Abstract

Coal bottom ash is used globally in various applications in the construction industry to reduce its negative environmental impacts. In this study, the potential utilization of lignite bottom ash from four power plants in Greece in concrete manufacturing was evaluated through granulometric, chemical, and mineralogical analyses. The particle-size distribution of bottom ash obtained from dry sieving resembles that of sand, making bottom ash suitable for replacing fine aggregates in the production of concrete. Its chemical composition, determined with selective point analyses energy dispersive spectroscopy (EDS), reveals high amounts of silica and alumina indicating pozzolanic properties, and high calcium contents suggesting hydraulic/cementitious character. Mineralogical characterization, obtained from powder X-Ray diffraction analyses (XRD), displays the prevalence of amorphous matter, calcite, quartz, aluminosilicate minerals, and portlandite, implying a beneficial pozzolanic and hydraulic activity in concrete manufacturing.

1. Introduction

Fly ash and bottom ash are the main coal combustion by-products derived from thermoelectric power plants, at approximately 80% and 20%, respectively [1,2]. They are used globally in the concrete industry, in construction, in geotechnical applications, etc. [3,4]. However, in Greece, a small proportion (approx. 10%) of fly ash is utilized in the concrete industry, while bottom ash is not used in any form [5]. Large quantities of bottom ash have already been abandoned due to the intensive exploitation of lignite deposits in the last fifty years, which is a threat to the environment and, henceforth, to human health.

Coal bottom ash is physically similar to natural aggregates, and its potential to be used as a fine or coarse replacement material in concrete has been explored by numerous researchers [6,7]. Furthermore, it has pozzolanic characteristics and resembles Portland Cement (PC) when pulverized into finer particles [8], so ground coal bottom ash could potentially be utilized in concrete as a cement-replacement material [9,10].

The use of coal bottom ash in the production of concrete will cause some beneficial changes to its properties, such as its workability, compressive strength, flexural strength, and durability [9,10,11]. In addition, concrete with bottom ash as an ingredient shows better resistance to chloride ion penetration and sulfuric acid attack, and exhibits better thermal insulation [7]. The utilization of bottom ash as a cement replacement is beneficial to the environment because it reduces CO2 emissions in cement production [3].

This paper aims: (a) to determine the morphological characteristics as well as the chemical and mineralogical composition of bottom ash produced in four power plants in Greece, and (b) to estimate the reactive character of the bottom ashes to evaluate their potential utilization in the concrete industry.

2. Materials and Methods

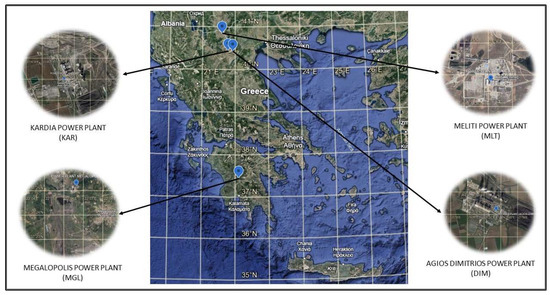

Seven representative bottom ash samples were collected from four lignite power plants in Greece, i.e., four samples from Agios Dimitrios (DIM), one sample from Kardia (KAR), one sample from Meliti (MLT) (Western Macedonia, northern Greece), and one sample from the Megalopolis (MGL) (Peloponnese, southern Greece) power plant (Figure 1).

Figure 1.

The location of the four lignite power plants in Greece used for this study: Agios Dimitrios (DIM), Meliti (MLT), Kardia (KAR), and Megalopolis (MGL).

All samples were dried in an oven at 100 °C for 24 h. Dry sieving was applied to define their particle-size distribution. Four distinct particle-size fractions (>1.25 mm, 0.63–1.25 mm, 0.18–0.63 mm, <0.18 mm) of bottom ash samples from each power plant were obtained after homogenization and subjected to chemical and mineralogical analysis after milling. For the mineralogical characterization, a Phillips PW1710 X-ray diffractometer was used with a CuKα radiation source. The powder-XRD patterns were obtained by step scanning from 3° to 63° at a scan speed of 0.020° 2θ/s. The Oxford INCA 250 EDS was used for the point chemical analysis in microscale. Moreover, a Euromex stereomicroscope was employed to study the microscopic features of the coarse fraction (>1.25 mm) of all samples, before grinding.

