Concrete vs. Ceramic Blocks: Environmental Impact Evaluation Considering a Country-Level Approach

Abstract

:1. Introduction

1.1. Contextualization: Housing Landscape in Brazil

1.2. Construction Sector and Life Cycle Assessment (LCA)

1.3. Research Questions and Objectives of the Study

2. Methodological Overview

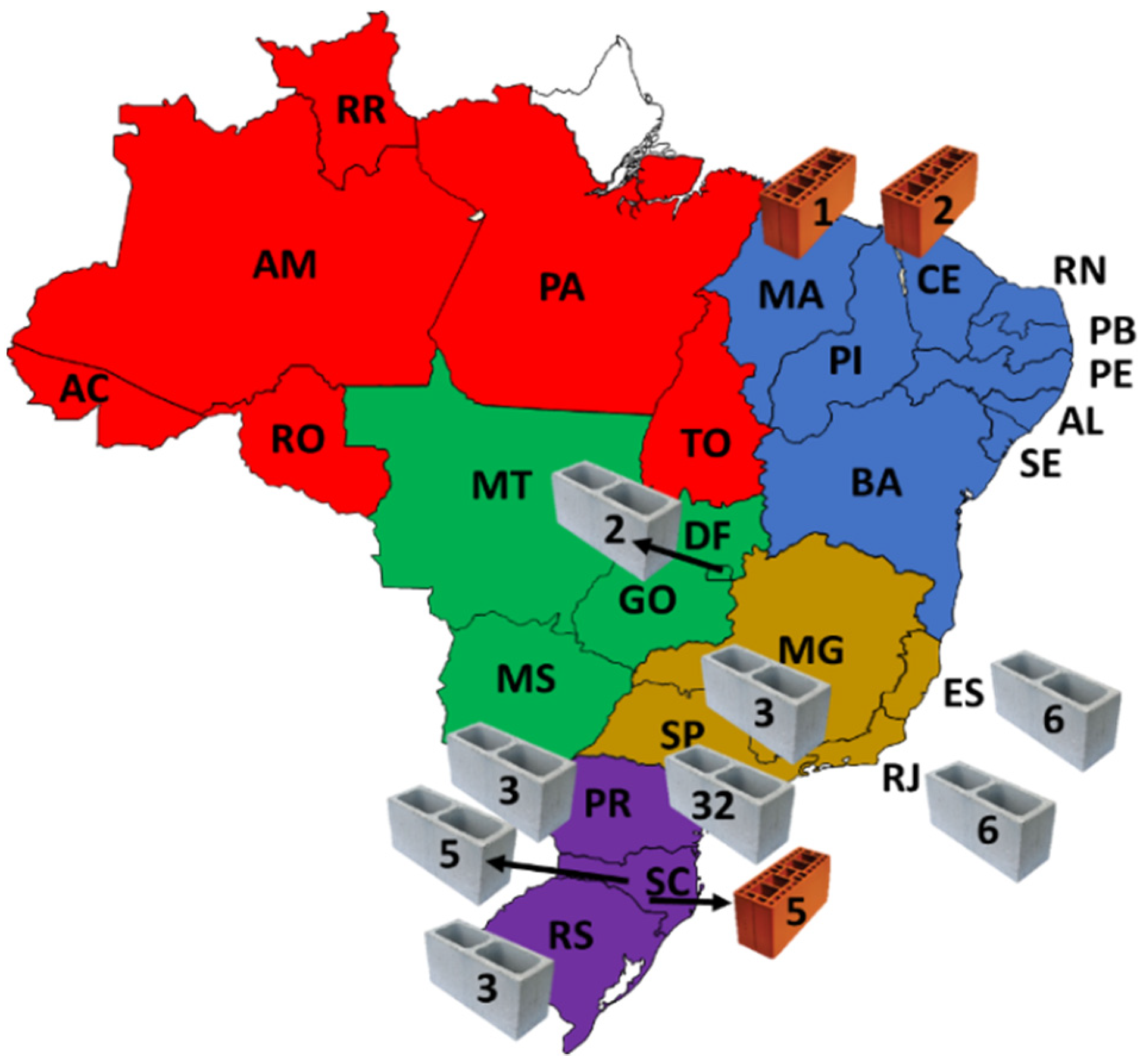

2.1. Block Specification, Factory, and Site Locations

- Northern region: Rio Branco—AC, Manaus—AM, Belém—PA, Porto Velho—RO, Boa Vista—RR;

- Northeastern region: Maceió—AL, Salvador—BA, Fortaleza—CE, São Luis—MA, João Pessoa—PB, Recife—PE; Teresina—PI, Natal—RN, Aracaju—SE;

- Central-western region: Brasília—DF, Goiânia—GO, Cuiabá—MT, Campo Grande MS;

- Southeastern region: Vitória—ES, Belo Horizonte—BH, São Paulo—SP, Rio de Janeiro—RJ;

- Southern region: Curitiba—PR, Porto Alegre—RS, Florianópolis—SC.

