Swelling of Highly Neutron Irradiated Beryllium and Titanium Beryllide

Abstract

1. Introduction

2. Materials and Methods

3. Results

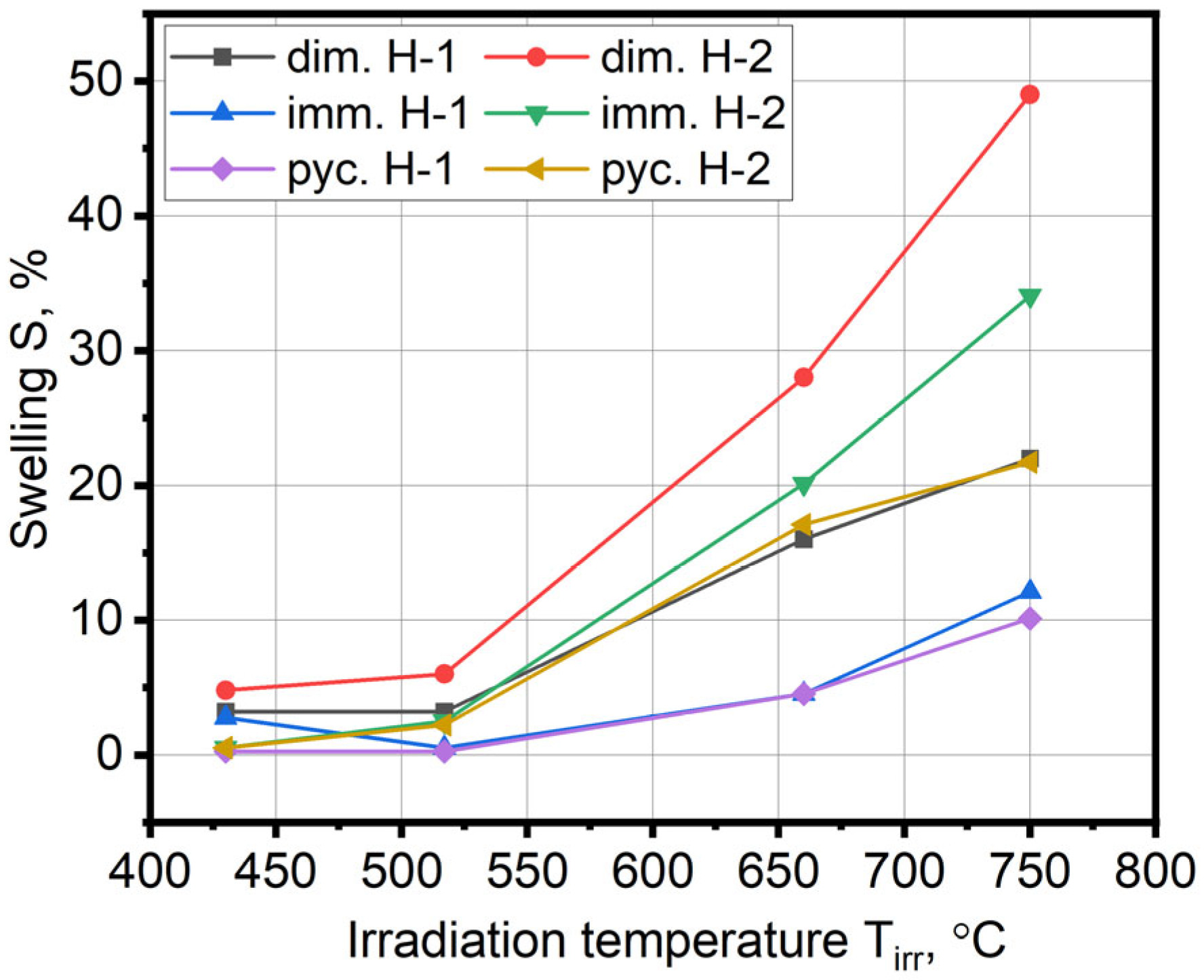