3. Results and Discussion

3.1. Granulometry and Morphology

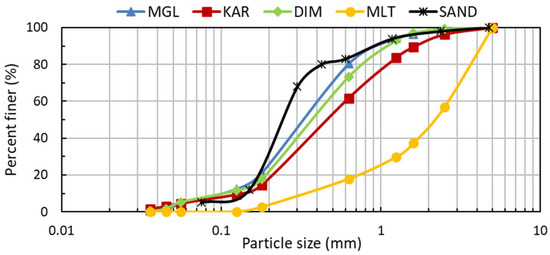

Granulometric analysis was executed on the bottom ash samples, and ten different particle-size fractions (>2.5 mm down to <0.036 mm) were obtained. The particle-size distribution curves of the analyzed bottom ash samples, as well as one for poorly graded natural river sand [12], are shown in Figure 2. The particle-size distribution curves indicate predominantly fine aggregates such as sand with a very low percentage of silt for the MGL, KAR and DIM bottom ashes, whereas the MLT bottom ash is coarser, resembling sand with gravels.

Figure 2.

Particle-size distribution curves for Agios Dimitrios (DIM), Meliti (MLT), Kardia (KAR), and Megalopolis (MGL) coal bottom ash samples, and for natural river sand.

As less than 5% of the bottom ash aggregates pass the No. 200 (0.075 mm) sieve (Figure 2), they can be classified in geotechnical terms according to the Unified Soil Classification System (ASTM D2487, 1993) [13]. The values of D10 (effective particle size), D30, D50 (average particle size), and D60, corresponding to the particle size for which 10%, 30%, 50%, and 60%, respectively, of the particles are finer by weight, have been obtained from the particle-size distribution curves. In addition, the uniformity coefficient (Cu) and the curvature coefficient (Cc) values have been estimated (Table 1).

Table 1.

Geometric properties determined from the particle-size distribution curves for Agios Dimitrios (DIM), Meliti (MLT), Kardia (KAR), and Megalopolis (MGL) coal bottom ash samples.

The MGL, KAR, and DIM bottom ash samples, characterized as sand, have a uniformity coefficient (Cu) value less than 6.0 and a coefficient of curvature (Cc) value close to 1.0. The uniformity coefficient (Cu) criterion for well-graded soils is not satisfied, so they are classified as poorly graded aggregates. On the other hand, the MLT bottom ash sample, characterized as sand with gravels, has a uniformity coefficient (Cu) value either greater than 6.0 for sand or greater than 4.0 for gravel, and a coefficient of curvature (Cc) at least 1.0 but not more than 3.0, criteria that are satisfied by well-graded aggregate. Moreover, the higher value of the uniformity coefficient (Cu) for the MLT bottom ash sample indicates that it consists of particles with different size ranges, in accordance with the particle-size distribution curve.

It is well known that the mechanical and durability properties of concrete depend on the grain size distribution of bottom ash [6,14]. In Figure 2, it is clear that the MGL, KAR, and DIM bottom ash aggregates have smooth particle-size distribution curves in the range of natural river sand curve, whereas the MLT bottom ash particle-size distribution curve is far away from them all. This good correlation shows that the MGL, KAR, and DIM bottom ashes possess ideal particle sizes, thereby enhancing the quality of concrete, especially for utilization in terms of strength. However, all the studied bottom ashes can successfully replace the fine and coarse aggregates in the manufacturing of concrete [14,15].

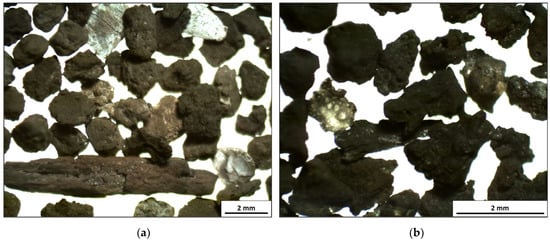

Under stereomicroscope viewing, the coarse fractions (>1.25 mm) of the bottom ash samples revealed organic and inorganic material with a variety of morphological and structural characteristics (Figure 3). Char particles of several dimensions and shapes, showing a black or brown color, a porous/vesicular structure, and a spherical or elongated morphology, were observed. Additionally, inorganic (some partially fused) particles of several dimensions, having round, angular, or irregular shapes, rough textures, and showing mostly a grey color, have also been observed. The porous texture of bottom ash reduces the density of pavement and concrete mixtures, making it a suitable lightweight aggregate for pavement and concrete production. Its porosity contributes to the ability of the bottom ash noise barrier wall to absorb more sound than the conventional wall [3].

