Finite Element-Based Multi-Objective Optimization of a New Inclined Oval Rolling Pass Geometry

Abstract

1. Introduction

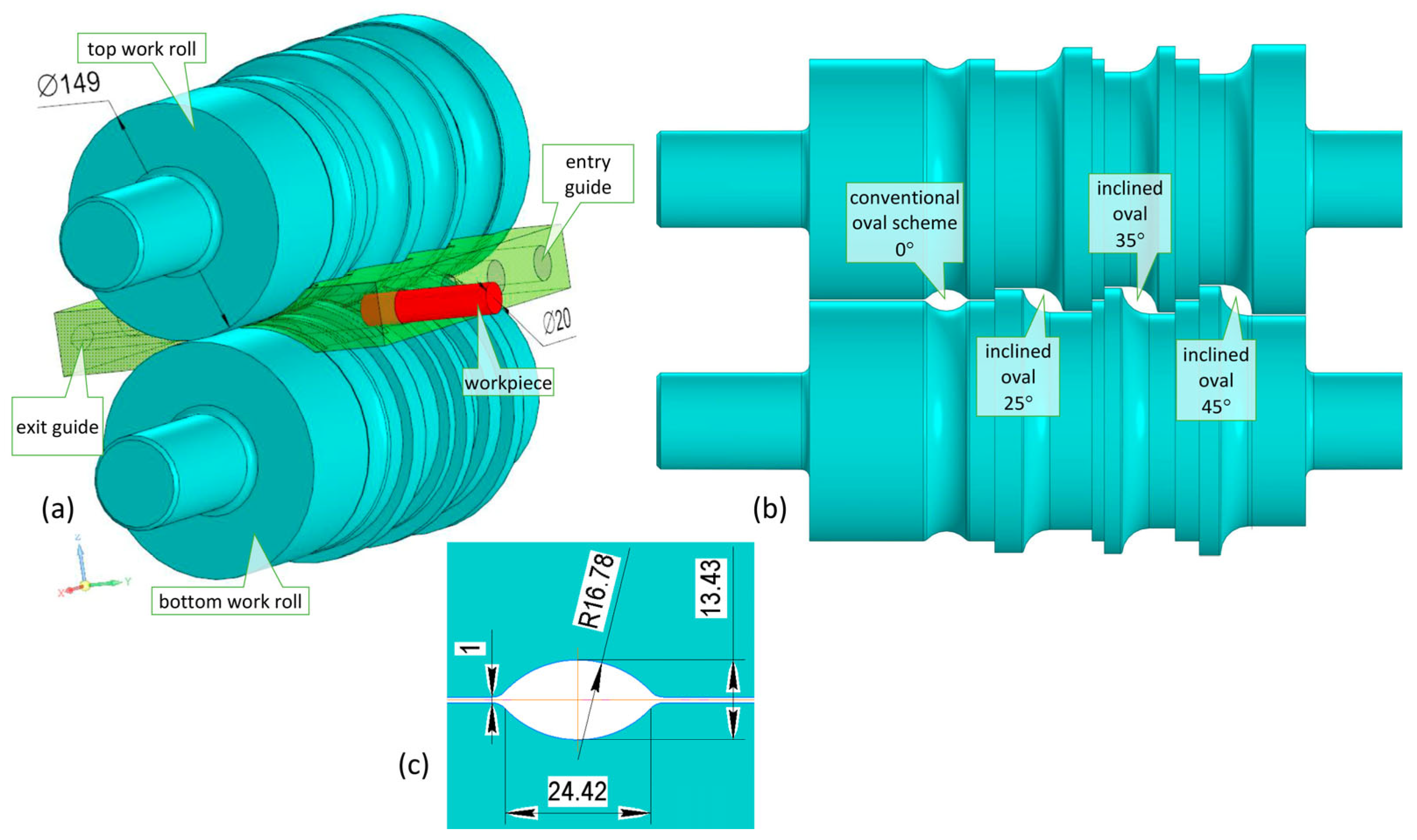

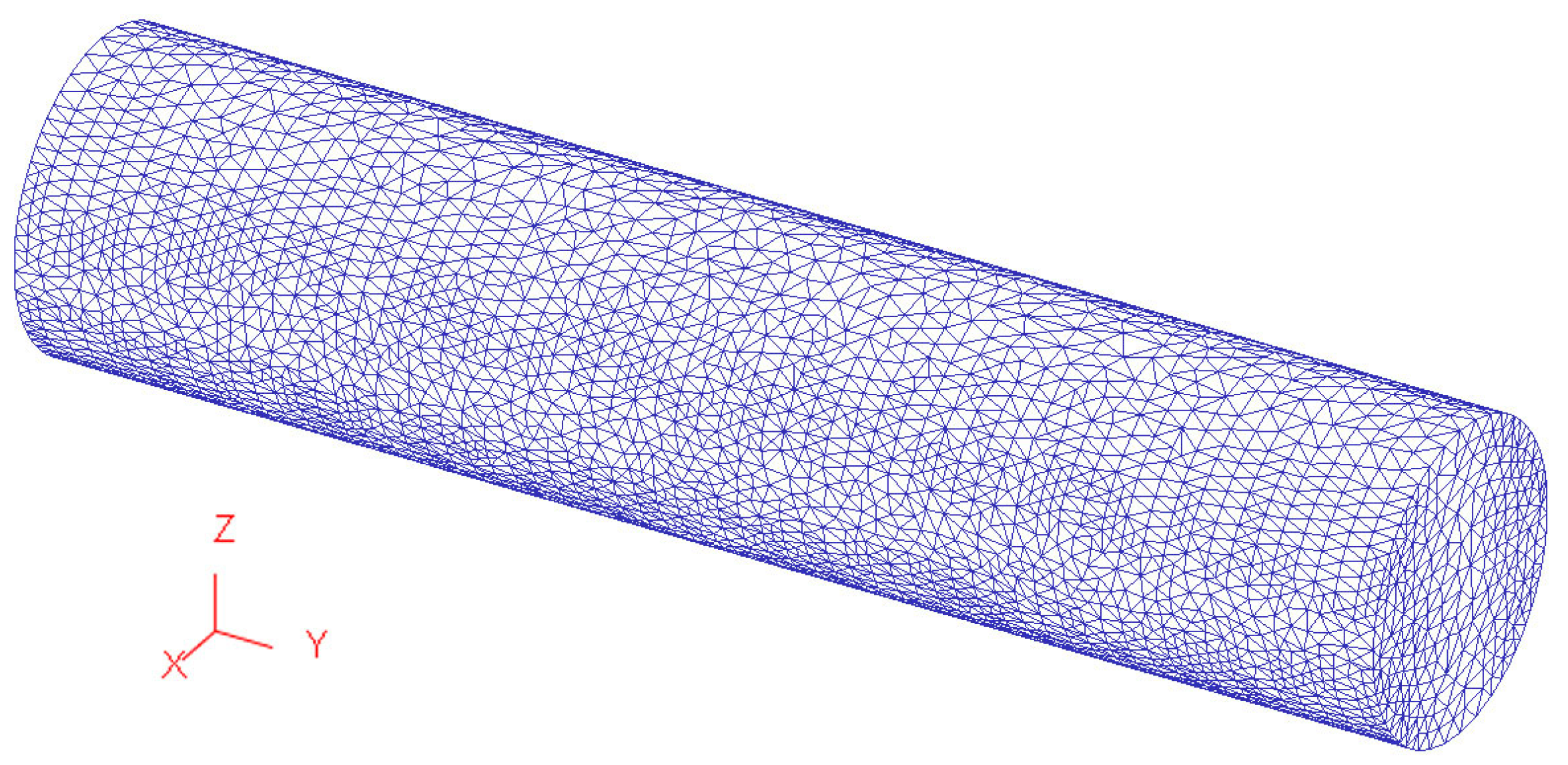

2. Numerical Modeling of Rolling in Oval Calibers

- Tool definition—the rolls were modeled as perfectly rigid bodies with surfaces of constant temperature (20°—the default roll temperature in the simulation software). This setup is widely used in FEM simulations of hot rolling since elastic deformations and thermal fluctuations of the rolls have only a minor influence on the overall metal flow field. Their exclusion significantly reduces computational costs. Examples include 3D solvers with rigid–viscoplastic formulations implemented in DEFORM-3D and other FEM packages [27,28].

- Workpiece material—assumed to be homogeneous and isotropic, with deformation modeled as viscoplastic flow. In hot rolling, the metal structure rapidly homogenizes due to dynamic recrystallization, which reduces anisotropy. Therefore, the use of isotropic viscoplastic models (e.g., Hoff–Norton type) adequately captures the main technological effects while allowing the focus to remain on flow kinematics and shear processes [24,28].

