AscentAM: A Software Tool for the Thermo-Mechanical Process Simulation of Form Deviations and Residual Stresses in Powder Bed Fusion of Metals Using a Laser Beam

Abstract

1. Introduction

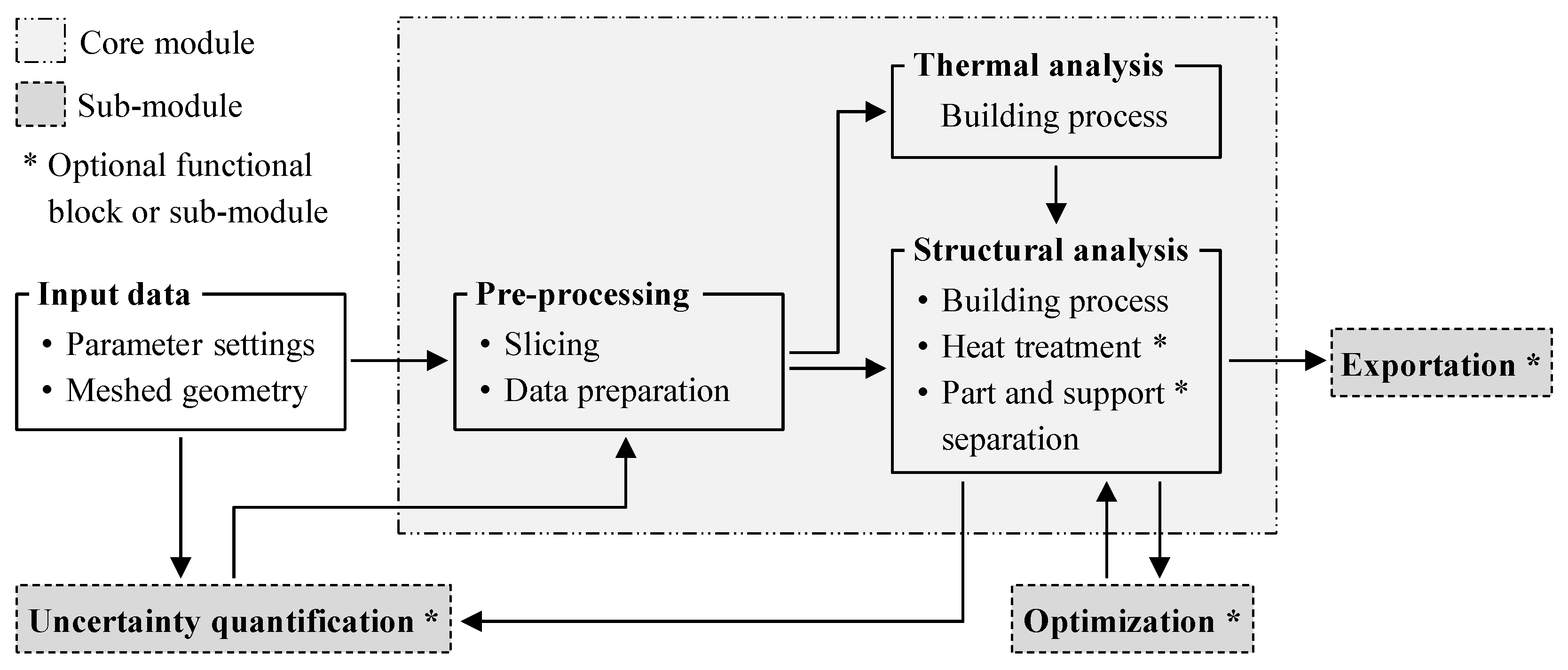

2. Simulation Framework

2.1. Core Module

2.1.1. Pre-Processing

2.1.2. Thermal Building Process

2.1.3. Structural Building Process

2.1.4. Heat Treatment

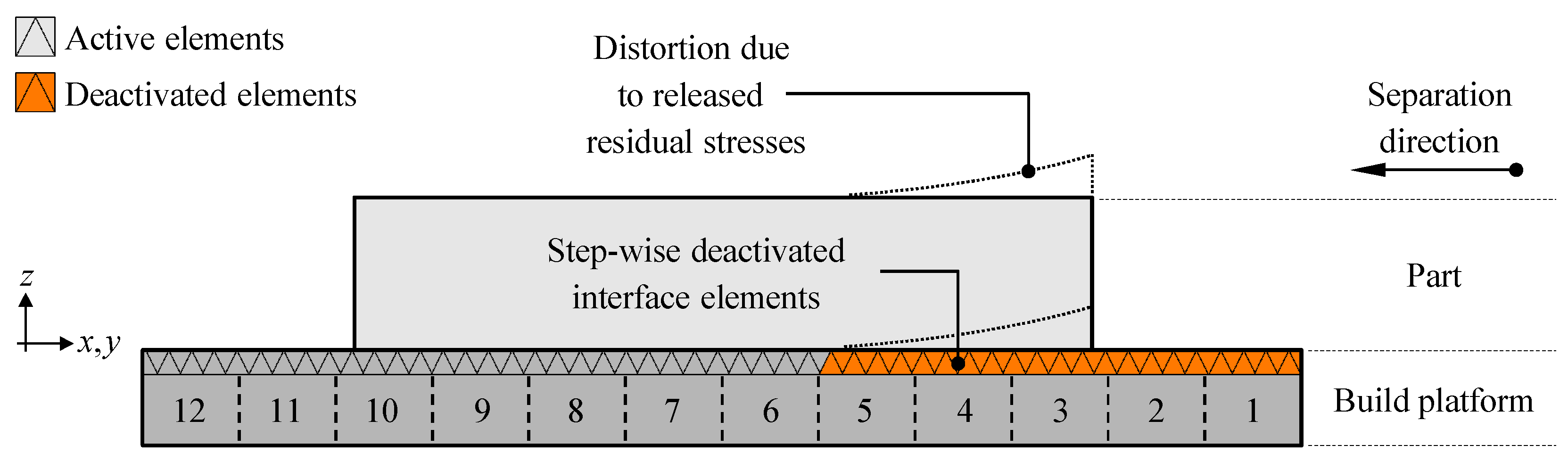

2.1.5. Part and Support Separation

2.2. Sub-Modules

2.2.1. Optimization

2.2.2. Exportation

2.2.3. Uncertainty Quantification

3. Materials and Methods

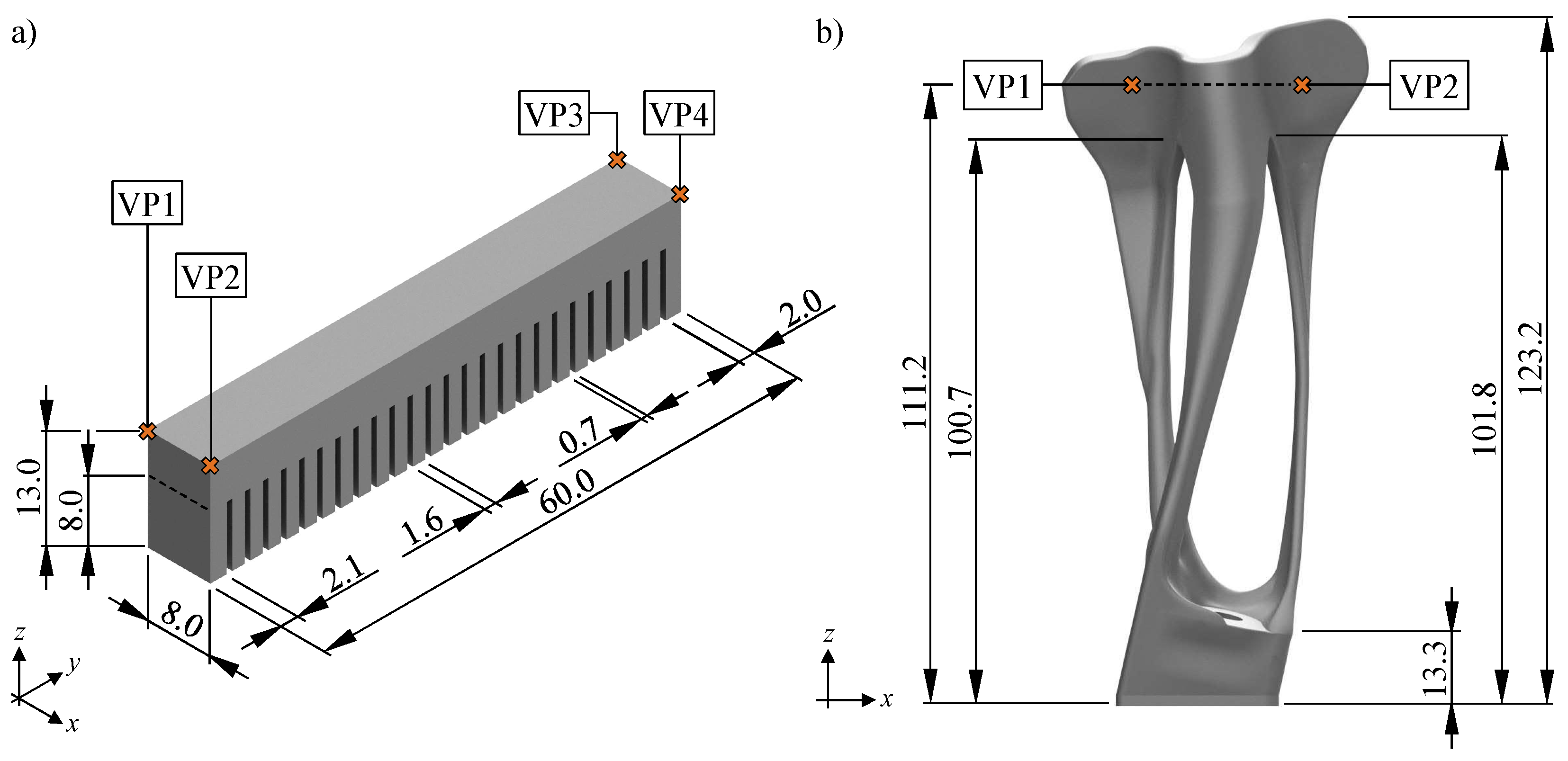

3.1. Part Geometries

3.2. Simulative Procedure

3.3. Experimental Procedure

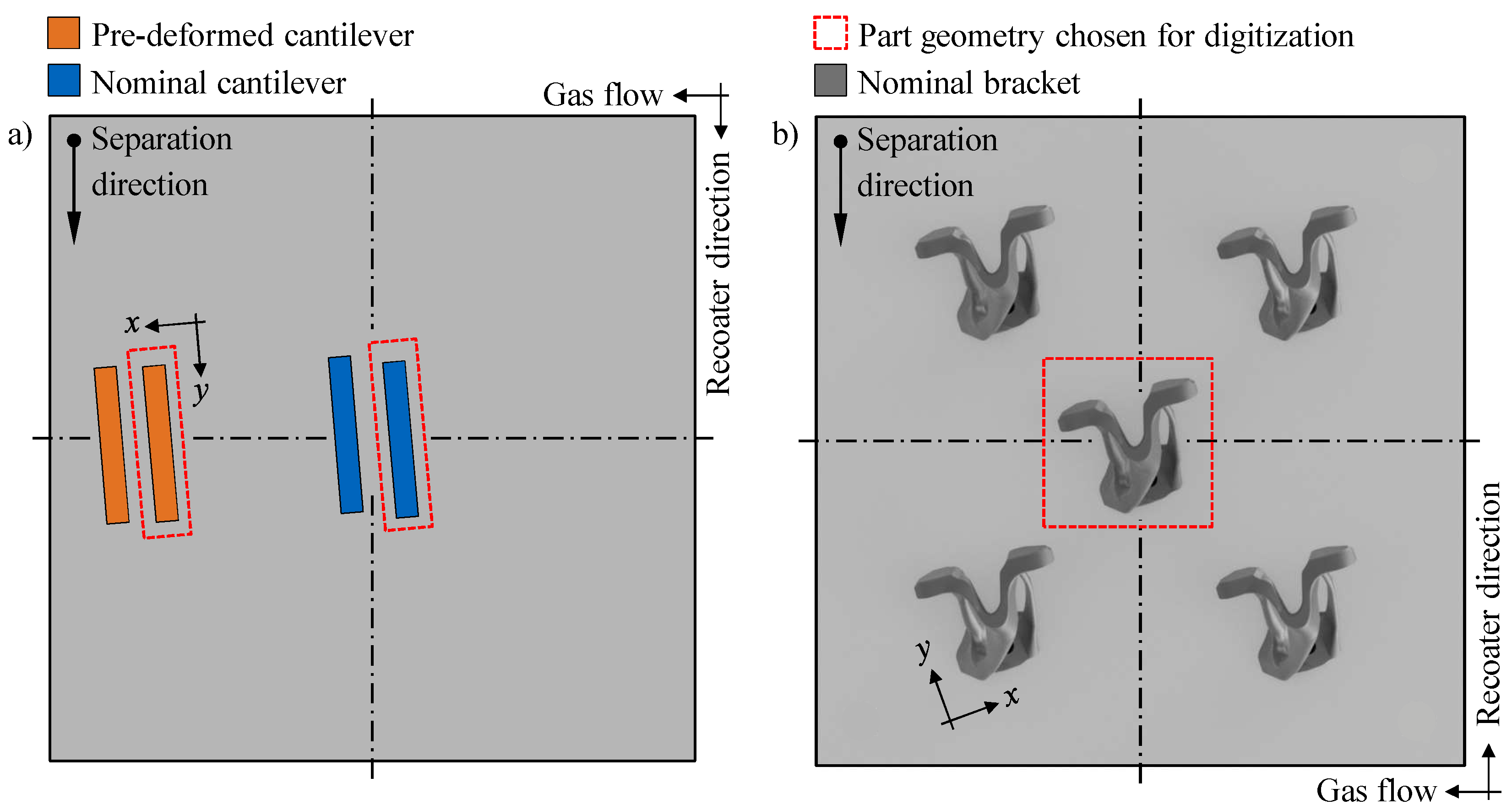

3.3.1. Experimental Layouts

3.3.2. Digitization

4. Results and Discussion

4.1. Verification of the Simulation

4.2. Experimental Validation

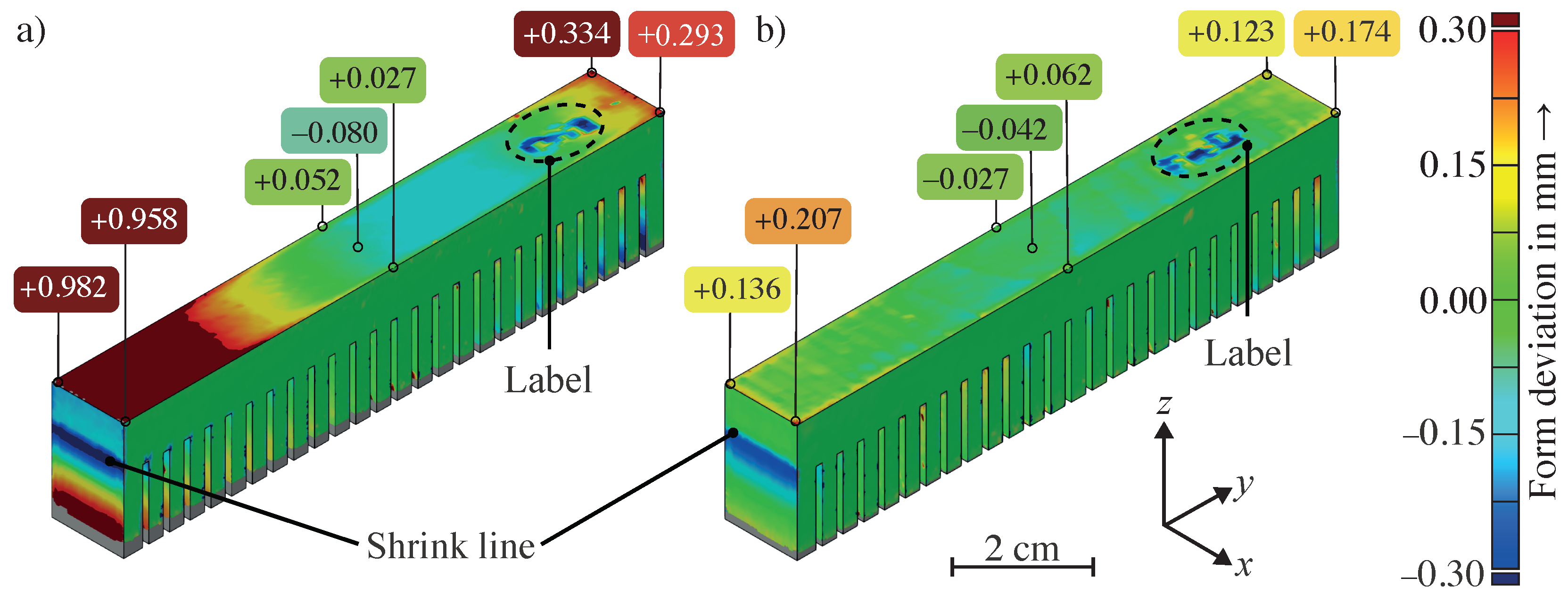

4.2.1. Cantilever Beam

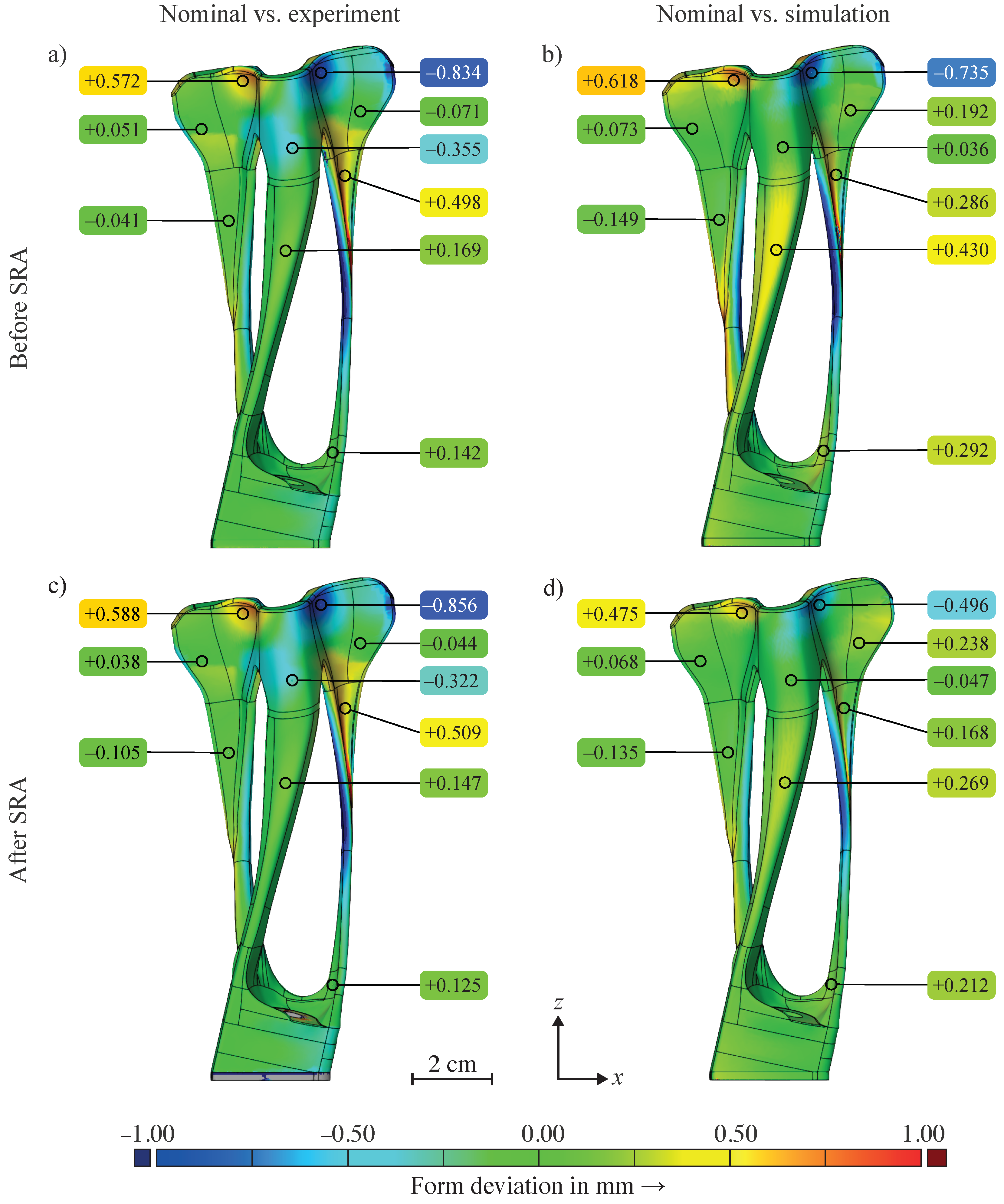

4.2.2. Bracket Geometry

5. Conclusions and Outlook

