Economic Analysis of a Conceptual Industrial Route for Printed Circuit Boards Processing Based on Mass and Energy Balances

Abstract

:1. Introduction

2. Materials and Methods

2.1. Process Statements

- (a)

- Device Dismantling: Disassembly of electronic equipment, where the internal components are liberated and separated.

- (b)

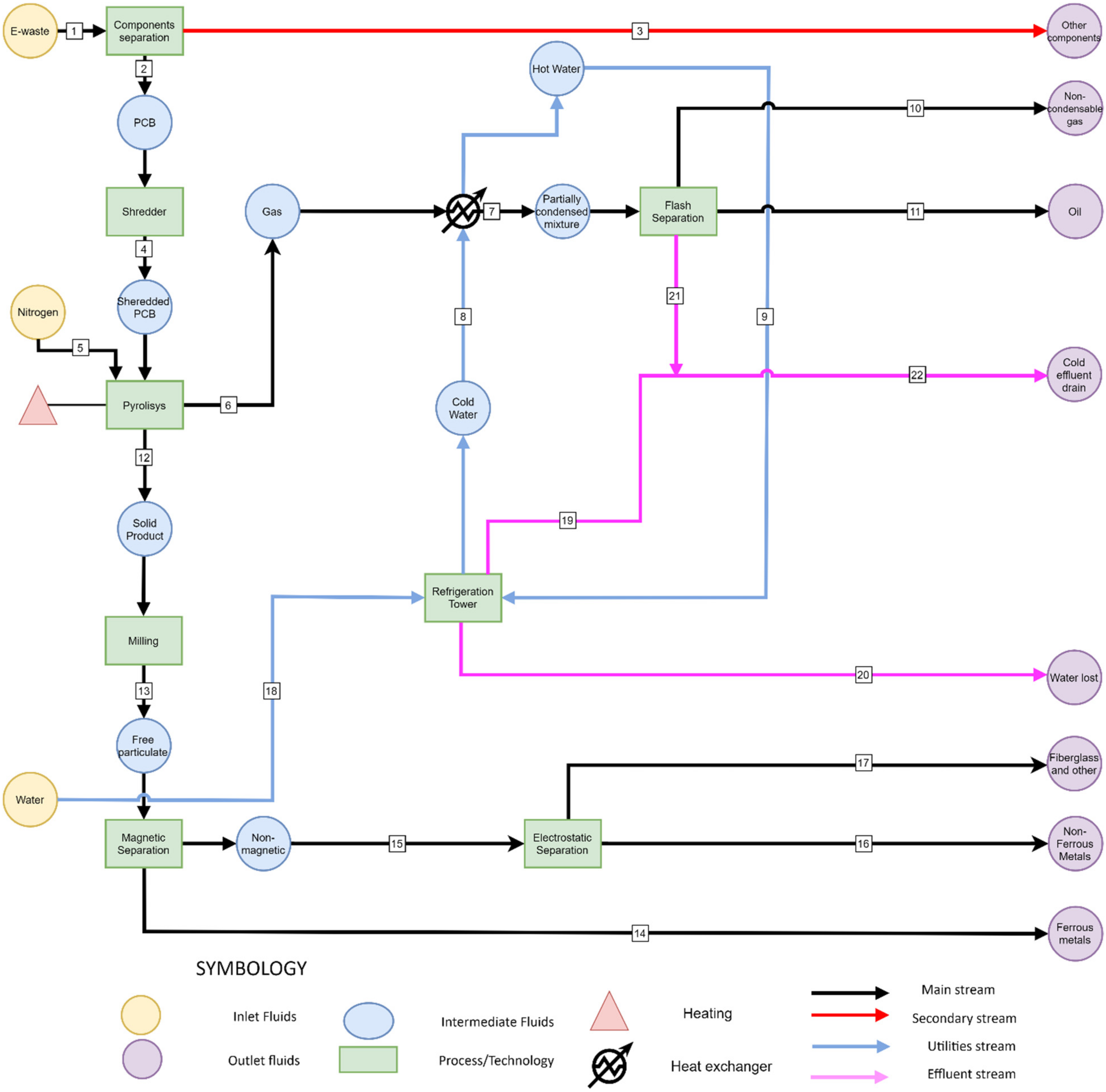

- Unit Operations of Mineral Processing: Reduction of the volume of PCBs and physical separation of the materials/components in them (e.g., plastics, ferrous metals, non-ferrous metals, fiberglass, among others).

- (c)

