A Proposal for the Use of Recycled Aggregates in Concrete in Greece †

Abstract

1. Introduction

- Coarse recycled aggregates (≥4 mm) are used at a rate of 20–100%, based on exposure and compressive strength classes. In most cases, coarse recycled aggregates of the high-quality class ≥Rc90, or ≥Rcu90, are used.

- The possibility of using recycled sand remains limited. Recycled sand usually includes impurities not compatible for the manufacture of concrete, except in the case where the recycled material is derived solely from concrete demolition. The cost of removing impurities leads to the use of recycled sand in other applications.

- Aggregate requirements are based on the ΕΝ 12620 standard, with additional ones depending on their nature, for example, alkali–silica reaction testing in Germany, or the use of recycled aggregates of complex granulometry [=all-in aggregates] in Austria.

- Various qualities (high and low, Type A, Type B, etc.) of recycled aggregates are distinguished, all of which are used in the production of concrete of different exposure classes, strength classes and percentages depending on their characteristics.

2. Raw Material Characterization

2.1. Cement

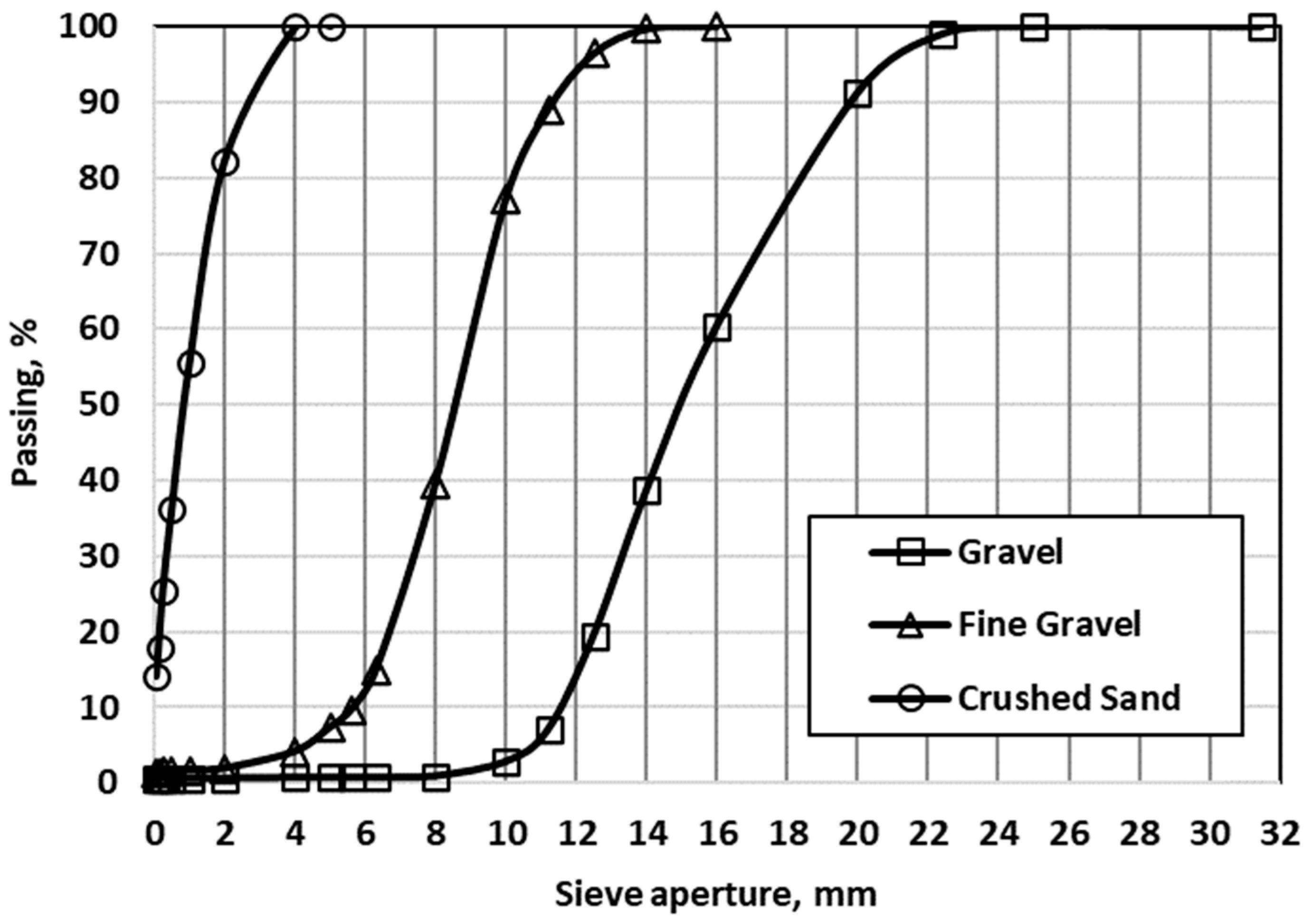

2.2. Crushed Aggregates

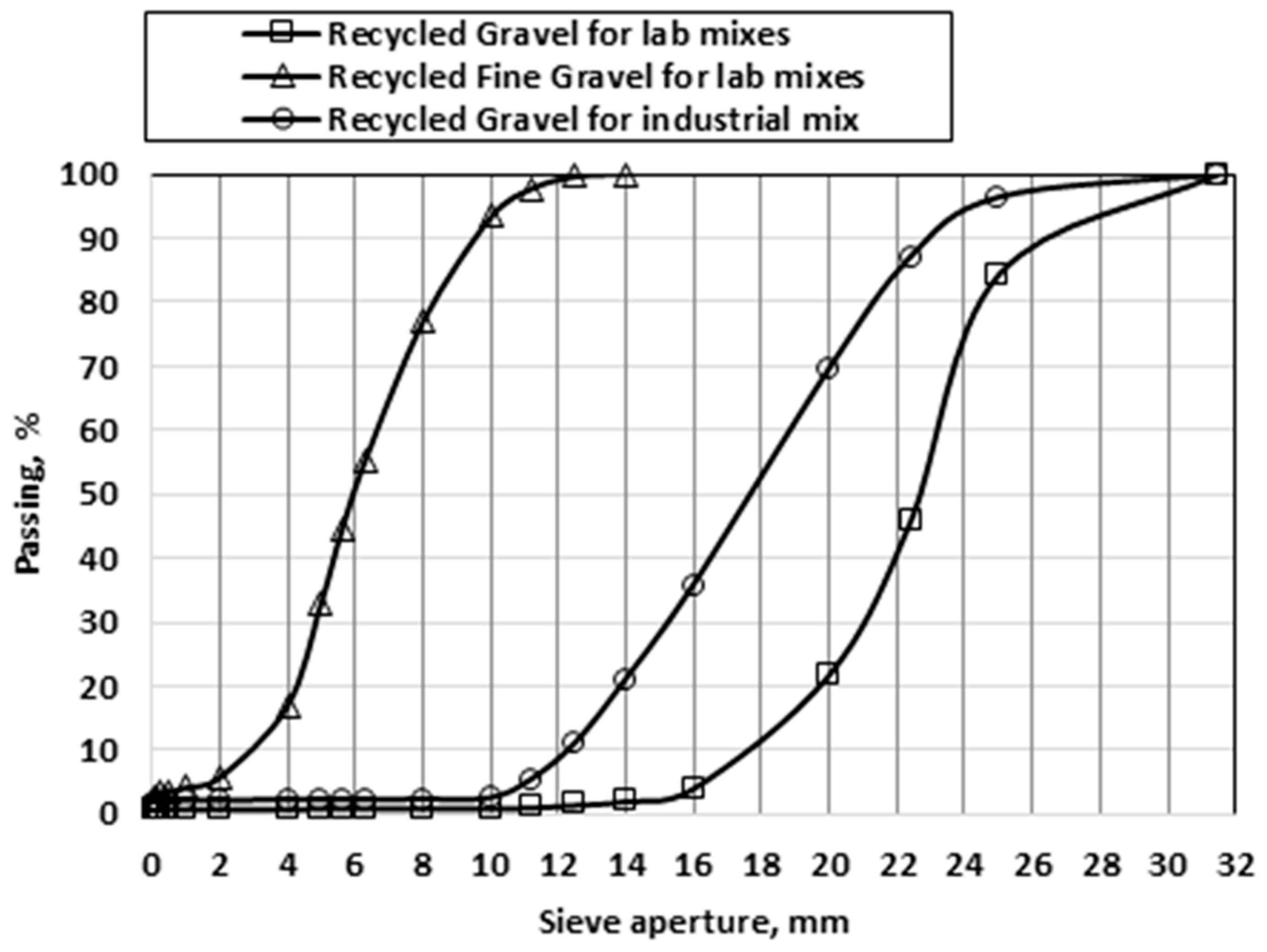

2.3. Recycled Aggregates

