Abstract

Over the last decades, the needs of the contemporary way of life and the ongoing population growth have affected the construction industry by causing rapid development of the sector. This accretion combined with the challenging management of construction and demolition waste (CDW) resulted in an increasing amount of waste being produced as well as an associated impact on the environment. Those impacts render their management necessary, in order to contribute to the concepts of sustainable development and Circular economy. The present paper discusses the usage of recycled aggregates (RAs) from CDW, in correlation with natural aggregates (NA) in the manufacture of concrete, both from quality and environmental perspectives. Upon analysis of the physical–chemical and mechanical properties, a replacement ratio of RAs of 50% was suggested, considering two factors: (1) the highest acceptable decrease in aggregate properties; and (2) the higher contribution to the environment, which is also accepted by the EN-12620 standard. Furthermore, it was calculated that the net carbon balance of aggregate utilization, based on the above scenario, is approximately 20% lower compared to NA.

1. Introduction

Worldwide demand for construction materials is rising. Over the last century, the economic growth that has taken place has left no room to consider the environmental impacts caused by human activity. The growing concern for environmental sustainability has driven extensive research into finding ways to reduce carbon emissions and minimize the ecological impact of construction activities. One promising approach is recycling concrete waste into aggregates, which can help decrease the demand for natural aggregates (NA) and mitigate the carbon footprint (CF) associated with concrete production. Concrete plays a crucial part in the increasing infrastructure development and it is massively produced and consumed for a variety of construction applications. Moreover, concrete is the second most used substance worldwide after water and the most used man-made material [1]. It is also responsible for almost 8% of global carbon dioxide emissions [2]. According to Verein Deutscher [3] as cited by Wang et al. [4], in the last two decades global cement production has increased by three times, from 1.10 Bt to 3.27 Bt and it is estimated to reach 4.83 Bt by 2030. This rise will also result in a developing demand for resources such as NA, since they typically make up 60–75% of the concrete’s volume. The production and consumption of concrete also generate waste. In the construction industry, 30% of the total solid waste produced is considered construction and demolition waste (CDW) [5].

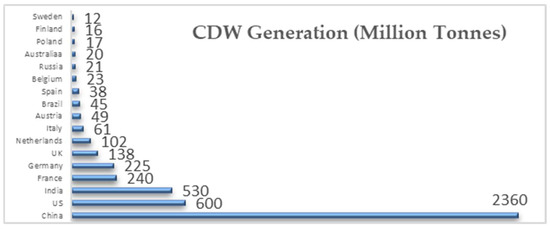

The global demand for aggregates in the construction sector was estimated between 25.9 to 29.6 Bt in 2012 [6] and is predicted to reach 47.5 Bt in 2023 [7]. The findings of Wang et al. [4] about worldwide CDW generation are illustrated in Figure 1. Globally, approximately 10 Bt of CDW are generated each year [8]. Kabirifar et al. [9] state that CDW occupies 35–65% of global landfill space. These numbers raise serious concerns. Since the usage of traditional materials is unsustainable, various waste materials have been repurposed in the manufacturing of concrete. In various studies, waste materials such as ground granulated blast-furnace slag (GGBS) [10,11]; fly ash [12]; glass [13,14], but also alternative materials such as rice husk ash, animal bones and human hair [15,16] are incorporated in concrete. CDW, due to the vast market for re-use, has a high potential for recycling. This combined with the aforementioned soaring growth and the immersed CDW generation, has rendered CDW a fast-growing commodity.

Figure 1.

Illustration of the countries with the highest CDW generation around the world in 2018 (processed data from Wang et al. [4]).

2. Materials and Methods

The primary goal of this research is to compare the properties of RAs with NA and also conduct a Life Cycle Assessment (LCA) to evaluate the environmental impact of their production. In the quality approach, the properties of RAs and RAC are being discussed and compared based on the literature. In the environmental approach, for the calculation of the CF, the LCA method is used. In order for RAC to achieve the same levels of compressive strength as NAC, more cement needs to be added. Cement accounts for 80% of the production of concrete emissions [17]. So, to illustrate the benefits of RAs, the system studied only focuses on the aggregate footprint.