- For the academic cantilever beam, the simulation results confirmed that the physics-based thermal equations, which are used to model the heat input and the subsequent cooling, were correctly implemented in AscentAM. The relevant cause-and-effect relationships were represented using the sequentially coupled thermo-mechanical modeling approach. An average element size mm and an LC height mm were determined as suitable simulation settings, which led to a required computation time of 592.14 s. By applying the optimization sub-module, the dimensional accuracy was increased by 16.2% to 85.8% for the as-built part after the separation from the build platform.

- The topology-optimized bracket was simulated using an element size mm and an LC height mm, which resulted in a computation time of 12,250.0 s for the thermo-mechanical analysis. Comparing the simulation result and the as-built part with each other, a dimensional accuracy of 94.7% and 88.6% was observed for the manufacturing state before the SRA, and after the separation of the stress-relief-annealed part, respectively. The distortions were slightly overestimated by the process simulation.

- Due to the contrasting complexity of the two parts, it was confirmed that the process simulation tool AscentAM shows a high result quality with an adequate computing time. The operation of the simulation tool in an industrial environment at MTU Aero Engines AG also confirmed its economic relevance for applications in the aerospace industry. In contrast to other commercial process simulations, an increased dimensional accuracy was achieved using the non-linear pre-deformation algorithm of the optimization sub-module.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CCX | CalculiX CrunchiX |

| EDM | Electrical discharge machining |

| FE | Finite element |

| LC | Layer compound |

| PBA | Probability bounds analysis |

| PBF-LB/M | Powder bed fusion of metals using a laser beam |

| SRA | Stress relief annealing |

| STL | Standard tesselation language |

| UQ | Uncertainty quantification |

| VP | Verification point |

References

- Duda, T.; Raghavan, L.V. 3D Metal Printing Technology. In Proceedings of the 17th IFAC Conference on International Stability, Technology and Culture TECIS 2016, Durrës, Albania, 26–28 October 2016; Volume 49, pp. 103–110. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S. Additive manufacturing: Recent trends, applications and future outlooks. Prog. Addit. Manuf. 2021, 7, 261–287. [Google Scholar] [CrossRef]