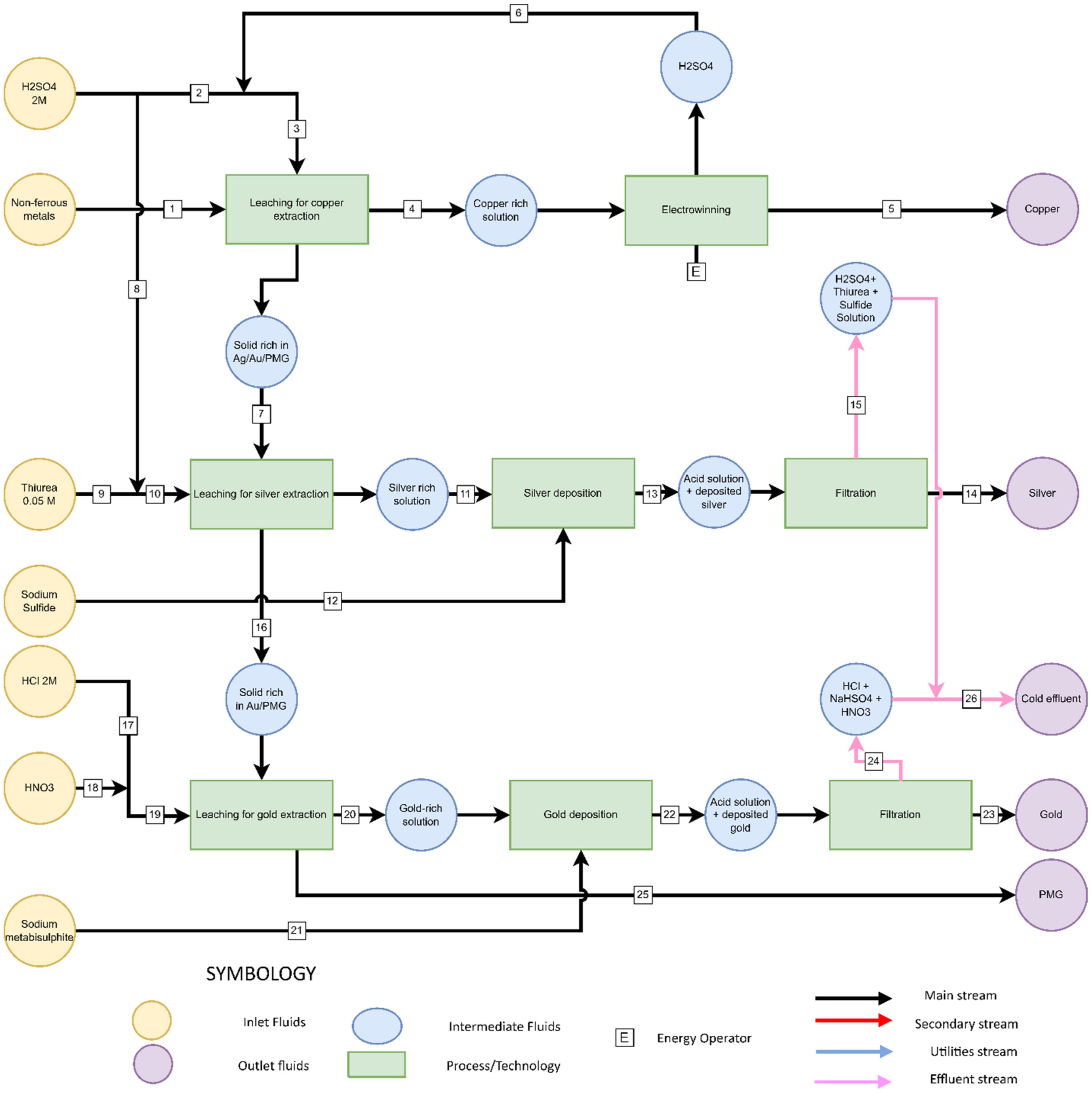

- Extractive Metallurgy Unitary Processes: recovery of high value-added metals (mainly gold, silver, palladium, and copper). At this stage, mainly pyrometallurgical or hydrometallurgical processes are applied.

