1. Introduction

The “Holy Grail” of nanomaterials science is the creation of innovative lightweight materials with precisely matched combinations of necessary nano-topological and physicochemical properties. The structure–property relationship is the most important paradigm in materials science. Whereas most modern materials have a complex of distinctive properties due to used materials and their combinations as well as appropriate technological processing, the unique topological and physicochemical properties of nanostructured metamaterials are due not to the properties of the raw components used, but to the unique features of the spatial structure distribution of the materials, such as the shape of periodic structures, their mutual orientations, and unusual geometric configurations.

Extreme lattice metamaterials (ELMs), with a set of unprecedented topological and physicochemical properties, represent a novel class of materials that are rarely or not found in nature and can be recognized as promising nanoscale construction elements.

The metamaterial-based multifunctional lattice structures have great potential to fundamentally alter both the items we use every day and the way that sectors such as aerospace, microelectronics, and medicine function [

1].

In the context of additive manufacturing, lattice structures open up unique design possibilities, as 3D printing technologies uncover possibilities for creating shapes and parts that were previously “unmanufacturable”.

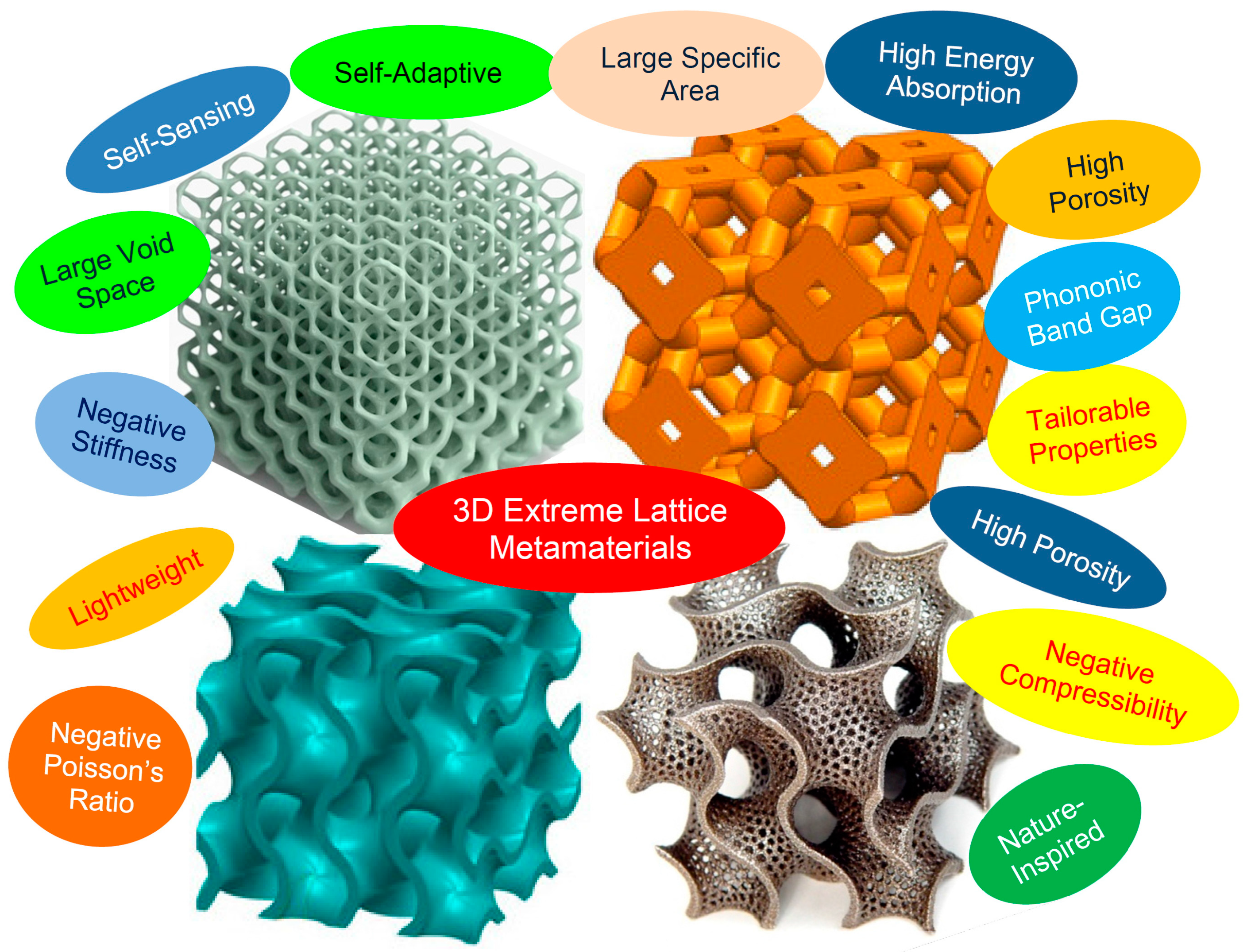

Figure 1 lists some characteristics of ELMs that are of particular interest to a wide range of research and engineering applications.

The further evolution of these metamaterials is “field-responsive mechanical metamaterials”, which are capable of almost instantly responding and stiffening 3D-printed structures when exposed to an external magnetic field. For usage in cutting-edge interactive applications, additive manufacturing technology enables grown objects to sense the external forces applied to them.

The high-precision multi-material additive manufacturing techniques that are currently available reveal practically infinite possibilities for the rational design of unique extreme lattice metamaterials, not only with complex topologies but also with arbitrary distributions of multiple materials within the selected topologies, resulting in distinct sets of combinations of topological features and physicochemical properties. Additive manufacturing, in particular, enables the blending of multiple materials into one topological component.

2. Fine-Tuning Vibrational Interactions

