µ-CT Investigation of Hydrogen-Induced Cracks and Segregation Effects in Austenitic Stainless Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Investigated Material

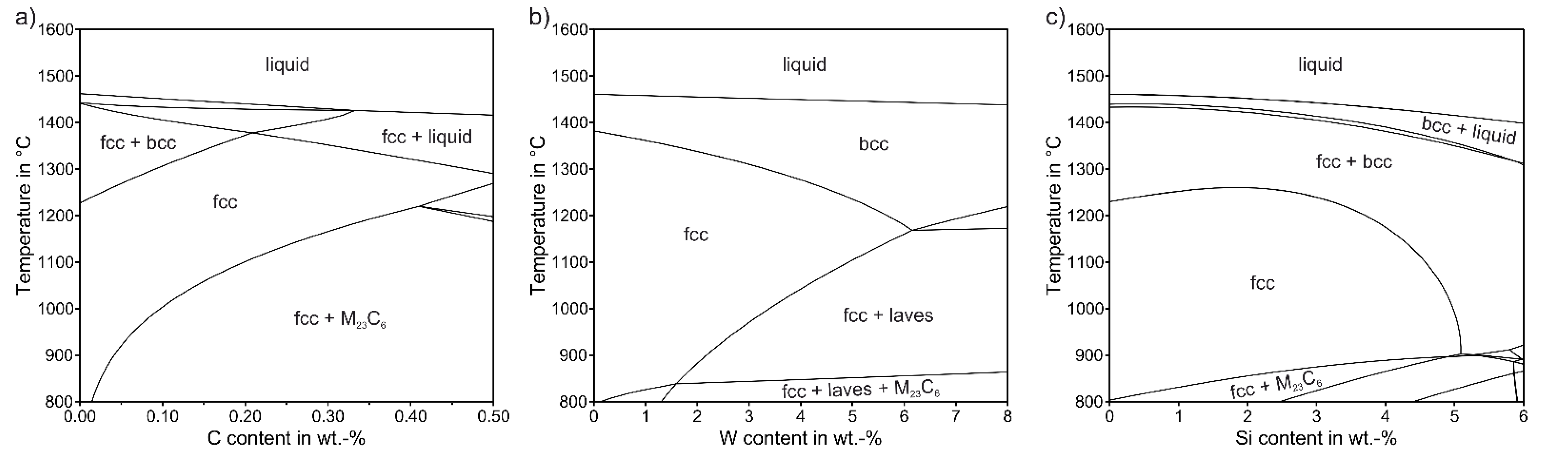

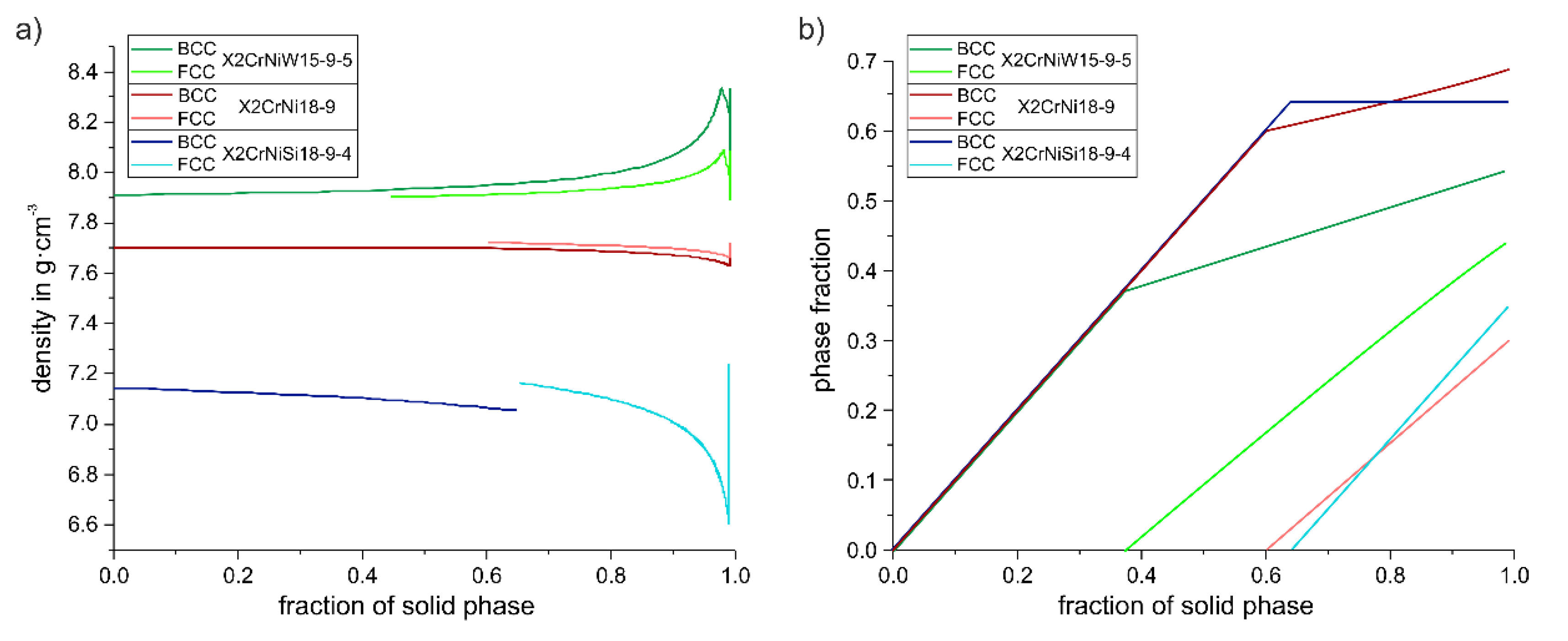

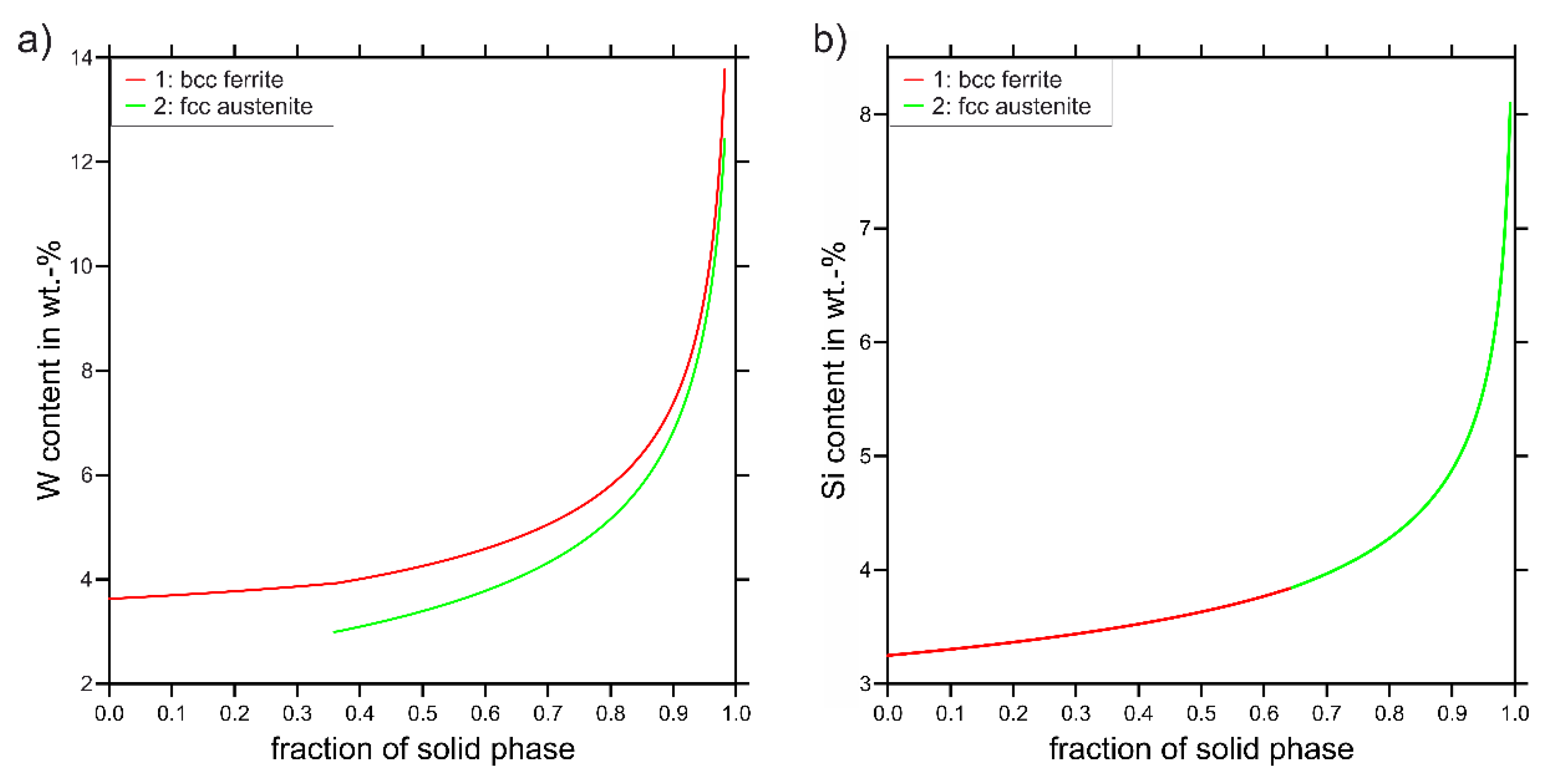

2.2. Thermodynamic Calculations

2.3. Microscopy

2.4. µ-CT

2.5. Image Analysis

3. Results and Discussion

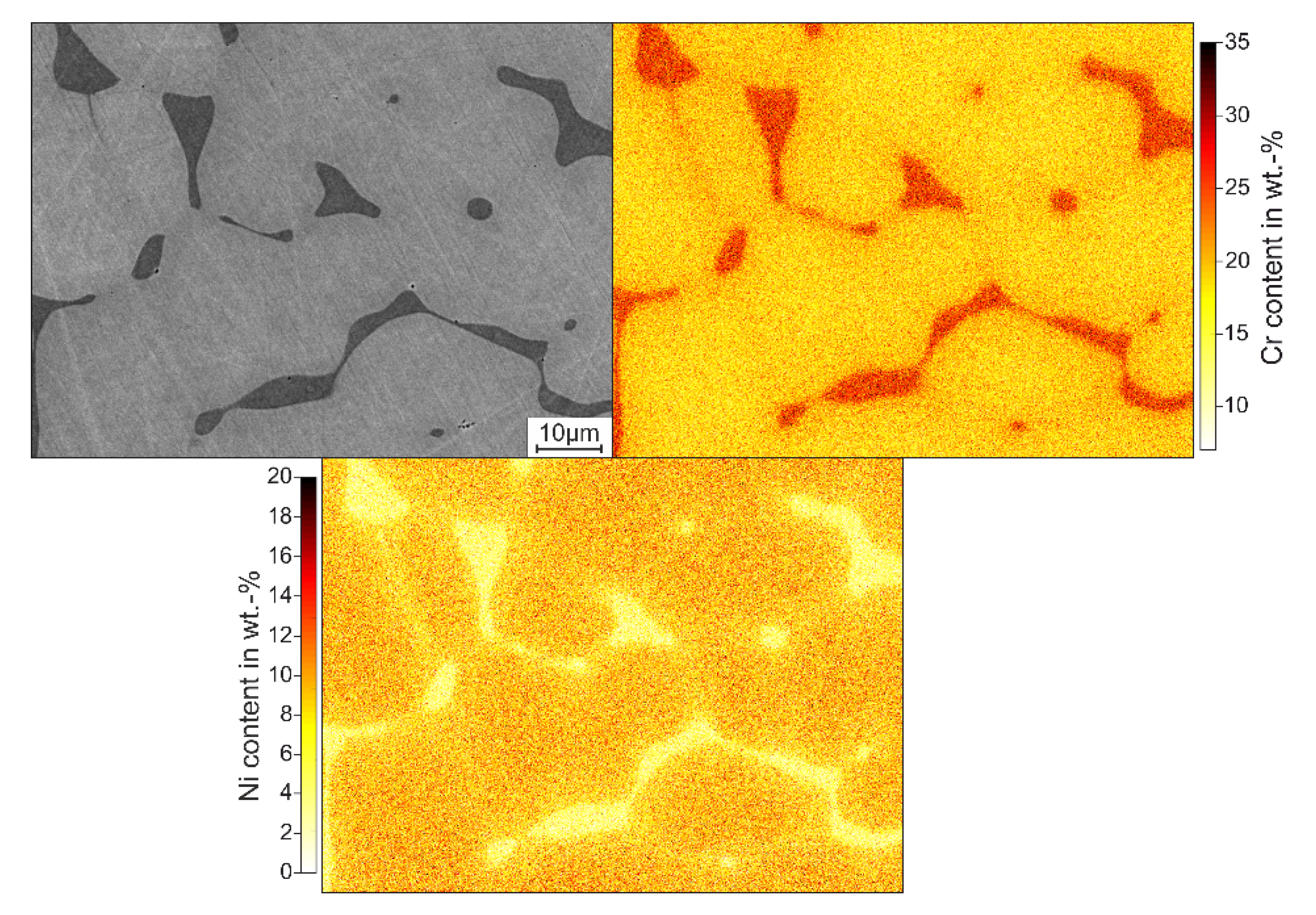

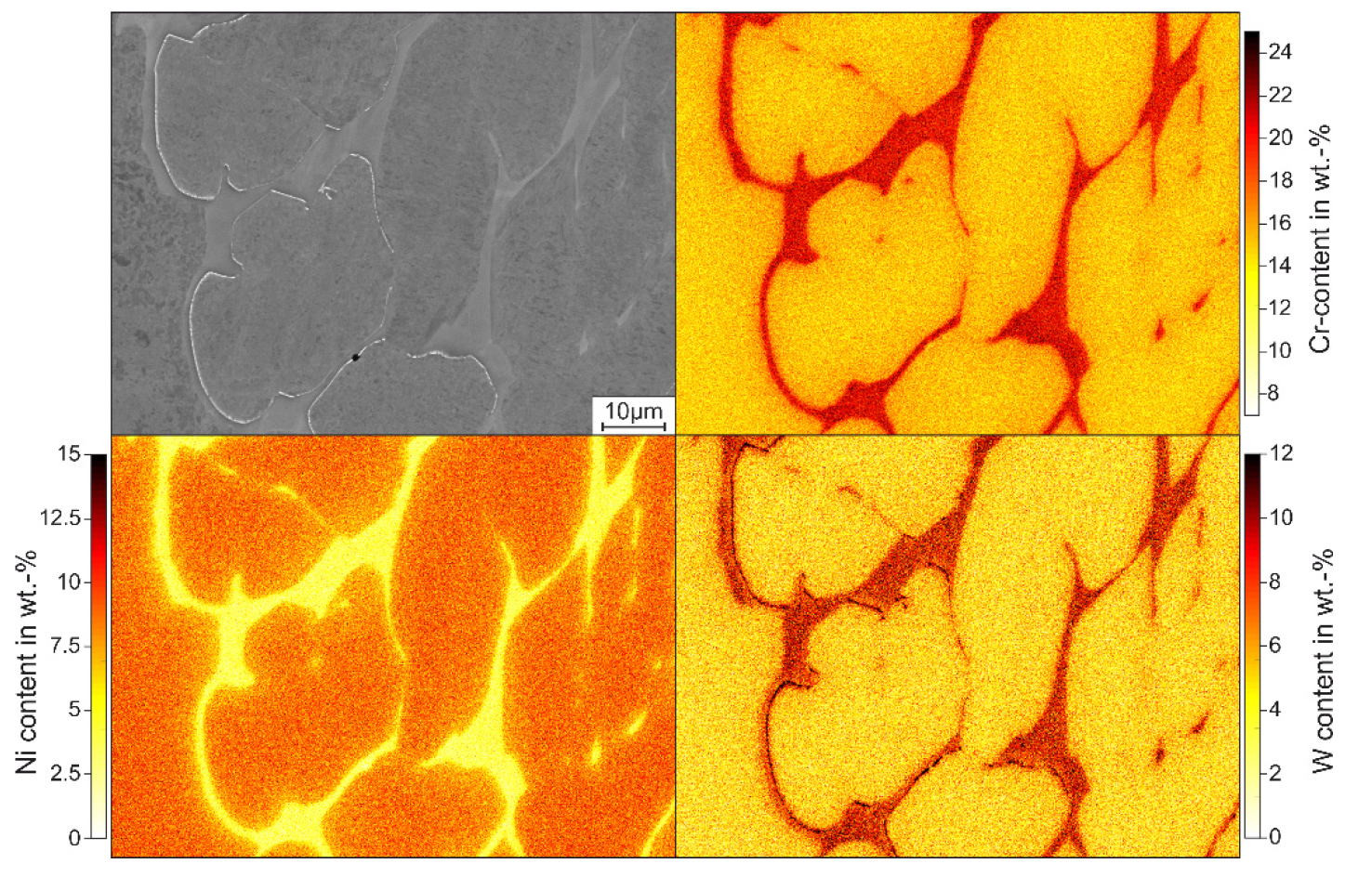

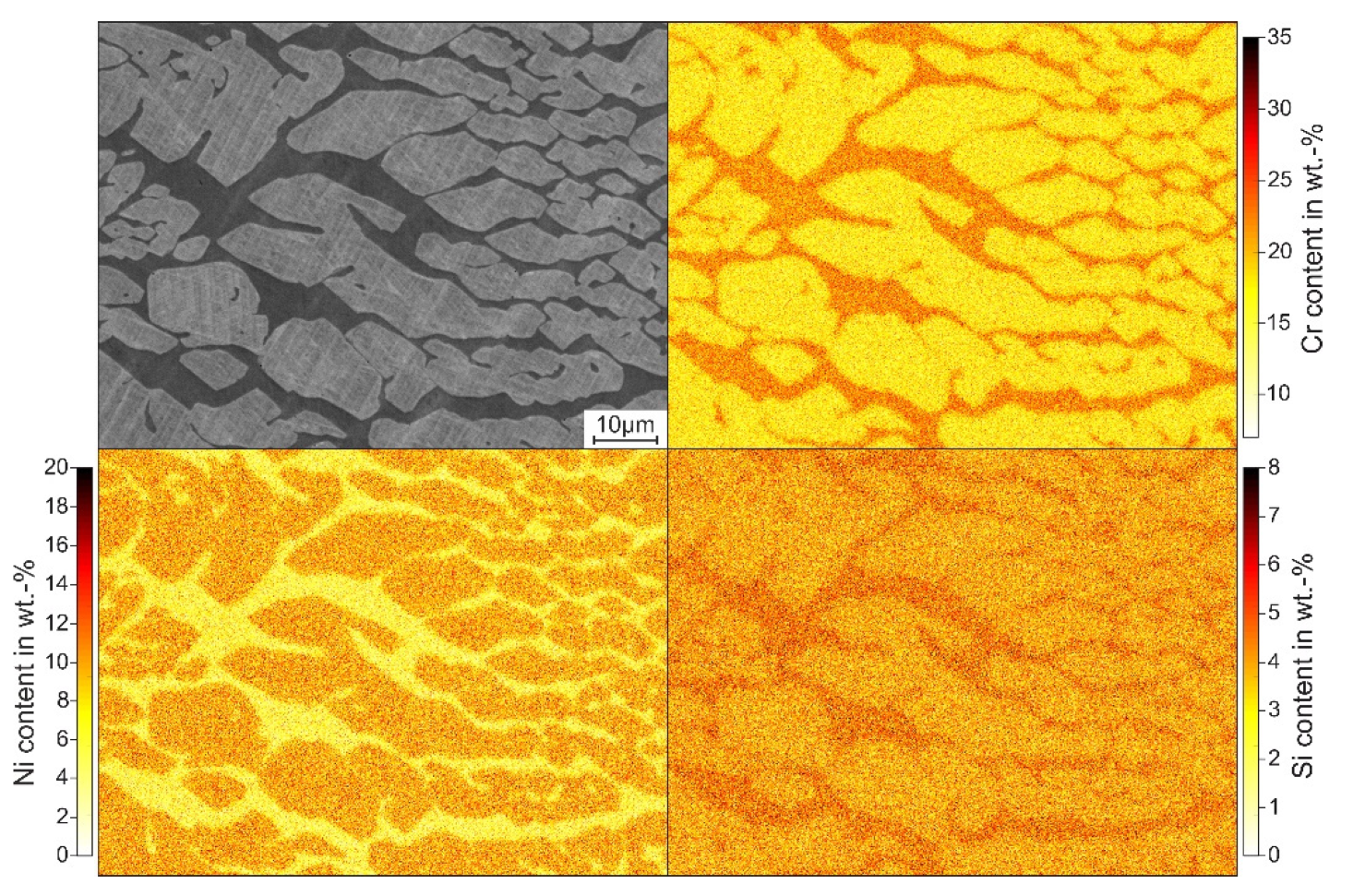

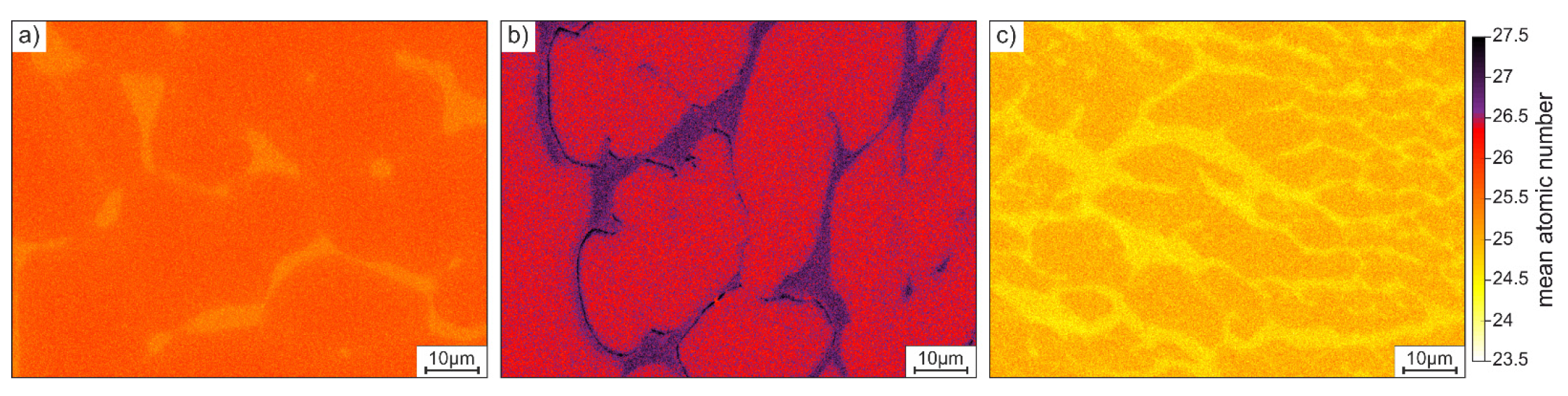

3.1. Detection of Segregation Structures

3.1.1. Design of the Model Alloys

