On the Construction of Freeform Volumetric 3D Puzzles

Abstract

1. Introduction

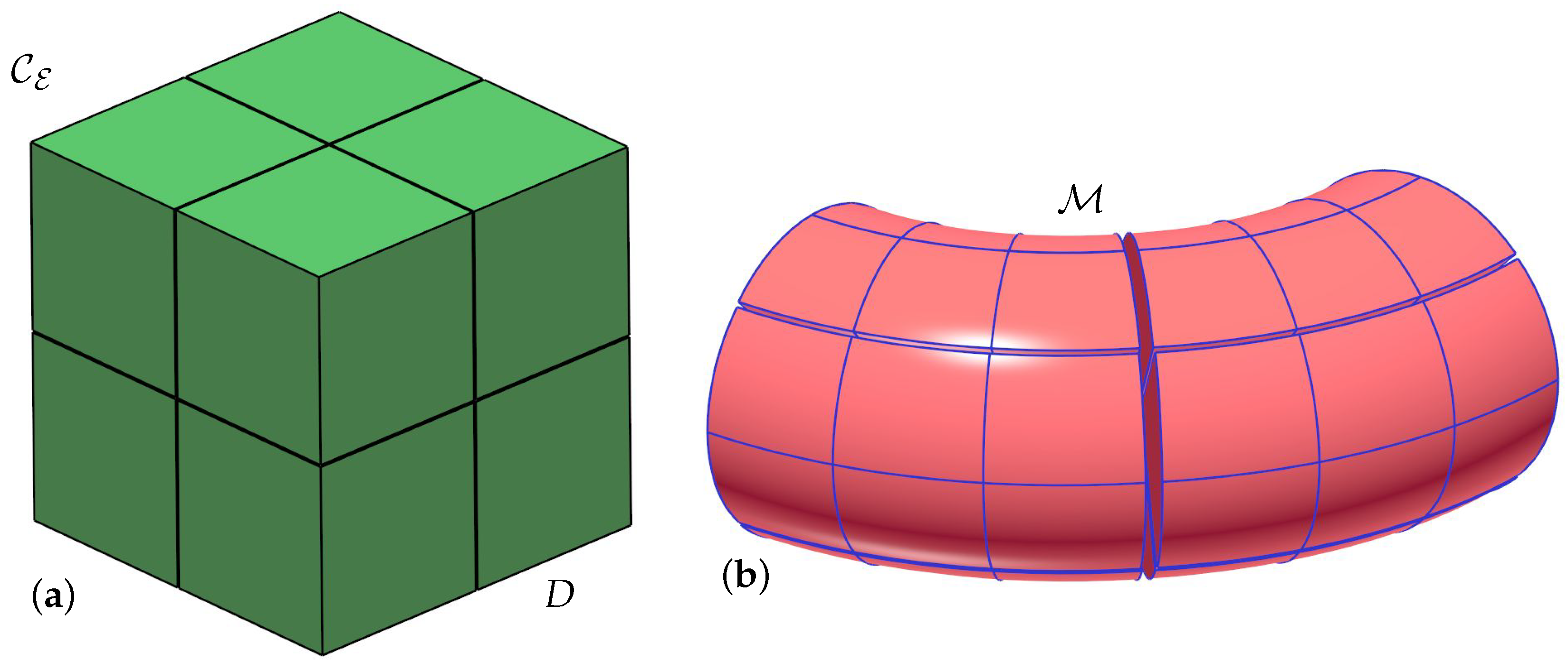

