Abstract

This paper presents a new approach to the spent nuclear fuel (SNF) problem, which is uniquely enabled by a liquid fuel form, specifically as in the case of molten salt reactor (MSR) systems. Managing the SNF problem is critical for public acceptance of nuclear power as a climate change solution. An MSR can be refueled while operating by adding more fresh fuel salt, which grows the in-core fuel salt volume. This growth will eventually double the size of the original fuel salt, allowing to start another core with this excess fuel so long as the daughter reactor is of the same design and there is sufficient excess fuel. This study explores how such a “sourdough” strategy would work in MSRs and provides an initial calculation methodology to find the correct refueling rates to match the desired growth curve of power generation. Higher uranium enrichment levels of the refuel salt result in lower refueling rates and thus a longer doubling time. As a result, the refuel salt uranium enrichment can be tailored to match a postulated clean power generation capacity expansion. This approach allows postponing the spent nuclear fuel disposal issue using the sourdough method. Along with the MSR fuel’s unique properties, it suggests a new path towards managing nuclear waste until long-term solutions become economically viable.

1. Introduction

Climate change is one of the most important issues facing the world today. Amongst escalating angst over the possible effects of climate change, the nations of the world gathered to form the Paris Agreement in 2016. In this agreement, countries promised to peak greenhouse gas (GHG) production and transition to climate neutral by mid century. The means by which each signatory state achieves this goal is left up to self-determination. This has left many to speculate what can and should be used to reduce and even eliminate GHG emissions. One obvious step a state could take towards becoming climate neutral is to increase nuclear power production. Nuclear power is a proven means of safe production of low-emission energy on a large scale [1]. However, there are drawbacks such as the upfront cost and public perception of the spent fuel disposal. Reference [2] explores the effects of increasing nuclear power production tenfold to reduce GHG emissions. The study concluded that a nuclear expansion would avoid significant proportion of emissions over the next century, but the major downside is the increase in nuclear waste.

1.1. The Issue of Nuclear Waste

High-level radioactive waste that comes from spent nuclear fuel is a troublesome issue for nuclear power. In the United States, the inability to create and use a long-term geological storage facility, such as Yucca Mountain Nuclear Waste Repository, has eroded public confidence in the ability to deal with high-level radioactive waste around the world. A recent report by Columbia University’s Center on Global Energy Policy provides a great summary and policy recommendation within the current paradigm [3]. A public opinion poll for the European Union found that 39% of those with a negative opinion of nuclear power would change their view to a positive outlook if there is a permanent solution to nuclear waste [4]. Therefore, there is an incentive for the nuclear industry to find a way to eliminate or otherwise permanently deal with high-level radioactive waste from open fuel cycles.

Fast spectrum reactor systems [5] are one attentive typically considered for transmutation and burnup of minor actinides [6]. Systems producing even more energetic neutrons have been considered for a nuclear waste transmutation that could also more effectively transmute fission products.

One possible method for reducing long-lived radioactive waste is through accelerator-driven waste transmutation [7]. In these systems, long-lived and highly radioactive isotopes capture spallation neutrons and transmute the isotopes into stable or short-lived ones. A major drawback of this method is the additional cost that is incurred.

Another method would be the introduction of fusion-fission hybrid reactors [8]. Fusion-fission hybrid reactors have an active fusion reaction surrounded by a subcritical mixture of actinide waste. The fast neutrons that escape the fusion chamber burn off the long-lived actinide and fission product waste. Fusion-fission hybrid reactors require significantly more research and development before any large-scale deployment.

These methods require a significant amount of time before they can be economically deployed. Consequently, any near-term future reactors would suffer the drawbacks of nuclear waste production. However, molten salt reactors (MSRs) possess inherent features that allow for a significant postponement of the final disposal of the spent nuclear fuel. A method how to accomplish this is explored in this paper.

1.2. Molten Salt Reactors

MSRs form a broad category of Generation-IV concepts that utilize a liquid fuel, in the form of an alkali-halide melt, instead of solid fuel pellets. For the purpose of this paper, we are focusing on circulating fuel MSRs, thermal spectrum converters fueled by low enriched uranium (LEU). Such systems are most similar to the 1960s era Molten-Salt Reactor Experiment (MSRE) [9], the only MSR with significant operational experience. Additionally, thermal spectrum reactors require much less fissile loading than fast spectrum machines, which can make them more economical. This type of reactor is currently popular as an option for the next generation nuclear power plants. Several private vendors are pursuing MSR designs of this type, including Terrestrial Energy and Thorcon Power. A thermal LEU MSR type design manifests itself in the Molten Salt Research Reactor at the Abilene Christian University representing academic interest as well as in the Chinese national program. See book [10] for a recent comprehensive review of MSR technology.

In circulating fuel MSRs, the liquid fuel mixture is circulated in the reactor core and out to heat exchangers. As a side effect of the fuel circulation, the fuel salt mixture is well mixed. Additionally, MSR refueling happens while operating where a chemically compatible (often identical) refuel salt is added to actively fissioning fuel salt. In this sense, the addition of refuel salt changes the material composition of the entire active fuel. During this, the core (active fissioning region) geometry remains the same. This makes the challenge of calculating the proper refueling strategy for MSRs a challenge of balancing fissile concentration. Incidentally, the addition of refuel salt to the primary fuel salt mixture increases the volume of the primary mixture, and as a result, the primary fuel salt mixture is continuously expanding throughout the fuel cycle of an MSR. In addition, the refuel uranium enrichment can be adjusted during the fuel depletion. However, lower enrichment require higher feed rates to maintain criticality.

At some point, depending on the refuel rate, the volume of primary fuel salt will have doubled in size. Since this fuel salt composition will be critical in the MSR core, the excess volume can be siphoned off to start another reactor as long as that reactor is of the same design. In effect, this fuel growth leads to a doubling time. This sourdough doubling time should not be confused with the traditional doubling time associated with breeder reactors, where new fissile material is created from fertile nuclei by neutron absorption followed by nuclear decays. Siphoning off the excess fuel to start another reactor is not too dissimilar from maintaining a sourdough starter for baking bread. Not only does the molten salt fuel expand to startup new identical reactors, but it also does not have a mechanical lifetime that solid fuels have imposed on it due to thermal and radiation damage. Therefore, the fuel salt in a reactor that has reached its lifetime can be moved to another core. The implication of this is that MSRs have the potential of exponential growth with little waste that needs immediate storage.

MSRs are receiving renewed interest in recent years, and despite this recent activity, the concept of MSRs date back to the early days of nuclear reactors. The plan for managing waste on large-scale deployments of MSRs was never finalized. There are many proposed options for the various MSR waste streams [11,12]. The waste streams are highly dependent on the chemical behavior of the radioactive species in the fuel salt. The three main categories are the fission products (FPs) that are gaseous and bubble out of the mixture, the FPs that precipitate out of the fuel salt mixture, and everything else that remains soluble (this includes both soluble FPs and actinides) [13,14]. Each of these three chemical groups forms a fundamental split in the waste stream. The proposed sourdough method only alters how the soluble waste is treated. Where other methods would reprocess and recycle the salt, the sourdough method skips this step, and utilizes the used fuel salt as is to fuel a new reactor.

1.3. Organization of This Paper

This paper explores what the implementation of a sourdough style refueling in MSRs would look like. As of the writing of this paper, there are no burnup modeling tools that can accurately capture this method of refueling. This paper uses Serpent 2 since it allows for online material addition and removal natively. Serpent 2, however, does not allow for cell volume adjustment during depletion. As a result, this research makes several assumptions to try to show the potential of this method as accurately as possible. Section 3 details these modeling assumptions. This section also shows the relation between refuel enrichment with the estimated feed rate and corresponding doubling time. A further discussion of the implications to grid capacity and waste management is presented in Section 4. Before either of those sections, the unique features of an MSR regarding refueling and burnup is presented in Section 2.

It should be noted that the specific numbers presented in this paper are not universal for every thermal LEU-fueled MSR, neither specific to a particular design concept. The doubling times vary with a reactor and fuel cycle design details. The presented calculations are also limited by the current code capability, which introduces systematic biases. The intention behind this work is to showcase the feasibility of the MSR capacity growth via the sourdough method, highlight specific issues of refueling and modeling of MSRs in general, and provide a starting point to future work with updated codes and specific MSR design concepts.