According to ISO 14040 [18], an LCA study is divided into four phases [19]:

- Goal and Scope definition: The assessments’ subject and framework are defined.

- Life cycle inventory analysis: Mention of inputs and outputs and assumptions.

- Life cycle impact assessment: Rate of impacts according to impact categories (is not regarded in this study).

- Interpretation: Evaluation of the findings in light of the goals of the study.

Phases of Calculation

1st Phase: This study solely takes CO2 emissions into account. The following three groups can be used to classify aggregate manufacturing scenarios:

- Obtaining NAs from quarries (1st scenario).

- Using CDW waste from the landfill to obtain RAs (2nd scenario).

- Combined approach as mentioned by Ghanbari, M. et al. [20], in which an optimum replacement ratio (ORR) is considered (3rd scenario).

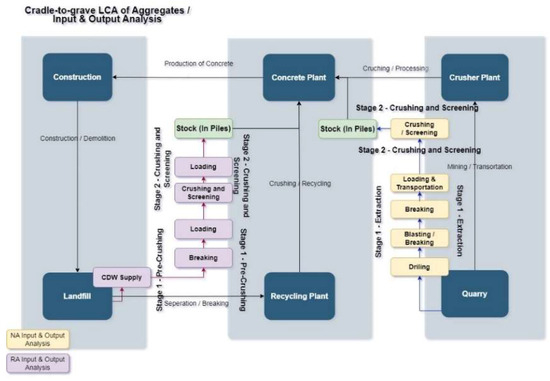

Figure 2 illustrates the cradle-to-grave analysis. The energy usage accounts for all inputs. The total CO2 emissions are the model’s outputs. The functional unit is Kg CO2/t of NA and/or RAs. The following equation [21], serves as the foundation for calculating CO2 emissions:

E = A × EF × (1 − ER/100),

Figure 2.

Cradle-to-grave life-cycle assessment and input and output analysis of aggregate production.

According to EPA [21], E stands for emissions, A stands for the activity data, hence the energy used, EF for emissions factor, and ER for emission reduction efficiency (disregarded in this study).

2nd Phase: Fuel oil is the energy source used by machinery and transportation, while electricity is used in the crushing machinery. All machinery is assumed to be in good condition and well maintained. All fuel oil-based machineries have an emission factor of 2.7 kg CO2/L. Na production is based on a quarry of primary limestone aggregate production of Titan Cement Greece S.A. The typical consumption of ANFO is 170 gr/t. The transportation distance is 0.8 to 1 km. This production has a primary, a secondary and a tertiary crushing phase, and a primary and a secondary screening phase. Where electricity is involved, the energy mix emissions account for 30% of fossil fuels (lignite) with the rest being natural gas and renewables. RA production is comparable to that of the NA. The facility is based on the landfill area, so there is no transportation distance. The production has only a primary and a secondary crushing and screening phase. Therefore, the consumption during that phase should be at least 33% lower than NA production, considering the usage of the same typical equipment. Data from other researchers support this assumption [20]. In conclusion, there may be assumptions that cannot be incorporated without further research. The 4th phase is stated in the next chapters.

3. Results

3.1. Approach on RA Quality Perspective

3.1.1. Classification of the Aggregates

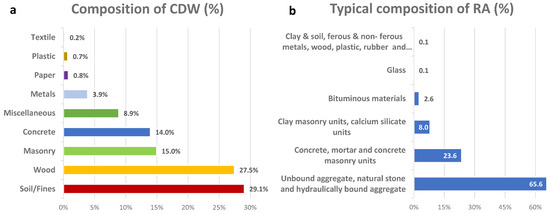

Construction and demolition waste (CDW) composition might vary, although materials like concrete, mortar, and ceramics its main components [22,23,24,25]. Figure 3a,b illustrate typical CDW and RA composition.

Figure 3.

(a) Composition of CDW (processed data from [22]). (b) Typical composition of 8–16 mm RA from a recycling plant (processed data from [24]).