Figure 3.

Stereomicroscopic images of bottom ash aggregates of coarse particles from (a) Agios Dimitrios (1.6–2.5 mm) and (b) Meliti (1.25–1.6 mm) power plants.

3.2. Chemical Composition

The chemical composition (on the basis of point analyses in microscale using SEM-EDS) of four particle-size fractions that were obtained, after homogenization (>1.25, 0.63–1.25, 0.18–0.63, <0.18 mm), from four representative bottom ash samples from the Agios Dimitrios (DIM) power plant, and one bottom ash sample from each of the Meliti (MLT), Kardia (KAR), and Megalopolis (MGL) power plants, is presented analytically in Iordanidis et al. (2020, 2021) [16,17]. In Table 2, the range of the major oxides concentration of all the analyzed bottom ash samples is shown, as well as the chemical constituents of Ordinary Portland Cement (OPC) for comparison.

Table 2.

Chemical composition (minimum–maximum of major oxides wt.%) of bottom ash samples from Agios Dimitrios (DIM), Meliti (MLT), Kardia (KAR), and Megalopolis (MGL) power plants and Ordinary Portland Cement (OPC).

According to these results, the CaO content in the DIM and KAR bottom ashes varies from moderate to very high (average 35.35 and 36.00 wt.%, respectively), and in the MLT bottom ashes it varies from low to high (average 25.49 wt.%), revealing a large sort range, while in the ashes from the Megalopolis power plant, (MGL) it is relatively low (average 17.57 wt.%). The SiO2 content varies from moderate to high in the KAR ashes (average 31.43 wt.%), and from moderate to very high in the DIM, MLT, and MGL ashes (average 32.92, 37.60, and 40.17 wt.%, respectively). The content of Al2O3 ranges from low to moderate for all the bottom ashes; the content of Fe2O3 is low; and the content of MgO is very low. The content of the other major oxides is limited.

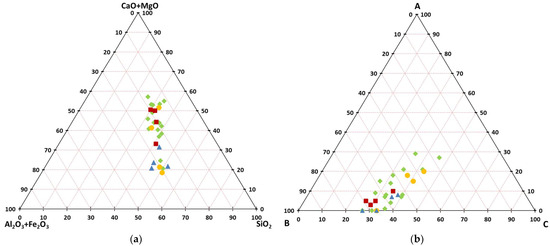

The coal bottom ash chemical compositions belong to the CaO–SiO2–Al2O3–Fe2O3 system. Therefore, they belong to the family of common supplementary cementitious materials (SCM) used in cement-based products [18]. In the ternary diagram (SiO2)–(CaO + MgO)–(Al2O3 + Fe2O3) (Figure 4a), it is clear that the chemical composition of the bottom ashes from the four power plants varies between two different marginal types: (i) (CaO + MgO)-rich type (> 40 wt.%) for the majority of the samples of Agios Dimitrios and Kardia bottom ash, similar to the composition of Agios Dimitrios and Kardia fly ashes [19], and (ii) SiO2-rich type (>40 wt.%) for Megalopolis bottom ash; whereas Meliti bottom ash samples span off one type (i) to other (ii). Regarding the enrichment of bottom ash samples in Al2O3 + Fe2O3, it is clear from the diagram that all the bottom ash samples from the four power plants are not very rich in Al2O3 + Fe2O3 (< 40 wt.%), but in particular, the bottom ash samples from Megalopolis, two samples from Agios Dimitrios and Meliti, and one sample from Kardia, which are SiO2-rich, and are also richer in Al2O3 + Fe2O3 (25–35 wt.%) comparatively to the others.

Figure 4.

(a) Chemical and (b) mineralogical composition of the bottom ashes from the Agios Dimitrios (DIM), Meliti (MLT), Kardia (KAR), and Megalopolis (MGL) power plants (symbols as in Figure 2). A, B, and C represent the total fraction of the mineral phases with hydraulic (A), inert (B), and amorphous phases with pozzolanic (C) character (as shown in Table 3).