- Riveiro, A.; del Val, J.; Comesaña, R.; Lusquiños, F.; Quintero, F.; Boutinguiza, M.; Pou, J. Laser Additive Manufacturing Processes for Near Net Shape Components. In Near Net Shape Manufacturing Processes; Gupta, K., Ed.; Springer International Publishing: Cham, Switzerland, 2019; pp. 105–141. [Google Scholar] [CrossRef]

- Sanchez, S.; Smith, P.; Xu, Z.; Gaspard, G.; Hyde, C.J.; Wits, W.W.; Ashcroft, I.A.; Chen, H.; Clare, A.T. Powder Bed Fusion of nickel-based superalloys: A review. Int. J. Mach. Tools Manuf. 2021, 165, 103729. [Google Scholar] [CrossRef]

- Cobbinah, P.V.; Nzeukou, R.A.; Onawale, O.T.; Matizamhuka, W.R. Laser Powder Bed Fusion of Potential Superalloys: A Review. Metals 2021, 11, 58. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Easton, M. 2—Powder bed fusion processes: An overview. In Laser Additive Manufacturing; Brandt, M., Ed.; Woodhead Publishing Series in Electronic and Optical Materials; Woodhead Publishing: Sawston, UK, 2017; pp. 55–77. [Google Scholar] [CrossRef]

- Narasimharaju, S.R.; Zeng, W.; See, T.L.; Zhu, Z.; Scott, P.; Jiang, X.; Lou, S. A comprehensive review on laser powder bed fusion of steels: Processing, microstructure, defects and control methods, mechanical properties, current challenges and future trends. J. Manuf. Process. 2022, 75, 375–414. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J.P. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Bartlett, J.L.; Li, X. An overview of residual stresses in metal powder bed fusion. Addit. Manuf. 2019, 27, 131–149. [Google Scholar] [CrossRef]

- Zaeh, M.; Branner, G. Investigations on residual stresses and deformations in selective laser melting. Prod. Eng. 2009, 4, 35–45. [Google Scholar] [CrossRef]

- Bayerlein, F.; Zeller, C.; Zaeh, M.F.; Weirather, J.; Wunderer, M.; Seidel, C. Improving cost effectiveness in additive manufacturing—Increasing dimensional accuracy in laser beam melting by means of a simulation supported process chain. In Proceedings of the ANSYS Conference 33. CAFDEM Users’ Meeting, Bremen, Germany, 24–26 June 2015; pp. 1–9. Available online: http://www.cae-wiki.info/wikiplus/images/d/d4/UM2015-2.02.12.pdf (accessed on 30 May 2024).

