Incorporating Pavement Friction Management into Pavement Asset Management Systems: State Department of Transportation Experience

Abstract

:1. Introduction

2. Study Objectives

- Discover the state policies and targets in utilizing PFM on the roadways managed by state DOTs.

- Define the state testing protocols, equipment, and data collection techniques to measure the pavement friction on the state highways.

- Investigate the strategies established by state DOTs to provide adequate pavement friction levels, especially at locations requiring higher friction demands.

- Highlight the trends of current pavement friction management practices and activities and define their relevant effectiveness.

- Provide the best practices of managing and planning the maintenance plans of pavement friction considering the feedback from both state DOT participants and literature.

- Develop appropriate pavement friction management framework and guidelines for state DOTs.

- Enhance road safety by developing a detailed process to treat pavement friction.

3. Background

4. Methodology

4.1. Survey Questionnaire

4.1.1. General Information

4.1.2. Data Collection

4.1.3. Analysis and Performance

4.1.4. Treatments and Maintenance Planning

4.2. Data Correlation

5. Survey Results

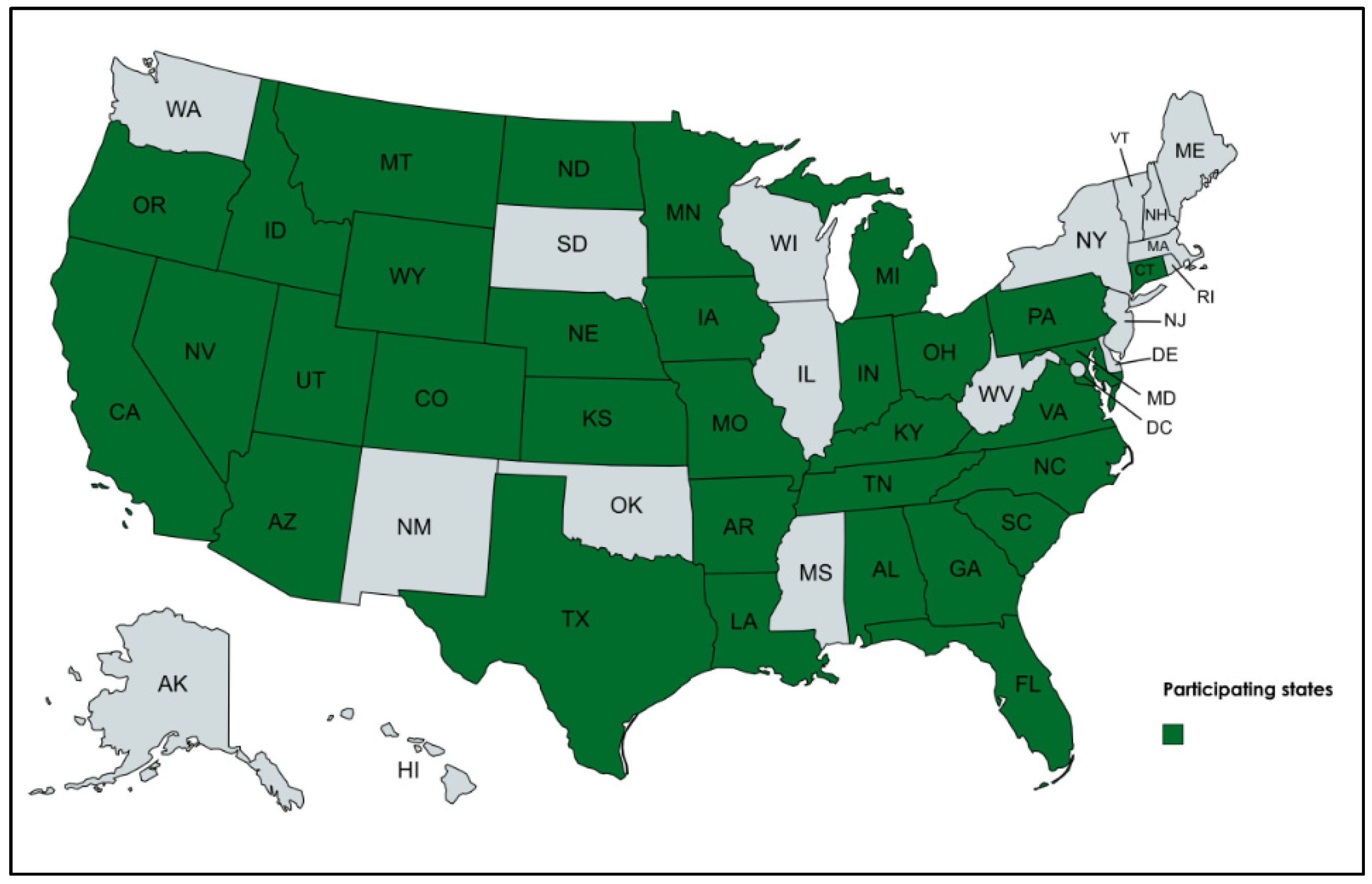

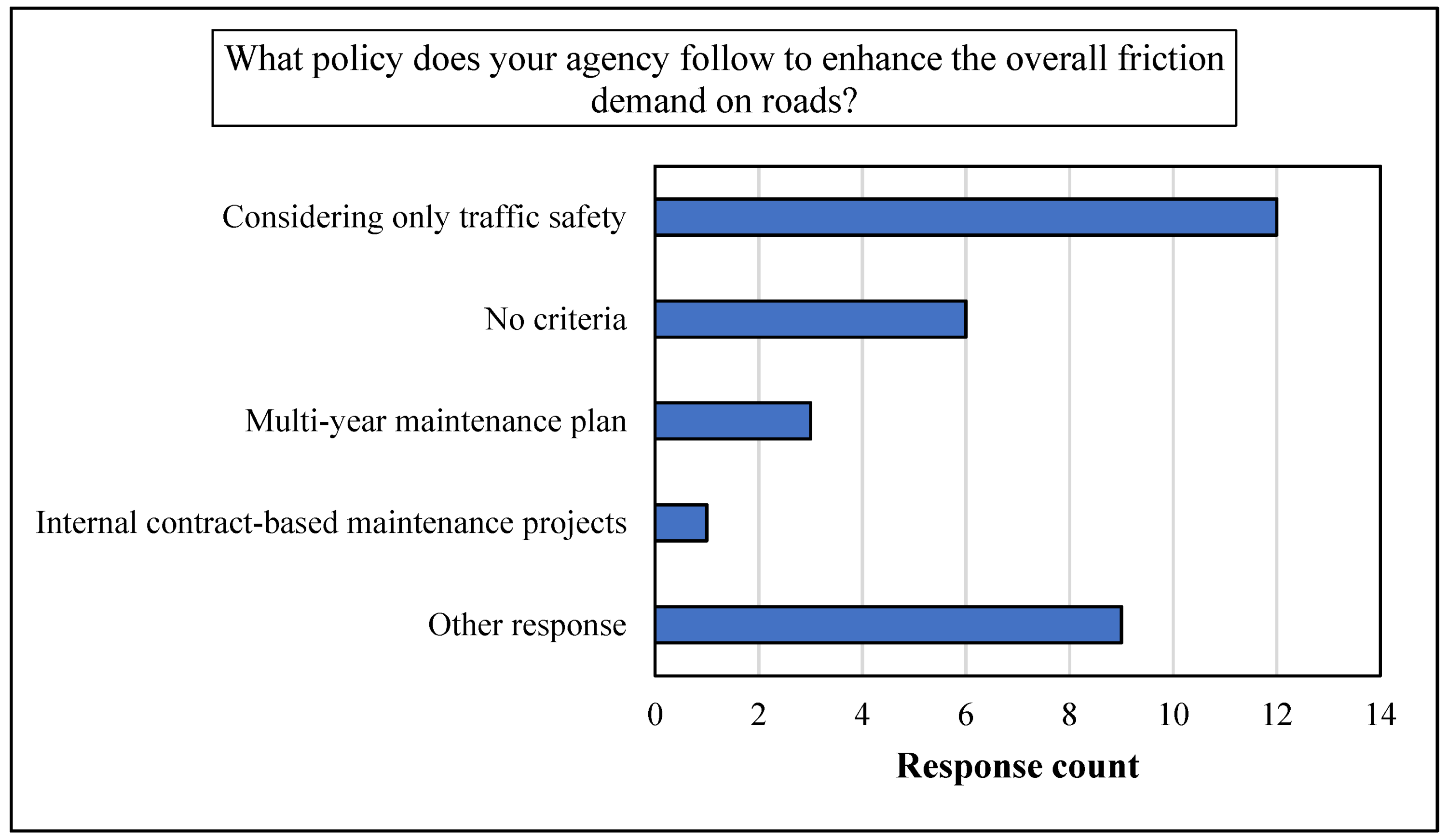

5.1. Policy of Management

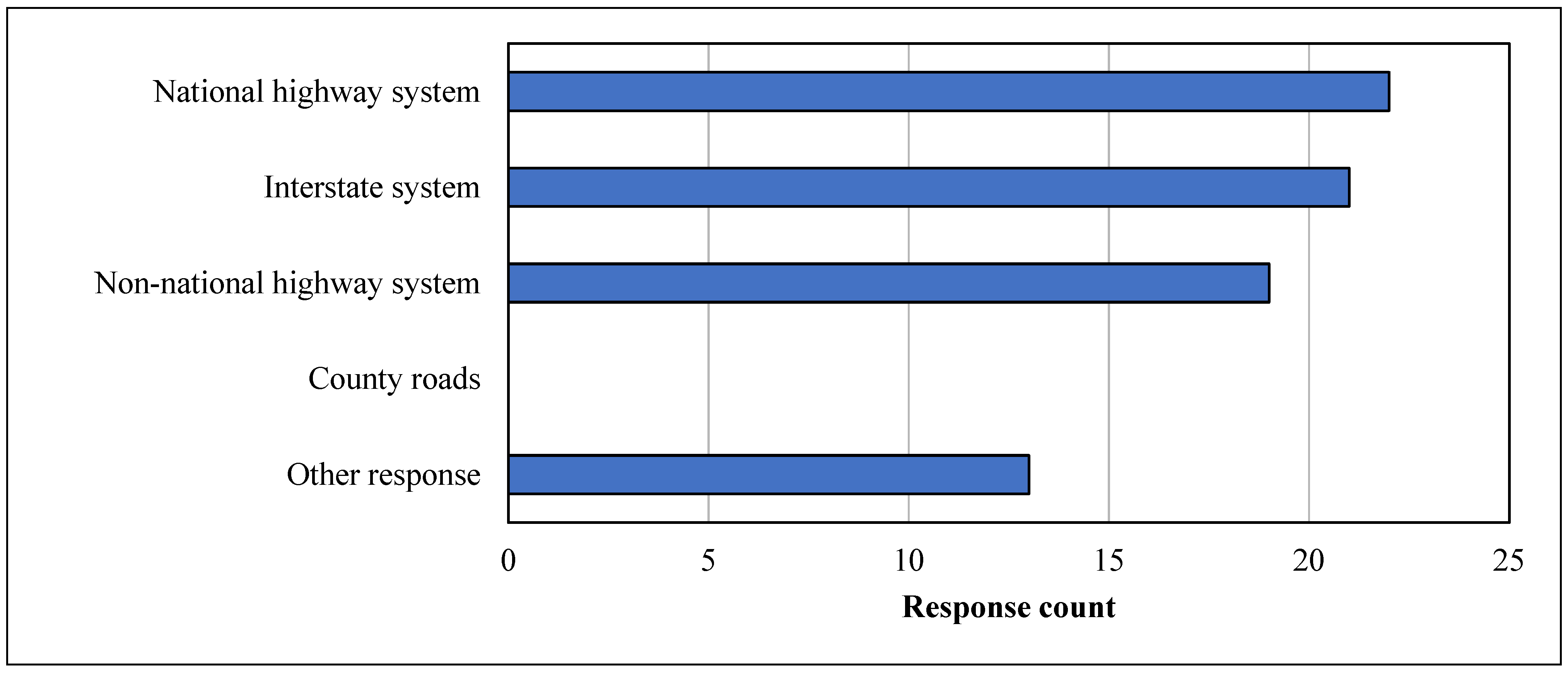

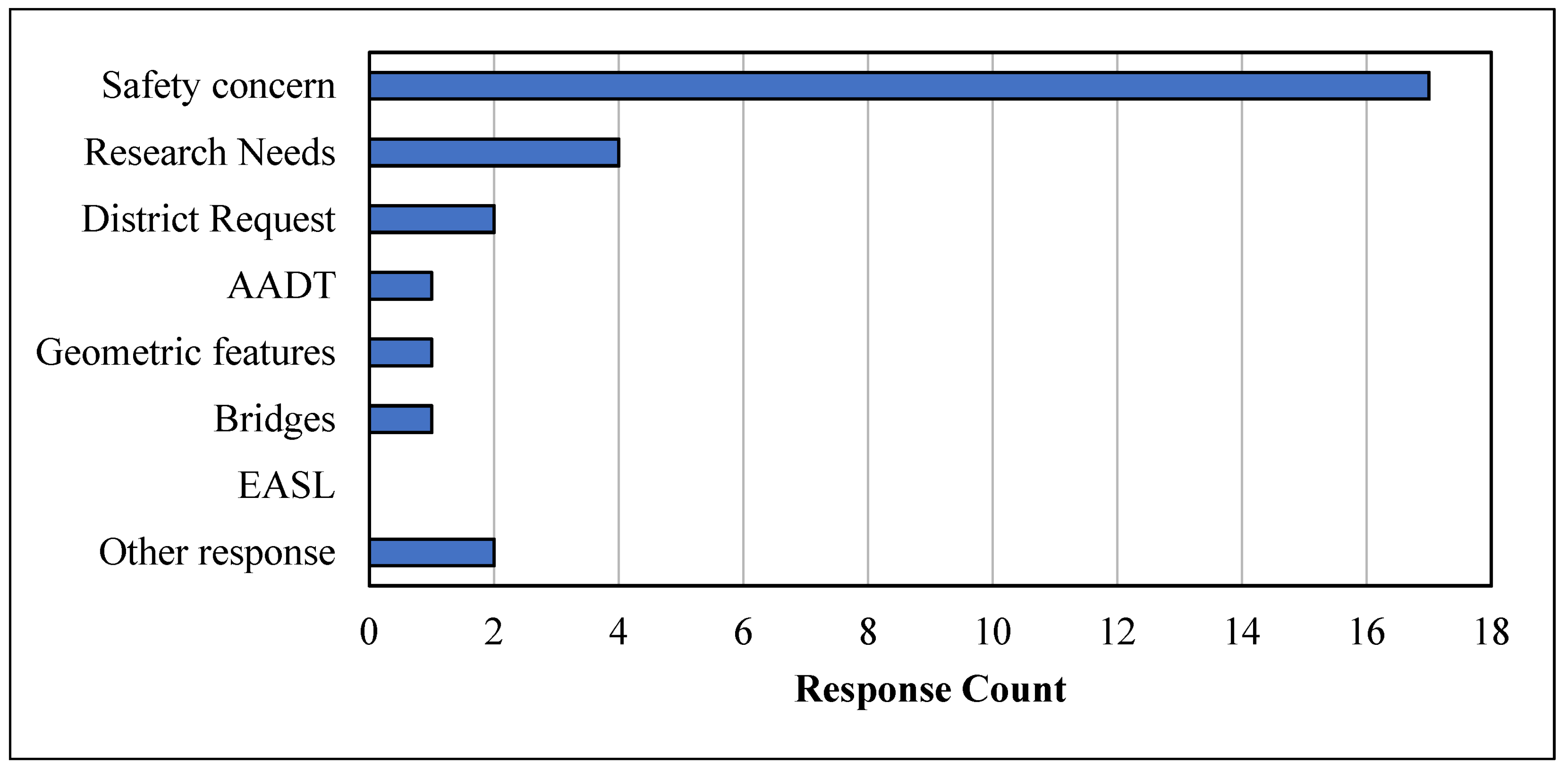