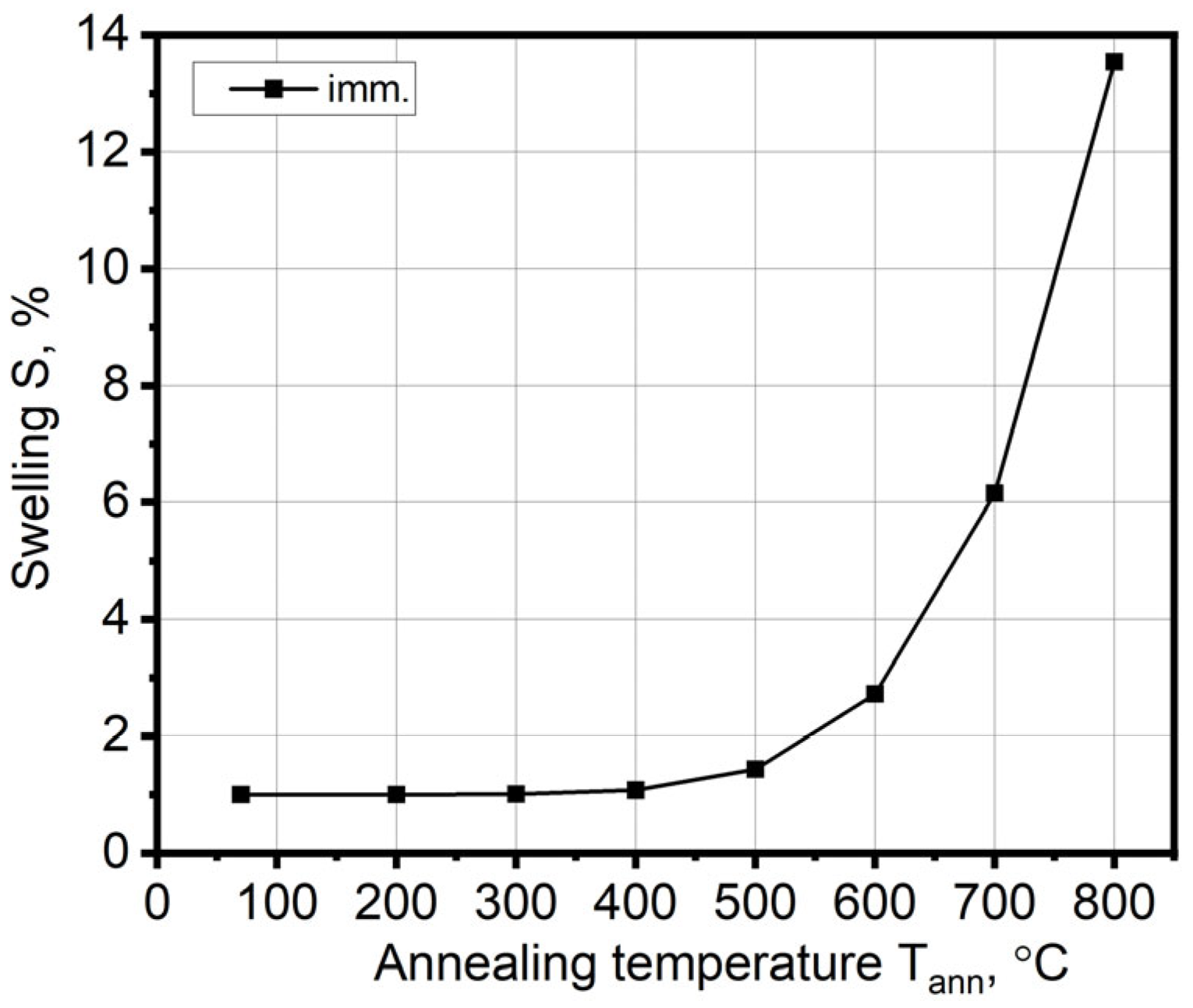

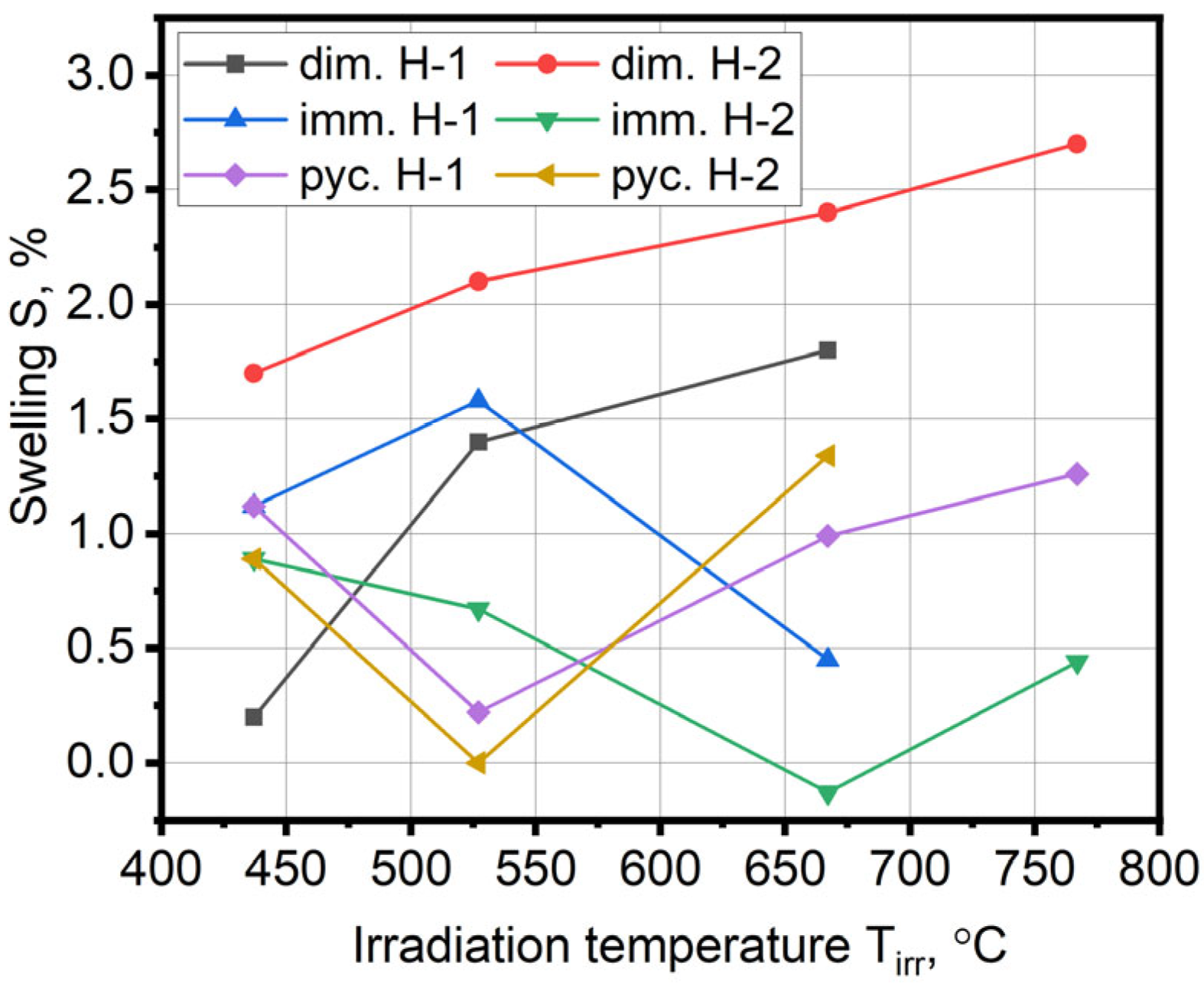

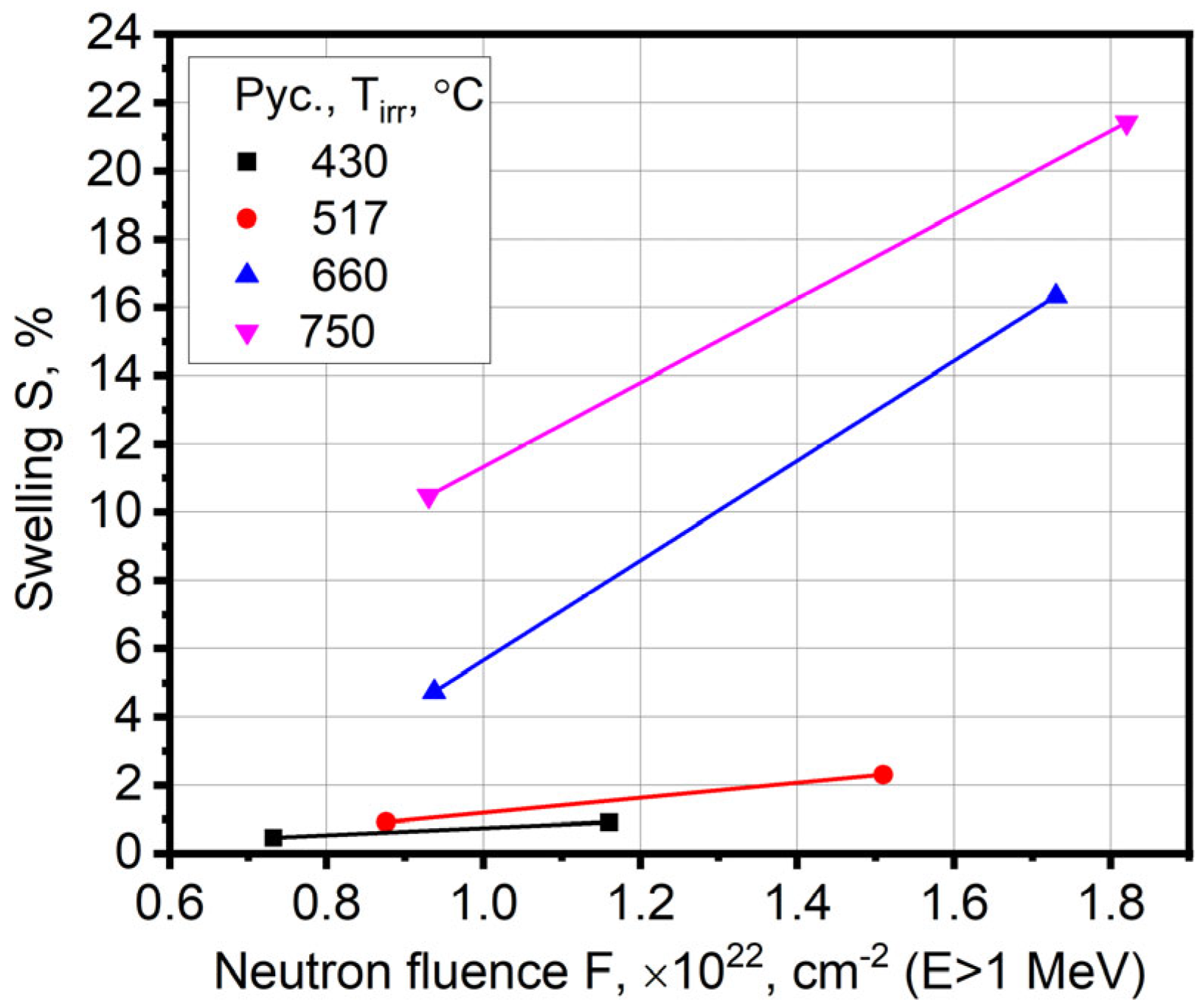

3.1. Temperature Dependence of Swelling