2.2. Economic Analysis of the Conceptual Route

3. Results

3.1. Conceptual Process Design

3.2. Mass and Energy Balance of the Conceptual Process

3.3. Cost and Investment Estimation Associated with the Conceptual Route

4. Discussion

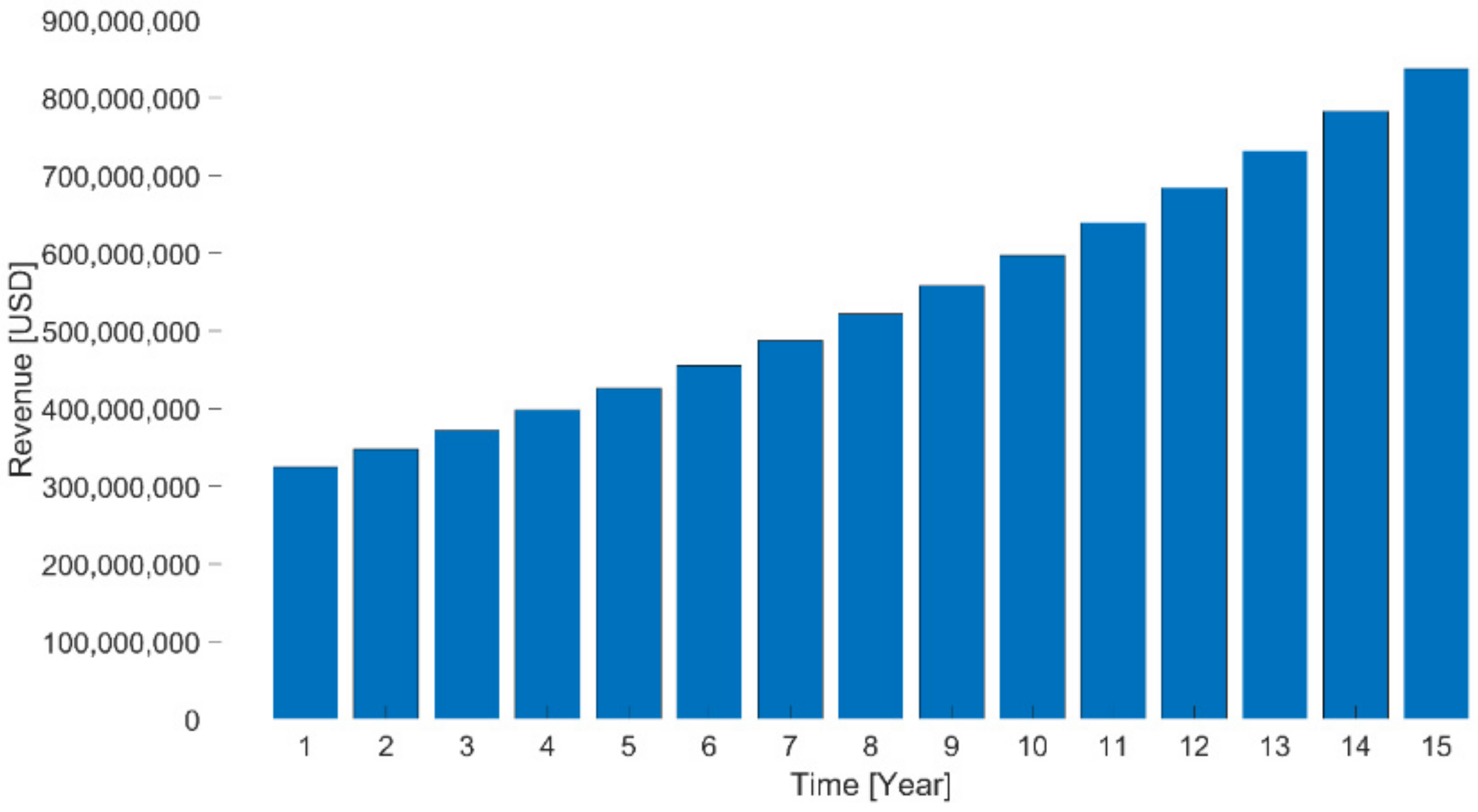

4.1. Economic Evaluation

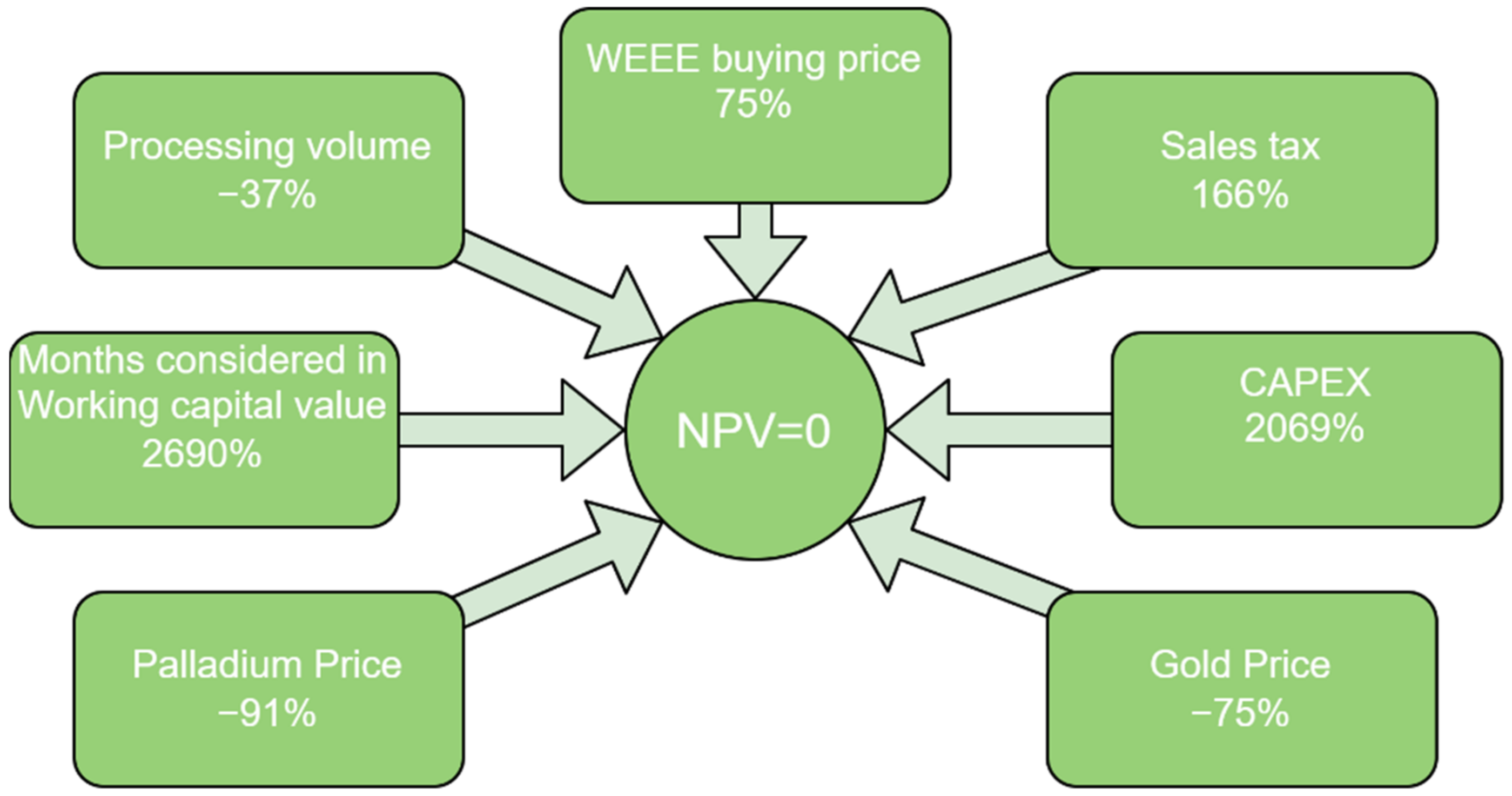

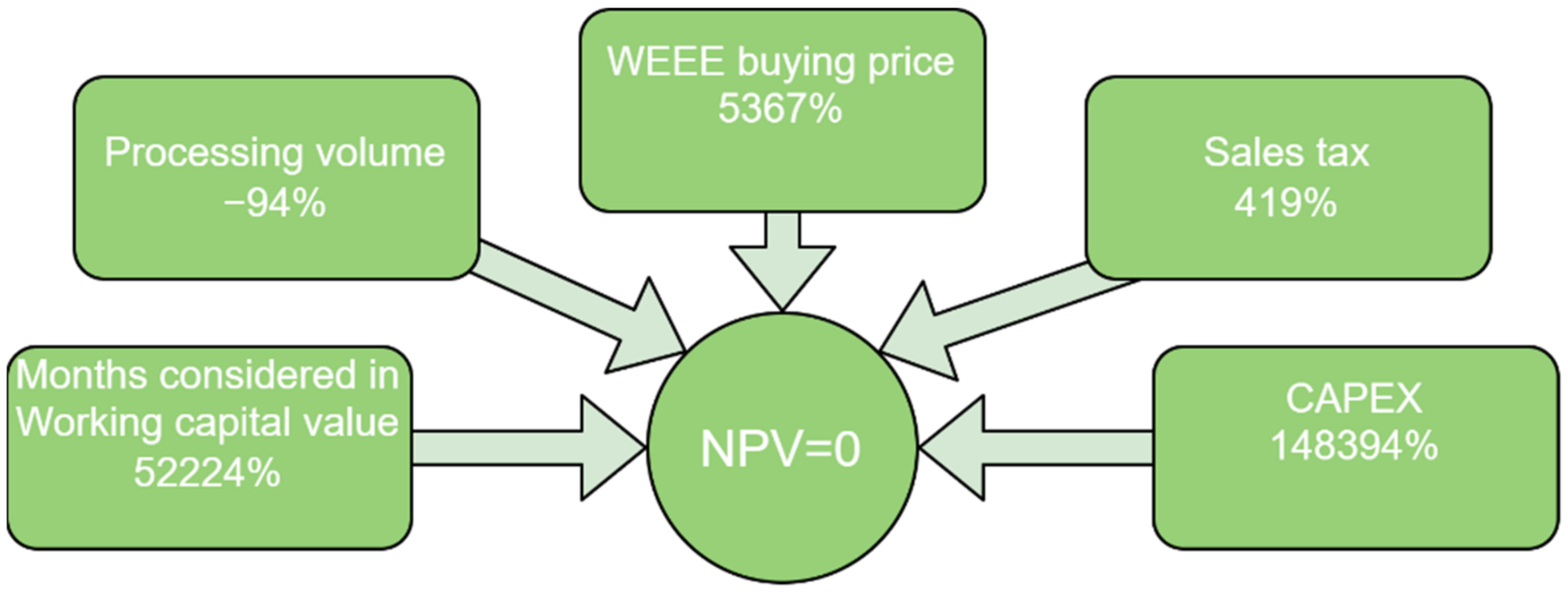

4.2. Sensitivity Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tesfaye, F.; Lindberg, D.; Hamuyuni, J.; Taskinen, P.; Hupa, L. Improving Urban Mining Practices for Optimal Recovery of Resources from E-Waste. Miner. Eng. 2017, 111, 209–221. [Google Scholar] [CrossRef]

- Shevchenko, T.; Laitala, K.; Danko, Y. Understanding Consumer E-Waste Recycling Behavior: Introducing a New Economic Incentive to Increase the Collection Rates. Sustainability 2019, 11, 2656. [Google Scholar] [CrossRef] [Green Version]

- Ottoni, M.; Dias, P.; Helena, L. A Circular Approach to the E-Waste Valorization through Urban Mining in Rio de Janeiro, Brazil. J. Clean. Prod. 2020, 261, 120990. [Google Scholar] [CrossRef]

- Adrian, C.S.; Drisse, M.B.; Cheng, Y.; Devia, L.; Deubzer, O. The Global E-Waste Monitor 2020; UNU-United Nations University: Geneva, Switzerland, 2020; ISBN 9789280891140. [Google Scholar]

- De Albuquerque, C.A.; Mello, C.H.P.; de Gomes, J.H.F.; dos Santos, V.C.; Zara, J.V. E-Waste in the World Today: An Overview of Problems and a Proposal for Improvement in Brazil. Environ. Qual. Manag. 2020, 29, 63–72. [Google Scholar] [CrossRef]

- D’Almeida, F.S.; de Carvalho, R.B.; dos Santos, F.S.; de Souza, R.F.M. On the Hibernating Electronic Waste in Rio de Janeiro Higher Education Community: An Assessment of Population Behavior Analysis and Economic Potential. Sustainability 2021, 13, 9181. [Google Scholar] [CrossRef]

