1. Introduction

With the global shift towards renewable energy and the digitalization of our economies and societies, demand for some critical raw materials is forecasted to rapidly increase in the coming decades [

1] The platinum group metals (PGMs) are a family of six structurally and chemically similar elements that are most valued for their wide range of industrial, medical, and electronic applications. These versatile metals play a significant role in many of the products we use every day [

2]. The NRE fleet is a unique, innovative electric robotic solution for underground mining aiming to increase safety and productivity while reducing capital and operating costs. The fleet is specifically designed for mining sub-horizontal platinum group elements (PGEs) deposits, but in the future, it can be used for mining other deposits. The annual worldwide production of PGM is around 450–460 metric tons, while the largest producers are South Africa and Russia (about 80% of the market), followed by the USA, Canada, Zimbabwe, Australia, and others.

2. Geological Features of the PGE Deposits

2.1. PGE Reef Deposits

The main geological characteristics of the PGE reefs are the following [

3]: (1) PGE reef deposits are associated with large, layered mafic–ultramafic intrusions; (2) layered mafic–ultramafic intrusions are stratified. The lowermost part is an ultramafic zone with dunite, harzburgite, pyroxenite, and chromitite grading upward to a central mafic zone with norite, gabbro, pyroxenite, and chromitite and an uppermost mafic zone with Fe-Ti-rich gabbros and diorite. The majority of the PGE reef mineralization is located within or in the vicinity of the central mafic zone; (3) PGE-bearing rocks are often chromitites or other cumulate rocks such as pyroxenite or late-stage pyroxenite pegmatites frequently associated with Cu-Ni-Co ore; (4) PGE-bearing intrusions are Archean to Proterozoic in age; however, younger equivalents found in Greenland are Eocene in age (Skaergaard intrusion); (5) the origin of PGE mineralization is related to sulfide immiscibility caused by magma mixing or crustal contamination and/or by hydrothermal fluid migrating upwards through the thick pile of crystalized cumulates; (6) mineralization is stratiform and syngenetic, mainly in the form of mineralized layers or lenses, spreading horizontally for tens of kilometers and having an economic-grade thickness from several meters to below 0,5 m; (7) mineralization is present as a disseminated chalcopyrite-pyrite-PGM assemblage, with the average PGE concentration usually below 10 ppm.

The Bushveld mafic–ultramafic intrusion (NSR) covers an area of 66,000 km

2 and hosts two PGE reefs (the Marensky Reef and UG2) with average thicknesses varying from <0.5 m to a maximum of 3 m (the majority being between 0.7 and 1.5 m). According to [

4], the Bushveld intrusion hosts 30+ PGE mines, representing the world’s largest PGE accumulation. The great dyke intrusion (Zimbabwe) hosts seven PGE mines with PGE reefs between 1.5 and 5 m in thickness [

4], while the Munni Munni intrusion (Australia) hosts six PGE mines with reef mineralization of an average of 2.5 m in thickness [

4]. Other important mafic–ultramafic intrusions Penikat & Portimo and Kemi (Finland), Stillwater, Mustox (Canada), Skaergaard (Greenland), Burakovski Fedorova Pansky and Tundra (Russia), and Yoko Dvyren (Chine) also host important PGE reef deposits of similar characteristics.

The European deposits are located within Finland and neighboring Sweden in three intrusive belts [

5]: (1) central Lapland (Koitelainen and Akanvaara intrusions), (2) northwestern Lapland (Tsohkoaivi, Kelottijarvi, Kurkovare, Keukiskero), and (3) the north–central Finland Tornio–Narankavaara belt (Penikat, Tornio, Kemi, Portimo, Koillismaa, and Narankavaara intrusions). For example, the Penikat intrusion contains six PGE-enriched horizons exposed along >20 km of strike with three economically important reefs: the Sompujarvi PGE Reef (3–7 ppm for Pt and Pd; 1–2 m thickness), the PV reef (average of 2.6 ppm for Pd and 4 ppm for Pt; 1.1 m thickness), and the AP1 reef (average of 6.2 ppm for Pd, 1.7 ppm of Pt over 0.7 m).

The Skaergaard intrusion, which is under development in Greenland, contains three PGE reefs (H0, H3, H5) with thicknesses below 1 m, dipping up to 20 degrees and continuing for around 6 km along the strike [

6]. The H0, H3, and H5 reefs contain 0.88 g/t gold and 1.33 g/t palladium and recoverable amounts of titanium, ilmenite, vanadium, copper, and gallium.

