Low-Velocity Impact Behaviour of Biomimetic Cornstalk-Inspired Lightweight Structures †

Abstract

1. Introduction

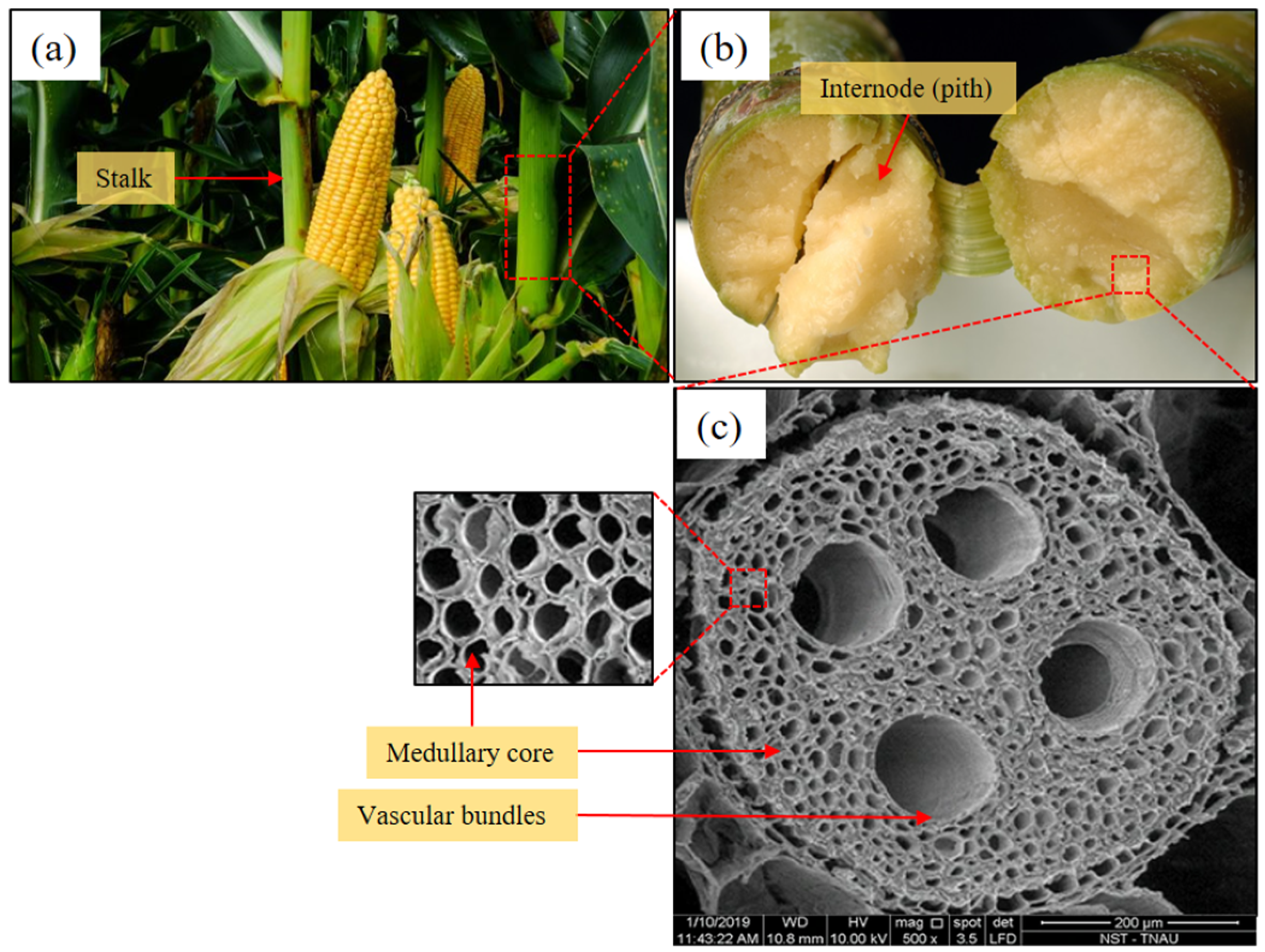

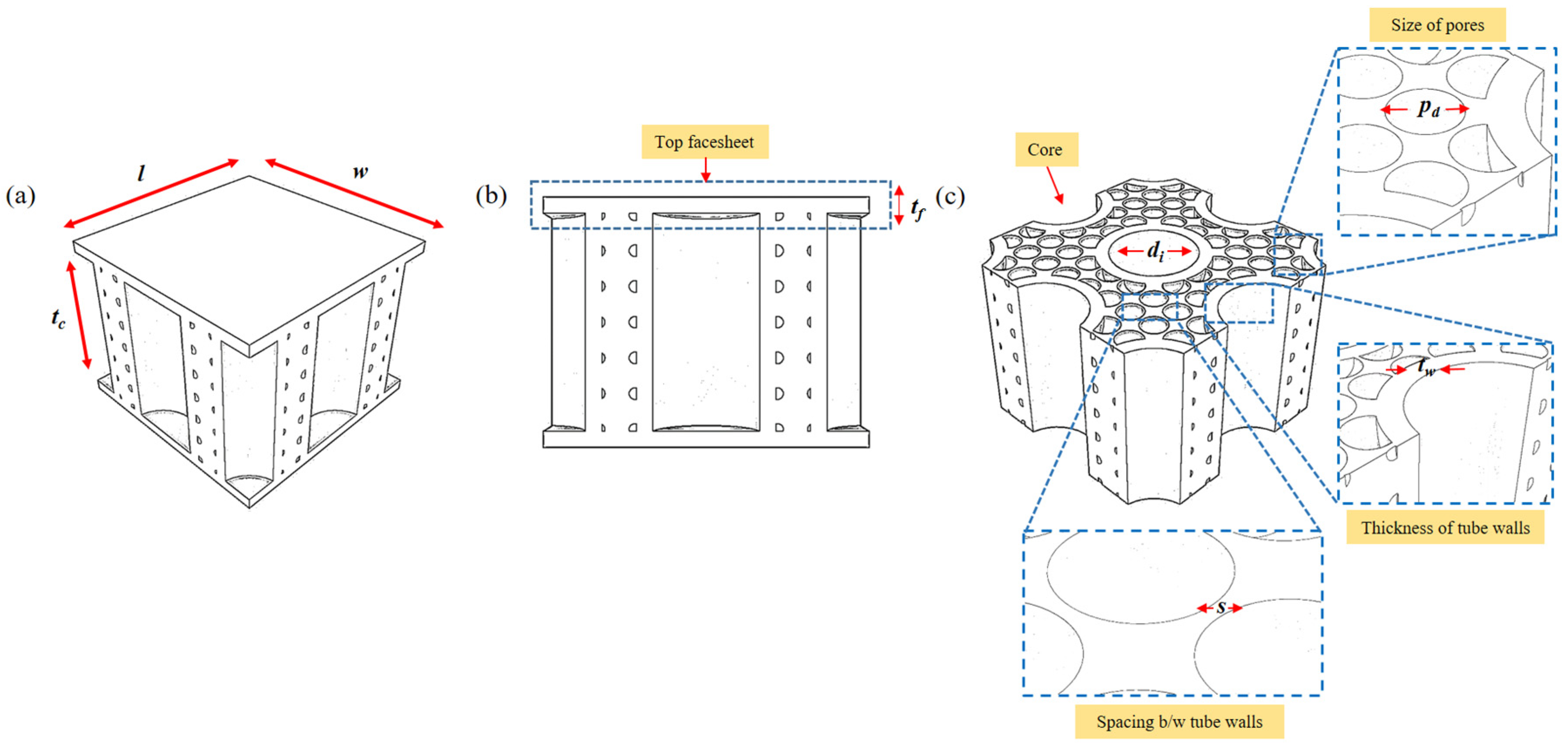

2. Biomimetic Designs and Materials

3. Methodology

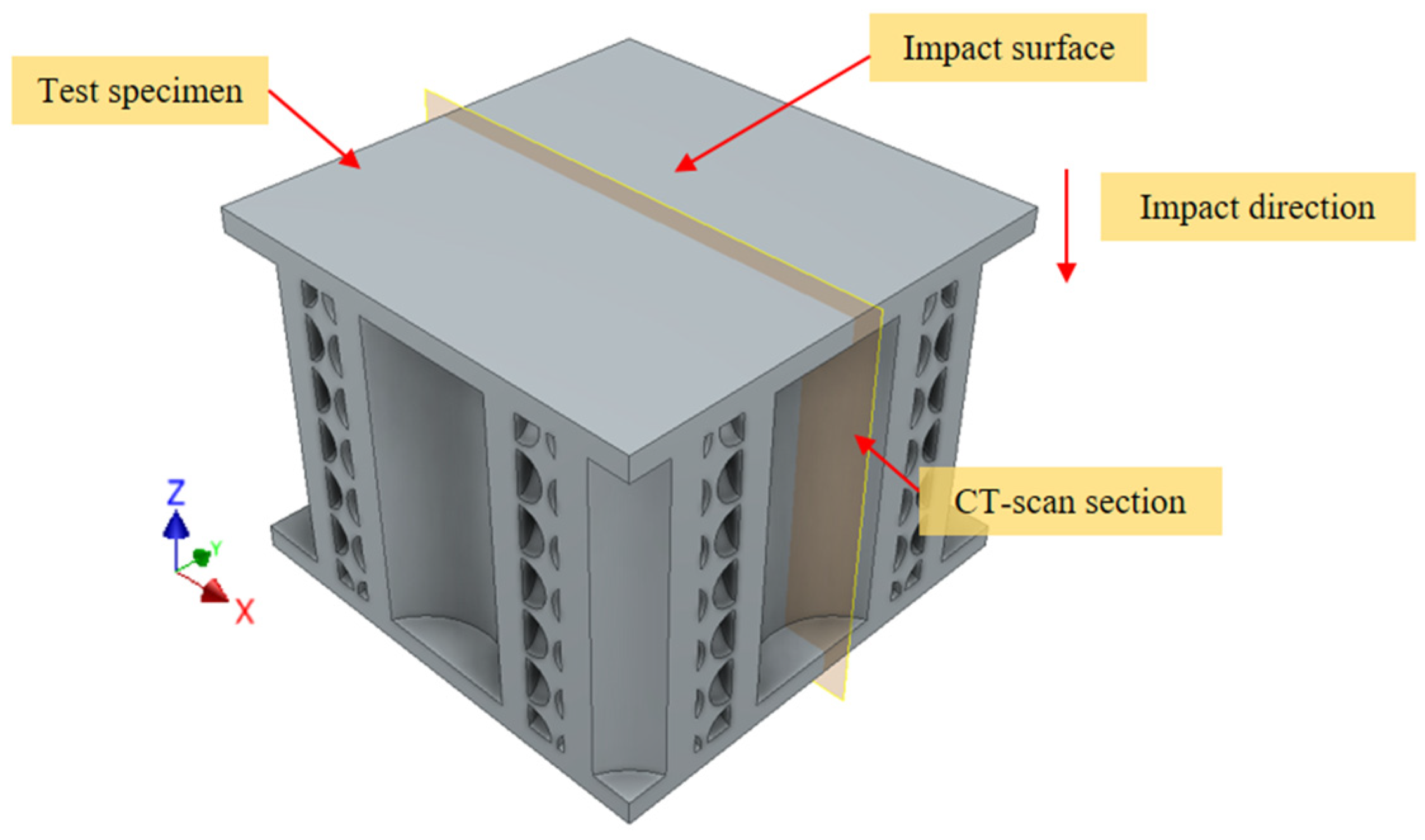

3.1. Drop-Weight Impact Tests

3.2. Damage Examination

4. Results and Discussions

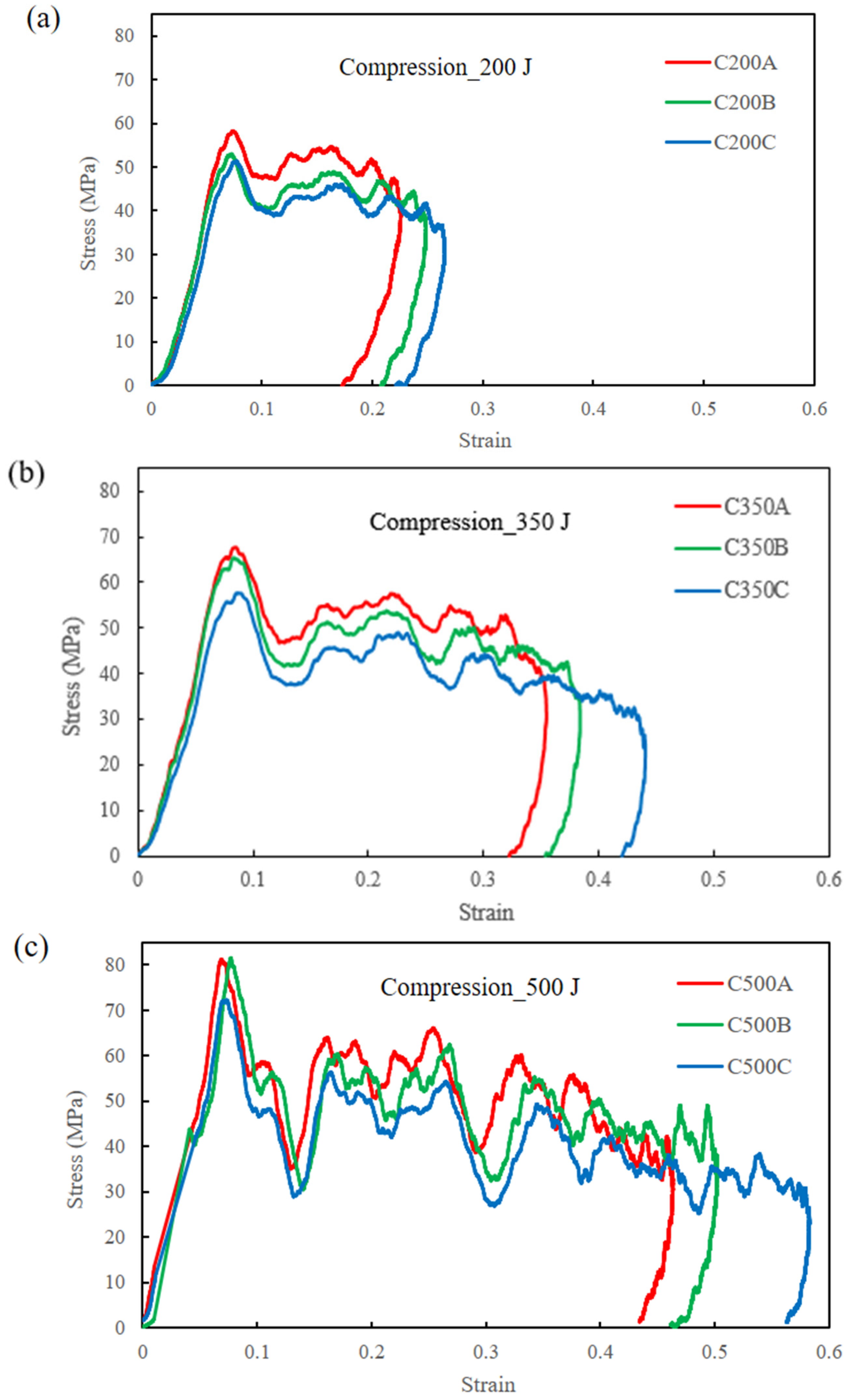

4.1. Effect of Varying Impact Energy

- The bio-inspired structures are designed with a hierarchical arrangement that mimics the natural design of cornstalks. This hierarchical structure includes a network of cells or hollow tubes that efficiently absorb and dissipate energy. The multiple levels of structural organisation allow for progressive deformation, which distributes the impact energy more evenly across the specimen and prevents localised failure [24];