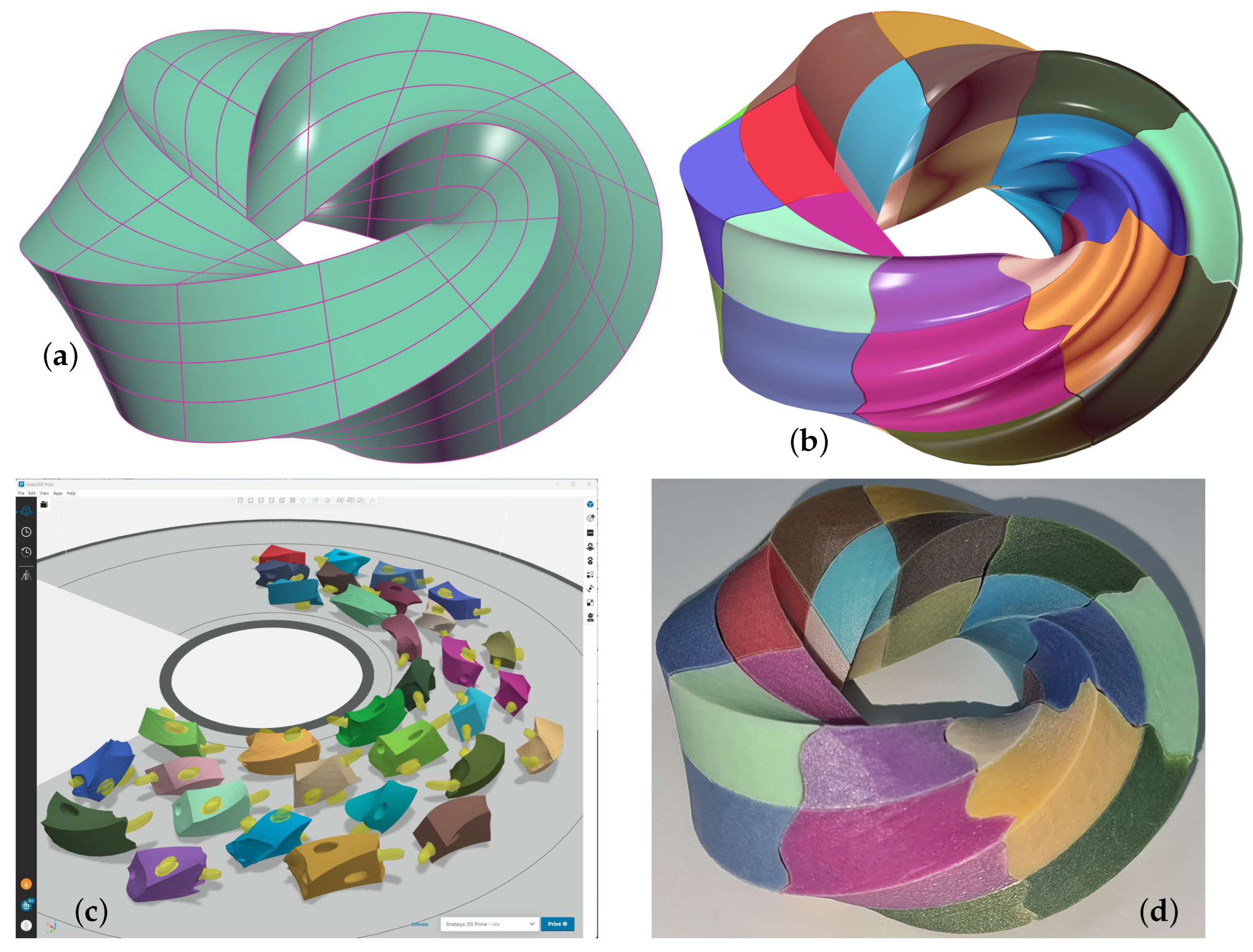

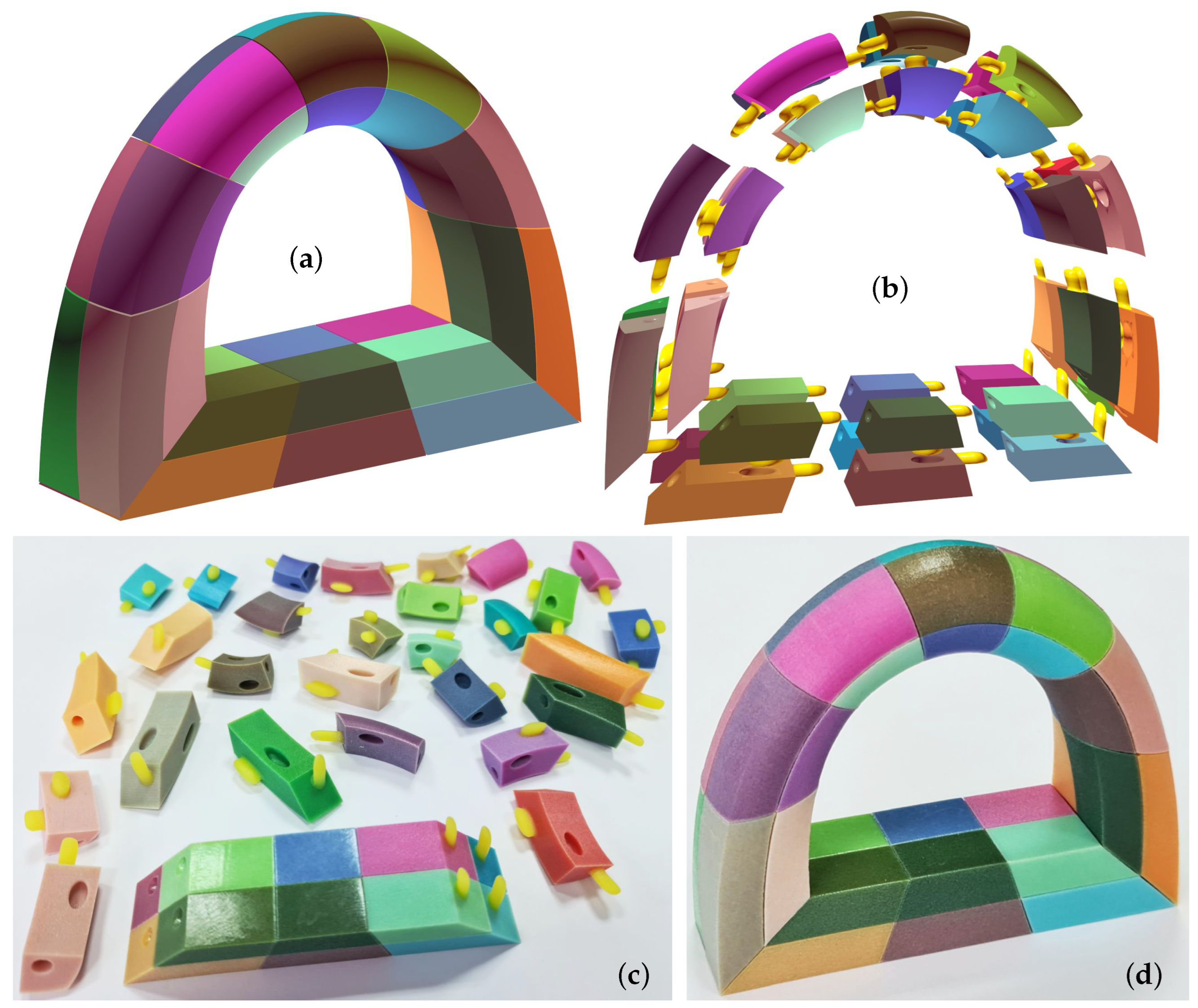

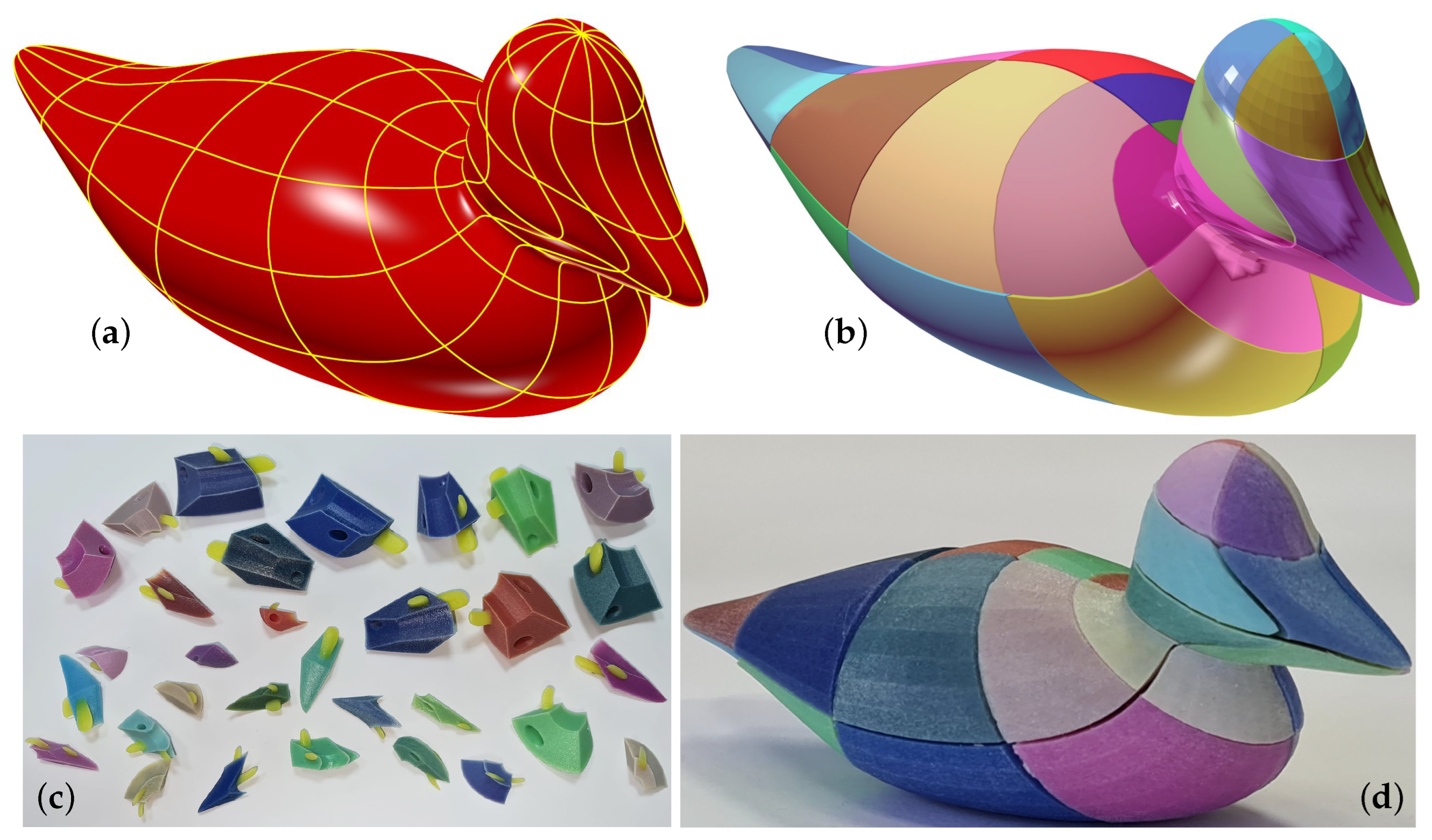