The origin of physicochemical properties, nano-topology, and functionality for nanomaterials is at the atomic scale. Important vibrational, mechanical, thermal, electronic, and transport characteristics of nanomaterials are controlled by phonons: by propagating atomic vibrational waves.

A recent fundamental discovery, based on the study of atomic-resolution imaging, confirmed the excitation of collective atomic vibrations (CAVs) in nanoscale systems, called phonon waves [

2]. In particular, these vibrations, or “phonon waves”, determine the processes of transfer of electric charges and heat in nanomaterials. In accordance with this discovery, phonons can generate a wave that has capability transfer across all subsequent materials, also known as a coherent effect. Phonons play a decisive role in the formation of the physical properties of nanomaterials. This explains why nanoscale interfaces are capable of demonstrating unique properties that are different from those of neighboring nanomaterials.

Within multilayer nanomaterials, phonon waves, manifested in the transition domains of multilayer nanostructures, are capable of inducing collective vibrational interactions with related materials at the nanoscale.

In other words, desired nanomaterial properties can be achieved by changing how different layers or components couple to each other, through changing the number of interacting layers as well as their thicknesses. For nanolayers smaller than 10–20 nm, vibrations of the most external atomic layers are relatively large and hence play a significant role in the formation of its properties.

The ability to manipulate via CAVs uncovers access to the predictive programming of the physicochemical properties of the lattice metamaterials.

We have created a breakthrough strategy for improving additively manufactured ELM performance and unlocking new functionalities through fine-tuning the atomic vibrational interlayer interactions within the transition zones of nanocomponents. This strategy is founded on the newly discovered CAV phenomenon, which is observed in the transition zones of multilayer nanostructures.

Interface designing, especially at the nanoscale, is one of the main driving paradigms of progress in the development of advanced functional nanomaterials. The interfaces play a significant role in determining the general material properties of nanocomposites.

We consider nano-enhanced interfaces as programmable nanodevices that serve as intelligent gateways and weak-signal amplifiers between nanocomponents via the excitation and fine-tuning self-synchronization of CAVs and phonon wave propagation.

For the predictive excitation and adjustment of the CAV phenomenon, we propose the incorporation of low-dimensional nanocarbon-based multilayer interfaces into the transition zones of nanocomponents via a multistage technological chain.