- The energy absorption mechanism of the bio-inspired design relies on both elastic and plastic deformation. At lower energy levels, the structures primarily absorb energy through elastic deformation, which allows them to return to their original shape upon unloading. At higher energy levels, the structures undergo plastic deformation, which further absorbs and dissipates energy through internal deformation mechanisms, such as fibre breakage or cellular collapse, without complete disintegration [25];

- The materials used in the bio-inspired structures are selected for their ability to withstand significant impact forces while maintaining structural integrity. These materials exhibit a combination of high strength and toughness, which contributes to the ability of the specimen to absorb large amounts of energy without failing [26];

- The geometry of the bio-inspired design used in this study and the material composition ensure that impact forces are distributed across a larger area, reducing the likelihood of catastrophic failure. This distribution helps the specimens to withstand higher energy loads more effectively, leading to enhanced energy absorption capabilities.

4.2. Effect of Geometry Variations

4.3. Post-Mortem Damage Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Du Plessis, A.; Broeckhoven, C. Chapter 10—Functional synergy of biomimicry and additive manufacturing: Toward a bio-enhanced engineering approach. In Biomimicry for Materials, Design and Habitats; Eggermont, M., Shyam, V., Hepp, A.F., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 269–289. [Google Scholar]

- Siddique, S.H.; Hazell, P.J.; Wang, H.; Escobedo, J.P.; Ameri, A.A. Lessons from nature: 3D printed bio-inspired porous structures for impact energy absorption—A review. Addit. Manuf. 2022, 58, 103051. [Google Scholar] [CrossRef]

- Du Plessis, A.; Broeckhoven, C.; Yadroitsava, I.; Yadroitsev, I.; Hands, C.H.; Kunju, R.; Bhate, D. Beautiful and functional: A review of biomimetic design in additive manufacturing. Addit. Manuf. 2019, 27, 408–427. [Google Scholar] [CrossRef]

- Hazell, P.J. Armour: Materials, Theory, and Design; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar]

- An, X.; Fan, H. Hybrid design and energy absorption of luffa-sponge-like hierarchical cellular structures. Mater. Des. 2016, 106, 247–257. [Google Scholar] [CrossRef]

- Bührig-Polaczek, A.; Fleck, C.; Speck, T.; Schüler, P.; Fischer, S.F.; Caliaro, M.; Thielen, M. Biomimetic cellular metals—Using hierarchical structuring for energy absorption. Bioinspir. Biomim. 2016, 11, 045002. [Google Scholar] [CrossRef]

- Tane, M.; Zhao, F.; Song, Y.; Nakajima, H. Formation mechanism of a plateau stress region during dynamic compression of porous iron: Interaction between oriented cylindrical pores and deformation twins. Mater. Sci. Eng. A 2014, 591, 150–158. [Google Scholar] [CrossRef]

- Rhee, H.; Tucker, M.T.; Whittington, W.R.; Horstemeyer, M.F.; Lim, H. Structure-property responses of bio-inspired synthetic foams at low and high strain rates. Sci. Eng. Compos. Mater. 2015, 22, 365–373. [Google Scholar] [CrossRef]