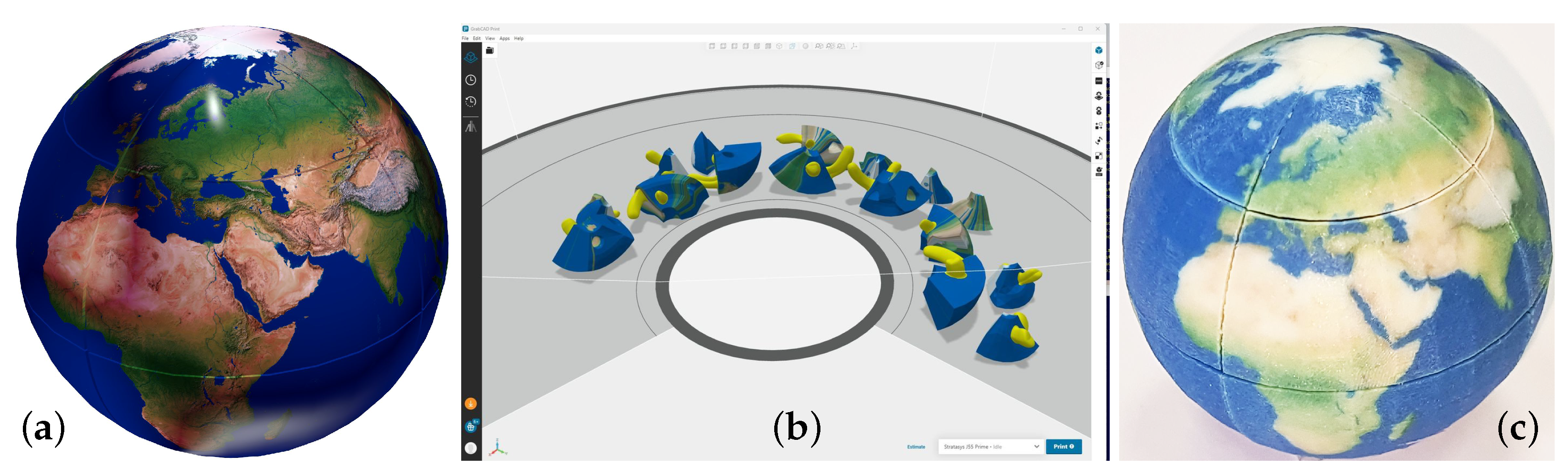

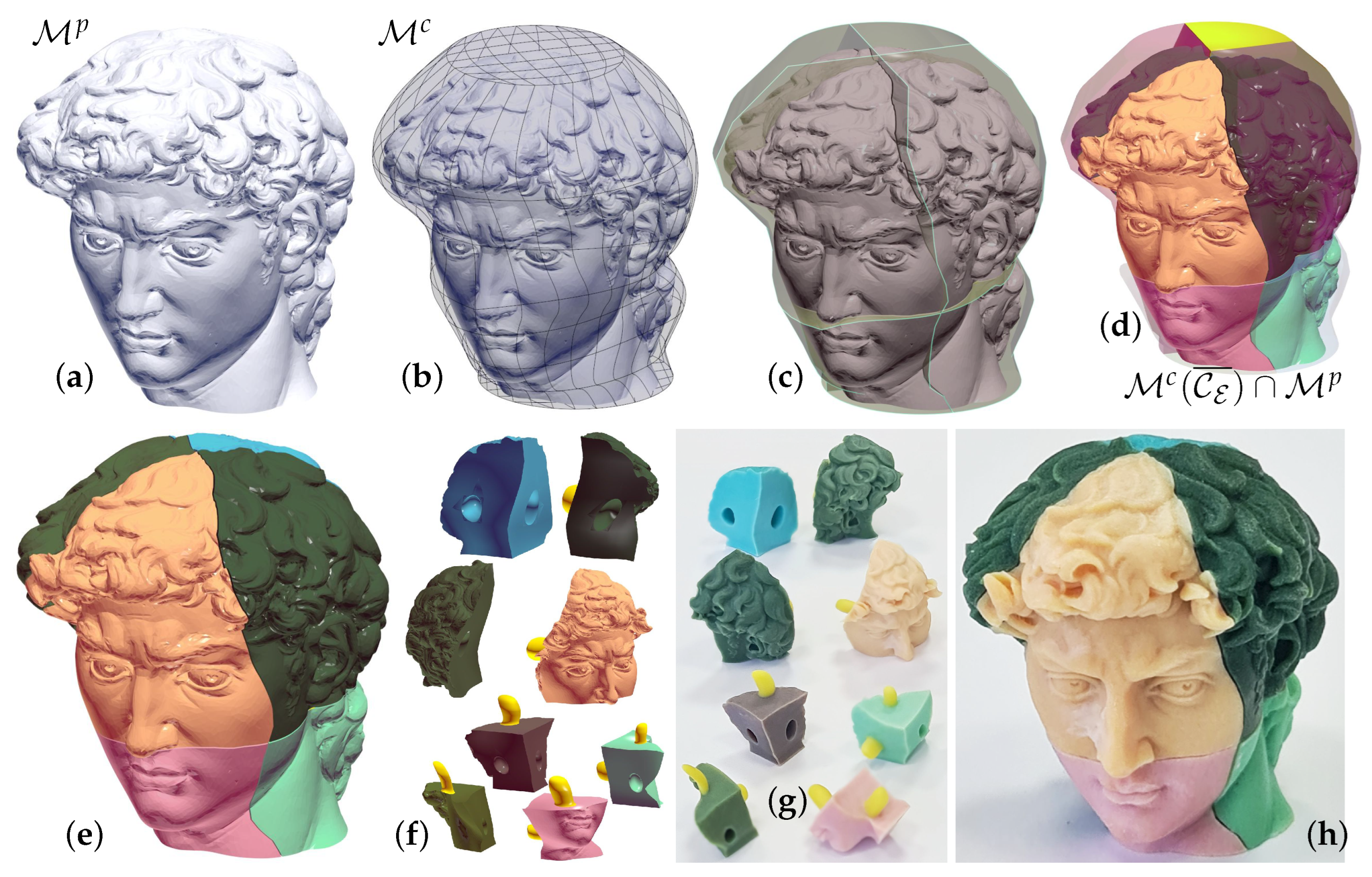

- A general algorithm is proposed for the synthesis of a 3D volumetric freeform puzzle for a geometric V-rep (and also B-rep surface/polygonal models as will be shown) CAD model, .