- Panzer, H.; Wolf, D.; Bachmann, A.; Zaeh, M.F. Towards a Simulation-Assisted Prediction of Residual Stress-Induced Failure during Powder Bed Fusion of Metals Using a Laser Beam: Suitable Fracture Mechanics Models and Calibration Methods. J. Manuf. Mater. Process. 2023, 7, 208. [Google Scholar] [CrossRef]

- Panzer, H.; Diller, J.; Ehrenfels, F.; Brandt, J.; Zäh, M.F. Experimental investigation of process parameter variations on the microstructure and failure behavior of IN718 structures in PBF-LB/M. J. Laser Appl. 2024, 36, 012015. [Google Scholar] [CrossRef]

- Huang, Y.; Leu, M.C.; Mazumder, J.; Donmez, A. Additive Manufacturing: Current State, Future Potential, Gaps and Needs, and Recommendations. J. Manuf. Sci. Eng. 2015, 137, 014001. [Google Scholar] [CrossRef]

- Baumers, M.; Dickens, P.; Tuck, C.; Hague, R. The cost of additive manufacturing: Machine productivity, economies of scale and technology-push. Technol. Forecast. Soc. Chang. 2016, 102, 193–201. [Google Scholar] [CrossRef]

- Zoch, H.W. Distortion engineering–interim results after one decade research within the Collaborative Research Center: Distortion Engineering—Ein Zwischenbericht nach einem Jahrzehnt des Sonderforschungsbereichs. Mater. Und Werkst. 2012, 43, 9–15. [Google Scholar] [CrossRef]

- Chiumenti, M.; Neiva, E.; Salsi, E.; Cervera, M.; Badia, S.; Moya, J.; Chen, Z.; Lee, C.; Davies, C. Numerical modelling and experimental validation in Selective Laser Melting. Addit. Manuf. 2017, 18, 171–185. [Google Scholar] [CrossRef]

- Park, H.S.; Shin, H.S.; Tran, N.H. A new approach for calculating inherent strain and distortion in additive manufacturing of metal parts. Int. J. Adv. Manuf. Technol. 2022, 121, 6507–6521. [Google Scholar] [CrossRef]

- Mohammadtaheri, H.; Sedaghati, R.; Molavi-Zarandi, M. Inherent strain approach to estimate residual stress and deformation in the laser powder bed fusion process for metal additive manufacturing—A state-of-the-art review. Int. J. Adv. Manuf. Technol. 2022, 122, 2187–2202. [Google Scholar] [CrossRef]

- Dong, W.; Liang, X.; Chen, Q.; Hinnebusch, S.; Zhou, Z.; To, A.C. A new procedure for implementing the modified inherent strain method with improved accuracy in predicting both residual stress and deformation for laser powder bed fusion. Addit. Manuf. 2021, 47, 102345. [Google Scholar] [CrossRef]

- Keller, N. Verzugsminimierung Bei Selektiven Laserschmelzverfahren Durch Multi-Skalen-Simulation. Ph.D. Thesis, University of Bremen, Bremen, Germany, 2017. Available online: http://nbn-resolving.de/urn:nbn:de:gbv:46-00105808-15 (accessed on 30 May 2024).

- Siewert, M.; Neugebauer, F.; Epp, J.; Ploshikhin, V. Validation of Mechanical Layer Equivalent Method for simulation of residual stresses in additive manufactured components. Comput. Math. Appl. 2019, 78, 2407–2416. [Google Scholar] [CrossRef]

- Bugatti, M.; Semeraro, Q. Limitations of the inherent strain method in simulating powder bed fusion processes. Addit. Manuf. 2018, 23, 329–346. [Google Scholar] [CrossRef]

- Seidel, C. Finite-Elemente-Simulation des Aufbauprozesses beim Laserstrahlschmelzen. Ph.D. Thesis, Technical University of Munich, Munich, Germany, 2016. Available online: https://nbn-resolving.de/urn/resolver.pl?urn:nbn:de:bvb:91-diss-20160728-1303906-1-5 (accessed on 30 May 2024).