- Zhang, Y.; He, S.; Liu, J.; Zhao, W.; Gong, X.; Yu, J. Density gradient tailoring of aluminum foam-filled tube. Compos. Struct. 2019, 220, 451–459. [Google Scholar]

- Chen, H. Lignocellulose Biorefinery Engineering: Principles and Applications; Woodhead Publishing: Sawston, UK, 2015. [Google Scholar]

- Bueckert, R.A. Simulated hail damage and yield reduction in lentil. Can. J. Plant Sci. 2011, 91, 117–124124. [Google Scholar] [CrossRef]

- Vollmer, J.; Johnson, B.L.; Deckard, E.L.; Rahman, M. Evaluation of simulated hail damage on seed yield and agronomic traits in canola (Brassica napus L.). Can. J. Plant Sci. 2020, 100, 597–608. [Google Scholar] [CrossRef]

- Li, Y.; Qin, T.; Chen, J.; Zhao, Z. Experiments and analysis on mechanical property of corn stalk reciprocating cutting. Trans. Chin. Soc. Agric. Eng. 2011, 27, 160–164. [Google Scholar]

- Siddique, S.H.; Hazell, P.J.; Pereira, G.G.; Wang, H.; Escobedo, J.P.; Ameri, A.A.H. On the Mechanical Behaviour of Biomimetic Cornstalk-Inspired Lightweight Structures. Biomimetics 2023, 8, 92. [Google Scholar] [CrossRef] [PubMed]

- Fiedler, T.; Taherishargh, M.; Krstulović-Opara, L.; Vesenjak, M. Dynamic compressive loading of expanded perlite/aluminum syntactic foam. Mater. Sci. Eng. A 2015, 626, 296–304. [Google Scholar] [CrossRef]

- Altenaiji, M.; Guan, Z.; Cantwell, W.; Zhao, Y.; Schleyer, G. Characterisation of aluminium matrix syntactic foams under drop weight impact. Mater. Des. 2014, 59, 296–302. [Google Scholar] [CrossRef]

- Pinnoji, P.; Mahajan, P.; Bourdet, N.; Deck, C.; Willinger, R. Impact dynamics of metal foam shells for motorcycle helmets: Experiments & numerical modeling. Int. J. Impact Eng. 2010, 37, 274–284. [Google Scholar]

- Islam, M.; Kader, M.; Brown, A.; Hazell, P.; Escobedo, J.; Saadatfar, M. Experimental investigation of mechanical behaviour of closed-cell aluminium foams under drop weight impact. In Characterization of Minerals, Metals, and Materials 2017; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Shah, D.U.; Reynolds, T.P.; Ramage, M.H. The strength of plants: Theory and experimental methods to measure the mechanical properties of stems. J. Exp. Bot. 2017, 68, 4497–4516. [Google Scholar] [CrossRef]

- Dura, H.B.; Hazell, P.J.; Wang, H.; Escobedo-Diaz, J. Effect of scale morphology on the mechanical response of bio-inspired fish-scale-based protective structures. Compos. Part A Appl. Sci. Manuf. 2023, 174, 107720. [Google Scholar] [CrossRef]

- Kader, M.; Hazell, P.; Islam, M.; Ahmed, S.; Hossain, M.; Escobedo, J.; Saadatfar, M. Strain-rate dependency and impact dynamics of closed-cell aluminium foams. Mater. Sci. Eng. A 2021, 818, 141379. [Google Scholar] [CrossRef]

- Zhang, K.; He, Y.; Zhang, H.; Li, H. Research on mechanical properties of corn stalk. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2017. [Google Scholar]

- Zhang, T.; Zhao, M.; Liu, F.; Tian, H.; Wulan, T.; Yue, Y.; Li, D. A discrete element method model of corn stalk and its mechanical characteristic parameters. BioResources 2020, 15, 9337–9350. [Google Scholar] [CrossRef]

- Seki, H.; Tane, M.; Nakajima, H. Effects of Pore Size Distribution and Loading Direction on Fatigue Property of Lotus-type Porous Copper. In MetFoam 2007: Porous Metals and Metallic Foams: Proceedings of the Fifth International Conference on Porous Metals and Metallic Foams, Montreal, Canada, 5–7 September 2007; DEStech Publications, Inc.: Lancaster, PA, USA, 2008. [Google Scholar]

- Jia, Z.; Yu, Y.; Hou, S.; Wang, L. Biomimetic architected materials with improved dynamic performance. J. Mech. Phys. Solids 2019, 125, 178–197. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.W.; Gou, J.H.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Sun, G.; Wang, E.; Wang, H.; Xiao, Z.; Li, Q. Low-velocity impact behaviour of sandwich panels with homogeneous and stepwise graded foam cores. Mater. Des. 2018, 160, 1117–1136. [Google Scholar] [CrossRef]