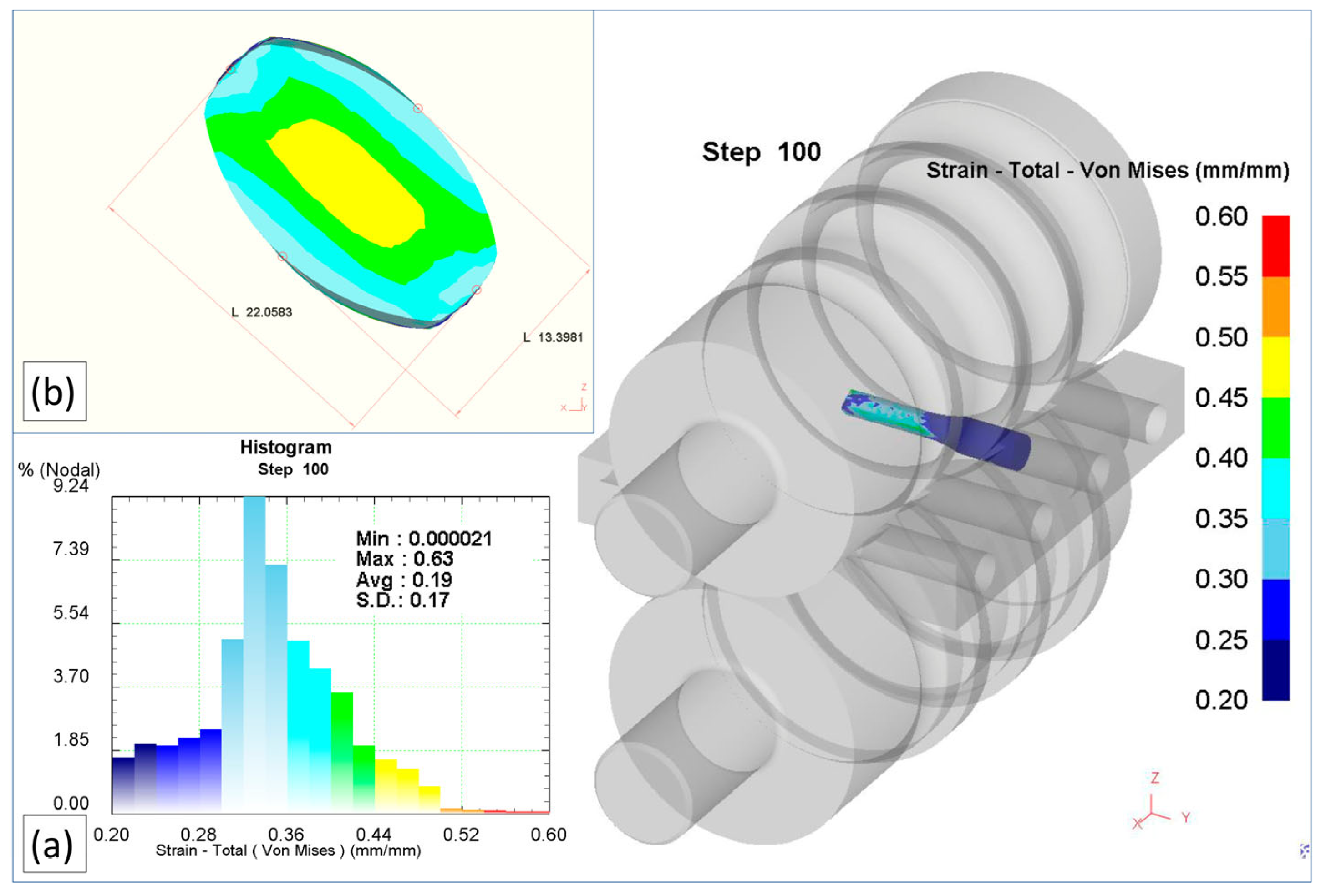

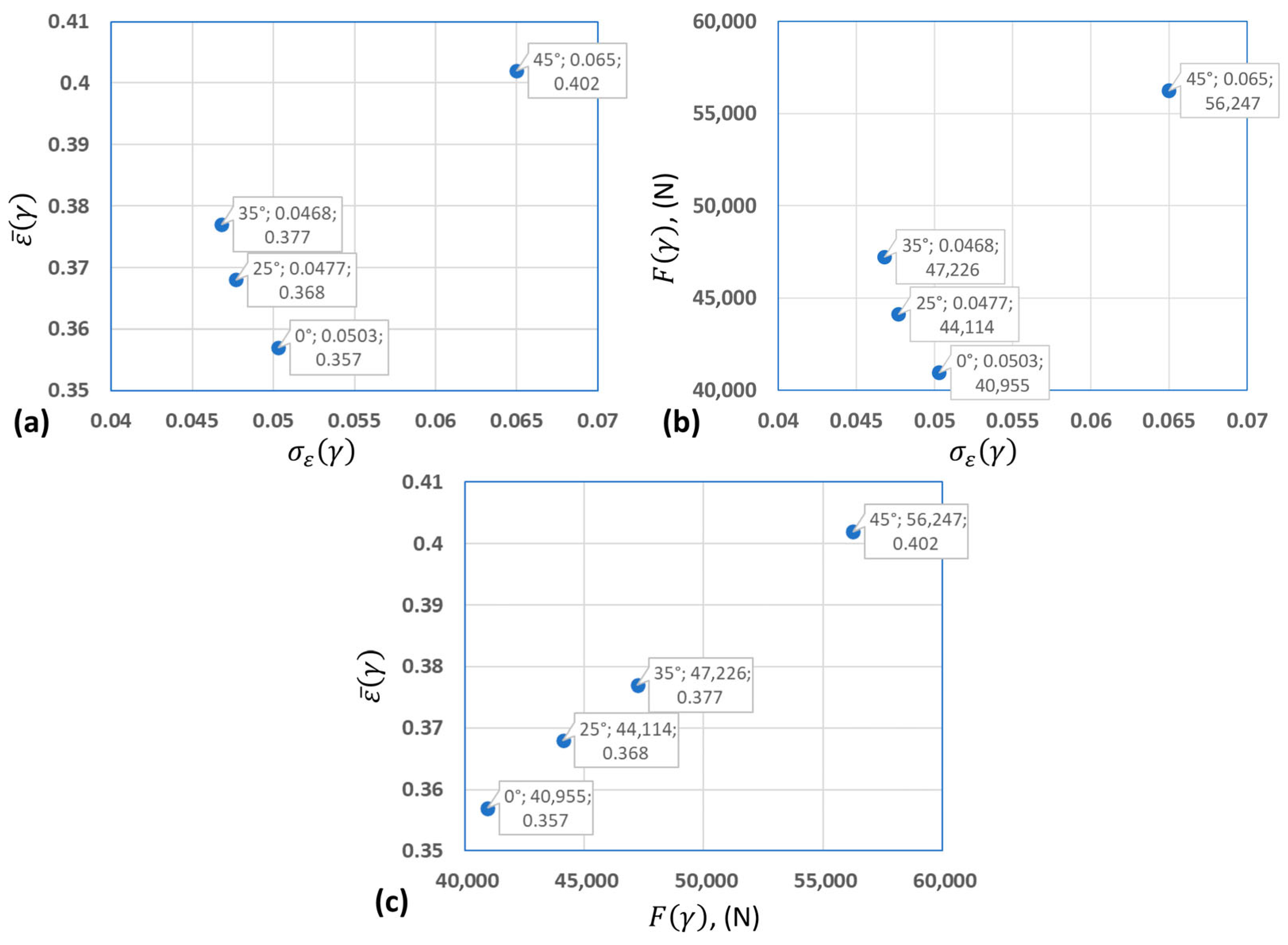

3. Multi-Objective Optimization of Inclined Oval-Caliber Angle

- 1.

- The average value of the effective strain in the transverse cross-section at the groove exit, , should be maximized. This metric quantitatively represents the overall plastic deformation and energy utilization. It is computed automatically by DEFORM-3D as the arithmetic mean of the effective strain values from all finite elements within the selected cross-sectional plane:where is the effective strain in the i-th mesh element, and N is the total number of elements in that section.

- 2.

- The standard deviation of the effective strain values, σε(γ), reflects the degree of uniformity of strain across the cross-section and should be