- Cossu, R.; Williams, I.D. Urban Mining: Concepts, Terminology, Challenges. Waste Manag. 2015, 45, 1–3. [Google Scholar] [CrossRef] [PubMed]

- Vermeşan, H.; Tiuc, A.E.; Purcar, M. Advanced Recovery Techniques for Waste Materials from IT and Telecommunication Equipment Printed Circuit Boards. Sustainability 2020, 12, 74. [Google Scholar] [CrossRef] [Green Version]

- Thakur, P.; Kumar, S. Metallurgical Processes Unveil the Unexplored “Sleeping Mines” e- Waste: A Review. Environ. Sci. Pollut. Res. 2020, 27, 32359–32370. [Google Scholar] [CrossRef]

- Abalansa, S.; El Mahrad, B.; Icely, J.; Newton, A. Electronic Waste, an Environmental Problem Exported to Developing Countries: The GOOD, the BAD and the UGLY. Sustainability 2021, 13, 5302. [Google Scholar] [CrossRef]

- Xavier, L.H.; Giese, E.C.; Ribeiro-Duthie, A.C.; Lins, F.A.F. Sustainability and the Circular Economy: A Theoretical Approach Focused on e-Waste Urban Mining. Resour. Policy 2019, 74, 101467. [Google Scholar] [CrossRef]

- Rocchetti, L.; Amato, A.; Beolchini, F. Printed Circuit Board Recycling: A Patent Review. J. Clean. Prod. 2018, 178, 814–832. [Google Scholar] [CrossRef]

- Zhang, D.J.; Dong, L.; Li, Y.T.; Wu, Y.; Ma, Y.X.; Yang, B. Copper Leaching from Waste Printed Circuit Boards Using Typical Acidic Ionic Liquids Recovery of E-Wastes’ Surplus Value. Waste Manag. 2018, 78, 191–197. [Google Scholar] [CrossRef]

- Arshadi, M.; Yaghmaei, S.; Mousavi, S.M. Content Evaluation of Different Waste PCBs to Enhance Basic Metals Recycling. Resour. Conserv. Recycl. 2018, 139, 298–306. [Google Scholar] [CrossRef]

- Becci, A.; Amato, A.; Rodríguez-Maroto, J.M.; Beolchini, F. Bioleaching of End-of-Life Printed Circuit Boards: Mathematical Modeling and Kinetic Analysis. Ind. Eng. Chem. Res. 2021, 60, 4261–4268. [Google Scholar] [CrossRef]