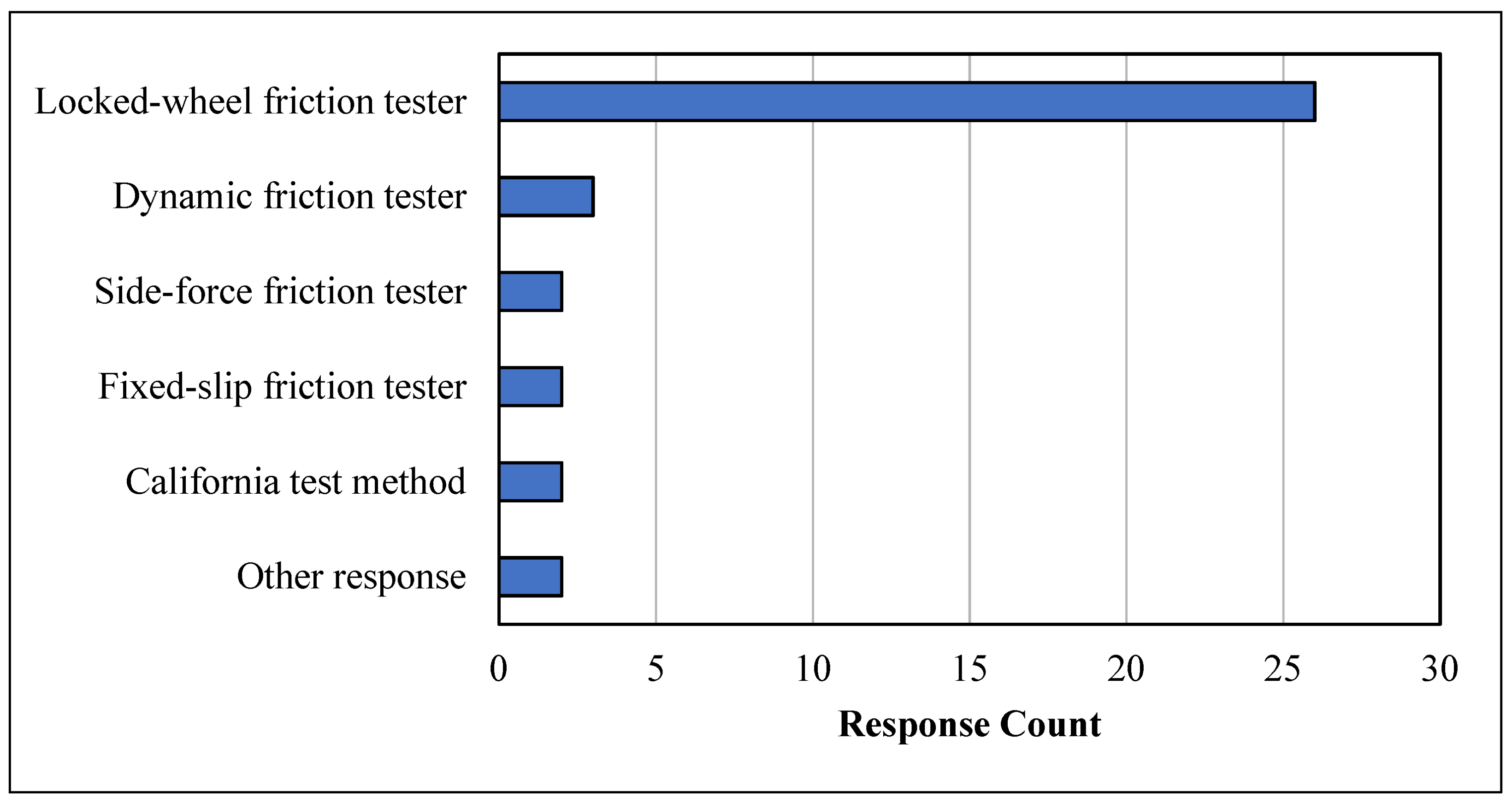

5.2. Friction Testing and Data Collection

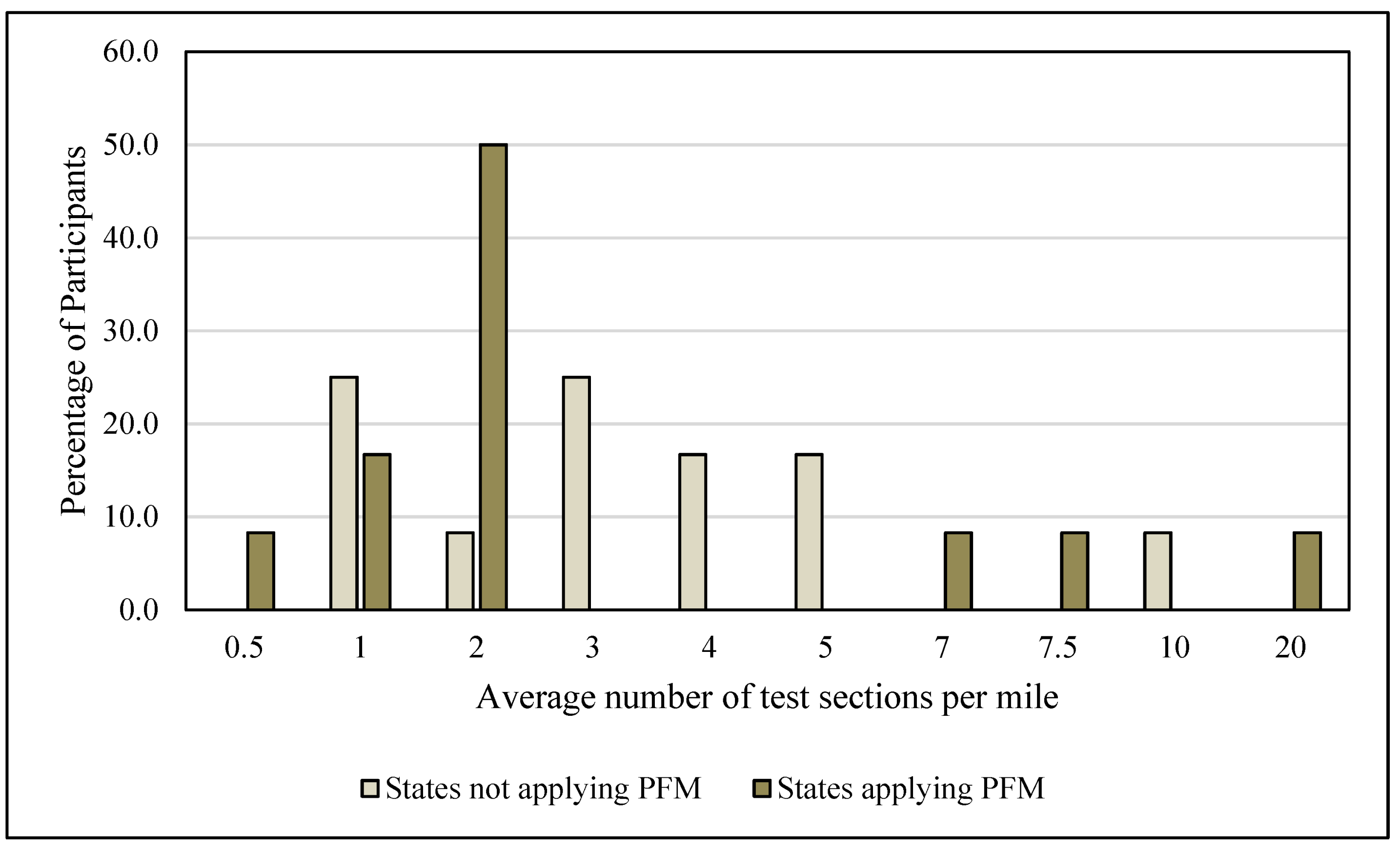

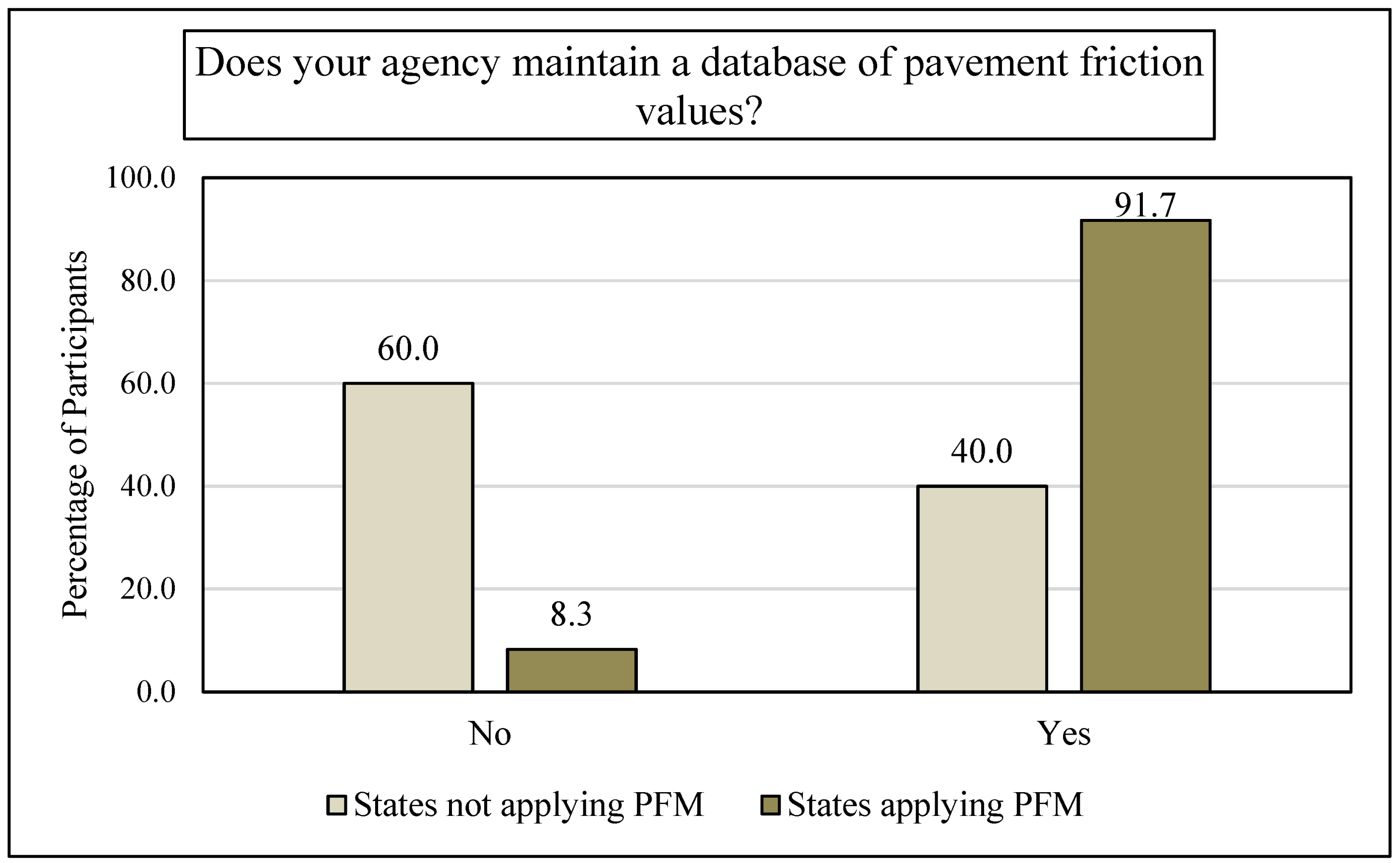

5.3. Performance Measurements

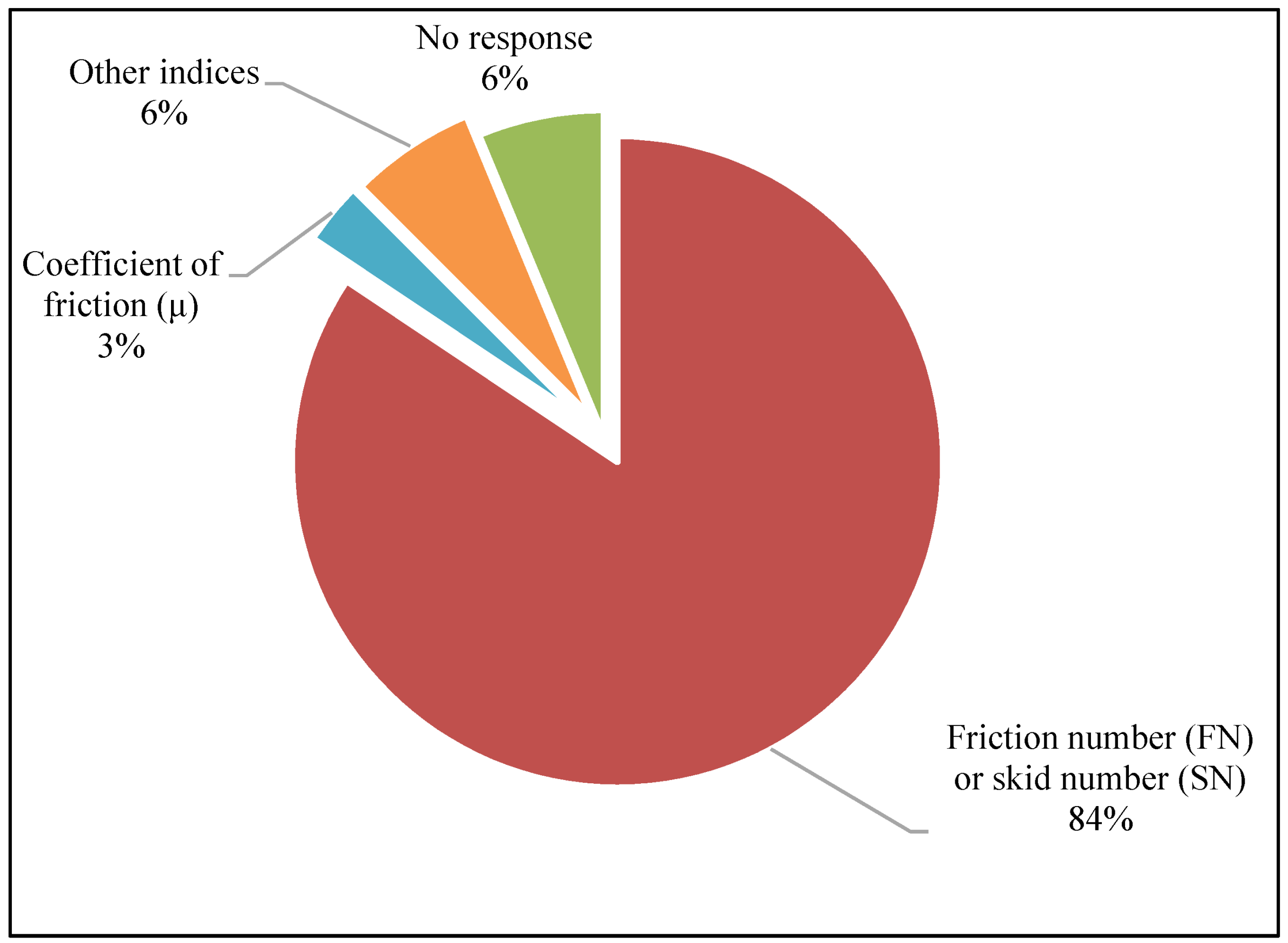

5.4. Friction Demands and Categories

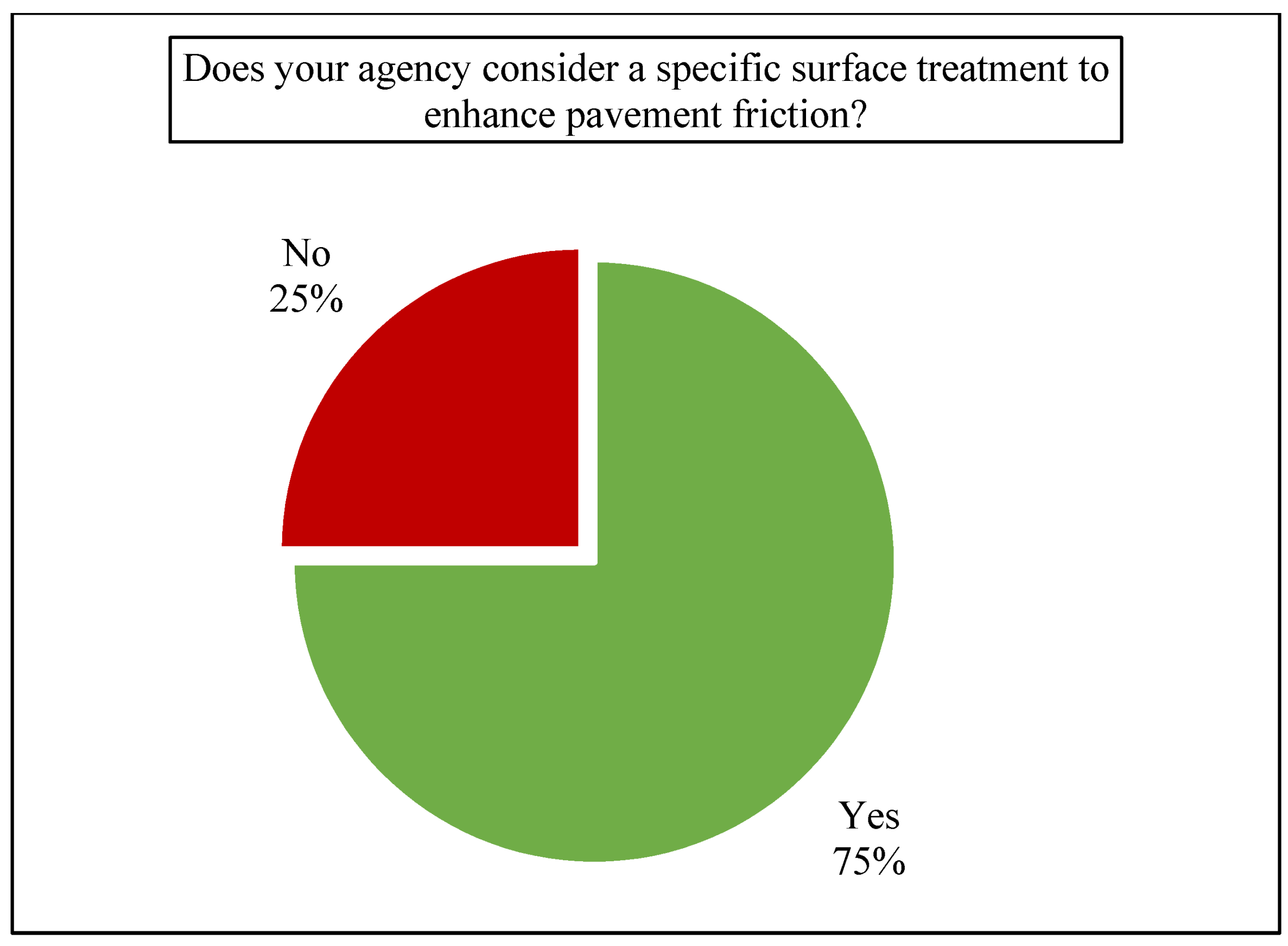

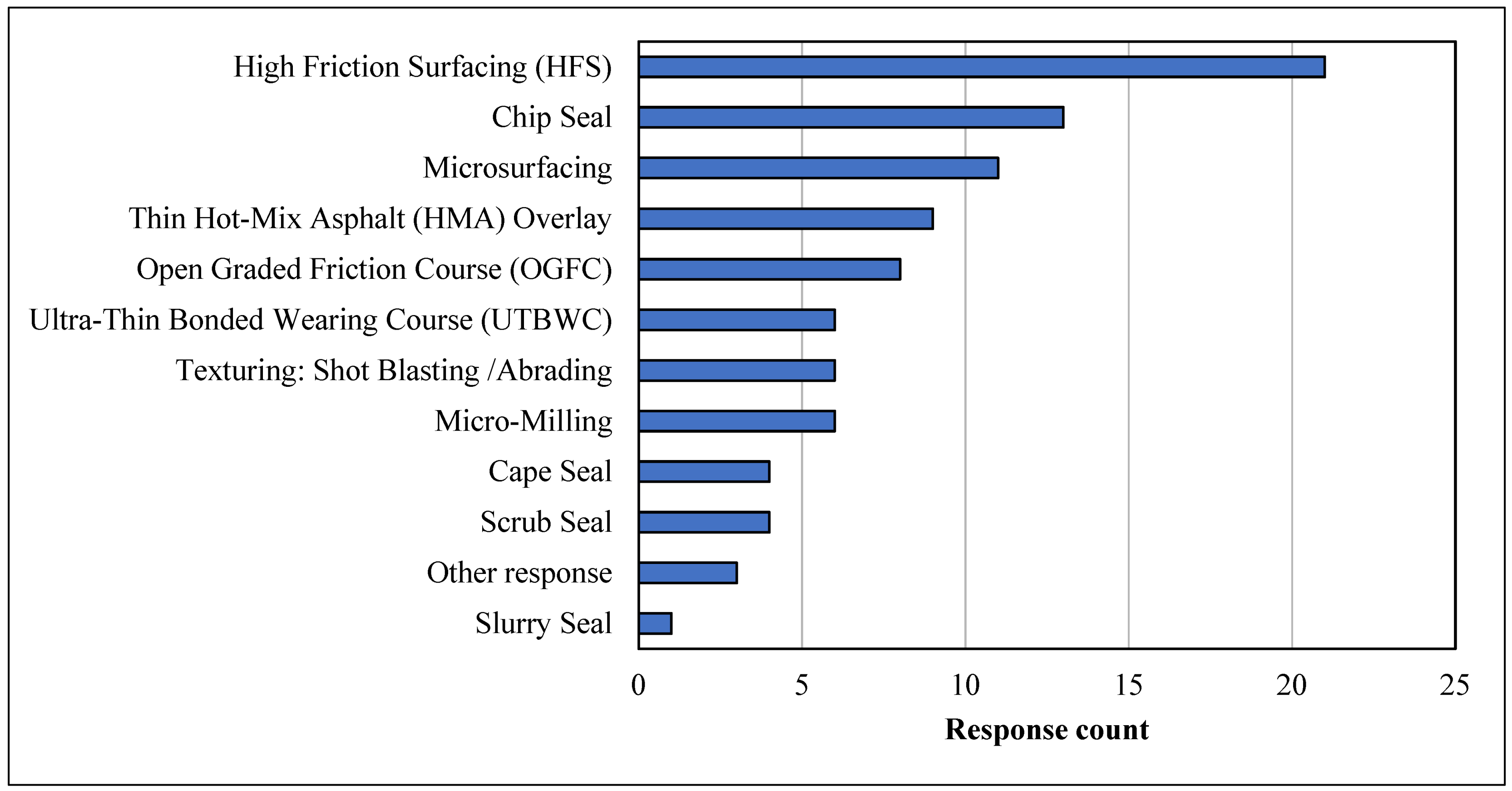

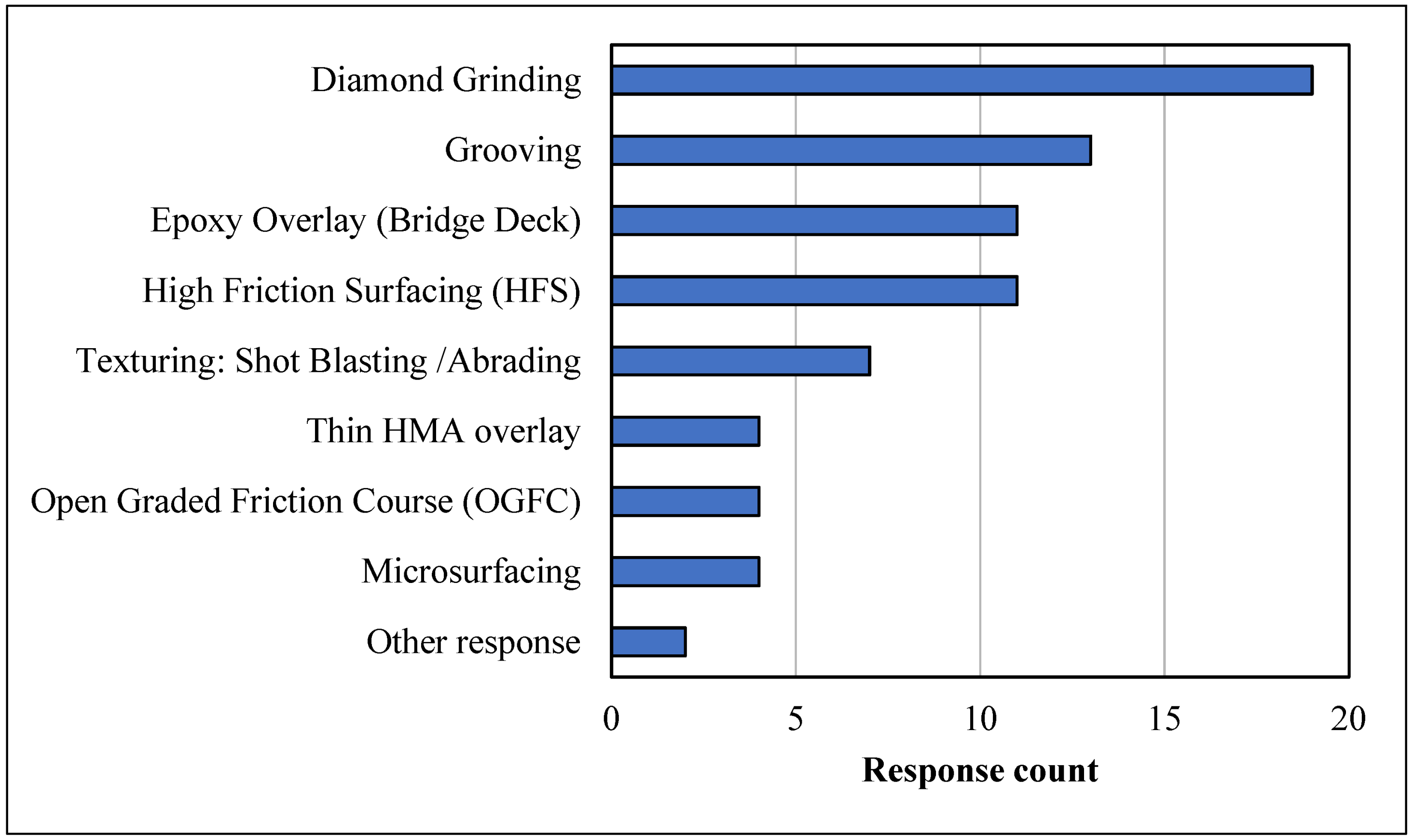

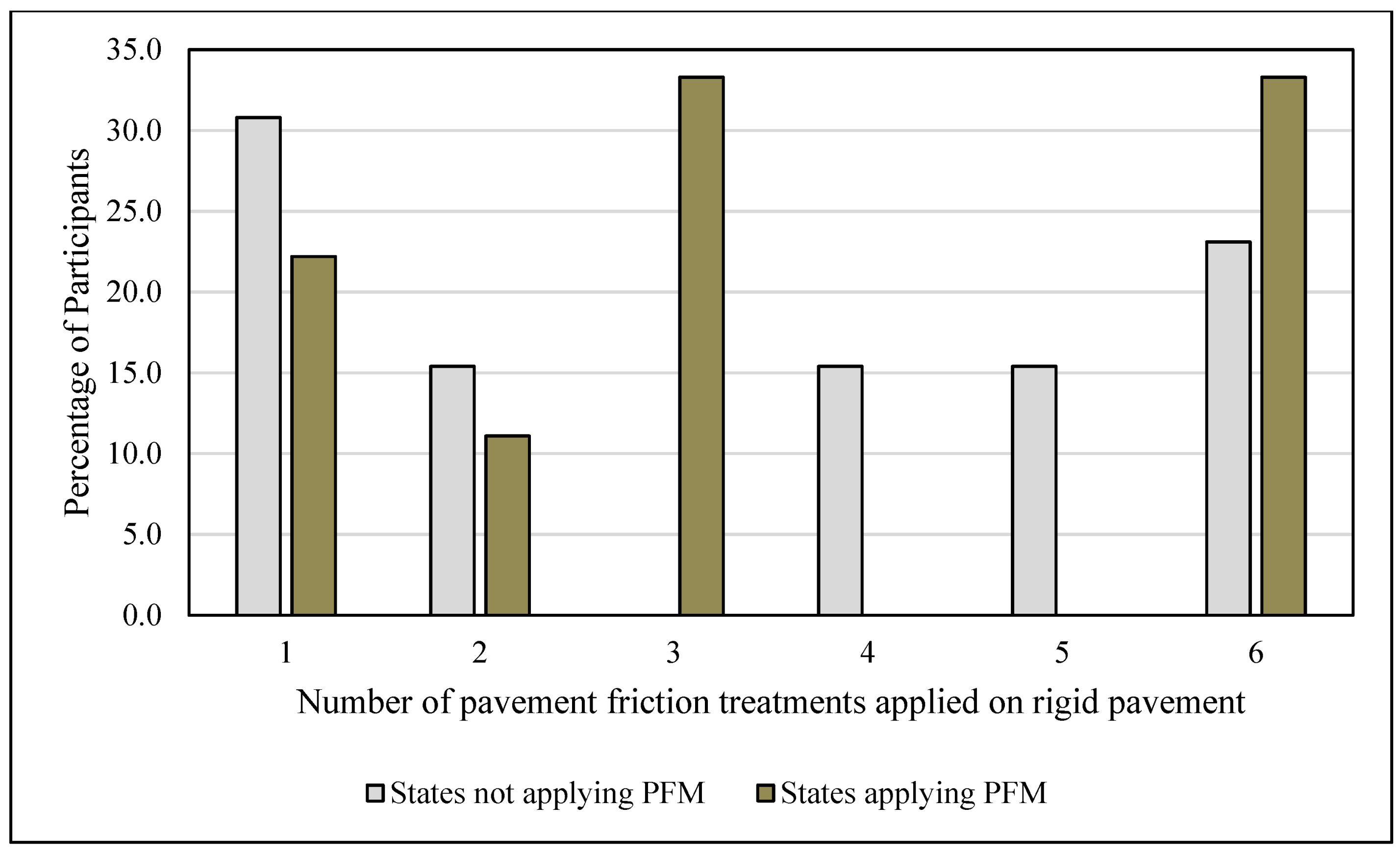

5.5. Treatments and Decision Making

6. Statistical Analysis

7. Current Merits, Limitations, and Potential Enhancements

7.1. State DOTs Not Applying Pavement Friction Management

7.2. State DOTs Applying Pavement Friction Management

8. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hall, J.W.; Smith, K.L.; Titus-Glover, L.; Wambold, J.C.; Yager, T.J.; Rado, Z. NCHRP Report 801: Guide for Pavement Friction; Transportation Research Board: Washington, DC, USA, 2009. [Google Scholar] [CrossRef] [Green Version]

- Ilse, M. Evaluation of tire/surfacing/base contact stresses and texture depth. Int. J. Transp. Sci. Technol. 2015, 4, 107–118. [Google Scholar] [CrossRef] [Green Version]

- Najafi, S.; Flintsch, G.W.; Medina, A. Linking roadway crashes and tire–pavement friction: A case study. Int. J. Pavement Eng. 2017, 18, 119–127. [Google Scholar] [CrossRef]

- Friction Management. Federal Highway Administration (FHWA). Available online: https://safety.fhwa.dot.gov/roadway_dept/pavement_friction/friction_management/ (accessed on 2 February 2022).