2.2. Life-Cycle Assessment (LCA)

2.2.1. Objective and Scope of the LCA and Functional Unit

2.2.2. Life Cycle Inventory (LCI)

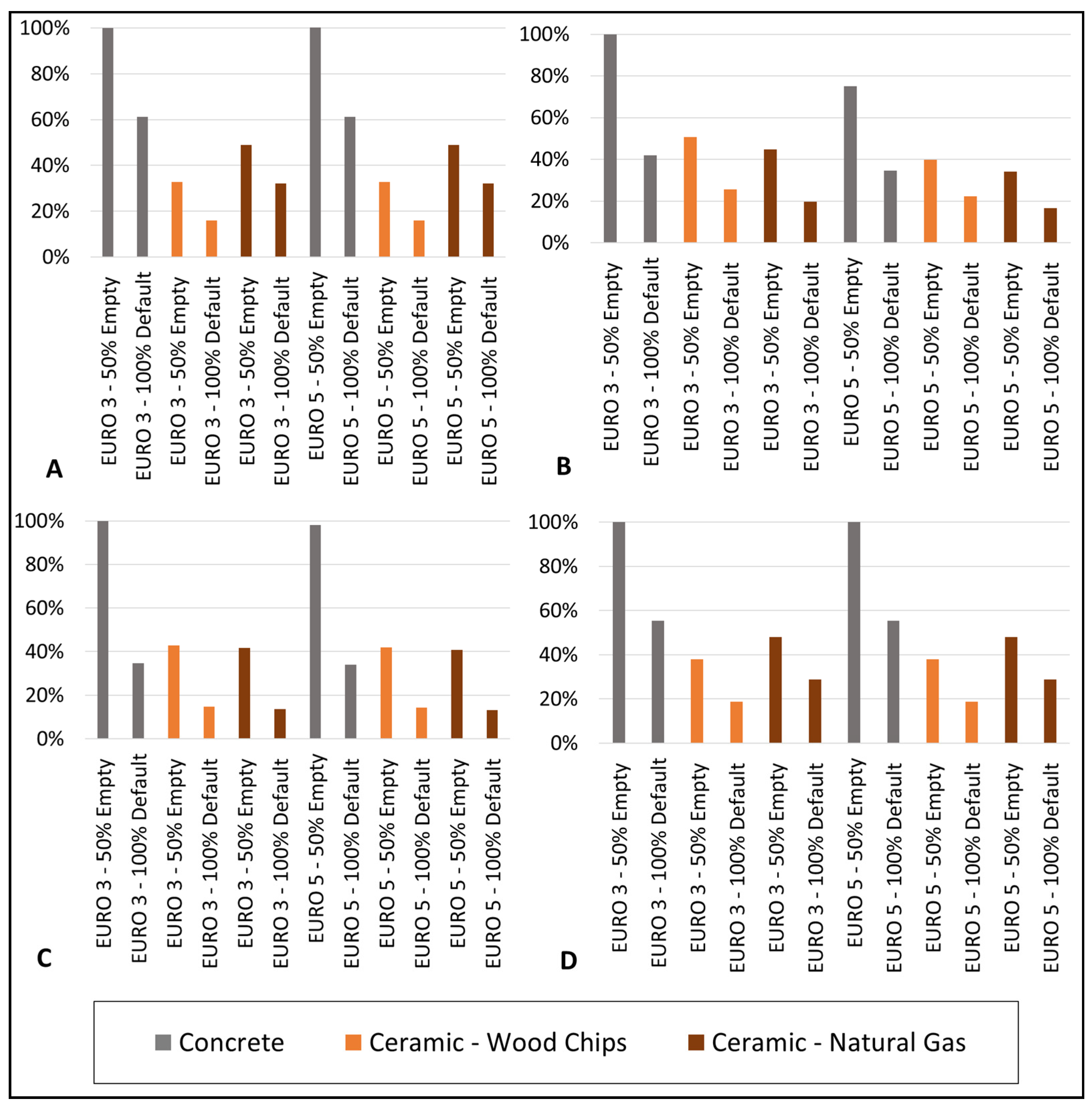

- Loaded 100%: 1 tkm Transport, truck 10–20 t, EURO3, 100%LF, default/GLO mass;

- Loaded 50% with empty return: 1 tkm Transport, truck 10–20 t, EURO3, 50%LF, empty return/GLO;

- Loaded 100%: 1 tkm Transport, truck 10–20 t, EURO5, 100%LF, default/GLO mass;

- Loaded 50% with empty return: 1 tkm Transport, truck 10–20 t, EURO5, 50%LF, empty return/GLO.