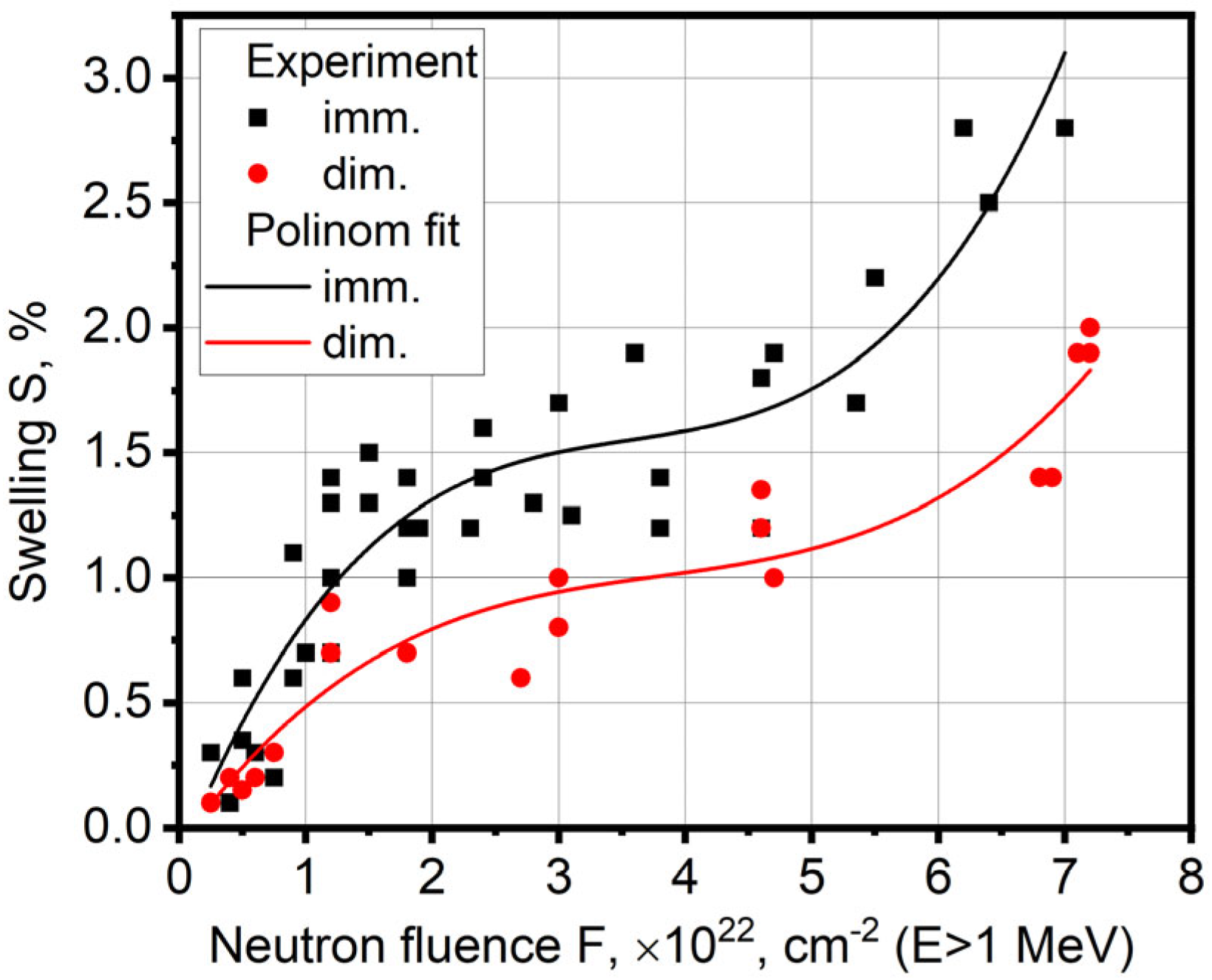

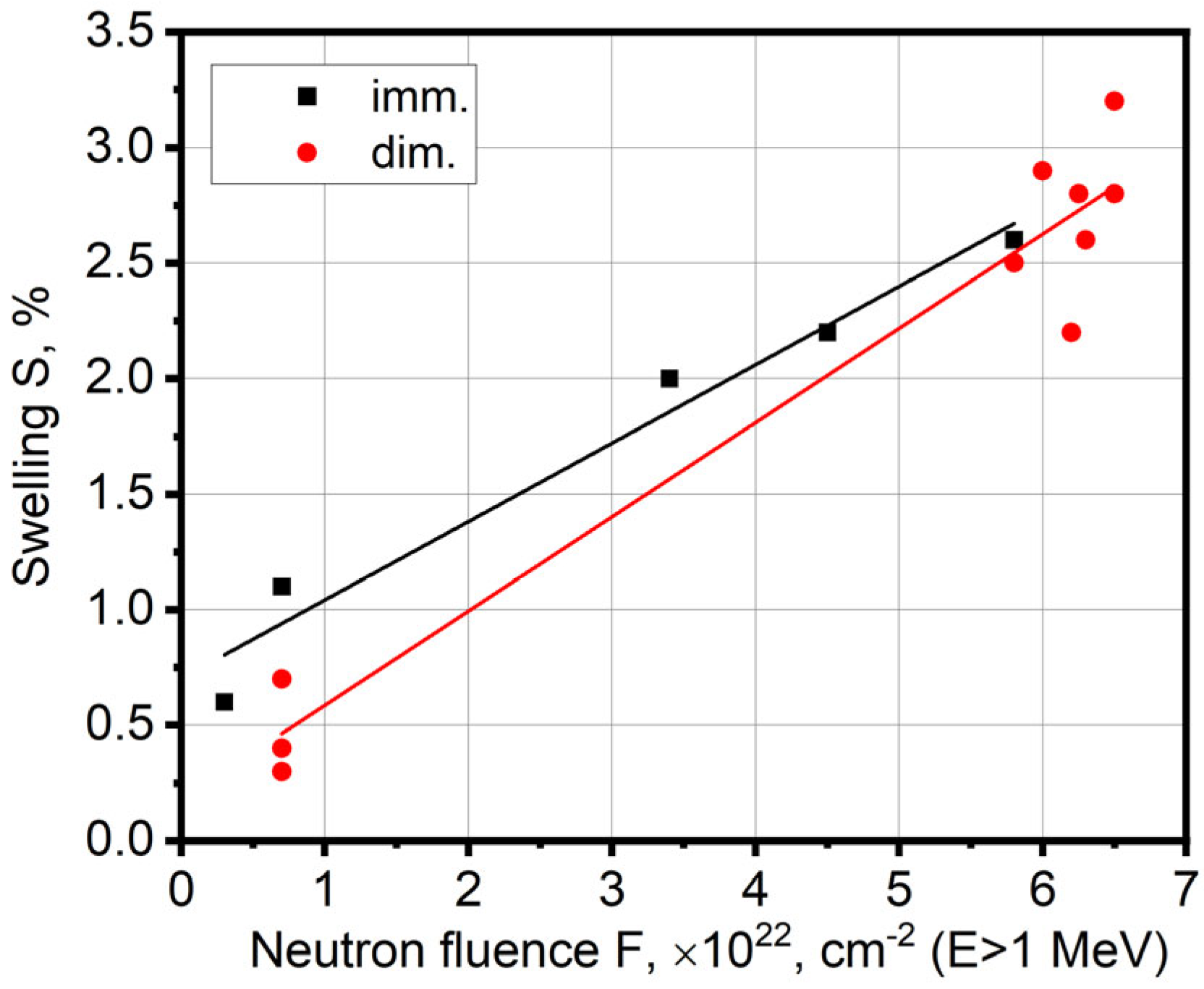

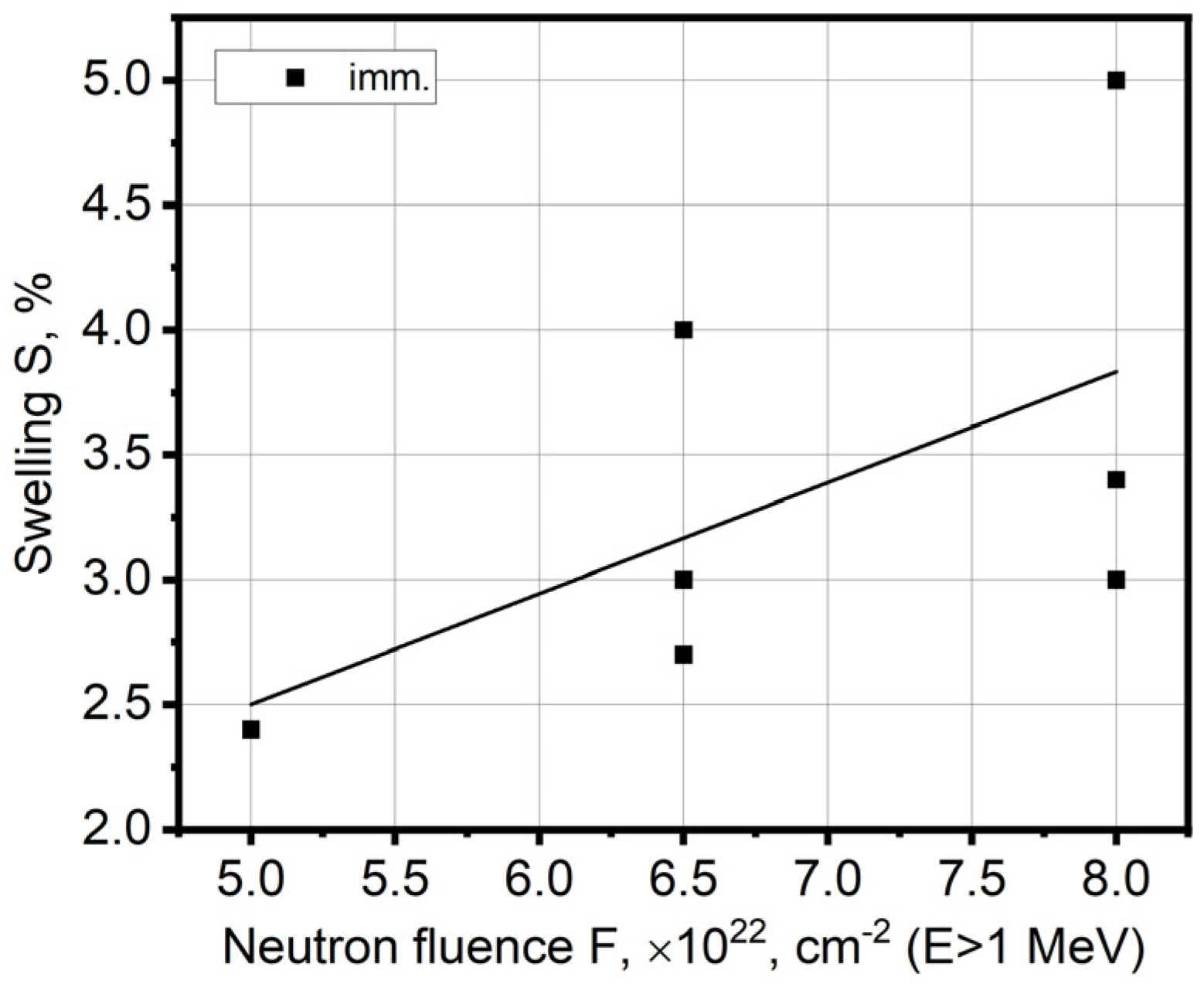

3.2. Dose Dependence of Swelling