2. Refueling in Molten Salt Reactors

2.1. Breeding Considerations

MSRs were first studied in the US during the Aircraft Reactor Program in the 1950s [15]. Research of MSRs later continued at Oak Ridge National Laboratory (ORNL) in the Molten-Salt Reactor Program during 1960s [16]. The purpose of the ORNL research was to developed a thorium-232 to uranium-233 breeder reactor. In the early times of nuclear power, fissile material breeding was considered critical for wide scale nuclear deployment due to then perceived scarcity of natural uranium. This consideration led to the push for early breeder development, primarily focused on sodium cooled fast spectrum reactors.

The breeding gain of a reactor can be expressed as the core doubling time, the time it takes to create enough new fissile material to start another identical core. However, uranium reserves are not as limited as previously thought, and the likelihood of extracting virtually unlimited amounts of uranium from seawater is becoming more economically feasible in the near future [17]. Therefore, the need to increase the amount of fissile materials is not an important issue facing the nuclear industry of today, and many different non-breeding variations of MSRs have been developed. Indeed, the current societal preference is the reduction of the fissile material stockpile.

2.2. Doubling Time of MSR Converter Volume

MSR converters, thermal systems with LEU fuel, with only limited salt processing will likely constitute the first generation of molten salt reactor technology deployment. These machines are started with a fuel salt bearing uranium enriched sufficiently for the core reach to criticality, typically ≈2% LEU. Once operated, MSR converters can be refueled with a chemically identical fuel salt mixture with higher uranium enrichment as a make-up fuel. Adding this refuel increases the volume of the primary salt. This volume increase can be easily accommodated in the primary vessel design since the overall core volume is mostly the moderator. The volume expansion will extend into the gas plenum present in the core. For the MSRE, this was in the pump bowl, but this is not necessary for every design [9]. Once the fuel salt volume grows to twice the original amount, the fuel salt can be siphoned off to another core of the same design and achieve criticality. In this sense, the MSR fuel has a doubling time, albeit not from breeding. This doubling time is highly dependent on the properties of the refuel salt, specifically the uranium enrichment. A side benefit of this method is that the new core’s initial fuel load has already been paid for while refueling the previous core, thus shift the new power plant’s upfront costs.

It should be noted that transporting the salt will be a significant challenge. There are a multitude of different effects resulting of the cooling and storing of fuel salt that will complicate transportation and storage [18]. In addition there is the high level of radio activity. This paper takes the assumption That these challenges can be handled with proper research and development. Pumping salt within a facility, say between adjacent units of modular reactors, would greatly simplify transportation.

There are several factors that a designer would need to take into account when developing a refueling strategy. Since refueling can be done online, there is no need for significant excess reactivity typical in current light water reactors. Instead, the MSR is continually refueled to maintain criticality. There are multiple factors that would cause one enrichment level to be more attractive than another. Uranium with a higher enrichment is more expensive but saves money by using less refuel salt. Different enrichments and their corresponding refuel rates affect the conversion ratio and the dilution of FP poisons. Designers and operators must consider the expansion with the fuel salt as well, either by designing extra volume or storage or by bringing new reactors online.

The doubling time is an under-studied aspect of MSRs. If the construction rate of new MSRs is slow and limited, refuel enrichment could be set to the higher levels. However, if there is no construction bottleneck, then MSRs can expand to meet the rapid growth target of clean grid capacity. Additionally, the enrichment can be changed over time to meet evolving expansion requirements. This study focuses on determining what enrichment would be needed to meet a projected grid capacity need, assuming no bottlenecks in MSR deployments. In reality, the grid capacity amenable for replacement would develop in time as old power plants age, demand grows with population and industrial growth, transportation becomes electrified, and societal priorities push for emission-free power.