- The puzzle elements can be of any shape as long as the mutually exclusive tiling with these elements resides in, and possibly covers, the domain of .

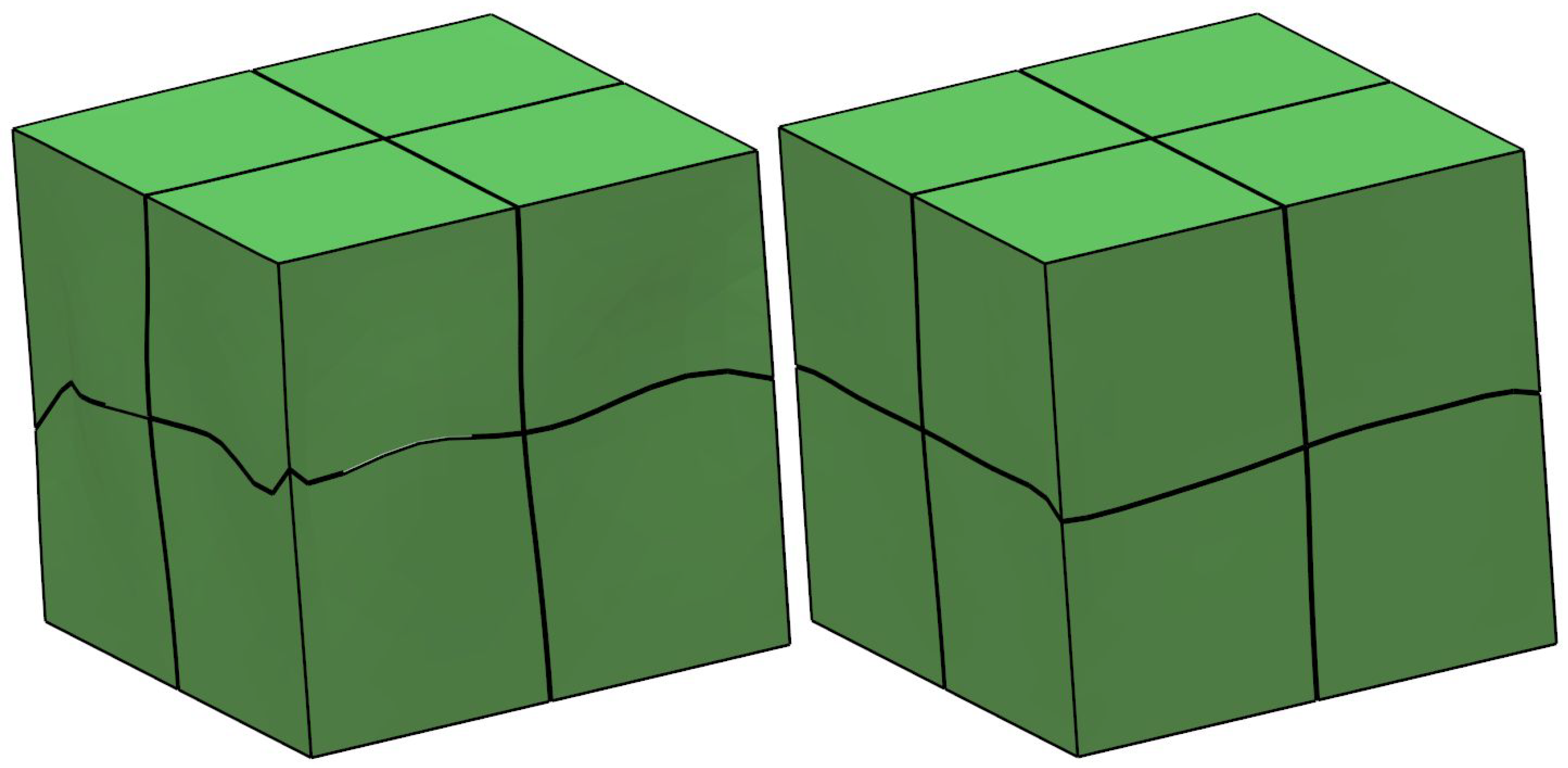

- -discontinuities in are possible and supported.

- The number of puzzle elements is arbitrary, and each element can be of an arbitrary shape, while preserving the continuity with its neighboring elements.

- Texture maps can be applied to the puzzle elements to reconstruct a desired image on the surfaces of when realized as a 3D puzzle.

