Study of Gas-Sensing Properties of Titania Nanotubes for Health and Safety Applications †

Abstract

:1. Introduction

2. Materials and Methods

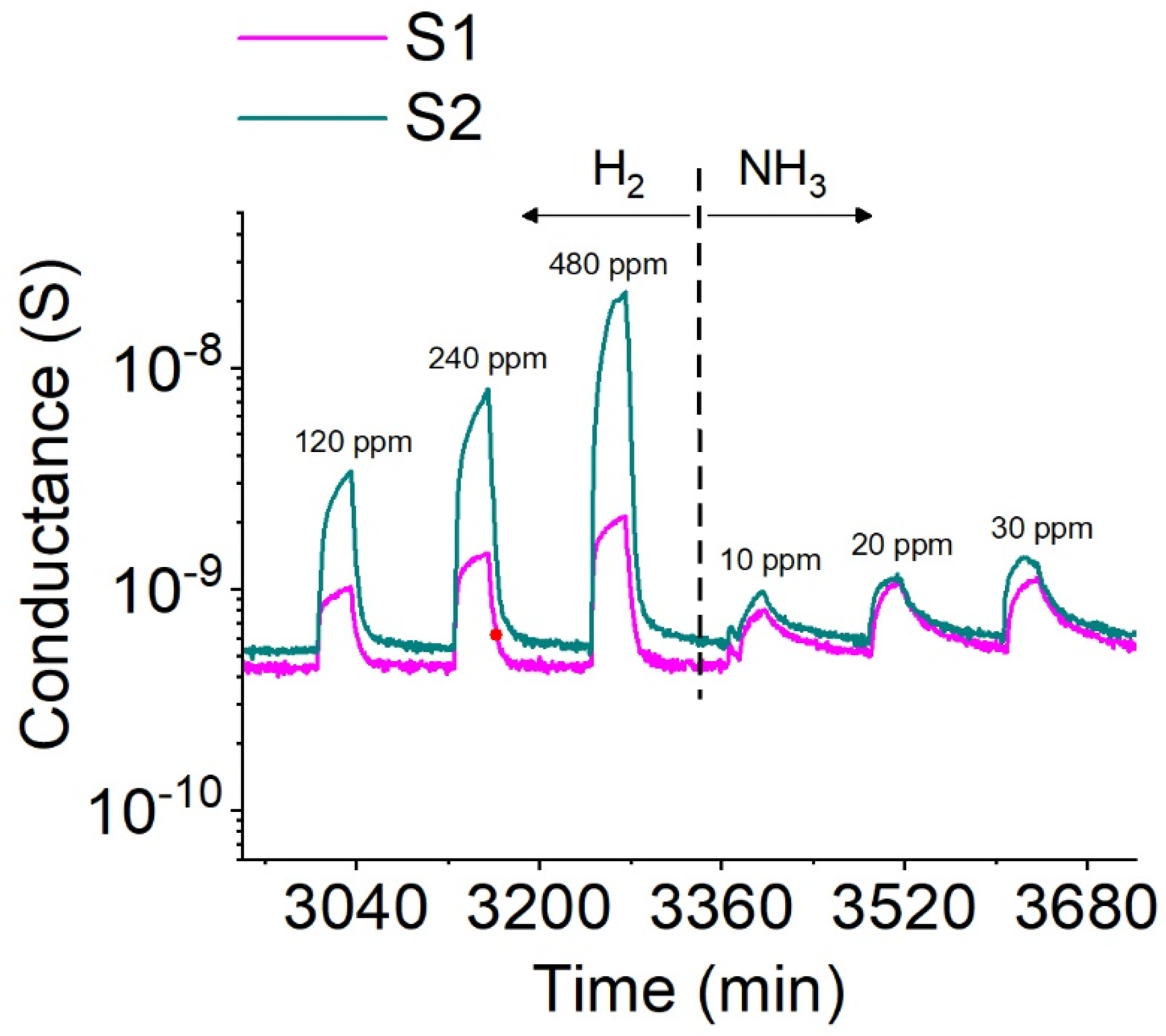

3. Results and Discussion

4. Conclusions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ahoulou, S.; Perret, E.; Nedelec, J.-M. Functionalization and characterization of silicon nanowires for sensing applications: A review. Nanomaterials 2021, 11, 999. [Google Scholar] [CrossRef] [PubMed]

- Fioravanti, A.; Marani, P.; Morandi, S.; Lettieri, S.; Mazzocchi, M.; Sacerdoti, M.; Carotta, M.C. Growth mechanisms of ZnO micro-nanomorphologies and their role in enhancing gas sensing properties. Sensors 2021, 21, 1331. [Google Scholar] [CrossRef] [PubMed]

- Cai, Z.; Park, S. Effect of nanoparticle-embedded 1 dimensional-nanostructures to fabricate highly sensitive and selective hydrogen gas sensors. J. Alloys Compd. 2021, 865, 158929. [Google Scholar] [CrossRef]

- Galstyan, V.; Kaur, N.; Zappa, D.; Núñez-Carmona, E.; Sberveglieri, V.; Comini, E. Chemical gas sensors studied at sensor lab, brescia (italy): From conventional to energy-efficient and biocompatible composite structures. Sensors 2020, 20, 579. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, G.; Hosomi, T.; Mizukami, W.; Liu, J.; Nagashima, K.; Takahashi, T.; Kanai, M.; Sugiyama, T.; Yasui, T.; Aoki, Y.; et al. A thermally robust and strongly oxidizing surface of WO3 hydrate nanowires for electrical aldehyde sensing with long-term stability. J. Mater. Chem. A 2021, 9, 5815–5824. [Google Scholar] [CrossRef]