3. Doubling Time Calculations

3.1. Methodology

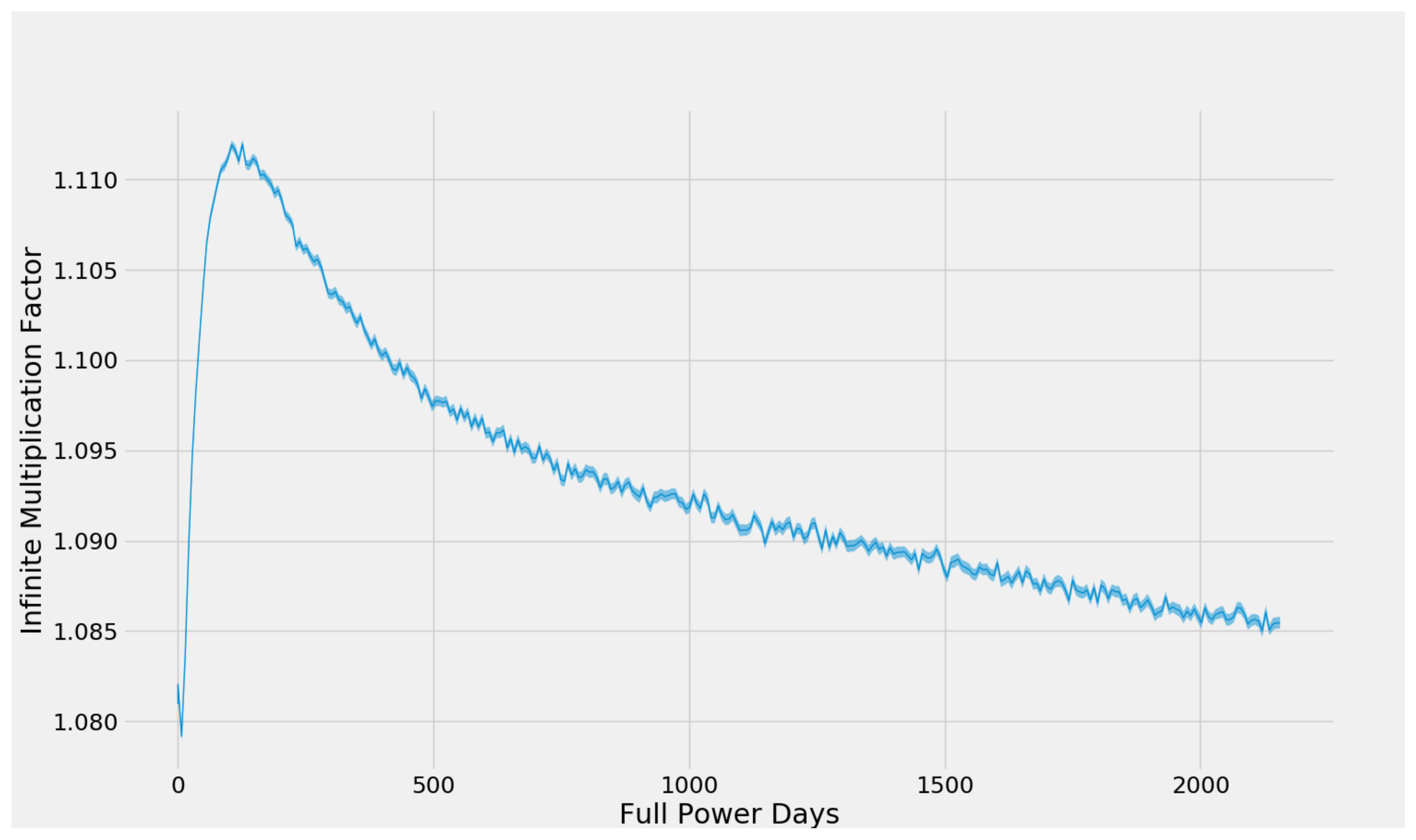

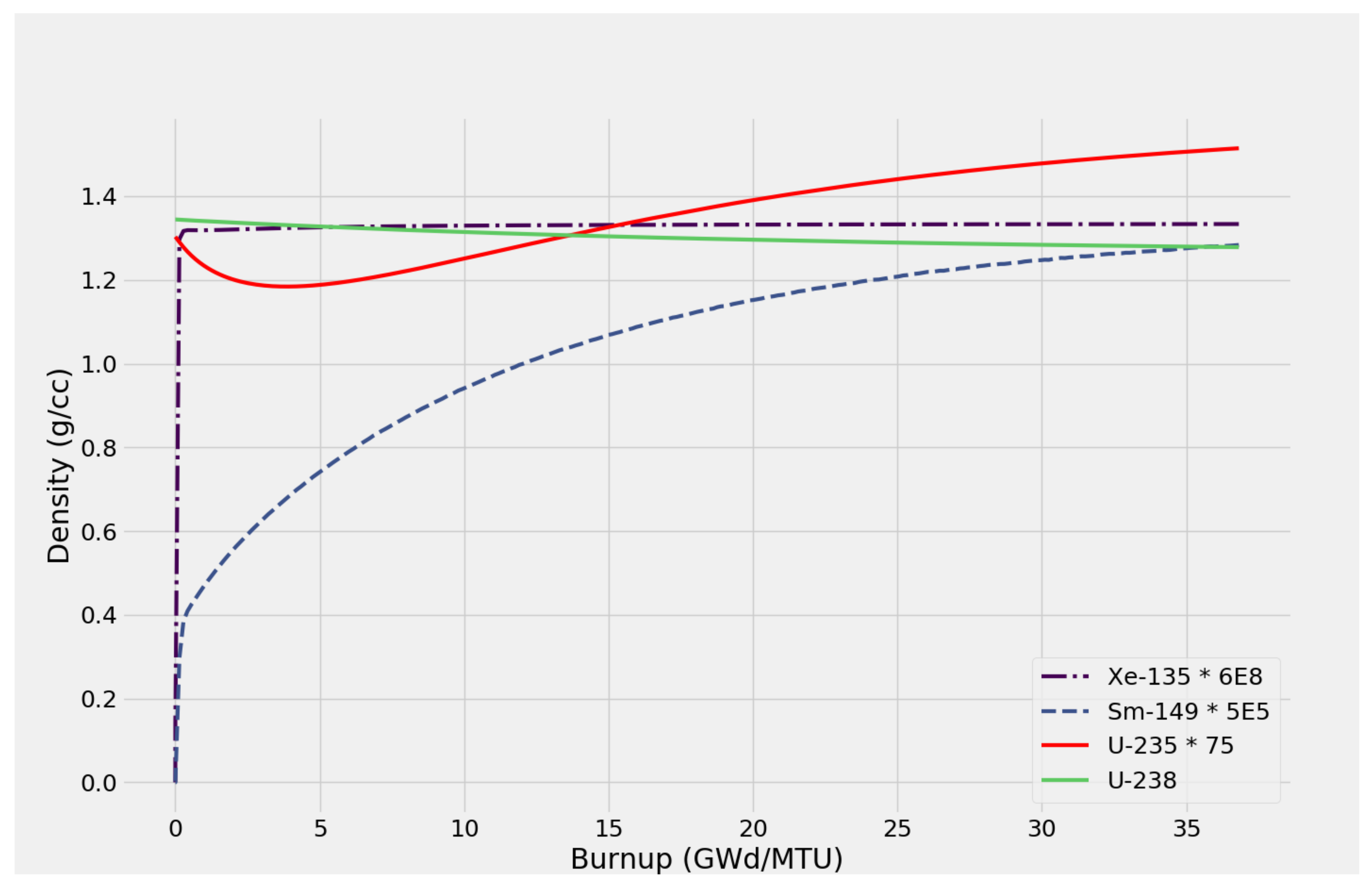

To determine the doubling time for any given enrichment, the average refueling rate of a reactor must be found. In this study, Serpent 2.1 was used to calculate this refueling rate [19]. The thermal LEU-fueled MSR that is modeled is similar to the MSRE with some variations as to be more applicable to currently considered designs. The core consists of a graphite-moderated, hexagonal lattice with cylindrical channels for fuel salt to flow through. The fuel channels have a radius of 2.7 cm and pitch of 14 cm. The fuel salt consists of 3.353 g/cm LiF-BeF-UF (72-16-12 mole%, 99.998% Li, 1.3% U). The graphite moderator is 1.8 g/cm carbon with a 1 ppm boron-equivalent impurity. The model has several limitations by the nature of its simplifying assumptions. First, the model is an infinitely repeating lattice, and as a result, does not account for boundary leakage. This is expected to shift the neutron spectrum but not outside an expected range of a thermal reactor. The second is that there is no chemistry control. The effects of this assumption is negligible since this can be done by adding a reducing agent. More details on the fuel chemistry control issue can be found in [20]. Another limitation is that the refueling rate would change over time, generally needing to be lower initially and slowly increased over time to account for FP build-up. This behavior is shown in Figure 1. In this study, the refueling rate is kept constant to keep the reactor at the same level of critically after the burnup of 36.5 GWd/MTU, when the multiplication factor begins to level out. This refueling rate is taken to be representative of refueling levels over time and used for the doubling time calculations. This study also ignores fuel cool-down before and during transfer from one reactor unit to the next one, and the associated fuel changes due to decays. All these assumptions are insignificant compared to the modeling limitations discussed below.

Figure 1.

Infinite multiplication factor over burnup given a constant refueling rate.

Unfortunately, Serpent 2 does not currently allow changes to material volume during depletion. To deal with this limitation, a flow rate of the fuel salt (homogeneous mixture) out of the core fuel volume to an overflow tank is set to maintain the fuel density. This excess fuel salt is not reintroduced to the core salt and is not subjected to burnup. This limitations of the modeling tool introduces the largest uncertainty, and underestimates burnup values. Given the purpose of this paper to introduce the sourdough method in the most general manner, we find this acceptable. However, before this method can be reasonably applied to a specific MSR design concept, the modeling tools need to be fixed. This requires modifications to the respective source code.