Silica, alumina, and ferric are the important compounds that characterize the pozzolanic property of the material [9]. According to the results in Table 2, the sum of the components SiO2 + Al2O3 + Fe2O3 ranges from approximately 40%wt. to 75%wt. (average 55%wt.), and as such, the studied bottom ashes conform to ASTM C 618-05 and are classified as Class C ash (SiO2 + Al2O3 + Fe2O3 > 50%) [20]. Since bottom ashes were included in Class C, they have pozzolanic properties, and also have some cementitious properties. In addition to this, they also contain lime (CaO) content higher than 12%.

The SO3 amounts are rather high, especially for the coarse fractions of the MGL samples (21.33 wt.%), a fact that is related to the high sulfur contents of the MGL lignite deposits. This fact inhibits a potential application in the concrete industry since the high sulfur content may cause losses in compressive strength and increase drying shrinkage in concrete applications [21].

3.3. Mineralogical Composition

Τhe range of semi-quantitative mineralogical results of the analyzed bottom ash samples from the four power plants [16,17] are shown in Table 3. It is evident that the amorphous phase is prevailing in all samples, with concentrations ranging between 26 and 46 wt.%. This amorphous phase is attributed either to unburned carbon or to the inorganic fused ash material [21,22,23] that has also been observed in stereomicroscope. The presence of unburnt carbon has frequently been considered beneficial for an overall improvement in concrete manufacturing [15].

Table 3.

Mineralogical composition (minimum–maximum values, wt.%) of four fractions of 28 bottom ash samples from Agios Dimitrios (DIM), Meliti (MLT), Kardia (KAR) and Megalopolis (MGL) power plants.

Calcite and quartz are the most dominant mineral phases, followed by plagioclase and gehlenite as additional main crystalline mineral phases that were identified in all samples. Substantial amounts of Ca-rich phases, i.e., gypsum, anhydrite, and portlandite were additionally found. Iron-rich phases, such as hematite, magnetite, and maghemite were found in small amounts. K-Feldspar and micas were also identified in very low amounts in several samples, and small amounts of pyroxene were found in the KAR, MLT, and MGL samples. The silica polymorphs, cristobalite, and moganite, as well as lime, larnite and ettringite, are present in very low amounts in the DIM samples, and dolomite the in KAR samples.

The prevalence of the amorphous phase, along with the presence of aluminosilicate minerals, portlandite, and calcite, suggest a beneficial pozzolanic activity in concrete manufacturing; although certain upper limits do occur for definite concrete applications [7,21]. The grinding process has no significant influence on the chemical composition of bottom ash but affects the physical properties of particles, such as particle size and specific gravity, and it plays important role in the development of a pozzolanic reaction [9,14]. Therefore, careful grinding and processing of the bottom ash material may provide bottom ash categories adapted for specific applications.

The content of the mineral phases found in the investigated bottom ash samples was grouped into three different groups according to their reactive character, and projected in a ternary diagram A–B–C (Figure 4b). Triangle diagrams of this kind, especially in connection with grain distribution data, are believed to be more appropriate than the chemical composition given in tables or diagrams to indicate the reactive character of the ash [19]. The first group (A) contains the sum of the amounts of the minerals having hydraulic properties, namely anhydrite, portlandite, gypsum, lime, larnite, gehlenite, dolomite, and ettringite (Table 3). The second group (B) involves the sum of the amounts of the inert minerals, namely quartz, calcite, plagioclase anorthite, feldspars, muscovite, pyroxene (augite), hematite, magnetite, maghemite, moganite, and cristobalite (Table 3). Finally, the third group (C) involves the amounts of the amorphous phases (mainly glass and the remains of clay minerals of the lignite decomposed by burning). Some of the amorphous components may exhibit pozzolanic or latent hydraulic reactivity [19].

Based on Figure 4b, it is clear that the high percentage of hydraulic reacting minerals present is mostly in the bottom ashes from the Agios Dimitrios and Meliti power plants, and less in the bottom ash from the Kardia and Megalopolis power plants, suggesting the hydraulic character of these ashes. The presence of very high amounts of amorphous phases in all bottom ash samples indicates a pozzolanic character, since the glass phase in the amorphous phases is of pozzolanic character.

4. Conclusions

Several fractions of bottom ash samples from four Greek lignite-fired power plants were analyzed in this study, regarding their granulometry, mineralogy, and geochemistry to evaluate their potential utilization in the concrete manufacturing. The conclusions drawn are:

- The particle-size distribution of all the studied bottom ashes satisfies the gradation criteria for utilization in concrete and geotechnical applications.