- Ning, C.; Lin, C.S.K.; Hui, D.C.W.; McKay, G. Waste Printed Circuit Board (PCB) Recycling Techniques. Top. Curr. Chem. 2017, 375, 43. [Google Scholar] [CrossRef]

- Kumar, A.; Holuszko, M.E.; Janke, T. Characterization of the Non-Metal Fraction of the Processed Waste Printed Circuit Boards. Waste Manag. 2018, 75, 94–102. [Google Scholar] [CrossRef]

- Kaya, M. Recovery of Metals and Nonmetals from Electronic Waste by Physical and Chemical Recycling Processes. Waste Manag. 2016, 57, 64–90. [Google Scholar] [CrossRef]

- Hao, J.; Wang, Y.; Wu, Y.; Guo, F. Metal Recovery from Waste Printed Circuit Boards: A Review for Current Status and Perspectives. Resour. Conserv. Recycl. 2020, 157, 104787. [Google Scholar] [CrossRef]

- Gu, F.; Summers, P.A.; Hall, P. Recovering Materials from Waste Mobile Phones: Recent Technological Developments. J. Clean. Prod. 2019, 237, 117657. [Google Scholar] [CrossRef]

- Valero Navazo, J.M.; Villalba Méndez, G.; Talens Peiró, L. Material Flow Analysis and Energy Requirements of Mobile Phone Material Recovery Processes. Int. J. Life Cycle Assess. 2014, 19, 567–579. [Google Scholar] [CrossRef]

- Yamane, L.H.; de Moraes, V.T.; Crocce, D.; Espinosa, R.; Alberto, J.; Tenório, S. Recycling of WEEE: Characterization of Spent Printed Circuit Boards from Mobile Phones and Computers. Waste Manag. 2011, 31, 2553–2558. [Google Scholar] [CrossRef]

- Bourgeois, D.; Lacanau, V.; Mastretta, R.; Contino-Pépin, C.; Meyer, D. A Simple Process for the Recovery of Palladium from Wastes of Printed Circuit Boards. Hydrometallurgy 2020, 191, 105241. [Google Scholar] [CrossRef]

- Yazici, E.Y.; Deveci, H. Extraction of Metals from Waste Printed Circuit Boards (WPCBs) in H2SO4-CuSO4-NaCl Solutions. Hydrometallurgy 2013, 139, 30–38. [Google Scholar] [CrossRef]

- Dias, P.; Machado, A.; Huda, N.; Bernardes, A.M. Waste Electric and Electronic Equipment (WEEE) Management: A Study on the Brazilian Recycling Routes. J. Clean. Prod. 2018, 174, 7–16. [Google Scholar] [CrossRef]

- Azevedo, L.P.; da Silva Araújo, F.G.; Lagarinhos, C.A.F.; Tenório, J.A.S.; Espinosa, D.C.R. E-Waste Management and Sustainability: A Case Study in Brazil. Environ. Sci. Pollut. Res. 2017, 24, 25221–25232. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, J.S.S.; Hacha, R.R.; D’almeida, F.S.; Almeida, C.A.; Moura, F.J.; Brocchi, E.A.; Souza, R.F.M. Electronic Waste Low-Temperature Processing: An Alternative Thermochemical Pretreatment to Improve Component Separation. Materials 2021, 14, 6228. [Google Scholar] [CrossRef] [PubMed]

- JGraph Ltd. Diagrams.Net. Available online: https://app.diagrams.net/ (accessed on 10 August 2021).

- Wang, H.; Zhang, S.; Li, B.; Pan, D.; Wu, Y.; Zuo, T. Recovery of Waste Printed Circuit Boards through Pyrometallurgical Processing: A Review. Resour. Conserv. Recycl. 2017, 126, 209–218. [Google Scholar] [CrossRef]

- Birloaga, I.; Vegliò, F. Overview on Hydrometallurgical Procedures for Silver Recovery from Various Wastes. J. Environ. Chem. Eng. 2018, 6, 2932–2938. [Google Scholar] [CrossRef]

- Quan, C.; Li, A.; Gao, N.; Dan, Z. Characterization of Products Recycling from PCB Waste Pyrolysis. J. Anal. Appl. Pyrolysis 2010, 89, 102–106. [Google Scholar] [CrossRef]

- Akcil, A.; Erust, C.; Gahan, C.S.; Ozgun, M.; Sahin, M.; Tuncuk, A. Precious Metal Recovery from Waste Printed Circuit Boards Using Cyanide and Non-Cyanide Lixiviants—A Review. Waste Manag 2015, 45, 258–271. [Google Scholar] [CrossRef]

- Becci, A.; Amato, A.; Rodríguez Maroto, J.M.; Beolchini, F. Prediction Model for Cu Chemical Leaching from Printed Circuit Boards. Ind. Eng. Chem. Res. 2019, 58, 20585–20591. [Google Scholar] [CrossRef]

- Azevedo, L.P.; da Araújo, F.G.S.; Lagarinhos, C.A.F.; Tenório, J.A.S.; Espinosa, D.C.R. Resource Recovery from E-Waste for Environmental Sustainability: A Case Study in Brazil. In Electronic Waste Management and Treatment Technology; Elsevier: Oxford, UK, 2019; pp. 175–200. ISBN 9780128161906. [Google Scholar] [CrossRef]

- Guarnieri, P.; e Silva, L.C.; Levino, N.A. Analysis of Electronic Waste Reverse Logistics Decisions Using Strategic Options Development Analysis Methodology: A Brazilian Case. J. Clean. Prod. 2016, 133, 1105–1117. [Google Scholar] [CrossRef]

- Brasil. Edital 01/2013 de Chamamento de Acordos Setoriais Para a Logística Reversa de Resíduos de Equipamentos Eletroeletrônicos 2013. Available online: http://www.abras.com.br/pdf/editaleletroeletronicos.pdf (accessed on 3 September 2021).