2.2. Komatiite-Hosted Ni-Cu-PGE Deposits

The geological features of the PGE komatiites are the following [

7]: (1) host rocks are komatiite basalts, ultramafic volcanic rocks with spinifex textures of olivine, having typically high MgO, Ni, and Cr contents and low SiO

2 and TiO

2 contents; (2) PGE deposits are associated with the central part of the thermally abraded komatiite flows; (3) PGE mineralization is related to disseminated Ni-Cu sulfides; (4) ore is syngenetic and stratiform, usually in the form of layers and lenses up to several meters in thicknesses; and (4) deposits are Archean or Paleoproterozoic in age.

Several European Ni-Cu-PGE-bearing komatiite deposits are located in Finland (Lomalampi, Sakatti, Vaara, Kauniinlampi, Peura-aho, and Tainiovaara).

3. Underground Mining of Sub-Horizontal PGE Ore Bodies

According to available data, 7 of the 10 largest platinum mines in the world are operated as underground mines, 2 of them in a combination of underground and open-pit mining, and only 1 in open-pit mining [

8]. Underground mining imposes very rigid constraints on mobile equipment design [

9]. The platinum mining industry is using a number of different mining methods, including variations of the same method, to extract the narrow reef tabular platinum [

10]. The choice of a particular mining ‘method’—i.e., the specific mix of techniques for excavation, ground support, and materials handling—is greatly influenced by the nature of the orebody being exploited. The mining method is based on the concept that on-reef development takes place on the strike, prior to stoping, thereby ensuring that all the necessary services and infrastructure are in place prior to stoping. This results in an improvement in the overall efficiency of the section and assists in providing a better understanding of the geology, which in turn will help to ensure better planning for the section before stoping commences [

11]

