Investigation of Industrial Residues and Waste Materials to Expand the Raw Material Base for the Production of Lightweight Aggregates †

Abstract

1. Introduction

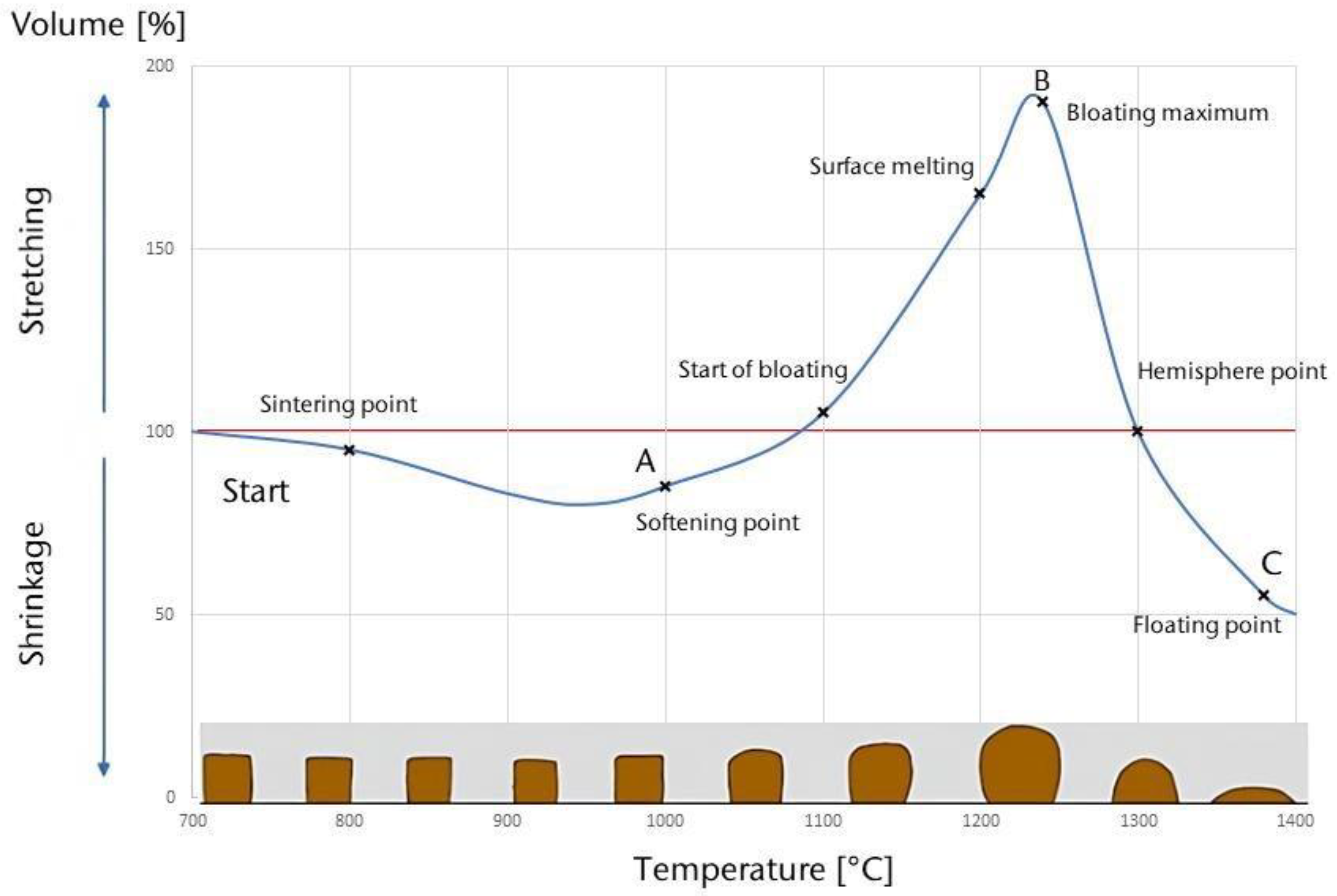

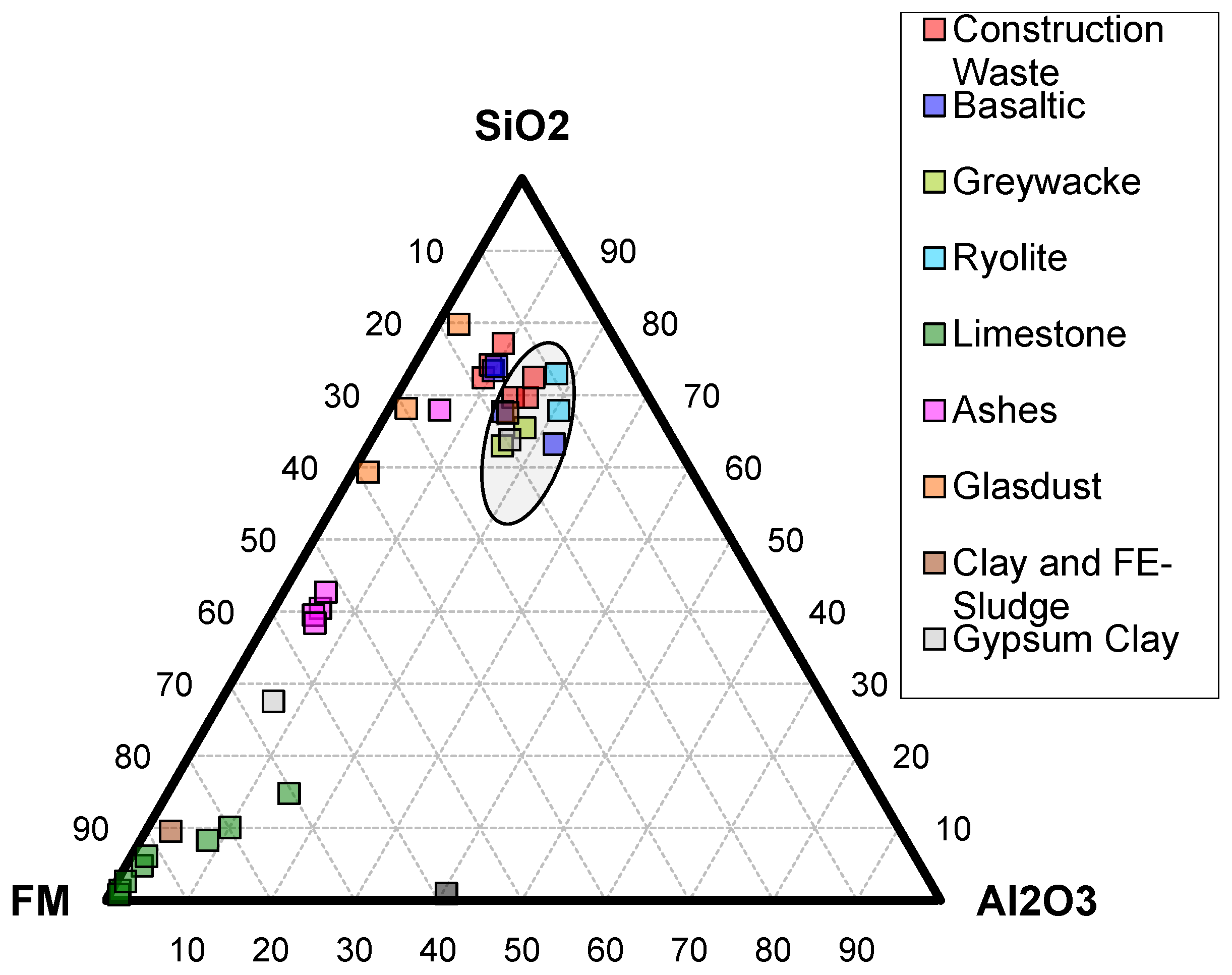

2. Theory of Bloating

3. Experimental Section

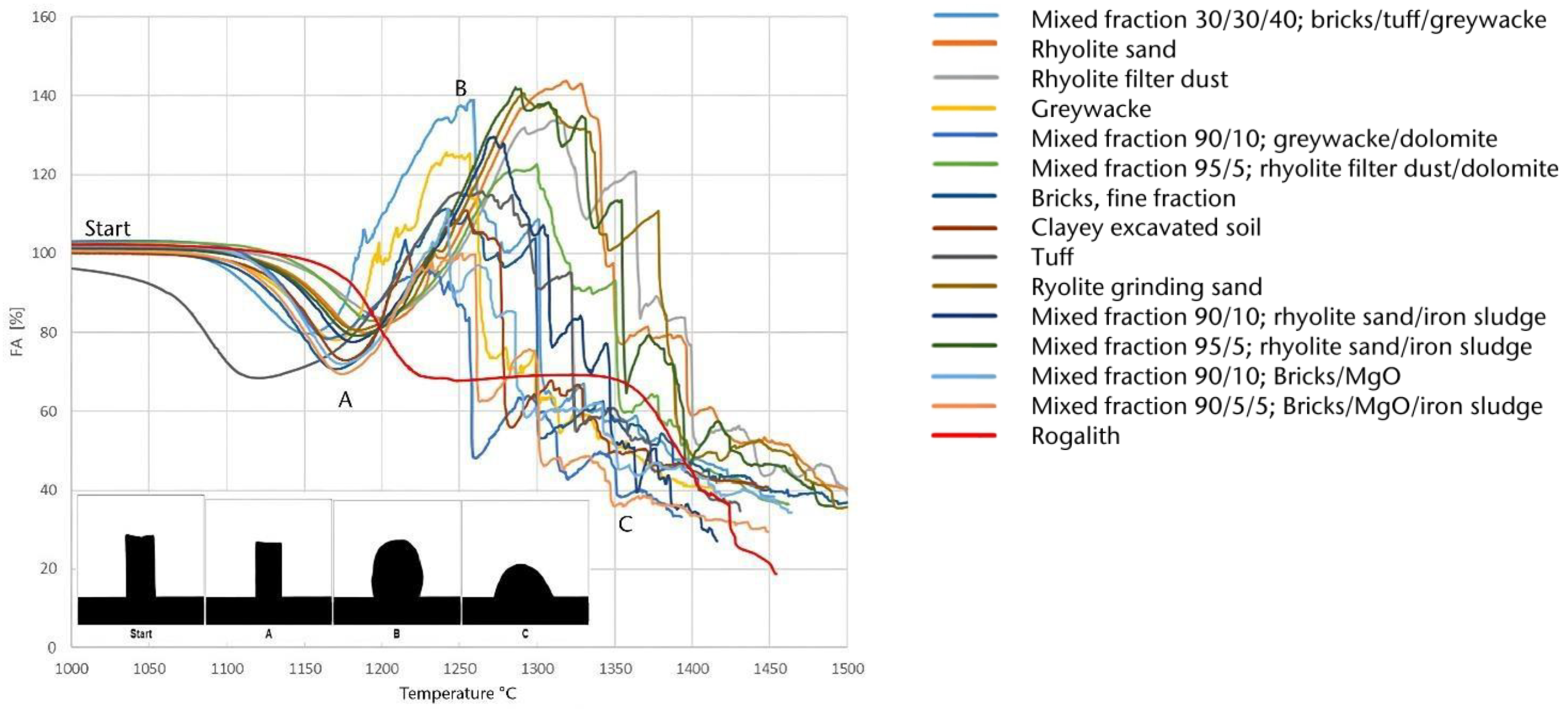

3.1. EMI Tests

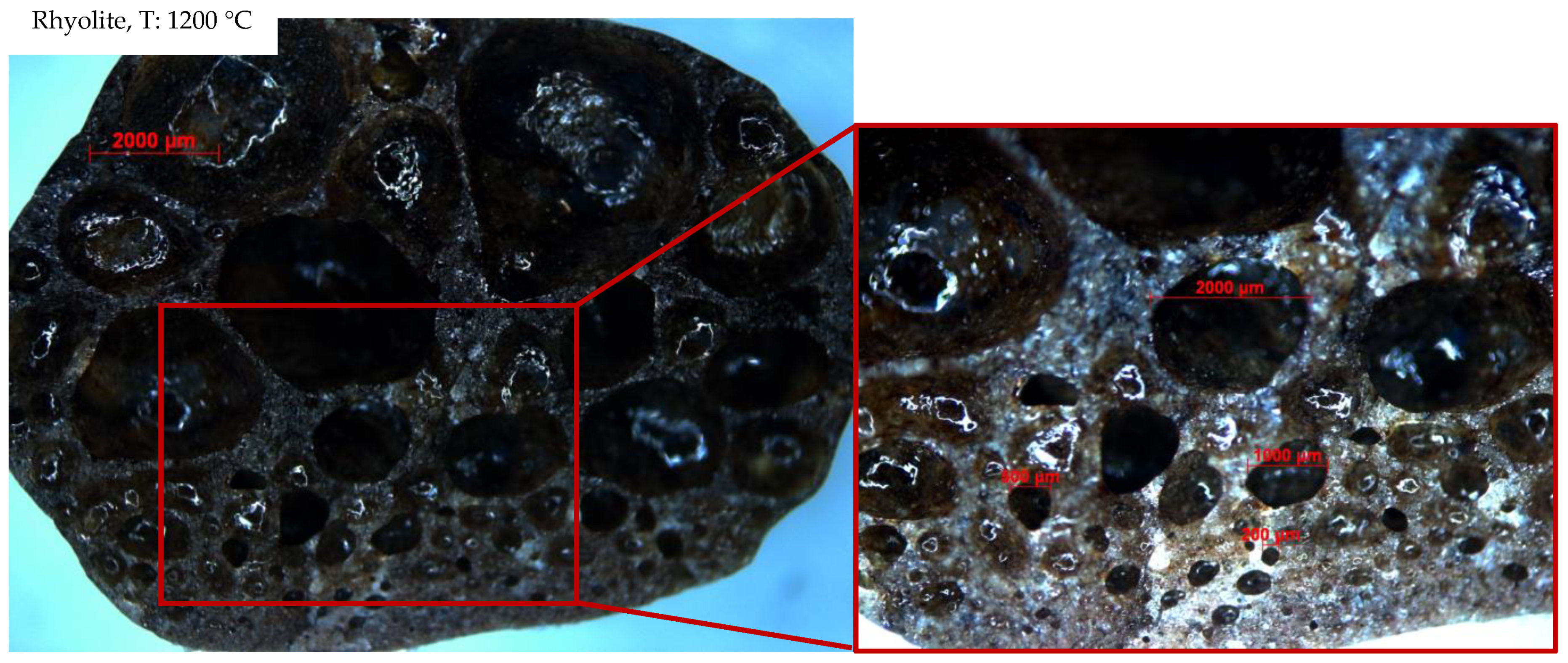

3.2. Oven Tests

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mineralische Bauabfälle Monitoring 2020. In Bericht zum Aufkommen und Verbleib mineralischer Bauabfälle im Jahr 2020; Bundesverband Baustoffe—Steine und Erden e.V.: Berlin, Germany, 2020.

- Projektblatt REALight. In Leichtgranulate und REA-Gips aus Bauschutt und Industriellen Nebenprodukten; Bundesministerium für Bildung und Forschung: Berlin, Germany, 2021.