- Lu, Y.; Purwidyantri, A.; Liu, H.; Wang, L.; Shih, C.; Pijanowska, D.G.; Yang, C. Photoelectrochemical detection of β-amyloid peptides by a TiO2 nanobrush biosensor. IEEE Sens. J. 2020, 20, 6248–6255. [Google Scholar] [CrossRef]

- Agrawal, M.; Prathyusha, E.; Ahmed, H.; Dubey, S.K.; Kesharwani, P.; Singhvi, G.; Naidu, V.G.M.; Alexander, A. Biomaterials in treatment of alzheimer’s disease. Neurochem. Int. 2021, 145, 105008. [Google Scholar] [CrossRef] [PubMed]

- Galstyan, V. “Quantum dots: Perspectives in next-generation chemical gas sensors”—A review. Anal. Chim. Acta 2021, 238192. [Google Scholar] [CrossRef] [PubMed]

- Milovanov, Y.S.; Skryshevsky, V.A.; Gavrilchenko, I.V.; Kostiukevych, O.M.; Gryn, S.V.; Alekseev, S.A. Ethanol gas sensing performance of electrochemically anodized freestanding porous sic. Diam. Relat. Mater. 2019, 91, 84–89. [Google Scholar] [CrossRef]

- Fioravanti, A.; Carotta, M.C. Year 2020: A snapshot of the last progress in flexible printed gas sensors. Appl. Sci. 2020, 10, 1741. [Google Scholar] [CrossRef] [Green Version]

- Nikolic, M.V.; Milovanovic, V.; Vasiljevic, Z.Z.; Stamenkovic, Z. Semiconductor gas sensors: Materials, technology, design, and application. Sensors 2020, 20, 6694. [Google Scholar] [CrossRef] [PubMed]

- Galstyan, V. Porous TiO2-based gas sensors for cyber chemical systems to provide security and medical diagnosis. Sensors 2017, 17, 2947. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chang, Y.H.; Liu, C.M.; Chen, C.; Cheng, H.E. The heterojunction effects of TiO2 nanotubes fabricated by atomic layer deposition on photocarrier transportation direction. Nanoscale Res. Lett. 2012, 7, 231. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Haryński, Ł.; Grochowska, K.; Kupracz, P.; Karczewski, J.; Coy, E.; Siuzdak, K. The in-depth studies of pulsed UV laser-modified TiO2 nanotubes: The influence of geometry, crystallinity, and processing parameters. Nanomaterials 2020, 10, 430. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yadav, S.; Nair, A.; Urs Mb, K.; Kamble, V.B. Protonic titanate nanotube–reduced graphene oxide composites for hydrogen sensing. ACS Appl. Nano Mater. 2020, 3, 10082–10093. [Google Scholar] [CrossRef]

- Galstyan, V.; Comini, E.; Baratto, C.; Ponzoni, A.; Ferroni, M.; Poli, N.; Bontempi, E.; Brisotto, M.; Faglia, G.; Sberveglieri, G. Large surface area biphase titania for chemical sensing. Sens. Actuators B-Chem. 2015, 209, 1091–1096. [Google Scholar] [CrossRef] [Green Version]

- Tian, X.; Cui, X.; Lai, T.; Ren, J.; Yang, Z.; Xiao, M.; Wang, B.; Xiao, X.; Wang, Y. Gas sensors based on TiO2 nanostructured materials for the detection of hazardous gases: A review. Nano Mater. Sci. 2021, in press. [Google Scholar] [CrossRef]

- Galstyan, V.; Vomiero, A.; Comini, E.; Faglia, G.; Sberveglieri, G. TiO2 nanotubular and nanoporous arrays by electrochemical anodization on different substrates. RSC Adv. 2011, 1, 1038–1044. [Google Scholar] [CrossRef]

- Galstyan, V.; Ponzoni, A.; Kholmanov, I.; Natile, M.M.; Comini, E.; Sberveglieri, G. Highly sensitive and selective detection of dimethylamine through Nb-doping of TiO2 nanotubes for potential use in seafood quality control. Sens. Actuators B Chem. 2020, 303, 127217. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galstyan, V.; Poli, N.; Comini, E. Study of Gas-Sensing Properties of Titania Nanotubes for Health and Safety Applications. Chem. Proc. 2021, 5, 16. https://doi.org/10.3390/CSAC2021-10625

Galstyan V, Poli N, Comini E. Study of Gas-Sensing Properties of Titania Nanotubes for Health and Safety Applications. Chemistry Proceedings. 2021; 5(1):16. https://doi.org/10.3390/CSAC2021-10625

Chicago/Turabian StyleGalstyan, Vardan, Nicola Poli, and Elisabetta Comini. 2021. "Study of Gas-Sensing Properties of Titania Nanotubes for Health and Safety Applications" Chemistry Proceedings 5, no. 1: 16. https://doi.org/10.3390/CSAC2021-10625

APA StyleGalstyan, V., Poli, N., & Comini, E. (2021). Study of Gas-Sensing Properties of Titania Nanotubes for Health and Safety Applications. Chemistry Proceedings, 5(1), 16. https://doi.org/10.3390/CSAC2021-10625