3. ECOPact Lab Mix Design Results

3.1. Mix Design–Fresh and Hardened Concrete Properties

3.2. Durability Results

4. C25/30 Industrial Mix Design Results

5. Conclusions

- Classes Rc90 and Rcu95;

- With production and quality certification;

- In concrete mix designs;

- Non-prestressed;

- In exposure classes up to XS1;

- In strength classes up to C30/37;

- With a substitution rate of recycled aggregates up to 30%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- EN 206:2021; Concrete–Specification, Performance, Production and Conformity. European Committee for Standardization: Brussels, Belgium, 2021.

- EN 12620:2002+A1; Aggregates for Concrete. European Committee for Standardization: Brussels, Belgium, 2008.

- LafargeHolcim. Use of Recycled Aggregates in Concrete Overview of National Rules; Corporate Workshop; LafargeHolcim: Lyon, France, 2021. [Google Scholar]

- ÖNORM B 4710-1:2018 01; Annex E of Austrian Concrete Standard–Use of Recycled Aggregates in Concrete. Austrian Standards Institute: Vienna, Austria, 2018.

- EN 196-1; Methods of Testing Cement—Part 1: Determination of Strength. European Committee for Standardization: Brussels, Belgium, 2016.

- ΕΝ 12390-18; Testing Hardened Concrete—Part 18: Determination of the Chloride Migration Coefficient. European Standard. European Committee for Standardization: Brussels, Belgium, 2018.