2. Previous Work

3. Algorithm

3.1. Building the Puzzle’s Topology

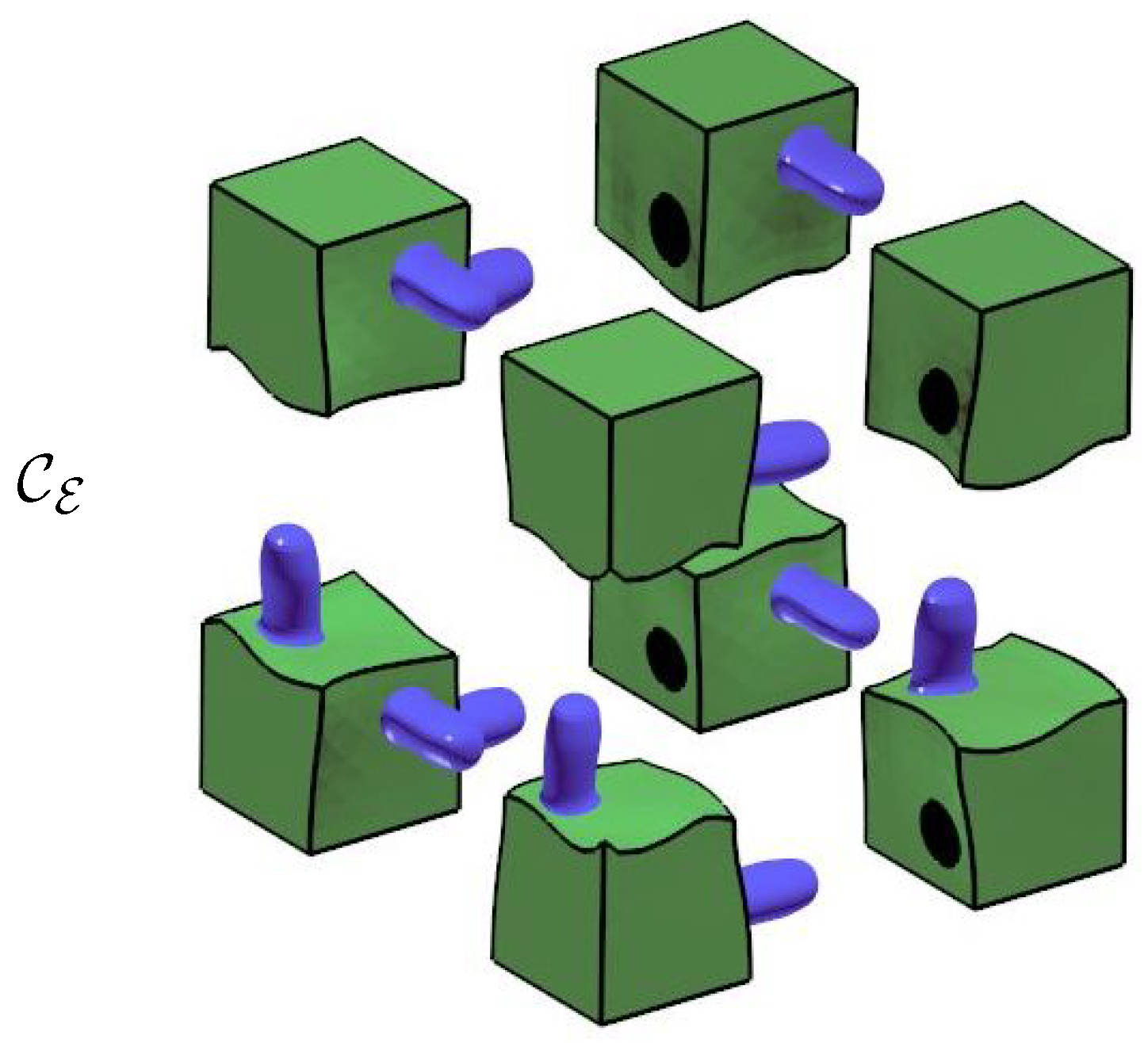

3.2. Building the Joints

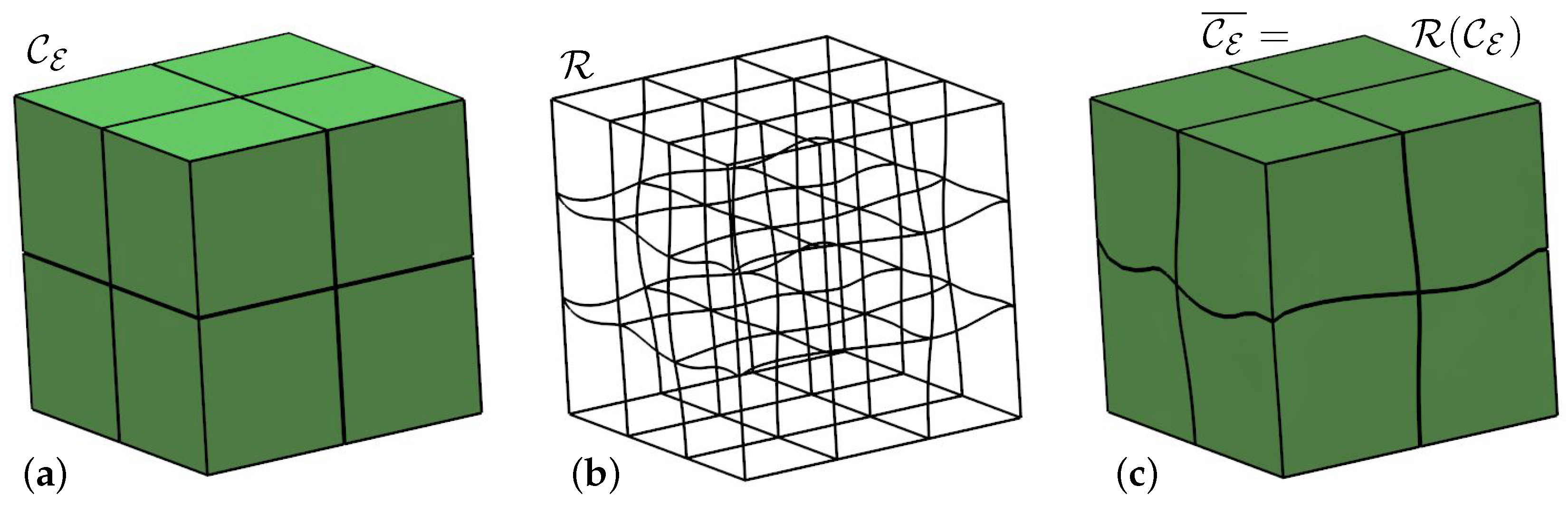

3.3. Randomizing the Shapes of the Puzzle Elements

- All internal control points ;

- All face-internal control points, in the faces’ planes.