3.1.2. Two-Dimensional Investigation of the As-Cast Microstructures

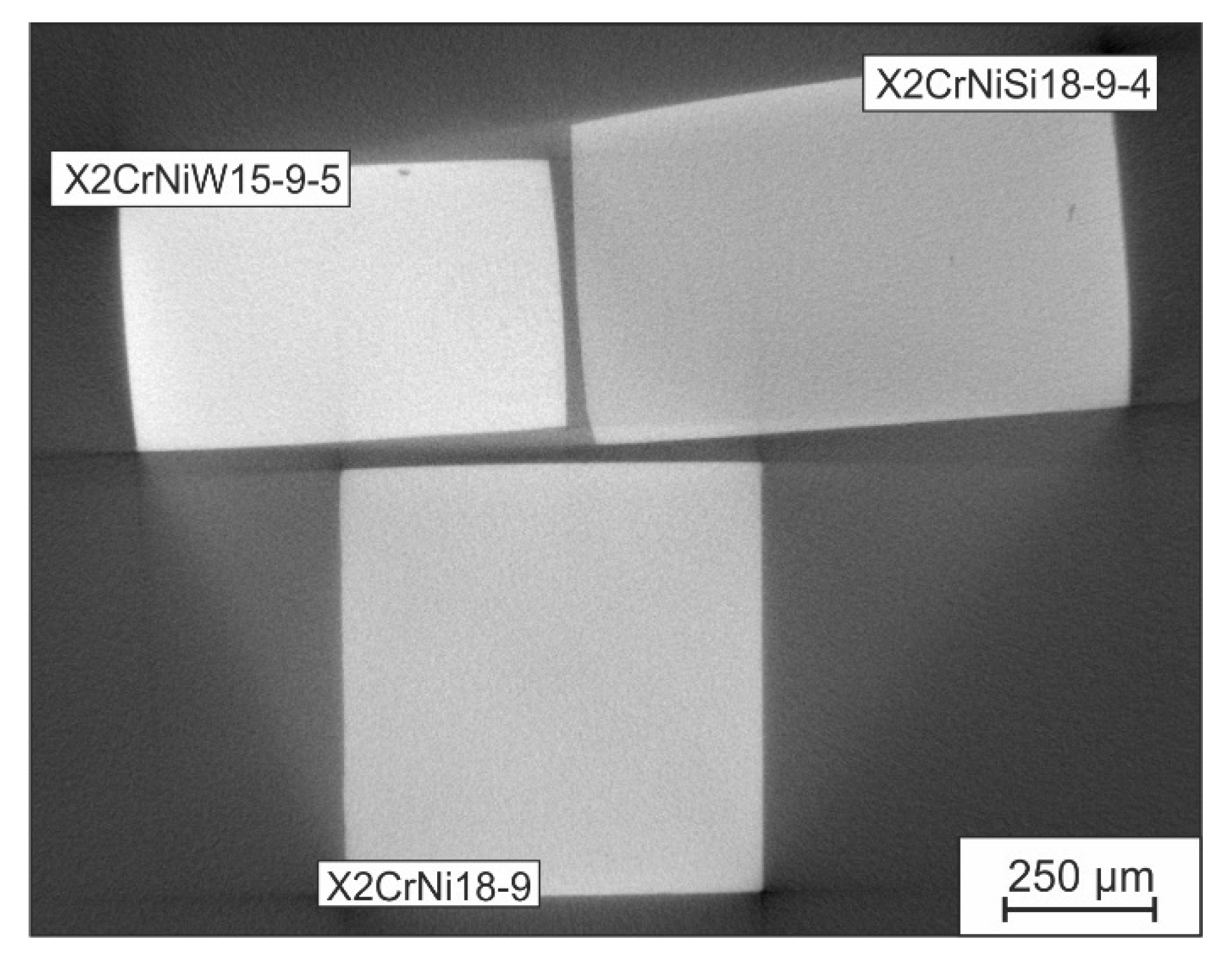

3.1.3. CT Investigations

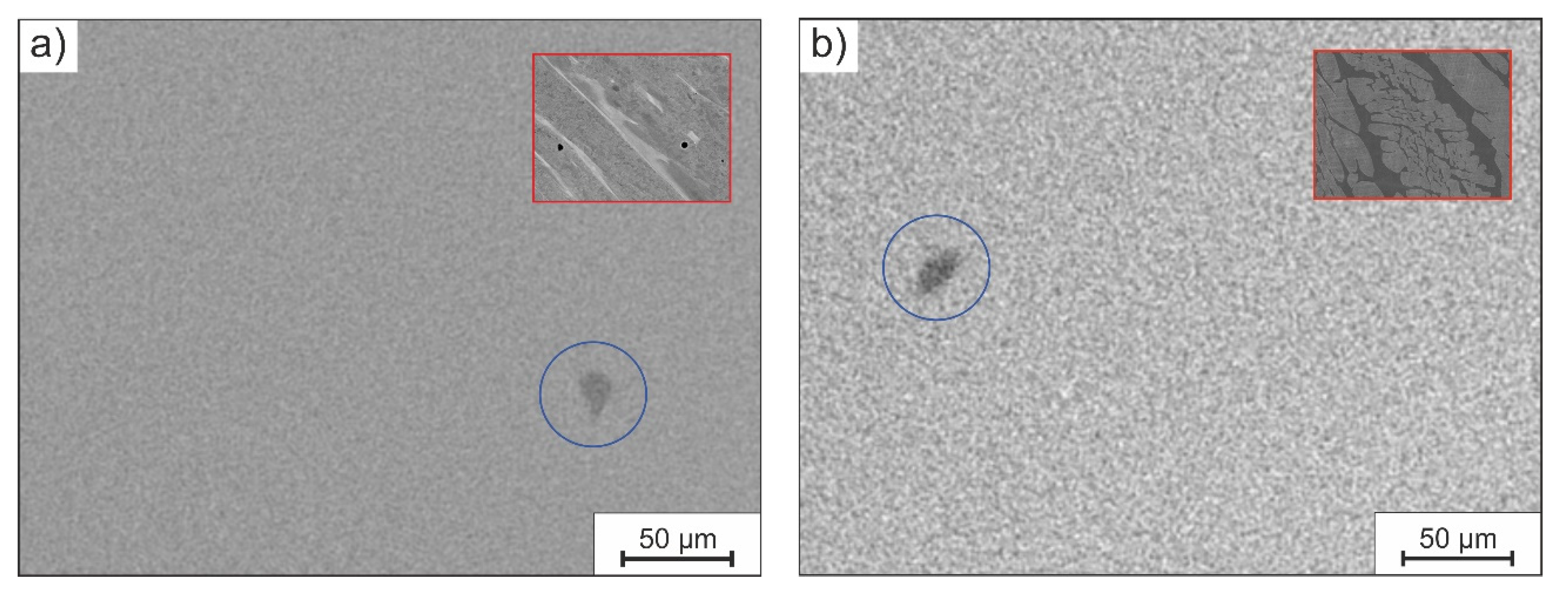

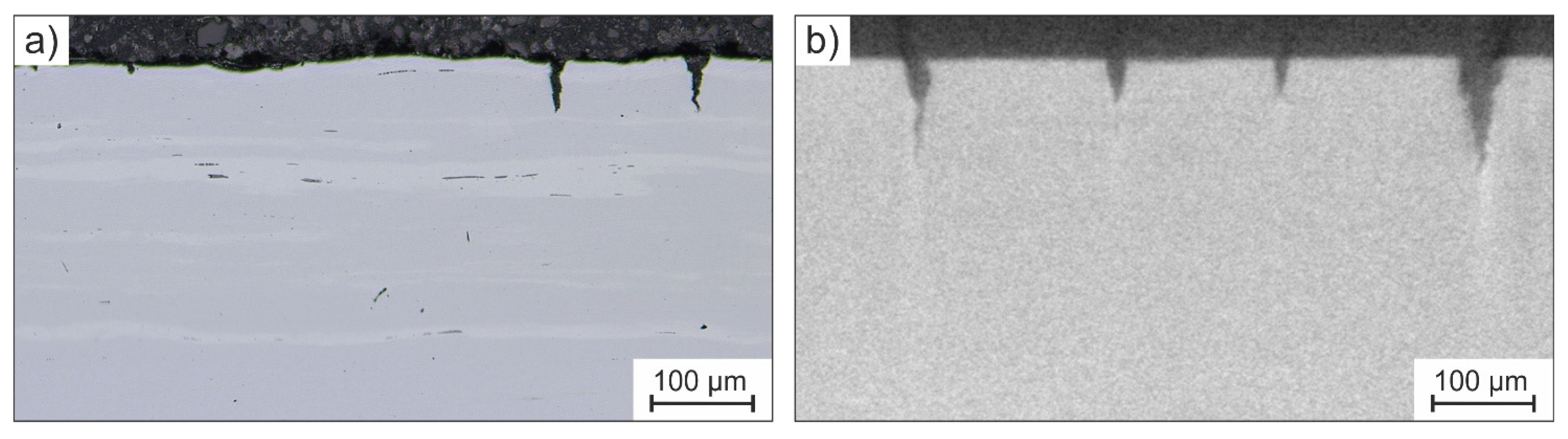

3.2. Detection of Hydrogen-Induced Cracks

4. Conclusions

- By modifying the alloy composition of X2CrNi18-9 with W or Si, a significant change in the X-ray attenuation can be achieved, which can be visualized via CT. Local segregation-related differences in the mean atomic number are also strongly increased by the alloy modifications and are believed to be sufficient for CT imaging. The fact that none of these structures could be visualized can most probably be attributed to their small size.