Silva et al. [26] classified the resulting RA in: (1) recycled concrete aggregate (RCA), (2) recycled masonry aggregate (RMA), (3) mixed recycled aggregates (MRA).

3.1.2. Physicochemical, Fresh, and Durability Properties

In general, the physical properties of RAs are considered to be inferior to the properties of NA (Table 1) [27].

Table 1.

Physical properties of RAs and NA, according to Makul et al. [27].

Water Absorption (WA) and Workability: High WA due to high porosity directly affects the concrete’s properties. Additional water is required in the concrete in order to match the desired workability. According to research [27,28,29,30], the increase in WA recycled aggregate concrete (RAC) in correlation to natural aggregate concrete (NAC) is up to 40% for a replacement ratio (RR) of 50%. Wang et al. [4] states that according to research [31,32,33,34], the consistency of fresh RAC had a lower slump value than NAC, due to RAs’ higher WA and the rougher surfaces and irregular shapes.

Density: The particle size distribution and shape have an impact on the density of concrete. In general, the density of RAC is slightly lower (5–15%) than the typical density NAC [35]. For an RR of 100%, the density loss is close to 5% [36].

Carbonation Depth (CD): As the RR of RAs increases, the CD of RAC also increases [37]. For an RR of up to 50% and with an increase in the water-cement (w/c) ratio, the rate of CD increases either slowly or remains essentially unaltered [38].

Chloride ion penetration (CIP): CIP rises with replacement level of RA in concrete. Consequently, the CIP is greater in RAC because of RAC’s higher porosity compared to NAC [4]. Guo et al. [39] state that when the RR of RAs rose, the CIP increased.

Freezing–Thawing Resistance (FTR): RAC usually has weak frost resistance, due to RA particles’ high absorption rate [39]. Nevertheless, Huda et al. [40] claim that the freeze–thaw durability test on coarse RAs produced with various RR indicated that the FTR of RAC is comparable to NAC.

Alkali-silica reaction resistance (ASR): When RAs are solely made of highly alkali reactive NA, ASR expansion in RAC increases with the rise in the RR of NA with RA [41]. RAs composed of non-reactive NA and non-reactive adhered mortar do not cause ASR.

Dry shrinkage and creep: Creep is affected by the aggregate’s modulus of elasticity. The creep of RAC with an RR of 50% increased by 19.6% [42]. The w/c ratio and the aggregate particles both influence drying shrinkage. Additionally, RAs can also have a lower compressive strength compared to NAs, which can result in increased shrinkage. For an RR of 50%, the shrinkage of RAC was 48% higher than NAC [42]. When the RR of RAs rises, both the shrinking and creep of RAC increases [43,44,45,46].

3.1.3. Mechanical Properties

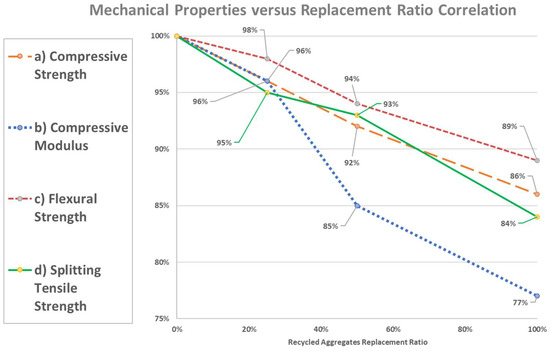

Compressive strength: Compressive strength of concrete decreases, as the RR of NA increases [4,23,26,27,29,31,32,46,47,48,49,50,51,52,53,54,55,56,57]. Figure 4. represents the findings of Wang et al. [4] in which the correlation between the mechanical properties and the RR of RAs is depicted. Up to a degree of 50% RR, RAs have no significant impact on the compressive strength of concrete [4,26,27,29,46,47,48,49,50,51,52,54,56].

Figure 4.

Plot of mechanical properties change with different RCA RR, and the sample size at each RR for (a) compression strength, (b) E-modulus, (c) flexural strength, and (d) splitting tensile strength (processed data from [4]).

Splitting Tensile and Flexural Strength: With an increase in the RR, both the tensile strength and the flexural strength exhibit generally descending trends [4,29,39,51].