- Based on the chemical analysis, the bottom ashes from the Agios Dimitrios and Kardia power plants are classified as CaO-rich. The Meliti bottom ashes span from CaO-rich to the SiO2-rich, while the Megalopolis bottom ashes are very rich in SiO2, poorer in CaO, and moderate in Al2O3 content.

- All ashes were found to be Class C pozzolanic materials, as per ASTM C618-05. The high amounts of silica and alumina contents, apparently in a glassy/amorphous state, are indicative for pozzolanic properties, while the high calcium contents suggest hydraulic/self-cementing properties.

- The mineralogical composition of the ashes of all power plants was relatively similar. All bottom ashes have been found to contain mineral phases with hydraulic and pozzolanic, as well as inert, behavior. The DIM and MLT bottom ashes contain minerals with more hydraulic character than the KAR and MGL bottom ashes.

- The presence of glassy/amorphous aluminosilicate phases in the components of the bottom ash samples, along with their calcareous nature, suggested a possible utilization in concrete and other geotechnical applications, considering specific limitations. Careful processing of the bottom ash could provide material that satisfies specific geotechnical needs.

- It is recommended for future works to carry out further research on the determination of workability and hardened properties (like compressive, tensile, and flexural strength), as well as on the strength and durability performances of concrete containing ground bottom ash as a cementitious material under aggressive environment such as those exposed to sulphate and chloride conditions.

Author Contributions

Conceptualization, A.A. and I.K.; methodology, A.A., I.K. and A.V.; validation, A.A. and A.V.; formal analysis, A.A.; investigation, A.A., I.K., A.V., K.K. and N.K.; resources, A.V.; data curation, A.A. and A.V.; writing—original draft preparation, A.A.; writing—review and editing, A.A., I.K., A.V. and N.K.; visualization, A.A.; supervision, A.A.; project administration, A.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research project (RESCOM 80288) was funded by the University of Western Macedonia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The University of Western Macedonia is kindly acknowledged for the financial support for the presentation of this research work at the congress.

Conflicts of Interest

The authors declare no conflict of interest.

Dedication

This research paper is dedicated to the memory of our beloved friend and colleague Professor Dr. Andreas Iordanidis who was the leader of this research project.

References

- Rafieizonooz, M.; Mirza, J.; Salim, M.R.; Hussin, M.W.; Khankhaje, E. Investigation of coal bottom ash and fly ash in concrete as replacement for sand and cement. Constr. Build. Mater. 2016, 116, 15–24. [Google Scholar] [CrossRef]

- Baig, A.; Varghese, V.P. Coal Bottom Ash as a Concrete Ingredient: Review (April 11, 2019). In Proceedings of the Sustainable Infrastructure Development & Management (SIDM) 2019, Nagpur, India, 22–23 February 2019. [Google Scholar]

- Mohammed, S.A.; Koting, S.; Katman, H.Y.B.; Babalghaith, A.M.; Abdul Patah, M.F.; Ibrahim, M.R.; Karim, M.R. A Review of the Utilization of Coal Bottom Ash (CBA) in the Construction Industry. Sustainability 2021, 13, 8031. [Google Scholar] [CrossRef]

- Nayak, D.K.; Abhilash, P.P.; Singh, R.; Kumar, R.; Kumar, V. Fly ash for sustainable construction: A review of fly ash concrete and its beneficial use case studies. Clean. Mater. 2022, 6, 100143. [Google Scholar] [CrossRef]

- Iordanidis, A.; Asvesta, A.; Kapageridis, I.; Vasileiadou, A.; Koios, K.; Oikonomidis, S.; Kantiranis, N. Characterization of the coarse fraction of lignite bottom ash samples from Greece. In Proceedings of the 5th EurAsia Waste Management Symposium, EWMS, Istanbul, Turkey, 26–28 October 2020; p. 5. [Google Scholar]

- Singh, N.; Mithulraj, M.; Arya, S. Influence of Coal Bottom Ash as Fine Aggregates Replacement on Various Properties of Concretes: A Review. Resour. Conserv. Recycl. 2018, 138, 257–271. [Google Scholar] [CrossRef]

- Muthusamy, K.; Rasid, M.H.; Jokhio, G.A.; Budiea, A.M.A.; Hussin, M.W.; Mirza, J. Coal Bottom Ash as Sand Replacement in Concrete: A review. Constr. Build. Mater. 2020, 236, 117507. [Google Scholar] [CrossRef]