- Hafez, M.; Farid, A.; Ksaibati, K. Managing Pavement Friction of Wyoming’s Roads Considering Safety; Wyoming Department of Transportation: Cheyenne, WY, USA, 2020; Available online: https://www.dot.state.wy.us/files/live/sites/wydot/files/shared/Planning/Research/Managing%20Pavement%20Friction%20of%20Wyoming%E2%80%99s%20Roads%20Considering%20Safety.pdf (accessed on 2 May 2022).

- MAP-21—Moving Ahead for Progress in the 21st Century Act. Federal Highway Administration (FHWA). Available online: https://www.fhwa.dot.gov/map21/ (accessed on 5 February 2022).

- Highway Safety Improvement Program (HSIP). Federal Highway Administration (FHWA). Available online: https://safety.fhwa.dot.gov/hsip/ (accessed on 5 February 2022).

- Guide for Pavement Friction; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2008.

- Pavement Friction Management. Technical Advisory, Federal Highway Administration (FHWA). Available online: https://www.fhwa.dot.gov/pavement/t504038.cfm (accessed on 1 July 2021).

- Shaffer, S.J.; Christiaen, A.C.; Rogers, M.J. Assessment of Friction-Based Pavement Methods and Regulations. Report No. DTFH61-03-X-00030; National Transportation Research Center: Knoxville, TN, USA, 2006. [Google Scholar]

- Design Manual for Roads and Bridges (DMRB)—Pavement Inspection and Assessment, CS 228, “Skidding Resistance”. (Highways England). Available online: https://www.standardsforhighways.co.uk/dmrb/ (accessed on 5 February 2022).

- Neaylon, K. Guidance for the Development of Policy to Manage Skid Resistance. Report No. AP-R374/11; Austroads: Sydney, Australia, 2011. [Google Scholar]

- McCarthy, R.; Flintsch, G.; de León Izeppi, E. Impact of Skid Resistance on Dry and Wet Weather Crashes. J. Transp. Eng. Part B Pavements 2021, 147, 04021029. [Google Scholar] [CrossRef]

- McCarthy, R.; Flintsch, G.; Katicha, S.; Izeppi, E.D.L.; Guo, F. Determining investigatory levels of friction with crash modelling. Int. J. Pavement Eng. 2021, 1–8. [Google Scholar] [CrossRef]

- de León Izeppi, E.; Flintsch, G.; Katicha, S.; McCarthy, R.; McGhee, K. Locked-Wheel and Sideway-Force CFME Friction Testing Equipment Comparison and Evaluation. Report No. FHWA-RC-19-001; Federal Highway Administration: Washington, DC, USA, 2019. [Google Scholar]

- Continuous Pavement Friction Measurement (CPFM). Federal Highway Administration (FHWA). Available online: https://safety.fhwa.dot.gov/roadway_dept/pavement_friction/cpfm/ (accessed on 5 February 2022).

- Li, S.; Noureldin, S.; Jiang, Y.; Sun, Y. Evaluation of Pavement Surface Friction Treatments. Report No. FHWA/IN/JTRP-2012/04; Indiana Department of Transportation: Indianapolis, IN, USA, 2011. [Google Scholar]

- High Friction Surface Treatments (HFST). Federal Highway Administration (FHWA). Available online: https://safety.fhwa.dot.gov/roadway_dept/pavement_friction/high_friction/ (accessed on 2 February 2022).

- Henry, J.J. Evaluation of Pavement Friction Characteristics. Report No. NCHRP-291; Transportation Research Board: Washington, DC, USA; National Academy: Washington, DC, USA, 2000. [Google Scholar]

- Speir, R.; Barcena, T.P.R.; Desaraju, P. Development of Friction Improvement Policies and Guidelines for the Maryland State Highway Administration. Report No. MD-07-SP708B4F; Maryland State Highway Administration: Baltimore, MD, USA, 2009. [Google Scholar]

- US Census Bureau. United States Summary, 2010: Population and Housing Unit Counts. US Department of Commerce, Economics and Statistics Administration; US Census Bureau: Suitland-Silver Hill, MD, USA, 2012. Available online: https://www.census.gov/prod/cen2010/cph-2-1.pdf (accessed on 10 February 2022).

- Highway Statistics 2019—Public Road Length. FHWA Table HM-10. Available online: https://www.fhwa.dot.gov/policyinformation/statistics/2019/hm10.cfm (accessed on 5 February 2022).

- Federal Highway Administration (FHWA). Highway Performance Monitoring System, Field Manual; US Department of Transportation: Washington, DC, USA, 2014. [Google Scholar]

- Tsai, J.Y.; Wu, Y.; Ai, C.; Pranav, C. Developing Georgia’s High Friction Surface Treatment (HFST) Program-HFST Site Characteristics (HFST-SC) Data Collection and Analysis. Report No. FHWA-GA-18-1504; Georgia Department of Transportation: Forest Park, GA, USA, 2018. [Google Scholar]

- ASTM E 274; Standard Test Method for Skid Resistance of Paved Surfaces Using a Full-Scale Tire. Annual Book of ASTM Standards. American Society for Testing and Materials: West Conshohocken, PA, USA, 1998.

- Izeppi, E.D.L.; Flintsch, G.; McCarthy, R. Evaluation of Methods for Pavement Surface Friction, Testing on Non-Tangent Roadways and Segments. Report No. FHWA/NC/2017-02; North Carolina Department of Transportation: Raleigh, NC, USA, 2017. [Google Scholar]

- FHWA Offers Highway Friction Tester Demonstrations; Publication Number: FHWA-HRT-14-012; Federal Highway Administration, US Department of Transportation: Washington, DC, USA, 2014. Available online: https://www.fhwa.dot.gov/publications/focus/14apr/14apr05.cfm (accessed on 10 February 2022).

- Correa, A.L.; Wong, B. Concrete Pavement Rehabilitation-Guide for Diamond Grinding. Report No. FHWA-SRC 1/10-01 (5M); Federal Highway Administration, US Department of Transportation: Washington, DC, USA, 2001. [Google Scholar]

- Khalili, M.; Amirkhanian, S.N.; Karakouzian, M.; Xiao, F.; Jadidi, K. Evaluation of New Innovations in Rubber-Modified Asphalt Binders and Rubberized Asphalt Mixes for Nevada DOT. Report No. 513-13-803; Nevada Department of Transportation: Carson City, NV, USA, 2016. [Google Scholar]

- Fuentes, L.; Gunaratne, M.; Hess, D. Evaluation of the effect of pavement roughness on skid resistance. J. Transp. Eng. 2010, 136, 640–653. [Google Scholar] [CrossRef]

- Susanna, A.; Crispino, M.; Giustozzi, F.; Toraldo, E. Deterioration trends of asphalt pavement friction and roughness from medium-term surveys on major Italian roads. Int. J. Pavement Res. Technol. 2017, 10, 421–433. [Google Scholar] [CrossRef]

- Noyce, D.A.; Bahia, H.U.; Yambo, J.M.; Kim, G. Incorporating Road Safety into Pavement Management: Maximizing Asphalt Pavement Surface Friction for Road Safety Improvements; Midwest Regional University Transportation Center (UMTRI): Madison, WI, USA, 2005. [Google Scholar]

- Oh, S.M.; Ragland, D.R.; Chan, C.Y. Evaluation of Traffic and Environment Effects on Skid Resistance and Safety Performance of Rubberized Open-Grade Asphalt Concrete. Report No. UCB-ITS-PRR-2010-14; University of California: Berkeley, CA, USA, 2010. [Google Scholar]

- Santos, A.; Freitas, E.F.; Faria, S.; Oliveira, J.R.; Rocha, A.M.A. Prediction of Friction Degradation in Highways with Linear Mixed Models. Coatings 2021, 11, 187. [Google Scholar] [CrossRef]