Modulus of Elasticity: The strength of concrete greatly impacts the modulus of elasticity of concrete. A 50% RR would result in a decrease of up to 15% [4,40].

3.2. Approach on RA Environmental Perspective

The United States National Stone Sand and Gravel Association (NSSGA) [58] states that the aggregate industry emits 14.6 MMT CO2 per year in the US (data based on the year 2018), which stands for approximately 0.22% of the total U.S. emissions of 6677.8 MMT CO2 per year [58]. Since aggregate extraction mostly entails a straightforward extraction without significant material process, in contrast with, e.g., cement, it has a low environmental impact. In order for RAC to achieve the same levels of compressive strength as NAC, more cement needs to be added. Cement accounts for 80% of the production of concrete emissions [55]. So, to illustrate the benefits of Ras, the system studied only focuses on the aggregate footprint. The CF of producing 1t of NA and RAs are shown in Table 2 and Table 3.

Table 2.

Calculation of natural aggregates CO2 footprint.

Table 3.

Calculation of Recycled Aggregates CO2 footprint.

3.3. Combined Approach

A higher Replacement ratio would decrease all of the concrete’s properties; however, it would also lead to a decrease in the environmental impact of the aggregates such as: (1) minimization of CF of aggregate production; (2) of landfill space utilized; and (3) of the use of natural resources. So, an ORR of 50% was determined based on: (1) The highest accepted impact on the concrete properties and (2) the higher contribution on the environment (Table 4).

Table 4.

Comparison of RAC properties and replacement ratio.

At any rate, EN 206:2013 + A1:2016 (EN 206, 2013) and EN 12620:2013 (EN 12620, 2013) allow up to a maximum RR of 50% in structural concrete [24].

Summarized data of CO2 emissions for each of those scenarios are presented in Table 5.

Table 5.

Summarized data on NA and RA production emissions.

One tone of NA and RA produces 3.067 and 1.854 Kg of CO2 emissions, respectively, which stands for a 39.57% reduction in CO2 total emissions (Table 5). Implementing the RR of 50% would result in a 19.78% reduction. To quantify the calculated values, i.e., the emissions already mentioned [58] could be at 11.7 MMT CO2 e per year, hence a reduction of 2.9 MMT CO2 emitted per year.

4. Conclusions

Generally, mechanical, physicochemical, and durability properties decrease as the replacement ratio (RR) rises. The optimum replacement ratio (ORR) of recycled aggregates (RAs) in concrete, considering (1) the highest accepted reduction in the concrete’s properties and (2) the higher contribution to the environment, is 50%, which is accepted by EN-12620. The carbon footprint of recycled aggregates production is lower than natural aggregates (NA). Their difference is less than 40%. A scenario with replacement of 50% of total aggregates by RR, exhibits about 20% reduced emissions to produce 1t of aggregate. Recycling construction and demolition waste (CDW) reduces the quantity of waste sent to the landfill, the least environmentally friendly option; it helps avoid the use of natural resources, prevents their rapid depletion, and saves on the expenses and damages associated with their exploitation. Moreover, it contributes to minimizing the carbon footprint of aggregate production. The outcome emphasizes RAs as a sustainable alternative to NAs when considering the RR and the environmental benefits.

Author Contributions

Conceptualization, C.V. and I.B.; methodology, C.V. and I.B.; formal analysis, C.V. and I.B.; investigation, C.V. and I.B.; resources, C.V. and I.B.; data curation, C.V. and I.B.; validation, C.V. and I.B.; writing—original draft preparation, I.B.; writing—review and editing, C.V. and I.B.; supervision, C.V.; project administration, C.V.; visualization, C.V. and I.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not relevant.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data supporting reported results have been included in the manuscript.

Conflicts of Interest

Authors declare no conflict of interest.

References

- Adesina, A. Recent advances in the concrete industry to reduce its carbon dioxide emissions. Environ. Chall. 2020, 1, 100004. [Google Scholar] [CrossRef]

- Warburton, Roger. “Global Warming Has Concrete Problem When It Comes to CO2.” EcoRi News 2019. Available online: https://www.ecori.org/climate-change/2019/10/4/global-warming-has-a-co2ncrete-problem (accessed on 2 December 2022).