- Hydrogen-induced cracks could be detected via CT, with the lower detection limit of the used setup being somewhat smaller than in microscopic investigations. The smallest cracks (<5 µm) were overlooked via CT. For the quantitative analysis of larger cracks, CT might serve well in the investigation of the whole volume of a specimen as it provides better statistics, compared to the microscopic investigation of single sections.

- This study attempted to visualize the segregation structures and hydrogen-induced cracks in separate CT measurements. Since maximum resolution is the limiting factor in both aspects, the simultaneous investigation of both aspects on a suitable sample is probably possible. The prerequisite for this would presumably be larger-scale segregation structures or the use of a measurement setup allowing better imaging, e.g., by synchrotron radiation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Birnbaum, H.K. Hydrogen Related Fracture of Metals. In Atomistics of Fracture; Latanision, R.M., Pickens, J.R., Eds.; Springer: Boston, MA, USA, 1970; ISBN 978-1-4613-3502-3. [Google Scholar]

- Abraham, D.P.; Altstetter, C.J. Hydrogen-enhanced localization of plasticity in an austenitic stainless steel. Metall. Trans. A 1995, 26, 2859–2871. [Google Scholar] [CrossRef]

- Robertson, I.M.; Tabata, T.; Wei, W.; Heubaum, F.; Birnbaum, H.K. Hydrogen embrittlement and grain boundary fracture. Scr. Metall. 1984, 18, 841–846. [Google Scholar] [CrossRef]

- Gavriljuk, V.G.; Shanina, B.D.; Shyvanyuk, V.N.; Teus, S.M. Hydrogen embrittlement of austenitic steels: Electron approach. Corros. Rev. 2013, 31, 33–50. [Google Scholar] [CrossRef]

- Rozenak, P. Effects of nitrogen on hydrogen embrittlement in AlSl type 316, 321 and 347 austenitic stainless steels. J. Mater. Sci. 1990, 25, 2532–2538. [Google Scholar] [CrossRef]

- San Marchi, C. Effects of alloy composition and strain hardening on tensile fracture of hydrogen-precharged type 316 stainless steels. Int. J. Hydrog. Energy 2008, 33, 889–904. [Google Scholar] [CrossRef]

- Zhang, L.; An, B.; Fukuyama, S.; Iijima, T.; Yokogawa, K. Characterization of hydrogen-induced crack initiation in metastable austenitic stainless steels during deformation. J. Appl. Phys. 2010, 108, 63526. [Google Scholar] [CrossRef]

- Gavriljuk, V.G.; Shanina, B.D.; Shyvanyuk, V.N.; Teus, S.M. Electronic effect on hydrogen brittleness of austenitic steels. J. Appl. Phys. 2010, 108, 83723. [Google Scholar] [CrossRef]