- ΕΝ 12390-12; Testing Hardened Concrete—Part 12: Determination of the Carbonation Resistance of Concrete–Accelerated Carbonation Method. European Committee for Standardization: Brussels, Belgium, 2020.

- EKET; HERACLES Group. TS_4641_16.06.2020_Recycled Aggregates for Concrete, Technical Recommendation; HERACLES Group: Athens, Greece, 2020. [Google Scholar]

- Anastasiou, E.; Papachristoforou, M.; Anesiadis, D.; Zafeiridis, K.; Tsardaka, E.C. Investigation of the Use of Recycled Concrete Aggregates Originating from a Single Ready-Mix Concrete Plant. Appl. Sci. 2018, 8, 2149. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J. Concrete, Microstructure, Properties and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

| Recycled Aggregate Type | Exposure Classes | |||

|---|---|---|---|---|

| X0 | XC1, XC2 | XC3, XC4, XF1, XA1, XD1 | All Other Exposure Classes a | |

| Type A:(Rc90, Rcu95, Rb10-, Ra1-, FL2-, XRg1-) | 50% | 30% | 30% | 0% |

| Type B b: (Rc50, Rcu70, Rb30-, Ra5-, FL2-, XRg2-) | 50% | 20% | 0% | 0% |

| Rc | Concrete, Concrete Products, Mortar, Concrete Masonry Units |

|---|---|

| Ru | Unbound aggregate, natural stone, hydraulically bound aggregate |

| Rb | Clay masonry units (i.e., bricks and tiles), calcium silicate masonry units, aerated non-floating concrete |