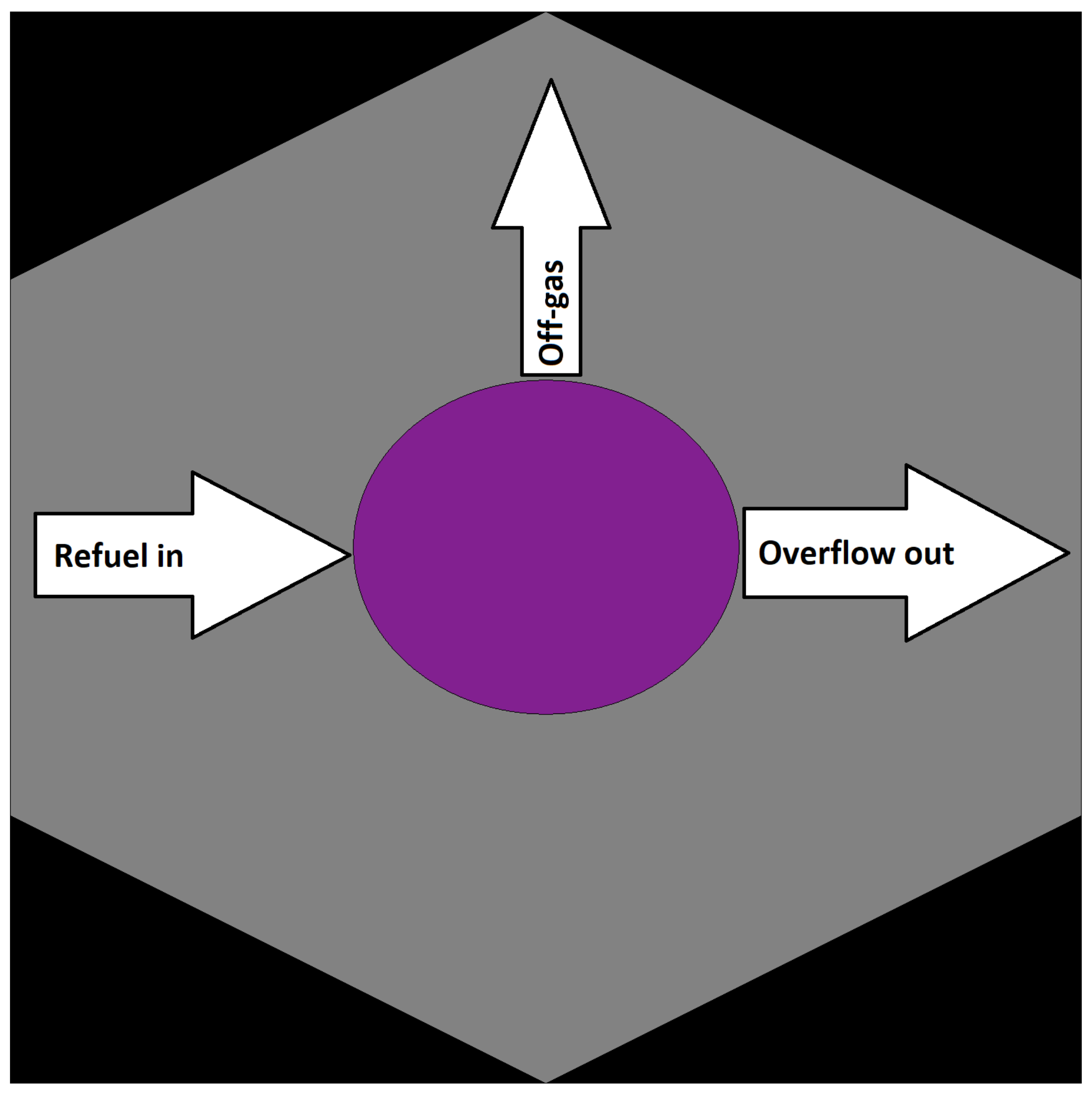

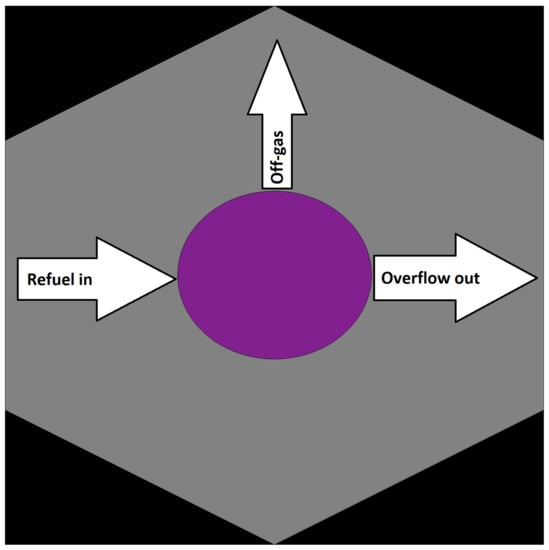

The refuel salt is chemically identical to the initial fuel salt save for the LEU enrichment. Several enrichments from 3% to the maximum LEU enrichment were used to find the refueling level which maintains core criticality. The flow setting for refueling is set to a constant rate (setting 0). In each case, the liquid nature of the fuel enables noble gases to bubble out, which results in an effective removal rate of the gases. This is accounted for with a 1%/s mass removal rate for the noble gasses (setting 1). This rate is based off of a estimate for the effective removal rate in the MSRE [20]. The removal rate for gasses in the MSRE is about 3%/s. This rate will not be the same for every design due to rate of gas sparging and fuel salt flow rates. This study uses a more conservative rate of removal to account for differences in designs. The overflow rate of fuel salt is set at the same the refueling rate, but with the density dependent setting 1. The result is that initially the flow rates are the same, but as noble gasses are removed, the overflow rate is lowered. There is a same drift in density due to the slight mismatch, but the change in density is <1%. The geometry of a single channel with the modeled flows is depicted in Figure 2. All mass flow rates in Serpent are expressed in units of time. Given the energy density of 20 MW/MTU in the calculations, the time units can be translated into energy units. The final resulting model has a k value of ∼1.08. It should be noted that Serpent 2 is a static neutronics code, and does not account for circulating delayed neutron precursors, which has minimal impact on the depletion calculation.

Figure 2.

Fuel salt channel with the mass flows captured in the model.

The number of neutrons traced each transport cycle and the number of cycles are set such that the error in the value of the infinity multiplication factor is less than a dollar (≈665 pcm). All the Serpent input files used in this paper are openly available in a GitHub repository.