2.2.3. Life Cycle Impact Assessment (LCIA)

2.3. Brazilian Housing Deficit and Reduction of Climate Change Potential

3. Results

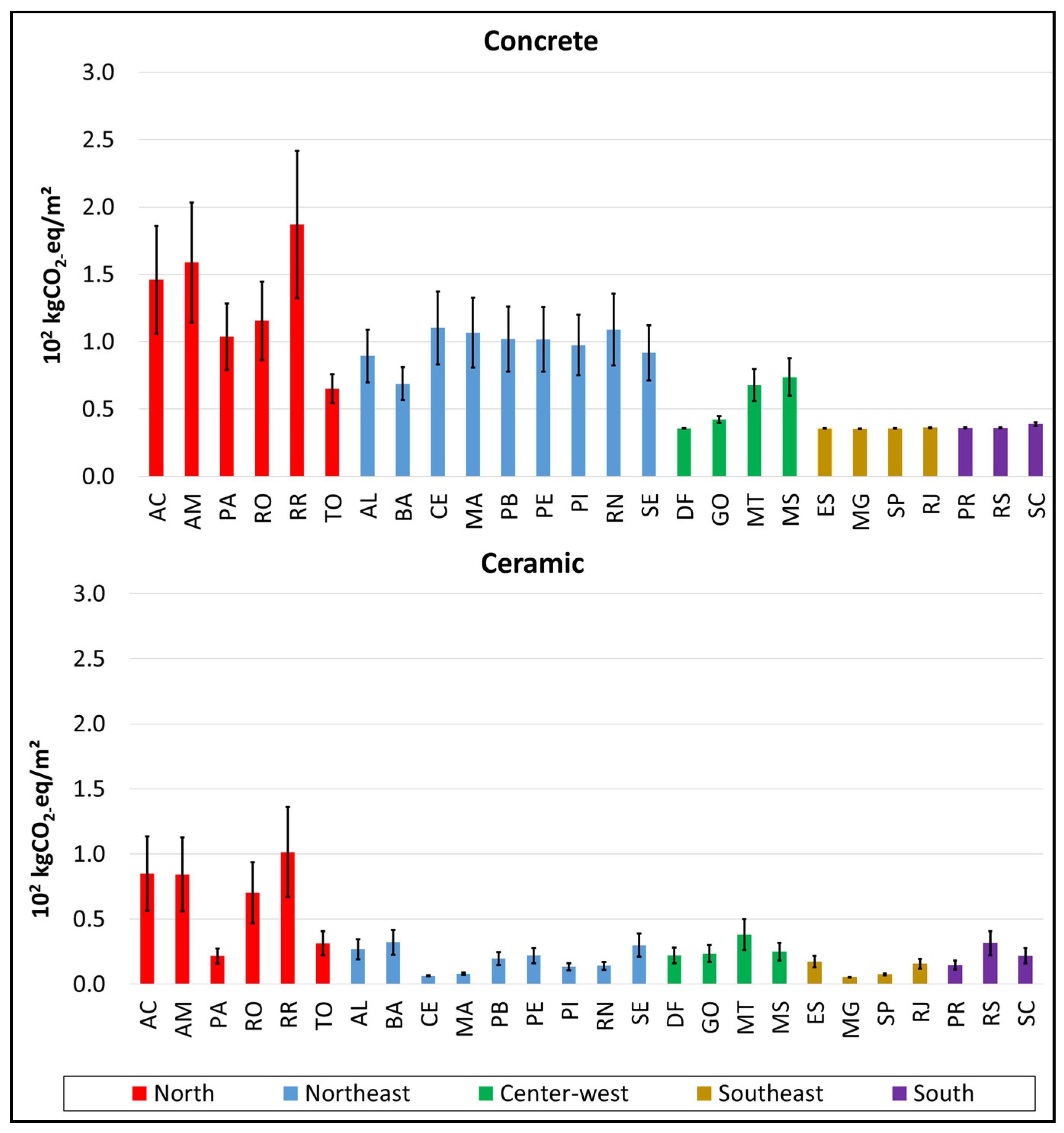

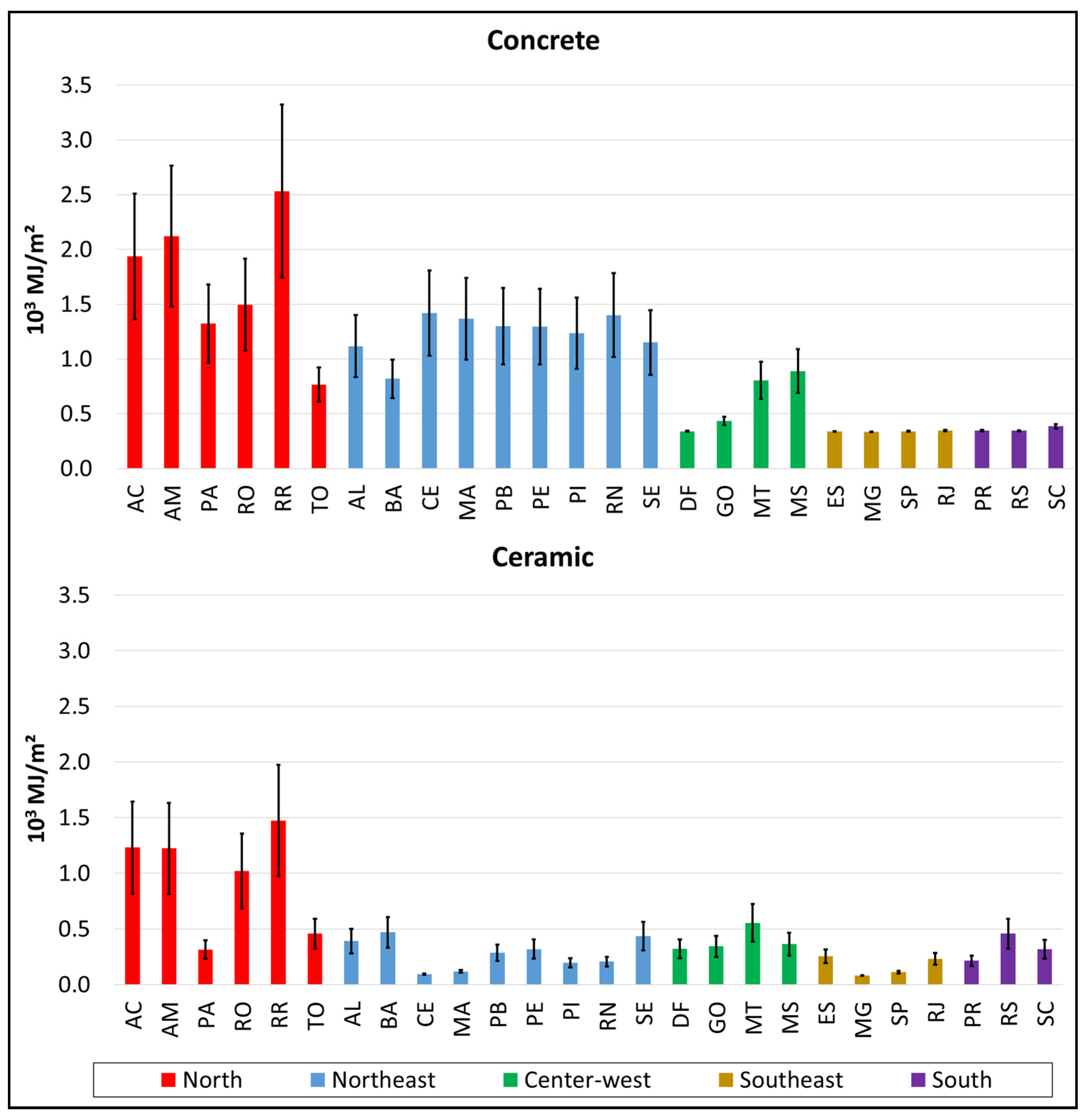

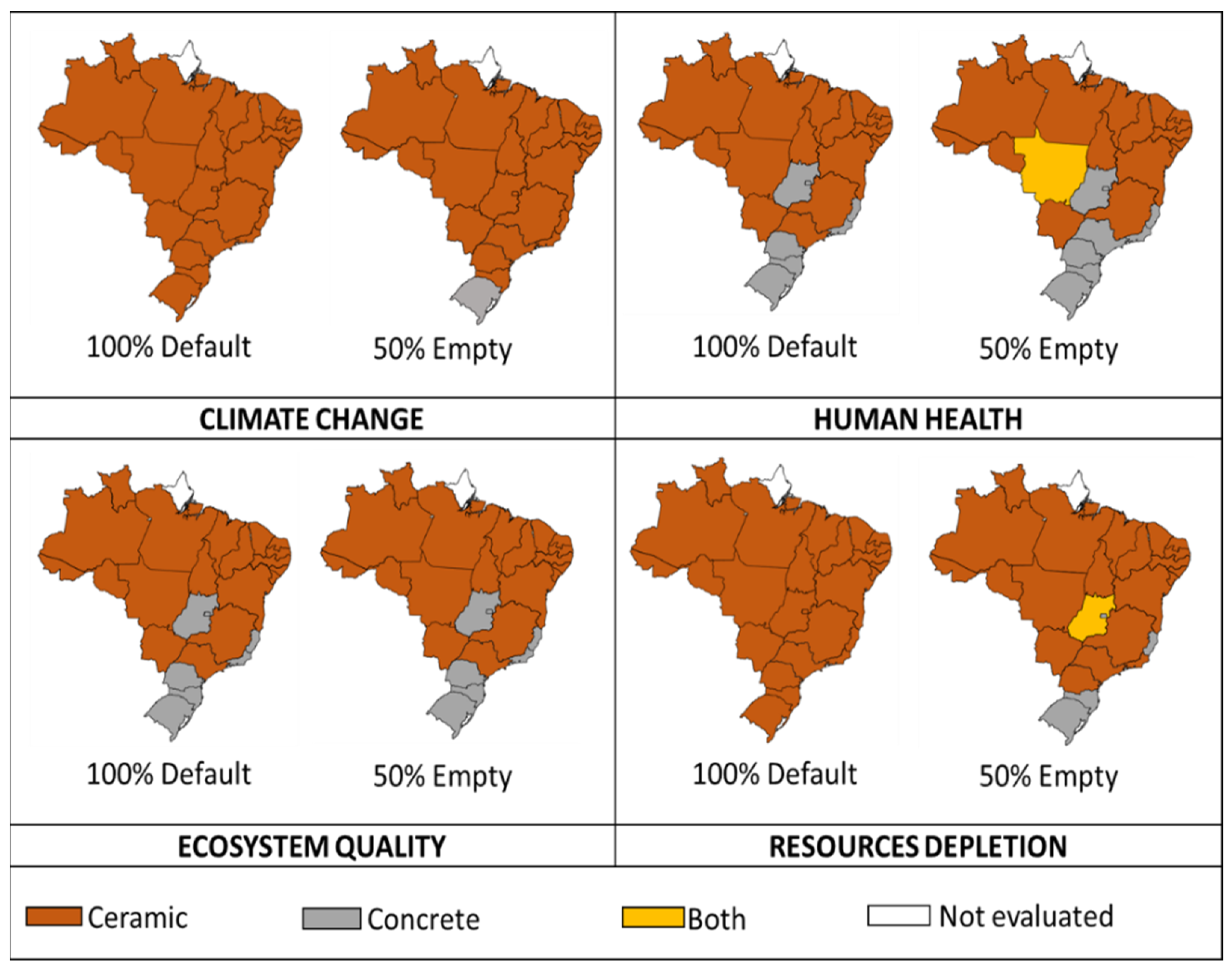

3.1. Concrete Blocks vs. Ceramic Blocks: Evaluation of Cradle-to-Site Impacts

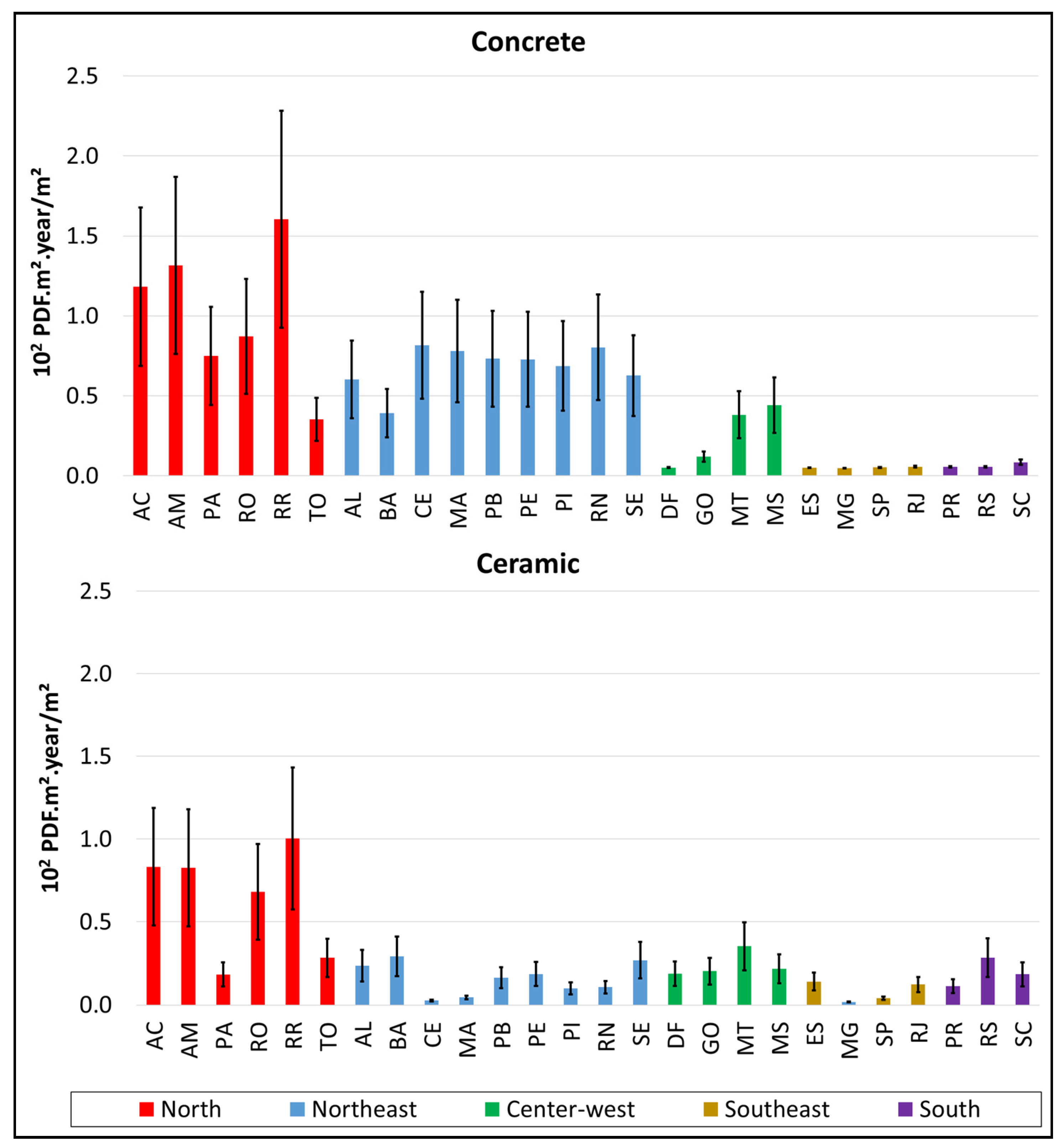

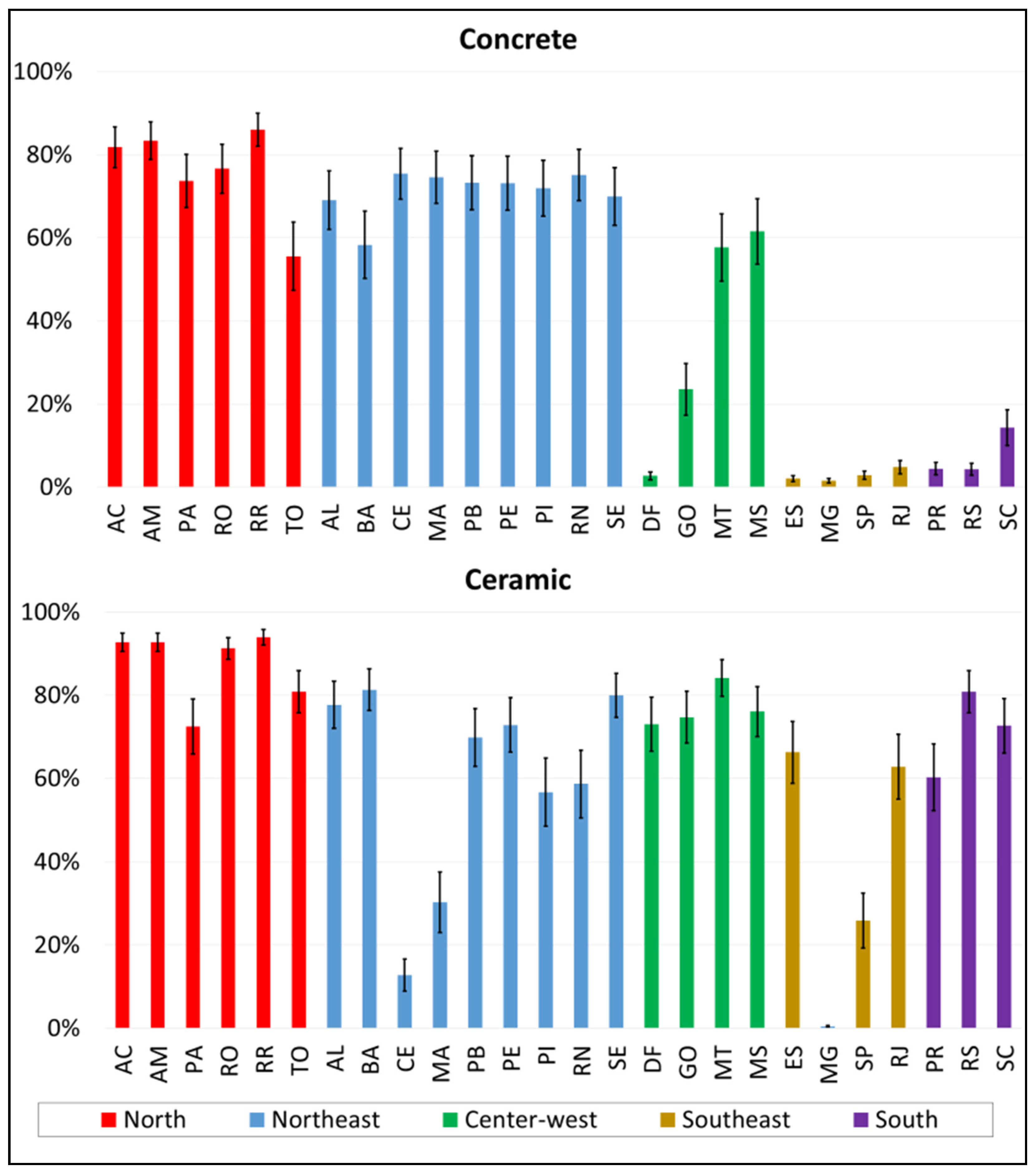

3.2. Contribution of the Transportation Stage in Relation to Total Impacts

3.3. Reduction of Climate Change Potential and Housing Deficit

4. Discussion

5. Conclusions

- Regarding this stage and its environmental impacts, the Northern and the Northeastern regions were the most affected, while the Southeastern region presented the lowest values.

- When the environmental impacts from cradle to site were evaluated, we concluded that ceramic blocks are the best option for most of the cases, especially when wood chips are used in the firing process. Therefore, their use for the mitigation of global warming and other environmental impacts should be encouraged.