| Ra | Bituminous materials |

| Rg | Glass |

| X | Other: cohesive (i.e., clay and soil) Miscellaneous: metals (ferrous and non-ferrous), non-floating wood, plastic and rubber, gypsum plaster |

| 90 | Index for content at least 90% |

| 2- | Index for content less than or equal 2% |

| Country | Fine Aggregates | Coarse Aggregates |

|---|---|---|

| Germany | No use mentioned | Defined as ≥2 mm |

| France | Use of recycled sand | |

| Austria | Use is allowed. Defined as ≤8 mm | |

| Poland | No use mentioned | Defined as ≥4 mm |

| United Kingdom | Not recommended | Defined as ≥4 mm |

| Belgium | Not recommended | |

| Netherlands | Recycled sand ≤ 4 mm may be used in substitution of up to 20% of non-recycled sand, without certification but not in combination with recycled coarse aggregates | |

| Italy | Not recommended | Defined as ≥4 mm |

| Spain | Not allowed | Defined as ≥4 mm |

| Country | Maximum Participation % for Each Exposure Class | Maximum Strength Class | ||||||

|---|---|---|---|---|---|---|---|---|

| X0 | XC1 | XC2 | XC3 | XC4 | XS1 | XS2 | ||

| Germany | 45 | 45 | 45 | 45 | 45 | |||

| France | 60 | 40 | 40 | 30 | 30 | 30 | 10 | |

| Austria | 50 | 50 | 50 | 50 | 50 | |||

| Poland | 50 | 30 | 30 | 30 | 30 | |||

| United Kingdom | 100 | 100 | 100 | 100 | 100 | C16/20 | ||

| 20 | 20 | 20 | 20 | 20 | 20 | 20 | C40/50 | |

| 100 | 100 | 100 | 100 | 100 | ||||

| Belgium | 50 | 30 | 30 | 20 | 20 | C30/37 | ||

| Netherlands (a) | 30 | 30 | 30 | 30 | 30 | 30 | 30 | C50/60 |

| (b) | 50 | 50 | 50 | 50 | 50 | 50 | 50 | |

| (c) | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| Italy | 30 | 30 | 30 | 30 | C30/37 | |||