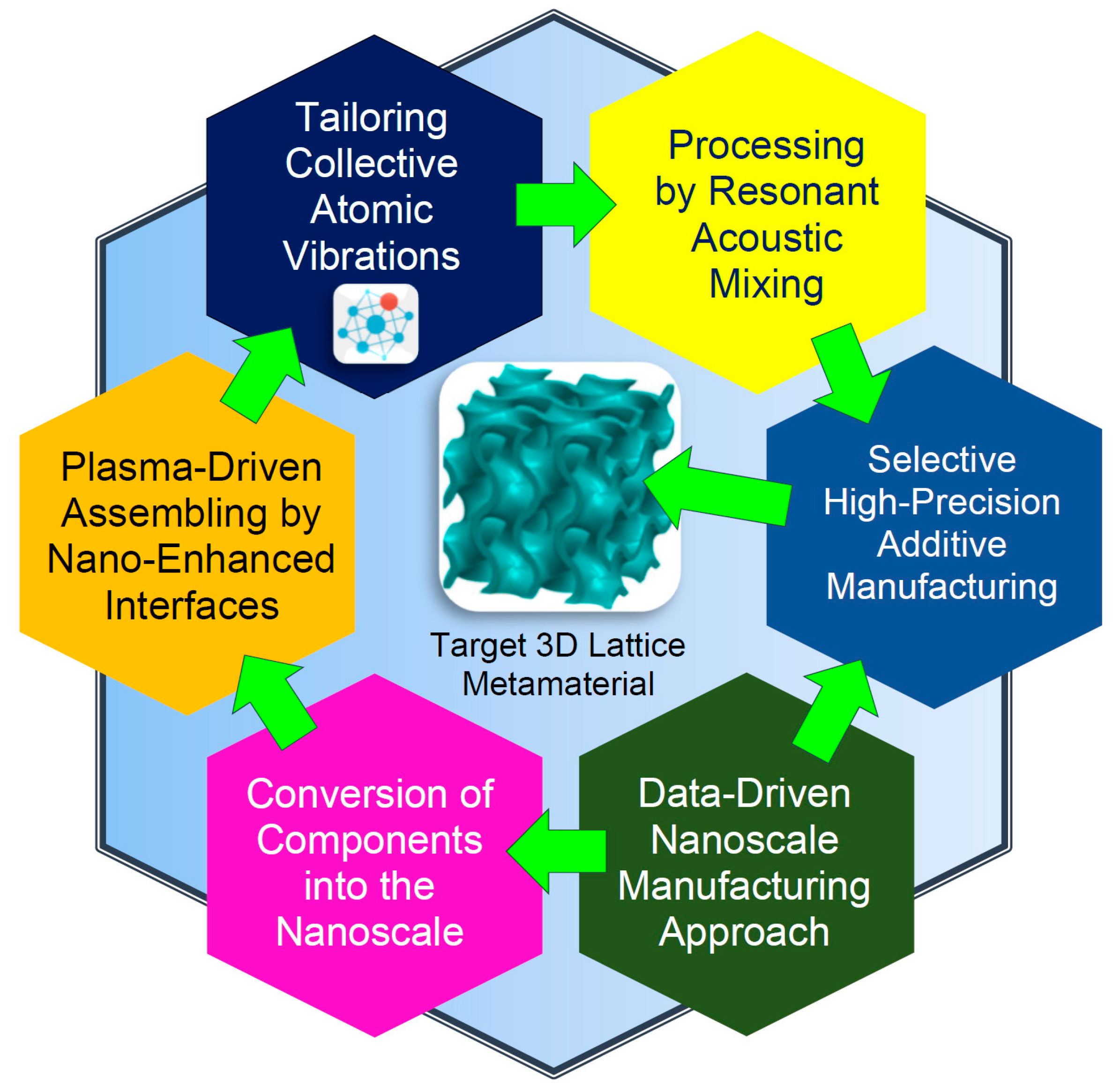

In particular, this chain includes a combination of a set of the following techniques: the conversion of all components into the nanoscale; the plasma-driven functionalization and assembling of components via multilayer nano-enhanced interfaces; the excitation of the allotropic phase conversions, driven by energy; the micro- and nanoscale manipulations assisted by surface acoustic waves during ion-assisted pulse plasma processing and functionalizing; pulse-plasma doping via atoms of various chemical elements; exciting oriented self-assembly by using high-frequency electromagnetic fields; the resonant acoustic mixing of all nanocomponents; growing high-end ELM elements via high-precision multi-material additive manufacturing as well as using the data-driven nanoscale inverse designing and manufacturing strategy. The developed technological chain is schematically shown in

Figure 2.