- Another item evaluated in this research is the contribution of the transportation stage concerning the total environmental impacts. The Northern region presented the highest percentage (reaching 98% for the concrete block walls and 99% for the ceramic block walls for the Ecosystem Quality impact in the least efficient scenario), while the Southeastern region had the lowest percentage (less than 1% for both materials) for the most efficient scenario in terms of the Climate Change impact.

- We recommend that the building LCA standards should highlight the importance of the consideration of this phase in evaluations, especially in cases where certification schemes are required for building materials’ acquisition.

- We also observed that the transportation efficiency of building materials is more relevant in terms of environmental impact mitigation than emission standards.

- Considering the growth of the housing deficit by 2050, it is possible to avoid 154 to 229 Mt CO2-eq by changing from concrete to ceramic blocks and 57 to 132 Mt CO2-eq by improving the transportation efficiency at the building-stock level.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations. Sustainable Development Goals. Available online: http://www.un.org/sustainabledevelopment/sustainable-development-goals (accessed on 22 May 2021).

- UN Environment and International Energy Agency. Towards a Zero-Emission, Efficient, and Resilient Buildings and Construction Sector; UN Environment and International Energy Agency: Paris, France, 2017. [Google Scholar]

- BSI. ISO 14040—Environmental Management—Life Cycle Assessment—Principles and Framework; BSI: London, UK, 2006; Volume 3. [Google Scholar]

- Paulsen, J.S.; Sposto, R.M. A life cycle energy analysis of social housing in Brazil: Case study for the program “MY HOUSE MY LIFE”. Energy Build. 2013, 57, 95–102. [Google Scholar] [CrossRef]

- Pinheiro, F.J. Déficit Habitacional No Brasil|2013–2014; Fantastic Journeys Publishing: Belo Horizonte, Brazil, 2016. [Google Scholar]

- Vasquez, E.M.A. Analise de Conforto Ambiental em Projetos de Habitações de Interesse Social Segundo a NBR 15575:2013, PUC-RIO. Ph.D. Thesis, Universidade Católica do Rio de Janeiro, Rio de Janeiro, Brazil, 2017. [Google Scholar]

- das Cidades, M. Programas Setoriais da Qualidade (PSQs); Governo do Brasil: Brasília, Brazil, 2018.

- Chau, C.K.; Leung, T.M.; Ng, W.Y. A review on Life Cycle Assessment, Life Cycle Energy Assessment and Life Cycle Carbon Emissions Assessment on buildings. Appl. Energy 2015, 143, 395–413. [Google Scholar] [CrossRef]