| 20 | 20 | 20 | 20 | 20 | 20 | 20 | C45/55 | |

| Spain | 20 | 20 | 20 | 0 | 20 | 20 | 20 | C40/50 |

| Lab Code | Compressive Strength (MPa) | ||

|---|---|---|---|

| 2 d | 7 d | 28 d | |

| 49863 | 22.8 | 34.5 | 44.3 |

| Property | Grade/Lab Code | ||

|---|---|---|---|

| Gravel/49377 | Fine Gravel/48436 | Crushed Sand/49378 | |

| Flakiness index, % (EN 933-3) | 4.7 | 8.8 | - |

| Sand equivalent, % (EN 933-8) | - | - | 77 |

| Methylene Blue value, g/kg (EN 933-9) | - | - | 0.25 |

| Los Angeles, % (EN 1097-2) | - | 26.0 | - |

| Apparent particle density ρa, kg/L (EN 1097-6) | 2.69 | 2.68 | 2.60 |

| Oven-dried particle density, ρrd, kg/L (EN 1097-6) | 2.66 | 2.65 | 2.57 |

| Water absorption, % (EN 1097-6) | 0.32 | 0.40 | 1.55 |

| Property | Grade/Lab Code | ||

|---|---|---|---|

| Gravel (a) /49859 | Fine Gravel (a),(b) /49860 | Gravel (b) /49957 | |

| Flakiness index, % (EN 933-3) | - | 8.5 | - |

| Los Angeles, % (EN 1097-2) | - | 28.4 | - |

| Classification (ΕΝ 933-11) | Rcu95 | Rcu95 | Rcu95 |

| Apparent particle density ρa, kg/L (EN 1097-6) | 2.71 | 2.72 | 2.70 |

| Oven-dried particle density, ρrd, kg/L (EN 1097-6) | 2.65 | 2.64 | 2.64 |

| Water absorption, % (EN 1097-6) | 0.77 | 1.04 | 0.90 |

| Property | § EN 12620 | Type | Category EN 12620 | Gravel | Fine Gravel |

|---|---|---|---|---|---|

| Fines content | 4.4 | A+Β | Value to be declared | 0.7–0.8 | 2.5–2.6 |

| Flakiness index | 4.6 | A+Β | ≤FI50 | 4.3 | 8.5 |

| Los Angeles | 5.2 | A+Β | ≤LI50 | - | 28.4 |

| Oven-dry density, ρrd | 5.4.1 | A | ≥2.1 Mg/m3 | 2.64–2.65 | 2.57–2.64 |

| Β | ≥1.7 Mg/m3 | - | - | ||

| Water absorption | 5.4.2 | A+Β | Value to be declared | 0.77–0.95 | 1.04–1.43 |

| Constituents | 6.3 | A | Rc90, Rcu95, Rb10-, Ra1-, FL2-, XRg1- | Rcu95 = 99%, Rb10- = 0%, Ra1- = 0%, FL2- = 0%, XRg1- = 0% | |