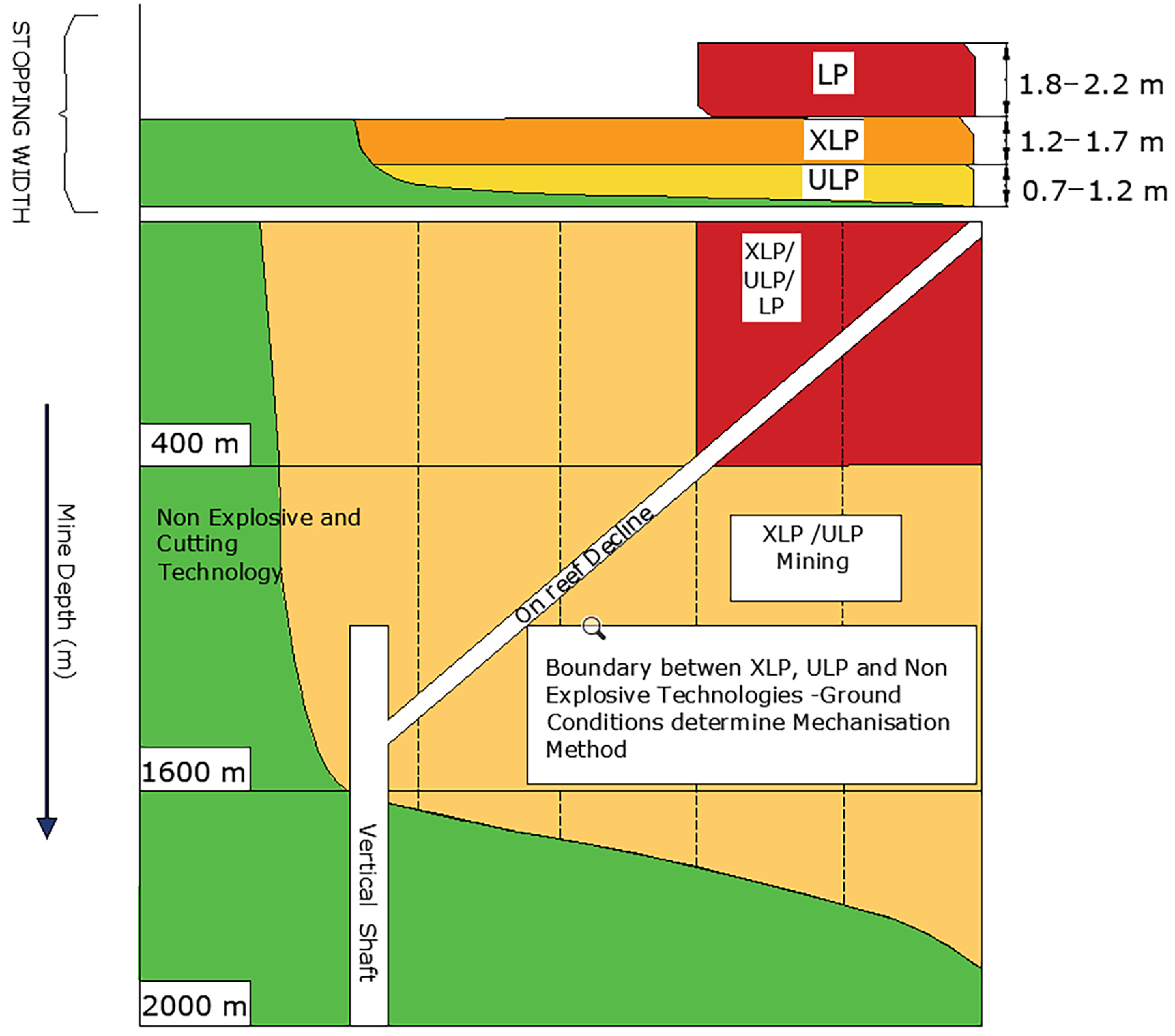

In terms of the stoping width, three types of equipment can be used for mining:

- -

LP—low-profile equipment;

- -

XPL—extra-low-profile equipment;

- -

ULP—ultra-low-profile equipment.

LP is mostly used in board and pillar mining; XLP and ULP are mostly used in breast mining.

Different mining methods and applications are shown in

Figure 1. A summary of the advantages and disadvantages of different equipment types in stoping is given in

Table 1.

4. NRE Fleet

NRE Fleet’s ultra-low profile and ability to work on the slopes up to 22° create possibilities for more optimum mine designs and development of the ore bodies that were unreachable or too costly to produce. The need to design and produce new types of equipment is further supported by the increasing demand for strategic and critical metals and minerals. This demand requires operators to be able to access more complex and geologically challenging deposits that were not able to be mined previously. If mining companies can meet these increasing demands in the future, they must be able to excavate deposits in a resource-efficient way. Therefore, there is a need for equipment that can meet these challenges. There are a number of pieces of equipment currently under development; DOK-ING is a company that works towards this goal.