- León, M.; Silva, J.; Carrasco, S.; Barrientos, N. Design, Cost Estimation and Sensitivity Analysis for a Production Process of Activated Carbon Fromwaste Nutshells by Physical Activation. Processes 2020, 8, 945. [Google Scholar] [CrossRef]

- Peter, M.; Timmerhaus, K. Plant Design and Economics for Chemical Engineers, 4th ed.; McGraw-Hill: New York, NY, USA, 1991. [Google Scholar]

- London Metal Exchange Metal Prices. Available online: https://www.lme.com/ (accessed on 30 July 2021).

- Qian, Y.; Ralescu, D.A.; Zhang, B. The Analysis of Factors Affecting Global Gold Price. Resour. Policy 2019, 64, 101478. [Google Scholar] [CrossRef]

- Qadan, M. Risk Appetite and the Prices of Precious Metals. Resour. Policy 2019, 62, 136–153. [Google Scholar] [CrossRef]

- Nadiri, M.I.; Prucha, I.R. Estimation of the depreciation rate of physical and R&D capital in the U.S. total manufacturing sector. Econ. Inq. 1996, 34, 43–56. [Google Scholar] [CrossRef] [Green Version]

- Banco Central do Brasil Relatório de Inflação. Available online: https://www.bcb.gov.br/content/ri/relatorioinflacao/202103/ri202103p.pdf (accessed on 17 August 2021).

- Silva, T.R.; Barros, R.M.; Tiago Filho, G.L.; dos Santos, I.F.S. Methodology for the Determination of Optimum Power of a Thermal Power Plant (TPP) by Biogas from Sanitary Landfill. Waste Manag. 2017, 65, 75–91. [Google Scholar] [CrossRef]

- De Lopes, D.C.; Steidle Neto, A.J.; Mendes, A.A.; Pereira, D.T.V. Economic Feasibility of Biodiesel Production from Macauba in Brazil. Energy Econ. 2013, 40, 819–824. [Google Scholar] [CrossRef]

- Guo, X.; Qin, F.G.F.; Yang, X.; Jiang, R. Study on Low-Temperature Pyrolysis of Large-Size Printed Circuit Boards. J. Anal. Appl. Pyrolysis 2014, 105, 151–156. [Google Scholar] [CrossRef]

- Kumari, A.; Jha, M.K.; Singh, R.P. Recovery of Metals from Pyrolysed PCBs by Hydrometallurgical Techniques. Hydrometallurgy 2016, 165, 97–105. [Google Scholar] [CrossRef]

- Sun, J.; Wang, W.; Liu, Z.; Ma, C. Recycling of Waste Printed Circuit Boards by Microwave-Induced Pyrolysis and Featured Mechanical Processing. Ind. Eng. Chem. Res. 2011, 50, 11763–11769. [Google Scholar] [CrossRef]

- Liu, K.; Yang, J.; Hou, H.; Liang, S.; Chen, Y.; Liu, B.; Xiao, K.; Hu, J.; Deng, H. A Facile and Cost-Effective Approach for Copper Recovery from Waste Printed Circuit Boards via a Sequential Mechanochemical/Leaching/Recrystallization Process A Facile and Cost-Effective Approach for Copp. Environ. Sci. Technol. 2019, 53, 2748–2757. [Google Scholar] [CrossRef]

- Hsu, E.; Barmak, K.; West, A.C.; Park, A.H.A. Advancements in the Treatment and Processing of Electronic Waste with Sustainability: A Review of Metal Extraction and Recovery Technologies. Green Chem. 2019, 21, 919–936. [Google Scholar] [CrossRef]

- Marchal, G. Industrial Experience with Clinker Grinding in the HOROMILL/Sup R/. In Proceedings of the 1997 IEEE/PCA Cement Industry Technical Conference XXXIX Conference Record (Cat. No.97CH36076), Hershey, PA, USA, 20–24 April 1997; pp. 195–211. [Google Scholar]

- Qiu, R.; Lin, M.; Ruan, J.; Fu, Y.; Hu, J.; Deng, M.; Tang, Y.; Qiu, R. Recovering Full Metallic Resources from Waste Printed Circuit Boards: A Refined Review. J. Clean. Prod. 2020, 244, 118690. [Google Scholar] [CrossRef]

- Kim, J.; Dodbiba, G.; Tanno, H.; Okaya, K.; Matsuo, S.; Fujita, T. Calcination of Low-Grade Laterite for Concentration of Ni by Magnetic Separation. Miner. Eng. 2010, 23, 282–288. [Google Scholar] [CrossRef]

- Senophiyah-Mary, J.; Loganath, R. A Novel Method of Utilizing Waste Printed Circuit Board for the Preparation of Fibre Reinforced Polymer. J. Clean. Prod. 2020, 246, 119063. [Google Scholar] [CrossRef]

- Diaz, L.A.; Clark, G.G.; Lister, T.E. Optimization of the Electrochemical Extraction and Recovery of Metals from Electronic Waste Using Response Surface Methodology. Ind. Eng. Chem. Res. 2017, 56, 7516–7524. [Google Scholar] [CrossRef]

- Barnwal, A.; Dhawan, N. Recycling of Discarded Mobile Printed Circuit Boards for Extraction of Gold and Copper. Sustain. Mater. Technol. 2020, 25, e00164. [Google Scholar] [CrossRef]

- Sharma, N.; Chauhan, G.; Kumar, A.; Sharma, S.K. Statistical Optimization of Heavy Metal (Cu2+ and Co2+) Extraction from Printed Circuit Boards and Mobile Batteries Using Chelation Technology. Ind. Eng. Chem. Res. 2017, 56, 6805–6819. [Google Scholar] [CrossRef]

- Alvarado, S. Long Term Energy-Related Environmental Issues of Copper Production. Energy 2002, 27, 183–196. [Google Scholar] [CrossRef]