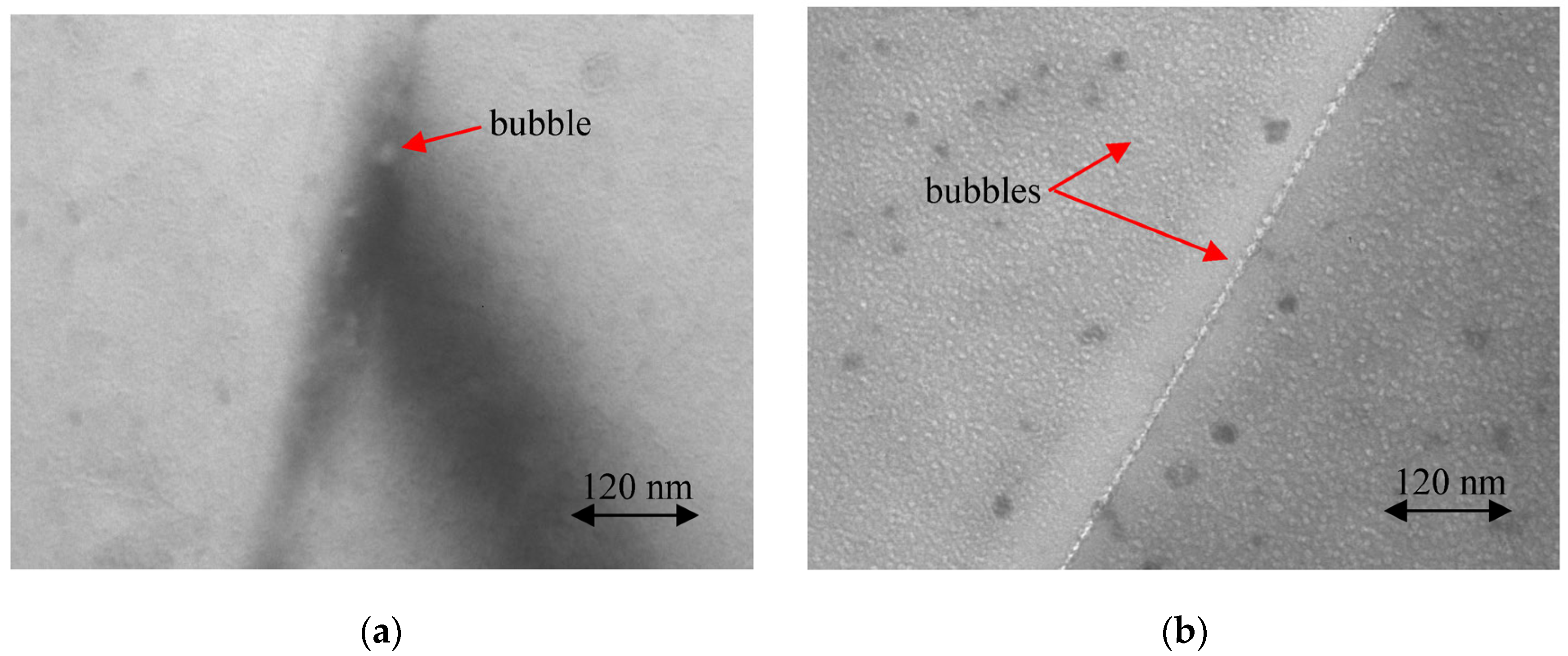

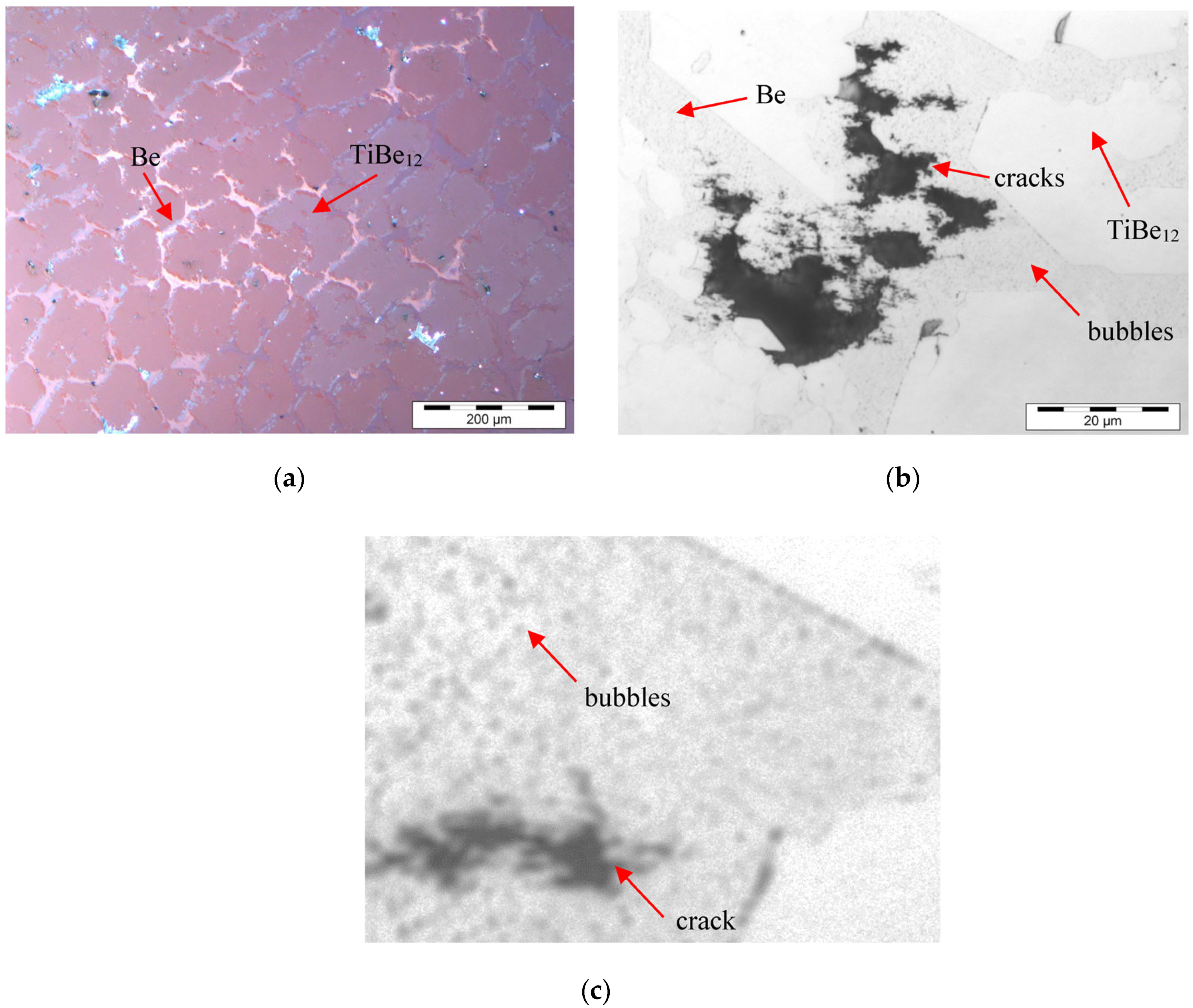

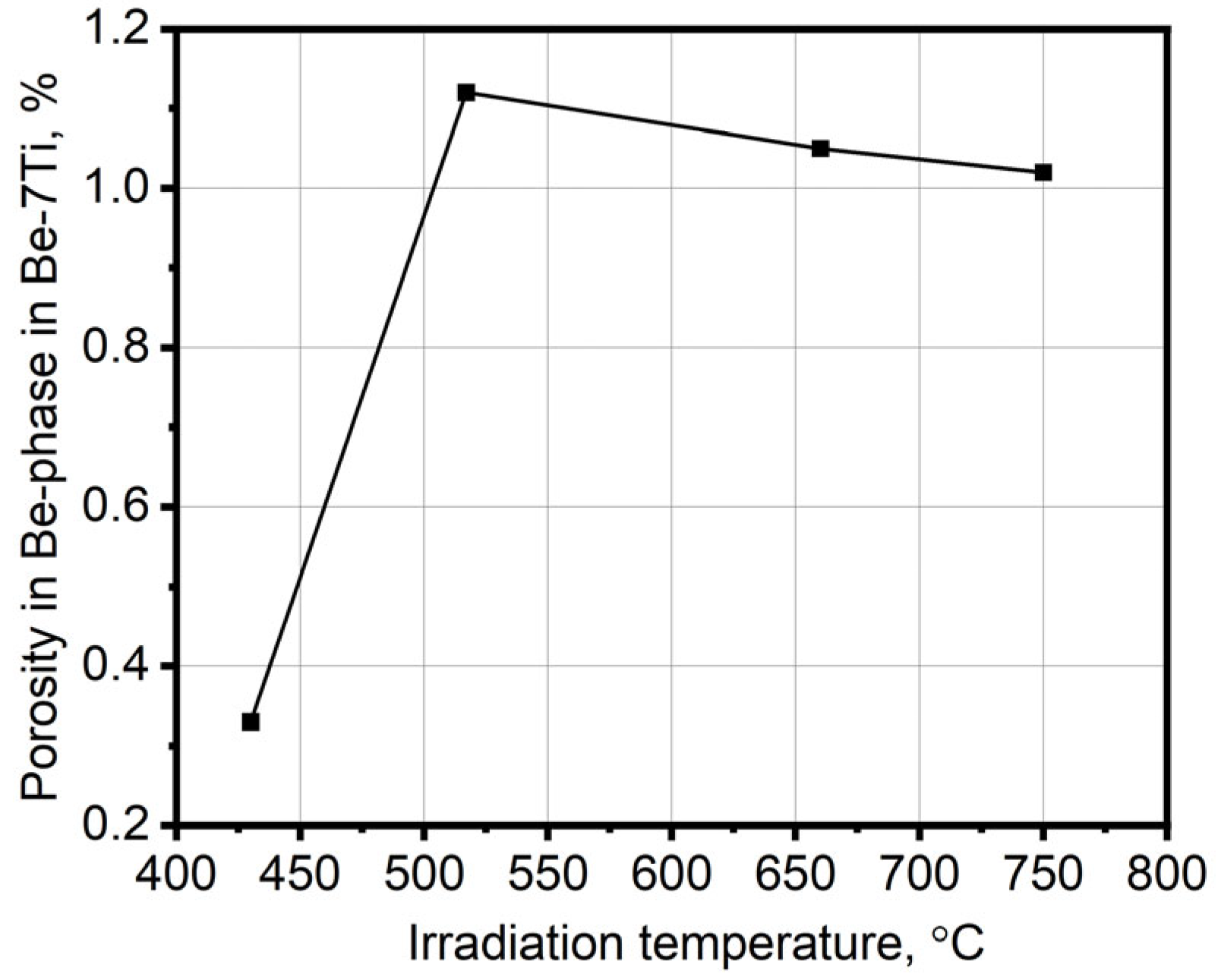

3.3. Microstructure of Irradiated Beryllium and Titanium Beryllide

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huffman, J.R. The Materials Testing Reactor as an Irradiation Facility. IDO-16, 122-PPCo, 31 August 1953. Available online: https://babel.hathitrust.org/cgi/pt?id=mdp.39015086573378&view=1up&seq=4 (accessed on 19 October 2022).