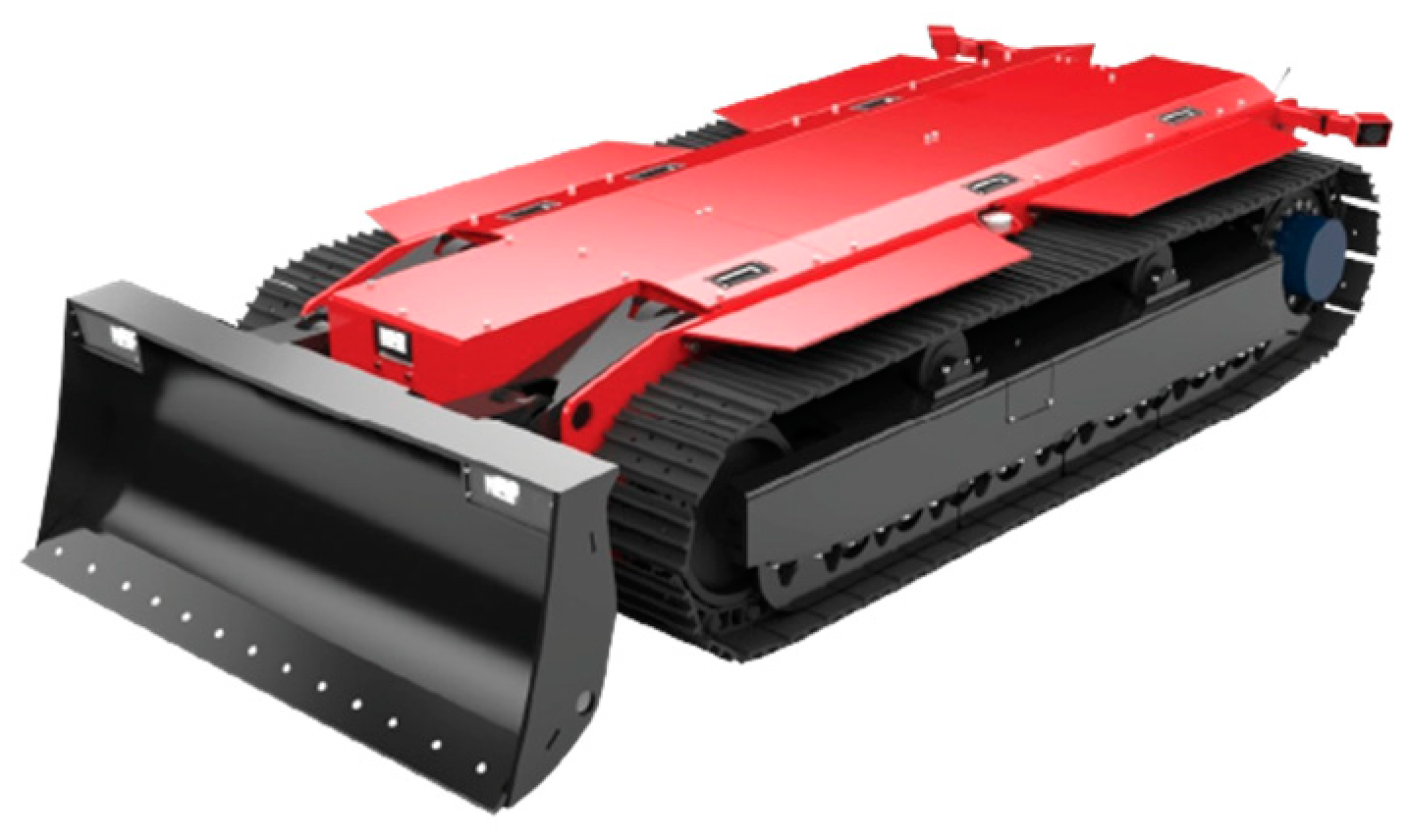

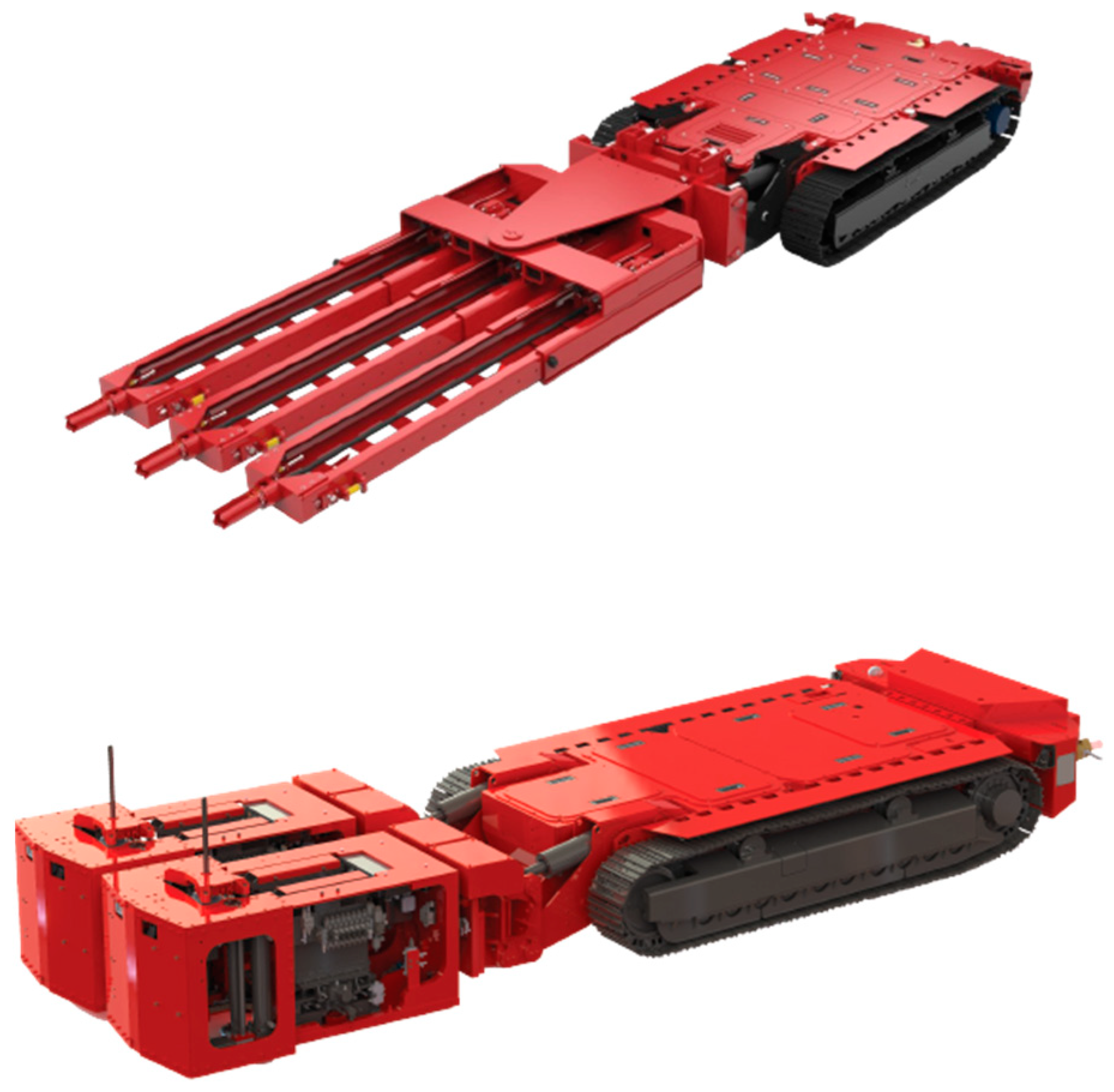

All three NRE machines operate between a panel width of 0.9 m and 1.7 m at a 22° slope (dozer up to 25° slope), are remote-controlled, fully automatic with tracked undercarriage, and are zero-emission due to electric drive. The NRE equipment (

Figure 2) is equipment only available for mechanized production of reefs thinner than 1.7 m and equipment that can only mechanize production from reef dips greater than 14 deg. All three prototypes were successfully deployed in 2017 in the Twickenem mine for proof of concept (POC) and have the following characteristics:

- (1)

NRE Dozer—used for cleaning production panels from blasted material with a battery capacity of 8–11 h of operation, allowing for completion of one working shift without being recharged.

- (2)

NRE Drill Rig—used for drilling blast holes. Contains three booms that drill three parallel holes simultaneously in a single cycle of 5 min. Has the ability to adjust angles, enabling unmatched control of blast direction.

- (3)

NRE Support Rig—used for supporting the hanging wall with a fully automated cycle of self-drilling resin bolt installation. Self-drilling resin bolts are an innovative support solution that secures self-drilling bolts in the hanging wall by pumping quick-setting resin, speeding up the process of supporting and having the ability to hold more than 20 tons per installed bolt.

NRE mechanization will be even more in use in the future for the following reasons:

Mechanization has inherent safety considerations, where the focus is to efficiently and effectively mine ore with increased productivity and reduced time lost.

There is a strong correlation between improved safety performance (lower injury frequency rates) and improved productivity (square meters per operating employee).

Additional time allocated to the mechanized mining cycle time is mitigated by the decreased time lost due to fall-of-ground and transportation-related incidents [

14]