- Verein Deutscher, Zementwerk. Available online: https://www.statista.com/statistics/373845/global-cement-production-forecast/ (accessed on 2 December 2022).

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A comprehensive review on recycled aggregate and recycled aggregate concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Ginga, C.P.; Ongpeng, J.M.C.; Daly, M.K.M. Circular economy on construction and demolition waste: A literature review on material recovery and production. Mater 2020, 13, 2970. [Google Scholar] [CrossRef] [PubMed]

- UNEP. Sand and Sustainability: Finding New Solutions for Environmental Governance of Global Sand Resources; United Nations Environment Programme: Geneva, Switzerland, 2019. [Google Scholar]

- The Freedonia Group. Available online: https://www.freedoniagroup.com/industry-study/global-construction-aggregates-3742.htm (accessed on 2 December 2022).

- Wang, J.; Wu, H.; Tam, V.W.; Zuo, J. Considering life-cycle environmental impacts and society’s willingness for optimizing construction and demolition waste management fee: An empirical study of China. J. Clean. Prod. 2019, 206, 1004–1014. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.C.; Tam, V.W. Effective construction and demolition waste management assessment through waste management hierarchy; a case of Australian large construction companies. J. Clean. Prod. 2021, 312, 12. [Google Scholar] [CrossRef]

- Arivalagan, S. Sustainable studies on concrete with GGBS as a replacement material in cement. JJCE 2014, 8, 263–270. [Google Scholar]

- Dhir, R.K.; El-Mohr, M.A.K.; Dyer, T.D. Chloride binding in GGBS concrete. Cem. Concr. Res. 1996, 26, 1767–1773. [Google Scholar] [CrossRef]

- Liu, M. Self-compacting concrete with different levels of pulverized fuel ash. Constr. Build. Mater. 2010, 24, 1245–1252. [Google Scholar] [CrossRef]

- de Castro, S.; de Brito, J. Evaluation of the durability of concrete made with crushed glass aggregates. J. Clean. Prod. 2013, 41, 7–14. [Google Scholar] [CrossRef]

- Park, S.B.; Lee, B.C.; Kim, J.H. Studies on mechanical properties of concrete containing waste glass aggregate. Cem. Concr. Res. 2004, 34, 2181–2189. [Google Scholar] [CrossRef]

- Ganesan, K.; Rajagopal, K.; Thangavel, K. Rice husk ash blended cement: Assessment of optimal level of replacement for strength and permeability properties of concrete. Constr. Build. Mater. 2008, 22, 1675–1683. [Google Scholar] [CrossRef]

- Petrounias, P.; Rogkala, A.; Giannakopoulou, P.P.; Lampropoulou, P.; Xanthopoulou, V.; Koutsovitis, P.; Koukouzas, N.; Lagogiannis, I.; Lykokanellos, G.; Golfinopoulos, A. An Innovative Experimental Petrographic Study of Concrete Produced by Animal Bones and Human Hair Fibers. Sustainability 2021, 13, 8107. [Google Scholar] [CrossRef]

- Shi, C.; Jiménez, A.F.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- Bird, N.; Cowie, A.; Cherubini, F.; Jungmeier, G. Using a Life Cycle Assessment Approach to Estimate the Net Greenhouse Gas Emissions of Bioenergy; IEA Bioenergy: Rotorua, New Zealand, 2011. [Google Scholar]

- Ghanbari, M.; Abbasi, A.M.; Ravanshadnia, M. Production of natural and recycled aggregates: The environmental impacts of energy consumption and CO 2 emissions. J. Mater. Cycles Waste Manag. 2018, 20, 810–822. [Google Scholar] [CrossRef]

- Environmental Protection Agency, EPA. Available online: https://www.epa.gov/air-emissions-factors-and-quantification/basic-information-air-emissions-factors-and-quantification (accessed on 31 October 2022).