minimized, as non-uniform deformation may lead to stress concentrations, structural defects, and reduced product quality. In DEFORM-3D, this statistic is computed automatically for all elements within the selected cross-sectional plane. Formally, it is defined as follows:

- 3.

- The rolling force, , which characterizes the energy consumption of the process and should be minimized to reduce equipment loads and energy costs.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bayoumi, L.S.; Lee, Y. Effect of interstand tension on roll load, torque and workpiece deformation in the rod rolling process. J. Mater. Process. Technol. 2004, 145, 7–13. [Google Scholar] [CrossRef]

- Hwang, J.-K. Hardening and softening behavior of caliber-rolled wire. Mater 2022, 15, 2939. [Google Scholar] [CrossRef]

- Schowtjak, A.; Wang, S.; Hering, O.; Clausmeyer, T.; Lohmar, J.; Schulte, R.; Ostwald, R.; Hirt, G.; Tekkaya, A.E. Prediction and analysis of damage evolution during caliber rolling and subsequent cold forward extrusion. Prod. Eng. 2019, 14, 33–41. [Google Scholar] [CrossRef]

- Hába, J.; Fabík, R. Optimizing of the degree of elongation in a single pass during hot bars rolling in the oval-round roll pass schedule. In Proceedings of METAL 2016 Conference; Technical University of Ostrava, Faculty of Metallurgy and Materials Engineering: Ostrava, Czech Republic, 2016; p. 285. Available online: https://www.confer.cz/metal/2016/read/1747-optimizing-of-the-degree-of-elongation-in-single-pass-during-hot-bars-rolling-in-the-oval-round-roll-pass-schedule.pdf (accessed on 8 August 2025).