| Β | Rc50, Rcu70, Rb30-, Ra5-, FL2-, XRg2- | - | - | ||

| Water-soluble sulfate content | 6.4.3 | A+Β | ≤SS0.2 | SS0,2 | |

| Acid-soluble chloride content | 6.5 | A+Β | 0.014% | ||

| Influence on the initial setting time | 6.7.1 | A+Β | ≤A40 | A10 | |

| C16/20 ECOPact | C20/25 ECOPact | |||

|---|---|---|---|---|

| Ref mix | Control mix | Ref mix | Control mix | |

| Lab code | 9479, 9546 | 9481, 9547 | 9483, 9516 | 9484, 9518 |

| Cement CEM II 32,5Ν, kg/m3 | 265 | 265 | 280 | 280 |

| Water, kg/m3 | 184 | 184 | 185 | 185 |

| Gravel, kg/m3 | 660 | 464 | 666 | 466 |

| Fine gravel, kg/m3 | 126 | 88 | 154 | 108 |

| Sand, kg/m3 | 1127 | 1129 | 1077 | 1077 |

| Recycled gravel, kg/m3 | 199 | 201 | ||

| Recycled fine gravel, kg/m3 | 40 | 47 | ||

| Admixture, kg/m3 | 1.06 | 1.06 | 1.68 | 1.68 |

| Slump 5 min, cm | 14 | 15 | 10 | 15 |

| Slump 30 min, cm | 9 | 10 | 7 | 10 |

| Cs 3d, MPa | 18.9 | 19.7 | 22.0 | 20.8 |

| Cs 7d, MPa | 24.8 | 25.1 | 28.5 | 25.8 |

| Cs 28d, MPa | 27.6 | 29.5 | 32.4 | 31.4 |

| Cs 90d, MPa | 29.5 | 29.6 | 37.0 | 33.9 |

| Modulus of elasticity at 28d, GPa | 34.2 | 32.4 | 34.0 | 29.3 |

| C25/30 ECOPact | C30/37 ECOPact | |||

|---|---|---|---|---|

| Ref mix | Control mix | Ref mix | Control mix | |

| Lab code | 9497, 9528 | 9498, 9529 | 9492, 9524 | 9493, 9526 |

| Cement CEM II 32,5Ν, kg/m3 | 330 | 330 | 320 | 320 |

| Water, kg/m3 | 180 | 180 | 170 | 170 |

| Gravel, kg/m3 | 642 | 450 | 680 | 477 |

| Fine gravel, kg/m3 | 212 | 148 | 168 | 118 |

| Sand, kg/m3 | 1009 | 1009 | 1053 | 1054 |

| Recycled gravel, kg/m3 | 193 | 205 | ||

| Recycled fine gravel, kg/m3 | 65 | 51 | ||

| Admixture, kg/m3 | 2.15 | 2.15 | 2.24 | 2.24 |

| Slump 5 min, cm | 14 | 14 | 23 | 22 |

| Slump 30 min, cm | 8 | 7 | 23 | 18 |

| Cs 3d, MPa | 27.4 | 27.6 | 32.2 | 31.7 |

| Cs 7d, MPa | 33.7 | 32.7 | 38.6 | 38.3 |

| Cs 28d, MPa | 39.5 | 40.5 | 48.6 | 46.1 |

| Cs 90d, MPa | 44.9 | 46.9 | 54.5 | 50.9 |

| Modulus of elasticity at 28 d, GPa | 38.6 | 37.1 | 38.9 | 36.6 |

| Test | Standard | Comments |

|---|---|---|

| Chloride migration coefficient | ΕΝ 12390-18 [6] | Cylindrical specimens: d 100 × h 200 mm Curing: 28 and 90 days Number of samples: 2/test |

| Accelerate carbonation | ΕΝ 12390-12 [7] | Cylindrical specimens: d 100 × h 200 mm Curing: 28 and 90 days Conditioning: 14 days Exposure: 28 and 70 days Number of samples: 2/test |