- Tabata, T.; Birnbaum, H.K. Direct observations of hydrogen enhanced crack propagation in iron. Scr. Metall. 1984, 18, 231–236. [Google Scholar] [CrossRef]

- Birnbaum, H.K. Hydrogen Embrittlement. In Encyclopedia of Materials: Science and Technology; Elsevier: Amsterdam, The Netherlands, 2001; pp. 3887–3889. [Google Scholar]

- Somerday, B.P.; Gangloff, R.P. (Eds.) Gaseous Hydrogen Embrittlement of Materials in Energy Technologies: Volume 1: The Problem, Its Characterisation and Effects on Particular Alloy Classes; Woodhead Publishing Ltd.: Cambridge, UK, 2012; ISBN 978-1-84569-677-1. [Google Scholar]

- San Marchi, C.; Michler, T.; Nibur, K.A.; Somerday, B.P. On the physical differences between tensile testing of type 304 and 316 austenitic stainless steels with internal hydrogen and in external hydrogen. Int. J. Hydrog. Energy 2010, 35, 9736–9745. [Google Scholar] [CrossRef]

- Michler, T.; Naumann, J. Microstructural aspects upon hydrogen environment embrittlement of various bcc steels. Int. J. Hydrog. Energy 2010, 35, 821–832. [Google Scholar] [CrossRef]

- Perng, T.P.; Altstetter, C.J. Comparison of hydrogen gas embrittlement of austenitic and ferritic stainless steels. Metall. Trans. A 1987, 18, 123–134. [Google Scholar] [CrossRef]

- Holzworth, M.L. Hydrogen Embrittlement of Type 304L Stainless Steel. Corrosion 1969, 25, 107–115. [Google Scholar] [CrossRef]

- Inoue, A.; Hosoya, Y.; Masumoto, T. The Effect of Hydrogen on Crack Propagation Behavior and Microstructures around Cracks in Austenitic Stainless Steels. ISIJ Int. 1979, 19, 170–178. [Google Scholar] [CrossRef]

- Michler, T.; Lee, Y.; Gangloff, R.P.; Naumann, J. Influence of macro segregation on hydrogen environment embrittlement of SUS 316L stainless steel. Int. J. Hydrog. Energy 2009, 34, 3201–3209. [Google Scholar] [CrossRef]

- Weber, S.; Martin, M.; Theisen, W. Impact of heat treatment on the mechanical properties of AISI 304L austenitic stainless steel in high-pressure hydrogen gas. J. Mater. Sci. 2012, 47, 6095–6107. [Google Scholar] [CrossRef]

- Egels, G.; Mujica Roncery, L.; Fussik, R.; Theisen, W.; Weber, S. Impact of chemical inhomogeneities on local material properties and hydrogen environment embrittlement in AISI 304L steels. Int. J. Hydrog. Energy 2018, 43, 5206–5216. [Google Scholar] [CrossRef]

- Kumar, B.S.; Kain, V.; Singh, M.; Vishwanadh, B. Influence of hydrogen on mechanical properties and fracture of tempered 13 wt% Cr martensitic stainless steel. Mater. Sci. Eng. A 2017, 700, 140–151. [Google Scholar] [CrossRef]

- Zhang, L.; Wen, M.; Imade, M.; Fukuyama, S.; Yokogawa, K. Effect of nickel equivalent on hydrogen gas embrittlement of austenitic stainless steels based on type 316 at low temperatures. Acta Mater. 2008, 56, 3414–3421. [Google Scholar] [CrossRef]

- Laureys, A.; Depover, T.; Petrov, R.; Verbeken, K. Microstructural Characterization of Hydrogen Induced Cracking in TRIP Steels by EBSD. AMR 2014, 922, 412–417. [Google Scholar] [CrossRef]

- Wilson-Heid, A.E.; Novak, T.C.; Beese, A.M. Characterization of the Effects of Internal Pores on Tensile Properties of Additively Manufactured Austenitic Stainless Steel 316L. Exp. Mech. 2019, 59, 793–804. [Google Scholar] [CrossRef]

- Cui, L.; Lei, X.; Zhang, L.; Zhang, Y.; Yang, W.; Gao, Y.; Liu, Y.; Liu, N. Three-Dimensional Characterization of Defects in Continuous Casting Blooms of Heavy Rail Steel Using X-ray Computed Tomography. Metall. Mater. Trans. B 2021, 52, 2327–2340. [Google Scholar] [CrossRef]

- Harrer, B.; Kastner, J.; Winkler, W.; Degischer, H.P. On the Detection of Inhomogeneities in Steel by Computed Tomography. In Proceedings of the 17th World Conference on Nondestructive Testing, Shanghai, China, 25–28 October 2008. [Google Scholar]

- Connolly, B.J.; Horner, D.A.; Fox, S.J.; Davenport, A.J.; Padovani, C.; Zhou, S.; Turnbull, A.; Preuss, M.; Stevens, N.P.; Marrow, T.J.; et al. X-ray microtomography studies of localised corrosion and transitions to stress corrosion cracking. Mater. Sci. Technol. 2006, 22, 1076–1085. [Google Scholar] [CrossRef]

- Marrow, T.J.; Steuwer, A.; Mohammed, F.; Engelberg, D.; Sarwar, M. Measurement of crack bridging stresses in environment-assisted cracking of duplex stainless by synchrotron diffraction. Fat Frac. Eng. Mat. Struct. 2006, 29, 464–471. [Google Scholar] [CrossRef]

- Marrow, T.J.; Babout, L.; Connolly, B.J.; Engelberg, D.; Johnson, G.; Buffiere, J.-Y.; Withers, P.J.; Newman, R.C. High-resolution, in-situ, tomographic observations of stress corrosion cracking. In Environment-Induced Cracking of Materials; Elsevier: Amsterdam, The Netherlands, 2008; pp. 439–447. ISBN 9780080446356. [Google Scholar]

- King, A.; Ludwig, W.; Engelberg, D.; Marrow, T.J. Diffraction contrast tomography for the study of polycrystalline stainless steel microstructures and stress corrosion cracking. Rev. Metall. 2011, 108, 47–50. [Google Scholar] [CrossRef]