- Zayed, E.M.; El-Sabbagh, A.; El-Mahallawy, N.A.; Shazly, M. Deformation behavior and properties of severe plastic deformation techniques for bulk materials: A review. Heliyon 2023, 9, e16700. [Google Scholar] [CrossRef]

- Bagherpour, E.; Pardis, N.; Reihanian, M.; Kim, H.S. An overview on severe plastic deformation: Research status, techniques classification, microstructure evolution, and applications. Int. J. Adv. Manuf. Technol. 2019, 100, 1647–1694. [Google Scholar] [CrossRef]

- Dolzhenko, P.; Tikhonova, M.; Odnobokova, M.; Kaibyshev, R.; Belyakov, A. Ultrafine-grained stainless steels after severe plastic deformation. Metals 2023, 13, 674. [Google Scholar] [CrossRef]

- Segal, V. Severe plastic deformation: Simple shear versus pure shear. Mater. Sci. Eng. A 2002, 338, 331–344. [Google Scholar] [CrossRef]

- Segal, V. Review: Modes and processes of severe plastic deformation (SPD). Materials 2018, 11, 1175. [Google Scholar] [CrossRef] [PubMed]

- Segal, V.M. Deformation mode and plastic flow in ultra fine grained metals. Mater. Sci. Eng. A 2005, 406, 205–216. [Google Scholar] [CrossRef]

- Naizabekov, A.B.; Bykhin, M.B.; Nogaev, K.A.; Bykhin, B.B. Study of the process of realization of high-rate plastic deformation in lengthwise rolling. In Proceedings of the 19th International Conference on Metallurgy and Materials (METAL 2010), Brno, Czech Republic, 18–20 May 2010; pp. 192–202. [Google Scholar]

- Abishkenov, M.; Ashkeyev, Z.; Nogaev, K. Investigation of the shape rolling process implementing intense shear strains in special diamond passes. Materialia 2022, 26, 101573. [Google Scholar] [CrossRef]

- Ashkeyev, Z.; Abishkenov, M.; Nogaev, K.; Bestembek, Y.; Azimbayev, K.; Tavshanov, I. Stress state of workpieces during upsetting with additional shear. Eng. Solid Mech. 2023, 11, 253–262. [Google Scholar] [CrossRef]

- Ma, C.; Li, T.; Xue, C.; Jin, R.; Chu, Z.; Shuai, M.; Tuo, L. Optimization of roll configuration and investigation of forming process in three-roll planetary rolling of stainless steel seamless tubes. Metals 2025, 15, 540. [Google Scholar] [CrossRef]

- Ojeda-López, A.; Botana-Galvín, M.; González-Rovira, L.; Botana, F.J. Numerical Simulation as a Tool for the Study, Development, and Optimization of Rolling Processes: A Review. Metals 2024, 14, 737. [Google Scholar] [CrossRef]

- Montemayor-de la Garza, K.; Zambrano-Robledo, P.d.C.; Zapata-Hernandez, O.J.; Leduc-Lezama, L.A. Finite Element Modeling of Hot Rolling of 1075 Carbon Steel Process with Variable Cross Section. Materials 2022, 16, 2. [Google Scholar] [CrossRef]

- Ojeda-López, A.; Botana-Galvín, M.; Collado-García, I.; González-Rovira, L.; Botana, F.J. Finite Element Simulation of Hot Rolling for Large-Scale AISI 430 Ferritic Stainless-Steel Slabs Using Industrial Rolling Schedules—Part 1: Set-Up, Optimization, and Validation of Numerical Model. Materials 2025, 18, 383. [Google Scholar] [CrossRef] [PubMed]

- Gavalas, E.; Papaefthymiou, S. Prediction of Plate Crown during Aluminum Hot Flat Rolling by Finite Element Modeling. J. Manuf. Mater. Process. 2019, 3, 95. [Google Scholar] [CrossRef]

- Pérez-Alvarado, A.; Arreola-Villa, S.A.; Calderón-Ramos, I.; Servín Castañeda, R.; Mendoza de la Rosa, L.A.; Chattopadhyay, K.; Morales, R. Numerical Simulation of the Hot Rolling Process of Steel Beams. Materials 2021, 14, 7038. [Google Scholar] [CrossRef]

- Rashad, M.; Magdi, A.; Ahmed, M.E.; Metwalli, S.M. Optimal design of round-oval-round roll pass for the steel bar rolling process. J. Eng. Appl. Sci. 2024, 71, 224. [Google Scholar] [CrossRef]