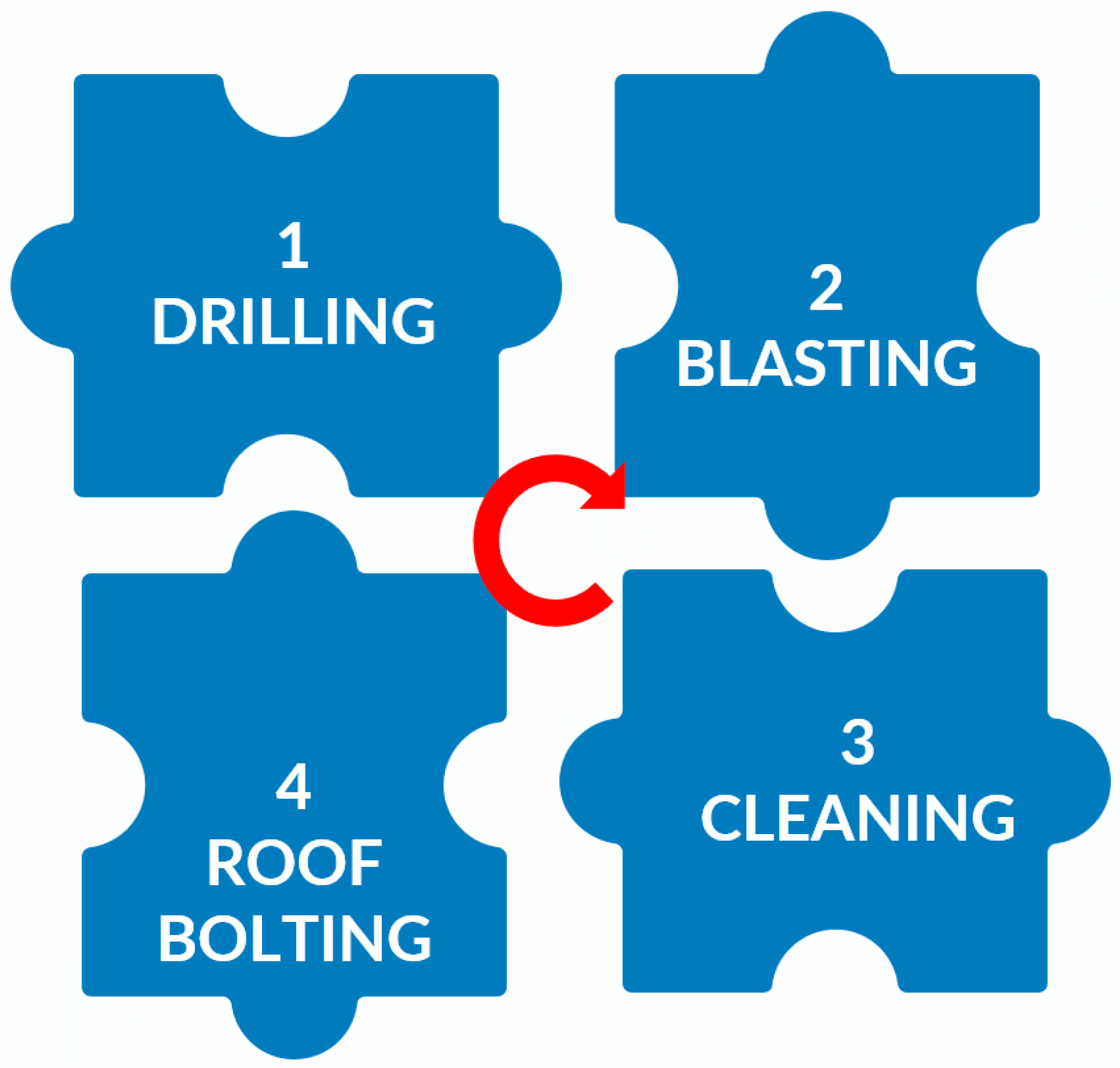

Mining with NRE should be organized in several separate panels that can be of different lengths and heights, and the mining is performed in mining cycles. Each mining cycle consists of individual mining operations. The mining cycle has four main operations, as shown in

Figure 3.

Except for blasting, in which blast holes are filled with explosives manually, all other operations can be performed using NRE equipment from a safe distance.

5. Conclusions

The majority of the layered mafic–ultramafic intrusions worldwide contain thin PGE reef deposits, where economically viable PGE production is conducted very often at thicknesses below 2 m. The sub-horizontal occurrences of the PGE ore, where inclination rarely exceeds 20 degrees, make these deposits an ideal type for implementing the NRE equipment.

The benefit of the solution is the increased efficiency of the NRE Fleet with the narrow reef mining method, which is 2.500–4.000 m2 per month, exceeding the classic mining method with conventional machines reaching 2.500–2.800 m2. By reducing the panel width, the NRE fleet can reduce the dilution of ore grade by up to 70%, reduce capital investment by up to 35%, and reduce operating expenses by up to 30%. Through mechanization of the production process, the fleet can reduce underground personnel by 70% (compared to conventional mining), increase production efficiency, and drastically increase the safety of the remaining personnel through remote control. The tracked undercarriage with electric drive enables the fleet to operate at a 22° slope, compared to conventional wheeled, diesel-powered equipment limited at slopes of 14°. Operating at higher slope angles, in turn, enables production from mine formations unreachable by conventional equipment, mine design flexibility, and significant mine development cost reduction. Extra benefits are a smaller carbon footprint, higher safety of workers, and access to new deposits or parts of old deposits that could not be mined until now.