These multilayer nano-enhanced interfaces can also serve as nanocarriers for doping via atoms of various chemical elements, as sensitive nano-links for external electromagnetic fields, as well as empower a material with the ability to “sense” its structural health.

As promising multilayer nano-enhanced interfaces, we propose using low-dimensional nanocarbon allotropes with a set of unique properties.

Carbon exhibits rich allotropy due to its capacity to accept several types of orbital hybridization. Carbyne, which is a one-dimensional chain of carbon atoms, is recognized as a “Holy Grail” of low-dimensional carbon allotropes.

The instability and high reactivity of this allotropic form of carbon prevent the growth of macroscopic crystals of carbyne, excluding the potential of practical application. To overcome this problem, an original route to compensate for the high reactivity of the carbon chains was found relatively recently [

3].

In particular, a new method for the encapsulation of monatomic carbon filaments—oriented linear chains of carbon atoms in an amorphous carbon matrix, based on ion-assisted pulse plasma deposition—has been developed.

In accordance with the obtained nano-topology of the grown nano-matrix, it was named as a 2D-ordered linear chain carbon (2D LCC).

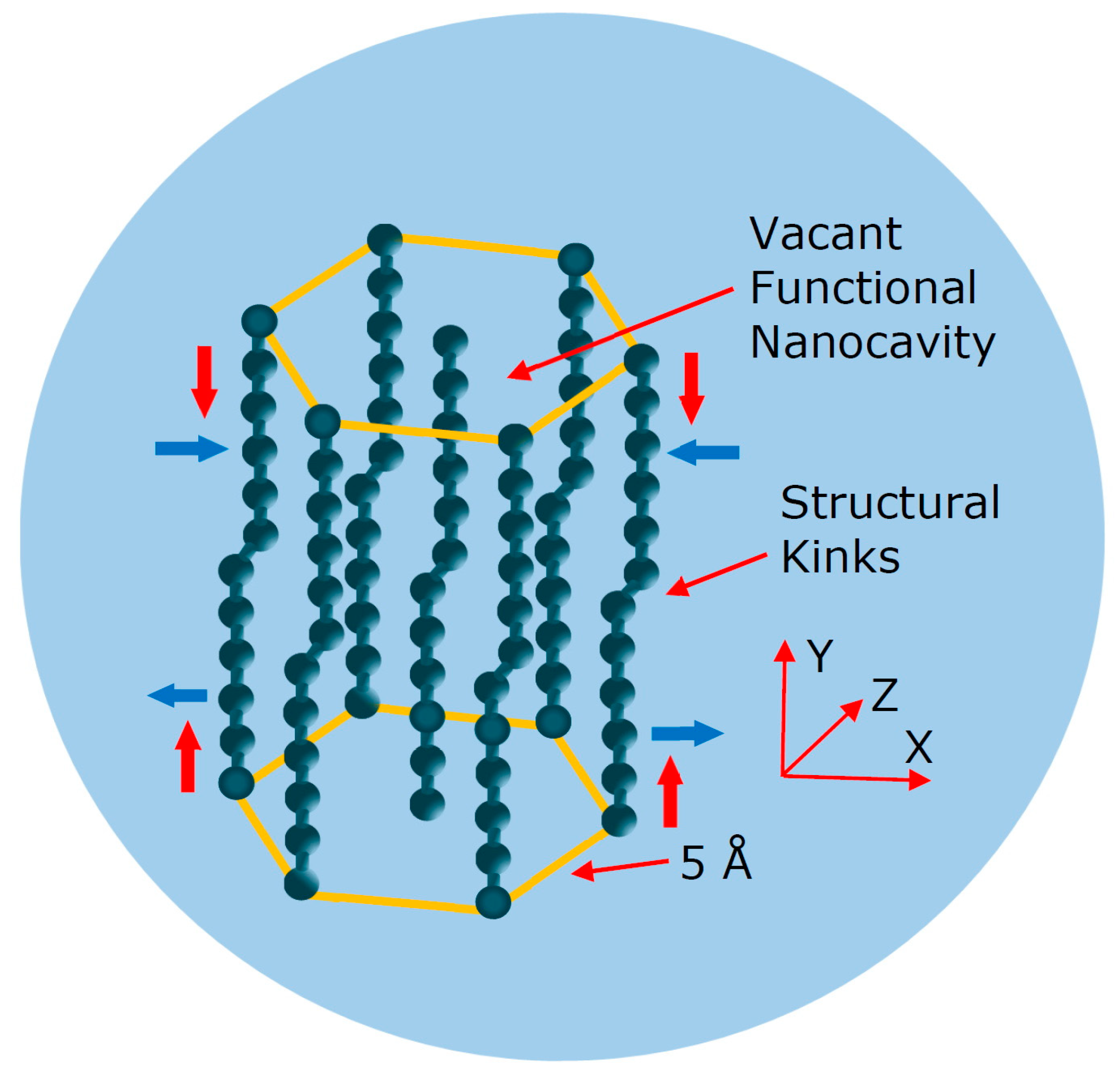

Due to its exceptional set of properties, this new nanomaterial can serve as an excellent multilayer nano-enhanced interface. The spatial structure of the 2D LCC nano-matrix can be represented as a two-dimensionally distributed hexagonal array, containing parallel one-dimensional carbon chains oriented perpendicular to the substrate surface. These parallel chains are held in the hexagonal array by van der Waals forces (

Figure 3).

Within the 2D LCC structure, the carbon chains are held by van der Waals forces at a distance of nearly five angstroms. In accordance with the spatial topology, the 2D LCC nano-matrix is a multiple-cavity structure with open functional nanoscale cavities capable of accepting the atoms as well as atomic clusters of various chemical elements and their combinations. The excitation and propagation of phonon waves can be controlled using the particular properties of the 2D-LCC-based multilayer nano-enhanced interfaces.

For ELM predictive performance improvement and unlocking new functionalities, we propose using a combination of a set of techniques for fine-tuning CAVs and vibrational interlayer interactions within the transition domains of multilayer interfaces.

The combination of multiple carbon nanostructured materials with various hybridizations within a single substance can uncover new unique properties.