- Bayat, M.; Klingaa, C.G.; Mohanty, S.; De Baere, D.; Thorborg, J.; Tiedje, N.S.; Hattel, J.H. Part-scale thermo-mechanical modelling of distortions in Laser Powder Bed Fusion—Analysis of the sequential flash heating method with experimental validation. Addit. Manuf. 2020, 36, 101508. [Google Scholar] [CrossRef]

- De Baere, D.; Van Cauwenbergh, P.; Bayat, M.; Mohanty, S.; Thorborg, J.; Thijs, L.; Van Hooreweder, B.; Vanmeensel, K.; Hattel, J.H. Thermo-mechanical modelling of stress relief heat treatments after laser-based powder bed fusion. Addit. Manuf. 2021, 38, 101818. [Google Scholar] [CrossRef]

- Singh, U.P.; Swaminathan, S.; Phanikumar, G. Thermo-mechanical approach to study the residual stress evolution in part-scale component during laser additive manufacturing of alloy 718. Mater. Des. 2022, 222, 111048. [Google Scholar] [CrossRef]

- O’Brien, J.; Montgomery, S.; Yaghi, A.; Afazov, S. Process chain simulation of laser powder bed fusion including heat treatment and surface hardening. CIRP J. Manuf. Sci. Technol. 2021, 32, 266–276. [Google Scholar] [CrossRef]

- Dhondt, G. CalculiX CrunchiX User’s Manual, Version 2.20; MIT Press: Cambridge, MA, USA, 2022. [Google Scholar]

- Branner, G. Modellierung Transienter Effekte in der Struktursimulation von Schichtbauverfahren. Ph.D. Thesis, Technical University of Munich, Munich, Germany, 2011. Available online: https://www.mec.ed.tum.de/fileadmin/w00cbp/iwb/Institut/Dissertationen/246_Branner.pdf (accessed on 30 May 2024).

- Chowdhury, S.; Yadaiah, N.; Prakash, C.; Ramakrishna, S.; Dixit, S.; Gupta, L.R.; Buddhi, D. Laser powder bed fusion: A state-of-the-art review of the technology, materials, properties & defects, and numerical modelling. J. Mater. Res. Technol. 2022, 20, 2109–2172. [Google Scholar] [CrossRef]

- Zeller, C. Adaption of Numerical Methods to the Specific Requirements of the Thermal Simulation in Laser Beam Melting. Ph.D. Thesis, Techniscal University of Munich, Munich, Germany, 2019. Available online: https://nbn-resolving.de/urn/resolver.pl?urn:nbn:de:bvb:91-diss-20191115-1482942-1-3 (accessed on 30 May 2024).

- Afazov, S.; Denmark, W.A.; Toralles, B.L.; Holloway, A.; Yaghi, A. Distortion prediction and compensation in selective laser melting. Addit. Manuf. 2017, 17, 15–22. [Google Scholar] [CrossRef]

- Denlinger, E.R.; Michaleris, P. Effect of stress relaxation on distortion in additive manufacturing process modeling. Addit. Manuf. 2016, 12, 51–59. [Google Scholar] [CrossRef]

- Megahed, M.; Mindt, H.W.; N’Dri, N.; Duan, H.; Desmaison, O. Metal additive-manufacturing process and residual stress modeling. Integr. Mater. Manuf. Innov. 2016, 5, 61–93. [Google Scholar] [CrossRef]

- Irwin, J.; Michaleris, P. A Line Heat Input Model for Additive Manufacturing. J. Manuf. Sci. Eng. 2016, 138, 111004. [Google Scholar] [CrossRef]

- Luo, Z.; Zhao, Y. A survey of finite element analysis of temperature and thermal stress fields in powder bed fusion Additive Manufacturing. Addit. Manuf. 2018, 21, 318–332. [Google Scholar] [CrossRef]

- Bayerlein, F.A. Managing Form Deviation in Laser Beam Melting by Pre-Deformation. Ph.D. Dissertation, Technical University of Munich, Munich, Germany, 2020. Available online: https://nbn-resolving.de/urn/resolver.pl?urn:nbn:de:bvb:91-diss-20201015-1535958-1-4 (accessed on 30 May 2024).

- Bayerlein, F.; Zeller, C.; Wunderer, M.; Weirather, J.; Schmid, M.; Seidel, C.; Zaeh, M.F.; Hessert, R.; Schlick, G.; Uihlein, T.; et al. Validation of modeling assumptions for the buildup simulation of laser beam melting on the basis of the residual stress distribution. In Proceedings of the VII European Congress on Computational Methods in Applied Sciences and Engineering, Crete, Greece, 5–10 June 2016. [Google Scholar] [CrossRef]

- Kolbus, L.; Payzant, E.; Cornwell, P.; Watkins, T.; Babu, S.; Dehoff, R.; Lorenz, M.; Ovchinnikova, O.; Duty, C. Comparison of Residual Stresses in Inconel 718 Simple Parts Made by Electron Beam Melting and Direct Laser Metal Sintering. Metall. Mater. Trans. A 2015, 46, 1419–1432. [Google Scholar] [CrossRef]

- Larson, F.; Miller, J. A Time-Temperature Relationship for Rupture and Creep Stresses. Trans. Am. Soc. Mech. Eng. 1952, 74, 765–771. [Google Scholar] [CrossRef]

- Oberkampf, W.L.; Roy, C.J. Verification and Validation in Scientific Computing; Cambridge University Press: New York, NY, USA, 2010. [Google Scholar]

- Peter, N.; Pitts, Z.; Thompson, S.; Saharan, A. Benchmarking build simulation software for laser powder bed fusion of metals. Addit. Manuf. 2020, 36, 101531. [Google Scholar] [CrossRef]