- White, D.W.; Burke, J.E. The Metal Beryllium; The American Society for Metals: Cleveland, OH, USA, 1955. [Google Scholar]

- Beeston, J.M. Beryllium metal as a neutron moderator and reflector material. Nucl. Eng. Des. 1970, 14, 445–474. [Google Scholar] [CrossRef]

- Chakin, V.P. Radiation damage of beryllium blocks of the SM reactor. Phys. Met. Metallogr. 1999, 88, 200–204. [Google Scholar]

- Dalle Donne, M.; Harries, D.R.; Kalinin, G.; Mattas, R.; Mori, S. Material problems and requirements related to the development of fusion blankets: The designer point of view. J. Nucl. Mater. 1994, 212–215, 69–79. [Google Scholar] [CrossRef]

- Boccaccini, L.V.; Giancarli, L.; Janeschitz, G.; Hermsmeyer, S.; Poitevin, Y.; Cardella, A.; Diegele, E. Materials and design of the European DEMO blankets. J. Nucl. Mater. 2004, 329–333, 148–155. [Google Scholar] [CrossRef]

- Federici, G.; Boccaccini, L.; Cismondi, F.; Gasparotto, M.; Poitevin, Y.; Ricapito, I. An overview of the EU breeding blanket design strategy as an integral part of the DEMO design effort. Fus. Eng. Des. 2019, 141, 30–42. [Google Scholar] [CrossRef]

- Zmitko, M.; Vladimirov, P.; Knitter, R.; Kolb, M.; Leys, O.; Heuser, J.; Schneider, H.-C.; Rolli, R.; Chakin, V.; Pupeschi, S.; et al. Development and qualification of functional materials for the European HCPB TBM. Fus. Eng. Des. 2018, 136, 1376–1385. [Google Scholar] [CrossRef]

- Hernandez, F.A.; Pereslavtsev, P.; Zhou, G.; Kiss, B.; Kang, Q.; Neuberger, H.; Chakin, V.; Gaisin, R.; Vladimirov, P.; Boccaccini, L.V.; et al. Advancements in the Helium-Cooled Pebble Bed Breeding Blanket for the EU DEMO: Holistic Design Approach and Lessons Learned. Fus. Sci. Technol. 2019, 75, 352–364. [Google Scholar] [CrossRef]

- Gaisin, R.; Chakin, V.; Vladimirov, P.; Hernandez Gonzalez, F.A.; Udartsev, S.; Vechkutov, A.; Kolmakov, M. Industrial-scale Manufacturing Experience of Titanium Beryllide Block for DEMO Blanket Application. Fus. Eng. Des. 2020, 161, 111862. [Google Scholar] [CrossRef]

- Ells, C.E.; Perryman, E.C. Effects of neutron-induced gas formation on beryllium. J. Nucl. Mater. 1959, 1, 73–84. [Google Scholar] [CrossRef]

- Foreman, A.J.E. Calculations on the Rate of Swelling of Gas Bubbles in Uranium; Report AERE-T/M-134; Great Britain Atomic Energy Research Establishment: Harwell, UK, March 1956. [Google Scholar]

- Barnes, R.S. A theory of swelling and gas release for reactor materials. J. Nucl. Mater. 1964, 11, 135–148. [Google Scholar] [CrossRef]

- Rich, J.B.; Redding, G.B.; Barnes, R.S. The effect of heating neutron irradiated beryllium. J. Nucl. Mater. 1959, 1, 96–105. [Google Scholar] [CrossRef]

- Rich, J.B.; Walters, G.P.; Barnes, R.S. The mechanical properties of some highly irradiated beryllium. J. Nucl. Mater. 1961, 3, 287–294. [Google Scholar] [CrossRef]

- Goltsev, V.P.; Sernyaev, G.A.; Chechetkina, Z.I. Radiation Material Science of Beryllium; Nauka i Tekhnika: Minsk, Belarus, 1977. (In Russian) [Google Scholar]

- Sernyaev, G.A. Radiation Damageability of Beryllium; Ekaterinburg Publishers: Yekaterinburg, Russia, 2001. [Google Scholar]

- Gelles, D.S.; Sernyaev, G.A.; Dalle Donne, M.; Kawamura, H. Radiation effects in beryllium used for plasma protection. J. Nucl. Mater. 1994, 212–215, 29–38. [Google Scholar] [CrossRef]

- Sannen, L.; De Raedt, C.; Moons, F.; Yao, Y. Helium content and induced swelling of neutron irradiated beryllium. Fus. Eng. Des. 1994, 29, 470–474. [Google Scholar] [CrossRef]

- Beeston, J.M.; Miller, L.G.; Wood, E.L.; Moir, R.W., Jr. Comparison of compression properties and swelling of beryllium irradiated at various temperatures. J. Nucl. Mater. 1984, 122–123, 802–809. [Google Scholar] [CrossRef][Green Version]

- Sernyaev, G.A. Swelling of beryllium at high-temperature neutron irradiation. Role of main structural factors. Vopr. At. Nauki Tek. 1992, 63–73. (In Russian) [Google Scholar]

- Kurinskiy, P.; Moeslang, A.; Chakin, V.; Klimenkov, M.; Rolli, R.; Van Til, S.; Goraieb, A.A. Characteristics of microstructure, swelling and mechanical behavior of titanium beryllide samples after high-dose neutron irradiation at 740 and 873 K. Fus. Eng. Des. 2013, 88, 2198–2201. [Google Scholar] [CrossRef]