- Zhou, J.; Guan, Z.; Cantwell, W. The energy-absorbing behaviour of composite tube-reinforced foams. Compos. Part B Eng. 2018, 139, 227–237. [Google Scholar] [CrossRef]

- Liu, W.; Lin, Z.; Wang, N.; Deng, X. Dynamic performances of thin-walled tubes with star-shaped cross section under axial impact. Thin-Walled Struct. 2016, 100, 25–37. [Google Scholar] [CrossRef]

- Wang, B.; Sullivan, T.N.; Pissarenko, A.; Zaheri, A.; Espinosa, H.D.; Meyers, M.A. Lessons from the ocean: Whale baleen fracture resistance. Adv. Mater. 2019, 31, e1804574. [Google Scholar] [CrossRef]

- Abdel-Wahab, A.A.; Maligno, A.R.; Silberschmidt, V.V. Micro-scale modelling of bovine cortical bone fracture: Analysis of crack propagation and microstructure using X-FEM. Comput. Mater. Sci. 2012, 52, 128–135. [Google Scholar] [CrossRef]

- Jia, Z.; Wang, L. 3D printing of biomimetic composites with improved fracture toughness. Acta Mater. 2019, 173, 61–73. [Google Scholar] [CrossRef]

- Zhang, L.; Bai, Z.; Bai, F. Crashworthiness design for bio-inspired multi-cell tubes with quadrilateral, hexagonal and octagonal sections. Thin-Walled Struct. 2018, 122, 42–51. [Google Scholar] [CrossRef]

- Mieszala, M.; Hasegawa, M.; Guillonneau, G.; Bauer, J.; Raghavan, R.; Frantz, C.; Kraft, O.; Mischler, S.; Michler, J.; Philippe, L. Micromechanics of amorphous metal/polymer hybrid structures with 3D cellular architectures: Size effects, buckling behavior, and energy absorption capability. Small 2017, 13, 1602514. [Google Scholar] [CrossRef]

| Length (l) | Width (w) | Core Thickness (tc) | Facesheet Thickness (tf) | Total Thickness (t) | |

|---|---|---|---|---|---|

| Dimensions | 30 | 30 | 20 | 1.5 | 23 |

| Specimen | Wall Thickness (tw) | Outer Diameter (do) | Inner Diameter (di) | Spacing (s) | Pore Diameter (pd) | Mass | Relative Density ρ |