- Lusic, H.; Grinstaff, M.W. X-ray-computed tomography contrast agents. Chem. Rev. 2013, 113, 1641–1666. [Google Scholar] [CrossRef]

- Lloyd, G.E. Atomic number and crystallographic contrast images with the SEM: A review of backscattered electron techniques. Mineral. Mag. 1987, 51, 3–19. [Google Scholar] [CrossRef]

- Raghavan, V.; Antia, D.P. The chromium equivalents of selected elements in austenitic stainless steels. Metall. Trans. A 1994, 25, 2675–2681. [Google Scholar] [CrossRef]

- Won, Y.-M.; Thomas, B.G. Simple model of microsegregation during solidification of steels. Metall. Trans. A 2001, 32, 1755–1767. [Google Scholar] [CrossRef]

- Wegrzyn, T. Delta ferrite in stainless steel weld metals. Weld. Int. 1992, 6, 690–694. [Google Scholar] [CrossRef]

- Kerr, H.W.; Kurz, W. Solidification of peritectic alloys. Int. Mater. Rev. 1996, 41, 129–164. [Google Scholar] [CrossRef]

- Aranda Villada, V.A.; García Hinojosa, J.A.; Cruz Mejía, H.; Balandra Aranzueta, A.A.; González, F.M.G.; Houbaert, Y. Study of the Macrosegregation of Silicon in Steels for Electrical Applications. MRS Proc. 2012, 1373, 412. [Google Scholar] [CrossRef]

- Weber, S.; Martin, M.; Theisen, W. Lean-alloyed austenitic stainless steel with high resistance against hydrogen environment embrittlement. Mater. Sci. Eng. A 2011, 528, 7688–7695. [Google Scholar] [CrossRef]

- Curtze, S.; Kuokkala, V.-T.; Oikari, A.; Talonen, J.; Hänninen, H. Thermodynamic modeling of the stacking fault energy of austenitic steels. Acta Mater. 2011, 59, 1068–1076. [Google Scholar] [CrossRef]

- Tian, L.; Liu, L.; Ma, B.; Zaïri, F.; Ding, N.; Guo, W.; Xu, N.; Xu, H.; Zhang, M. Evaluation of maximum non-metallic inclusion sizes in steel by statistics of extreme values method based on Micro-CT imaging. Metall. Res. Technol. 2022, 119, 202. [Google Scholar] [CrossRef]

- Shang, Z.; Li, T.; Yang, S.; Yan, J.; Guo, H. Three-dimensional characterization of typical inclusions in steel by X-ray Micro-CT. J. Mater. Res. Technol. 2020, 9, 3686–3698. [Google Scholar] [CrossRef]

- Gulliksrud, K.; Stokke, C.; Martinsen, A.C.T. How to measure CT image quality: Variations in CT-numbers, uniformity and low contrast resolution for a CT quality assurance phantom. Phys. Med. 2014, 30, 521–526. [Google Scholar] [CrossRef]

- Goldman, L.W. Principles of CT: Radiation dose and image quality. J. Nucl. Med. Tsechnol. 2007, 35, 213–225. [Google Scholar] [CrossRef]

- Brunke, O.; Neuser, E.; Suppes, A. High resolution industrial CT systems: Advances and comparison with synchrotron-based CT. In Proceedings of the Internal Symposium on Digital Industrial Radiology and Computed Tomography, Berlin, Germany, 20–22 June 2011; pp. 20–22. [Google Scholar]

- Mayo, S.C.; Stevenson, A.W.; Wilkins, S.W. In-Line Phase-Contrast X-ray Imaging and Tomography for Materials Science. Materials 2012, 5, 937–965. [Google Scholar] [CrossRef]

| Alloy | C | Si | Mn | Cr | Ni | Mo | N | W |

|---|---|---|---|---|---|---|---|---|

| X2CrNi18-9 | 0.015 | 0.71 | 1.94 | 17.60 | 8.50 | 0.30 | 0.050 | - |

| X2CrNiW15-9-5 | 0.008 | 0.53 | 2.04 | 14.78 | 8.66 | 0.02 | 0.014 | 4.47 |

| X2CrNiSi18-9-4 | 0.005 | 4.11 | 2.04 | 17.61 | 8.49 | 0.02 | 0.015 | - |

| Alloy | Average 8-Bit Grayscale Value | |

|---|---|---|

| X2CrNi18-9 | 25.5 | 169 |

| X2CrNiW15-9-5 | 26.4 | 210 |

| X2CrNiSi18-9-4 | 24.9 | 140 |

| Method | Σ Cracks | Crack Density (mm−1) | Mean Depth (mm) | Min. Depth (mm) |

|---|---|---|---|---|

| Light microscopy | 52 | 4.7 | 18.0 ± 10.1 | 1.9 |

| CT | 54 | 4.9 | 22.5 ± 15.1 | 5.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Egels, G.; Schäffer, S.; Benito, S.; Weber, S. µ-CT Investigation of Hydrogen-Induced Cracks and Segregation Effects in Austenitic Stainless Steel. Hydrogen 2023, 4, 60-73. https://doi.org/10.3390/hydrogen4010005

Egels G, Schäffer S, Benito S, Weber S. µ-CT Investigation of Hydrogen-Induced Cracks and Segregation Effects in Austenitic Stainless Steel. Hydrogen. 2023; 4(1):60-73. https://doi.org/10.3390/hydrogen4010005

Chicago/Turabian StyleEgels, Gero, Simon Schäffer, Santiago Benito, and Sebastian Weber. 2023. "µ-CT Investigation of Hydrogen-Induced Cracks and Segregation Effects in Austenitic Stainless Steel" Hydrogen 4, no. 1: 60-73. https://doi.org/10.3390/hydrogen4010005

APA StyleEgels, G., Schäffer, S., Benito, S., & Weber, S. (2023). µ-CT Investigation of Hydrogen-Induced Cracks and Segregation Effects in Austenitic Stainless Steel. Hydrogen, 4(1), 60-73. https://doi.org/10.3390/hydrogen4010005