3.4. Mapping to a Freeform 3D Puzzle

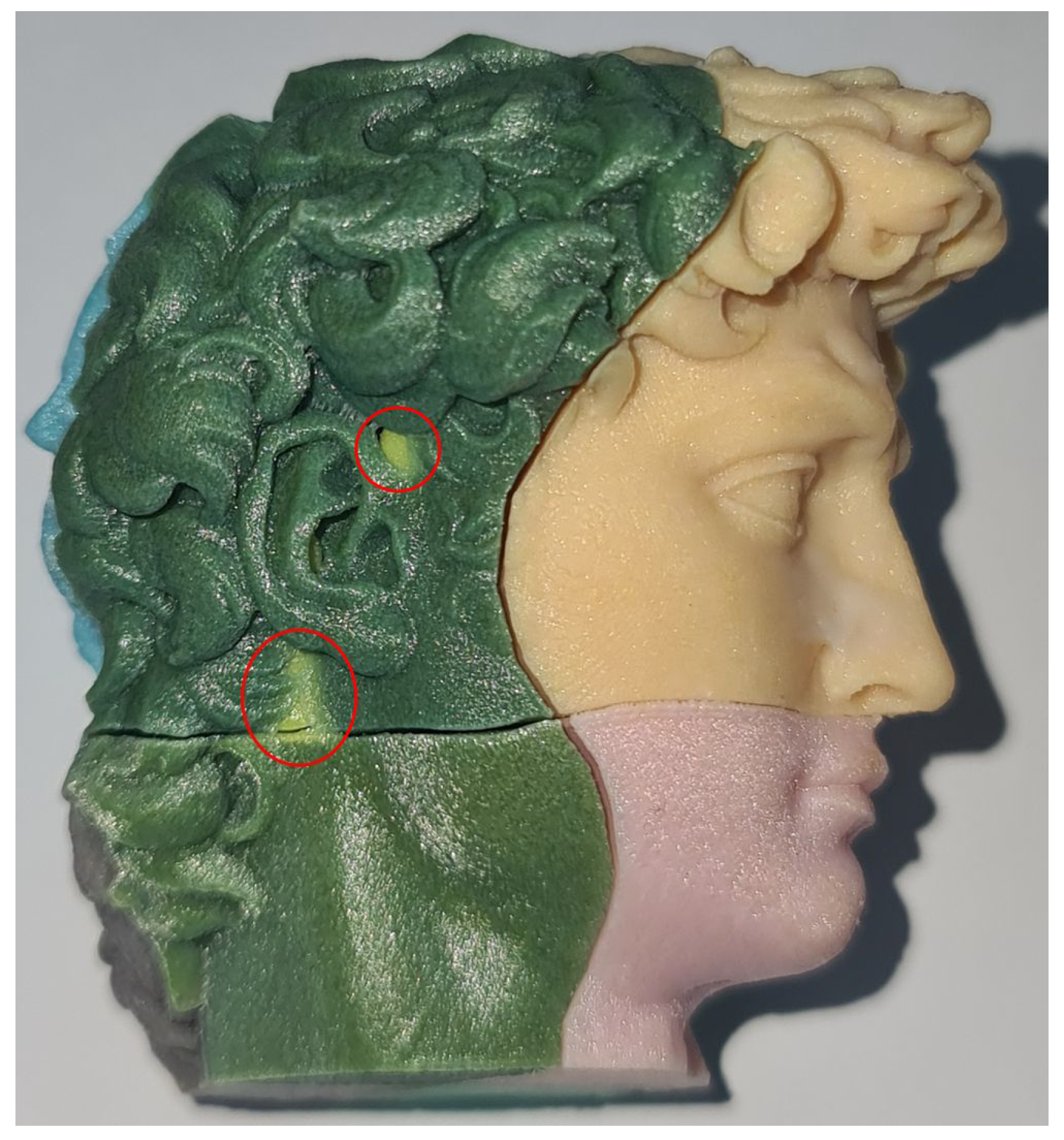

4. Results

5. Extending Algorithms Toward Polygonal Input Models

6. Conclusions and Future Work

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Coffin, S. Geometric Puzzle Design; A.K. Peters: Wellesley, MA, USA, 2006. [Google Scholar]

- Pillai, J.A.; Hall, C.B.; Dickson, D.W.; Buschke, H.; Lipton, R.B.; Verghese, J. Association of crossword puzzle participation with memory decline in persons who develop dementia. J. Int. Neuropsychol. Soc. 2011, 17, 1006–1013. [Google Scholar] [CrossRef] [PubMed]

- Cohen, E.; Riesenfeld, R.F.; Elber, G. Geometric Modeling with Splines; A.K. Peters: New York, NY, USA, 2001. [Google Scholar]

- Farin, G. Curves and Surfaces for CAGD: A Practical Guide; Morgan Kaufmann: San Francisco, CA, USA, 2002. [Google Scholar]

- Hoschek, J.; Lasser, D. Fundamentals of Computer Aided Geometric Design; A.K. Peters: Wellesley, MA, USA, 1993. [Google Scholar]