|---|---|---|---|---|---|---|---|

| Specimen A | 2.5 | 15 | 10 | 1 | 3 | 16.21 (±0.15) | 0.65 |

| Specimen B | 2 | 14 | 10 | 2 | 3 | 15.13 (±0.08) | 0.62 |

| Specimen C | 1.5 | 13 | 10 | 3 | 3 | 14.82 (±0.11) | 0.58 |

| Properties | ABS |

|---|---|

| Density (g/cm3) | 1068 |

| Young’s modulus (Gpa) | 1.85 |

| Yield strength (Mpa) | 36 |

| Ultimate strength (Mpa) | 40 |

| Poisson’s ratio | 0.35 |

| Failure strain at break | 0.047 |

| Hardness (shore D) | 76 |

| Cowper–Symonds, C (s−1) | 678.7 |

| Cowper–Symonds, p | 3.23 |

| S/N | Sample Label | Specimen | Impact Energy (J) | Number of Samples |

|---|---|---|---|---|

| 1 | C200A | Specimen A | 200 | 3 |

| 2 | C200B | Specimen B | 3 | |

| 3 | C200C | Specimen C | 3 | |

| 4 | C350A | Specimen A | 350 | 3 |

| 5 | C350B | Specimen B | 3 | |

| 6 | C350C | Specimen C | 3 | |

| 7 | C500A | Specimen A | 500 | 3 |

| 8 | C500B | Specimen B | 3 | |

| 9 | C500C | Specimen C | 3 |

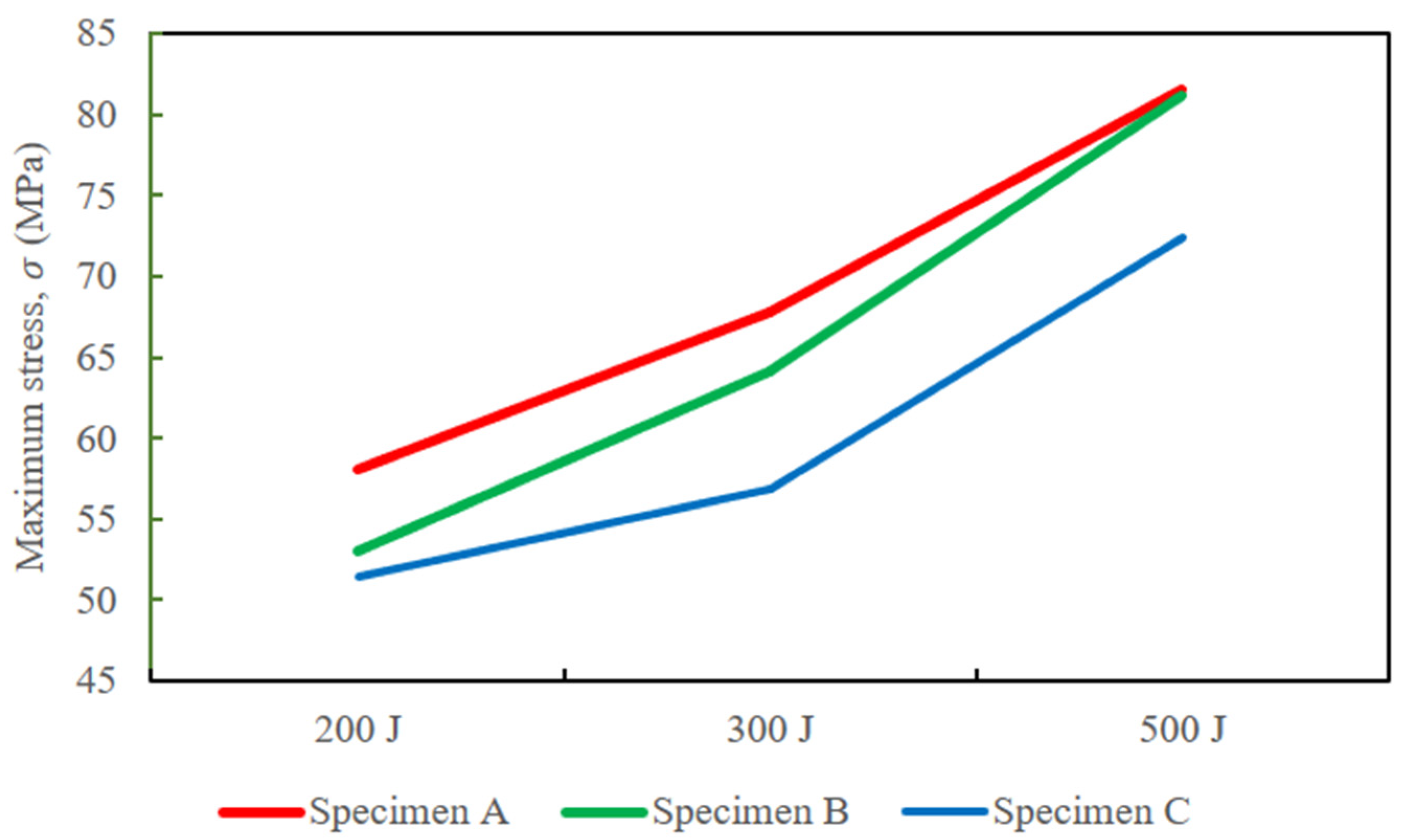

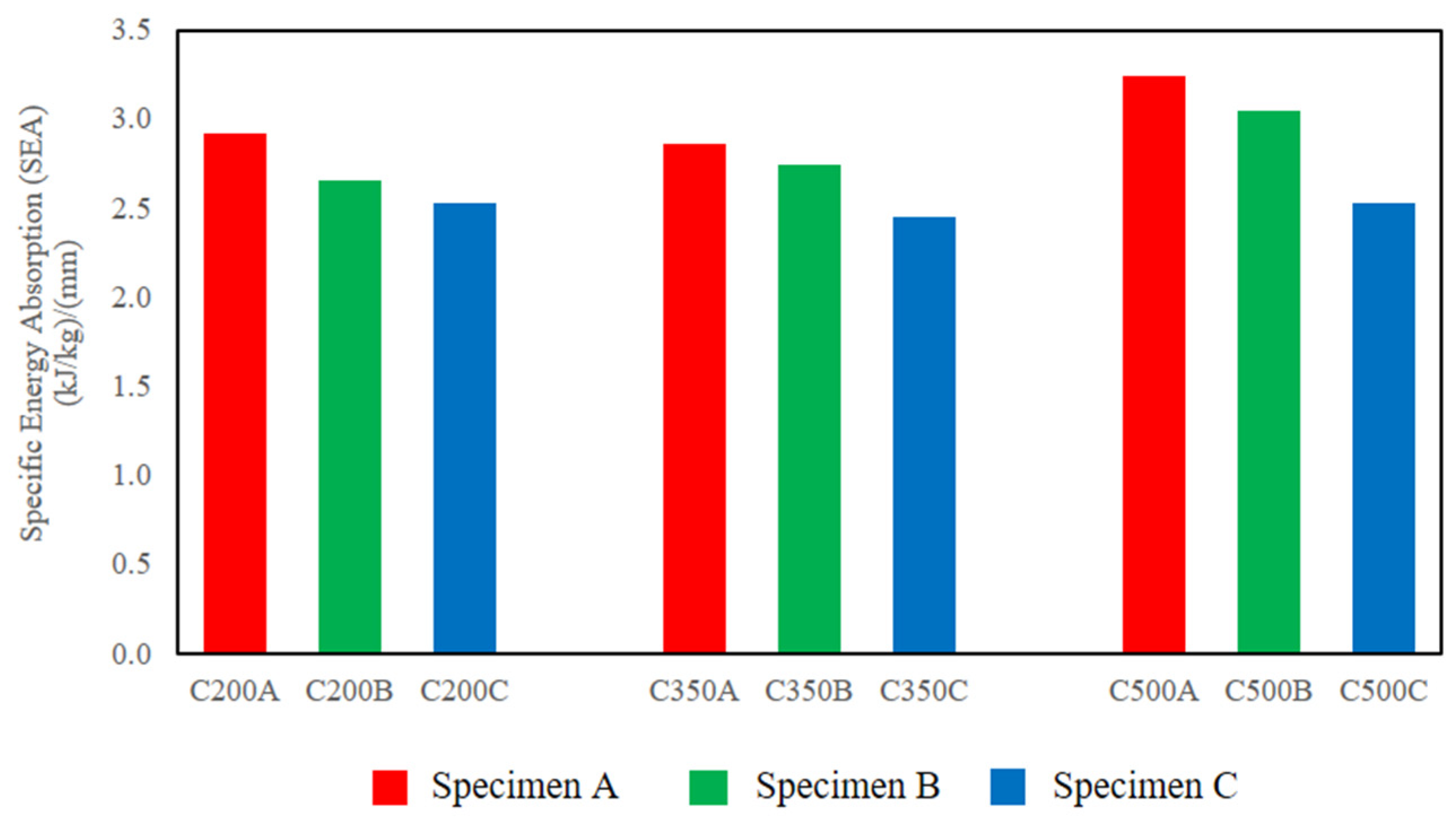

| Impact Energy (J) | Sample Label | Maximum Stress (MPa) | Strain | Energy (J) | SEA (kJ/kg)/(mm) |

|---|---|---|---|---|---|

| 200 | C200A | 58.12 (±0.008) | 0.17 (±0.002) | 185.79 (±0.05) | 2.9 (±0.4) |

| C200B | 52.99 (±0.011) | 0.20 (±0.009) | 189.85 (±0.07) | 2.7 (±0.2) | |

| C200C | 51.38 (±0.004) | 0.22 (±0.001) | 191.82 (±0.07) | 2.5 (±0.1) | |

| 350 | C350A | 67.72 (±0.009) | 0.32 (±0.012) | 343.79 (±0.08) | 2.9 (±0.4) |