- Xing, W.D.; Sohn, S.H.; Lee, M.S. A Review on the Recovery of Noble Metals from Anode Slimes. Miner. Process. Extr. Metall. Rev. 2020, 41, 130–143. [Google Scholar] [CrossRef]

- Biswas, B.K.; Inoue, K.; Ohto, K.; Harada, H.; Kawakita, H.; Hoshino, A. E-Waste Management through Silver Recovery from Scrap of Plasma TV Monitors. In Proceedings of the International Conference on Environmental Aspects of Bangladesh (ICEAB10), Tokyo, Japan, 4 September 2010; pp. 207–209. [Google Scholar]

- Wu, Z.; Yuan, W.; Li, J.; Wang, X.; Liu, L.; Wang, J. A Critical Review on the Recycling of Copper and Precious Metals from Waste Printed Circuit Boards Using Hydrometallurgy. Front. Environ. Sci. Eng. 2017, 11, 8. [Google Scholar] [CrossRef]

- Smallwood, J.; Robertson, C.; Ravindra, K.D.; Mukesh, C.L.; Moray, D.N. Recovery and Recycling of Paper; Thomas Telford Ltd.: London, UK, 2001; ISBN 978-0-7277-2993-4. [Google Scholar]

- Zhengzhou Shuguang Heavy Machinery Co. Shredder Quote. Available online: https://www.alibaba.com/product-detail/Shredder-pto-waste-e-waste-shredder_62459652025.html (accessed on 24 August 2021).

- Shangqiu Zhongming New Energy Technology Co. Pyrolizer Quote. Available online: https://www.alibaba.com/product-detail/Small-scale-pyrolyzer-with-CE-ISO_1600251089552.html?spm=a2700.galleryofferlist.normal_offer.d_image.33ff1458TyhbOH (accessed on 20 August 2021).

- Luoyang Zhongde Heavy Industries Co. Ball Grinding Mil Quote. Available online: https://www.alibaba.com/product-detail/Industrial-ball-mill-lab-ball-mill_62531081548.html?spm=a2700.details.0.0.1be75f39MJd5HN (accessed on 24 August 2021).

- Kinetic (Hubei) Energy Equipment Engineering Co. Plate Filter Quote. Available online: https://www.alibaba.com/product-detail/Filtro-Prensa-Recessed-Plate-Filter-Press_62582402569.html?spm=a2700.galleryofferlist.0.0.1cd750b9qsoAqB&s=p (accessed on 9 August 2021).

- Qijin Magnet Co. Electrostatic Separator Quote. Available online: https://www.alibaba.com/product-detail/Eccentic-Eddy-Current-Separator-Non-Ferrous_62510105383.html?spm=a2700.md_pt_PT.pronpeci14.2.72aa572aZgw09l (accessed on 19 August 2021).

- Qijin Magnet Co. Magnetic Separator Quote. Available online: https://portuguese.alibaba.com/product-detail/suspended-overband-magnetic-separator-for-conveyor-belt-1093017526.html?spm=a2700.galleryofferlist.0.0.486550fbmLTSLC&s=p (accessed on 19 August 2021).

- Hengshui Aoliande Trading Co. Electrowinning Cells Quote. Available online: https://www.alibaba.com/product-detail/Factory-Supply-Electrolysis-Cell-electrowinning-cells_62442019499.html?spm=a2700.galleryofferlist.normal_offer.d_image.4a796784HkjD75 (accessed on 2 August 2021).

- Alves, R.; Ferreira, K.L.A.; da Lima, R.S.; Moraes, F.T.F. An Action Research Study for Elaborating and Implementing an Electronic Waste Collection Program in Brazil. Syst. Pract. Action Res. 2021, 34, 91–108. [Google Scholar] [CrossRef]

| Fraction | Mass Fraction for Electronic Waste in General (Base Case A) | Reference | Mass Fraction for Cell Phones (Base Case B) | Reference |

|---|---|---|---|---|

| PCB | 0.045 | [14] | 0.25 | [29,30] |

| Polymer decomposed in pyrolysis | 0.238 | [31] | 0.13 | [22] |

| Condensable gases in pyrolysis | 0.76 | [31] | 0.76 | [31] |

| Non-magnetic | 0.9 | [21,27] | 0.9 | [21,27] |

| Au | 0.00025 | [11,16,32] | 0.000347 | [20,21] |

| Ag | 0.0003 | [16] | 0.00363 | [20,21] |

| Cu | 0.25 | [18,33] | 0.128 | [20,21] |

| Pd | 0.00014 | [1] | 0.00015 | [20,21] |

| Fiberglass | 0.3 | [18] | 0.24 | [22] |

| Inlet Fluid | Case A Flow (kg·h−1) | Case B Flow (kg·h−1) |

|---|---|---|

| WEEE | 2000 | 2000 |

| Water | 18.51 | 56.16 |

| Nitrogen | (only used for initial inertization, not accounted for) | (only used for initial inertization, not accounted for) |

| Outlet Fluid | Case A Flow (kg·h−1) | Case B Flow (kg·h−1) |

| Other components | 1910 | 1500 |

| Non-Condensable Gases | 5.1 | 15.6 |

| Oil | 16.3 | 49.4 |

| Water lost | 18.5 | 56.16 |

| Fiberglass and Others | 39.2 | 127.3 |

| Non-ferrous metals | 22.6 | 264.3 |

| Ferrous metals | 6.9 | 43.5 |

| Inlet Fluid | Case A Flow (kg·h−1) | Case B Flow (kg·h−1) |

|---|---|---|

| H2SO4 | 0.13 | 33.85 |

| Non-ferrous metals | 22.6 | 264.3 |

| Thiourea | 0.13 | 33.85 |

| Sodium Sulfide | 0.1 | 3.75 |

| HCl | 0.0675 | 2.082 |

| HNO3 | 0.02 | 0.69 |

| Sodium Metabisulphite | 0.17 | 5.28 |

| Outlet Fluid | Case A Flow (kg·h−1) | Case B Flow (kg·h−1) |

| Copper | 22.5 | 256 |

| Silver | 0.27 | 7.26 |

| Gold | 0.0225 | 0.694 |

| Palladium | 0.0126 | 0.30 |

| Process | Energy Consumption for Case A [MJ·h−1] | Energy Consumption for Case B [MJ·h−1] | Reference |