- Elber, G. A review of a b-spline based volumetric representation: Design, analysis and fabrication of porous and/or heterogeneous geometries. Comput.-Aided Des. 2023, 163, 103587. [Google Scholar] [CrossRef]

- Kita, N.; Miyata, K. Computational design of polyomino puzzles. Vis. Comput. 2021, 37, 777–787. [Google Scholar] [CrossRef]

- Lo, K.; Fu, C.; Li, H. 3D polyomino puzzle. ACM Trans. Graph. 2009, 28, 1–8. [Google Scholar] [CrossRef]

- Golomb, S. Polyominoes: Puzzles, Patterns, Problems, and Packings, 2nd ed.; Princeton University Press: Princeton, NJ, USA, 1994. [Google Scholar]

- Zhang, X.; Kry, P.; Vouga, E. On Understanding Disentanglement Puzzles. In Proceedings of the Bridges 2023 Conference, Halifax, NS, Canada, 27–31 July 2023. [Google Scholar]

- Bickel, B.; Cignoni, P.; Malomo, L.; Pietroni, N. State of the art on stylized fabrication. Comput. Graph. Forum 2018, 37, 325–342. [Google Scholar] [CrossRef]

- Séquin, C. Prototyping dissection puzzles with layered manufacturing. In Proceedings of the Fabrication and Sculpture Track, Shape Modeling International, College Station, TX, USA, 22–25 May 2012. [Google Scholar]

- Chen, R.; Wang, Z.; Song, P.; Bickel, B. Computational design of high-level interlocking puzzles. ACM Trans. Graph. 2022, 41, 1–15. [Google Scholar] [CrossRef]

- Kita, N.; Saito, T. Computational design of generalized centrifugal puzzles. Comput. Graph. 2020, 90, 21–28. [Google Scholar] [CrossRef]

- Song, P.; Fu, C.; Cohen-Or, D. Recursive interlocking puzzles. ACM Trans. Graph. 2012, 31, 1–10. [Google Scholar] [CrossRef]

- Song, P.; Fu, Z.; Liu, L.; Fu, C. Printing 3D objects with interlocking parts. Comput. Aided Geom. Des. 2015, 35, 137–148. [Google Scholar] [CrossRef]

- Tang, K.; Song, P.; Wang, X.; Deng, B.; Fu, C.; Liu, L. Computational design of steady 3D dissection puzzles. Comput. Graph. Forum 2019, 38, 291–303. [Google Scholar] [CrossRef]

- Yuan, Y.; Zheng, C.; Coros, S. Making burr puzzles from 3D models. ACM Trans. Graph. 2011, 30, 1–8. [Google Scholar] [CrossRef]

- Sun, T.; Zheng, C. Computational design of twisty joints and puzzles. ACM Trans. Graph. 2015, 34, 1–11. [Google Scholar] [CrossRef]

- Yuan, Y.; Zheng, C.; Coros, S. Computational design of transformables. Comput. Graph. Forum 2018, 37, 103–113. [Google Scholar] [CrossRef]

- Zhou, Y.; Sueda, S.; Matusik, W.; Shamir, A. Boxelization: Folding 3D objects into boxes. ACM Trans. Graph. 2014, 37, 1–8. [Google Scholar] [CrossRef]

- Ebert, M.; Akleman, E.; Krishnamurthy, V.; Kulagin, R.; Estrin, Y. VoroNoodles: Topological Interlocking with Helical Layered 2-Honeycombs. Adv. Eng. Mater. 2024, 26, 2300831. [Google Scholar] [CrossRef]

- Elber, G.; Kim, M.S. Synthesis of 3D Jigsaw Puzzles over Freeform 2-Manifolds. Comput. Graph. 2021, 102, 339–348. [Google Scholar] [CrossRef]

- Sederberg, T.W.; Parry, S.R. Free-form deformation of solid geometric models. SIGGRAPH Comput. Graph. 1986, 20, 151–160. [Google Scholar] [CrossRef]

- Elber, G.; Cohen, E. Second Order Surface Analysis Using Hybrid Symbolic and Numeric Operators. j-tog 1993, 12, 160–178. [Google Scholar] [CrossRef]

- Ströter, D.; Thiery, J.M.; Hormann, K.; Chen, J.; Chang, Q.; Besler, S.; Mueller-Roemer, J.S.; Boubekeur, T.; Stork, A.; Fellner, D.W. A Survey on Cage-based Deformation of 3D Models. Comput. Graph. Forum 2024, 43, e15060. [Google Scholar] [CrossRef]

- Shpitalni, M.; Elber, G.; Lenz, E. Automatic Assembly of Three Dimensional Structures via Connectivity Graphs. Ann. CIRP 1988, 38, 25–28. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elber, G. On the Construction of Freeform Volumetric 3D Puzzles. Modelling 2025, 6, 90. https://doi.org/10.3390/modelling6030090

Elber G. On the Construction of Freeform Volumetric 3D Puzzles. Modelling. 2025; 6(3):90. https://doi.org/10.3390/modelling6030090

Chicago/Turabian StyleElber, Gershon. 2025. "On the Construction of Freeform Volumetric 3D Puzzles" Modelling 6, no. 3: 90. https://doi.org/10.3390/modelling6030090

APA StyleElber, G. (2025). On the Construction of Freeform Volumetric 3D Puzzles. Modelling, 6(3), 90. https://doi.org/10.3390/modelling6030090