- Kotas, M.; Fabík, R.; Gajdzica, T.; Kliber, J. Finite Elements Method (FEM) Simulation of Bar Rolling in Oval–Circle Pass Schedule. In Proceedings of the 19th International Conference on Metallurgy and Materials—METAL 2010, Roznov pod Radhostem, Czech Republic, 18–20 May 2010. [Google Scholar]

- Moon, C.H.; Lee, Y. Analytical model to predict the free surface profile of outgoing material in oval-to-round pass rolling when cross-section of incoming material is not circular and roll gap changes. ISIJ Int. 2023, 63, 111–119. [Google Scholar] [CrossRef]

- Kawano, M.; Isogawa, S.; Kawanishi, K. Evaluation of roll pass designs by thermal mechanical FEM simulation. DENKI-SEIKO 1999, 70, 255–260. [Google Scholar] [CrossRef]

- González-Castillo, A.C.; Cruz-Rivera, J.d.J.; Ramos-Azpeitia, M.O.; Garnica-González, P.; Garay-Reyes, C.G.; Pacheco-Cedeño, J.S.; Hernández-Rivera, J.L. 3D-FEM simulation of hot rolling process and characterization of the resultant microstructure of a light-weight Mn steel. Crystals 2021, 11, 569. [Google Scholar] [CrossRef]

- Kainz, A.J.; Ilie, S.; Parteder, E.; Zeman, K. From slab corner cracks to edge-defects in hot rolled strip: Experimental and numerical investigations. Steel Res. Int. 2008, 79, 861–867. [Google Scholar] [CrossRef]

- Gu, S.D.; Ruan, J.H.; Zhang, L.W.; Yue, C.X.; He, W.B.; Chen, H. 3D FE modelling of plate shape during heavy plate rolling. Ironmak. Steelmak. 2014, 41, 199–205. [Google Scholar] [CrossRef]

- Jiang, Z.Y.; Tieu, A.K. Modelling of the rolling processes by a 3-D rigid plastic/visco-plastic finite element method. Int. J. Mech. Sci. 2001, 79, 2727–2740. [Google Scholar] [CrossRef]

- Gangopadhyay, T.; Ohdar, R.K.; Pratihar, D.K.; Basak, I. Three-dimensional finite element analysis of multi-stage hot forming of railway wheels. Int. J. Adv. Manuf. Technol. 2011, 53, 301–312. [Google Scholar] [CrossRef]

- AISI 1045 Medium Carbon Steel. Available online: https://www.azom.com/article.aspx?ArticleID=6130 (accessed on 9 September 2025).

- Jantepa, N.; Siripath, N.; Suranuntchai, S. Predictive Modeling and Optimization of Hot Forging Parameters for AISI 1045 Ball Joints Using Taguchi Methodology and Finite Element Analysis. Metals 2024, 14, 1198. [Google Scholar] [CrossRef]

- Wusatowski, Z. Fundamentals of Rolling: Principles of Roll-Pass Design, Illustrated ed.; Pergamon Press: Oxford, UK, 1969; pp. 99–121. [Google Scholar] [CrossRef]

- Eisenträger, S.; Duvigneau, F.; Gabbert, U. The Finite Cell Method for Tetrahedral Meshes. Finite Elem. Anal. Des. 2016, 121, 18–32. [Google Scholar] [CrossRef]

- Flanagan, F.; O’Connor, A.N.; Erfanian, M.; Music, O.; Brambley, E.J.; O’Kiely, D. Careful Finite Element Simulations of Cold Rolling with Accurate Through-Thickness Resolution and Prediction of Residual Stress. arXiv 2024, arXiv:2408.03242. [Google Scholar] [CrossRef]

- Hwang, J.-K. Effect of contact pressure on strain distribution during compression-type bulk forming processes. Materials 2023, 16, 5041. [Google Scholar] [CrossRef]