- Bahramian, M.; Yetilmezsoy, K. Life cycle assessment of the building industry: An overview of two decades of research (1995–2018). Energy Build. 2020, 219, 109917. [Google Scholar] [CrossRef]

- Çankaya, S. Investigating the environmental impacts of alternative fuel usage in cement production: A life cycle approach. Environ. Dev. Sustain. 2019, 22, 7495–7514. [Google Scholar] [CrossRef]

- Vogtländer, J.; van der Lugt, P.; Brezet, H. The sustainability of bamboo products for local and Western European applications. LCAs and land-use. J. Clean. Prod. 2010, 18, 1260–1269. [Google Scholar] [CrossRef]

- Bribián, I.Z.; Capilla, A.V.; Usón, A.A. Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Bolin, C.A.; Smith, S.T. Life cycle assessment of borate-treated lumber with comparison to galvanized steel framing. J. Clean. Prod. 2011, 19, 630–639. [Google Scholar] [CrossRef]

- Cobut, A.; Blanchet, P.; Beauregard, R. The environmental footprint of interior wood doors in non-residential buildings e part 1: Life cycle assessment. J. Clean. Prod. 2015, 109, 232–246. [Google Scholar] [CrossRef] [Green Version]

- Christoforou, E.; Kylili, A.; Fokaides, P.A.; Ioannou, I. Cradle to site Life Cycle Assessment (LCA ) of adobe bricks. J. Clean. Prod. 2016, 112, 443–452. [Google Scholar] [CrossRef]