- Schlender, R.M.; Bruckner, R.H. Setting up for recovery of construction & demolition waste. Solid Waste Power 1993, 7, 28. [Google Scholar]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Availability and processing of recycled aggregates within the construction and demolition supply chain: A review. J. Clean. Prod. 2017, 143, 598–614. [Google Scholar] [CrossRef]

- Whittaker, M.J.; Grigoriadis, K.; Soutsos, M.; Sha, W.; Klinge, A.; Paganoni, S.; Casado, M.; Brander, L.; Mousavi, M.; Scullin, M.; et al. Novel construction and demolition waste (CDW) treatment and uses to maximize reuse and recycling. Adv. Build. Energy Res. 2021, 15, 253–269. [Google Scholar] [CrossRef]

- Waskow, R.P.; Dos Santos, V.L.; Ambrós, W.M.; Sampaio, C.H.; Passuello, A.; Tubino, R.M. Optimization and dust emissions analysis of the air jigging technology applied to the recycling of construction and demolition waste. J. Environ. Manag. 2020, 266, 110614. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Makul, N.; Fediuk, R.; Amran, M.; Zeyad, A.M.; Murali, G.; Vatin, N.; Klyuev, S.; Ozbakkaloglu, T.; Vasilev, Y. Use of recycled concrete aggregates in production of green cement-based concrete composites: A review. Crystals 2021, 11, 232. [Google Scholar] [CrossRef]

- Jo, B.W.; Park, S.K.; Park, J.C. Mechanical properties of polymer concrete made with recycled PET and recycled concrete aggregates. Constr. Build. Mater. 2008, 22, 2281–2291. [Google Scholar] [CrossRef]

- Dimitriou, G.; Savva, P.; Petrou, M.F. Enhancing mechanical and durability properties of recycled aggregate concrete. Constr. Build. Mater. 2018, 158, 228–235. [Google Scholar] [CrossRef]

- Li, X. Recycling and reuse of waste concrete in China: Part I. Material behaviour of recycled aggregate concrete. Resour. Conserv. Recycl. 2008, 53, 36–44. [Google Scholar] [CrossRef]

- Smith, J.T. Recycled Concrete Aggregate–A Viable Aggregate Source for Concrete Pavements. Ph.D. Dissertation, Department of Civil Engineering, University of Waterloo, Waterloo, ON, Canada, 2010. [Google Scholar]

- Liu, J.; Chen, B. Property of high strength concrete made with field-demolished concrete aggregates. In Proceedings of the Transportation Research Board 87th Annual Meeting, Washington, DC, USA, 13 January 2008. [Google Scholar]

- Sturtevant, J.R. Performance of Rigid Pavements Containing Recycled Concrete Aggregates. Master’s Thesis, University of New Hampshire, Durham, NH, USA, 2007. [Google Scholar]

- Lotfi, S.; Deja, J.; Rem, P.; Mróz, R.; van Roekel, E.; van der Stelt, H. Mechanical recycling of EOL concrete into high-grade aggregates. Resour. Conserv. Recycl. 2014, 87, 117–125. [Google Scholar] [CrossRef]

- Nováková, I.; Mikulica, K. Properties of concrete with partial replacement of natural aggregate by recycled concrete aggregates from precast production. Procedia Eng. 2016, 151, 360–367. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Fresh-state performance of recycled aggregate concrete: A review. Constr. Build. Mater. 2018, 178, 19–31. [Google Scholar] [CrossRef]

- Silva, R.V.; Neves, R.; De Brito, J.; Dhir, R.K. Carbonation behavior of recycled aggregate concrete. Cem. Concr. Compos. 2015, 62, 22–32. [Google Scholar] [CrossRef]

- Deng, Z.; Liu, B.; Huang, Y. Investigation of carbonation resistance of recycled aggregate concrete. Mater. Sci. Eng. 2021, 1028, 012014. [Google Scholar] [CrossRef]

- Guo, H.; Shi, C.; Guan, X.; Zhu, J.; Ding, Y.; Ling, T.C.; Zhang, H.; Wang, Y. Durability of recycled aggregate concrete—A review. Cem. Concr. Compos. 2018, 89, 251–259. [Google Scholar] [CrossRef]