- Sheu, J.-J.; Ho, C.-J.; Yu, C.-H.; Kao, C.-Y. High-order groove-shape curve roll design for aluminum alloy 7075 wire rolling. Metals 2022, 12, 1071. [Google Scholar] [CrossRef]

- Huang, B.; Xing, K.; Abhary, K.; Spuzic, S. Optimization of oval–round pass design using genetic algorithm. Robot. Comput.-Integr. Manuf. 2012, 28, 493–499. [Google Scholar] [CrossRef]

- Marler, R.T.; Arora, J.S. The weighted sum method for multi-objective optimization: New insights. Struct. Multidiscipl. Optim. 2010, 41, 853–862. [Google Scholar] [CrossRef]

- Babajamali, Z.; Khaje Khabaz, M.; Aghadavoudi, F.; Farhatnia, F.; Eftekhari, S.A.; Toghraie, D. Pareto multi-objective optimization of tandem cold rolling settings for reductions and inter-stand tensions using NSGA-II. ISA Trans. 2022, 130, 399–408. [Google Scholar] [CrossRef] [PubMed]

- Bejarano, L.A.; Espitia, H.E.; Montenegro, C.E. Clustering analysis for the Pareto optimal front in multi-objective optimization. Computation 2022, 10, 37. [Google Scholar] [CrossRef]

- Li, W.; Zhang, G.; Zhang, T.; Huang, S. Knee point-guided multiobjective optimization algorithm for microgrid dynamic energy management. Complexity 2020, 2020, 8877008. [Google Scholar] [CrossRef]

| C | Mn | P | S |

|---|---|---|---|

| 0.42–0.50 | 0.60–0.90 | ≤0.040 | ≤0.050 |

| Criterion | Oval Inclination Angle (°) | |||

|---|---|---|---|---|

| 0 | 25 | 35 | 45 | |

| 0.357 | 0.368 | 0.377 | 0.402 | |

| 0.0503 | 0.0477 | 0.0468 | 0.065 | |

| , (H) | 40,955 | 44,114 | 47,226 | 56,247 |

| , (°) | ||||

|---|---|---|---|---|

| 0 | 0 | 0.1926 | 0 | 0.3975 |

| 25 | 0.2444 | 0.0495 | 0.2061 | 0.3333 |

| 35 | 0.4444 | 0 | 0.4061 | 0.2835 |

| 45 | 1 | 1 | 1 | 0.6667 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nogayev, K.; Kamarov, A.; Abishkenov, M.; Ashkeyev, Z.; Sembayev, N.; Kydyrbayeva, S. Finite Element-Based Multi-Objective Optimization of a New Inclined Oval Rolling Pass Geometry. Modelling 2025, 6, 110. https://doi.org/10.3390/modelling6030110

Nogayev K, Kamarov A, Abishkenov M, Ashkeyev Z, Sembayev N, Kydyrbayeva S. Finite Element-Based Multi-Objective Optimization of a New Inclined Oval Rolling Pass Geometry. Modelling. 2025; 6(3):110. https://doi.org/10.3390/modelling6030110

Chicago/Turabian StyleNogayev, Kairosh, Aman Kamarov, Maxat Abishkenov, Zhassulan Ashkeyev, Nurbolat Sembayev, and Saltanat Kydyrbayeva. 2025. "Finite Element-Based Multi-Objective Optimization of a New Inclined Oval Rolling Pass Geometry" Modelling 6, no. 3: 110. https://doi.org/10.3390/modelling6030110

APA StyleNogayev, K., Kamarov, A., Abishkenov, M., Ashkeyev, Z., Sembayev, N., & Kydyrbayeva, S. (2025). Finite Element-Based Multi-Objective Optimization of a New Inclined Oval Rolling Pass Geometry. Modelling, 6(3), 110. https://doi.org/10.3390/modelling6030110