3.2. Results

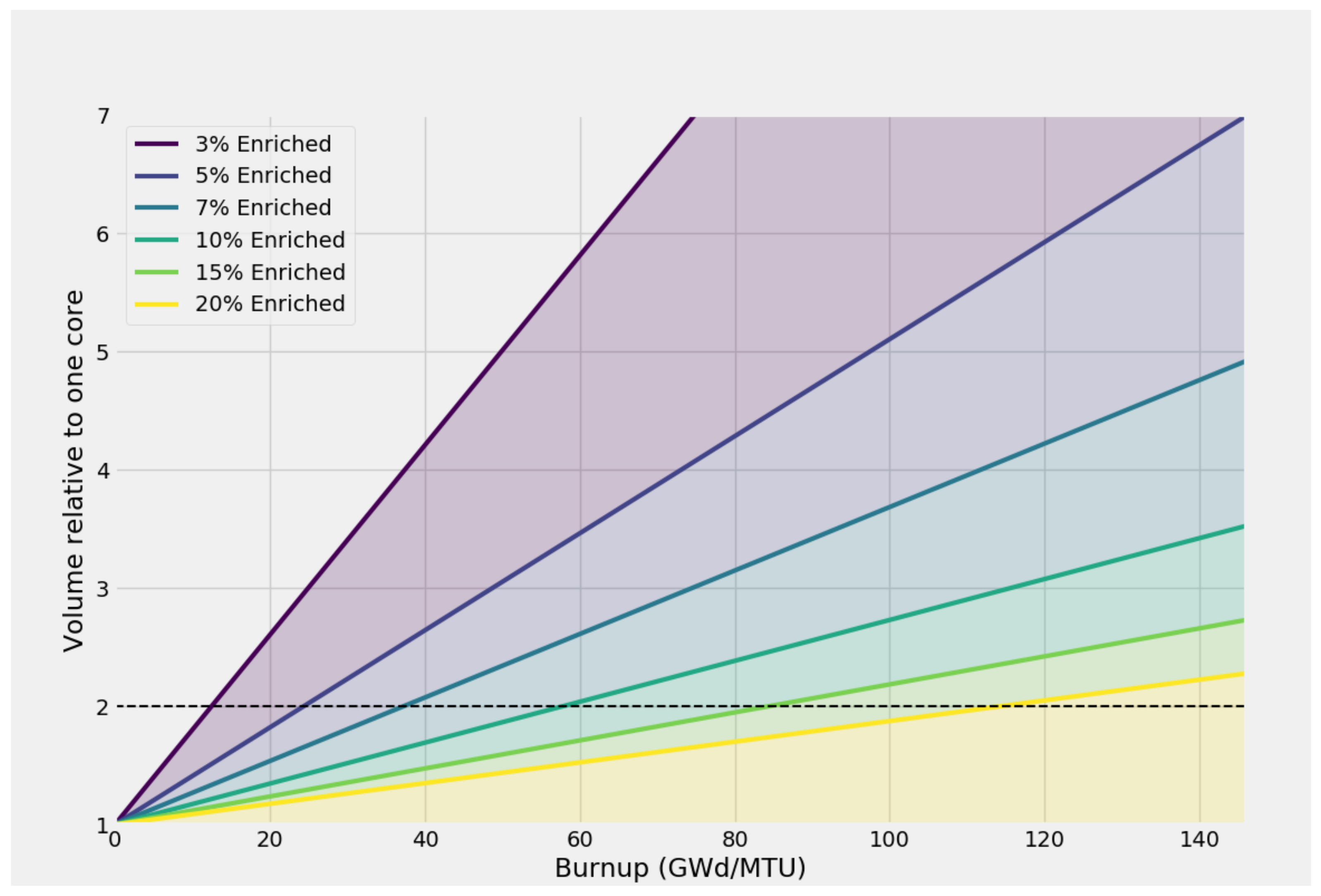

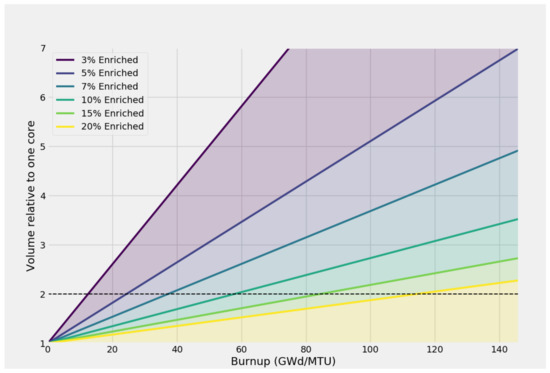

Table 1 shows the doubling time for each refueling enrichment in terms of burnup. Note that this is not the lifetime of the fuel, just the level of burnup needed to reach a doubling in volume. As expected, lower enrichment required higher refueling rates and therefore smaller doubling time. However, doubling the enrichment did not half the refueling rate. This can be attributed to (a) the different levels of fertile nuclei where lower enrichment increases conversion ratio, and (b) the dilution of FP poisons caused by in-mixing of larger volume of lower enrichment salt reducing absorption. Naturally, the differing doubling times can result in a significant difference in volume over time. The fuel salt volume growth is illustrated in Figure 3. It should be noted that the power density in the Figure 3 is in reference to the power over the amount of initial fissile material and does not include the expanded fuel salt. In an actual MSR, the power density should drop with the expanded fuel volume. It can be seen from the figure that there is a significant increase in volume over time. As mentioned earlier, the majority of the volume in a thermal MSR core is filled with graphite, so designs can easily accommodate an increase in volume, to a point. If there are no new reactors to move the excess fuel salt, then on-site storage would need to be built, or reprocessing would need to be introduced.

Table 1.

Doubling times for various makeup fuel enrichments with corresponding initial daily refueling rates.

Figure 3.

The relative fuel salt volume as a function of reactor burnup for different enrichments of refuel salt. The dashed line indicates when there is enough excess fuel to start another core.

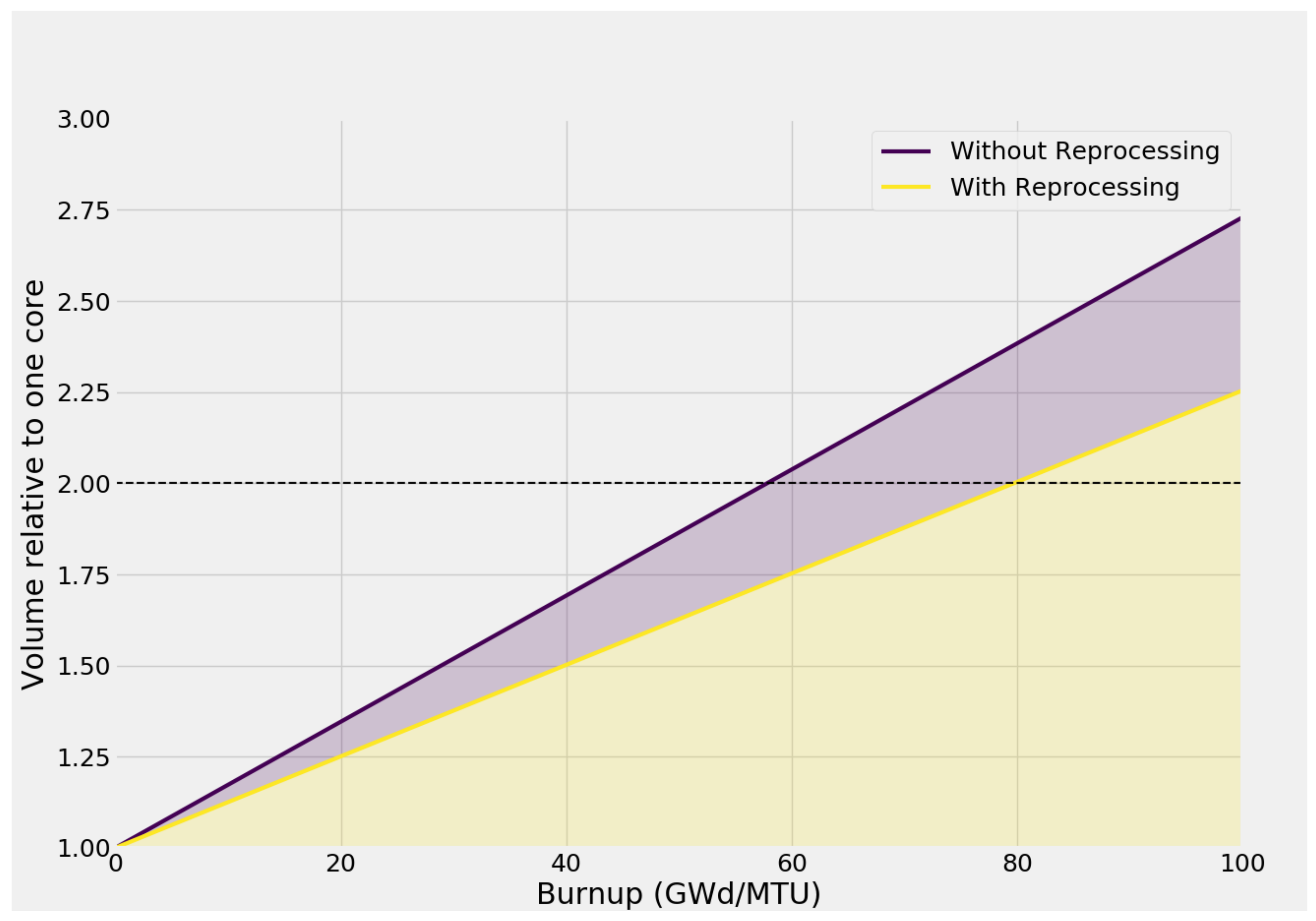

3.3. Effects of Reprocessing

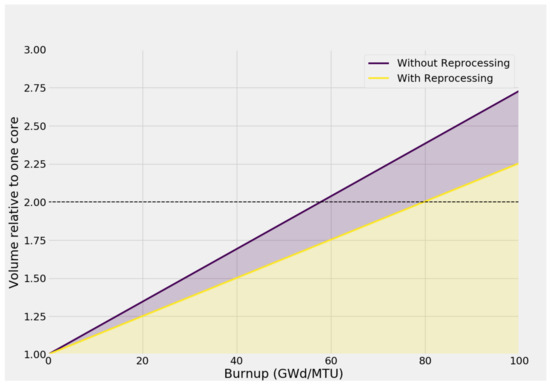

MSR’s liquid fuel is attractive to designers who wish to implement reprocessing in the fuel cycle. Many proposed fuel cycles for MSRs incorporate fuel salt reprocessing, with specific benefits [21]. As such, it is interesting to consider how the addition of reprocessing would affect the sourdough method. The growth rate in the previously presented case with 10% enrichment refuel salt is reevaluated when reprocessing is present. The elements and rates for this case are the same as what is presented in paper [22]. It should be noted that the study [22] uses CHEMtrition, a feature available in future SCALE code release, which may handle material flow differently. The calculated difference in growth rate is illustrated in Figure 4. The addition of reprocessing causes a 25% decrease in the volume growth rate of the fuel. This reduction mainly results from the fact that fission products removed by reprocessing constitute a small fraction of the volume but negatively impact the neutron economy. With reprocessing included, less refuel salt needs to be added to the reactor core.

Figure 4.

The relative fuel salt volume as a function of reactor burnup both with and without reprocessing.

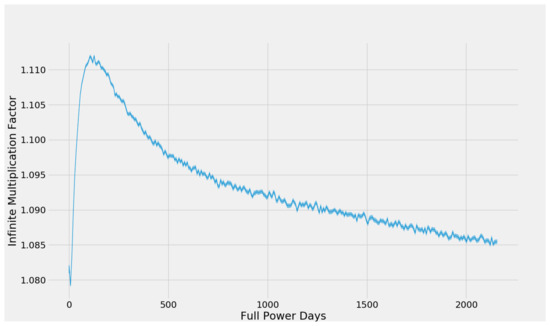

3.4. Isotopic Vectors

When refuel salt is added to the fuel salt, the volume increases, and the fuel salt mixture becomes an average of the refuel and fuel salt based on mass (or volume since the densities are almost the same). As the refueling rate approaches infinity, the fuel salt composition approaches the refuel salt composition. To get a critical core, the sourdough method mixes a (slightly) subcritical burnt fuel salt with a supercritical higher enrichment refuel salt. The rate that these need to mix is dependent on the refuel enrichment. It is a similar case for burnable poisons. The refuel salt has none, so the concentration of burnable poisons decreases with refuel salt addition.