- Bundesanstalt für Geowissenschaften und Rohstoffe (BGR); Elsner, H.; Kuhn, K.U.; Schmitz, M. Heimische mineralische Rohstoffe—Unverzichtbar für Deutschland. In Industrieminerale in Deutschland; Bundesanstalt für Geowissenschaften und Rohstoffe (BGR): Hannover, Germany, 2017. [Google Scholar]

- Schonung natürlicher Ressourcen durch Materialkreisläufe in der Bauwirtschaft; Kommission Nachhaltiges Bauen am Umweltbundesamt: Dessau-Roßlau, Germany, 2019.

- Müller, A.; Schnell, A.; Rübner, K. Die Herstellung von Leichtgranulaten aus Mauerwerkbruch. Mauerwerk 2013, 17, 365–371. [Google Scholar] [CrossRef]

- Schnell, A.; Rübner, K.; Seher, J.; Müller, A.; Liebezeit, S.; Fenner, J.; Martin, F.U.; Pniok, N. REALight—Leichtgranulate und REA-Gips aus Feinkörnigen REALight—Leichtgranulate und REA-Gips aus Feinkörnigen Sulfatbelasteten Bau- und Abbruchabfällen und Industriellen Nebenprodukten; WILEY Online Library: Weimar, Germany, 2023. [Google Scholar]

- Molinari, C.; Zanelli, C.; Guarini, G.; Dondi, M. Bloating mechanism in lightweight aggregates: Effect of processing variables and properties of the vitreous phase. Constr. Build. Mater. 2020, 261, 119980. [Google Scholar] [CrossRef]

- Moreno-Maroto, J.M.; Cobo-Ceacero, C.J.; Uceda-Rodríguez, M.; Cotes-Palomino, T.; García, C.M.; Alonso-Azcárate, J. Unraveling the expansion mechanism in lightweight aggregates: Demonstrating that bloating barely requires gas. Constr. Build. Mater. 2020, 247, 118583. [Google Scholar] [CrossRef]

- Kraus, J. Herstellung von Leichtzuschlagsstoffen aus Klärschlamm. Ph.D. Thesis, Universität Fridericiana zu Karlsruhe, Karlsruhe, Germany, 2003. [Google Scholar]

- Leismann, A. Verwertung der Industriellen Reststoffe. Steinkohlebergematerial und Rotschlamm zur Herstellung von Blähton-Granulat. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 1996. [Google Scholar]

- Chang, C.-T.; Hong, G.-B.; Lin, H.-S.; Prieto, D.M.; Devesa-Rey, R.; Rubinos, D.A.; Díaz-Fierros, F.; Barral, M.T.; Qin, X.; Liu, F.; et al. Artificial Lightweight Aggregate from Different Waste Materials. Environ. Eng. Sci. 2016, 33, 283–289. [Google Scholar] [CrossRef]