- Huda, S.B.; Shahria Alam, M. Mechanical and freeze-thaw durability properties of recycled aggregate concrete made with recycled coarse aggregate. J. Mater. Civ. Eng. 2015, 27, 04015003. [Google Scholar] [CrossRef]

- Barreto Santos, M.; De Brito, J.; Santos Silva, A. A review on alkali-silica reaction evolution in recycled aggregate concrete. J. Mater. 2020, 13, 2625. [Google Scholar] [CrossRef] [PubMed]

- Lv, Z.; Liu, C.; Zhu, C.; Bai, G.; Qi, H. Experimental study on a prediction model of the shrinkage and creep of recycled aggregate concrete. J. Appl. Sci. 2019, 9, 4322. [Google Scholar] [CrossRef]

- Domingo-Cabo, A.; Lázaro, C.; López-Gayarre, F.; Serrano-López, M.A.; Serna, P.; Castaño-Tabares, J.O. Creep and shrinkage of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2545–2553. [Google Scholar] [CrossRef]

- Matias, D.; de Brito, J.; Rosa, A.; Pedro, D. Durability of concrete with recycled coarse aggregates: Influence of superplasticizers. J. Mater. Civ. Eng. 2014, 26, 06014011. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Comparative analysis of existing prediction models on the creep behavior of recycled aggregate concrete. Eng. Struct. 2015, 100, 31–42. [Google Scholar] [CrossRef]

- Cachim, P.B. Mechanical properties of brick aggregate concrete. Constr. Build. Mater. 2009, 23, 1292–1297. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- López-Uceda, A.; Ayuso, J.; López, M.; Jimenez, J.R.; Agrela, F.; Sierra, M.J. Properties of non-structural concrete made with mixed recycled aggregates and low cement content. J. Mater. 2016, 9, 74. [Google Scholar] [CrossRef] [PubMed]

- Medina, C.; De Rojas, M.S.; Frías, M. Properties of recycled ceramic aggregate concretes: Water resistance. Cem. Concr. Compos. 2013, 40, 21–29. [Google Scholar] [CrossRef]

- Rahal, K. Mechanical properties of concrete with recycled coarse aggregate. Build. Environ. 2007, 42, 407–415. [Google Scholar] [CrossRef]

- Tran, D.V.P.; Allawi, A.; Albayati, A.; Cao, T.N.; El-Zohairy, A.; Nguyen, Y.T.H. Recycled concrete aggregate for medium-quality structural concrete. Materials 2021, 14, 4612. [Google Scholar] [CrossRef] [PubMed]

- de Brito, J.M.C.L.; Gonçalves, A.P.; Santos, R. Recycled aggregates in concrete production-Multiple recycling of concrete coarse aggregates. Rev. Ing. Constr. 2006, 21, 33–40. [Google Scholar]

- Piccinali, A.; Diotti, A.; Plizzari, G.; Sorlini, S. Impact of Recycled Aggregate on the Mechanical and Environmental Properties of Concrete: A Review. J. Mater. 2022, 15, 1818. [Google Scholar] [CrossRef] [PubMed]

- Zheng, C.; Lou, C.; Du, G.; Li, X.; Liu, Z.; Li, L. Mechanical properties of recycled concrete with demolished waste concrete aggregate and clay brick aggregate. Results Phys. 2018, 9, 1317–1322. [Google Scholar] [CrossRef]

- De Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Bai, G.; Zhu, C.; Liu, C.; Liu, B. An evaluation of the recycled aggregate characteristics and the recycled aggregate concrete mechanical properties. Constr. Build. Mater. 2020, 240, 117978. [Google Scholar] [CrossRef]

- Poon, C.S.; Kou, S.C.; Lam, L. Use of recycled aggregates in molded concrete bricks and blocks. Constr. Build. Mater. 2002, 16, 281–289. [Google Scholar] [CrossRef]

- National Stone Sand & Gravel Association, NSSGA. Available online: https://www.nssga.org (accessed on 3 February 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).