For manipulating phonon wave propagation through the predictive combining of multiple differently hybridized nanocarbons within a single substance, we propose using the excitation of allotropic phase conversions, driven through energy within the multilayer nano-enhanced interfaces via concurrent electron beam and ion irradiation. The mechanism of this effect is associated with competition between the formation and breaking of carbon bonds with different types of hybridization.

The carbyne concentration in the grown nanostructures is determined by the scale and depth of the initiated phase transformations.

Taking into account that the 2D-LCC-based multilayer nano-matrix represents a nanomaterial having acoustic sensitivity, we assisted nano-matrix growth via Rayleigh-type surface acoustic waves, accompanied by patterning phenomena, leading to significant modification of the nanoarchitectures and vibrational characteristics [

4]. The nano-matrix growth assisted by surface acoustic waves is combined with pulse plasma doping via atoms of various chemical elements.

Combinations of various acoustic exciting frequencies and waveforms produced in the nano-matrix growth zone excite particular unified templates that serve as both programming for the necessary nanoarchitecture of the grown nanostructures as well as for spatial markings for growing the multilayer nano-matrix.

The use of external high-frequency electromagnetic fields is capable of enhancing the vibrational interactions as well as energy exchange inside a growing nano-matrix. A unique phenomenon that Rice University researchers identified through a relatively recent experimental study revealed a method for the direct self-assembly of low-dimensional nanocarbon allotropes [

5]. According to this discovery, nanomaterials of practically all kinds, including nanocarbon allotropes, can demonstrate self-assembly over relatively long distances, depending on the energy of the high-frequency electromagnetic emission used. For instance, under the influence of a force field called Teslaphoresis, carbon nano-tubes exhibit polarization, macrolevel self-assembly into relatively long chains, and conductor-like characteristics. Teslaphoresis is able to provide additional stabilization of long carbon chains and, in fact, changes the physical mechanism for growing long carbon chains within a 2D-LCC-based nano-matrix.

A 2D-LCC-based nano-matrix can be converted into a piezoelectric material with programmable properties through a little chemical doping. A 2D-LCC-based nano-matrix can be assembled by piezoelectric nanomaterial clusters, such as lithium atoms or zinc oxide (ZnO) nanoparticles, to create piezoelectric nanogenerators that can be used to regulate the distribution of electric charge within the multilayer nano-matrix growing zone.