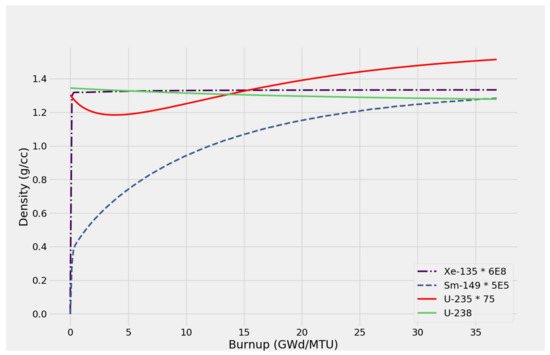

Figure 5 shows how concentrations of several key isotopes evolve during the sourdough refueling. Notice that the data is scaled differently for different isotopes to fit the same scale. The plot shows that the concentration of U isotope (solid green line) slightly decreases during the operation of the reactor, while the U concentration (red line) slowly increases over time, after initial drop. The decrease of U concentration, and the U increase, are due to the higher enrichment of the refuel salt compared to the startup salt. The burnable poisons approach an equilibrium.

Figure 5.

Mass densities of key uranium isotopes and fission product poisons as a function of burnup. Note the scaling factors.

4. Discussion of Waste Management and Grid Expansion

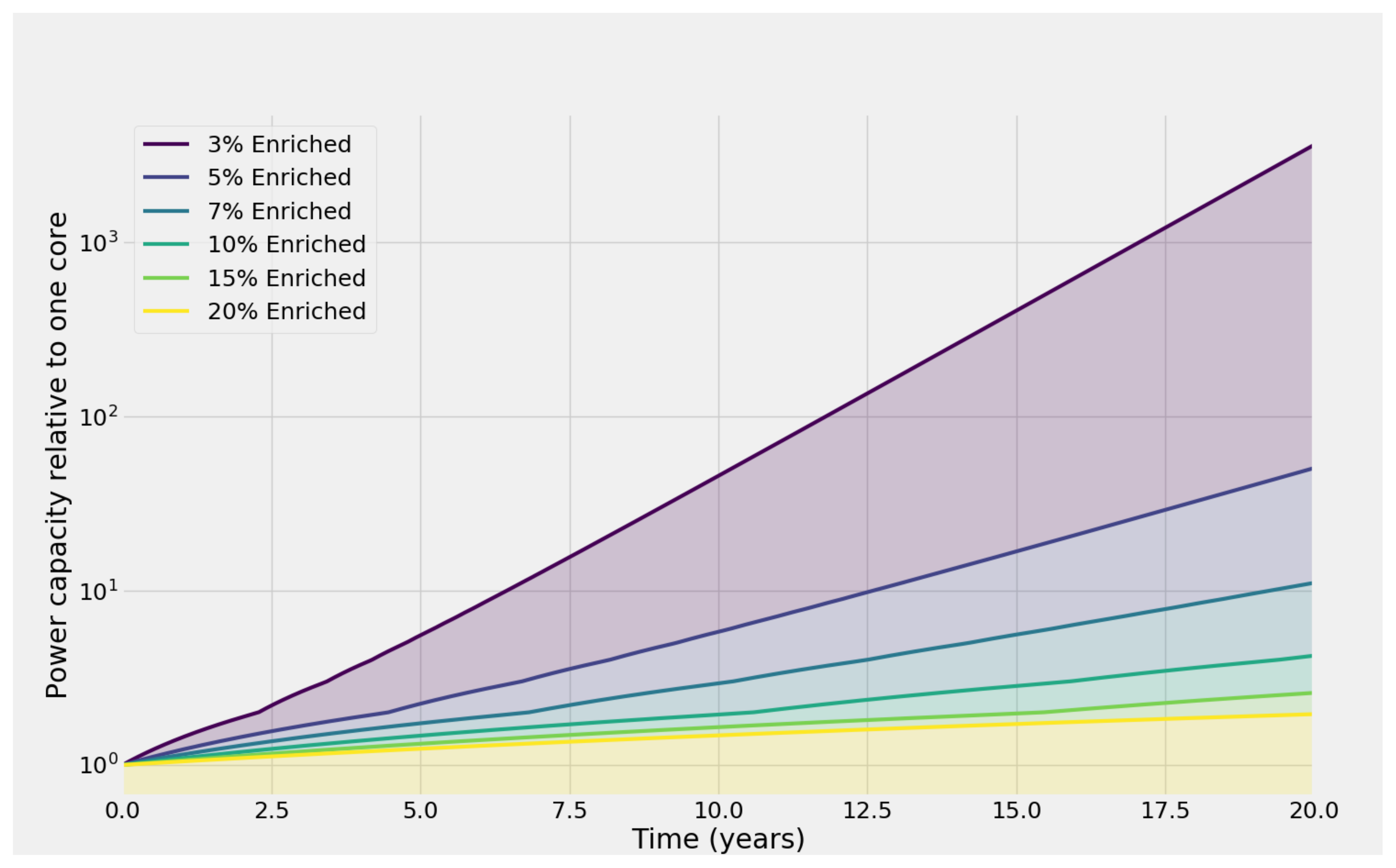

4.1. Grid Growth by Sourdough Doubling

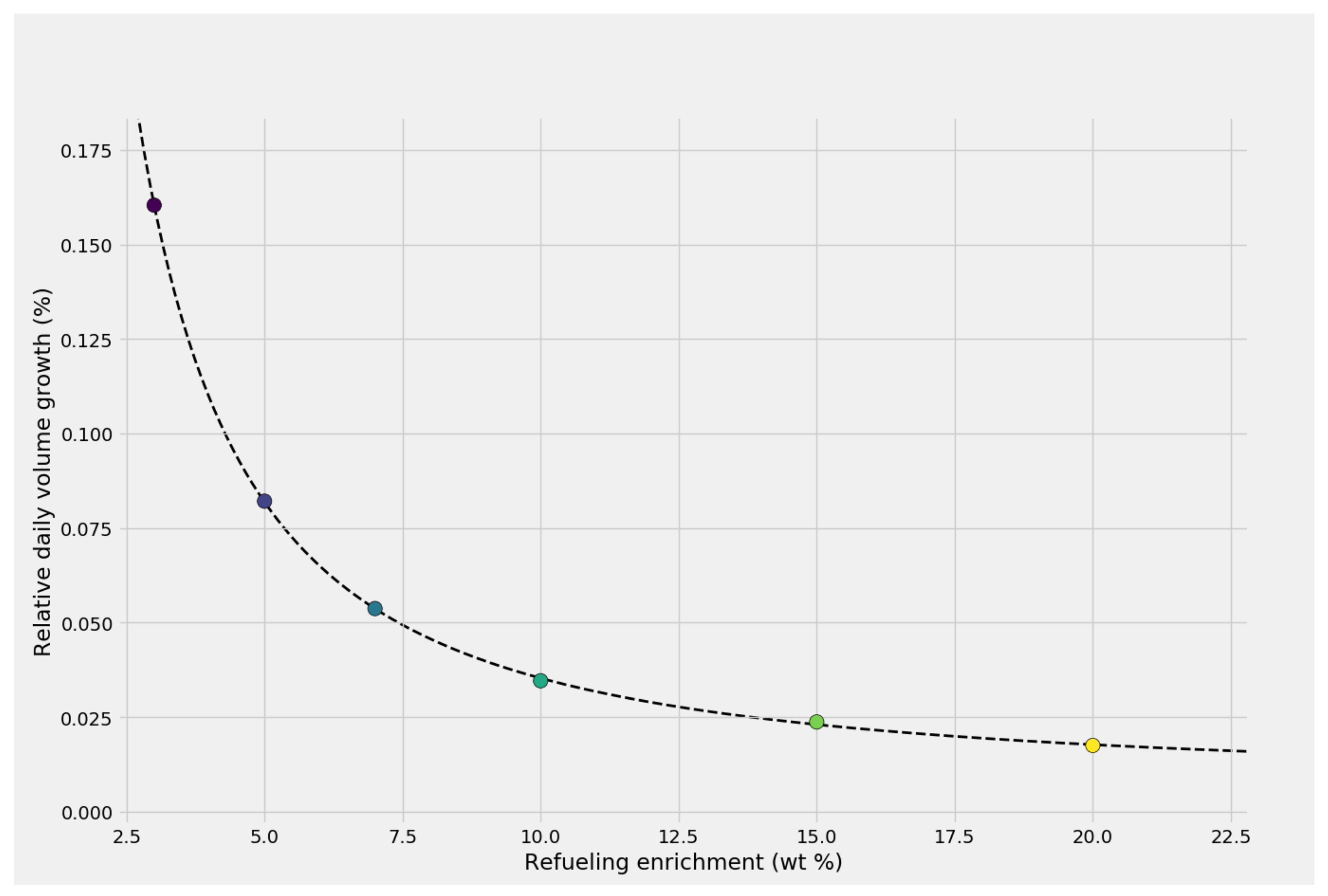

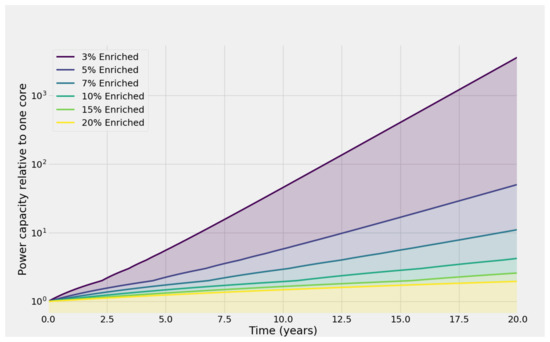

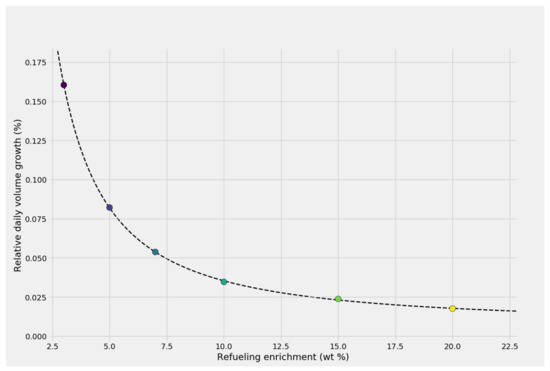

With the calculated doubling times, MSR grid capacity can undergo exponential growth, with growth rate adjustable by refuel enrichment. An example of this growth can be seen in Figure 6. The growth curves are set in units of time given the initial energy density of 0.02 GW/MTU (decreasing proportional to fuel volume) and the same assumptions as above. Changes in doubling time lead to differences in power generation capacity over time. However, during operation, the enrichment of the refueling salt can be changed to meet a different growth rate. For example, if there is a need for a 10-fold increase in capacity within 5 years, but after that, the expansion rate would only need to be doubled after the next 20 years. For this scenario, ≈3% enriched refuel would be used for the first 5 years, after which the refuel salt will be switched to ≈15% enriched. Indeed, there is a large range of doubling times achievable by varying the refuel enrichment in the LEU range. Figure 7 shows the relation to the growth rate more clearly over the possible refuel enrichments with the calculated refueling rate as the colored points, and an exponential curve fit to guide the eyes.

Figure 6.

The power capacity of an MSR fleet in time for different enrichments of the refuel salt, given a 20 MW/MTU power density.

Figure 7.

The relative percent daily growth in fuel salt volume for different enrichments of the refuel salt, given a 20 MW/MTU power density. The dashed curve is to guide the eyes.

Note the assumption that there is no cool-down time between a core doubling fuel salt volume and starting a new reactor. In many proposed MSR concepts there will be such decay time to reduce salt activity and facilitate handling. However, if a facility was built to contain multiple modular reactors, the near zero holding time would be appropriate.

Additionally, there is a concern regarding the insoluble fission products, a group of FP elements that will neither dissolve in the fuel salt nor escape as gases or volatiles. These will be circulated as suspension through our the primary loop and could plate out on its colder surfaces or collect on the free surface of the fuel salt melt analogously to smelting slug. Some MSR designers consider using sponges or other filtration methods to remove the insoluble FPs. The exact behavior is not known with certainty, but it is likely that a portion of the insoluble fission products will precipitate out of the fuel in between the sourdough starter reactor (or mother reactor) and the daughter reactor. In the most extreme case, where all insoluble fission products remain suspended in the fuel salt of the mother reactor and are removed while the salt is transferred to the daughter reactor, the k of the daughter increased to ∼1.12. Then, as the daughter reactor operates with refueling, the k approaches to the original value as the insoluble fission products build up to their steady-state concentrations. The same case occurs for the granddaughter reactor. However, if the insoluble fission products remain the same, the daughter reactors maintain the same criticality with the same refuel salt.