- Sprinkel, M.M.; McGhee, K.K.; de León Izeppi, E.D. Virginia’s experience with high-friction surface treatments. Transp. Res. Rec. 2015, 2481, 100–106. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Wang, Z. Evaluation of pavement surface friction subject to various pavement preservation treatments. Constr. Build Mater. 2013, 48, 194–202. [Google Scholar] [CrossRef]

- Chan, S.; Lane, B.; Kazmierowski, T.; Lee, W. Pavement preservation: A solution for sustainability. Transp. Res. Rec. 2011, 2235, 36–42. [Google Scholar] [CrossRef] [Green Version]

- Najafi, S.; Flintsch, G.W.; Khaleghian, S. Fuzzy logic inference-based Pavement Friction Management and real-time slippery warning systems: A proof of concept study. Accid. Anal. Prev. 2016, 90, 41–49. [Google Scholar] [CrossRef] [PubMed]

- Najafi, S.; Flintsch, G.W.; Khaleghian, S. Pavement friction management–artificial neural network approach. Int. J. Pavement Eng. 2019, 20, 125–135. [Google Scholar] [CrossRef]

- Marcelino, P.; de Lurdes Antunes, M.; Fortunato, E.; Gomes, M.C. Machine learning for pavement friction prediction using scikit-learn. In Proceedings of the EPIA Conference on Artificial Intelligence, Porto, Portugal; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- McDonald, M.P.; Crowley, L.G.; Turochy, R.E. Determining the Causes of Seasonal Variation in Pavement Friction: Observational Study with Datapave 3.0 Database. Transp. Res. Rec. 2009, 2094, 128–135. [Google Scholar] [CrossRef]

- Amjadi, R.; Sherwood, J.; Flintsch, D.G. Seasonal Temperature Changes Impact on Pavement Safety Performance: Case Study. In Proceedings of the Draft Paper Prepared for 3rd International Friction Conference, Gold Coast, Australia, 15–18 May 2011. [Google Scholar]

| Question | Variable | Description |

|---|---|---|

| Q2 | PFM application | Does your agency apply skid resistance and pavement friction management (PFM) into your state pavement management system (PMS)? |

| Q4 | Data volume | Do you collect friction data statewide or at specific locations? |

| Q7 | Ownership | Do you use your own friction devices to collect your data? |

| Q10 | Tire | What type of tire does your agency use for the locked-wheel tester? |

| Q13 | Specific location | Do you conduct friction testing on specific roads characteristics (such as curves, ramps, intersections, etc.)? |

| Q14 | Tests/mile | On average, how many friction tests are conducted per mile? |

| Q16 | Database | Does your agency maintain a database of pavement friction values? |

| Q22 | Minimum FN | Does your agency have a minimum friction value on your roads? |

| Q26 | Treatment decision | Does your agency consider a specific surface treatment to enhance pavement friction? |

| Q27 | Treatments on flexible | How many surface treatments are applied by your agency? (Flexible pavement) |

| Q28 | Treatments on rigid | How many surface treatments are applied by your agency? (Rigid pavement) |

| Q33 | Studies | Are there any studies developed by your agency related to skid resistance? |

| Variable | Type | Label | Value |

|---|---|---|---|

| PFM application | Categorical (Binary) | No | 0 |

| Yes | 1 | ||

| Data volume | Categorical | No response | 0 |

| Specific locations only | 1 | ||

| Statewide | 2 | ||

| Both statewide and specific locations | 3 | ||

| Ownership | Categorical (Binary) | No | 0 |

| Yes | 1 | ||

| Tire | Categorical | Do not use it/No response | 0 |

| Smooth | 1 | ||

| Ribbed | 2 | ||

| Both | 3 | ||

| Specific location | Categorical (Binary) | No | 0 |

| Yes | 1 | ||

| Tests/mile | Ratio | - | Scale |

| Database | Categorical (Binary) | No | 0 |

| Yes | 1 | ||

| Minimum FN | Categorical (Binary) | No | 0 |

| Yes | 1 | ||

| Treatment decision | Categorical (Binary) | No | 0 |

| Yes | 1 | ||

| Treatments on flexible | Ratio | - | Scale |

| Treatments on rigid | Ratio | - | Scale |

| Ownership | Categorical (Binary) | No | 0 |

| Yes | 1 |

| Question | State DOT Response | |

|---|---|---|

| Yes | No | |

| Does your agency incorporate a skid resistance and pavement friction management into your state pavement management system PMS? | Idaho, Indiana, Iowa, Kansas, Kentucky, Louisiana, Maryland, Nevada, Oregon, Pennsylvania, Texas, Wyoming | Alabama, Arizona, Arkansas, California, Colorado, Connecticut, Florida, Georgia, Michigan, Minnesota, Missouri, Montana, Nebraska, North Carolina, North Dakota, Ohio, South Carolina, Tennessee, Utah, Virginia |

| Response count | 12 | 20 |

| Response rate | 38% | 62% |

| Question | State DOT Response | ||||

|---|---|---|---|---|---|

| By Request | Every Year | Every 2 Years | Research Needs Only | Other Response | |

| How frequently does your agency collect friction data? | Arizona, Missouri, Montana, Ohio, Pennsylvania, Virginia | Connecticut, Kentucky, Michigan, Minnesota, Nevada, Texas, Utah | Oregon, Tennessee, Wyoming | Colorado | Alabama, California, Florida, Georgia, Idaho, Indiana, Iowa, Kansas, Louisiana, Maryland, North Carolina, South Carolina |

| Response count | 6 | 7 | 3 | 1 | 12 |

| Response rate | 21% | 24% | 10% | 3% | 41% |

| State DOT | Minimum Friction Value | ||

|---|---|---|---|

| Interstate | National Highway | Non-National Highway | |

| Maryland | FN * = 46 for urban FN * = 49 for rural | No defined criteria | No defined criteria |

| Florida | FN * = 40 | ||

| Idaho | Depending on speed (s): FN * = 35 if s > (45 mile per h) FN * = 30 if s ≤ (45 mile per h) | ||

| Indiana | FN40S = 20 | ||

| Wyoming | FN40R = 40 | ||

| Variable 1 | Variable 2 | Coefficient | Method |

|---|---|---|---|

| PFM application | Data volume | 0.172 | Cramer’s V |

| PFM application | Ownership | 0.254 | Phi |

| PFM application | Tire | 0.378 | Cramer’s V |

| PFM application | Specific location | 0.119 | Phi |

| PFM application | Tests/mile | 0.852 | Eta |

| PFM application | Database | 0.509 | Phi |

| PFM application | Minimum FN | 0.289 | Phi |

| PFM application | Treatment decision | 0 | Phi |

| PFM application | #Treatments on flexible | 0.2 | Eta |

| PFM application | #Treatments on rigid | 0.503 | Eta |

| PFM application | Studies | 0.279 | Phi |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elkhazindar, A.; Hafez, M.; Ksaibati, K. Incorporating Pavement Friction Management into Pavement Asset Management Systems: State Department of Transportation Experience. CivilEng 2022, 3, 541-561. https://doi.org/10.3390/civileng3020032

Elkhazindar A, Hafez M, Ksaibati K. Incorporating Pavement Friction Management into Pavement Asset Management Systems: State Department of Transportation Experience. CivilEng. 2022; 3(2):541-561. https://doi.org/10.3390/civileng3020032

Chicago/Turabian StyleElkhazindar, Alaa, Marwan Hafez, and Khaled Ksaibati. 2022. "Incorporating Pavement Friction Management into Pavement Asset Management Systems: State Department of Transportation Experience" CivilEng 3, no. 2: 541-561. https://doi.org/10.3390/civileng3020032

APA StyleElkhazindar, A., Hafez, M., & Ksaibati, K. (2022). Incorporating Pavement Friction Management into Pavement Asset Management Systems: State Department of Transportation Experience. CivilEng, 3(2), 541-561. https://doi.org/10.3390/civileng3020032