Author Contributions

V.B. and S.B.Š., conceptualization; L.P., resources; L.P., V.B. and S.B.Š., writing—original draft preparation; V.B. and S.B.Š., writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by EIT RawMaterials as part of project 23024—NRE-ElectRA (Electric, Remote Control, Automatic Narrow Reef Mining Equipment).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- European Commission. Brussels Regulation of the European Parliament and of the Council Establishing a Framework for Ensuring a Secure and Sustainable Supply of Critical Raw Materials and Amending Regulations (EU) 168/2013, (EU) 2018/858, 2018/1724 and (EU) 2019/1020; European Commission: Brussels, Belgium, 2023.

- Shaffer, C. What Are the Platinum Group Metals and Why Do They. In Accelerating Science; Thermo Fisher Scientific: Waltham, MA, USA, 2015; pp. 1–2. [Google Scholar]

- Charlier, B.; Namur, O.; Latypov, R.; Tegner, C. Layered Intrusions; Springer: Berlin/Heidelberg, Germany, 2015; pp. 1–748. [Google Scholar] [CrossRef]

- Wilson, A.H. Platinum-Group Element Mineralisation in the Great Dyke, Zimbabwe, and Its Relationship to Magma Evolution and Magma Chamber Structure. S. Afr. J. Geol. 2001, 104, 319–342. [Google Scholar] [CrossRef]

- Makkonen, H.V.; Halkoaho, T.; Konnunaho, J.; Rasilainen, K.; Kontinen, A.; Eilu, P. Ni-(Cu-PGE) Deposits in Finland—Geology and Exploration Potential. Ore Geol. Rev. 2017, 90, 667–696. [Google Scholar] [CrossRef]

- Nielsen, T.F.D.; Andersen, J.C.Ø.; Holness, M.B.; Keiding, J.K.; Rudashevsky, N.S.; Rudashevsky, V.N.; Salmonsen, L.P.; Tegner, C.; Veksler, I.V. The Skaergaard PGE and Gold Deposit: The Result of in Situ Fractionation, Sulphide Saturation, and Magma Chamber-Scale Precious Metal Redistribution by Immiscible Fe-Rich Melt. J. Petrol. 2015, 56, 1643–1676. [Google Scholar] [CrossRef]

- Konnunaho, J.; Halkoaho, T.; Hanski, E.; Törmänen, T. Komatiite-Hosted Ni-Cu-PGE Deposits in Finland. In Mineral Deposits of Finland; Elsevier: Amsterdam, The Netherlands, 2015; pp. 93–131. [Google Scholar] [CrossRef]

- Technology, M. World’s Ten Largest Platinum Mines in 2021. Available online: https://www.mining-technology.com/marketdata/ten-largest-platinums-mines-2021/ (accessed on 24 May 2023.).

- Olsen, S.G.; Hall, R.A.; Daneshmend, L.K.; Murphy, P.F.R. Integrated Design of an XLP Dozer. In Proceedings of the 3rd South African Institute of Mining and Metallurgy International Platinum Conference, Sun City, South Africa, 5–9 October 2008; pp. 263–268. [Google Scholar]

- Musingwini, C.; Minnitt, R.C.A. Ranking the Efficiency of Selected Platinum Mining Methods Using the Analytic Hierarchy Process (AHP). In Proceedings of the Third International Platinum Conference “Platinum in Transformation”, Sun City, South Africa, 5–9 October 2008; pp. 319–326. [Google Scholar]

- Fourie, F.; Valicek, P.; Krafft, G.; Sevenoaks, J. Narrow Reef Mechanized Mining Layout at Anglo American Platinum. In Proceedings of the 6th International Platinum Conference, ‘Platinum–Metal for the Future’, Sun City, South Africa, 20–24 October 2014; pp. 261–280. [Google Scholar]

- Fourie, F.; Valicek, P.; Krafft, G.; Sevenoaks, J. Narrow-Reef Mechanized Mining Layout at Anglo American Platinum. J. S. Afr. Inst. Min. Metall. 2017, 117, 263–274. [Google Scholar] [CrossRef][Green Version]

- DOK-ING NRE Dozer NRE Support Rig NRE Drill Rig. Available online: https://dok-ing.hr/underground-mining/# (accessed on 5 March 2023.).

- Valicek, P.; Fourie, F.; Krafft, G.; Sevenoaks, J. Optimization of Mechanized Mining Layout within Anglo American Platinum; The Southern African Institute of Mining and Metallurgy Platinum: Johannesburg, South Africa, 2012; pp. 1–35. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).