| C350B | 64.15 (±0.012) | 0.36 (±0.011) | 344.53 (±0.15) | 2.7 (±0.3) | |

| C350C | 56.84 (±0.011) | 0.42 (±0.007) | 347.19 (±0.11) | 2.4 (±0.1) | |

| 500 | C500A | 81.53 (±0.003) | 0.43 (±0.009) | 471.32 (±0.02) | 3.2 (±0.3) |

| C500B | 81.21 (±0.001) | 0.46 (±0.002) | 478.89 (±0.05) | 3.0 (±0.2) | |

| C500C | 72.43 (±0.004) | 0.56 (±0.005) | 483.11 (±0.07) | 2.5 (±0.5) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siddique, S.H.; Hazell, P.J.; Pereira, G.G.; Wang, H.; Escobedo, J.P. Low-Velocity Impact Behaviour of Biomimetic Cornstalk-Inspired Lightweight Structures. Mater. Proc. 2025, 20, 3. https://doi.org/10.3390/materproc2025020003

Siddique SH, Hazell PJ, Pereira GG, Wang H, Escobedo JP. Low-Velocity Impact Behaviour of Biomimetic Cornstalk-Inspired Lightweight Structures. Materials Proceedings. 2025; 20(1):3. https://doi.org/10.3390/materproc2025020003

Chicago/Turabian StyleSiddique, Shakib Hyder, Paul J. Hazell, Gerald G. Pereira, Hongxu Wang, and Juan P. Escobedo. 2025. "Low-Velocity Impact Behaviour of Biomimetic Cornstalk-Inspired Lightweight Structures" Materials Proceedings 20, no. 1: 3. https://doi.org/10.3390/materproc2025020003

APA StyleSiddique, S. H., Hazell, P. J., Pereira, G. G., Wang, H., & Escobedo, J. P. (2025). Low-Velocity Impact Behaviour of Biomimetic Cornstalk-Inspired Lightweight Structures. Materials Proceedings, 20(1), 3. https://doi.org/10.3390/materproc2025020003