- Spachtholz, J.; Fischersworring-Bunk, A.; Neuhäusler, S. Use of a Modified IQI Standard—A Way Forward in NDI of Metallic AM Parts? In Proceedings of the ASTM International Conference on Additive Manufacturing (ICAM 2022), Orlando, FL, USA, 31 October–4 November 2022. [Google Scholar]

- Schilp, J.; Seidel, C.; Krauss, H.; Weirather, J. Investigations on Temperature Fields during Laser Beam Melting by Means of Process Monitoring and Multiscale Process Modelling. Adv. Mech. Eng. 2014, 6, 217584. [Google Scholar] [CrossRef]

- Seidel, C.; Zaeh, M.; Wunderer, M.; Weirather, J.; Krol, T.; Ott, M. Simulation of the Laser Beam Melting Process—Approaches for an Efficient Modelling of the Beam-material Interaction. In Proceedings of the 8th International Conference on Digital Enterprise Technology—DET 2014 Disruptive Innovation in Manufacturing Engineering towards the 4th Industrial Revolution, Stuttgart, Germany, 25–28 March 2014; Volume 25, pp. 146–153. [Google Scholar] [CrossRef][Green Version]

- Madenci, E.; Guven, I. The Finite Element Method and Applications in Engineering Using ANSYS®; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Williams, R.J.; Vecchiato, F.; Kelleher, J.; Wenman, M.R.; Hooper, P.A.; Davies, C.M. Effects of heat treatment on residual stresses in the laser powder bed fusion of 316L stainless steel: Finite element predictions and neutron diffraction measurements. J. Manuf. Process. 2020, 57, 641–653. [Google Scholar] [CrossRef]

- Zhang, W.; Guo, D.; Wang, L.; Davies, C.M.; Mirihanage, W.; Tong, M.; Harrison, N.M. X-ray diffraction measurements and computational prediction of residual stress mitigation scanning strategies in powder bed fusion additive manufacturing. Addit. Manuf. 2023, 61, 103275. [Google Scholar] [CrossRef]

- Goetz, D.; Wolf, D.; Lehmann, M.; Zaeh, M.F. A novel approach for the quantitative characterization of shrink lines in the Powder Bed Fusion of metals using a laser beam. In Proceedings of the 12th CIRP Conference on Photonic Technologies [LANE 2022], Fürth, Germany, 4–8 September 2022. [Google Scholar] [CrossRef]

- Goetz, D.; Diller, J.; Achatz, K.; Zaeh, M.F. Shrink line impact on the fatigue resistance of Inconel 718 parts manufactured by powder bed fusion of metals using a laser beam. J. Manuf. Process. 2024, 115, 481–490. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Ambient temperature | 293.15 | K | |

| Build platform temperature | 353.15 | K | |

| Process temperature | 473.15 | K | |

| Melting temperature | 1523.15 | K | |

| Build platform convection [38] | 100.0 | W/(m2K) | |

| Part convection [24] | 10.6 | W/(m2K) |

| Verification Point | Discretization Parameters | |||

|---|---|---|---|---|

| = 0.50 mm | = 1.00 mm | = 1.50 mm | = 2.00 mm | |

| = 1.00 mm | = 2.00 mm | = 3.00 mm | = 4.00 mm | |

| VP1 | 0.885 mm | 1.086 mm | 1.595 mm | 1.237 mm |

| VP2 | 1.004 mm | 1.119 mm | 1.455 mm | 1.198 mm |

| RMS | 0.947 mm | 1.103 mm | 1.527 mm | 1.218 mm |

| Simulation time | 665,864.8 s | 41,933.0 s | 26,974.5 s | 12,250.0 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goetz, D.; Panzer, H.; Wolf, D.; Bayerlein, F.; Spachtholz, J.; Zaeh, M.F. AscentAM: A Software Tool for the Thermo-Mechanical Process Simulation of Form Deviations and Residual Stresses in Powder Bed Fusion of Metals Using a Laser Beam. Modelling 2024, 5, 841-860. https://doi.org/10.3390/modelling5030044

Goetz D, Panzer H, Wolf D, Bayerlein F, Spachtholz J, Zaeh MF. AscentAM: A Software Tool for the Thermo-Mechanical Process Simulation of Form Deviations and Residual Stresses in Powder Bed Fusion of Metals Using a Laser Beam. Modelling. 2024; 5(3):841-860. https://doi.org/10.3390/modelling5030044

Chicago/Turabian StyleGoetz, Dominik, Hannes Panzer, Daniel Wolf, Fabian Bayerlein, Josef Spachtholz, and Michael F. Zaeh. 2024. "AscentAM: A Software Tool for the Thermo-Mechanical Process Simulation of Form Deviations and Residual Stresses in Powder Bed Fusion of Metals Using a Laser Beam" Modelling 5, no. 3: 841-860. https://doi.org/10.3390/modelling5030044

APA StyleGoetz, D., Panzer, H., Wolf, D., Bayerlein, F., Spachtholz, J., & Zaeh, M. F. (2024). AscentAM: A Software Tool for the Thermo-Mechanical Process Simulation of Form Deviations and Residual Stresses in Powder Bed Fusion of Metals Using a Laser Beam. Modelling, 5(3), 841-860. https://doi.org/10.3390/modelling5030044