4.2. Benefits of Sourdough Refueling

Notice that the fuel required for the next “doubled” unit startup is purchased, as re-fuel, while the previous reactor is operating. This moves the cost of first fuel load from the upfront cost of a new unit since it is already payed for during the previous reactor operation. Reducing nuclear power plant upfront cost is currently highly desirable.

An important feature of this sourdough fuel management is that all used fuel stays contained within the reactors, as each new reactor consumes the excess fuel salt. Only once the MSR expansion via doublings has reached the full desired grid capacity for MSR power plants, the need for treatment of excess spent fuel arises. This may take well over a century, in particular, if the growth rate of the fleet is managed by increasing refuel enrichment. Fleet growth using the outlined sourdough method effectively utilizes active MSR cores as an “intermediate storage” for used nuclear fuel. This strategy can significantly delay the need for final spent fuel disposition, however it does not eliminate it.

While the spent nuclear fuel contains many valuable isotopes, recycling these materials back into the broader value-adding chains is hampered by economic considerations. The current light water reactor spent fuel is very inconvenient for reprocessing. The oxide matrix needs to be converted into a form suitable for chemical separation, such as into molten salt. Furthermore, the physical form of ≈15 feet long rods necessitates even longer hot cells. These rods can be cut prior to processing the material inside the rods, along with related transportation and handling difficulties. Contrary to MSRs, where the fuel is already in the chemical form amenable for separation and processing, and its liquid form allows comparatively easy separation of small samples. Imagine a sampling system that would produce sand grain-sized fuel salt drops, which could be, after a cool-down period, easily shielded and shipped to many chemical laboratories for exploration of different separation techniques, in addition to experimentation with nonradioactive surrogates. The availability of used fuel salt will be an incentive for the development of processing and partitioning technologies to liberate the economic potential of the used nuclear fuel, thus eliminating the problem of “nuclear waste” for good, at least alleviating it in the public perspective when benefits became obvious to see.

Further, with technological progression, more options for dealing with the spent fuel will likely be available in future. Earlier mentioned fast reactors, accelerator-driven transmuters, or fusion-fission hybrid systems are options and possibilities of what the future may hold, and MSR fuel partitioning appears as a complimentary technology alternative. The availability of such appropriate fuel could indeed incentivize investments into research and development of such futuristic concepts. In any case, the sourdough fuel cycle presents an appealing strategy with inherent incentives.

5. Conclusions and Future Work

Low-enriched uranium-based circulating-fuel MSR fuel cycle features a volume doubling time caused by the addition of refueling salt without reprocessing. The specific doubling time depends on the enrichment of the refuel salt, and this enrichment can be adjusted to fit desired capacity growth rates. In addition, the vast majority of fission products and transuranics, which form the bulk of the high-level waste, are suspended in the fuel salt. In this sense, the reactors provide an intermediate waste repository service while either public opinion changes or advanced means of waste reduction, reuse, or disposal are developed. Additionally, a new unit’s upfront cost is reduced since the sourdough doubling provides the first fuel load. Thus, taking a positive outlook, the sourdough approach provides an attractive tool for overcoming or reducing several notorious and significant nuclear expansion hurdles.