- Chakin, V.; Rolli, R.; Vladimirov, P.; Moeslang, A. Tritium release from highly neutron irradiated constrained and unconstrained beryllium pebbles. Fus. Eng. Des. 2015, 95, 59–66. [Google Scholar] [CrossRef]

- Klimenkov, M.; Chakin, V.; Moeslang, A.; Rolli, R. TEM study of beryllium pebbles after neutron irradiation up to 3000 appm helium production. J. Nucl. Mater. 2013, 443, 409–416. [Google Scholar] [CrossRef]

- Zimber, N.; Vladimirov, P.; Klimenkov, M.; Kuksenko, V. Investigation of a high-dose irradiated beryllium microstructure. J. Nucl. Mater. 2020, 540, 152374. [Google Scholar] [CrossRef]

- Fedorov, A.V.; Van Til, S.; Stijkel, M.P.; Nakamichi, M.; Zmitko, M. Post irradiation characterization of beryllium and beryllides after high temperature irradiation up to 3000 appm helium production in HIDOBE-01. Fus. Eng. Des. 2016, 102, 74–80. [Google Scholar] [CrossRef]

- Chakin, V.P.; Posevin, A.O.; Obukhov, A.V.; Silantyev, P.P. Radiation growth of beryllium. J. Nucl. Mater. 2009, 386–388, 206–209. [Google Scholar] [CrossRef]

- Geguzin, Y.E. Ascending diffusion and the diffusion aftereffect. Sov. Phys. Uspekhi 1986, 29, 467–473. [Google Scholar] [CrossRef]

- Chakin, V.; Rolli, R.; Schneider, H.-C.; Moeslang, A.; Kurinskiy, P.; Van Renterghem, W. Pores and cracks in highly neutron irradiated beryllium. J. Nucl. Mater. 2011, 416, 3–8. [Google Scholar] [CrossRef]

- Rabaglino, E.; Hiernaut, J.P.; Ronchi, C.; Scaffidi-Argentina, F. Helium and tritium kinetics in irradiated beryllium pebbles. J. Nucl. Mater. 2002, 307–311, 1424–1429. [Google Scholar] [CrossRef]

- Rabaglino, E.; Baruchel, J.; Boller, E.; Elmoutaouakkil, A.; Ferrero, C.; Ronchi, C.; Wiss, T. Study by microtomography of 3D porosity networks in irradiated beryllium. Nucl. Instr. Methods Phys. Res. Sect. B 2003, 200, 352–357. [Google Scholar] [CrossRef]

- Chakin, V.; Rolli, R.; Vladimirov, P.; Moeslang, A. Tritium and helium release from beryllium pebbles neutron-irradiated up to 230 appm tritium and 3000 appm helium. Nucl. Mater. Ener. 2016, 9, 207–215. [Google Scholar] [CrossRef]

| Grade | Be | Fe | Al | Ni | Cu | Mg | Mn | Cr | Si | U | BeO | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HE-56 | balance | 0.17 | 0.026 | 0.017 | 0.004 | 0.0005 | 0.01 | 0.041 | 0.016 | 0.0003 | 1.48 | - |

| VHP-400 * | - | - | - | - | - | - | - | - | - | - | - | |

| Cast Be | 0.1 | 0.07 | 0.01 | <0.01 | 0.05 | 0.007 | <0.01 | 0.03 | 0.0068 | 0.02 | - | |

| Cast Be-7Ti | 0.031 | 0.06 | 0.003 | 0.004 | <0.001 | 0.007 | 0.005 | 0.033 | 0.0041 | 0.27 | 28.5 |

| Grade | Reactor | Tirr, °C | F · 1022, cm−2 (E > 1 MeV) | Helium Production, appm | Tritium Production, appm |

|---|---|---|---|---|---|

| HE-56 | SM-3 | 70 | 0.25–7.7 | 1071–33,000 | 152–4675 |

| 200 | 0.3–6.5 | 1286–27,857 | 182–3946 | ||

| VHP-400 | BOR-60 | 420 | 5–8 | 6125–9800 | 178–285 |

| Cast Be | HFR | 430 | 0.73; 1.16 | 2370; 4144 | 215; 430 |

| 517 | 0.87; 1.51 | 2860; 5142 | 279; 550 | ||

| 660 | 0.94; 1.73 | 3070; 5757 | 305; 625 | ||

| 750 | 0.93; 1.82 | 3060; 5992 | 301; 653 | ||

| Cast Be-7Ti | HFR | 430 | 0.73; 1.16 | 2370; 4144 | 215; 430 |

| 517 | 0.87; 1.51 | 2860; 5142 | 279; 550 | ||

| 660 | 0.94; 1.73 | 3070; 5757 | 305; 625 | ||

| 750 | 0.93; 1.82 | 3060; 5992 | 301; 653 |

| Tirr, °C | S, % | |||||

|---|---|---|---|---|---|---|

| Immersion | Pycnometry | Open Pores | ||||

| H-1 | H-2 | H-1 | H-2 | H-1 | H-2 | |

| 660 | 4.52 | 20.13 | 4.52 | 17.09 | 0 | 3.04 |

| 750 | 12.12 | 34.06 | 10.12 | 21.71 | 2 | 12.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chakin, V.; Fedorov, A.; Gaisin, R.; Zmitko, M. Swelling of Highly Neutron Irradiated Beryllium and Titanium Beryllide. J. Nucl. Eng. 2022, 3, 398-408. https://doi.org/10.3390/jne3040026

Chakin V, Fedorov A, Gaisin R, Zmitko M. Swelling of Highly Neutron Irradiated Beryllium and Titanium Beryllide. Journal of Nuclear Engineering. 2022; 3(4):398-408. https://doi.org/10.3390/jne3040026

Chicago/Turabian StyleChakin, Vladimir, Alexander Fedorov, Ramil Gaisin, and Milan Zmitko. 2022. "Swelling of Highly Neutron Irradiated Beryllium and Titanium Beryllide" Journal of Nuclear Engineering 3, no. 4: 398-408. https://doi.org/10.3390/jne3040026

APA StyleChakin, V., Fedorov, A., Gaisin, R., & Zmitko, M. (2022). Swelling of Highly Neutron Irradiated Beryllium and Titanium Beryllide. Journal of Nuclear Engineering, 3(4), 398-408. https://doi.org/10.3390/jne3040026