- Vieira, D.R.; Calmon, J.L.; Zulcão, R.; Coelho, F.Z. Consideration of strength and service life in cradle-to-gate life cycle assessment of self-compacting concrete in a maritime area: A study in the Brazilian context. Environ. Dev. Sustain. 2018, 20, 1849–1871. [Google Scholar] [CrossRef]

- Celik, K.; Meral, C.; Gursel, A.P.; Mehta, P.K.; Horvath, A.; Monteiro, P.J.M. Cement & Concrete Composites Mechanical properties, durability, and life-cycle assessment of self-consolidating concrete mixtures made with blended portland cements containing fly ash and limestone powder. Cem. Concr. Compos. 2015, 56, 59–72. [Google Scholar] [CrossRef] [Green Version]

- Gursel, A.P.; Maryman, H.; Ostertag, C. A life-cycle approach to environmental, mechanical, and durability properties of “green” concrete mixes with rice husk ash. J. Clean. Prod. 2016, 112, 823–836. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Sheehan, M.; Combe, M.; Collister, T. A life cycle assessment of recycled polypropylene fi bre in concrete footpaths. J. Clean. Prod. 2016, 112, 2231–2242. [Google Scholar] [CrossRef]

- Silvestre, D.; Kurda, R.; Brito, J.D. Influence of recycled aggregates and high contents of fl y ash on concrete fresh properties. Cem. Concr. Compos. 2019, 84, 198–213. [Google Scholar] [CrossRef]

- Serres, N.; Braymand, S.; Feugeas, F. Environmental evaluation of concrete made from recycled concrete aggregate implementing life cycle assessment. J. Build. Eng. 2016, 5, 24–33. [Google Scholar] [CrossRef]

- Blengini, G.A.; Garbarino, E.; Šolar, S.; Shields, D.J.; Hámor, T.; Vinai, R.; Agioutantis, Z. Life Cycle Assessment guidelines for the sustainable production and recycling of aggregates: The Sustainable Aggregates Resource Management project (SARMa). J. Clean. Prod. 2012, 27, 177–181. [Google Scholar] [CrossRef]

- Caldas, L.R.; Saraiva, A.B.; Lucena, A.F.P.; Da Gloria, M.Y.; Santos, A.S.; Filho, R.D.T. Building materials in a circular economy: The case of wood waste as CO2-sink in bio concrete. Resour. Conserv. Recycl. 2021, 166, 105346. [Google Scholar] [CrossRef]

- Utama, N.A.; Mclellan, B.C.; Gheewala, S.H.; Ishihara, K.N. Embodied impacts of traditional clay versus modern concrete houses in a tropical regime. Build. Environ. 2012, 57, 362–369. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Salzer, C.; Wallbaum, H.; Ostermeyer, Y.; Kono, J. Environmental performance of social housing in emerging economies: Life cycle assessment of conventional and alternative construction methods in the Philippines. Int. J. Life Cycle Assess. 2017, 22, 1785–1801. [Google Scholar] [CrossRef] [Green Version]

- Pittau, F.; Krause, F.; Lumia, G.; Habert, G. Fast-growing bio-based materials as an opportunity for storing carbon in exterior walls. Build. Environ. 2018, 129, 117–129. [Google Scholar] [CrossRef]

- Morales, M.; Moraga, G.; Kirchheim, A.P.; Passuello, A. Regionalized inventory data in LCA of public housing: A comparison between two conventional typologies in southern Brazil. J. Clean. Prod. 2019, 238, 117869. [Google Scholar] [CrossRef]

- Göswein, V.; Gonçalves, A.B.; Dinis, J.; Freire, F.; Habert, G.; Kurda, R. Resources, Conservation & Recycling Transportation matters—Does it? GIS-based comparative environmental assessment of concrete mixes with cement, fly ash, natural and recycled aggregates. Resour. Conserv. Recycl. 2018, 137, 1–10. [Google Scholar] [CrossRef]

- Condeixa, K.; Haddad, A.; Boer, D. Life Cycle Impact Assessment of masonry system as inner walls: A case study in Brazil. Constr. Build. Mater. 2014, 70, 141–147. [Google Scholar] [CrossRef]

- de Souza, D.M.; Lafontaine, M.; Charron-Doucet, F.; Bengoa, X.; Chappert, B.; Duarte, F.; Lima, L. Comparative Life Cycle Assessment of ceramic versus concrete roof tiles in the Brazilian context. J. Clean. Prod. 2015, 89, 165–173. [Google Scholar] [CrossRef]

- Souza, D.M.; Lafontaine, M.; Charron-doucet, F.; Chappert, B.; Kicak, K.; Duarte, F.; Lima, L. Comparative life cycle assessment of ceramic brick, concrete brick and cast-in-place reinforced concrete exterior walls. J. Clean. Prod. 2016, 137, 70–82. [Google Scholar] [CrossRef]

- Bueno, C.; Zwicky, M.; Roberto, A. Sensitivity analysis of the use of Life Cycle Impact Assessment methods: A case study on building materials. J. Clean. Prod. 2016, 112, 2208–2220. [Google Scholar] [CrossRef] [Green Version]

- Caldas, L.R.; Sposto, R.M. Emissões de CO2 referentes ao transporte de materiais de construção no Brasil: Estudo comparativo entre blocos estruturais cerâmicos e de concreto. Ambient. Construído 2017, 17, 91–108. [Google Scholar] [CrossRef] [Green Version]

- Bomberg, M.; Romanska-Zapala, A.; Yarbrough, D. Towards a New Paradigm for Building Science (Building Physics). World 2021, 2, 13. [Google Scholar] [CrossRef]

- Weißenberger, M.; Jensch, W.; Lang, W. The convergence of life cycle assessment and nearly zero-energy buildings: The case of Germany. Energy Build. 2014, 76, 551–557. [Google Scholar] [CrossRef] [Green Version]

- Caldas, L.R.; Saraiva, A.B.; Andreola, V.M.; Toledo Filho, R.D. Bamboo bio-concrete as an alternative for buildings’ climate change mitigation and adaptation. Constr. Build. Mater. 2020, 263, 120652. [Google Scholar] [CrossRef]

- Pini. TCPO 2014: Tabelas de Composições de Preços para Orçamentos, 14th ed.; Pini, Ed.; Pini: São Paulo, Brazil, 2012. [Google Scholar]

- Google Developers. Google Maps Documentation. Available online: https://developers.google.com/maps/documentation/ (accessed on 22 May 2021).

