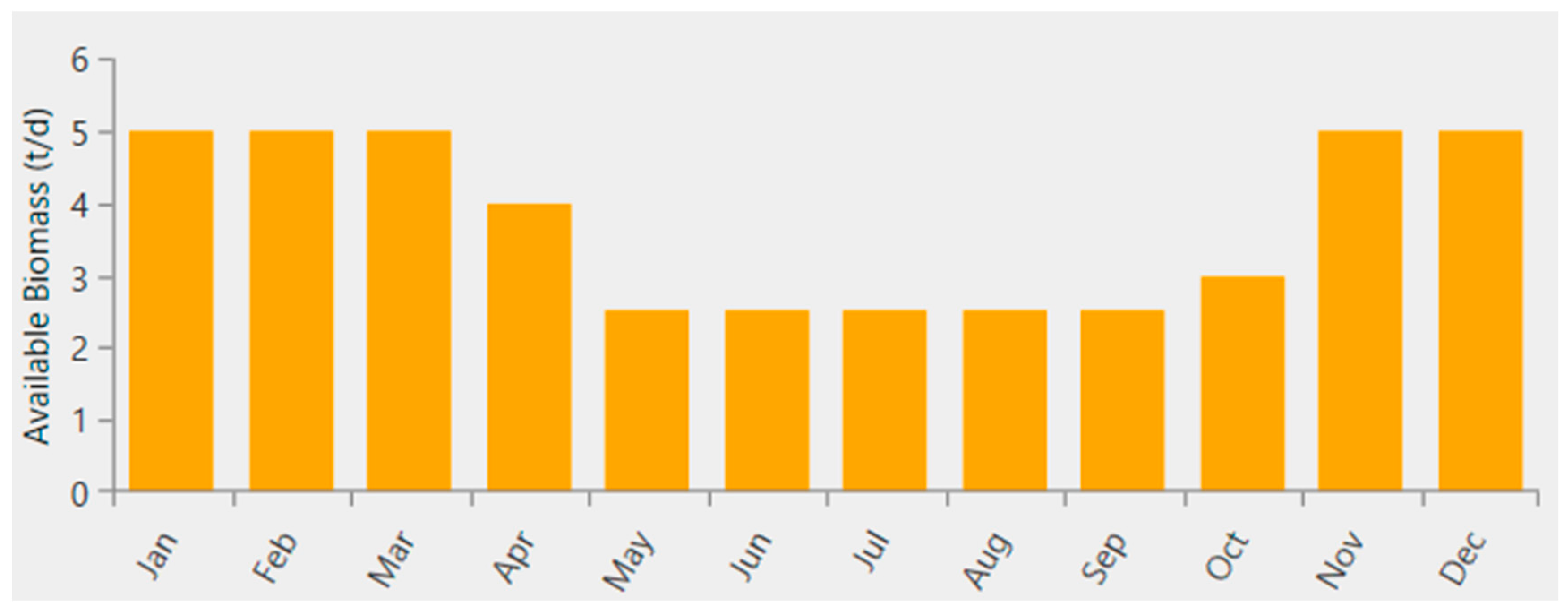

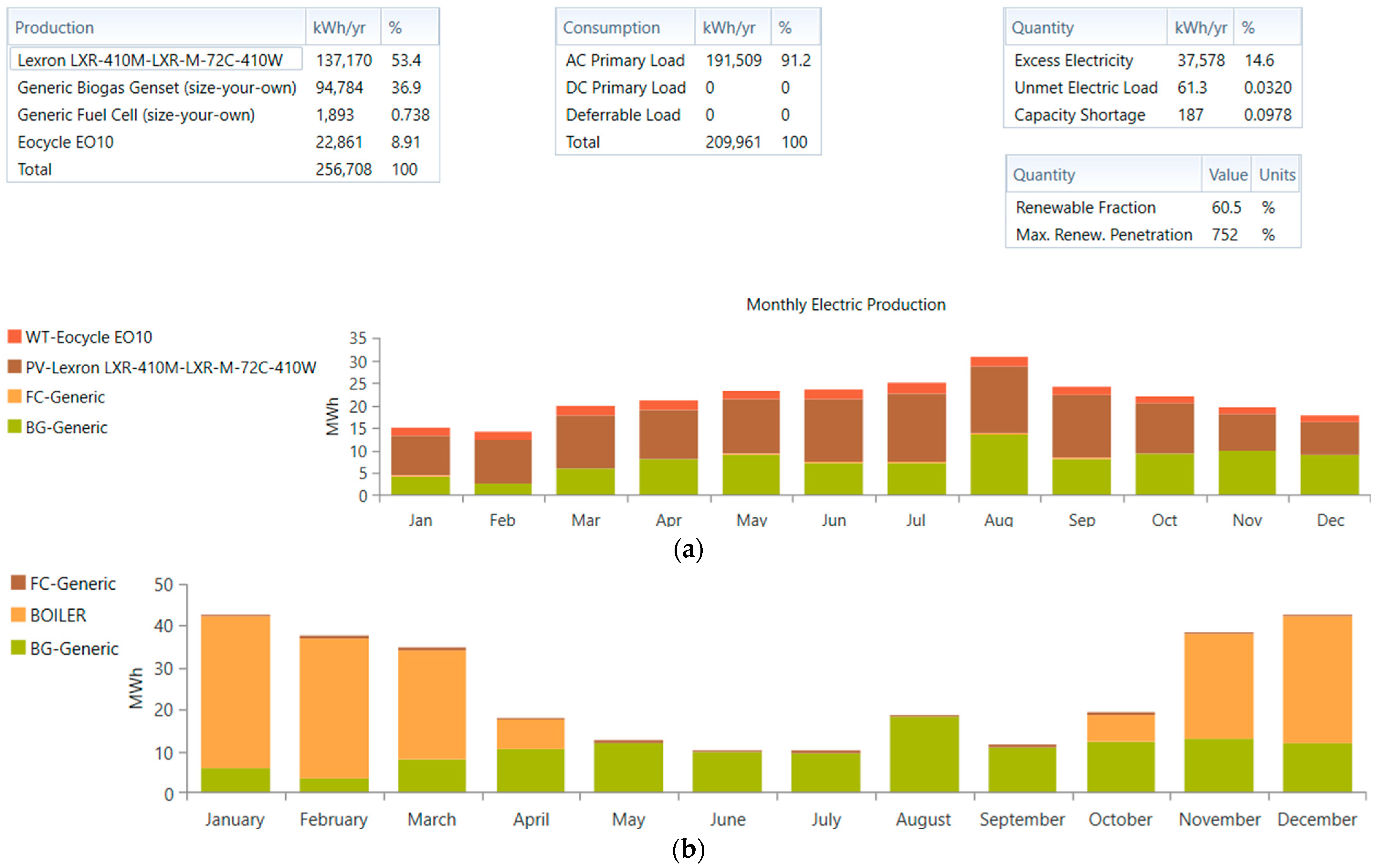

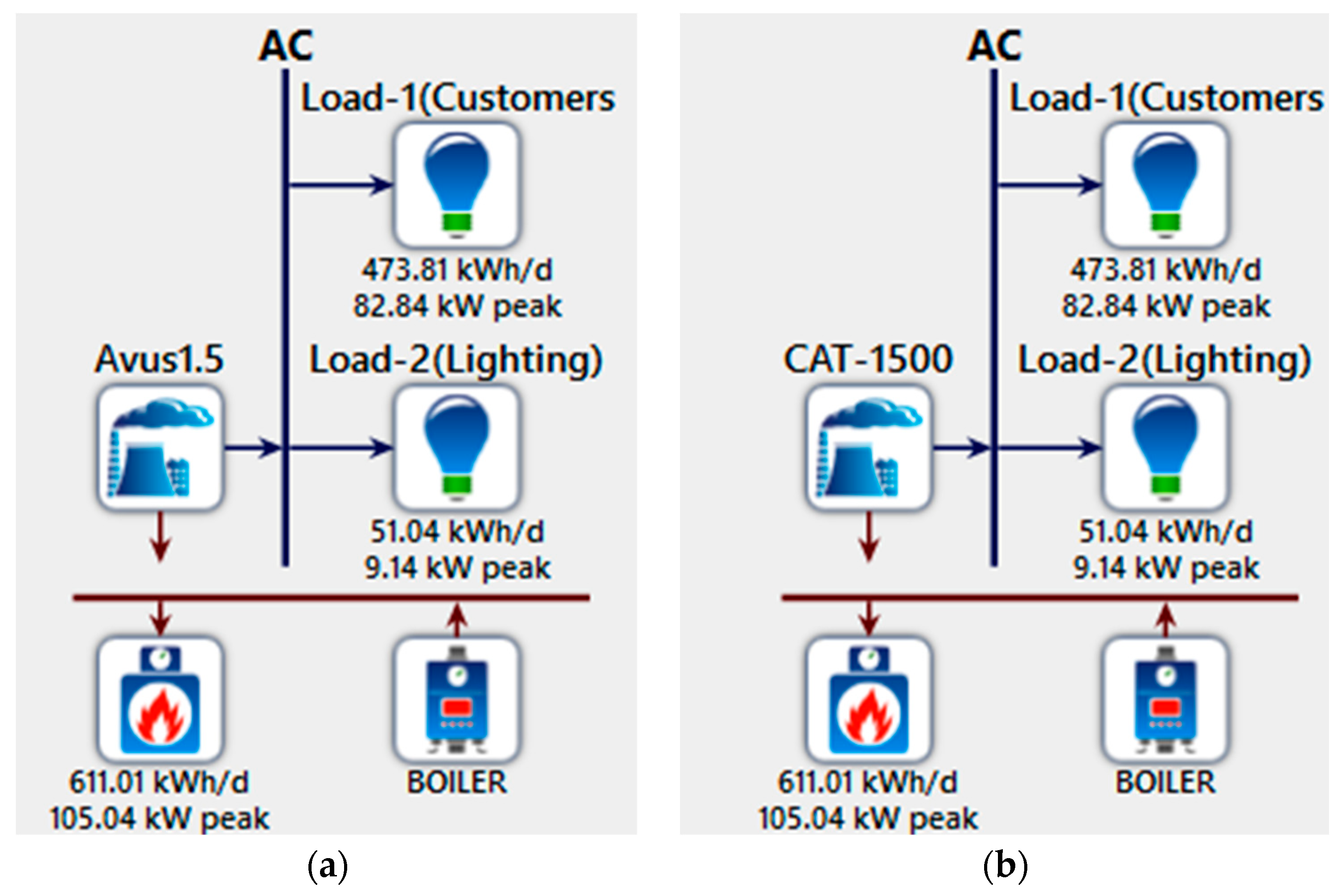

This study aims to design a hybrid generating system considering the mentioned difficulties and to evaluate the resources of the village of Yiğit Harman, consisting of 111 households, located in the Bingöl Province, to meet its energy needs. The resources available in the village are considered in the system design. The targeted benefits of this study are as follows:

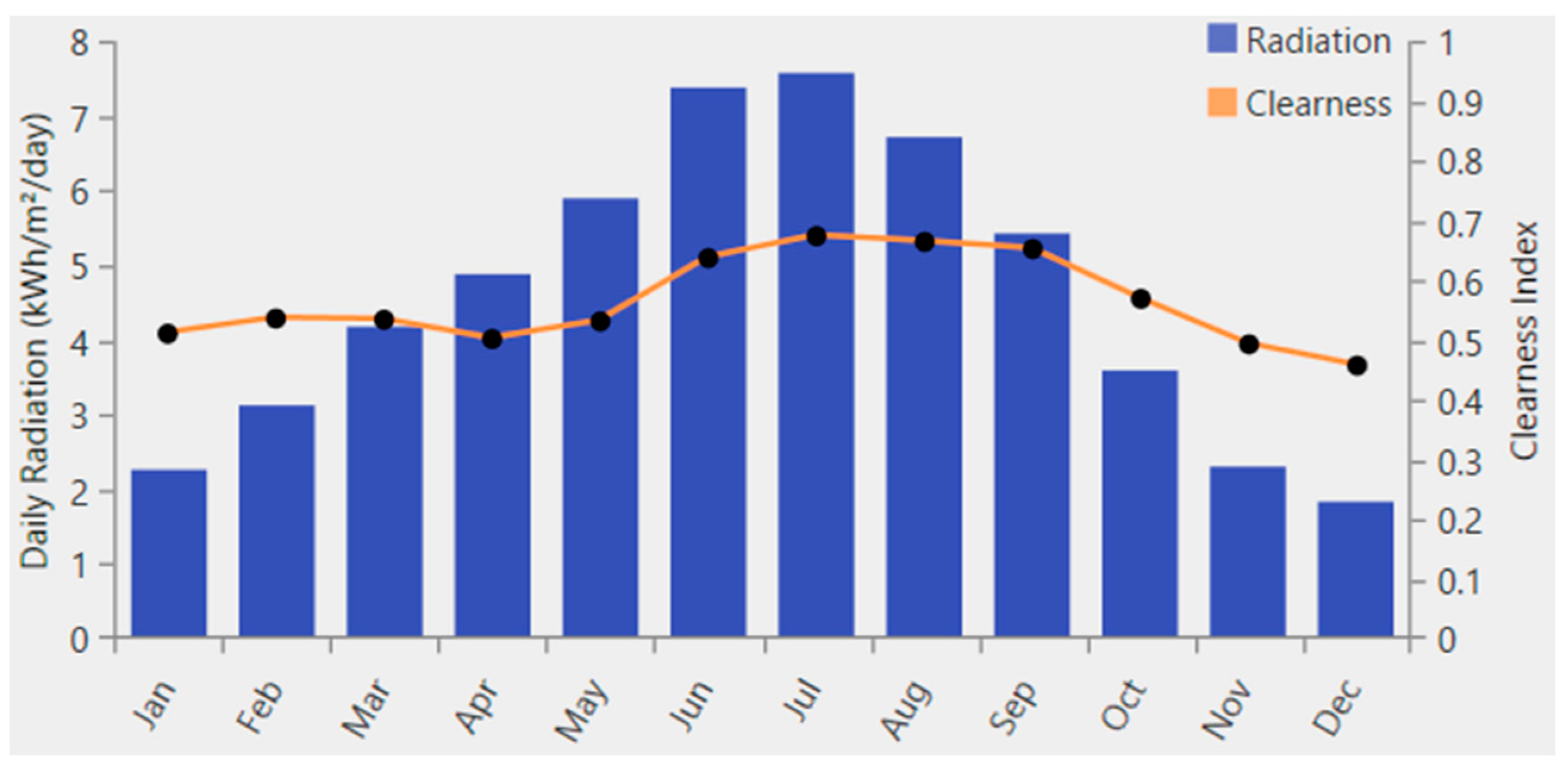

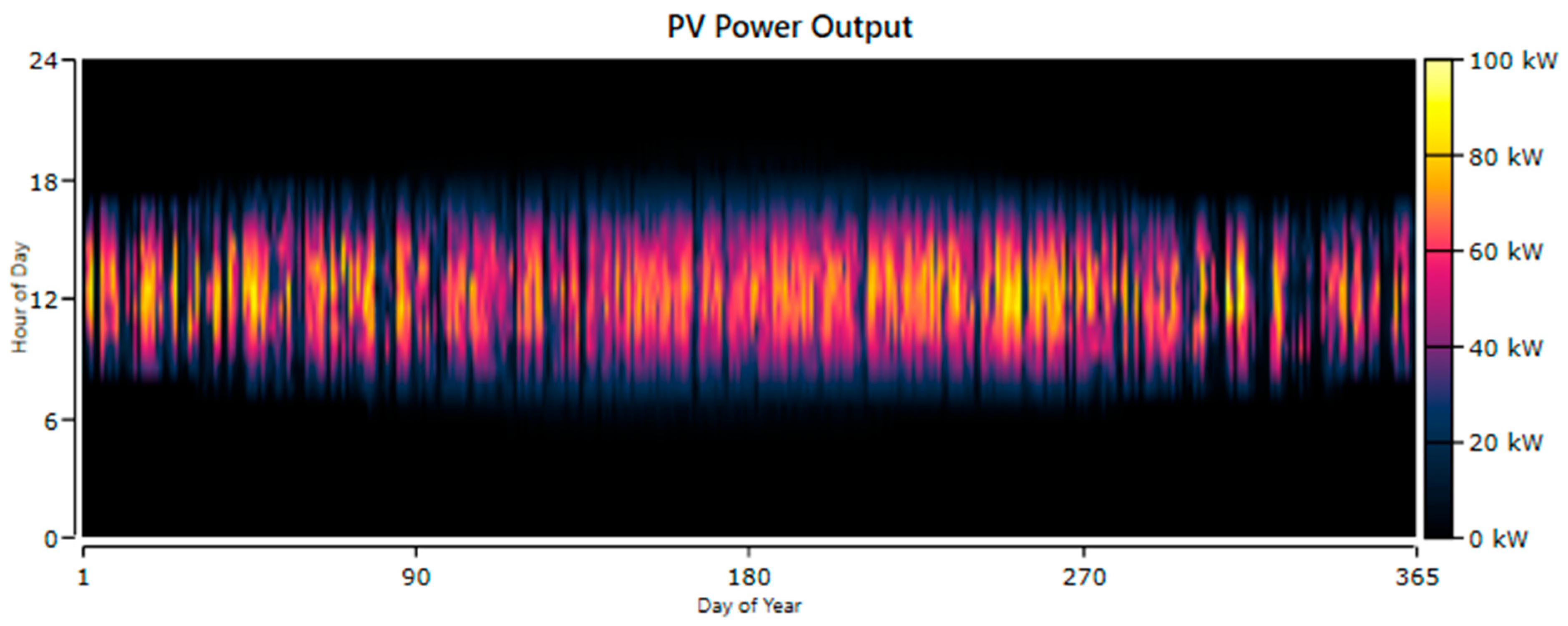

Yiğit Harman Village has a fortunate location in terms of solar and wind potential. Therefore, all the needed electrical energy and half of the thermal energy will be met cleanly and reliably by using the RESs of the village.

Agriculture and livestock are the main livelihoods of the village. For this reason, agricultural and animal wastes are used in the production of electricity and heat energy, aiming to eliminate environmental waste and meet the energy needs of the village with its means.

When wind and solar energy are high, hydrogen is produced with these resources, and when production is low, electricity is produced with the help of fuel cells (FCs). Since fuel cells have a high operating temperature, heat energy is also generated while producing electrical energy. In the designed model, the heat energy generated by the fuel cells is used for heating homes. This way, both clean and reliable energy supply was ensured, and a highly efficient model was achieved.

On 6 February 2023, two major earthquakes with magnitudes of Mw7.7 and Mw7.6 occurred successively in the Pazarcık and Elbistan districts of Kahramanmaraş Province. According to the report titled the “2023 Kahramanmaraş and Hatay Earthquakes Report” by the Presidency of Strategy and Budget of the Republic of Turkey, the earthquakes resulted in the collapse of 11 towers connecting 1128 km of power transmission lines belonging to TEİAŞ, damage to transformer stations and equipment with a total capacity of 4088 MVA, and an economic loss amounting to USD 38 million. The report also states that the repairs to eliminate these damages took more than three days [

19]. As demonstrated by this disaster, meeting the energy needs of earthquake-prone regions from local sources is of critical importance for minimizing economic losses and ensuring the safe continuation of post-earthquake search and rescue operations. Bingöl Province is one of the most important earthquake regions in Türkiye, and earthquakes of 7 and above on the Richter scale are frequently experienced.

Although this study was carried out for Yiğit Harman Village, it will be encouraging for settlements with similar characteristics. The optimization of the system was carried out using the software application known as HOMER, developed by the National Renewable Energy Laboratory (NREL) based in the United States.

The remaining part of the study is as follows: In

Section 2, the “HOMER Pro” software is introduced, and the modeling of system components is explained. In

Section 3, the analysis results are presented. In

Section 4, the obtained results are evaluated, and suggestions for new studies are provided.