- Diettrich, H. Beitrag zur Bestimmung der Bläheigenschaften Keramischer Rohstoffe; Fakultät für Energie- und Wirtschaftswissenschaften der Technischen Universität Clausthal: Clausthal-Zellerfeld, Germany, 1970. [Google Scholar]

- VEG Kombinat bau- und Grobkeramik Halle (Hrsg.): Technologie der Keramik. Thermische Prozesse; 50 Tabellen; Verlag für Bauwesen: Berlin, Germany, 1985; Volume 3.

- Hoffmann, H. Einfluß der organischen Substanz auf das Blähvermögen von Tongestein. Ziegelind. Heft 1971, 6, 261–264. [Google Scholar]

- Lee, K.H.; Lee, J.H.; Wie, Y.M.; Lee, K.G. Bloating Mechanism of Lightweight Aggregates due to Ramping Rate. Adv. Mater. Sci. Eng. 2019, 2019, 2647391. [Google Scholar] [CrossRef]

- Dondi, M.; Cappelletti, P.; D’amore, M.; de Gennaro, R.; Graziano, S.; Langella, A.; Raimondo, M.; Zanelli, C. Lightweight aggregates from waste materials: Reappraisal of expansion behavior and prediction schemes for bloating. Constr. Build. Mater. 2016, 127, 394–409. [Google Scholar] [CrossRef]

- Riley, C.M. Relation of Chemical Properties to the Bloating of Clays. J. Am. Ceram. Soc. 1951, 34, 121–128. [Google Scholar] [CrossRef]

- Lee, K.G. Bloating Mechanism of Lightweight Aggregate with the Size. J. Korean Ceram. Soc. 2016, 53, 241–245. [Google Scholar] [CrossRef]

- Wie, Y.M.; Lee, K.G.U.; Lee, K.H. Chemical design of lightweight aggregate to prevent adhesion at bloating activation temperature. J. Asian Ceram. Soc. 2020, 8, 245–254. [Google Scholar] [CrossRef]

| Phase | Share [%] |

|---|---|

| SiO2 | 50–78 |

| Al2O3 | 12–25 |

| FM | 8–25 |

| Organic carbon | 0.6–5 |

| Fe2O3 | 5–10 (or higher) |

| CaO | <5 |

| FeS2 | a lot (fine-grained) |

| Phase | Share [%] |

|---|---|

| Greywacke | 1.4 |

| Rhyolite | 1.4 |

| Broken bricks 0–8 mm | 1.1 |

| Tuff | 1.1 |

| Rogalith | 0 |

| Temperature °C | Density [g/cm3] | Share [%] |

|---|---|---|

| 1000 | 2.1 | 0.9 |

| 1050 | 1.8 | 0.8 |

| 1100 | 1.6 | 1.1 |

| 1150 | 1.1 | 1.5 |

| 1200 | 0.9 | 1.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fenner, J.; Zeller, A.; Liebezeit, S.; Knorr, M.; Schnell, A.; Mettke, L.; Goldmann, D. Investigation of Industrial Residues and Waste Materials to Expand the Raw Material Base for the Production of Lightweight Aggregates. Mater. Proc. 2023, 15, 71. https://doi.org/10.3390/materproc2023015071

Fenner J, Zeller A, Liebezeit S, Knorr M, Schnell A, Mettke L, Goldmann D. Investigation of Industrial Residues and Waste Materials to Expand the Raw Material Base for the Production of Lightweight Aggregates. Materials Proceedings. 2023; 15(1):71. https://doi.org/10.3390/materproc2023015071

Chicago/Turabian StyleFenner, Jacob, Andrej Zeller, Steffen Liebezeit, Manuela Knorr, Alexander Schnell, Luka Mettke, and Daniel Goldmann. 2023. "Investigation of Industrial Residues and Waste Materials to Expand the Raw Material Base for the Production of Lightweight Aggregates" Materials Proceedings 15, no. 1: 71. https://doi.org/10.3390/materproc2023015071

APA StyleFenner, J., Zeller, A., Liebezeit, S., Knorr, M., Schnell, A., Mettke, L., & Goldmann, D. (2023). Investigation of Industrial Residues and Waste Materials to Expand the Raw Material Base for the Production of Lightweight Aggregates. Materials Proceedings, 15(1), 71. https://doi.org/10.3390/materproc2023015071