- CEN. EN 15978:2011—Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method; iTeh, Inc.: Newark, DE, USA, 2011. [Google Scholar]

- Anderson, J.; Moncaster, A. Embodied carbon of concrete in buildings, Part 1: Analysis of published EPD. Build. Cities 2020, 1, 198–217. [Google Scholar] [CrossRef]

- Dong, Y.; Ng, S.T.; Liu, P. A comprehensive analysis towards benchmarking of life cycle assessment of buildings based on systematic review. Build. Environ. 2021, 204, 108162. [Google Scholar] [CrossRef]

- Empresa de Pesquisa Energética. Brasil Balanço Energético Nacional; Empresa de Pesquisa Energética: Brasília, Brazil, 2018. [Google Scholar]

- Caldas, L.R.; Lira, J.S.d.M.; Sposto, R.M. Avaliação do Ciclo de Vida de habitações de alvenaria estrutural de blocos cerâmicos e painéis pré-moldados de concreto considerando diferentes zonas bioclimáticas. R. Latino-Amer. Aval. Ciclo Vida 2017, 1, 138–167. [Google Scholar] [CrossRef]

- Ministério das Cidades. Demanda Futura por Moradias: Demografia, Habitação e Mercado; UFF: Niterói, Brazil, 2018. [Google Scholar]

- ABNT. NBR 12721—Avaliação de Custos Unitários de Construção Para Incorporação Imobiliária e Outras Disposições Para Condomínios Edifícios—Procedimento; ABNT: Rio de Janeiro, Brazil, 2006. [Google Scholar]

- ABNT. NBR 15575. Edificações Habitacionais—Desempenho; ABNT: Rio de Janeiro, Brazil, 2013. [Google Scholar]

- CBCS. Projeto Avaliação de Ciclo de Vida Modular de Blocos e Pisos de Concreto; CBCS: São Paulo, Brazil, 2014. [Google Scholar]

- ANICER. Dados Oficiais. Associaçao Nacional da Indústria Ceramica; ANICER: Rio de Janeiro, Brazil, 2011; Document in Portuguese; p. 52. Available online: https://www.anicer.com.br/wp-content/uploads/2016/11/relatorio_2011.pdf (accessed on 22 May 2021).

- Barbosa, N.; Monteiro, R.; Neto, M.; Aparecida, E. Environmental assessment in concrete industries. J. Clean. Prod. 2021, 327, 129516. [Google Scholar] [CrossRef]

- Mahecha, R.E.G.; Caldas, L.R.; Garaffa, R.; Lucena, A.F.P.; Szklo, A.; Toledo Filho, R.D. Constructive systems for social housing deployment in developing countries: A case study using dynamic life cycle carbon assessment and cost analysis in Brazil. Energy Build. 2020, 227, 110395. [Google Scholar] [CrossRef]

- Loiseau, E.; Aissani, L.; Le Feon, S.; Laurent, F.; Cerceau, J.; Sala, S.; Roux, P. Territorial Life Cycle Assessment (LCA): What exactly is it about? A proposal towards using a common terminology and a research agenda. J. Clean. Prod. 2018, 176, 474–485. [Google Scholar] [CrossRef] [Green Version]

| Material Properties | Concrete Block | Ceramic Block |

|---|---|---|

| Dimensions (cm) | 14 × 19 × 39 | 14 × 19 × 39 |

| Blocks/m² | 12.5 [38] | 12.5 [38] |

| kg/block | 11.8 [38] | 6.9 [38] |

| Waste generated in construction 1 | 3% [38] | 5% [38] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caldas, L.R.; Pittau, F.; Schaeffer, R.; Saraiva, A.K.E.B.; Paiva, R.d.L.M.; Toledo Filho, R.D. Concrete vs. Ceramic Blocks: Environmental Impact Evaluation Considering a Country-Level Approach. World 2021, 2, 482-504. https://doi.org/10.3390/world2040030

Caldas LR, Pittau F, Schaeffer R, Saraiva AKEB, Paiva RdLM, Toledo Filho RD. Concrete vs. Ceramic Blocks: Environmental Impact Evaluation Considering a Country-Level Approach. World. 2021; 2(4):482-504. https://doi.org/10.3390/world2040030

Chicago/Turabian StyleCaldas, Lucas R., Francesco Pittau, Roberto Schaeffer, Anna K. E. B. Saraiva, Rayane de L. M. Paiva, and Romildo D. Toledo Filho. 2021. "Concrete vs. Ceramic Blocks: Environmental Impact Evaluation Considering a Country-Level Approach" World 2, no. 4: 482-504. https://doi.org/10.3390/world2040030

APA StyleCaldas, L. R., Pittau, F., Schaeffer, R., Saraiva, A. K. E. B., Paiva, R. d. L. M., & Toledo Filho, R. D. (2021). Concrete vs. Ceramic Blocks: Environmental Impact Evaluation Considering a Country-Level Approach. World, 2(4), 482-504. https://doi.org/10.3390/world2040030