| A/A | Lab Mix Design | 28 Days | 90 Days | ||||

|---|---|---|---|---|---|---|---|

| Dnssm∙10−12 (m2/s) | Sr | CoV% | Dnssm∙10−12 (m2/s) | Sr | CoV% | ||

| 1 | 9479-ref | 29.0 | 2.4 | 8.4 | 19.9 | 1.6 | 7.9 |

| 2 | 9481-cont. | 29.9 | 1.6 | 5.4 | 23.3 | 2.7 | 11.6 |

| 3 | 9516-ref | 30.1 | 2.3 | 7.5 | 20.6 | 1.4 | 6.6 |

| 4 | 9518-cont. | 29.8 | 3.3 | 11.0 | 20.1 | 1.3 | 6.7 |

| 5 | 9524-ref | 26.0 | 1.3 | 4.9 | 13.5 | 0.6 | 4.3 |

| 6 | 9526-cont. | 23.2 | 1.7 | 7.5 | 12.3 | 1.3 | 10.6 |

| 7 | 9528-ref | 18.7 | 0.6 | 3.3 | 13.6 | 1.2 | 8.6 |

| 8 | 9529-cont. | 19.5 | 1.1 | 5.6 | 11.7 | 0.4 | 3.6 |

| A/A | Lab Mix Design | 28 Days | 70 Days | ||||

|---|---|---|---|---|---|---|---|

| CO2 Depth (mm) | Sr | Cov% | CO2 Depth (mm) | Sr | Cov% | ||

| 1 | 9479-28 (ref) | 8.4 | 0.4 | 5.2 | 14.9 | 0.3 | 2.2 |

| 2 | 9481-28 (cont.) | 8.7 | 0.4 | 4.4 | 14.4 | 0.4 | 2.7 |

| 3 | 9516-28 (ref) | 9.8 | 1.3 | 13.2 | 16.2 | 0.6 | 3.6 |

| 4 | 9518-28 (cont.) | 7.5 | 1.7 | 22.7 | 13.5 | 0.9 | 7.0 |

| 5 | 9524-28 (ref) | 5.8 | 0.2 | 3.6 | 9.5 | 0.1 | 1.2 |

| 6 | 9526-28 (cont.) | 4.5 | 0.8 | 17.0 | 7.5 | 0.4 | 5.5 |

| 7 | 9528-28 (ref) | 5.9 | 0.9 | 15.4 | 9.9 | 0.7 | 6.8 |

| 8 | 9529-28 (cont.) | 4.9 | 1.3 | 26.6 | 9.0 | 1.4 | 15.0 |

| A/A | Lab Mix Design | 28 Days | 70 Days | ||||

|---|---|---|---|---|---|---|---|

| CO2 Depth (mm) | Sr | Cov% | CO2 Depth (mm) | Sr | Cov% | ||

| 1 | 9479-90 (ref) | 8.0 | 0.9 | 11.0 | 15.9 | 1.7 | 10.7 |

| 2 | 9481-90 (cont.) | 7.2 | 1.4 | 19.6 | 17.9 | 1.4 | 7.6 |

| 3 | 9516-90 (ref) | 12.3 | 0.0 | 0.00 | 17.2 | 2.1 | 12.0 |

| 4 | 9518-90 (cont.) | 10.0 | 1.4 | 13.6 | 14.5 | 0.9 | 6.5 |

| 5 | 9524-90 (ref) | 5.8 | 1.3 | 22.6 | 8.2 | 0.8 | 9.7 |

| 6 | 9526-90 (cont.) | 3.6 | 1.4 | 38.0 | 5.0 | 3.1 | 60.8 |

| 7 | 9528-90 (ref) | 2.1 | 0.6 | 28.8 | 6.0 | 0.5 | 8.4 |

| 8 | 9529-90 (cont.) | 3.8 | 0.0 | 0.0 | 8.0 | 1.1 | 13.9 |

| Ref Mix | Control Mix | |

|---|---|---|

| Cement CEM II 32,5Ν, kg/m3 | 310 | 310 |

| Water, kg/m3 | 174 | 176 |

| Gravel, kg/m3 | 625 | 438 |

| Fine gravel, kg/m3 | 160 | 160 |

| Sand, kg/m3 | 1115 | 1115 |

| Recycled gravel, kg/m3 | 188 | |

| Admixture, kg/m3 | 2.17 | 2.17 |

| Slump 5, cm | 14 | 15 |

| Slump 30, cm | 9 | 11 |

| Slump 60, cm | 6 | 9 |

| Cs 3d, MPa | 26.9 | 27.8 |

| Cs 7ημ, MPa | 35.2 | 37.4 |

| Cs 28d, MPa | 41.1 | 43.2 |

| Modulus of elasticity 28d, GPa | 34.4 | 33.9 |

| Water depth under pressure at 28 d, mm | 15.2 | 15.1 |

| Pore volume at 28 d, % v/v | 11.9 | 11.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nomikou, M.; Kouris, C.; Karkaletsis, T.; Kaloidas, V.; Badogiannis, E. A Proposal for the Use of Recycled Aggregates in Concrete in Greece. Mater. Proc. 2023, 15, 92. https://doi.org/10.3390/materproc2023015092

Nomikou M, Kouris C, Karkaletsis T, Kaloidas V, Badogiannis E. A Proposal for the Use of Recycled Aggregates in Concrete in Greece. Materials Proceedings. 2023; 15(1):92. https://doi.org/10.3390/materproc2023015092

Chicago/Turabian StyleNomikou, Maria, Charalampos Kouris, Thalassis Karkaletsis, Vasileios Kaloidas, and Efstratios Badogiannis. 2023. "A Proposal for the Use of Recycled Aggregates in Concrete in Greece" Materials Proceedings 15, no. 1: 92. https://doi.org/10.3390/materproc2023015092

APA StyleNomikou, M., Kouris, C., Karkaletsis, T., Kaloidas, V., & Badogiannis, E. (2023). A Proposal for the Use of Recycled Aggregates in Concrete in Greece. Materials Proceedings, 15(1), 92. https://doi.org/10.3390/materproc2023015092