- Ankur, N.; Singh, N. Performance of cement mortars and concretes containing coal bottom ash: A comprehensive review. Renew. Sustain. Energy Rev. 2021, 149, 111361. [Google Scholar] [CrossRef]

- Mangi, S.A.; Wan Ibrahim, M.H.; Jamaluddin, N.; Arshad, M.F.; Mudjanarko, S.W. Recycling of Coal Ash in Concrete as a Partial Cementitious Resource. Resources 2019, 8, 99. [Google Scholar] [CrossRef]

- Mangi, S.A.; Wan Ibrahim, M.H.; Jamaluddin, N.; Arshad, M.F.; Ramadhansyah, P.J. Effects of Ground Coal Bottom Ash on the Properties of Concrete. J. Eng. Sci. Technol. 2019, 14, 338–350. [Google Scholar]

- Hamada, H.; Alatta, A.; Tayeh, B.; Yahaya, F.; Adesina, A. Sustainable application of coal bottom ash as fine aggregates in concrete: A comprehensive review. Case Stud. Constr. Mater. 2022, 16, e01109. [Google Scholar] [CrossRef]

- Mir, B.A.; Saba, A. Evaluation of Load-Settlement Behaviour of Square Model Footings Resting on Geogrid Reinforced Granular Soils. In Proceedings of the 2nd GeoMEast, Cairo, Egypt, 24–28 November 2018; pp. 103–126. [Google Scholar]

- ASTM D 2487; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). American Society for Testing and Materials, ASTM International: West Conshohocken, PA, USA, 1993.

- Singh, N.; Mithulraj, M.; Arya, S. Utilization of Coal Bottom Ash in Recycled Concrete Aggregates Based Self Compacting Concrete Blended with Metakaolin. Resour. Conserv. Recycl. 2019, 144, 240–251. [Google Scholar] [CrossRef]

- Pant, A.; Ramana, G.V.; Datta, M.; Gupta, S.K. Coal Combustion Residue as Structural Fill Material for Reinforced Soil Structures. J. Clean. Prod. 2019, 232, 417–426. [Google Scholar] [CrossRef]

- Iordanidis, A.; Asvesta, A.; Kapageridis, I.; Vasileiadou, A.; Koios, K.; Oikonomidis, S.; Kantiranis, N.; Evagelopoulos, V. Temporal variation in the compositional and thermal characteristics of Greek lignite bottom ash samples. Solid Fuel Chem. 2020, 54, 427–435. [Google Scholar] [CrossRef]

- Iordanidis, A.; Asvesta, A.; Kapageridis, I.; Vasileiadou, A.; Koios, K.; Oikonomidis, S.; Kantiranis, N. A comprehensive analytical characterization of Greek lignite bottom ash samples. Therm. Sci. 2021, 25, 1879–1889. [Google Scholar] [CrossRef]

- Argiz, C.; Sanjuán, M.Á.; Menéndez, E. Coal Bottom Ash for Portland Cement Production. Adv. Mater. Sci. Eng. 2017, 2017, 6068286. [Google Scholar] [CrossRef]

- Kostakis, G. Characterization of the fly ashes from the lignite burning power plants of northern Greece based on their quantitative mineralogical composition. J. Hazard. Mater. 2009, 166, 972–977. [Google Scholar] [CrossRef] [PubMed]

- ASTM C618-05; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. American Society for Testing and Materials, ASTM International: West Conshohocken, PA, USA, 2005.

- Singh, N.; Bhardwaj, A. Reviewing the role of coal bottom ash as an alternative of cement. Constr. Build. Mater. 2020, 233, 117276. [Google Scholar] [CrossRef]

- Kantiranis, N.; Georgakopoulos, A.; Filippidis, A.; Drakoulis, A. Mineralogy and organic matter content of bottom ash samples from Agios Dimitrios power plant, Greece. Bull. Geol. Soc. Greece 2004, 36, 320–326. [Google Scholar] [CrossRef][Green Version]

- Iordanidis, A.; Georgakopoulos, A.; Markova, K.; Filippidis, A.; Kassoli-Fournaraki, A. Application of TG–DTA to the study of Amynteon lignites, northern Greece. Thermochim. Acta 2001, 371, 137. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).