The sourdough method does have drawbacks, however. It does not provide a permanent solution to high-level nuclear waste. Instead, it puts off the need for disposal until a future date when a complete means of high-level waste disposal can be agreed upon. Similarly, the sourdough strategy would require an expansion of the MSR fleet. Otherwise, the excess volume would represent a new engineering challenge to be accounted for. The largest limitation to this method is the inability of Serpent to capture the effects of volume changes during operation. Reactor analysis codes need to be updated to include volume evolution when materials are fed to or removed from cells to be applicable for fuel cycle modeling of a wider variety of MSR design concepts. This way, the full effects of the changing power density and growing volume can be explored with increased accuracy.

When reactor codes are improved to handle volume growth, this method should be applied to a specific MSR design concept. Then, design dependent results of doubling times, uranium consumption, etc. would be obtained, without the simplifying assumptions and modeling limitations used in this work.

The authors are currently working on modifications to the Serpent source code to alleviate the assumption of constant cell volume during the depletion calculation. A followup paper under preparation will apply the sourdough method to a open source graphite moderated LEU fueled MSR model. Applying the sourdough methodology to a specific MSR concept will provide results in terms of power generation capacity growth and material flows. Additionally, applying this method to a specific design will account for the spectral effects due to leakage as well as allow for realistic fuel decays between loads. Although, further research would need to be done to fully understand what effects would occur during salt transport between reactor sites.

Author Contributions

Conceptualization, A.M.W. and O.C.; methodology, A.M.W.; software, A.M.W.; validation, A.M.W. and O.C.; formal analysis, A.M.W. and O.C.; investigation, A.M.W. and O.C.; resources, O.C.; data curation, A.M.W.; writing—original draft preparation, A.M.W.; writing—review and editing, O.C.; visualization, A.M.W.; supervision, O.C.; project administration, O.C.; funding acquisition, O.C. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by a Nuclear Energy University Programs grant sponsored by the U.S. Department of Energy, Office of Nuclear Energy, award number DE-NE0008793.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All models used are archived in the following public GitHublink: https://github.com/awheel13/Sourdough.

Acknowledgments

This work was supported by a Nuclear Energy University Programs grant sponsored by the U.S. Department of Energy, Office of Nuclear Energy, award number DE-NE0008793. The authors would like to thank reviewers for their time and effort while commenting on this paper’s draft. Their effort increased the clarity of this manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kharecha, P.A.; Hansen, J.E. Prevented Mortality and Greenhouse Gas Emissions from Historical and Projected Nuclear Power. Environ. Sci. Technol. 2013, 47, 4889–4895. [Google Scholar] [CrossRef] [PubMed]

- van der Zwaan, B.C. Nuclear energy: Tenfold expansion or phase-out? Technol. Forecast. Soc. Chang. 2002, 69, 287–307. [Google Scholar] [CrossRef]

- Bowen, M. Forging a Path Forward on U.S. Nuclear Waste Management: Options for Policy Makers; Technical report; Columbia University’s Center on Global Energy Policy: New York, NY, USA, 2021. [Google Scholar]

- Eurobarometer, S. Attitudes towards radioactive waste. In Special Eurobarometer 297/Wave 69.1–TNS Opinion & Social; Directorate General for Communication: Brussels, Belgium, 2008. [Google Scholar]

- Hejzlar, P.; Todreas, N.E.; Shwageraus, E.; Nikiforova, A.; Petroski, R.; Driscoll, M.J. Cross-comparison of fast reactor concepts with various coolants. Nucl. Eng. Des. 2009, 239, 2672–2691. [Google Scholar] [CrossRef]

- Egorov, A.V.; Khomyakov, Y.S.; Rachkov, V.I.; Rodina, E.A.; Suslov, I.R. Minor actinides transmutation in equilibrium cores of next generation FRs. Nucl. Energy Technol. 2019, 5, 353–359. [Google Scholar] [CrossRef] [Green Version]

- Bowman, C.D. Accelerator-driven systems for nuclear waste transmutation. Annu. Rev. Nucl. Part. Sci. 1998, 48, 505–556. [Google Scholar] [CrossRef] [Green Version]

- Kotschenreuther, M.; Valanju, P.; Mahajan, S.; Schneider, E.A. Fusion-fission transmutation scheme—Efficient destruction of nuclear waste. Fusion Eng. Des. 2009, 84, 83–88. [Google Scholar] [CrossRef]

- Haubenreich, P.N.; Engel, J.R. Experience with the Molten-Salt Reactor Experiment. Nucl. Appl. Technol. 1970, 8, 118–136. [Google Scholar] [CrossRef]

- Dolan, T. Molten Salt Reactors and Thorium Energy; Woodhead Publishing: Cambridge, UK, 2017. [Google Scholar]

- Riley, B.J.; McFarlane, J.; DelCul, G.D.; Vienna, J.D.; Contescu, C.I.; Forsberg, C.W. Molten salt reactor waste and effluent management strategies: A review. Nucl. Eng. Des. 2019, 345, 94–109. [Google Scholar] [CrossRef]

- Choe, J.; Ivanova, M.; LeBlanc, D.; Mohaptra, S.; Robinson, R. Fuel Cycle Flexibility of Terrestrial Energy’s Integral Molten Salt Reactor (IMSR). In Proceedings of the 38th Annual Conference of the Canadian Nuclear Society and 42nd Annual CNS/CNA Student Conference, Saskatoon, SK, Canada, 3–6 June 2018; pp. 3–6. [Google Scholar]

- Compere, E.; Kirslis, S.; Bohlmann, E.; Blankenship, F.; Grimes, W. Fission Product Behavior in the Molten Salt Reactor Experiment; Technical report; Oak Ridge National Lab.: Oak Ridge, TN, USA, 1975. [Google Scholar]

- Wheeler, A.M.; Singh, V.; Miller, L.F.; Chvála, O. Initial calculations for source term of Molten Salt Reactors. Prog. Nucl. Energy 2021, 132, 103616. [Google Scholar] [CrossRef]

- Cottrell, W.B. Reactor Program of the Aircraft Nuclear Propulsion Project; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 1952. [Google Scholar]

- MacPherson, H.G. The Molten Salt Reactor Adventure. Nucl. Sci. Eng. 1985, 90, 374–380. [Google Scholar] [CrossRef]

- Dungan, K.; Butler, G.; Livens, F.; Warren, L. Uranium from seawater–Infinite resource or improbable aspiration? Prog. Nucl. Energy 2017, 99, 81–85. [Google Scholar] [CrossRef]

- Flanagan, G.F.; Holcomb, D.E.; Poore, W.P. III. Molten Salt Reactor Fuel Qualification Considerations and Challenges; Technical report; Ridge National Laboratory: Oak Ridge, TN, USA, 2018. [Google Scholar]

- Leppänen, J.; Pusa, M.; Viitanen, T.; Valtavirta, V.; Kaltiaisenaho, T. The Serpent Monte Carlo code: Status, development and applications in 2013. In Proceedings of the SNA + MC 2013-Joint International Conference on Supercomputing in Nuclear Applications + Monte Carlo. EDP Sciences, Paris, France, 27–31 October 2014; p. 06021. [Google Scholar]

- Ridley, G.; Chvala, O. A method for predicting fuel maintenance in once-through MSRs. Ann. Nucl. Energy 2017, 110, 265–281. [Google Scholar] [CrossRef]

- Betzler, B.R.; Powers, J.J.; Worrall, A.; Robertson, S.; Dewan, L.; Massie, M. Two-Dimensional Neutronic and Fuel Cycle Analysis of the Transatomic Power Molten Salt Reactor; Technical report; Oak Ridge National Lab.(ORNL): Oak Ridge, TN, USA, 2017. [Google Scholar]

- Betzler, B.R.; Powers, J.J.; Worrall, A. Molten salt reactor neutronics and fuel cycle modeling and simulation with SCALE. Ann. Nucl. Energy 2017, 101, 489–503. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).