|---|---|---|---|

| Shredding | 12.3 | 68.5 | [21] |

| Pyrolysis | 1772.3 | 9846 | [46] |

| Milling | 324 | 324 | [51] |

| Magnetic separation | 504 | 504 | [53] |

| Electrostatic separation | 18 | 18 | [62] |

| Electrowinning | 225 | 2560 | [58] |

| Palladium recovery | 807.9 | 19,236 | [21] |

| Total | 3663.5 | 32,556.5 |

| Main Process Equipment | Quantity | Total Cost [USD] | Reference | |

|---|---|---|---|---|

| 1 | Shredder | 1 | 56,700 | [63] |

| 2 | Pyrolizer | 1 | 108,000 | [64] |

| 3 | Ball Mill | 1 | 56,700 | [65] |

| 4 | Plate filter press | 2 | 58,320 | [66] |

| 5 | Electrostatic separator | 1 | 40,500 | [67] |

| 6 | Magnetic separator | 1 | 13,500 | [68] |

| 7 | Electrowinning Cells | 3 | 81,000 | [69] |

| Total main equipment cost | 414,720 | |||

| Total main + Auxiliary Equipment (10% of the Total main) | 456,192 | |||

| Item | [USD] | ||

|---|---|---|---|

| A | Direct Costs | ||

| 1 | Main Equipment | 100% | 456,192.00 |

| 2 | Purchased-equipment installation | 38% | 173,352.96 |

| 3 | Instrumentation and controls (installed) | 13% | 59,304.96 |

| 4 | Piping (installed) | 29% | 132,295.68 |

| 5 | Electrical (installed) | 18% | 82,114.56 |

| 6 | Buildings (including services) | 35% | 159,667.20 |

| 7 | Yard improvements | 10% | 45,619.20 |

| 8 | Service facilities (installed) | 56% | 255,467.52 |

| 9 | Land (purchase is required) | 5% | 22,809.60 |

| B | Indirect Costs | ||

| 10 | Engineering and supervision | 40% | 182,476.80 |

| 11 | Construction expenses | 45% | 205,286.40 |

| 12 | Contractor’s fee | 9% | 41,057.28 |

| 13 | Contingency | 41% | 187,038.72 |

| Total (A + B) | 2,002,682.88 | ||

| Item | Case A | Case B | ||

|---|---|---|---|---|

| Variable Costs [USD] | ||||

| 1 | WEEE | 7,876,569.60 | ||

| 2 | Water | 319.80 | 970.44 | |

| 3 | H2SO4 | 21,755.03 | 5,849,684.85 | |

| 4 | Thiourea | 13,053.02 | 3,509,810.91 | |

| 5 | Sodium Sulfide | 1204.39 | 323,847.44 | |

| 6 | HCL | 5248.80 | 161,896.32 | |

| 7 | HNO3 | 1360.80 | 41,973.12 | |

| 8 | Sodium metabisulphite | 14,802.03 | 456,560.41 | |

| 9 | Energy | 866,507.54 | 8,204,237.98 | |

| C | Total | 8,800,821.00 | 26,425,551.06 | |

| Fixed Costs [USD] | ||||

| 10 | Telephone/Internet Service | 4800.00 | 4800.00 | |

| 11 | R&D a | 303,470.23 | 8,603,532.12 | |

| 12 | General costs | 24,000.00 | 24,000.00 | |

| 13 | Maintenance Service | 12,000.00 | 12,000.00 | |

| 14 | Accounting Service | 4800.00 | 4800.00 | |

| 15 | Contingencies | 54,919.88 | 1,375,203.50 | |

| D | Total | 418,884.27 | 10,378,958.55 | |

| Labor Cost b [USD] | ||||

| Function | Quantity | Value | ||

| 16 | Plant Manager | 1 | 51,840.00 | |

| 17 | Engineer | 4 | 167,616.00 | |

| 18 | Operator | 10 | 172,800.00 | |

| 19 | Assistants | 15 | 162,000.00 | |

| 20 | Administrative | 5 | 86,400.00 | |

| 21 | General Services | 5 | 32,400.00 | |

| 22 | Security | 10 | 108,000.00 | |

| E | Total | 781,056.00 | ||

| Total (C + D + E) | 10,000,761 | 37,585,455 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

d’Almeida, F.S.; de Carvalho, R.B.; dos Santos, F.S.; de Souza, R.F.M. Economic Analysis of a Conceptual Industrial Route for Printed Circuit Boards Processing Based on Mass and Energy Balances. World 2022, 3, 434-448. https://doi.org/10.3390/world3030023

d’Almeida FS, de Carvalho RB, dos Santos FS, de Souza RFM. Economic Analysis of a Conceptual Industrial Route for Printed Circuit Boards Processing Based on Mass and Energy Balances. World. 2022; 3(3):434-448. https://doi.org/10.3390/world3030023

Chicago/Turabian Styled’Almeida, Felipe Seabra, Roberto Bentes de Carvalho, Felipe Sombra dos Santos, and Rodrigo Fernandes Magalhães de Souza. 2022. "Economic Analysis of a Conceptual Industrial Route for Printed Circuit Boards Processing Based on Mass and Energy Balances" World 3, no. 3: 434-448. https://doi.org/10.3390/world3030023

APA Styled’Almeida, F. S., de Carvalho, R. B., dos Santos, F. S., & de Souza, R. F. M. (2022). Economic Analysis of a Conceptual Industrial Route for Printed Circuit Boards Processing Based on Mass and Energy Balances. World, 3(3), 434-448. https://doi.org/10.3390/world3030023